Westcode Semiconductors Distributed Gate Thyristors Catalog

Distributed Gate Thyristors

IXYS UK Westcode Ltd is recognised as the

worldwide leader in distributed gate

technology.

These devices are available with blocking voltages to

4.5kV, average current to 4kA, and tq from 10 to 300µs.

The distributed gate design and lifeme control features

give these devices both high di/dt capability and fast, low

recovery turn-o, while maintaining a low on-state voltage

drop. Ideally suited to applicaons including: inducon

power supplies, high frequency inverters/converters,

resonant power supplies and pulsed power.

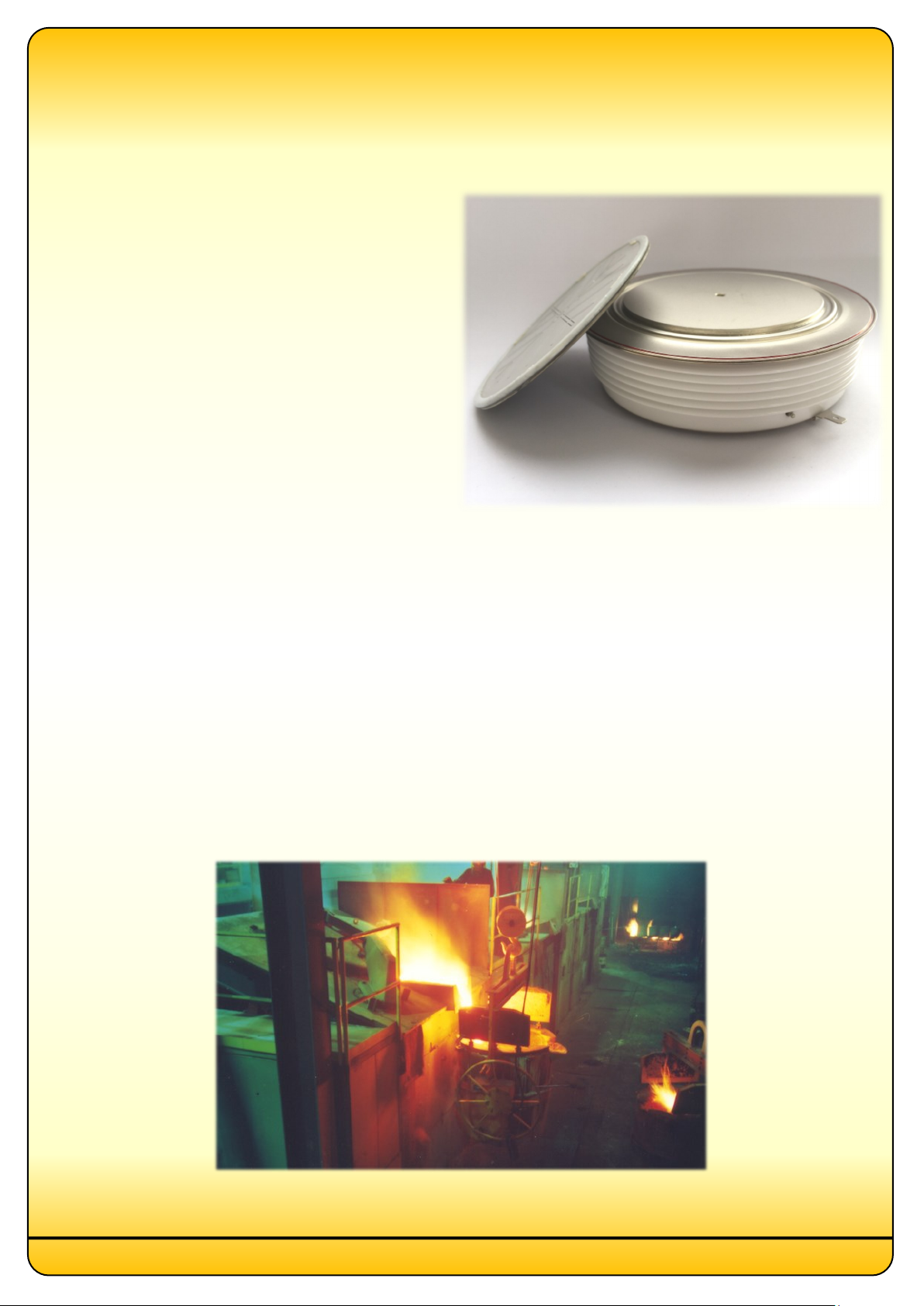

Newly introduced to this range is an opmised 96mm die

distributed gate thyristor. This devices is constructed using

an all diused silicon slice, fused to a metal disc,

encapsulated in an industry standard package oering

higher current density and improved turn-o

characteriscs. The thermal capacity of the metal disc and

its direct fusion to the silicon slice enhances performance,

presenng excellent transient thermal characteriscs and

higher surge current rangs, as required in the dicult

environment of resonant power supplies. This device is

available with a current rang of 5370A, voltage rangs up

to 2200V and typical tq ranging between 70µs and 100µs.

Features and benets

High average current

rangs

Low thermal resistance

Double side cooling

Opmised parts have higher

surge current rang and

enhanced mechanical

design for maximum power

to package rao

Industry standard, fully

hermec packages

Suitable for applicaons up

to 20kHz

Applicaons

