Page 1

Page 2

INTRODUCTION

WELCOME TO THE WERNER

TM

CLIMBING PRO

This program is about ladder safety. The two principal causes of ladder

related injuries are using the wrong ladder for the job and misusing or abusing

climbing equipment.

Our goals are very simple: We want to help you better understand how to

choose the right ladder for the job and learn how to use ladders more safely.

Your work will be easier and more productive too. Ladder related injuries are

preventable, but it takes “you” to prevent them.

If you have product or safety questions, please ask your Werner Ladder

Distributor or call the Werner Customer Service Department at

1-888-523-3371 for assistance.

SAFETY TRAINING

LADDER SAFETY PROGRAM GUIDE ...............................................................................................................................4-5

LADDER STYLES .............................................................................................................................................................6-7

CHOOSING THE RIGHT LADDER FOR THE JOB ................................................................................................................. 8

SIZE ...................................................................................................................................................................... 8

DUTY RATING .......................................................................................................................................................9

MATERIAL ........................................................................................................................................................... 10

LADDER INSTRUCTION LABELS ................................................................................................................................. 11-12

PROPER HANDLING ......................................................................................................................................................... 13

SETUP AND USE .......................................................................................................................................................... 14-15

SAFE CLIMBING HABITS - RIGHT WAY / WRONG WAY .............................................................................................. 16-18

STEPLADDERS .................................................................................................................................................................. 19

EXTENSION LADDERS .................................................................................................................................................21-26

CARE AND MAINTENANCE ............................................................................................................................................... 27

LADDER COMPONENTS ..............................................................................................................................................28-29

LADDER INSPECTION ................................................................................................................................................ 30-34

FREQUENTLY ASKED QUESTIONS ................................................................................................................................... 35

KNOWLEDGE CHECK ........................................................................................................................................................ 36

WERNER CO. BRAND PORTFOLIO ....................................................................................................................................39

The Werner Climbing PRO™ Training Program is not intended to be a complete ladder safety training program. It is designed to provide a general

overview of basic Werner ladder safety through ladder selection and illustrated safety tips.

Numerous federal, state, local, OSHA and industry regulations apply to ladders. It is your responsibility to be aware of and to comply with these

rules and regulations. OSHA regulations mandate that employers provide training regarding the proper use of ladders. For further information,

contact your local OSHA office.

2

Page 3

Werner ladders are manufactured and tested to the strictest quality standards. All Werner ladders meet or exceed

American National Standards Institute (ANSI) and Occupational Safety and Health Administration (OSHA) requirements,

where applicable.

OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION CODE

All Type II, I, IA and IAA fiberglass, aluminum and wood

ladders, ladder jacks and extension planks meet or exceed

code. OSHA CODE applies to ladders used in the workplace.

Werner Co. recommends Type II or heavier duty rated ladders

for these applications.

AMERICAN NATIONAL

STANDARDS INSTITUTE

PRODUCT LINES MEET OR

EXCEED ANSI CODE

Fiberglass Ladders .....................A14.5 (2017)

Aluminum Ladders .....................A14.2 (2017)

Ladder Jacks ..............................A10.8 (2019)

Extension Planks ........................A10.8 (2019)

Scaffolding .................................A10.8 (2019)

Stages ........................................A10.8 (2019)

Work Platforms ..........................A10.8 (2019)

Attic Ladders ..............................A14.9 (2019)

Ladder Accessories ....................A14.8 (2013)

Step Stools ..............................A14.11 (2018)

3

Page 4

LADDER SAFETY PROGRAM GUIDE

RECOMMENDED TRAINING PROGRAM STRUCTURE

I Advance Preparation

This ladder training consists of:

V3

1. LADDER SAFETY

2. LADDER SAFETY

Prior to conducting your first training session, please review the Video and thoroughly study the training manual. As you view

the Video and read the manual, think about the questions that might arise.

Werner products, if available should be taken from customer’s existing inventory for demonstration purposes:

1. Stepladder (1)

2. Extension ladder (1)

3. Podium ladder (1)

4. Twin Stepladder (1)

5. Leansafe ladder (1)

II Conducting the Training Course

training manual (1 copy)

V3

training video (English & Spanish)

A. Introduce the program by reviewing the benefits, then discuss the two leading causes of ladder related injuries: (5 minutes)

a. Using the wrong ladder for the job

b. Misusing or abusing climbing equipment

This program has been established into sections:

a. “How To Choose” the right ladder for the job

b. “How to Use” ladders safely

B. Play the Video (Approximately 20 minutes)

C “How To Choose” the right ladder

i. Style

1. Determine if a stepladder, extension ladder or special application ladder is required

2. Review the various designs available and where they can be used:

EXAMPLE:

1. Twin stepladders are used when two people need to work together on the same job

2. Fiberglass tripod ladders are used to work in tight areas, around corners, through studs and uneven ground

3. Leansafe ladders are used to securely lean against a flat wall surface, wall corner, pole, wall stud and perform

as a standard stepladder.

ii. Select Height (Size)

1. Choose the right stepladder, extension ladder or specialty ladder height

2. Discuss the highest standing level or length

3. Refer to chart located on page 8

4

Page 5

II Conducting the Training Course (continued)

iii. Select Performance (Duty Rating)

1. Review the different duty ratings and what they mean

a. Duty rating is the total weight the ladder is designed to support (Total weight is the sum of a person’s weight plus the

weight of any tools, clothing and materials.); this total weight must not exceed the duty rating.

iv. Select Material

1. Discuss the various materials used in the fabrication of ladders and their unique advantages

a. Fiberglass:

i. 7-layer construction

ii. For use around electricity

iii. Durable and corrosion resistant

iv. Pro-preferred

b. Aluminum

i. Lightweight

ii. Not for use around electricity

iii. Durable and Corrosion resistant

D. “How to use a ladder”

a. Reading instruction labels

i. Discuss general information on labels and show the label order form

b. Proper handling

c. Setup and use

d. Safe Climbing Habits - Right Way

e. Safe Climbing Habits - Wrong Way

f. Care and Maintenance

i. Plan and implement regular maintenance program

ii. Keep ladder clean

iii. Replace worn or damaged parts or ladders; “If in doubt, tag it out of service.”

iv. Important: Discuss the availability of replacements parts. Only Werner replacements parts should be used on Werner

ladders.

