Page 1

WH2200/WH2500/WH3000 SERIES

Wood Attic Ladder

Installation Instructions

Escalera de ático de madera

Instrucciones de instalación

Échelle de grenier en bois

Instructions d'installation

THIS STAIRWAY IS DESIGNED FOR RESIDENTIAL USE ONLY.

READ THE INSTRUCTIONS COMPLETELY BEFORE STARTING. TWO PEOPLE ARE

REQUIRED FOR PROPER AND EASIER INSTALLATION.

FAILURE TO COMPLY WITH ALL INSTRUCTIONS MAY RESULT IN SERIOUS INJURY.

ESTA ESCALERA ESTÁ DISEÑADA SÓLO PARA USO RESIDENCIAL.

ANTES DE COMENZAR LEA TODAS LAS INSTRUCCIONES. SE NECESITAN DOS

PERSONAS PARA QUE LA INSTALACION SEA CORRECTA Y MAS FACIL.

SI NO SE CUMPLE CON TODAS LAS INSTRUCCIONES,

PUEDEN RESULTAR EN LESIONES GRAVES.

CETTE ÉCHELLE D’ÉCHELLE EST CONÇUE POUR UNE

UTILISATION RÉSIDENTIELLE UNIQUEMENT.

LISEZ CES INSTRUCTIONS COMPLÈTEMENT AVANT DE COMMENCER LE TRAVAIL. IL FAUT

DEUX PERSONNES POUR QUE L’INSTALLATION SOIT CORRECTE ET PLUS FACILE.

LE NON-RESPECT DE CES INSTRUCTIONS PEUT ENTRAÎNER UNE BLESSURE GRAVE

Page 2

Page 3

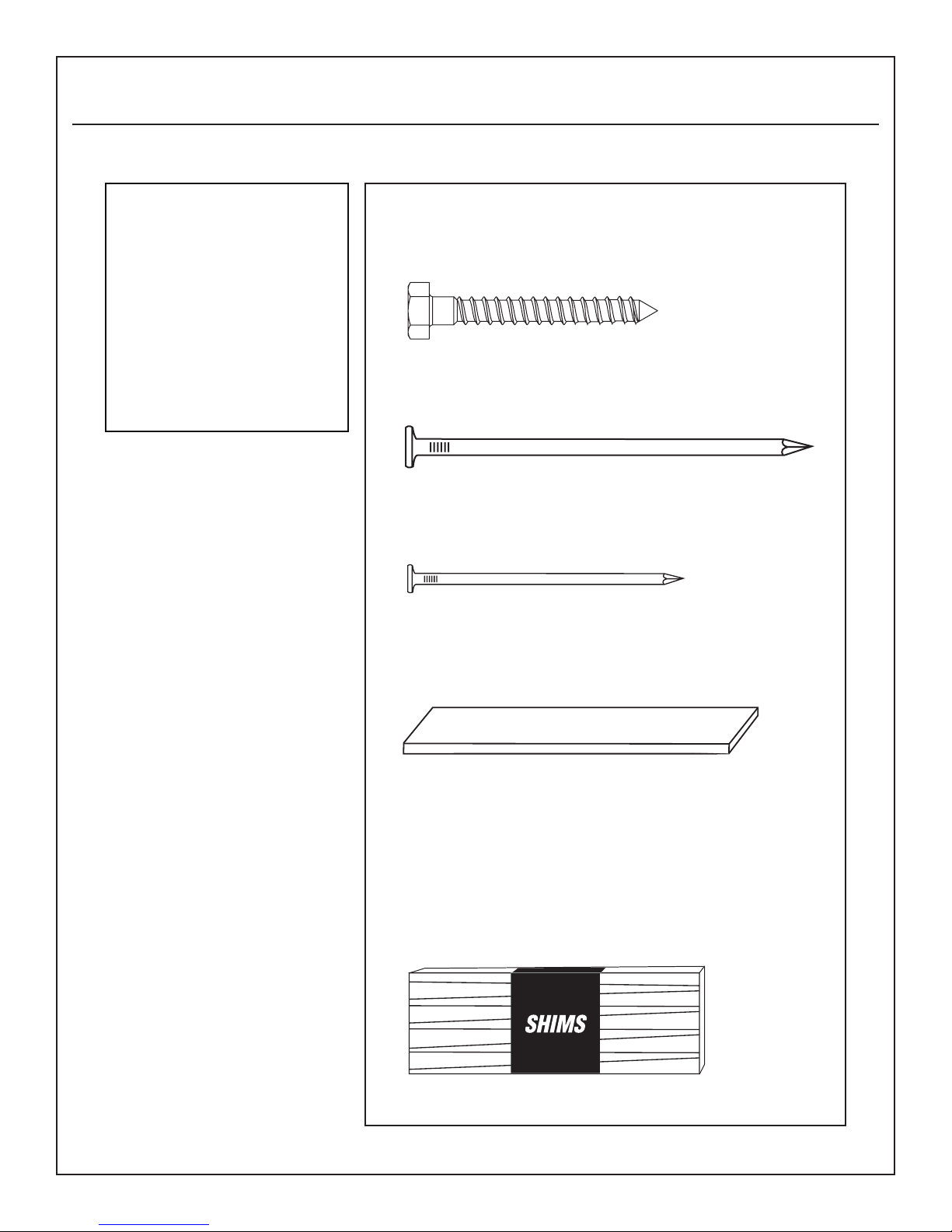

TOOLS AND MATERIALS NEEDED FOR INSTALLATION

TOOLS NEEDED:

Hammer

Ladder

Philips-head screwdriver

Slot-head screwdriver

Square

Tape Measure

Saw

ADDITIONAL MATERIALS NEEDED:

3" Lag Screws (optional)

16d Nails

8d Nails

1 x 4 temporary support slats (2

pieces approximately 32" long)

Braces with same

dimensions as joists

1/4" or 3/8" plywood for shims

Page 4

STEP 1:

BEFORE INSTALLATION:

Verify that this product and its installation meet all

applicable building codes. Check stair carefully

for shipping damage. Please mark the model

name and size of the stair you purchased on the

Installation Instructions for future reference. Keep

this instruction brochure with the installed stair. You

should have experience with squaring, leveling,

sawing, and aligning structural supports before

attempting to install this unit. If you do not have the

skills to install a window frame or door unit, please

hire a professional to install this stairway. Improper

installation could result in stairway collapse and

possible bodily injury.

