Wesco 272397 User Manual

Stainless Steel Rotary Drum Pump

(P/N 272397)

Operating Instructions and Parts Manual

The Wesco Stainless Steel Rotary Pump is commonly used

for aggressive chemicals, such as Esters, Alcohols, Alkali,

Strong Acids, and Hydrocarbons that are compatible with

pump materials of construction. Also suitable for transferring

Petroleum based fluids, such as Automotive Additives,

Diesel, Lube Oils, Kerosene, Solvents, Thinner, Benzene,

Cleaning Solutions, Fuel Oils, Transmission Fluid and water

based chemicals, Anti-Freeze, Soaps, Waxes, Edible Liquids,

etc. Supplied with 2” bung adapter, and a 3-piece stainless

steel suction tube to fit most 15, 30 and 55 gallon drums.

This product is distributed by:

Wesco Industrial Products, Inc

1250 Welsh Road

North Wales, PA 19454

Tel: 215-699-7031 Fax: 215-699-3836

Contact the factory for parts information and ordering.

Visit us on the web at www.wescomfg.com

When unpacking the Wesco Product, check carefully for

shipping damage and missing parts. If damage has occurred

or any parts are missing, file a claim with the delivering carrier

within 24 hours and notify the dealer from whom the unit was

purchased.

The Wesco Stainless Steel Rotary Pumps are designed for specific functions. To insure proper use, the following instructions

must be adhered to:

(1) Always carefully read, thoroughly understand and follow the pump operating instructions. Use this pump correctly and

with care for the purpose for which it is intended. Failure to do so may cause damage or personal injury and will invalidate

the warranty. Retain instructions for future reference.

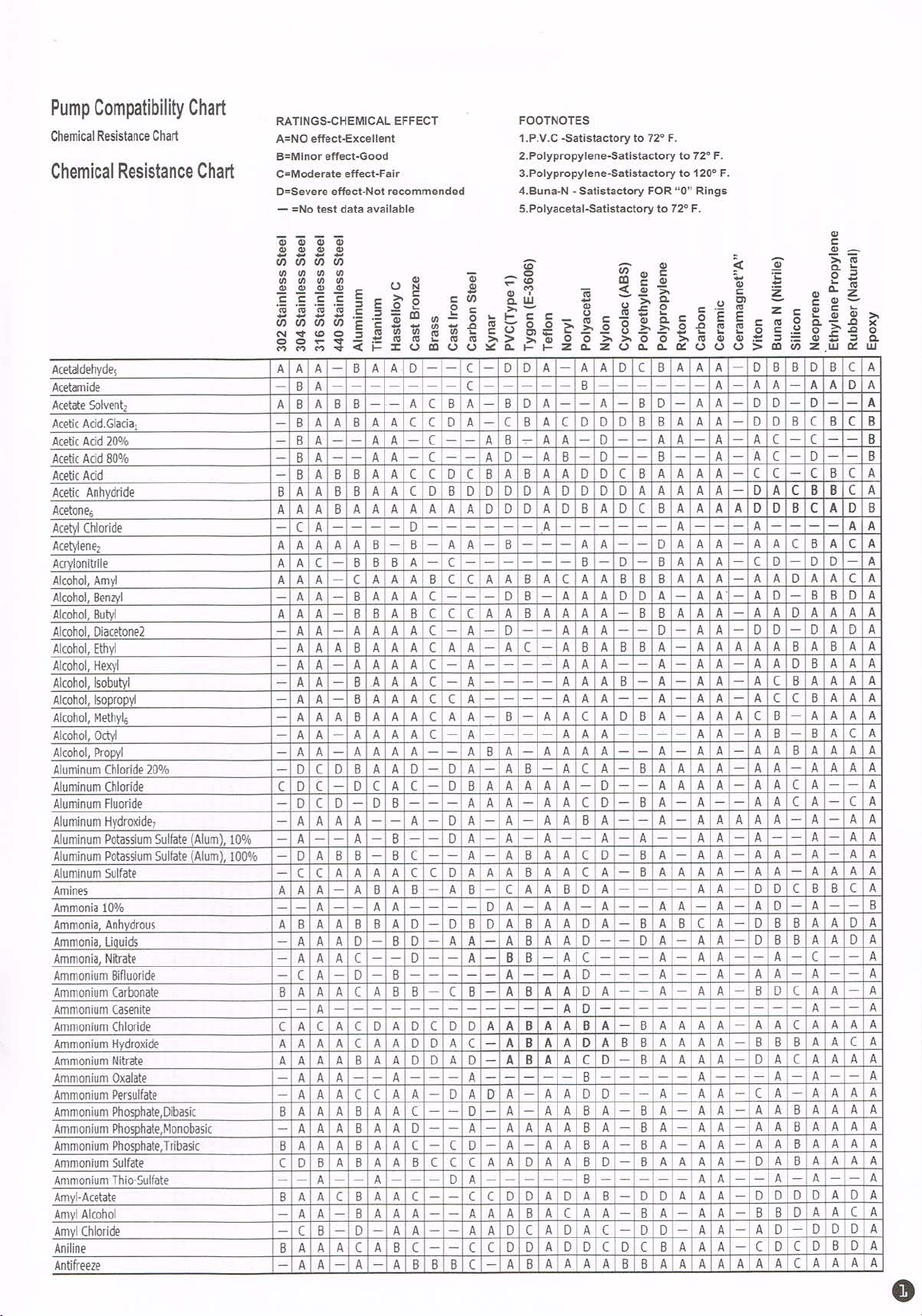

(2) Contact your chemical or fluid supplier to check for compatibility with pump prior to installation and operation.