g. Ladder Inspection

i. Procedure for examining a ladder prior to climbing

ii. Know the various components of the ladder

Iii. Show different ladder inspection forms

Scan me

DOWNLOAD LADDER

SAFETY TRAINING

5

Page 6

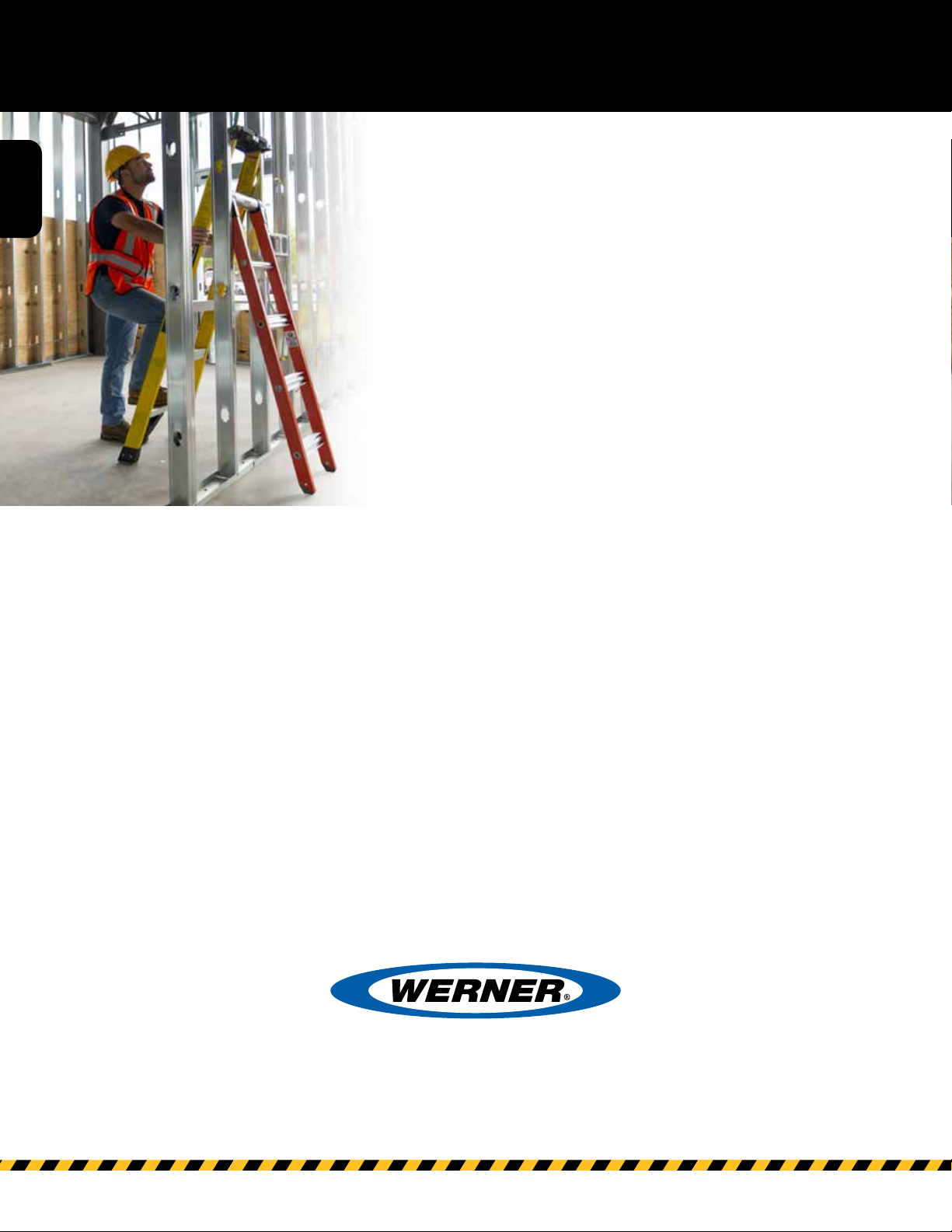

LADDER STYLES

KNOW THE DIFFERENCE

Some workers might not realize the differences from one ladder to the next and they think a ladder is a ladder WRONG!

Having the right ladder for the job is the safest way to complete any task. Using the wrong ladder is extremely

dangerous, as it often leads to ladder misuse or abuse, and can result in serious injury or even death.

6200 STEPLADDER

• Used for applications at low

or medium heights.

• Ladder tops and pail

shelves can hold tools,

small parts and paint

buckets.

LEANSAFE™

• Securely leans against walls,

poles, corners, and wall

studs.

• Ladder top has non-marring

rubber bumper and holds

tools to increase productivity.

• Color and branding

differentiates LEANSAFE™

from standard stepladders.

PODIUM

• 4X Work Zone to reach

all directions

• Extra-large platform for long

standing comfort

• LOCKTOP™ extended

guardrail

LEANSAFE® X3

• Seamlessly go from step

to straight ladder in one

adjustment

• One handed lock adjustment

• All in one top, no adjustment

needed

• Non-marring rubber top

protects work surfaces

• Compact rear rails fit

between framing studs

TRIPOD

• Enhance stability on uneven

surfaces

• Back rail fits easily into tight

corners and other confined

spaces.

6

Page 7

TWIN STEP

• Ideal for many painting,

framing, siding and other

construction applications.

• Steps on both sides for

two-way access

• Two people can work on a

task from one ladder.

EXTENSION LADDER

• Work in an extremely wide

range of tasks at varying

elevations

• Exclusive ALFLO® rung

joint means TWIST-PROOF®

performance

TRESTLE

• Adjustable center trestle

system. Often used in pairs

with either a 12" or 14"

wide stage or plank at fixed

heights.

• The center section can be

extended to approximately 20’

on the 12' model.

STRAIGHT LADDER

• Provide easy access to

mid-range heights

• Single one-section

non-extendable

SECTIONAL LADDER

• Designed for use mainly by

electrical, telephone, and

cable utilities.

• Provides versatility where

transit, storage or access

requires short sections to be

coupled together.

ACCESSORIES

• Create climbing equipment

systems with extension

ladders, ladder jacks and

aluminum stages.

• Great for working side to side.

7

Page 8

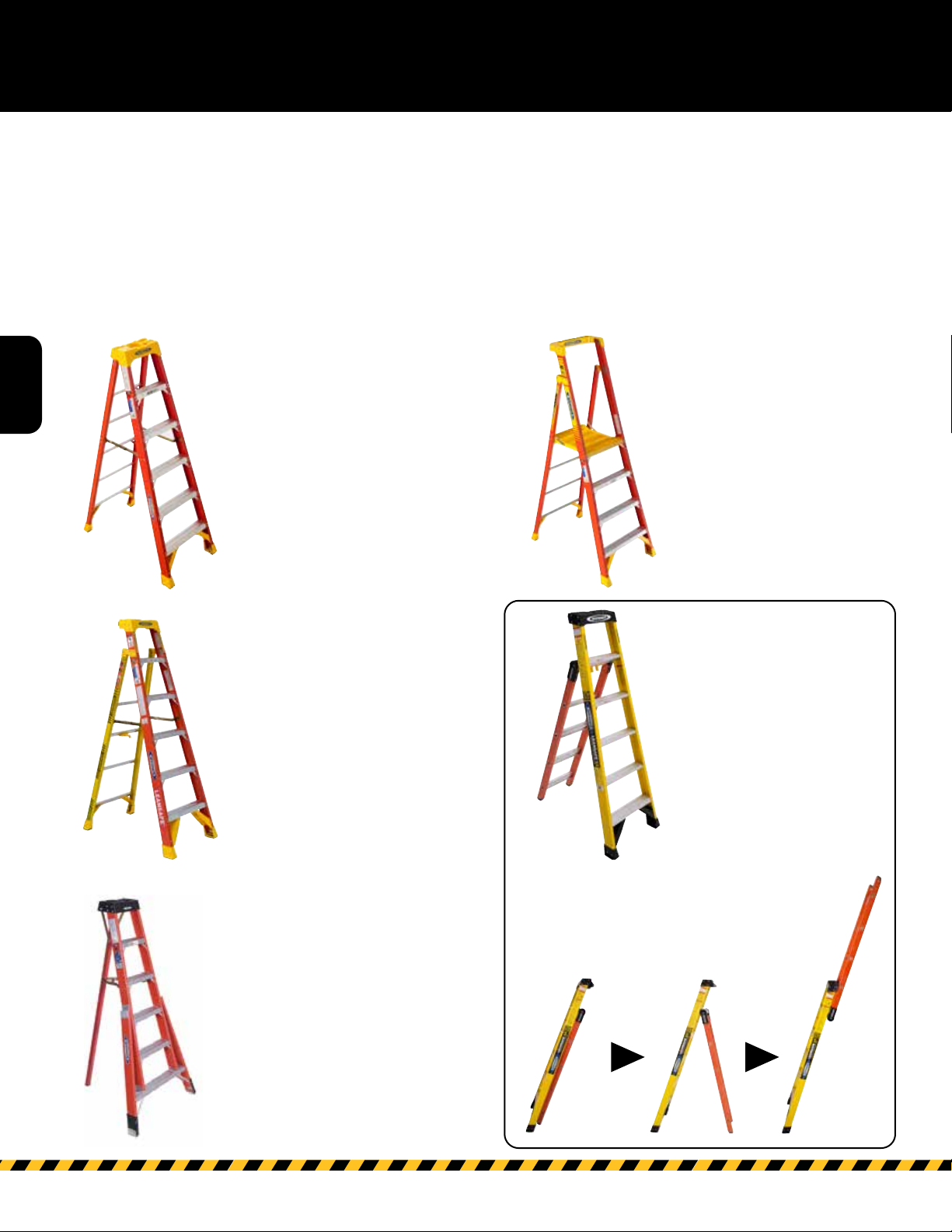

CHOOSING THE RIGHT LADDER FOR THE JOB

Average Heights

Average Heights

11'

19'

17'

25'

STEPLADDERS

17'

11'

To ensure you choose the ladder best suited

to your needs, follow the Werner height

safety charts.

The highest permitted standing level on a step

25'

19'

ladder is two steps down from the top. A person

standing higher may lose their balance and fall.

A person’s maximum safe reaching height is

approximately 4’ higher than the height of the

ladder. For example, a typical person can safely

reach an 8’ ceiling on a 4’ ladder*.

EXTENSION LADDERS

Support Points

Extension ladders should be 7 to 10 feet longer

than the highest support or contact point, which

may be the wall or roof line. This will allow

enough length for proper setup, the overlap of

ladder sections, height restrictions of the highest

standing level, and where appropriate, the

extension of the ladder above the roof line. The

highest standing level is four rungs down from

the top.

8

Page 9

200-225lb

LOAD CAPACITY

TYPE III - TYPE II

250lb

LOAD CAPACITY

TYPE I

LIGHT DUTY - BASIC DESIGNS

300lb

LOAD CAPACITY

TYPE IA

HEAVY DUTY - RUGGED & DURABLE

Ladders are designed and constructed to safely hold up to a

specific amount of weight. Werner ladders come in different

Duty Ratings, identified by their grade and type.