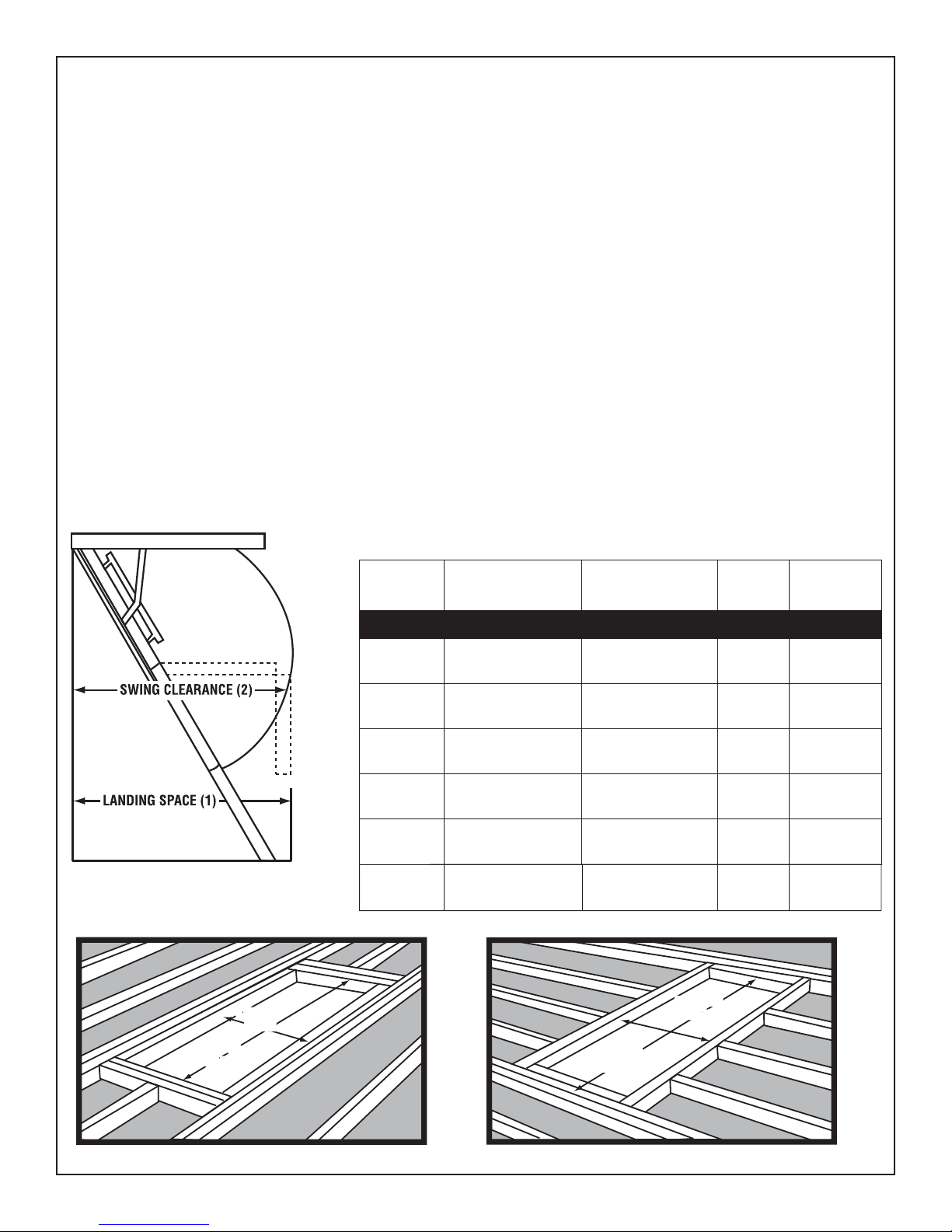

STEP 3:

LOCATING THE STAIRWAY:

A. Measure and verify ceiling height (the distance

from the nished oor to the nished ceiling)

prior to beginning installation.

B. Allow sufficient area for a safe landing space

at the bottom of the stairway. Be sure there

is enough clearance for the swing of the stair as

it is being unfolded to its full length (see FIGURE 1

for “landing space” and “swing clearance”;

match the ceiling heights shown on the packing

carton with the same ceiling height in TABLE A to

determine proper landing space and swing

clearance requirements).

STEP 2:

INSPECTION OF MERCHANDISE:

DO NOT DISASSEMBLE STAIRWAY! MAKE SURE ALL

NUTS, BOLTS AND SCREWS ARE SECURELY FASTENED.

Remove cord and pull-handle from stairway, place

through hole in plywood door and knot the end.

Model #*

WH2208

WH2210

WH2508

WH2510

WH3008

FIGURE 1 - WOOD STAIRWAYS

WH3010

*Products sold in Canada will have model numbers ending in "CA".

STEP 4:

MAKING THE OPENING:

A. Cut the rough opening through the ceiling material as

shown in TABLE A.

B. Frame the rough opening to the size shown in TABLE A.

C. If it is necessary to cut ceiling joists. BE SURE to tie the

cut members to other joists with a header or stringer

brace of the same dimensions

(see FIGURES 2 and 3).