Inducon power supplies for:

Melng

Billet heang

Surface condioning

Resonant power supplies

IUK-TSM-2015-003 Issue 2 1 03/05/2016

New — 5370A, 2200V Distributed Gate

Thyristor

IXYS UK Westcode Ltd. announces a new pressure contact

distributed gate thyristor with increased power density. This

new fast thyristor with current rang 5370A is symmetrical

blocking with V

for both voltage and current fed applicaons.

The device oers both higher current and faster turn-o

when comparted to other parts in the same footprint

package size. New improved designs benet from an

increased electrical performance in a smaller package than

older designs as well as improved thermal performance

giving them a higher current density. The improvement in

performance is achieved by maximising the die size and

improved distributed gate geometry.

The 96mm silicon die is bonded and encapsulated in fully

hermec 85mm electrode contact diameter ceramic

packages, with an industry standard overall diameter of

124mm. The larger die sizes and higher current rang oer

more exibility in customising the parts to meet the needs of

customer specic applicaons.

up to 2200V and therefore suitable

drm/Vrrm

Device is available in two dierent switching classes, dened by turn-o me and two dierent voltage classes: R5370EA18M with

tq 70µs & V

R5370EA22N with tq 100µs & V

Typical applicaons for this device include: Inducon power supplies for melng, billet heang and surface treatments; as well as

resonant power supplies and pulse switches for applicaons including high power magnets and lasers.

DRM/VRRM

1800V, R5370EA18N with tq 100µs & V

DRM/VRRM

2200V.

