1/16 & 1/32 DIN TEMPERATURE CONTROLLER

MANUAL (59423-2)

MECHANICAL INSTALLATION

The Controllers are designed to be mounted either in a 1/16 or a 1/32 DIN panel cutout. The units are sleeve mounted with the front

bezel assembly rated NEMA4/IP66 provided that:

− the panel is smooth and the panel cutout is accurate;

− the mounting instructions are carefully followed.

DIN PANEL CUTOUT

1/16 DIN: 45.0mm +0.6 / 0.0 wide, 45.0mm +0.6 / 0.0 high 1/32 DIN: 45.0mm +0.6 / -0 wide, 22.2mm +0.3 / -0 high

Maximum panel thickness 9.5mm

Minimum spacing 20mm vertical, 10mm horizontal

MOUNTING

To mount a Controller proceed as follows:

1 Check that the controller is correctly orientated and then slide the unit into the cutout.

2 Slide the panel clamp over the controller sleeve pressing it firmly against the panel until the controller is held firmly.

3 The controller front bezel and circuit board assembly can be unplugged from the sleeve. Grasp the bezel firmly by the recesses on

each side and pull. A screwdriver can be used as a lever if required.

4 When refitting the bezel assembly it is important to press it firmly into the sleeve until the latch clicks in order to compress the

gasket and seal to NEMA4X/IP66.

CLEANING

Wipe down with damp cloth (water only)

Note: The controller should be isolated before removing or refitting it in the sleeve, and electrostatic precautions should be observed

when handling the controller outside the sleeve.