Rough

Opening

Ceiling Height Range

WH Series (Load Rating: 350lbs./159 kg)

22 ½" x 54"

(0.57 m x 1.37 m)

22 ½" x 54"

(0.57 m x 1.37 m)

25" x 54"

(0.64 m x 1.37 m)

25" x 54"

(0.64 m x 1.37 m)

30" x 54"

(0.76 m x 1.37 m)

30" x 54"

(0.76 m x 1.37 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

Landing

Space (1)

56"

(1.42 m)

64"

(1.63 m)

56"

(1.42 m)

64"

(1.63 m)

56"

(1.42 m)

64"

(1.63 m)

Swing

Clearance (2)

62"

(1.57 m)

72"

(1.83 m)

62"

(1.57 m)

72"

(1.83 m)

62"

(1.57 m)

72"

(1.83 m)

TABLE A

STRINGER

STRINGER

BRACE

BRACE

HEADER

HEADER

BRACE

BRACE

NOTE: KEEP THE CORNERS SQUARE TO SIMPLIFY INSTALLATIONFIGURE 2 FIGURE 3

HEADER

BRACE

STRINGER

STRINGER

BRACE

BRACE

Page 5

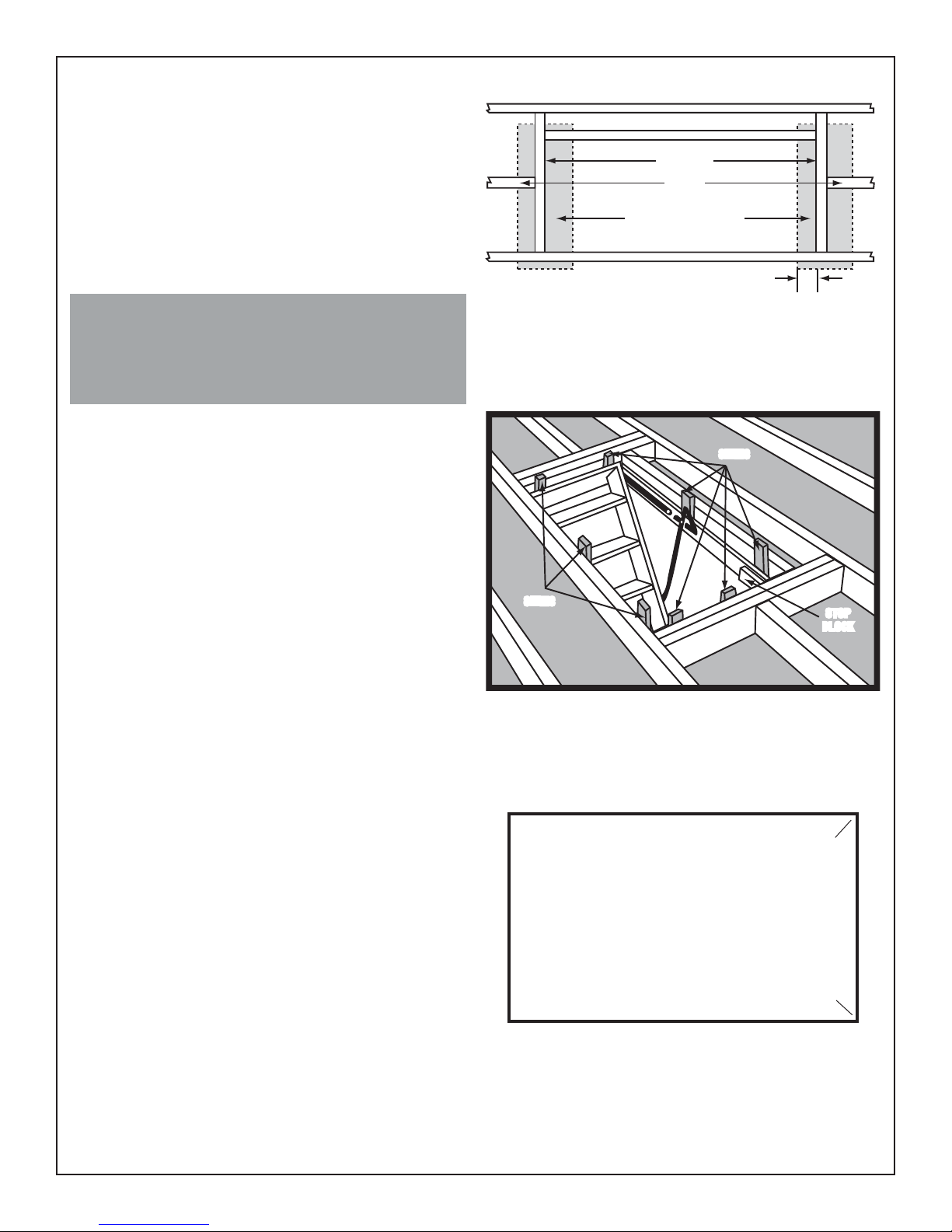

STEP 5:

INSTALLING TEMPORARY SUPPORTS

It is necessary to temporarily support the stairway in the

prepared rough opening by using 1 x 4 slats that extend

from edge to edge across each end of the rough opening.

The slats form a ledge to support the stairway before it is

permanently secured. Care is important in positioning the

slats. Nail the slats below the ceiling onto the headers as

close to the edges of the rough opening as practical for

maximum strength. They should extend only 3/8" - 5/8"

(0.95 cm x 1.59 cm) into the rough opening. The plywood

panel must be free to swing open (see FIGURE 4).

CEILING JOIST

HEADERS

JOIST

TEMPORARY SUPPORTS

3/8" to 5/8" (0.95cm x 1.59cm)

The slats must be nailed securely enough to temporarily

support the weight of the stairway when it is placed in the rough

opening.

CAUTION: DO NOT PLACE ANY WEIGHT ON THE STAIRWAY

UNTIL PERMANENT NAILING IS COMPLETED

STEP 6:

PLACING STAIRWAY INTO OPENING

A. While closed, the stairway should now be raised into the

rough opening and positioned on the ledges formed by

the slats. Working above with a helper below, raise the

stairway through the rough opening at an angle so it will

clear the slats. Position the stairway in the rough opening.

DO NOT STAND ON OR OPEN THE STAIRWAY AT THIS

TIME. Make sure you have a helper below who can open

the stairway to allow completion of the installation.

B. Using at least three evenly spaced 8d nails per side,

temporarily affix the stairway in the opening by nailing,

at an angle, the well sides to the adjacent joists. Do not

drive these nails in all the way so they can be removed

later after the permanent nailing is completed.

C. Once the temporary nailing has been completed, have

your helper below open the stairway door panel and lower

the stair sections so that the area for permanent nailing is

exposed. DO NOT STAND ON THE STAIRWAY AT THIS

TIME.

STEP 7:

PERMANENT MOUNTING OF STAIRWAY

A. Be sure stairway is square and level in the rough opening.

If the stair frame has bowed while the stairway was in

inventory, nails and blocks of wood used as shims will

straighten it. Bowing is normal since wood parts are

subjected to strong spring tension for some time before

purchase and installation (see FIGURE 5).