The Duty Rating, is defined as the maximum safe load

capacity of the ladder. A person’s fully clothed weight plus

the weight of any tools and materials that are carried onto the

ladder must be less than the duty rating.

Workers should be advised to consider both the weight,

which will be on the ladder and the work application, and to

select the proper grade of ladder, which is designed to handle

anticipated usage.

MEDIUM DUTY - LIGHTWEIGHT DESIGNS

375lb

LOAD CAPACITY

TYPE IAA

COMMERCIAL GRADE - MOST DURABLE

APPROXIMATE MATERIAL WEIGHTS

Bundle of Shingles 70lbs

5 gallons roof coating 70lbs

5 gallons paint 60lbs

Tool box with tools 35lbs

Portable sprayer 20lbs

Ceiling fan 30lbs

3x4 window 80lbs

Garage door opener 40lbs

Basketball hoop 60lbs

Sheet of plywood 80lbs

(3) 4x4’s 80lbs

9

Page 10

LADDER INSTRUCTION LABELS

ST

ST

NON CONDUCTIVE FOR WORKING

NEAR ELECTRICITY

WON’T DENT, SHATTER, RUST

OR CORRODE

DESIGNED AND TESTED FOR

EXTREME TEMPERATURES

HIGH VISIBILITY COLOR

NON CONDUCTIVE FOR WORKING

NEAR ELECTRICITY

WON’T DENT, SHATTER, RUST

OR CORRODE

DESIGNED AND TESTED FOR

EXTREME TEMPERATURES

HIGH VISIBILITY COLOR

DESIGNED AND TESTED FOR

EXTREME TEMPERATURES

NOT FOR USE

NEAR ELECTRICITY

WON’T DENT, SHATTER, RUST

OR CORRODE

NON CONDUCTIVE FOR WORKING

NEAR ELECTRICITY

WON’T DENT, SHATTER, RUST

OR CORRODE

DESIGNED AND TESTED FOR

EXTREME TEMPERATURES

HIGH VISIBILITY COLOR

NON CONDUCTIVE FOR WORKING

NEAR ELECTRICITY

DESIGNED AND TESTED FOR

EXTREME TEMPERATURES

Most fiberglass ladders used by Pros are orange and yellow. Make sure to check

the I.D. label to confirm the duty rating of your ladder.

NOT FOR USE

NEAR ELECTRICITY

DESIGNED AND TESTED FOR

EXTREME TEMPERATURES

WON’T DENT, SHATTER, RU

OR CORRODE

HIGH VISIBILITY COLOR

WON’T DENT, SHATTER, RU

OR CORRODE

10

Page 11

I.D. & SAFETY LABELS

MANUFACTURER CERTIFIES

CONFORMANCE TO

APPLICABLE STANDARDS

Model Number

Número de modelo

Highest Standing Level

El nivel más alto pa ra

colocarse de pi e

Ladder Size

Tamaño de la escaler a

Maximum Reach*

Alcance máxi mo*

*

Assumes a 5ft 6in

person with a

vertical 12in re ach

*

Se asume una persona

con altura de 1.68m con u n

alcance vertic al de .30m

376

Mk 32

MANUFACTURER CERTIFIES

CONFORMANCE TO

APPLICABLE STANDARDS

3ft 10in

1.17m

10ft

3.05m

6ft

1.83m

ANSI A14.2

© 2018 Werner Co.

Greenville, PA 16125

P/N 114852-79 Rev C 7/18

Made in Mexico / Hecho en Mexico

114852

PROFESSIONAL

PERFORMANCE

Desempeño profesional

Capacidad de car ga 136kg / Tipo IA

TYPE

IA

MAX. LOAD

CAPACITY

300

lb

Includes User and Material s

Incluye el Usuario y los Material es

MANUFACTURER CERTIFIES

CONFORMANCE TO

APPLICABLE STANDARDS

Model Number

Número de modelo

Highest Standing Level

El nivel más alto pa ra

colocarse de pi e

Ladder Size

Tamaño de la escaler a

Maximum Reach*

Alcance máxi mo*

*

Assumes a 5ft 6in

person with a

vertical 12in re ach

*

Se asume una persona

con altura de 1.68m con u n

alcance vertic al de .30m

7306

Mk 6

MANUFACTURER CERTIFIES

CONFORMANCE TO

APPLICABLE STANDARDS

3ft 10in

1.17m

10ft

3.05m

6ft

1.83m

ANSI A14.5

© 2017 Werner Co.

Greenville, PA 16125

P/N 115091-13 Rev B 08/18

Made in Mexico / Hecho en Mexico

Non-Conductive

Fiberglass

Side Rails

Rieles Laterales de

Fibra de Vidrio

No-Conductores de

la Electricidad

INDUSTRIAL

PERFORMANCE

Capacidad de car ga 170kg / Tipo IA A

TYPE IAA

MAX. LOAD

CAPACITY

375

lb

Includes User and Material s

Incluye el Usuario y los Material es

115091

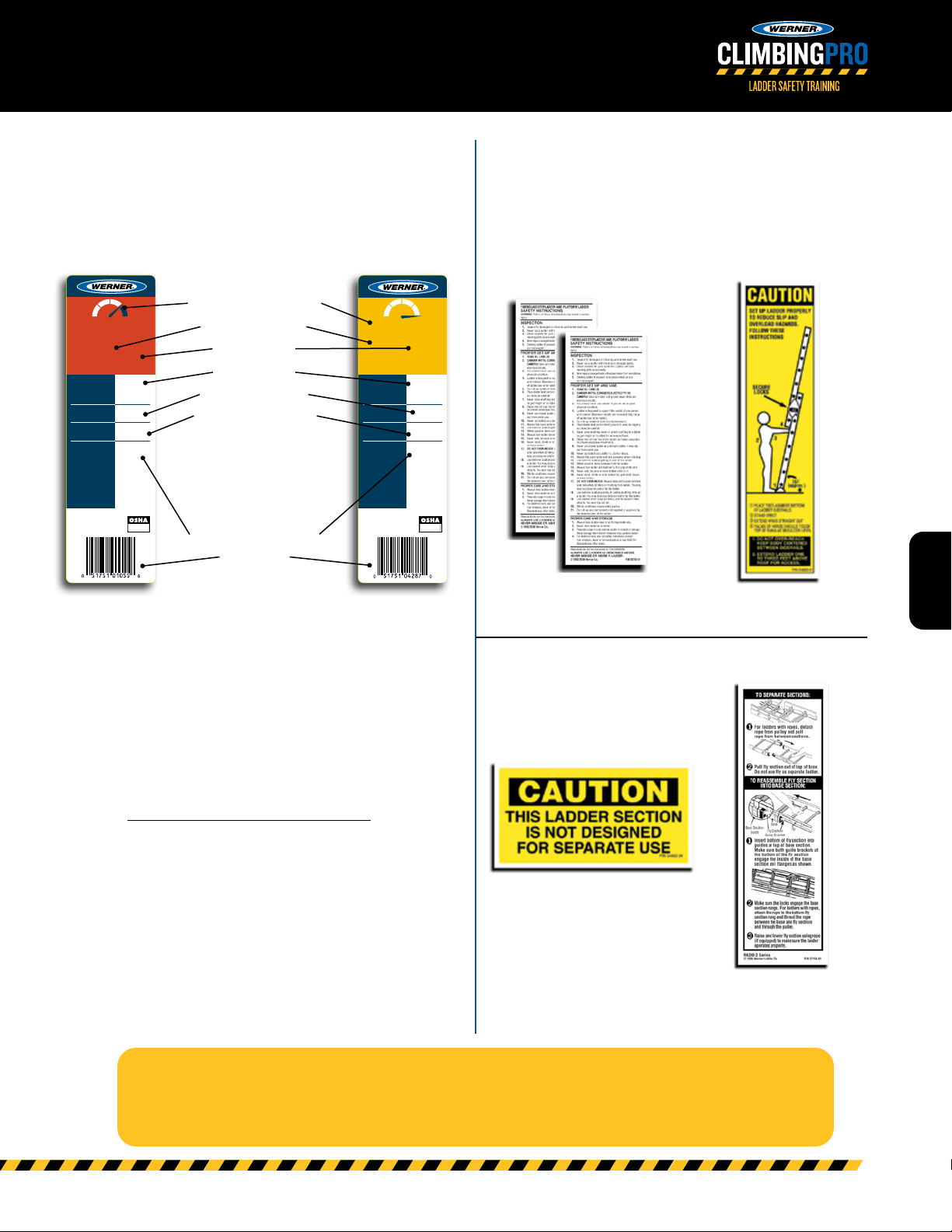

LADDER IDENTIFICATION LABELS

I.D. labels provide important information regarding each ladder’s

Model Number, Type, Duty Rating, Size, and Highest Standing

Level.