DIMENSIONS: MODELS

1/32 DIN – 48 x 24mm 51.0 28.5 44.8 22.0 116.2 106.7

1/16 DIN – 48 x 48mm 51.0 51.0 44.8 44.8 116.2 106.7

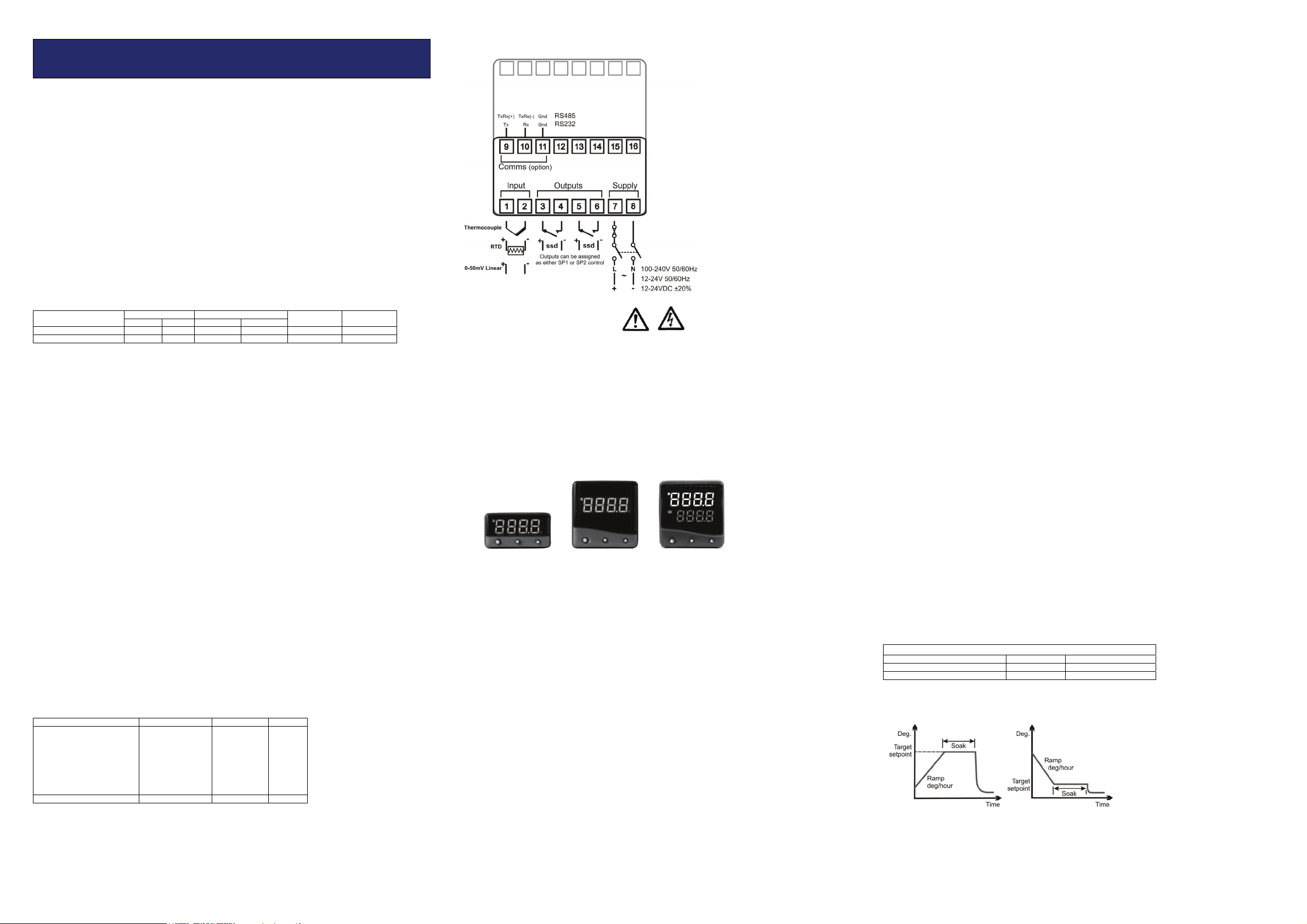

ELECTRICAL INSTALLATION

OUTPUT DEVICES

Two of the following output devices are fitted to the controllers, depending on the model.

1 Solid state relay drive (SSd/SSd1/SSd2) 5Vdc +0/-15%, 15mA non isolating. To switch a remote SSR (or logic)

2 Miniature power relay (rLY/rLY1) 2A/250V AC resistive, Form A/SPST contacts.

3 Sub miniature power relay (rLY2) 1A/250V AC resistive, Form A/SPST contacts.

OUTPUT DEVICE ALLOCATION

Any of the available outputs may be chosen for the main setpoint (SP1), the remaining device being automatically allocated to the

second setpoint (SP2).

Dual relay or dual SSd output models are available to order. Please contact your local distributor for details.

Designed for use with the following supply voltages:

1). 100 - 240V 50-60 Hz 4.5 VA (nominal) +/-10% maximum permitted fluctuation

2). 12V - 24V (AC/DC) +/-20% 4.5 VA Polarity not required

WIRING THE CONNECTOR

Prepare the cable carefully, remove a maximum of 8mm insulation and ideally tin to avoid bridging. Prevent excessive cable strain.

Maximum recommended wire size: 32/0.2mm 1.0mm2 (18AWG).

INDUCTIVE LOADS

To prolong relay contact life and suppress interference it is recommended engineering practice to fit a snubber (0.1uf/100 ohms)

between terminals 5 and 6.

CAUTION:Snubber leakage current can cause some electro-mechanical devices to be held ON.

Check with the manufacturers specifications.

EN61010 - /CSA 22.2 No 1010.1 92

− Compliance shall not be impaired when fitted to the final installation.

− Designed to offer a minimum of Basic Insulation only.

− The body responsible for the installation is to ensure that supplementary insulation suitable for Installation Category II or III is

achieved when fully installed.

− To avoid possible hazards, accessible conductive parts of the final installation should beprotectively earthed in accordance with

EN6010 for Class 1 Equipment.

− Output wiring should be within a Protectively Earthed cabinet.

− Sensor sheaths should be bonded to protective earth or not be accessible.

− Live parts should not be accessible without the use of a tool.

− When fitted to the final installation, an IEC/CSA APPROVED disconnecting device should be used to disconnect both LINE and

NEUTRAL conductors simultaneously.

− A clear instruction shall be provided not to position the equipment so that it is difficult to operate the disconnecting device.