(3) Prior to use, always carefully and thoroughly read and understand the OSHA information contained in the Safety Data

Sheet supplied for the chemical which is to be pumped.

(4) Wear protective clothing (goggles, face masks, long sleeves, long pants, gloves, aprons, etc.) as set forth in the OSHA

Safety Data Sheet when pumping hazardous chemicals.

(5) When using flammable liquids, pump containers should be grounded to avoid static electricity.

(6) Any pump used for transferring flammable liquids must be stored in a ventilated area after use.

(7) Pump should be washed out before it is used since processing lu bricants may contaminate the fluids.

(8) Prior to use, inspect your pump thoroughly verifying its proper assembly.

(9) If pump is removed from drum, it should be thoroughly rinsed in a liquid that is compatible with both the pump and fluid.

Description

Unpacking

LIMITED WARRANTY

WESCO INDUSTRIAL PRODUCTS (WESCO) warrants to the purchaser of this product for a period of ninety (90) days from the date of purchase that this product shall be free of

defects in material and/or workmanship, as follows:

1. WESCO will supply, at no charge, new or rebuilt replacements for any part that fails through a defect in material and/or workmanship during the warranty period. To obtain warranty

service, you must deliver the product prepaid, to the WESCO factory.

2. This warranty does not cover any product or product part which has been subject to accident, misuse, abuse or negligence. WESCO shall only be liable under this warranty if the

product is used the manner intended by the manufacturer as specified in the written instructions furnished with this product.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE PURCHASER. ANY EXPRESS WARRANTY NOT PROVIDED IN

THIS WARRANTY DOCUMENT, AND ANY REMEDY FOR BREACH OF CONTRACT THAT, BUT FOR THIS PROVISION, MIGHT ARISE BY IMPLICATION OR OPERATION OF LAW,

IS HEREBY EXCLUDED AND DISCLAIMED. UNDER NO CIRCUMSTANCES SHALL WESCO BE LIABLE TO PURCHASER OR ANY OTHER PERSON FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES, WHETHER ARISING OUT OF BREACH OF WARRANTY, EXPRESS OR IMPLIED, A BREACH OF CONTRACT OR OTHERWISE. EXCEPT TO THE

EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE ARE EXPRESSLY LIMITED

IN DURATION TO THE DURATION OF THIS LIMITED WARRANTY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on how long any implied warranty lasts, so the above limitations may not

apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

ATTENTION: TO INSURE SAFE AND EASY USE OF YOUR WESCO ROTARY

PUMP, READ THESE INSTRUCTIONS BEFORE USING.

Specifications

Pump Type Rotary – Vane

Flow 9.5 oz / Stroke

Maximum Fluid Temperature 140° F / 60° C

Bung Adapter 2” Male

Inlet 1-1/4” O.D.

Outlet 1” O.D. Curved Spout

Maximum Viscosity 2,000 SSU

Warranty Repairs

If the unit does not work properly, contact your dealer or the

factory (215-699-7031) for units less than 90 days old.

Non-Warranty Service

If units are older than 90 days, repairs can be made easily

on site with factory supplied parts.

NOTE: Do not send units to the factory for service without

first obtaining a “Return Merchandise Authorization” (RMA)

number from the customer service department. We will not

be responsible for merchandise returned without proper

authorization.

General Safety Information

Stainless Steel Rotary Drum Pump

(P/N 272397)

