Page 1

Mounting

It is important to observe the correct mounting procedures when using Power Semiconductors to ensure

effective cooling, good current conduction and

procedure.

(1)

ALUMINIUM

Apply a

25mm rotary wire cup brush

or surfaces,

clamp

approximately

grease

(2)

Ensure that the device contact surface is clean (a scouring pad, such

effectively) then apply a thin film of mounting grease

free of mounting grease.

Assembly procedures are important:

(1)

Using 'bar' clamps, either double side or single side, it

before tightening. The screws should

the nuts should be alternately tightened half a turn until the pressure indicating system shows that the

required pressure has been achieved. .

Using a 'box' clamp, position it over the device ensuring that the pins are correctly located.

square steel plate over the central rod, feed bolts (with shakeproof washer) through the clamp whilst

holding it firmly

touches the heatsink

small amount of mounting

in

position observing the clamping procedures below. Warning: a small amount of grease of

will cause a high voltdrop across the joint and affect heat transfer.

STUD

CAPSULE devices:-

BASE devices:-

HEATSINKSC') for CAPSULE and FLAT BASE devices:-

grease(b)

is

ideally suited); this action produces a 'slurry'. Clean the mounting surface,

in

the case of double cooling. Apply a thin film of mounting grease to the semiconductor, and

0.1

mm diameter should be squeezed out of the device/heatsink joint. Excessive use of

be

in

place. Screw the bolts 'finger tight', then alternately, clockwise, half a turn until the box

all

the

way

round.

to the heatsink. Scrub the heatsink area with a wire brush (a

'finger' tightened initially, then, using a suitable spanner (wrench)

Procedures

reliability. Heatsink preparation

as

'Scotchbrite', will remove dirt

to

the device ensuring that the threads are clean and

is

important to ensure that all faces are parallel

is

a vital part of the

Position the

(2)

FLAT

(SQUARE)

Apply mounting grease

screws, then 'finger' tighten them, followed by a torque controlled spanner (wrench)

torque.

(3)

STUD

Ensure that no mounting grease is

controlled spanner (wrench)

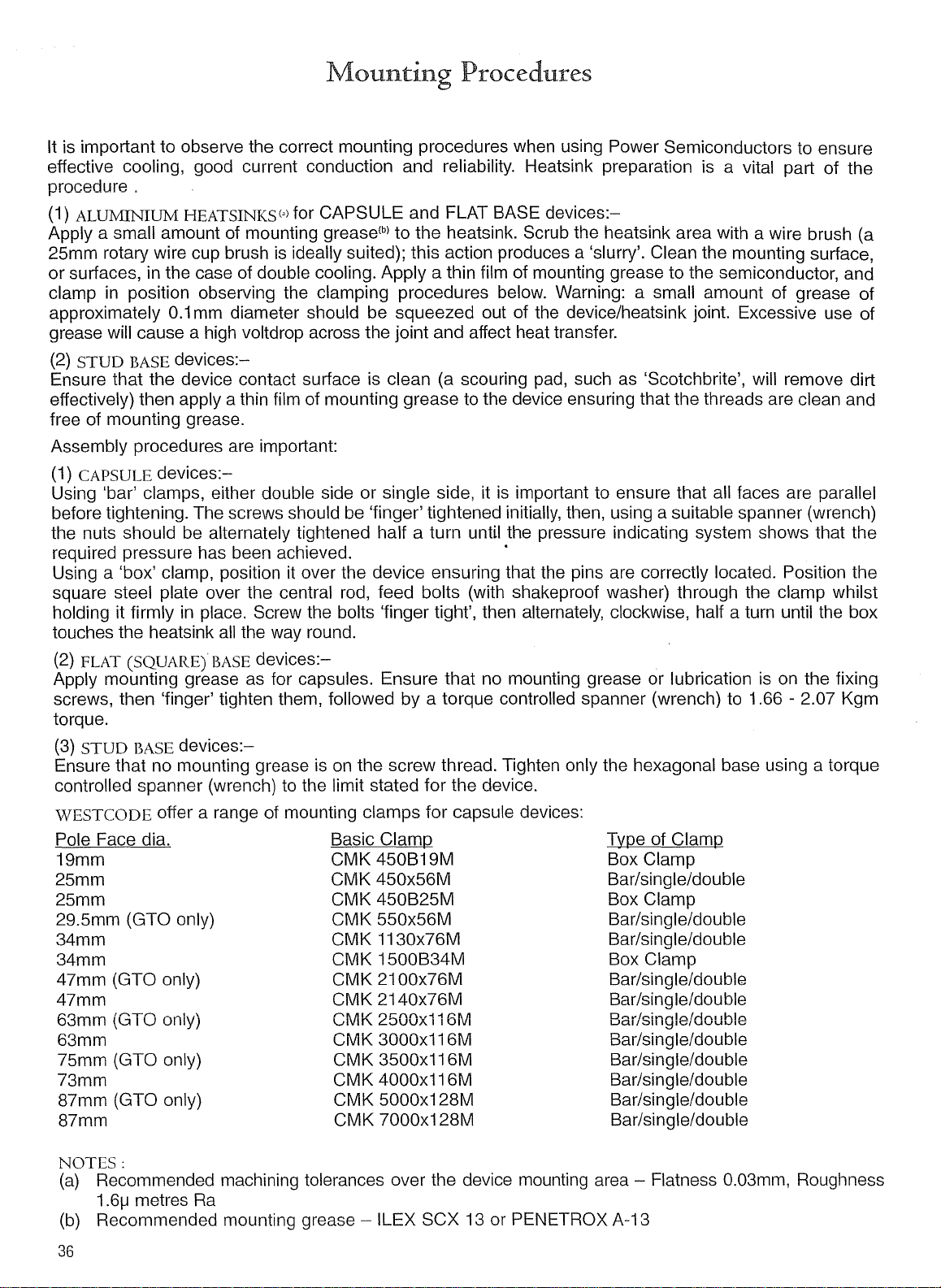

WESTCODE

Pole Face dia. Basic Clamp

19mm CMK

25mm CMK 450x56M

25mm CMK 450B25M

29.5mm (GTO only) CMK 550x56M

34mm CMK 1130x76M

34mm CMK 1500B34M

47mm (GTO only) CMK

47mm CMK 2140x76M

63mm (GTO only) CMK 2500x116M

63mm CMK 3000x116M

75mm (GTO only) CMK 3500x116M

73mm CMK 4000x116M

87mm (GTO only) CMK 5000x128M

87mm CMK 7000x128M

BASE

offer a range of mounting clamps for capsule devices:

BASE

devices:-

devices:-

as

for capsules. Ensure that

on

the screw thread. Tighten only the hexagonal base using a torque

to

the limit stated for the device.

450B19M

21

00x76M

no

mounting grease or lubrication is

Type of Clamp

Box Clamp

Bar/single/double

Box Clamp

Bar/single/double

Bar/single/double

Box Clamp

Bar/single/double

Bar/single/double

Bar/single/double

Bar/single/double

Bar/single/double

Bar/single/double

Bar/single/double

Bar/single/double

on

the fixing

to

1.66 - 2.07 Kgm

NOTES:

(a)

Recommended machining tolerances over the device mounting area - Flatness 0.03mm, Roughness

1.6\-1

metres

(b)

Recommended mounting grease

Ra

-ILEX

sex

13

or PENETROX A-13

36

Loading...

Loading...