B. Nail the sides (jambs) of the stairway frame to the rough

opening frame, using 16d nails or 3" lag screws. Holes

are provided in the pivot plates and piano hinge brackets.

Also nail through the end boards into the rough opening

headers. Complete permanent installation by using 16d

nails or 3" lag screws to secure stairway frame on all four

sides of the rough opening according to the diagram in

FIGURE 6. Use at least three evenly spaced fasteners on

each box end and at least ve evenly spaced fasteners on

each box side. Remove the 8d nails and the slats used

for temporary support.

FIGURE 4 - FRAMED OPENING WITH TEMPORARY

SUPPORT SLATS READY TO RECEIVE STAIRS

SHIMSSHIMS

SHIMSSHIMS

FIGURE 5

X

X

X

X

BOX SIDE

BOX END

X

PIVOT PLATE

X

PIVOT PLATE

X

BOX SIDE

X

- INDICATES RECOMMENDED LOCATION OF 16d NAILS 3" OR LAG SCREWS

X

FIGURE 6

X X

BLOCK

BLOCK

X

CORNER

BRACKET

CORNER

BRACKET

XX

STOP

STOP

HEADER

X

XX

Page 6

STEP 8:

CRITICAL STEP: Proper measurement and cutting of the ladder rails is important for

safe operation of your attic ladder. For instructional video, go to www.wernerladder.com.

ADJUSTING STAIRWAY TO CEILING HEIGHT

Pull stairway down applying pressure so that hardware arms are

fully extended. Open the stair sections, folding bottom section

under the middle section. The top and middle sections should

form a straight line. Aligning your ruler on the same plane as the

two upper sections, measure the distance from the bottom of the

middle section to the oor on the front and back (see FIGURE

7A). Mark the distances obtained on the front and back sides of

the ends of the bottom section.

Trim bottom sections at the proper length and angles by cutting

across them. With the bottom section cut to the proper length and

angle, joints will be tight at each section with weight on the stairs.

If either of the trim lines pass through any part of the

step, remove the 14 gauge nail between the rail-to-step

connection on both sides of ladder section. Once the

nail is removed, cut the rail ush to the underside of the

step on both sides of section (see FIGURE 7B). Gently

tap the tread side of the step with a hammer to remove

(see FIGURE 7C).

FIGURE 7B FIGURE 7C

Adjusting your stairway is

accomplished in 3 easy steps:

1. MEASURE 2. MARK 3. CUT

PIANO HINGE

BRACKETS

CUT ACCORDING

3

TO MEASUREMENT

TRIM LINE

FIGURE 7A - ADJUSTMENT TO CEILING HEIGHTS

PIVOT PLATE

B

A

B

A

MARK MEASUREMENTS ON BOTTOM

2

SECTION TO MAKE TRIM LINE

END BOARD

1

MEASURE THESE

DISTANCES

WARNING: The bottom section must t ush with the oor. Failure to cut properly could result in undue stress on the

component parts of the stairway, resulting in serious injury (see FIGURES 8A, 8B and 8C).

FIGURE 8B - INCORRECT SETUP FIGURE 8C - INCORRECT SETUPFIGURA 8A - CORRECT SETUP

STEP 9:

TRIMMING THE STAIRWAY OPENING

A. Select a molding that blends with the trim in your home: a

5/8" or 2-1/4" Clam Shell molding is a popular choice.

B. Leave a 3/8" space between the door panel and the trim

at the hinge end of the stairway to provide clearance

when the stairway is opened.

C. The balance of the trim may be placed approximately 1/8"

from the edges of the plywood door panel.

D. Your installation is complete.

CAUTION: SAFETY TIP

t.BLFDFSUBJOUIFTUBJSXBZJTBMJHOFE

properly before each use.

Page 7

HERRAMIENTAS Y MATERIALES REQUERIDOS PARA LA INSTALACION

HERRAMIENTAS

REQUERIDOS:

Martillo

Escalera

Destornillador para

tornillos cruciformes

Destornillador para tor-

nillos de ranura

Escuadra

Cinta métrica

Serrucho

MATERIALES ADICIONALES NECESARIOS:

Tornillos Tirafondo de 3 pulgs

Clavos 16d

Clavos 8d

Listones de 1 x 4 para sostén temporal

(2 piezas de 32 pulgs. de largo aproximadamente)

Puntales con las mismas

dimensiones que las viguetas

Madera contrachapada de 1/4 o 3/8 de pulg. para calzas

Page 8

PASO 1:

ANTES DE LA INSTALACIÓN:

Verique que este producto y su instalación cumplen

todos los códigos de construcción aplicables. Revise

cuidadosamente la escalera en busca de daño por

transporte. Por favor escriba el nombre de modelo y

el tamaño de la escalera que usted compró, en las

Instrucciones de Instalación, para futura consulta.

Mantenga este folleto de instrucciones con la

escalera instalada. Usted debe tener experiencia con

el escuadreo (instalación de elementos en ángulo

recto), nivelación, aserrado y alineación de soportes

estructurales, antes de intentar instalar esta unidad.

Si usted no tiene las habilidades para instalar un

marco de ventana o una puerta, por favor contrate

un profesional para que instale esta escalera. La

instalación inapropiada podría resultar en desplome

de la escalera y posible lesión corporal.

PASO 2:

INSPECCION DEL PRODUCTO:

¡NO DESARME LA ESCALERA! VERIFIQUE QUE TODAS LAS

TUERCAS, PERNOS Y TORNILLOS ESTEN BIEN APRETADOS.

Quite la cuerda y la borla de la escalera, hágala pasar

por el oricio en la puerta de madera contrachapada y

haga un nudo en el extremo.

PASO 3:

UBICACION DE LA ESCALERA:

A. Antes de comenzar la instalación, mida y verique

la altura del techo (cielo raso) (la distancia

entre el piso terminado y el techo terminado).

B. Deje un área suciente para el espacio para el

descanso seguro de la parte inferior de la escalera.