Stepladder

I.D. Label

PERFORMANCE

LOAD CAPACITY

DUTY RATING

LADDER SIZE

MAXIMUM REACH

HIGHEST STANDING

LEVEL

is the maximum safe

working height

• Stepladders: 2nd step down

from the top

• Extension ladders: 4th rung

down from the top

MODEL (ID) NUMBER

UPC CODE

Extension Ladder

I.D. Labe

l

SAFETY INSTRUCTIONS FOR

STEP & EXTENSION LADDERS EXTENSION LADDER SETUP

Safety instruction labels

contain information

regarding the inspection,

setup and use, and care

and storage of ladders.

This label provides safety

instructions to properly

set-up an extension ladder

and check that it is at a

75-½° angle.

Extra Heavy Duty

Combined weight of user and material should not exceed duty rating

Orange Label

For Type IA

APPROXIMATE MATERIAL WEIGHTS

Bundle of shingles 70 lbs.

5 gallon roof coating 70 lbs.

5 gallons paint 60 lbs.

Tool box with tools 35 lbs.

Portable sprayer 20 lbs.

Ceiling fan 30 lbs.

3 x 4 window 80 lbs.

Garage door opener 40 lbs.

Basketball hoop 60 lbs.

Sheet of plywood 80 lbs.

(3) 4 x 4’s 80 lbs.

Gold Label

For Type IAA

Special Duty

Think Safety! Read Labels Before Climbing.

• Ladder Inspection

• Proper Set-up and Use

• Proper Care and Storage

Step & Extension Ladder

Safety Instructions

Extension Ladder

Set-Up Label

SEPARATING EXTENSION LADDER SECTIONS

Certain extension ladders may be

separated and the base and fly

sections used independently.

Instructions may vary by model.

On most models, the fly section

must not be used as a single

ladder. Refer to labels on

ladder.

For Your Customer’s Safety:

Werner offers replacement

safety instruction labels.

Extension Ladder

Separation Instructions

for Fly & Base Sections

11

Page 12

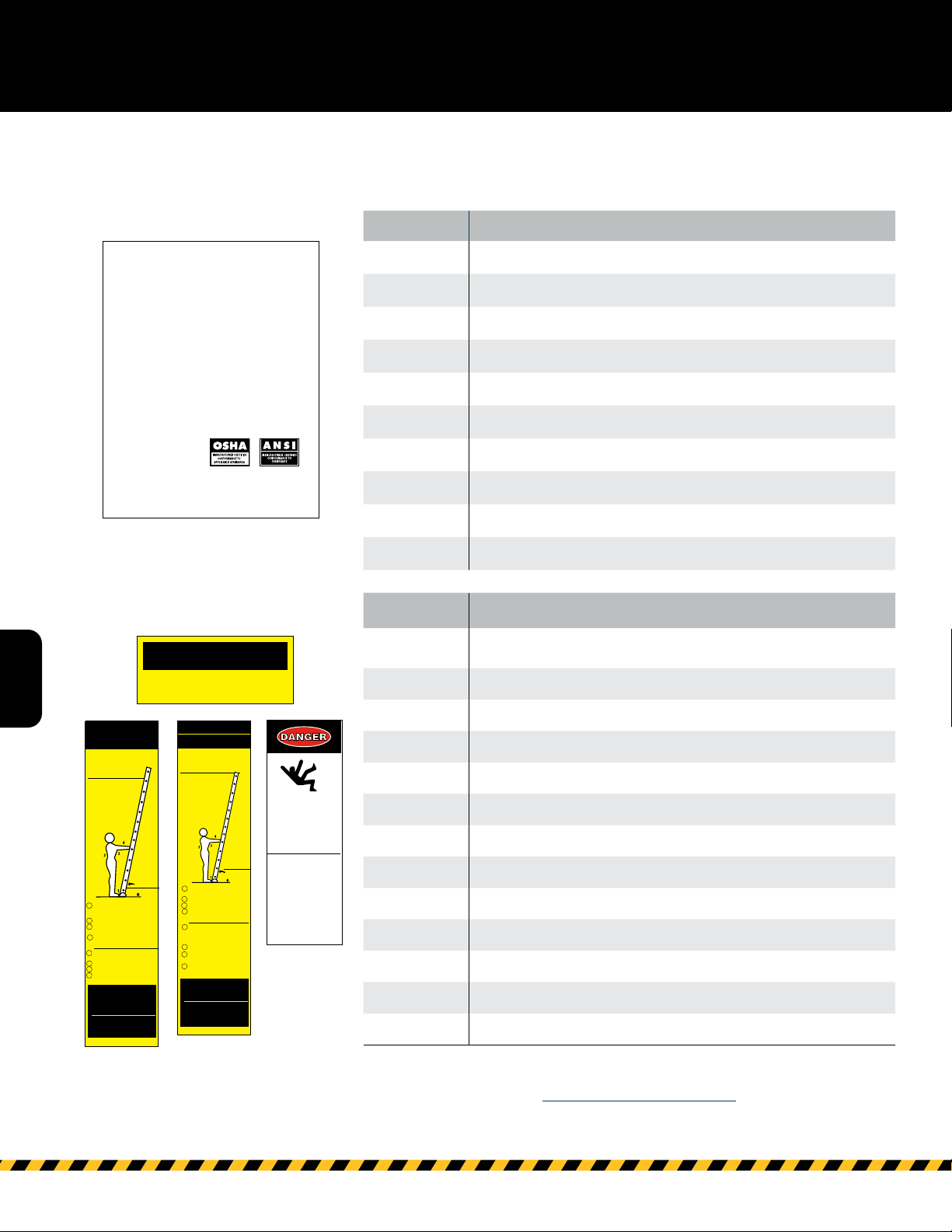

LADDER REPLACEMENT LABEL KITS

LADDER REPLACEMENT LABEL KITS

FOR A COMPLETE SET OF LABELS YOU MUST ORDER 1 MODEL NUMBER FROM EACH CATEGORY

CAUTION

For a complete set of labels, you must order 1 model number from each category.

Category 1 Duty Rating Label ONLY

LOAD CAPACITY

LDR200 200# Rated Duty Rating Sticker for all Ladders except Twin Stepladders

LDR225 225# Rated Duty Rating Sticker for all Ladders except Twin Stepladders

375lbs.

LDR250 250# Rated Duty Rating Sticker for all Ladders except Twin Stepladders

LDR300 300# Rated Duty Rating Sticker for all Ladders except Twin Stepladders

LDR300-100 300# Duty Rating Label 100 pcs

LDR375 375# Rated Duty Rating Sticker for all Ladders except Twin Stepladders

LDR375-100 375# Duty Rating Label 100 pcs

LDRT250 250# Rated Duty Rating Sticker for all Twin Stepladders

LDRT300 300# Rated Duty Rating Sticker for all Twin Stepladders

LDRT375 375# Rated Duty Rating Sticker for all Twin Stepladders

Category 2 Includes Safety, Hazard, and Instruction Labels

LFS100

For all Fiberglass Steps, Platforms,Twins, Twin Platforms,

Tripod Stepladder, and Podiums

LPFS100-100* FRP Step Ladder Label Replacement Kit 100 pcs

LAS100 For all Aluminum Steps, Platforms, Twins, Twin Platforms, and Podiums

LFE100 For all Fiberglass Extensions

LPFE100-100* FRP Extension Ladder Label Replacement Kit 100 pcs

LAE100 For all Aluminum Extensions

LMT100 For all MT Ladders

LFC100 For Fiberglass Combination Ladders

LFL100 For Leaning Ladders

LFM100 Safety Labels-M7100-1 Manhole Ladder

LPL100 For Straight and Tapered Posting Ladders

LET100 For Extension Trestle Ladders

LFPS100 Safety Labels-S7700 Parallel Sectional Ladder

*When ordering kits of 100 pcs, you will receive a roll of 100 for each label in that kit

Includes User and Materials

CAPACIDAD DE CARGA

170kg

Incluye el Usuario y los Materiales

Type IAA

Tipo IAA

© 2010 Werner Co.

CAUTION

PRECAUCIÓN

THIS LADDER SECTION IS NOT

DESIGNED FOR SEPARATE USE

ESTASECCIÓN DE ESCALERA NO ESTÁ

DISEÑADA PARAUSO SEPARADO

PRECAUCIÓN

CAUTION

COLOQUE APROPIADAMENTE

LA ESCALERA PARA

REDUCIR LOS PELIGROS

DE RESBALAMIENTO Y

SOBRECARGA. SIGA

ESTAS INSTRUCCIONES.

SET UP LADDER PROPERLY TO

REDUCE SLIP AND

OVERLOAD HAZARDS.