DRM/VRRM

1800V, R5370EA22M with tq 70µs & V

DRM/VRRM

2200V,

IUK-TSM-2015-003 Issue 2 2 03/05/2016

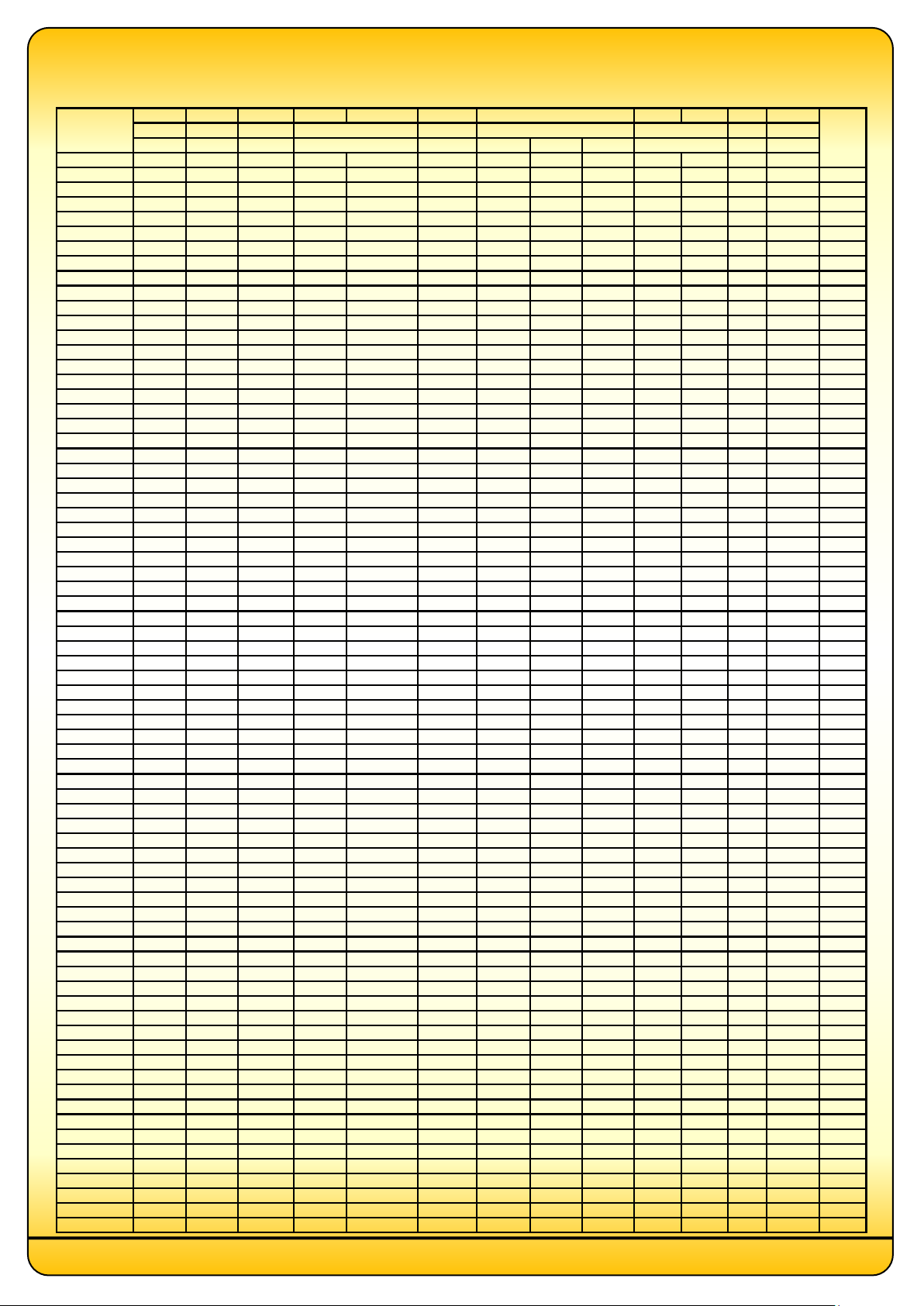

Full product range

V

V

V V A A A2s µs µC A A/µs V K/W oC K/W

R0472YC12E 1200 1200 472 4300 92.5 x 10

R0472YC12F 1200 1200 472 4300 92.5 x 10

R0472YC16E 1600 1600 472 4300 92.5 x 10

R0472YC16F 1600 1600 472 4300 92.5 x 10

R0487YC12D 1200 1200 487 4300 92.5 x 10

R0487YC12E 1200 1200 487 4300 92.5 x 10

R0487YC14D 1400 1400 487 4300 92.5 x 10

R0487YC14E 1400 1400 487 4300 92.5 x 10

R0577YC12C 1200 1200 577 6000 180 x 10

R0577YC12D 1200 1200 577 6000 180 x 10

R0577YC12E 1200 1200 577 6000 180 x 10

R0633YC12D 1200 1200 633 6300 200 x 10

R0633YC12E 1200 1200 633 6300 200 x 10

R0633YC12F 1200 1200 633 6300 200 x 10

R0717LC14G 1400 1400 717 7050 248.5 x 10

R0717LC18G 1800 1800 717 7050 248.5 x 10

R0736LC20J 2000 2000 736 6800 231 x 10

R0736LC20K 2000 2000 736 6800 231 x 10

R0736LC22J 2200 2200 736 6800 231 x 10

R0736LC22K 2200 2200 736 6800 231 x 10

R0736LC25J 2500 2500 736 6800 231 x 10

R0736LC25K 2500 2500 736 6800 231 x 10

R0736LC25L 2500 2500 736 6800 231 x 10

R0736LC25M 2500 2500 736 6800 231 x 10

R0809LC10A 1000 1000 809 8000 320 x 10

R0809LC10B 1000 1000 809 8000 320 x 10

R0830LC12C 1200 1200 830 8500 361 x 10

R0830LC12D 1200 1200 830 8500 361 x 10

R0830LC12E 1200 1200 830 8500 361 x 10

R0830LC12F 1200 1200 830 8500 361 x 10

R0830LC14C 1400 1400 830 8500 361 x 10

R0830LC14D 1400 1400 830 8500 361 x 10

R0830LC14E 1400 1400 830 8500 361 x 10

R0830LC14F 1400 1400 830 8500 361 x 10

R0878LC18K 1800 1800 878 7500 281 x 10

R0878LC18L 1800 1800 878 7500 281 x 10

R0878LC18M 1800 1800 878 7500 281 x 10

R0878LC20K 2000 1800 878 7500 281 x 10

R0878LC20L 2000 1800 878 7500 281 x 10

R0878LC20M 2000 1800 878 7500 281 x 10

R0878LC21K 2100 1800 878 7500 281 x 10

R0878LC21L 2100 1800 878 7500 281 x 10

R0878LC21M 2100 1800 878 7500 281 x 10

R0929LC10A 1000 1000 929 9000 405 x 10

R0929LC10B 1000 1000 929 9000 405 x 10

R0929LC10C 1000 1000 929 9000 405 x 10

R0929LC12A 1200 1200 929 9000 405 x 10

R0929LC12B 1200 1200 929 9000 405 x 10

R0929LC12C 1200 1200 929 9000 405 x 10

R0929LC12D 1200 1200 929 9000 405 x 10