Operating Instructions and Parts Manual

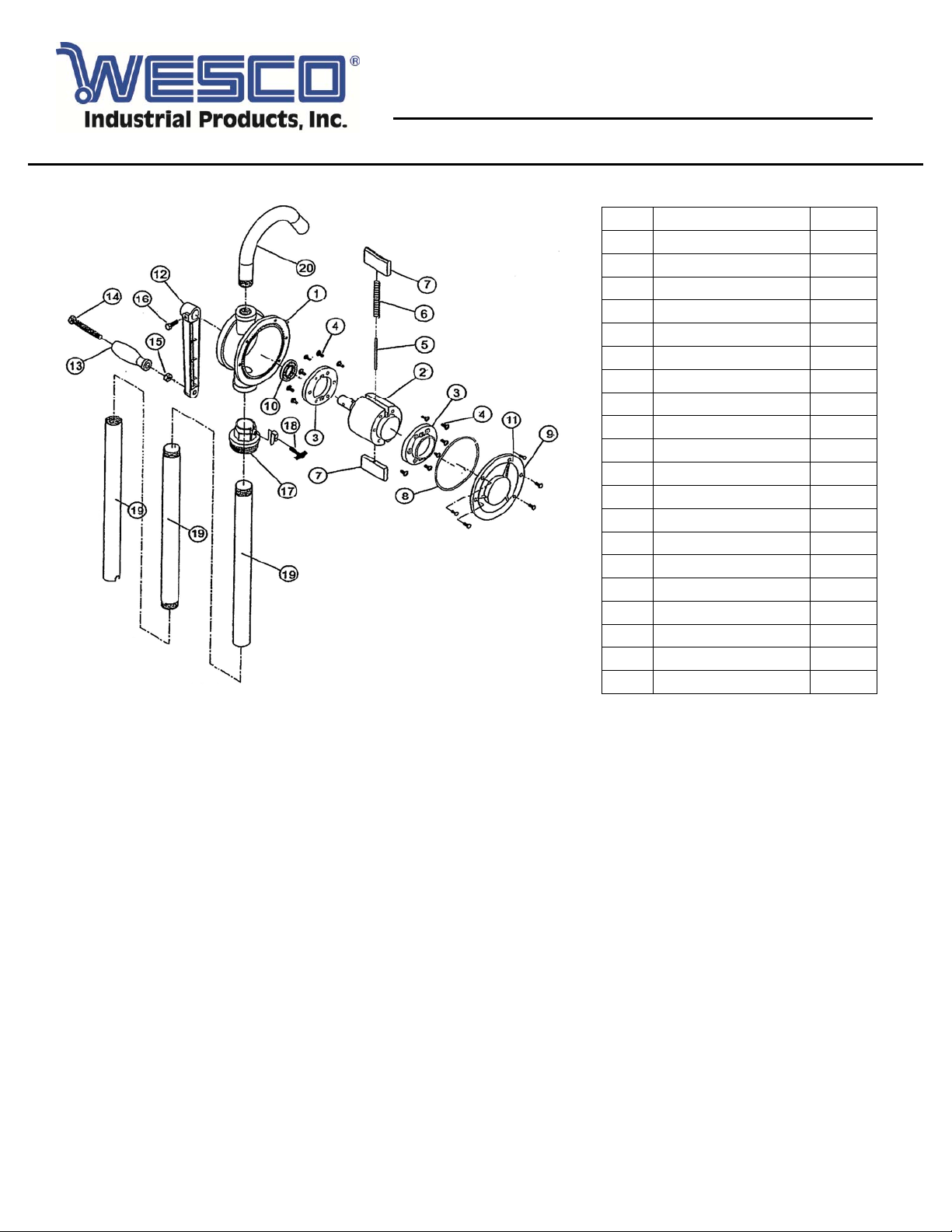

Part Breakdown

(1) Check to see if all parts are included.

(2) Screw and discharge spout (Item 20) into pump body (Item 1) outlet using PTFE sealant tape provided. Do not use pipe

sealant.

(3) Screw handle assemble to crank arm (Item 12) using hex nut (Item 15) supplied. Keep handle shaft from turning. Tighten

hex nut against crank arm. Then insert crank arm assembly onto pump shaft, taking care to align set screw (Item 16) to

indent in rotor (Item 2).

(4) In order to avoid leakage, please use PTFE tape provided to seal three suction tubes (Item 19). Insert bung adapter

(Items 17) into section tube (Item 19) and thread suction tube into pump inlet.

(5) Insert pump and suction tube assembled with bung adapter into the drum, and then tighten bung adapter thumb screw

(Item 18) by hand. Be sure to set pump and suction tube assembly so that suction tube is at the desired depth in the

drum and is not blocked.

(1) To begin pumping fluid, rotate handle clockwise several times making complete revolutions until fluid begins to flow.

Several revolutions will be made with no fluid dispensed as pump needs to prime, once primed, fluid flow begins as

handle is rotated.

(2) For siphoning or draining fluid back into drum, place handle in the straight down position.

(3) To stop siphoning and maintain suction or prime, leave handle in horizontal position.

(4) If corrosion builds up in pump due to lack of use or fluid being pumped, adding penetrating oil into the pump inlet may

help free pump. Remove pump from application, add penetrating oil, let soak, and then crank several times.

(5) Regularly check pump and suction tubes for leaks. Leaks in the suction line or in pump housing will cause inefficient

pumping and loss of prime.

ATTENTION: TO INSURE SAFE AND EASY USE OF YOUR WESCO ROTARY

PUMP, READ THESE INSTRUCTIONS BEFORE USING.

Parts List

Item Description Qty

1 Pump Body

2 Rear Cover

3 Front Cover

4 Rotor

5 Vane

6 Spring

7 Spring Rod

8 Lip Seal

9 Discharge Spout

10 Cap Screw

11 O-Ring

12 Crank Arm

13 Set Screw

14 Handle

15 Handle Shaft

16 Hex Bridge

17 Bung Adapter

18 Fixed Nut

19 Fixed Ring

20 Suction Tube

Assembly and Installation

Operation

1

1

1

1

2

1

1

1

1

10

2

1

1

1

1

1

1

1

1

1

Loading...

Loading...