FOLLOW THESE

INSTRUCTIONS.

(aproximadamente)

75° (approx.)

1 COLOQUE LAS PUNTAS DE LOS PIES

CONTRA LA PARTE INFERIOR DE LOS

RIELES LATERALES DE LA ESCALERA.

2 PONTE DERECHO.

3 EXTIENDA LOS BRAZOS EN LÍNEA

RECTA HACIA EL FRENTE.

4 LAS PALMAS DE LAS MANOS DEBEN

TOCAR LA PARTE SUPERIOR DEL

PELDAÑO AL NIVEL DEL HOMBRO.

1 PLACE TOES AGAINST BOTTOM OF

LADDER SIDE RAILS.

2 STAND ERECT.

3 EXTEND ARMS STRAIGHT OUT.

4 PALMS OF HANDS SHOULD TOUCH

TOP OF RUNG AT SHOULDER LEVEL.

1.NO SE EXTIENDA MÁS ALLÁ DE SU

ALCANCE. MANTENGA EL CUERPO

CENTRADO ENTRE LOS RIELES

LATERALES.

2.EXTIENDA LA ESCALERA 0,914M

SOBRE EL TECHO PARA TENER

ACCESO.

1.DO NOT OVER-REACH. KEEP BODY

CENTERED BETWEEN SIDE RAILS.

2.EXTEND LADDER THREE FEET ABOVE

ROOF FOR ACCESS.

P/N62190-03 Rev H 12/17

75°

PRECAUCIÓN

SET UP LADDER PROPERLY TO

REDUCE SLIP AND OVERLOAD

HAZARDS. FOLLOW THESE

INSTRUCTIONS.

COLOQUE APROPIADAMENTE

LA ESCALERA PARA

REDUCIR LOS PELIGROS

DE RESBALAMIENTO Y

SOBRECARGA. SIGA

ESTAS INSTRUCCIONES.

1 PLACE TOES AGAINST BOTTOM OF

LADDER SIDE RAILS.

2 STAND ERECT.

3 EXTEND ARMS STRAIGHT OUT.

4 PALMS OF HANDS SHOULD

TOUCH TOP OF RUNG AT SHOUL-

DER LEVEL.

N

U

A

S

P

O

U

Q

O

L

C

L

E

1

A

P

N

O

A

L

R

S

C

T

P

E

I

A

S

R

O

E

S

L

D

L

L

E

E

I

S

C

A

R

A

L

E

E

2

N

O

O

H

D

R

P

T

C

E

E

E

.

A

R

S

B

O

A

L

D

N

E

X

T

E

I

3

R

A

A

H

C

R

C

A

E

T

L

E

F

I

M

A

A

S

P

A

A

S

D

L

L

L

E

4

R

S

A

P

R

A

T

L

E

C

O

A

T

,

O

Ñ

N

V

E

A

L

A

D

L

P

E

L

I

1.DO NOT OVER-REACH. KEEP BODY

CENTERED BETWEEN SIDE RAILS.

2.EXTEND LADDER THREE FEET

ABOVE ROOF FOR ACCESS.

1. NO SE EXTIENDA MÁS ALLÁ DE SU

ALCANCE. MANTENGA EL CUERPO

CENTRADO ENTRE LOS RIELES LATERALES.

2. EXTIENDA LA ESCALERA TRES PIES SOBRE

EL TECHO PARA TENER ACCESO.

P/N62190-01 RevC 7/05

P/N 100195-09

75° (approx.)

75°

(aproximadamente)

S

O

A

S

D

L

T

E

R

O

R

N

R

E

F

A

T

E

I

I

A

S

D

A

R

L

L

T

E

E

E

N

A

N

E

S

E

O

L

Z

Í

N

E

T

E

.

M

N

S

D

O

N

B

E

A

E

S

R

O

D

R

P

U

E

E

L

I

M

O

R

D

O

H

B

E

L

.

Rev B 10/10

P/N54053-01

RevG 3/08

FAILURE TO READ

AND FOLLOW

INSTRUCTIONS

INCLUDING THOSE UNDER

THE PLATFORM OR STEP

ON THIS PRODUCT, MAY

RESULT IN INJURIES

OR DEATH.

NE PAS LIRE OU SUIVRE

LES INSTRUCTIONS, DONT

CELLES SE TROUVANT

SOUS LA PLATEFORME OU

LE MARCHEPIED DE CE

PRODUIT, PEUT

ENTRAÎNER DES

BLESSURES OU LA MORT.

P/N106020-03 Rev C 8/14

TO PLACE AN ORDER, EMAIL orders@wernerco.com

**Add “HOT” in the subject line for RUSH orders**

12

Page 13

PROPER HANDLING

Users should understand the proper and safe methods to select, transport, erect and secure ladders. Time spent

learning how to correctly handle ladders can pay off in greater safety, productivity, and longevity. Different people

and applications require different ladders. Remind yourself that safety begins with using the right ladder for the task.

Carry an extension

ladder with the

center balanced

and resting on

your shoulder with

your arm through

the ladder.

For better control,

the ladder should

be fully closed.

Secure the ladder

on vehicles before

transporting.

Improperly

securing a ladder

can cause

damage.

Wear damage

caused from

transit vibration

may weaken a

ladder if not

properly secured.

When storing

ladders, provide

proper support.

Make sure you don’t drop

a ladder when loading or

unloading it from a

vehicle. Be extra careful

when moving ladders.

Do not drag your

ladder.

For longer ladders

use two people to

make it easier to

carry.

13

Page 14

SET UP & USE - THE RIGHT WAY

Use fiberglass

ladders if there

is even a remote

possibility of

working near

electricity or

overhead power

lines.

Fiberglass side rails

are electrically

non-conductive.

Check for and replace

frayed or damaged

electrical cords.

Use double

insulated power tools

as well

as grounded cords

and outlets.

Be sure that all

ladder feet are on firm,

level ground. Solid

footing is necessary

for safe ladder use.

* Ladder shoes

equipped with spur

plates are for use on

penetrable surfaces.

* Werner extension

ladder shoes are

designed to pivot for

use on firm, nonslippery surfaces.

Be careful if you use

a tool belt. Make sure

that tools do not catch

on the ladder when

climbing.

Wear shoes that have

non-slip soles.

Make sure they are

free of mud, oil, or

anything slippery.

14

Use extra caution in

windy weather.

Climb a ladder in

rain or other severe

weather only in

emergency

situations and with the

ladder fully secured.

Have another

person hold

the ladder.

Page 15

SET UP & USE - THE WRONG WAY

Never drop or

throw ladders,

doing so can

damage or weaken

them and cause

serious injury to

others.

Never use any

ladder that has

been exposed to

fire, acids, caustics

or other strong

chemicals. These

may damage or

weaken the ladder.

Never place or use

a ladder on slippery

surfaces or on

uneven ground

that may cause an

accident.

Don’t move the

ladder with materials

on it. They may fall

and cause damage

or an injury.

Never position the

ladder where it

blocks foot traffic,

work vehicles, or

where it could be

bumped by a door.

If it is necessary

to use a ladder in

front of a door,

lock or barricade the

door and put

up a caution sign.

Never leave a

ladder unattended.

This may present

a hazard to others

in the area.

Do not allow

children to play or

climb on ladders.

15

Page 16

SAFE CLIMBING HABITS - THE RIGHT WAY

Ladders are such common tools that many people assume they know how to climb safely when in fact they may not.

Safe and efficient use of ladders is not complicated or difficult, but it does require that users learn and practice proper ladder safety habits. Start by carefully reading and following all instructions.

Climb facing the

ladder. Center

your body

between the

rails. Maintain

a firm grip.

Keep your body

centered on the

ladder while

working.

As a general

guide, never let your

belt buckle pass

beyond

either ladder rail.

Otherwise, you

could lose your

balance or tip

the ladder.

Move materials

with extreme

caution.

Be careful pushing

or pulling anything

while on a ladder.

You may lose

your balance or

tip the ladder.

Never hurry or

skip steps. Always

move one step at a

time, firmly setting

one foot before

moving the other.

Maintain a firm grip

while on the ladder.

Get help with

a ladder that is

too heavy to

handle alone.

If possible, have

another person hold

the ladder when you

are working on it.

16

Haul materials up

on a line rather than

carry them up an

extension ladder.

Page 17

SAFE CLIMBING HABITS - THE WRONG WAY

Never climb a ladder

while under the

influence of drugs

or alcohol or if your

mental or physical

health is not up to

the task; doing so

may result in serious

injury.

Never attempt to cut

anything on a ladder

- only use a properly

equipped ladder or a

saw horse.

Don’t place blocks,

bricks or other loose

materials under a

ladder to adjust for

uneven ground.

Don’t over-reach,

lean to one side or

stand on one foot.