R0929LC12E 1200 1200 929 9000 405 x 10

R0964LC10C 1000 1000 964 9400 442 x 10

R0964LC10D 1000 1000 964 9400 442 x 10

R0964LC10E 1000 1000 964 9400 442 x 10

R0964LC12C 1200 1200 964 9400 442 x 10

R0964LC12D 1200 1200 964 9400 442 x 10

R0964LC12E 1200 1200 964 9400 442 x 10

R0990LC08A 800 800 990 11000 605 x 10

R0990LC08B 800 800 990 11000 605 x 10

R0990LC08C 800 800 990 11000 605 x 10

R1124NC18J 1800 1800 1124 13500 0.91 x 10

R1124NC18K 1800 1800 1124 13500 0.91 x 10

R1124NC18L 1800 1800 1124 13500 0.91 x 10

R1124NC18M 1800 1800 1124 13500 0.91 x 10

R1124NC20J 2000 1800 1124 13500 0.91 x 10

R1124NC20K 2000 1800 1124 13500 0.91 x 10

R1124NC20L 2000 1800 1124 13500 0.91 x 10

R1124NC20M 2000 1800 1124 13500 0.91 x 10

R1124NC21J 2100 1800 1124 13500 0.91 x 10

R1124NC21K 2100 1800 1124 13500 0.91 x 10

R1124NC21L 2100 1800 1124 13500 0.91 x 10

R1124NC21M 2100 1800 1124 13500 0.91 x 10

DRM

TK=55oC 10ms 1/2 sine @ T

VR - ≤ 60% V

RRM

I

I

TAV

I

TSM

2

t t

200V/µs Qrr @ ITM @ di/dt @TJM Sine

RRM

3

25 155 550 40 1.648 1.125 125 0.0500 W58

3

30 155 550 40 1.648 1.125 125 0.0500 W58

3

25 155 550 40 1.648 1.125 125 0.0500 W58

3

30 155 550 40 1.648 1.125 125 0.0500 W58

3

20 90 550 40 1.738 0.943 125 0.0500 W58

3

25 90 550 40 1.738 0.943 125 0.0500 W58

3

20 90 550 40 1.738 0.943 125 0.0500 W58

3

25 90 550 40 1.738 0.943 125 0.0500 W58

3

15 150 550 40 1.510 0.640 125 0.0500 W58

3

20 150 550 40 1.510 0.640 125 0.0500 W58

3

25 150 550 40 1.510 0.640 125 0.0500 W58

3

20 125 550 40 1.250 0.614 125 0.0500 W58

3

25 125 550 40 1.250 0.614 125 0.0500 W58

3

30 125 550 40 1.250 0.614 125 0.0500 W58

3

3

3

50 640 1000 60 1.842 0.619 125 0.0320 W10

3

60 640 1000 60 1.842 0.619 125 0.0320 W10

3

50 640 1000 60 1.842 0.619 125 0.0320 W10

3

60 640 1000 60 1.842 0.619 125 0.0320 W10

3

50 640 1000 60 1.842 0.619 125 0.0320 W10

3

60 640 1000 60 1.842 0.619 125 0.0320 W10

3

65 640 1000 60 1.842 0.619 125 0.0320 W10

3

70 640 1000 60 1.842 0.619 125 0.0320 W10

3

10 120 1000 60 2.100 0.300 125 0.0320 W10

3

12 120 1000 60 2.100 0.300 125 0.0320 W10

3

15 285 1000 60 1.900 0.357 125 0.0320 W10

3