Verique que haya suciente espacio libre para

la oscilación de la escalera, cuando ésta sea

desdoblada a su longitud total (vea en la FIGURA 1

"espacio para descanso" y

; iguale las alturas del techo mostradas en la caja

giro"

de empaque con la misma altura del techo en la TABLA

A, para determinar los requerimientos correctos para

los espacios para descanso y

"espacio libre para

espacio libre para giro).

PASO 4:

PARA HACER LA ABERTURA:

A. Corte la abertura preliminar en el material del techo tal

como se muestra en la TABLA A.

B. Enmarque la abertura preliminar al tamaño mostrado en

TABLA A.

C. Si es necesario cortar viguetas del techo, CERCIORESE

de asegurar los miembros cortados a otras viguetas

con un puntal de travesaño o larguero de las mismas

dimensiones (vea las FIGURAS 2 y 3).

ESPACIO LIBRE

PARA GIRO (2)

ESPACIO PARA

DESCANSO (1)

FIGURA 1 - ESCALERA DE MADERA

TRAVESAÑO

LONGITUDINAL

Modelo #* Abertura preliminar

Rango de alturas del

cielo raso

Espacio para

aterrizaje (1)

Serie WH (Capacidad de carga: 350 lbs./159 kg)

WH2208

WH2210

WH2508

WH2510

WH3008

WH3010

Los productos que se venden en Canadá tendrán los números de modelo con

la terminación "CA".

22 ½" x 54"

(0.57 m x 1.37 m)

22 ½" x 54"

(0.57 m x 1.37 m)

25" x 54"

(0.64 m x 1.37 m)

25" x 54"

(0.64 m x 1.37 m)

30" x 54"

(0.76 m x 1.37 m)

30" x 54"

(0.76 m x 1.37 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

TRAVESAÑO

LONGITUDINAL

56"

(1.42 m)

64"

(1.63 m)

56"

(1.342 m)

64"

(1.63 m)

56"

(1.42 m)

64"

(1.63 m)

Espacio libre

para giro (2)

62"

(1.57 m)

72"

(1.83 m)

62"

(1.57 m)

72"

(1.83 m)

62"

(1.57 m)

72"

(1.83 m)

TABLA A

TRAVESAÑO

CABECERO

NOTA: MANTENGA EN ÁNGULO RECTO LAS ESQUINAS PARA SIMPLIFICAR LA INSTALACIÓNFIGURA 2 FIGURA 3

TRAVESAÑO

CABECERO

Page 9

PASO 5:

INSTALACION DE LOS SOSTENES TEMPORALES

Es necesario sostener la escalera temporalmente dentro de la

abertura preliminar preparada, utilizando los listones de 1 x 4 que

se extienden de borde a borde a cada extremo de la abertura

preliminar. Los listones forman un resalto para sostener la

escalera antes que sea jada permanentemente. Es importante

tener cuidado al poner en posición los listones. Clave los listones

por debajo del techo a los travesaños tan cerca de los bordes

de la abertura preliminar como sea posible, para máxima

resistencia. Los listones deben sobresalir solamente de 3/8 a

5/8 de pulg. dentro de la abertura preliminar. El panel de madera

contrachapada debe quedar libre para poder oscilar y abrirse

(vea la FIGURA 4).

Los listones/tablillas deben asegurarse con clavos de manera

suficientemente firme para soportar temporalmente el peso de la

escalera cuando se coloque en la abertura preliminar.

PRECAUCIÓN: NO COLOQUE NINGÚN PESO SOBRE LA

ESCALERA HASTA FINALIZAR EL ASEGURAMIENTO

PERMANENTE CON CLAVOS

PASO 6:

COLOCACION DE LA ESCALERA

DENTRO DE LA ABERTURA

A. La escalera cerrada debe ser ahora levantada e introducida

dentro de la abertura preliminar y colocada en posición sobre

los resaltos formados por los listones. Trabajando por encima

con un ayudante por debajo, levante la escalera a través

de la abertura preliminar en ángulo para que pueda pasar

por los listones. Coloque la escalera en posición dentro de

la abertura preliminar. EN ESTE MOMENTO NO SE PARE

SOBRE LA ESCALERA NI LA ABRA. Asegúrese de que

tiene un ayudante debajo de la escalera para que pueda

abrirla y para terminar la instalación.

B. Utilizando varios clavos 8d, je la escalera temporalmente

dentro de la abertura clavando en ángulo los lados del

hueco a las viguetas adyacentes. No clave estos clavos

completamente para que se pueda sacarlos después que se

ha completado el clavado permanente.

C. Una vez que se ha completado el clavado temporal, instruya

a su ayudante que está debajo que quite los listones

temporales y que abra con cuidado el panel de la puerta de

la escalera, y que baje las secciones de la escalera de forma

que el área para el clavado permanente quede expuesto. NO

SE PARA SOBRE LA ESCALERA EN ESTE MOMENTO.

PASO 7:

MONTAJE PERMANENTE DE LA ESCALERA

A. Verique que la escalera está en escuadra y a nivel dentro

de la abertura preliminar. Si el marco de la escalera se

ha combeado mientras estaba almacenado, se lo puedo

enderezar con clavos y bloques de madera. El combeado es

normal debido a que las piezas de madera están sujetas a

la fuerte tensión del resorte durante un tiempo, antes de la

compra e instalación (vea la FIGURA 5).

B. Con los clavos 16d o con los tornillos tirafondos de 3 pulgados,

clave los lados (jambas) del marco de la escalera al marco de

la abertura preliminar. Se proveen oricios ya hechos en las

placas pivote y ménsulas de bisagra de piano. También clave

las tablas de los extremos dentro de los dinteles de la abertura

preliminar. Complete la instalación permanente clavando

sucientes clavos 16d para asegurar el marco de la escalera a

los cuatro lados de la abertura preliminar. Saque los clavos 8d

y los listones usados para sostén temporal.