SENSOR SELECTION

Thermocouples Description Sensor Range Linearity

tC b

tC E

tC J

tC K

tC L

tC n

tC r

tC s

tC t

Resistance Thermometer RTD Pt100/RTD-2 -200 to 400°C 0.25*

Linear process inputs (Input mV range: 0 to 50mV)

Displays 0 - 20mV 4 - 20mV setpoint limits

Lin1 0 - 100 0 – 400 ± 0.5%

Lin2 0 - 100 -25 - 400 ± 0.5%

Lin3 0 - 1000 0 - 3000 ± 0.5%

Lin4 0 - 1000 -250 - 3000 ± 0.5%

Lin5 0 - 2000 0 - 3000 ± 0.5%

Notes: 1 Linearity: 5-95% sensor range

2 * Linearity B:5° (70º - 500°C) K/N:1° >350°C exceptions: R/S: 5°<300°C T:1° <- -25° >150°C

RTD/Pt100: 0.5° <-100°C

Bezel* Behind panel Model

Width Height Width Height

(Also see important Safety Information)

Pt-30% Rh/Pt-6%Rh

Chromel/Con

Iron/Constantan

Chromel/Alumel

Fe/Konst

NiCrosil/NiSil

Pt-13% Rh/Pt

Pt-10% Rh/Pt

Copper/Con

0 to 1800°C

0 to 600°C

0 to 800°C

-50 to 1200°C

0 to 800°C

-50 to 1200°C

0 to 1600°C

0 to 1600°C

-200 to 250°C

2.0*

0.5

0.5

0.25*

0.5

0.25*

2.0*

2.0*

0.25

Overall

length

Behind panel

length*

Dimensions in mm

* includes gasket

CONNECTION DIAGRAM

F1 Fuse: 1A time lag type to IEC127. CSA/UL rating

250Vac

S1 Switch: IEC/CSA/UL Approved disconnecting

device

F1

S1

SAFETY INFORMATION

INSTALLATION

Designed for use:

UL873 - only in products where the acceptability is determined by Underwriters Laboratories Inc.

EN61010-1 / CSA 22.2 No 1010.1 - 92

To offer a minimum of Basic Insulation only.

Suitable for installation within Category II and III and Pollution Degree 2.

SEE ELECTRICAL INSTALLATION It is the responsibility of the installation engineer to ensure this equipment is installed as

specified in this manual and is in compliance with appropriate wiring regulations.

CONFIGURATION

All functions are front selectable, it is the responsibility of the installing engineer to ensure that the configuration is safe. Use the

program lock to protect critical functions from tampering.

ULTIMATE SAFETY ALARMS

Do not use SP2 as the sole alarm where personal injury or damage may be caused by equipment failure.

INSTRUMENT PANEL FEATURES

Green Display: Process temperature or program Function/Option

Orange Display: Setpoint temperature or program Option (Dual Display only)