20 285 1000 60 1.900 0.357 125 0.0320 W10

3

25 285 1000 60 1.900 0.357 125 0.0320 W10

3

30 285 1000 60 1.900 0.357 125 0.0320 W10

3

15 285 1000 60 1.900 0.357 125 0.0320 W10

3

20 285 1000 60 1.900 0.357 125 0.0320 W10

3

25 285 1000 60 1.900 0.357 125 0.0320 W10

3

30 285 1000 60 1.900 0.357 125 0.0320 W10

3

60 720 1000 60 1.447 0.480 125 0.0320 W10

3

65 720 1000 60 1.447 0.480 125 0.0320 W10

3

70 720 1000 60 1.447 0.480 125 0.0320 W10

3

60 720 1000 60 1.447 0.480 125 0.0320 W10

3

65 720 1000 60 1.447 0.480 125 0.0320 W10

3

70 720 1000 60 1.447 0.480 125 0.0320 W10

3

60 720 1000 60 1.447 0.480 125 0.0320 W10

3

65 720 1000 60 1.447 0.480 125 0.0320 W10

3

70 720 1000 60 1.447 0.480 125 0.0320 W10

3

10 150 1000 60 1.549 0.350 125 0.0320 W10

3

12 150 1000 60 1.549 0.350 125 0.0320 W10

3

15 150 1000 60 1.549 0.350 125 0.0320 W10

3

10 150 1000 60 1.549 0.350 125 0.0320 W10

3

12 150 1000 60 1.549 0.350 125 0.0320 W10

3

15 150 1000 60 1.549 0.350 125 0.0320 W10

3

20 150 1000 60 1.549 0.350 125 0.0320 W10

3

25 150 1000 60 1.549 0.350 125 0.0320 W10

3

15 170 1000 60 1.530 0.309 125 0.0320 W10

3

20 170 1000 60 1.530 0.309 125 0.0320 W10

3

25 170 1000 60 1.530 0.309 125 0.0320 W10

3

15 170 1000 60 1.530 0.309 125 0.0320 W10

3

20 170 1000 60 1.530 0.309 125 0.0320 W10

3

25 170 1000 60 1.530 0.309 125 0.0320 W10

3

10 90 1000 60 1.350 0.350 125 0.0320 W10

3

12 90 1000 60 1.350 0.350 125 0.0320 W10

3

15 90 1000 60 1.350 0.350 125 0.0320 W10

6

50 640 1000 60 1.540 0.379 125 0.0240 W11

6

60 640 1000 60 1.540 0.379 125 0.0240 W11

6

65 640 1000 60 1.540 0.379 125 0.0240 W11

6

70 640 1000 60 1.540 0.379 125 0.0240 W11

6

50 640 1000 60 1.540 0.379 125 0.0240 W11

6

60 640 1000 60 1.540 0.379 125 0.0240 W11

6

65 640 1000 60 1.540 0.379 125 0.0240 W11

6

70 640 1000 60 1.540 0.379 125 0.0240 W11

6

50 640 1000 60 1.540 0.379 125 0.0240 W11

6

60 640 1000 60 1.540 0.379 125 0.0240 W11

6

65 640 1000 60 1.540 0.379 125 0.0240 W11

6

70 640 1000 60 1.540 0.379 125 0.0240 W11

Typ. Reverse Recovery Charge VT0 rT TJM R

q

JM

35 425 1000 60 1.752 0.732 125 0.0320 W10

35 425 1000 60 1.752 0.732 125 0.0320 W10

thJK

Fig.

No.