VIGA DE CIELO RASO

CABECEROS

VIGA

SOPORTES TEMPORALES

3/8" to 5/8" (0.95 cm x 1.59 cm)

FIGURA 4 - ABERTURA ENMARCADA CON LISTONES DE SOPORTE

TEMPORAL LISTOS PARA RECIBIR LA ESCALERA

CALCES

CALCES

BLOQUE

DE TOPE

FIGURA 5

X

X

X

LADO DE CAJA

EXTREMO DE CAJA

X

X

PLACA DE PIVOTE

X

SOPORTE DE

ESQUINA

X

PLACA DE PIVOTE

X

LADO DE CAJA

X

- INDICA LA UBICACIÓN RECOMENDADA DE CLAVOS 16d

X

DE 3" ó TORNILLOS PARA MADERA

FIGURA 6

X X

SOPORTE DE

ESQUINA

XX

CABECERO

X

XX

Page 10

PASO 8:

PASO CRITICO: Medir y cortar correctament los rieles de la escalera es importante para la segura

operación de su escalera de atico. Para instrucciones en video, visite www.wernerladder.com.

AJUSTE DE LA ESCALERA A LA ALTURA DEL TECHO

Tire de la ecalera hacia abajo, aplicando presión para que los brazos

metálicos queden totalmente extendidos. Abra las secciones de la

escalera, doblando la sección inferior debajo de la sección del medio.

Las secciones superior y del medio deben formar una linea recta.

Alineando su regla al mismo plano de las dos secciones superiores,

mida la distancia desde la parte inferior de la sección del medio hasta

el piso, adelante y atrás (vea la FIGURA 7A). Marque las distancias

obtenidas de los lados de adelante y de atrás de los extremos de la

sección inferior.

Rebaje las secciones inferiores a la longitud y ángulos correctos

cortándolas transversalmente. Con la sección inferior cortada a la

longitud y ángulo correctos, las articulaciones estarán apretadas en

cada sección cuando haya peso sobre la escalera.

Si cualquiera de las líneas para recorte pasa a través

del cualquier parte del escalón, remueva el clavo calibre

14 entre la conexión de riel a peldaño en ambos lados

de la sección de escalera. Después de remover el clavo,

corte el riel a ras hasta el lado de abajo del peldaño en

ambos lados de la sección (vea la FIGURA 7B). Golpee

suavemente con un martillo el lado con huella del peldaño

para remover (vea la FIGURA 7C).

LÍNEA PARA RECORTE

FIGURA 7B FIGURA 7C

Ajustar su escalera se realiza a travez de los

siguientes 3 faciles pasos:

1. MIDA 2. MARQUE 3. CORTE

SOPORTES DE

BISAGRA TIPO

PIANO

CORTE DE ACUERDO

A LA MEDIDA

3

PLACA DE PIVOTE

B

A

MARQUE LAS MEDIDAS EN LA SECCION INFERIOR

2

B

PARA HACER LA LINEA DE CORTE

FIGURA 7A - AJUSTE DE ACUERDO A LAS ALTURAS

DEL CIELO RASO/TECHO

1

A

TABLA DE

EXTREMO

MIDA ESTAS

DISTANCIAS

ADVERTENCIA: La sección inferior debe apoyarse al ras con el piso. Si no es cortada correctamente, se podrían aplicar

esfuerzos indebidos a las piezas componentes de la escalera, y causar lesiones graves (vea las FIGURAS 8A, 8B y 8C).

SEPARACIÓN

LAS PATAS ESTÁN A

RAS CON EL PISO

FIGURA 8A

INSTALACIÓN CORRECTA

NO HAY

SEPARACIÓN

INSTALACIÓN INCORRECTA

SEPARACIÓNNO HAY

LAS PATAS NO ESTÁN A

RAS CON EL PISO

FIGURA 8B

SEPARACIÓN

LAS PATAS NO ESTÁN A

RAS CON EL PISO

FIGURA 8C

INSTALACIÓN INCORRECTA

PASO 9:

MONTAJE DE CONTRAMARCOS EN LA ABERTURA DE LA ESCALERA

A. Escoja una moldura que combine con las molduras en su casa: una moldura de 5/8

o 2-1/4 pulgadas Clam Shell (almeja) es una selección popular.

B. Deje un espacio de 3/8 de pulgada entre el panel de la puerta y la moldura en el

lado de las bisagras de la escalera, para proveer el espacio libre cuando se abre la

escalera.

C. El resto de la moldura puede ser colocado aproximadamente a 1/8 de pulgada de

los bordes del panel de la puerta de madera contrachapada.

D.

Su instalación está nalizada.

t"OUFTEFDBEBVTPDFSDJØSFTF

de que la escalera esté alineada

correctamente.

PRECAUCION:

CONSEJO DE SEGURIDAD

Page 11

OUTILS ET MATÉRIAUX NÉCESSAIRES POUR L'INSTALLATION

OUTILS NÉCESSAIRES :

Marteau

Échelle

Tournevis à pointe Philips

Tournevis pour vis à tête

mortaisée

Équerre

Mètre à ruban

Scie

MATÉRIAUX ADDITIONNELS NÉCESSAIRES :

Tire-fond de 3" (optionnel)

Clous 16d

Clous 8d

Planchettes de support temporaire de 1 x 4 (2 morceaux de

longueur 32" ou 81 cm environ)

Renforts de mêmes dimensions que les solives

Contreplaqué de 1/4" ou 3/8" pour faire des cales

Page 12

ÉTAPE 1 :

AVANT L’INSTALLATION :

Vériez que ce produit et son installation sont conformes

à toutes les normes de construction applicables.

Vériez l’échelle d’échelle soigneusement pour déceler

d’éventuels dommages par le transport. Veuillez

noter le nom du modèle et la taille de cette échelle

achetée sur son document d’instructions d’installation

comme référence ultérieure. Conservez ce document

d’installation sur le lieu du produit installé. Vous devez

avoir suffisamment d’expérience d’équerrage, de mise à

niveau, de sciage et d’alignement de supports structurels

avant de tenter d’installer cette unité. Si vous n’avez

pas les compétences pour installer un encadrement de

fenêtre ou de porte, veuillez embaucher un professionnel

pour installer cette échelle d’échelle. Une installation

incorrecte pourrait résulter en un effondrement de

l’échelle et de possibles blessures corporelles.

ÉTAPE 2 :

INSPECTION DE LA MARCHANDISE :

NE DÉMONTEZ PAS L’ÉCHELLE! ASSUREZ-VOUS QUE

L’ENSEMBLE DES ÉCROUS, BOULONS ET VIS EST BIEN SERRÉ.