Green LED: Setpoint 1 output indicator

Red/Orange LED: Setpoint 2 output indicator

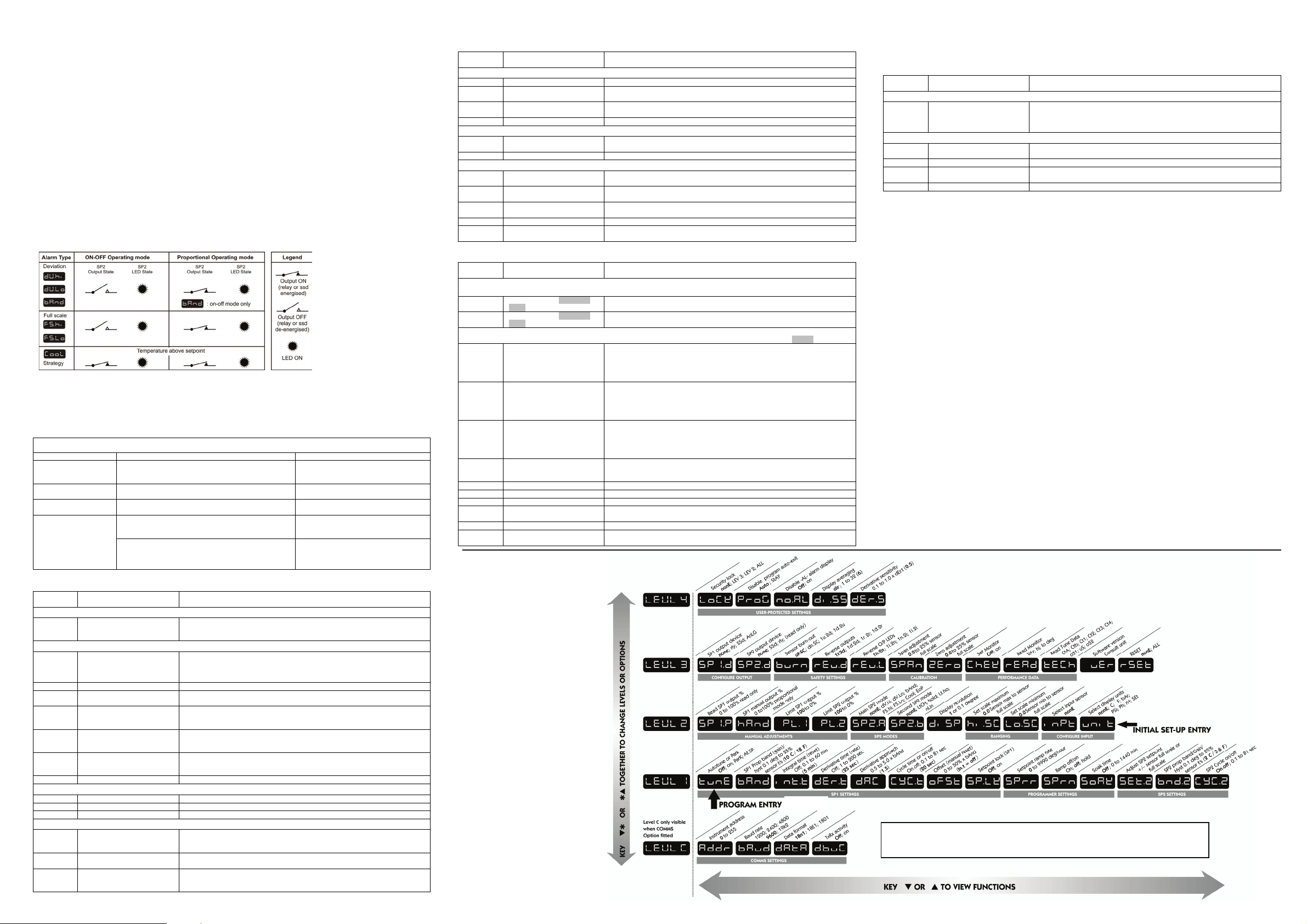

ADJUSTMENTS

To enter or exit program mode: Press V W together for 3 seconds

To scroll through functions: Press V or W

To change levels or options: Press 4 V together or 4 W together

To view setpoint: Press 4

To increase setpoint: Press 4 V together

To decrease setpoint: Press 4 W together

To reset an alarm or fault condition: Press V W together briefly

Notes: If in difficulty by becoming “lost” in program mode, press V and W together for 3 seconds to return to

display mode, check the INSTRUMENT ADJUSTMENTS above and try again.

When in program mode, after 60 seconds of key inactivity the display will revert to either inPt : nonE or, if the

initial configuration has been completed, the measured value. Any settings already completed will be retained.

GETTING STARTED

After power-up the controller requires programming with the following information:

− Type of Sensor

− Operating unit

− Allocation of Output Device to SP1/SP2 (Relay or SSd)

− Temperature Setpoint

When the above information has been programmed into the controller it will be operational with the following factory settings.

Proportional band/Gain 10ºC/18ºF

Integral time/Reset 5 mins

Derivative time/Rate 25 secs

Proportional cycle-time 20 secs (Typical setting for relay output)

DAC Derivative approach control 1.5 (Average setting for minimum overshoot)

NOTE: The instruments covered in this manual may be fitted with either a single or a dual display. Where a single display

shows more than one reading, it will alternate between them.

INITIAL SET-UP

On power-up the controller will display the self test sequence followed by the initial display inPt : none

Select input sensor.

− Press and hold 4 and use the V or W buttons to scroll through the sensor selection list until the correct sensor is

displayed. Release the buttons. The display will now read selected sensor type e.g. inPt : tCs

− Press V once The display will now read unit : none

Select unit.

− Press and hold 4 and use the V or W buttons to scroll through the unit selection list until the correct unit is

displayed. Release the buttons. The display will read selected unit e.g. unit : °C

− Press V once The display will now read SP1.d : nonE

Select SP1 (Main setpoint output device)

Note: Dual Relay and Dual SSd Output Options Models have their outputs pre-configured. Move to Step 4.

− Press and hold 4 and use the V or W buttons to select SSd or rLY as required. The controller will now read

To enter initial configuration into controller memory

Note: For precise control of an application the controller may need to be TUNED. Please see the following section on AUTOTUNE

AUTOTUNE

This is a single shot procedure to match a controller to the process. Select either Tune or Tune at Setpoint from the criteria below.