You could lose your

balance or tip the

ladder.

Never permit more

than one person

on a single-sided

stepladder or on any

extension

ladder. They are designed to hold only

one person

at a time.

Don’t climb down

a ladder with your

back to the ladder.

You could easily slip

or fall.

17

Page 18

SAFE CLIMBING HABITS - THE WRONG WAY

Don’t climb on or

off a ladder from

the side. You could

push the ladder

away and fall.

Don’t climb from one

ladder to another.

You may tip the

ladder or

slip and fall.

Never use metal

ladders or water

logged wood

ladders near

electrical current

or power lines.

* Metal conducts

electricity.

Don’t stand above

the highest safe

standing level.

Never try to move

a ladder while on

it by bouncing or

“walking” the

ladder. Step down

and carry the

ladder to the new

working position.

18

Page 19

STEPLADDER SAFETY

Fully open the

stepladder and firmly

lock both spreaders.

If you need to

adjust the ladder

throughout the

course of the job,

you should remove

your tools or use a

proper accessory

to secure them in

place.

Never climb a closed

stepladder. It may

slip out from under

you.

Never stand or

sit on a pail shelf.

It is not designed to

carry your weight.

The pail shelf may

break or the ladder

could tip.

Werner tops are built

to handle a variety

of tools

for this purpose.

Don’t climb on

the back of a

single sided

stepladder. It is not

designed to carry

a person’s weight.

Doing so can

damage the

ladder or result

in an injury.

Don’t stand or sit

on a stepladder top.

You could easily lose

your balance or tip

the ladder. Ladder

tops warn users not

to stand or sit on

them.

19

Page 20

SAFE CLIMBING HABITS - 3 POINTS OF CONTACT

20

ALWAYS MAINTAIN THREE POINTS OF CONTACT

WHILE USING LADDERS.

Page 21

EXTENSION LADDER SETUP

Step 1.

BLOCK THE FEET:

Base section

on top

The ladder should be closed. Position the ladder with the base

section on top of the fly section. Block or “foot” the ladder

against the base of the building or another secure object.

Block against

building

Step 2.

WALK IT UP:

Walk up,

hand-over-hand

First check for sufficient overhead clearance and make sure

there are no power lines. Carefully erect the ladder by “walking” it up to a vertical position. Be sure the bottom is securely

blocked against a fixed object or “footed” by another person.

NOTE: While raising an extension ladder, keep knees bent

slightly and back straight to avoid lifting injuries.

Step 3.

LIFT INTO POSITION:

Move back 1/4

the distance of

the ladder

length to the

support point.

Move the ladder away from the building

so that it can be set at the proper angle.

Carefully and firmly grip the ladder

before moving – keep it vertical.

Get help with heavier ladders.

Step 4.

RAISE FLY SECTION:

Use extra

caution if windy

Fly

Base

Place foot on

bottom run of

base section

Carefully raise the fly section using

the rope and pulley system. After the

bottom rung of the fly section clears the

bottom rung of the base section, place

one foot on the base rung to provide

continuous firm footing.

Step 5.

PLACE AGAINST BUILDING

Firm and

secure

contact

Carefully lean ladder against building

at the correct 75-½° angle. The base

should be 1 foot out for each 4 feet of

ladder length to the upper support point.

Extend the ladder 3 feet above the roof

edge for access. Be sure both end caps

or contact points are resting firmly and

securely against the building.

21

Page 22

EXTENSION LADDER SETUP

4

3

2

75½°

1

ALWAYS CHECK FOR THE CORRECT ANGLE:

To ensure that the ladder is at the correct angle:

1. Place your toes against the

bottom of the ladder side rails.

2. Stand erect.

3. Extend your arms straight out.

4. The palms of your hands

should touch the top of the

rung at shoulder level.

The four-to-one ladder length

to set-back relationship

creates the safest ladder use

angle. Ladders placed either

too close or too far may tip

over at the top or slip out at

the bottom.

Place an extension ladder at a 75-½° angle. The set-back

(“S”) needs to be 1 foot away from the building for each 4 feet

of length (“L”) to the upper support point.

Ladder Length

to Support

Point “L”

12’ 3’

16’ 4’

20’ 5’

24’ 6’

28’ 7’

32’ 8’

*NOTE: For a quick estimate, count

the rungs. They are spaced 12" apart.

Set-Back Between

Support Point &

Ladder Base “S”

75

FLY S ECT IO N

1

°

2 ANGLE

Upper

Support

Point

BAS E SEC TI ON

“L”

Base

“S”

22

Page 23

EXTENSION LADDER SETUP TIPS

Extension ladders are typically large and bulky. The following tips should help users set them up safely against a

house or similar building.

“BLOCK” OR “FOOT” THE LADDER ONE OF 2 WAYS:

One person:

Place the ladder flat on the ground with the bottom blocked

against a building or other securely fixed object. By “blocking”

the ladder against a fixed object, you inhibit the bottom from

sliding out.

ALWAYS CHECK LOCKS:

Open end

of lock fully

hooked over

rung

Fly Section

1

3

Base Section

Always be sure that the locks are fully engaged and the fly

is in front of the base before climbing.

1. Fly Section

2. Base Section

3. Lock

LOCKED:

Examine both locks to be sure that the open end

is fully hooked and seated over the rung.

2

Two people:

If a fixed object is not in close proximity, have another person

“foot” the ladder by securely standing with one foot on the

bottom rung of the ladder. As you lift the ladder, he/she can

keep the bottom from sliding out and help guide it up.

ALWAYS CHECK SHOES:

Make sure both feet

are on firm, level and

non-slippery surfaces.

For proper use of spur

plate, position the safety

shoe with the rubber foot

pad toward user when

climbing ladder.

Use spur plate on

penetrable surfaces.

23

Page 24

EXTENSION LADDER SAFETY - THE RIGHT WAY

Place the ladder

top so both rails are

fully supported. The

support area should

be at least 12” wide

on both sides of the

ladder.

Tie-off an

extension ladder to

roof or firm gutter

supports whenever

possible to prevent

slipping.

12”

min.

12”

min.

Stake or tie-down

the top and bottom

of an extension

ladder whenever

possible to prevent

outward slipping.

Properly use

spur plates on

penetrable

surfaces.

Check for overhead

clearance and

ensure there are

no live electrical

wires nearby before

extending the

ladder.

Raise an extension

ladder only while

standing on the

ground. Place one

foot on the bottom

rung of the base

section to help

secure the ladder.

Use the rope and

pulley to raise the

fly section.

24

LADDER SAFETY

TRAINING VIDEO

Scan me

Page 25

EXTENSION LADDER SAFETY - THE WRONG WAY

Don’t tie two

ladders together

to make a longer

section. You can

exceed the load

capacity of the

ladders or they may

come apart.

Never set up or use

an extension ladder

or an

individual

extension ladder

section upside down

or

backwards.

The fly section must

be nearest climber.

Never carry an

extension ladder

in the unlocked or

extended position.

Don’t use an

extension ladder

as a lever, brace,

support or hoist.

This can damage

the ladder.

Don’t place

the base of an

extension ladder too

close to the building

as it may

tip over backward.

Don’t place the base

of an extension

ladder too far away

from its vertical

support point, as

it may slip out at

the bottom. Follow

instructions for

proper set-up

of ladder at correct

75-½° working angle.

Don’t use an

extension ladder

in the horizontal

(flat) position. You

may damage the

ladder as it is not

designed to support

people or materials

this way. You may

also lose your

balance and fall.

25

Page 26

UTILITY LADDER ACCESSORIES

Cable, communications, and utility workers often require

the use of specialty fiberglass extension ladders and

accessories for working around poles. Werner offers a

broad line of specialty accessories designed for either

field or factory installation. These accessories are only

for personnel specifically trained for their use.

NOTE: Specific accessory models may vary by ladder.

74 CABLE HOOKS

• Help to prevent ladder from

slipping when it is leaned

against a cable or strand.

• Fold easily within ladder

rails after use for convenient

storage.

81 ADJUSTABLE POLE

LASH

• Designed for all diameter

poles, secures the top of a

ladder tightly against the pole.

92 CABLE HOOK AND

V-RUNG ASSEMBLY

• Cable hook and V-rung

combination replaces the

top rung.

• May be used on strands or to

lean against poles less than 10"

diameter at contact point.

• Use in conjunction with

adjustable pole strap or Ladder-Cinch™.

71 PADDED FIXED V-RUNG

• Slip-resistant rubber grip

attached to steel V-rung for

leaning ladder against wood,

metal, or concrete poles.

• Werner’s adjustable pole strap

or Ladder-Cinch™ should be

used in conjunction with a

V-rung.

72 ADJUSTABLE

POLE STRAP

• Nylon strap fits circumference

of most poles.