IUK-TSM-2015-003 Issue 2 3 03/05/2016

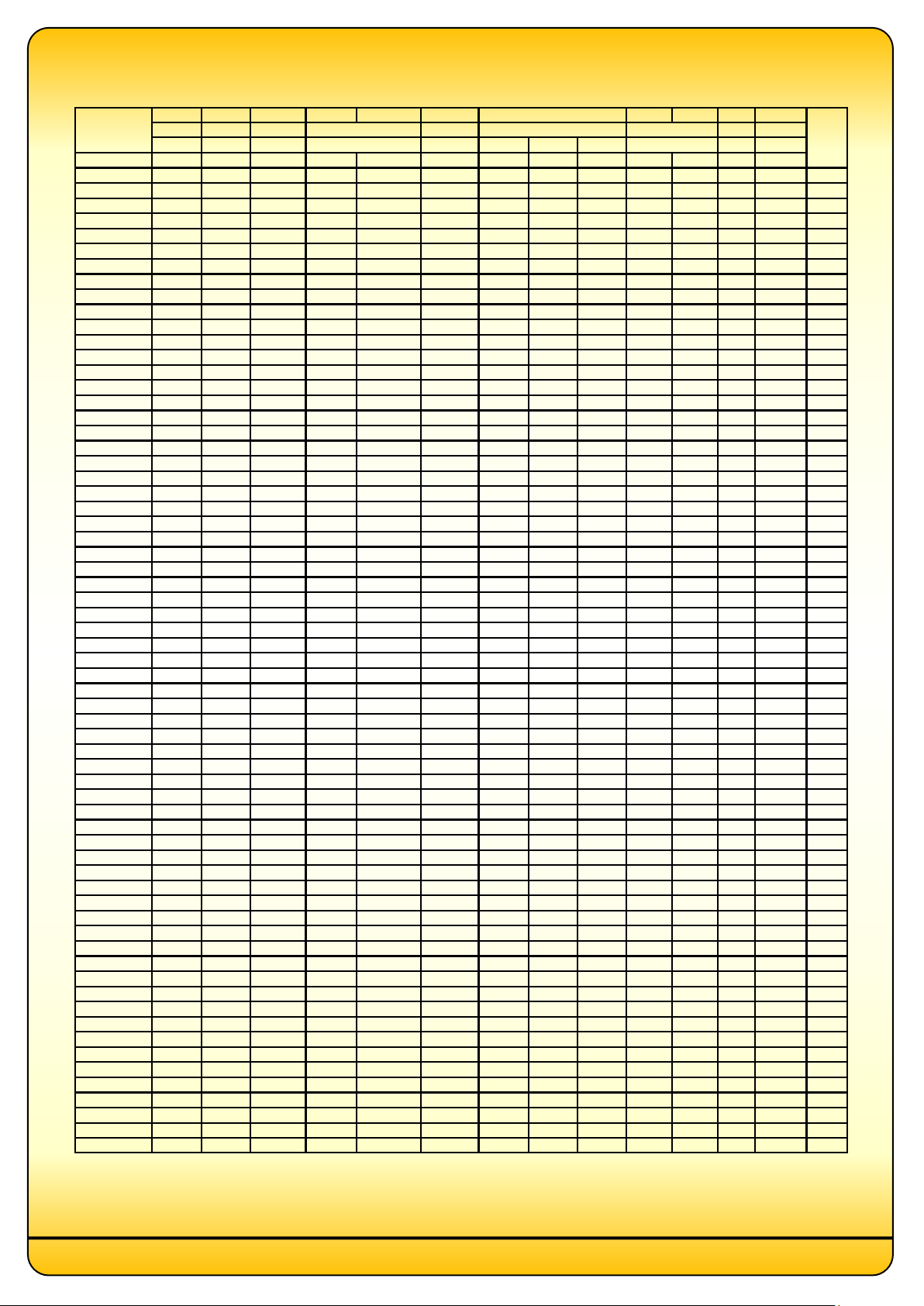

Full product range

V

V

DRM

V V A A A2s µs µC A A/µs V K/W oC K/W

R1127NC32P 3200 3200 1127 12800 819 x 10

R1127NC32R 3200 3200 1127 12800 819 x 10

R1127NC32S 3200 3200 1127 12800 819 x 10

R1127NC32T 3200 3200 1127 12800 819 x 10

R1127NC34R 3400 3400 1127 12800 819 x 10

R1127NC34S 3400 3400 1127 12800 819 x 10

R1127NC34T 3400 3400 1127 12800 819 x 10

R1127NC36R 3600 3600 1127 12800 819 x 10

R1127NC36S 3600 3600 1127 12800 819 x 10

R1127NC36T 3600 3600 1127 12800 819 x 10

R1158NC26N 2600 2600 1158 14500 1.05 x 10

R1158NC26P 2600 2600 1158 14500 1.05 x 10

R1158NC26T 2600 2600 1158 14500 1.05 x 10

R1178NC14E 1400 1400 1178 17000 1.45 x 10

R1178NC14F 1400 1400 1178 17000 1.45 x 10

R1178NC14G 1400 1400 1178 17000 1.45 x 10

R1211NC12C 1200 1200 1211 17600 1.548 x 10

R1211NC12D 1200 1200 1211 17600 1.548 x 10

R1211NC12E 1200 1200 1211 17600 1.548 x 10

R1271NC12B 1200 1200 1271 18000 1.62 x 10

R1271NC12C 1200 1200 1271 18000 1.62 x 10

R1271NC12D 1200 1200 1271 18000 1.62 x 10

R1271NC12E 1200 1200 1271 18000 1.62 x 10

R1275NC18J 1800 1800 1275 15500 1.20 x 10

R1275NC18K 1800 1800 1275 15500 1.20 x 10

R1275NC18L 1800 1800 1275 15500 1.20 x 10

R1275NC18M 1800 1800 1275 15500 1.20 x 10

R1275NC20J 2000 1800 1275 15500 1.20 x 10

R1275NC20K 2000 1800 1275 15500 1.20 x 10

R1275NC20L 2000 1800 1275 15500 1.20 x 10

R1275NC20M 2000 1800 1275 15500 1.20 x 10

R1275NC21J 2100 1800 1275 15500 1.20 x 10

R1275NC21K 2100 1800 1275 15500 1.20 x 10

R1275NC21L 2100 1800 1275 15500 1.20 x 10

R1275NC21M 2100 1800 1275 15500 1.20 x 10

R1279NC22J 2200 2200 1279 14800 1.10 x 10

R1279NC22K 2200 2200 1279 14800 1.10 x 10

R1279NC22L 2200 2200 1279 14800 1.10 x 10

R1279NC22M 2200 2200 1279 14800 1.10 x 10

R1279NC25J 2500 2500 1279 14800 1.10 x 10

R1279NC25K 2500 2500 1279 14800 1.10 x 10

R1279NC25L 2500 2500 1279 14800 1.10 x 10

R1279NC25M 2500 2500 1279 14800 1.10 x 10

R1280NC21J 2100 2100 1280 14800 1.10 x 10