The Tune program should be used when the load temperature is at or near ambient. The procedure will apply disturbances when

the temperature reaches 75% of the setpoint value, causing overshoot which is monitored in order to adjust the DAC overshoot

inhibit feature. Care should be taken to ensure that any overshoot is safe for the process.

The Tune at Setpoint program is recommended when:

Notes: DAC is not re-adjusted by Tune at setpoint.

Hereafter in the Manual the symbol (VW) signifies both buttons are held pressed for 3 seconds to ENTER or EXIT

program mode.

TUNE OR TUNE AT SETPOINT PROGRAM

Enter program (V W) and from the display tunE : oFF press and hold 4 and press V to display tunE : on or tunE : At.SP

Exit program mode (V W).

The TUNE program will now start. The display will show tunE as the process temperature climbs to setpoint.

Note: During tuning, the main setpoint (SP1) LED will flash.

When the TUNE or TUNE AT SETPOINT program is complete the PID values are entered automatically. The process temperature

will rise to setpoint and control should be stable. If not, this may be because optimum cycle time is not automatically implemented.

To set the cycle time see PROPORTIONAL CYCLE-TIME.

PROPORTIONAL CYCLE-TIME

The choice of cycle-time is influenced by the external switching device or load. eg. Contactor or SSR. A setting that is too long for a

process will cause oscillation or a setting that is too short will cause unnecessary wear to an electro-mechanical switching device.

Factory set - To use the 20 sec factory set cycle-time no action is needed whether autotune is used or not.

To Manually Select AUTOTUNE Calculated CYCLE-TIME

When AUTOTUNE is completed, enter program (V W) and select CYC.t in Level 1. The display will read CYC.t:20 (factory setting)

To view the new calculated optimum value, press and hold both 4 and W buttons until indexing stops. The calculated value will be

displayed eg. A16. If acceptable, exit program (V W) to implement this setting.

To Pre-select Automatic Acceptance of AUTOTUNE Calculated CYCLE-TIME

Before AUTOTUNE is initiated select CYC.t in Level1, press and hold both

program (

To Manually Pre-select Preferred CYCLE-TIME

Before AUTOTUNE is initiated select CYC.t in Level 1, press and hold both 4 and V or W buttons until indexing stops at

preferred value then exit program (V W) to accept.

CYCLE-TIME RECOMMENDATIONS

Output device Factory setting Recommended minimum

Internal relay : rLY / rLY1 / rLY2 20 seconds 10 seconds

Solid state drives : SSd / SSd1 / SSd2 20 seconds 0.1 seconds

PROGRAMMER - RAMP-SOAK

This feature enables the controller to ramp up or down from current temperature to a target setpoint at a pre-determined rate. It then

controls at the target setpoint for an adjustable soak period before switching off the SP1 output.

Notes: In Ramp on configuration, if power is removed from the controller, the Ramp will re-start when power is restored.

WARNING: The Soak timer is triggered when the ramp setpoint reaches the target setpoint. If the ramp rate is set too fast for the

process, the Soak timer will be triggered before the process temperature reaches the target setpoint.

selected output device e.g. SP1.d : SSd

− Press and hold both V and W buttons for 3 seconds. The display will now read ParK and measured variable

(temperature) (eg. 23 ) ParK is displayed because a setpoint has not yet been entered.

− To display setpoint

Press and hold 4 The displays will now read unit (eg. °C ) and 0

− To enter setpoint

Press and hold 4 and use V button to increase or W button to decrease the reading and scroll to required setpoint

value. (The digit roll-over rate increases with time).

THE CONTROLLER IS NOW OPERATIONAL WITH FACTORY SETTINGS

− The process is already at setpoint and control is poor

− The setpoint is less than 100°C

− Re-tuning after a large setpoint change

− Tuning multi-zone and/or heat-cool applications.

Proportional Cycle Time can be pre-selected before running the Autotune program.

V W) to accept calculated value automatically.

The Ramp hold option suspends the ramp at its last value.

If no Soak period has been set, control at target setpoint continues indefinitely.

SP2 deviation alarms follow the ramp setpoint and can be used to alarm “out of limits” ramp rate.