• Slip-resistant rubber grip

stitched to strap reduces

ladder movement on the pole.

26

94 LADDER-CINCH™

• Helps keep extension ladders

from sliding away from or

rotating around utility poles.

• Can also be used as a quick

tie down.

• Designed for all diameter

poles.

PK70 LEVELOK® LEVELER

• Provides up to 10” of automatic

leveling of straight and

extension ladders.

• Ideal for most steps or

uneven ground.

• Attaches to ladder side rail

with bolts and lock nuts.

• Available with swivel shoes.

Page 27

CARE & MAINTENANCE

All good tools require a certain amount of care and maintenance. By practicing basic maintenance, customers can

keep ladders in proper working order and extend their useful life.

Promptly clean

spills or drips

from the ladder.

Keep the ladder

free from oil,

paint or other

slippery materials.

Keep ladders in

good condition.

Clean and lightly

lubricate moving

parts such as

spreader bars,

hinges, locks

and pulleys.

Routinely inspect

and properly

replace damaged or

worn components

and labels according

to manufacturer’s

instructions. Use

only Werner Co.

authorized

replacement parts.

Please refer to

Werner’s Full Line

Product Catalog

(C-100) for

more information.

Always inspect the

rails of fiberglass

ladders for

weathering, cracks

or splitting.

Keep the ladder

protected from

heat, weather,

and corrosive

materials.

SAFETY NOTE

The Werner ClimbingPROTM Training Program is intended to provide certain general safety guidelines and instructions for the

proper selection and use of climbing equipment. It is not intended to be all-inclusive, nor contain complete instructions

or warnings.

Werner will not be responsible for any misinterpretation or failure to review and follow regulations, instructions and warnings.

Common sense still prevails. A ladder user is responsible for his or her own actions.

Although Werner Co. has attempted to provide current information, ANSI, OSHA, and other regulations, and product

features change periodically.

Thoroughly review the appropriate regulations and ladder labels for additional cautions and for more specific warnings and

instructions concerning the actual ladder being used.

Check with Werner Co. or refer to appropriate ANSI A14 Standards for additional ladder guidelines. The information

included in this publication applies only to Werner products.

27

Page 28

STEPLADDER COMPONENTS

Right-Handed Drill

Socket

Built-In Magnet

Pipe Channel

Small Parts Bin

Paint Can Holder

Tool Slots

ANSI Required

Rear

Rail

Rear

Horizontal

Labeling

Plastic Molded

LockTop

®

Traction-Tred

Serrated Steps

®

Front

Rail

*Diagram shows typical ladder parts. Parts

and features may differ by ladder model.

28

Diagonal

Brace

Rear

Foot

Spreader Assembly

Oversized

Foot Pad

Integrated

Rail Shield

Front

Foot

Page 29

EXTENSION LADDER COMPONENTS

Fly Section (Top)

End Caps

(Full Cover)†

External

Guide

Brackets

ALFLO

Twist-Proof

Rung Joint

Instructions

®

®

Safety

End Closure

(Partial Cover)†

Pulley

Rope

Rungs

Lock Assembly

Interlocking

Side Rails

Internal

Guide

Bracket

End Cap

(Full Cover)†

Wear

Sleeve

† End Cap’s and End Closure’s positions differ by ladder models.

End Caps - completely cover the rail.

End Closures - partially cover the rail, leaving clearance for the mating ladder section.

Shield

Rail

Flipper

& Spring

Diagonal

Brace

Safety

Shoe

Base Section (Bottom)

29

Page 30

LADDER INSPECTION

WALK IT DOWN

All ladders should be thoroughly inspected from

top to bottom before every use. Ladders can be

damaged while in transit or storage, and through

misuse and abuse.

Examine the ladders carefully for damaged or

missing parts. Never use a bent or damaged

ladder or one that has been exposed to excessive

heat or acid.

LAY IT DOWN

• Check the rails - not cracked, split or frayed

• Check the rungs – make sure they are not

cracked, bent or missing

• Make sure the feet pads are not missing

LIFT IT UP

• Make sure the ladder top is not cracked

or loose

• Check the spreaders, make sure they are not

too loose

• Make sure all components are there and

working correctly

• Labels need to be on and legible

(Instructions, Warnings, and Duty Ratings)

• DO NOT tape or drill into any ladder. If you

see any signs of this, remove the ladder

from service.

USE THE

LADDER INSPECTION FORMS

AT THE END OF THIS GUIDE

30

EVERY TIME

YOU INSPECT A LADDER!

Page 31

Look over the

ladder carefully

before buying and

each time before

climbing.

Look for missing,

damaged, or loose

components.

Never use a

damaged ladder.

Damaged ladders

must be tagged for

repair or disposal.

Make sure that

working parts move

properly

and that all

connections

are secure.

Carefully check

components such as

spreaders, extension

ladder locks,

flippers, and safety

shoes.

Read and

carefully follow

all instructions,

warning labels,

and manuals.

Be aware of and

comply with all

federal, state,

local, ANSI, OSHA

and other codes

and regulations.

Never test a ladder

by jumping on it.

This could damage

or weaken the

ladder, or you may

slip and fall.

DON’T FORGET!

Read Safety Instruction Labels:

Werner ladders, stages, planks and

accessories are sold with safety instructions to

guide users. These instructions and warnings

should always be read before climbing.

Failure to follow all instructions and warnings

may result in an injury or death.

Damaged ladders must be tagged for repair

or disposal.

31

Page 32

LADDER INSPECTION

STEPLADDER

Size: ________ ft. Size: ________ ft. Size: ________ ft.

Fiberglass

Aluminum

Wood

Circle Areas

of Damage

Steps:

Loose, cracked, bent, or missing

Rails:

Cracked, bent, split or frayed

rail shields

Labels:

Missing or not readable

Pail Shelf:

Loose, bent, missing, or broken

Top:

Cracked, loose, or missing

Spreader:

Loose, bent, or broken

General:

Rust, corrosion, or loose

Other:

Bracing, shoes, or rivets

6206

YES NO YES NO

PODIUM LEANSAFE

Fiberglass

Aluminum

Circle Areas

of Damage

Steps:

Loose, cracked, bent, or missing

Rails:

Cracked, bent, split or frayed

rail shields

Labels:

Missing or not readable

Top:

Cracked, loose, or missing

Spreader:

Loose, bent, or broken

Platform:

Cracked or bent

General:

Rust, corrosion, or loose

Other:

Bracing, shoes, or rivets

PD6204 L6206

Circle Areas

of Damage

Steps:

Loose, cracked, bent, or missing

Rails:

Cracked, bent, split or frayed

rail shields

Labels:

Missing or not readable

Hinge Mechanism:

Loose, bent, missing, or broken

Top:

Cracked, loose, or missing

Spreader:

Loose, bent, or broken

General:

Rust, corrosion, or loose

Other:

Bracing, shoes, or rivets

Fiberglass

Aluminum

YES NO

ACTIONS:

Ladder tagged as damaged

and removed from use

Ladder is in good condition

32

ACTIONS:

Ladder tagged as damaged

and removed from use

Ladder is in good condition

ACTIONS:

Ladder tagged as damaged

and removed from use

Ladder is in good condition

Page 33

LEANSAFE X3

Size: ________ ft. Size: ________ ft.

EXTENSION LADDER

Circle Areas

of Damage

Steps:

Loose, cracked, bent, or missing

Rails:

Cracked, bent, split or frayed

rail shields

Labels:

Missing or not readable

Hinge Mechanism:

Loose, bent, missing, or broken

Top:

Cracked, loose, or missing

Spreader:

Loose, bent, or broken

General:

Rust, corrosion, or loose

Other:

Bracing, shoes, or rivets

LDP7306

Fiberglass

Aluminum

Circle Areas

of Damage

YES NO YES NO

Rungs:

Loose, cracked, bent, or missing

Rails:

Cracked, bent, split, or frayed

Labels:

Missing or not readable

Rung Locks:

Loose, bent, missing, or broken

Hardware:

Damaged, loose, or missing

Shoes:

Worn, broken, or missing

Rope / Pulley:

Loose, bent, or broken

General:

Rust, corrosion, or loose

Other:

Bracing rivets

Fiberglass

Aluminum

D6224

ACTIONS:

Ladder tagged as damaged

and removed from use

Ladder is in good condition

ACTIONS:

Ladder tagged as damaged

and removed from use

Ladder is in good condition

33

Page 34

LADDER INSPECTION

SPECIALTY LADDER

Fiberglass

Aluminum

Wood

PT1074-4C E1078 M7108-1

Model Number: _______________________

Mark all that apply

Steps / Rungs:

Loose, cracked, bent, or missing

Rails:

Cracked, bent, split, or frayed

Labels:

Missing or not readable

Hardware:

Missing, loose, or broken

Fasteners:

Rust, corrosion, loose, or missing

Top:

Cracked, loose, or missing

Spreader:

Loose, bent, or broken

Outriggers:

Missing, rust, corrosion, or

loose for scaffolding

General:

Rust, corrosion, or loose

Hinges:

Loose, bent, or missing

Locks:

Loose, bent, broken, or missing

Bracing Front, Rear:

Loose, bent, broken, or missing

Rivets:

Rust, corrosion, loose, or missing

Shoes:

Worn, broken, or missing

Platform:

Loose, bent, broken, or missing

Rail Shield:

Missing or loose

Shoulder Bolt:

Rust, corrosion, or loose

Casters:

Rust, corrosion, or loose

for scaffolding

YES NO

34

4203-18

ACTIONS:

Ladder tagged as damaged

and removed from use

Ladder is in good condition

Page 35

FREQUENTLY ASKED QUESTIONS

WHERE CAN I BUY WERNER CLIMBING PRODUCTS?