Enlevez le cordon et la poignée de tirage de l’échelle,

placez-les au travers du trou dans la trappe en contreplaqué et faites un nœud à l’extrémité.

ÉTAPE 4 :

LOCALISATION DE L’ÉCHELLE :

A. Mesurez et vériez la hauteur de plafond (la distance

entre la nition de plancher et la nition de plafond)

avant de commencer l’installation.

B. Prévoyez une zone suffisante pour un espace de contact

d’arrivée au sol en bas de l’échelle. Assurez-vous qu’il y

a assez d’espacement pour le déploiement de l’échelle

quand il est déplié sur toute sa longueur (Voir la FIGURE

1 pour l’espace de contact et la projection ; comparez les

hauteurs de plafond montrées sur le carton d’emballage

avec la même hauteur de plafond au TABLEAU A, pour

déterminer les besoins adéquats en espace de contact

au sol et en projection).

ÉTAPE 4 :

RÉALISATION DE L’OUVERTURE :

A. Découpez l’ouverture brute dans le matériau du plafond

comme montré au TABLEAU A.

B. Dimensionnez l’ouverture brute à la taille montrée au

Tableau A.

C. S’il est nécessaire de couper des solives du plafond : NE

MANQUEZ PAS de xer les membres coupés à d’autres

solives avec un chevêtre ou un tirant comme renfort, des

mêmes dimensions (Voir les FIGURES 2 et 3).

RAYON DE ROTATION (2)

ESPACE DE CONTACT (1)

FIGURE 1 – ÉCHELLES EN BOIS

N° de

modèle

Ouverture

brute

Plage de hauteur

de plafond

Espace de

contact (1)

Série WH (Classification de charge : 350 lbs./159 kg)

WH2208

WH2210

WH2508

WH2510

WH3008

WH3010

Les numéros de modèles de produits vendus au Canada se termineront par "CA".

22 ½" x 54"

(0.57 m x 1.37 m)

22 ½" x 54"

(0.57 m x 1.37 m)

25" x 54"

(0.64 m x 1.37 m)

25" x 54"

(0.64 m x 1.37 m)

30" x 54"

(0.76 m x 1.37 m)

30" x 54"

(0.76 m x 1.37 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

84" - 105"

(2.30 m x 2.67 m)

105" - 124"

(2.67 m x 3.15 m)

56"

(1.42 m)

64"

(1.63 m)

56"

(1.42 m)

64"

(1.63 m)

56"

(1.42 m)

64"

(1.63 m)

Rayon de

rotation (2)

62"

(1.57 m)

72"

(1.83 m)

62"

(1.57 m)

72"

(1.83 m)

62"

(1.57 m)

72"

(1.83 m)

TABLEAU A

STRINGER

RENFORT

BRACE

PAR TIRANT

HEADER

RENFORT PAR

BRACE

CHEVÊTRE

REMARQUE : GARDEZ LES ANGLES BIEN D’ÉQUERRE POUR SIMPLIFIER L’INSTALLATION FIGURE 3FIGURE 2 FIGURE 3

STRINGER

RENFORT PAR

BRACE

HEADER

RENFORT PAR

BRACE

CHEVÊTRE

TIRANT

Page 13

ÉTAPE 5 :

INSTALLATION DE SUPPORTS TEMPORAIRES :

Il est nécessaire de supporter temporairement l’échelle dans

l’ouverture brute préparée en utilisant des planchettes de 1 x 4"

de section, qui s’étendent de bord à bord en travers de chaque

extrémité de l’ouverture brute. Ces planchettes forment des appuis

pour supporter l’échelle avant qu’elle soit xée de façon permanente.

Il est important de positionner soigneusement les planchettes.

Clouez les planchettes sous le plafond dans les chevêtres aussi

près des bords de l’ouverture brute que possible en pratique pour

avoir une résistance maximale. Elles ne doivent dépasser que de

3/8" - 5/8" (9.5 - 15.9 mm) dans l’ouverture brute. Le panneau en

contreplaqué doit pouvoir s’ouvrir librement (Voir la FIGURE 4).

SOLIVE DE PLAFOND

CHEVÊTRES

SOLIVE

SUPPORTS

TEMPORAIRES

3/8 x 5/8" (0.95 x 1.59 cm)

Les planchettes doivent être clouées assez bien pour supporter

temporairement le poids de l’échelle quand il est placé dans l’ouverture

brute.

ATTENTION : NE PLACEZ AUCUNE CHARGE SUR L’ÉCHELLE AVANT

QUE SON CLOUAGE PERMANENT SOIT TERMINÉ.

ÉTAPE 6 :

PLACEMENT DE L’ÉCHELLE DANS L’OUVERTURE

A. En étant fermée, l’échelle doit maintenant être hissée dans

l’ouverture brute et positionnée sur les appuis formés par

les planchettes. En travaillant au-dessus avec une aide en

dessous, levez l’échelle au travers de l’ouverture brute avec

une inclinaison de façon à passer les planchettes. Positionnez

l’échelle dans l’ouverture brute.

NE VOUS TENEZ PAS SUR L’ÉCHELLE, OU NE L’OUVREZ

PAS À CE STADE. Assurez-vous que votre aide en bas pourra

ouvrir l’échelle pour permettre de terminer l’installation.

B. En utilisant au moins trois clous 8d espacés régulièrement sur

chaque côté, xez temporairement l’échelle dans l’ouverture en

clouant avec un angle les côtés du puits aux solives adjacentes.

N’enfoncez pas complètement ces clous, pour pouvoir les

enlever aisément plus tard après le clouage permanent.

C. Une fois que ce clouage temporaire est ni, demandez à

votre aide en bas d’ouvrir le panneau de trappe de l’échelle

et d’abaisser ses sections de sorte que la zone pour le

clouage permanent soit exposée. NE VOUS TENEZ PAS SUR

L’ÉCHELLE À CE STADE.

ÉTAPE 7 :

MONTAGE PERMANENT DE L’ÉCHELLE

A. Assurez-vous que l’échelle est bien d’équerre et de niveau dans

l’ouverture brute. Si le cadre de l’échelle a travaillé pendant

que l’échelle était en inventaire, des clous et des blocs de bois

utilisés comme cales vont le redresser. Du cintrage est normal

car les pièces en bois sont soumises à une forte tension de

ressort pendant un certain temps entre l’achat et l’installation

(Voir la FIGURE 5).