4 and W buttons until indexing stops at A – –. Exit

− Set Setpoint ramp rate (0 to 9995 deg/hour)

− From SPrr in Level 1, press and hold

or W to scroll to required ramp rate.

− Set Soak (if required) 0 to 1440 minutes

− From SoAk – – in Level 1, press and hold 4 and

V or W to scroll to required Soak time.

− Set Ramp on (Off: On: Hold)

− From Sprn in Level 1, press and hold

press

V to select On

− Exit program (V W) to enter settings into

memory and commence ramp to target setpoint.

4 and V

4 , then

SECOND SETPOINT (SP2)

SECOND SETPOINT (SP2) Alarm Output

Configure SP2 output to operate as an alarm from SP2.A in Level 2 and set the temperature alarm setting in SEt.2 Level 1. The

alarm will be triggered when the process temperature changes according to the options listed below.

dV.hi Rises above the main setpoint by the value inserted at SEt.2.

dV.Lo Falls below the main setpoint by the value inserted at SEt.2.

Band Rises above or falls below the main setpoint by the value inserted at SEt.2.

FS.hi Rises above the main setpoint by a SEt.2 value that is greater than the setpoint.

FS.Lo Falls below the main setpoint by a SEt.2 value that is smaller than the setpoint.

SUBSIDIARY SP2 MODE

The following additional alarm functions can be added to the above alarm configurations using the features found in SP2.b in Level 2

LtCh Once activated, the alarms will latch and can be manually reset when the alarm condition has been removed.

Hold This prevents any alarm operation on power-up and is automatically disabled once the process reaches setpoint in

Lt.ho Combines the effects of both LtCh & Hold and can be applied

SECOND SETPOINT (SP2) Proportional control output

Configure in Level 1 using CyC.2 to select proportional cycle time and bnd.2 to adjust proportioning band.

For Heat/Cool operation see full operating manual.

In on/off mode, bnd.2 adjusts SP2 hysterisis.

SP2 OUTPUT AND LED INDICATION STATES - IN ALARM CONDITION

SP2 ALARM ANNUNCIATOR

When an SP2 alarm mode is selected in SP2.A the alarm annunciator -AL- is displayed, alternating with the process temperature,

during alarm condition.

Notes: The alarm will be automatically reset when the temperature returns within the bnd.2 setting in Level 1.

The annunciator may be disabled by selecting function no.AL : on in level 4.

SP2 in cool strategy See full operating manual (ADVANCED SETTINGS)

order to allow normal alarm operation.

ERROR MESSAGES

Display Flashes Fault Type Action

inPt: FAiL SENSOR FAULT

dAtA : FAiL NON-VOLATILE MEMORY ERROR

hAnd : FAiL MANUAL POWER ERROR

tunE : FAiL

Thermocouple burnout RTD/Pt100 open or short circuit

or negative over-range.

SP1 set to ON/OFF in CYC.t

IMMEDIATE FAIL ON AUTOTUNE START

Note: To reset and clear error press

V W together briefly to cancel message.

FAIL LATER DURING AUTOTUNE CYCLE

The thermal characteristics of the load exceed the

autotune algorithm limits. The failure point is indicated by

any display 0.0 in tech e.g. Ctb = 0.0

Check sensor/wiring

De-power briefly.

Replace unit if problem persists

Select proportional mode

1. If display setpoint=0 then enter setpoint

2. If SP1 set to ON/OFF in CyC.t then

select proportional mode

1. Change conditions. eg. raise setpoint

2. Try tunE : At.SP

3. If the error message persists, call local

CAL representative for advice.

FUNCTION LIST (LEVELS 1 TO 4) - LEVEL 1

Function Options [Factory settings]

Select Autotune

tunE [oFF], on, ParK, At.Sp Used to switch the Autotune feature on and off, to select ParK or tune at setpoint.

SP1 Operating Parameters

bAnD 0.1 to * C/°F [10ºC/18ºF] SP1 proportional band/Gain or Hysteresis

int.t oFF, 0.1 to 60 minutes [5.0] SP1 integral time/reset Auto-corrects proportional control offset error

dEr.t oFF 1 - 200 seconds [25] SP1 derivate time/rate Suppresses overshoot and speeds response to

dAC 0.5 - 5.0 x bAnd [1.5] SP1 derivative approach control dAC Tunes warm-up characteristics,

CyC.t A – –, on.oF, 0.1 - 81 sec [20] SP1 proportional cycle-time (see section above)

oFSt [0] to * °C/°F SP1 offset/manual reset

SP.LK [oFF] on Lock main setpoint Locks the setpoint preventing unauthorised adjustment.