R1280NC21K 2100 2100 1280 14800 1.10 x 10

R1280NC21L 2100 2100 1280 14800 1.10 x 10

R1280NC21M 2100 2100 1280 14800 1.10 x 10

R1280NC22J 2200 2100 1280 14800 1.10 x 10

R1280NC22K 2200 2100 1280 14800 1.10 x 10

R1280NC22L 2200 2100 1280 14800 1.10 x 10

R1280NC22M 2200 2100 1280 14800 1.10 x 10

R1280NC25J 2500 2100 1280 14800 1.10 x 10

R1280NC25K 2500 2100 1280 14800 1.10 x 10

R1280NC25L 2500 2100 1280 14800 1.10 x 10

R1280NC25M 2500 2100 1280 14800 1.10 x 10

R1331NC10B 1000 1000 1331 18200 1.66 x 10

R1331NC10C 1000 1000 1331 18200 1.66 x 10

R1331NC10D 1000 1000 1331 18200 1.66 x 10

R1331NC12B 1200 1200 1331 18200 1.66 x 10

R1331NC12C 1200 1200 1331 18200 1.66 x 10

R1331NC12D 1200 1200 1331 18200 1.66 x 10

R1446NC12C 1200 1200 1446 19500 1.90 x 10

R1446NC12D 1200 1200 1446 19500 1.90 x 10

R1446NC12E 1200 1200 1446 19500 1.90 x 10

R1446NC12F 1200 1200 1446 19500 1.90 x 10

TK=55oC 10ms 1/2 sine @ T

VR - ≤ 60% V

RRM

I

I

TAV

I

TSM

2

t t

200V/µs Qrr @ ITM @ di/dt @TJM Sine

RRM

3

3

3

3

3

3

3

3

3

3

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

Typ. Reverse Recovery Charge VT0 rT TJM R

q

JM

120 3500 1000 60 1.500 0.474 125 0.0220 W11

140 3500 1000 60 1.500 0.474 125 0.0220 W11

160 3500 1000 60 1.500 0.474 125 0.0220 W11

200 3500 1000 60 1.500 0.474 125 0.0220 W11

140 3500 1000 60 1.500 0.474 125 0.0220 W11

160 3500 1000 60 1.500 0.474 125 0.0220 W11

200 3500 1000 60 1.500 0.474 125 0.0220 W11

140 3500 1000 60 1.500 0.474 125 0.0220 W11

160 3500 1000 60 1.500 0.474 125 0.0220 W11

200 3500 1000 60 1.500 0.474 125 0.0220 W11

100 1600 1000 60 1.600 0.400 125 0.0220 W11

120 1600 1000 60 1.600 0.400 125 0.0220 W11

200 1600 1000 60 1.600 0.400 125 0.0220 W11

25 320 1000 60 1.600 0.300 125 0.0240 W11

30 320 1000 60 1.600 0.300 125 0.0240 W11

35 320 1000 60 1.600 0.300 125 0.0240 W11

6

15 230 1000 60 1.720 0.230 125 0.0240 W11

6

20 230 1000 60 1.720 0.230 125 0.0240 W11

6

25 230 1000 60 1.720 0.230 125 0.0240 W11

12 200 1000 60 1.547 0.237 125 0.0240 W11