B. Clouez les côtés (montants) du cadre d’échelle sur

l’encadrement de l’ouverture brute, en utilisant des clous 16d

ou des tire-fond de 3". Des trous sont fournis dans les plaques

de pivotement et les supports de charnières à piano. Clouez

aussi au travers des planches d’extrémité dans les linteaux de

l’ouverture brute. Complétez l’installation permanente en utilisant

des clous 16d ou des tire-fond de 3" pour xer le cadre d’échelle

sur les quatre côtés de l’ouverture brute selon le diagramme

de la FIGURE 6. Utilisez au moins trois xations espacées

régulièrement sur chaque extrémité de boîte, et au moins cinq

xations espacées régulièrement sur chaque côté de boîte.

Enlevez les clous 8d plantés et les planchettes utilisées comme

support temporaire.

FIGURE 4 – OUVERTURE ENCADRÉE AVEC PLANCHETTES DE SUPPORT TEM-

CALESCALES

PORAIRE PRÊTE À RECEVOIR L’ÉCHELLE

CALESCALES

FIGURE 5

BLOC

BLOC

D’ARRÊT

D’ARRÊT

X

X

X

CÔTÉ DE BOÎTE

EXTRÉMITÉ DE BOÎTE

X

X

CÔTÉ DE BOÎTE

X

X

X

- INDIQUE L’EMPLACEMENT RECOMMANDÉ POUR LES CLOUS

X

PLAQUE DE PIVOTEMENT

PLAQUE DE PIVOTEMENT

X X

16D OU LES TIRE-FOND 3"

FIGURE 6

X

SUPPORT

D’ENCOIGNURE

EXTRÉMITÉ DE BOÎTE

SUPPORT

D’ENCOIGNURE

XX

X

XX

Page 14

ÉTAPE 8 :

ÉTAPE CRITIQUE : Une mesure et une coupe appropriées des montants de l’échelle sont importantes pour un

fonctionnement sûr de votre échelle de grenier. Pour visionner une vidéo d’instructions, allez sur le site www.wernerladder.com.

AJUSTAGE DE L’ÉCHELLE À LA HAUTEUR DU PLAFOND

Tirez en appliquant une pression an que les bras mécaniques soient

complètement déployés. Ouvrez les sections de l’échelle, en pliant la

section inférieure sous la section du milieu. Les sections supérieure et

du milieu doivent être alignées. Alignez votre mètre à ruban sur le même

plan que les deux sections du haut, mesurez la distance restante entre

le bas de la section du milieu et le plancher à l’avant et à l’arrière (Voir

la FIGURE 7A). Marquez les distances obtenues sur les côtés avant et

arrière des extrémités de la section du bas.

Coupez les sections du bas à la longueur appropriée et en biseau en

travers. La section du bas ayant été coupée avec les longueurs et l’angle

de coupe adéquats, les jonctions doivent être serrées à chaque section

avec une charge sur l’échelle.

Si l’une des lignes de découpe passe par une quelconque

partie de marche, enlevez le clou de 14 entre la connexion de

montant sur marche, des deux côtés de la section d’échelle.

Une fois ce clou ôté, coupez le montant au niveau de la face

inférieure de la marche des deux côtés de section (Voir la

FIGURE 7B). Frappez doucement le côté avec lets de la

marche avec un marteau pour l’enlever (Voir la FIGURE 7C).

FIGURE 7B FIGURE 7C

Le réglage de votre échelle se fait en

3 étapes faciles :

1. MESURE 2. MARQUAGE 3. COUPE

SUPPORTS DE

CHARNIÈRES À PIANO

COUPEZ SELON LES

3

MESURES

LIGNE DE COUPE

FIGURE 7A - AJUSTEMENT AUX HAUTEURS DE PLAFONDS

PLAQUE DE PIVOTEMENT

B

A

B

A

ARQUEZ LES MESURES SUR LA

2

SECTION DU BAS POUR TRACER UNE

LIGNE DE RACCOURCISSEMENT

PLANCHE

D’EXTRÉMITÉ

1

MESUREZ CES

DISTANCES

AVERTISSEMENT : La section du bas doit arriver pile au plancher. Le fait de ne pas couper correctement peut entraîner une contrainte

anormale sur les parties constitutives de l’échelle, et provoquer une blessure grave (Voir les FIGURES 8A, 8B et 8C).

PAS D’INTERVALLE

PAS D’INTERVALLE

LES PIEDS SONT

AU NIVEAU DU

PLANCHER

FIGURE 8B – MISE EN PLACE INCORRECTE FIGURE 8C – MISE EN PLACE INCORRECTEFIGURE 8 – MISE EN PLACE CORRECTE

INTERVALLE

LES PIEDS SONT

AU NIVEAU DU

PLANCHER

INTERVALLE

LES PIEDS SONT

AU NIVEAU DU

PLANCHER

ÉTAPE 9 :

HABILLAGE DE L’OUVERTURE D’ÉCHELLE

A. Sélectionnez une moulure qui soit assortie avec celles dans votre

maison : une moulure double face de 5/8" ou 2-1/4" est un choix

populaire.

B. Laissez un espace de 3/8" entre le panneau de trappe et la gar-

niture à l’extrémité de charnière de l’échelle, pour laisser la place

nécessaire quand l’échelle est ouvert.

C. Le centrage de la garniture peut être placé à environ 1/8" des bords

du panneau de trappe en contreplaqué.

D. Votre installation est terminée.

ATTENTION : CONSEILS DE SÉCURITÉ

t$POUSÙMF[RVFMÏDIFMMFFTUDPSSFDUFNFOU

alignée avant chaque utilisation.

Page 15

Page 16

Werner Co.

93 Werner Rd.

Greenville, PA 16125-9499

Werner Access Products Canada, ULC

60 Admiral Blvd.

Mississauga, ON L5T 2W1

Telephone/Teléfono/Téléphone:

(U.S.) 888-523-3370

(Canada) 877-553-7004

www.wernerladder.com/atticladder

PN104366-01 Rev A 10/11 ©2011 Werner Co.

Loading...

Loading...