Programmer Settings

SPrr [0] to 9995 deg/hour Sets the ramp rate

SPrn on [oFF] hold Switches the ramp on or off, or hold at last ramp value

SoAK – – [oFF] 0 to 1440 min Sets the soak time

SP2 Operating Parameters

SEt.2 0 to * °C/°F [0] Adjust SP2 setpoint

bnd.2 0.1 - * °C/°F [2.0 °C/3.6°F] Adjust SP2 hysteresis or proportional band/gain (see CyC.2 setting)

CyC.2 [on.oFF] 0.1–81 seconds Select SP2 ON/OFF or proportional cycle-time

shown in brackets

Description

ParK temporarily turns the output(s) off. To use select ParK and exit program

mode. To disable re-enter program at tunE and select oFF.

* 25% sensor maximum Proportional control eliminates the cycling of on-off

control. Heater power is reduced, by time proportioning action, across the

proportional band.

disturbances

independent of normal operating conditions, by controlling when derivative action

starts during warm-up (smaller dAC value = nearer setpoint).

Determines the cycle rate of the output device for proportional control. Select

on.oF for ON/OFF mode.

* ±50% bAnd. Applicable in proportional and ON/OFF mode with integral disable:

Int.t : oFF.

* Deviation Alarms DV.hi, DV.Lo, bAnd 25% sensor maximum.

* Full scale alarms FS.hi, FS.Lo sensor range f/s

* 25% of sensor full scale

Select on.oFF for ON/OFF mode, or the cycle rate of SP2 output device for

proportional mode.

LEVEL 2

Function Options [Factory settings]

Manual Control Modes

SPI.P 0 to 100 % ‘read only’ Read SP1 output percentage power

hAnd [oFF] 1 to 100 % (not in

PL.1 100 to 0 % duty cycle [100] Set SP1 power limit percentage Limits maximum SP1 heating power during

PL.2 100 to 0 % duty cycle [100] Set SP2 percentage power limit (cooling)

SP2 Operating Modes

SP2.A [none] dV.hi dV.Lo bAnd

SP2.b [none] LtCh hoLd nLin Subsidiary SP2 mode: latch/sequence ,Non-linear cool proportional band

Input Selection and Ranging

dI.SP [1] 0.1 Select display resolution: for display of process temperature, setpoint, OFSt,

hi.SC sensor minimum [sensor

Lo.SC [sensor minimum] sensor

inPt [nonE] Select input sensor (See SENSOR SELECTION table)

Unit [nonE] °C °F bAr Psi Ph rh

shown in brackets

ON/OFF)

FS.hi FS.Lo Cool

maximum] °C/°F

maximum °C/ºF

SEt

Description

SP1 manual percentage power control For manual control should a sensor fail.

Record typical SP1.P values beforehand.

warm-up and in proportional band.

Main SP2 operating mode

Set.2, hi.SC, LoSC

Set full scale

Set scale minimum (default 0°C or 32°F)

Select °C/°F or process units

LEVEL 3

Function Options [Factory settings]

Output Configuration

Note: ‘Read only’ after initial configuration. rSET ALL full reset to factory settings required to change SP1.d subsequently.

SP1.d [nonE] rLY SSd rLY1 rLY2

SP2.d [nonE] SSd rLY rLY2 rLY1

For SP1.d & SP2.d

Note: (when in initial configuration only) Hold 4 and V or W for 10 seconds to move to or from output options shaded.

burn SP1 / SP2

rEu.d SP1 / SP2

rEu.L SP1 / SP2

SPAn [0.0] to ±25% sensor

ZEro [0.0] to ±25% sensor f/s Zero sensor error (see Sensor span adjust above).

ChEK [oFF] on Select control accuracy monitor

rEAD [Var] hi Lo Read control accuracy monitor

tECh [Ct A] CT b Ct 1 Ct 2 Ct 3 Ct

UEr Software version number

rSET [nonE] ALL Resets all functions to factory settings

shown in brackets

SSd1

SSd2

[uP.SC] Upscale/Upscale

dn.SC Downscale/Downscale

1u.2d Upscale/Downscale

1d.2u Downscale/Upscale

[1r.2d] Reverse Direct

1d.2d Direct Direct

1r.2r Reverse Reverse

1d.2r Direct Reverse

[1n.2n] Normal Normal

1i.2n Invert Normal

1n.2i Normal Invert

1i.2i Invert Invert

maximum

4 oS 1 uS oS 2

Description

Select SP1 output device

Dual Relay and Dual SSd output options are factory set.