15 200 1000 60 1.547 0.237 125 0.0240 W11

20 200 1000 60 1.547 0.237 125 0.0240 W11

25 200 1000 60 1.547 0.237 125 0.0240 W11

50 940 1000 60 1.207 0.342 125 0.0240 W11

60 940 1000 60 1.207 0.342 125 0.0240 W11

65 940 1000 60 1.207 0.342 125 0.0240 W11

70 940 1000 60 1.207 0.342 125 0.0240 W11

50 940 1000 60 1.207 0.342 125 0.0240 W11

60 940 1000 60 1.207 0.342 125 0.0240 W11

65 940 1000 60 1.207 0.342 125 0.0240 W11

70 940 1000 60 1.207 0.342 125 0.0240 W11

50 940 1000 60 1.207 0.342 125 0.0240 W11

60 940 1000 60 1.207 0.342 125 0.0240 W11

65 940 1000 60 1.207 0.342 125 0.0240 W11

70 940 1000 60 1.207 0.342 125 0.0240 W11

50 1250 1000 60 1.440 0.330 125 0.0220 W11

60 1250 1000 60 1.440 0.330 125 0.0220 W11

65 1250 1000 60 1.440 0.330 125 0.0220 W11

70 1250 1000 60 1.440 0.330 125 0.0220 W11

50 1250 1000 60 1.440 0.330 125 0.0220 W11

60 1250 1000 60 1.440 0.330 125 0.0220 W11

65 1250 1000 60 1.440 0.330 125 0.0220 W11

70 1250 1000 60 1.440 0.330 125 0.0220 W11

50 1200 1000 60 1.440 0.330 125 0.0220 W11

60 1200 1000 60 1.440 0.330 125 0.0220 W11

65 1200 1000 60 1.440 0.330 125 0.0220 W11

70 1200 1000 60 1.440 0.330 125 0.0220 W11

50 1200 1000 60 1.440 0.330 125 0.0220 W11

60 1200 1000 60 1.440 0.330 125 0.0220 W11

65 1200 1000 60 1.440 0.330 125 0.0220 W11

70 1200 1000 60 1.440 0.330 125 0.0220 W11

50 1200 1000 60 1.440 0.330 125 0.0220 W11

60 1200 1000 60 1.440 0.330 125 0.0220 W11

65 1200 1000 60 1.440 0.330 125 0.0220 W11

70 1200 1000 60 1.440 0.330 125 0.0220 W11

12 200 1000 60 1.450 0.285 125 0.0220 W11

15 200 1000 60 1.450 0.285 125 0.0220 W11

20 200 1000 60 1.450 0.285 125 0.0220 W11

12 200 1000 60 1.450 0.285 125 0.0220 W11

15 200 1000 60 1.450 0.285 125 0.0220 W11

20 200 1000 60 1.450 0.285 125 0.0220 W11

15 300 1000 60 1.304 0.199 125 0.0240 W11

20 300 1000 60 1.304 0.199 125 0.0240 W11

25 300 1000 60 1.304 0.199 125 0.0240 W11

30 300 1000 60 1.304 0.199 125 0.0240 W11

thJK

Fig.

No.

IUK-TSM-2015-003 Issue 2 4 03/05/2016

Loading...

Loading...