Read SP2 output device(read only)

Dual Relay and Dual SSd output options are factory set.

Sensor burn-out/break protection

Caution: Settings affect fail safe state.

Select output modes: Direct/Reverse

Select Reverse on SP1 for heating and Direct for cooling applications.

Caution: Settings affect fail safe state.

Select SP1/2 LED indicator modes

Sensor span adjust

For recalibrating to align readings with another instrument e.g. External Meter,

data logger. See Full Operating Manual (ADVANCED SETTINGS).

Read Autotune tuning cycle data (see Operating Manual)

Caution: This selection will lose all of the current settings.

FUNCTIONS MENU

LEVEL 4

Access to level 4 is gained through UEr in level 3. Press and hold V or W for 10 seconds.

Enter level 4 at Lock, release V or W together. Display reads LoCK nonE

Function Options [Factory settings]

Security

LoCK [none] LEV.3 LEV.2 ALL Program security using Lock

Function Options

ProG [Auto] StAY Program mode auto-exit switch. Auto-exit returns display to normal if 60

no.AL [oFF] on Disable SP2 alarm annunciator–AL Select on to disable -AL

di.SS

dEr.S

shown in brackets

Dir, 1 to 32 [6]

0.1 to 1.0 [0.5]

Description

LEV.3 locks level 3 and 4 only- Technical Functions.

LEV.2 locks levels 2, 3 and 4 only - Configuration and technical Functions.

ALL locks all functions LoCK ALL

seconds of key inactivity, select StAY to disable

Display sensitivity

dir = direct display of input 1 = maximum, 32 = minimum sensitivity

Derivative sensitivity

SPECIFICATION

Thermocouple 9 types

Standards: IPTS/68/DIN 43710

CJC rejection: 20:1 (0.05°/°C) typical

External resistance: 100Ω maximum

Resistance thermometer RTD-2/Pt100 2 wire

Standards: DIN 43760 (100Ω 0°C/138.5Ω 100°C Pt)

Bulb current: 0.2mA maximum

Linear process inputs

mV range: 0 to 50mV

Applicable to all inputs SM = sensor maximum

Calibration accuracy: ±0.25%SM ±1°C

Sampling frequency: input 10Hz, CJC 2 sec.

Common mode rejection: Negligible effect up to 140dB, 240V, 50-60Hz

Series mode rejection: 60dB, 50-60Hz

Temperature coefficient: 150ppm/°C SM

Reference conditions: 22°C ±2°C, rated voltage after 15 minutes settling time.

Output devices

SSd/SSd1/SSd2: solid state relay driver: To switch a remote SSR 5Vdc +0/-15% 15mA non-isolated

Miniature power relay: form A/SPST contacts (AgCdO) rLY and rLY1: 2A/250ac resistive load rLY2: 1A/250ac resistive load

General

Displays: Upper, 4 Digits, high brightness green LED. 10mm (0.4”) high.

Lower, 4 Digits, Orange LED. 9mm (0.35”) high (dual display version only)

Digital range - -199 to 9999

Hi-res mode - -199.9 to 999.9

LED output indicators - flashing, SP1 square, green; SP2 round, red

Keypad: 3 elastomeric buttons

Environmental

Humidity: Max 80%

Altitude: up to 2000M

Installation: Categories ll and lll

Pollution: Degree ll

Protection: NEMA 4X, lP66

EMC emission: EN50081-1 FCC Rules 15 subpart J Class A

EMC immunity: EN50082-2

Ambient: 0-50ºC (32-130°F)

Mouldings: flame retardant polycarbonate

Weight: 1/32 DIN - 110g (3.9oz), 1/16 DIN single display - 120g (4.2oz), 1/16 DIN dual display - 130g (4.6oz).

Approv als CE, UL (file number E81867), cUL, FM (3545)

Range of Adjustment shown under description. If applicable, factory settings shown in bold.

Note: The letter K appears in the instrument display as the character K

Loading...

Loading...