A retailer near you can be found by using the “Where to Buy” locator at www.wernerco.com. Pricing can be provided

by the dealer of your choice.

WHERE CAN I PURCHASE REPLACEMENT PARTS FOR MY WERNER LADDER?

Werner Co. offers replacement parts for products manufactured by Werner Co. only. If you cannot find the

replacement parts you are looking for on www.wernerco.com, please contact Customer Service at 888-523-3370.

When ordering replacement parts, you will need to provide the Werner Co. Model Number and a description of the

part you need.

CAN I OBTAIN PARTS FOR MY KELLER LADDER?

Replacement Parts for Keller Ladders purchased after the year 2000 are available by contacting Customer Service at

888-523-3370.

CAN I PURCHASE A REPLACEMENT SECTION FOR MY EXTENSION LADDER?

For safety reasons, Werner Co. does not offer replacement of the individual sections of an extension ladder.

HOW CAN I REPAIR MY DAMAGED LADDER OR DOES WERNER CO. OFFER A LADDER

REPAIR SERVICE?

Werner Co. does not recommend repairing a damaged ladder and does not offer a repair service through the

company.

DO YOU OFFER A WARRANTY ON YOUR LADDERS?

Werner Co. does not have a written warranty on their products. However, we do stand behind the quality of our

products.

WHY ARE PAIL SHELVES NOT ON ALL FIBERGLASS LADDERS?

The unique design of our multi-functional top eliminates the needs for pail shelves in most cases. However, there are

a limited number of models available with pail shelves. Pail shelves are also available as an accessory. Refer to www.

wernerco.com for more information and options.

DO YOU OFFER CUSTOM ATTIC LADDERS WITH VARIOUS ROUGH OPENINGS?

While Werner Co. offers a large selection of attic ladders in various lengths and material, they are designed to fit

standard rough openings of: 22-1/2“ x 54”, 25” x 54”, 25-1/2” x 64” & 30” x 54”.

DO I NEED FALL PROTECTION IF I AM USING A LADDER?

Fall protection must be provided for employees climbing or working on FIXED LADDERS above 24 feet. 29 CFR

1926.1053(a)(19) states that fall protection must be provided whenever the length of climb on a fixed ladder equals

or exceeds 24 feet.

35

Page 36

KNOWLEDGE CHECK

1. Which of the following are important to consider when selecting a ladder? Circle all that apply.

A. Style B. Size

C. Duty rating D. Material

2. Duty rating must take into account which of the following? Circle all that apply.

A. Worker’s weight B. Weight of any tools and material

C. Weight of clothing D. Ladder weight

3. A person’s maximum safe reaching height is approximately eight feet higher than the height of the ladder.

A. True B. False

4. How often should you inspect your ladder for wear, damage and missing or loose components?

A. Weekly B. Bi-weekly

C. Monthly D. Prior to every use

5. When handling a ladder, it is important to remember which of the following? Check all that apply.

A. Do not drag it across the ground.

B. Loosely secure your ladder in transit, allowing for some vibration.

C. Do not carry an extension ladder in its extended position.

D. Do not drop a ladder when loading or unloading it from a vehicle.

6. It is okay to store other materials on top of a ladder.

A. True B. False

7. Which of the following are common mistakes with stepladder and extension ladder use? Circle all that apply.

A. Facing the ladder while climbing and descending B. Overreaching

C. Walking or moving the ladder while on it D. Twisting excessively while on ladder

.

8. If your ladder has bent rails, split rails, loose feet or missing feet, what should you do?

A. Nothing B. Attempt to fix it

C. Tag it out of service and do not use D. Keep using it until it breaks

9. When using a stepladder, never stand higher than two steps from the top of the ladder.

A. True B. False

10. Which of the following is the correct height-to-ground ratio to use when setting up an extension ladder?

A. 3:1 B. 5:1

C. 4:1 D. 8:1

11. Improper leveling using job-site scraps can make the ladder unstable.

A. True B. False

12. To verify the extension ladder is at the correct angle from the wall, place your toes against the bottom of the side rails and stand erect with

your arms straight out. The ___ should touch the top of the rung nearest to shoulder level.

A. Tips of your fingers B. Palms of your hands

C. Underside of your forearms D. Inside of your wrists

13. A ___ can safely hold two workers at a time.

A. Stepladder B. Platform ladder

C. Twin stepladder D. Both a and c

14. A platform ladder allows for consistent and predictable reach.

A. True B. False

15. To maximize your safety, you should do which of the following? Circle all that apply.

A. Consider size, duty rating, style, and material when selecting a ladder

B. Inspect the ladder before every use

C. Never climb a damaged ladder

D. Ensure the proper set-up and stability of the ladder

36

Page 37

NOTES

37

Page 38

WERNER CO. BRAND PORTFOLIO

Werner Co.’s strong brand portfolio allows us to address the broadest array of markets

and end users with a wide range of products.Werner Co. delivers millions of products to

customers around the world.

Werner’s line of fall protection equipment

FALL PROTECTION

extends from that same philosophy that has

made our ladders preferred by professionals.

We begin with the Werner Product Promise

that establishes our design and ensures

satisfaction.

Scan me

LINK TO ALL

PRODUCT

®

KNAACK

jobsite storage equipment, including storage

chests, workstations, rolling workbenches

and hand tool boxes.

WEATHER GUARD

truck and van equipment, including drawer

units, shelving and cabinets, and racks for

full size and compact pickups, vans and

utility vehicles.

is the leading manufacturer of

®

offers a complete line of

Scan me

Scan me

LINK TO ALL

PRODUCT

LINK TO ALL

PRODUCT

38

Better Built is an industry leader in Pro value

work truck equipment and jobsite storage

solutions

Scan me

LINK TO ALL

PRODUCT

Page 39

All of these considerations are important in maximizing your safety while climbing.

D. Ensure the proper set-up and stability of the ladder

C. Never climb a damaged ladder

B. Inspect the ladder before every use

A. Consider size, duty rating, style, and material when selecting a ladder

15. To maximize your safety, you should do which of the following? Circle all that apply.

allow you to have a greater range of movement that ultimately helps reduce worker fatigue.

For a job that calls for consistent and predictable reach, platform ladder may be your best bet. Platform ladders

A. True

14. A platform ladder allows for consistent and predictable reach.

Only a twin stepladder can safely hold two workers at a time.

C. Twin Stepladder

13. A ___ can safely hold two workers at a time.

The palms of your hands should touch the top of the rung nearest shoulder level if the extension ladder is set up at the correct angle.

B. Palms of your hands

your arms straight out. The ___ should touch the top of the rung nearest to shoulder level.

12. To verify the extension ladder is at the correct angle from the wall, place your toes against the bottom of the side rails and stand erect with

Never use your ladder on uneven ground. In order to make sure your ladder is stable, use a proper leveling device.

A. True

11. Improper leveling using job-site scraps can make the ladder unstable.

the ladder to tip over backward. Placing the ladder too far from its vertical support may cause the ladder to slip out at the bottom.

to the upper support point. This 4 to 1 ratio is essential to your safety. Placing an extension ladder base too close to the building can cause

The base of the ladder should be positioned one foot away from the building for every four feet of ladder length, as measured from the base

C. 4:1

10. Which of the following is the correct height-to-ground ratio to use when setting up an extension ladder?

Standing two steps or lower from the top of the ladder will help prevent falls.

A. True

9. When using a stepladder, never stand higher than two steps from the top of the ladder.

Never use a ladder that has bent rails, split rails, loose feet or missing feet. Remember, when in doubt, tag it and throw it out.

C. Tag it out of service and do not use

8. If your ladder has bent rails, split rails, loose feet or missing feet, what should you do?

common mistakes with stepladder and extension ladder use.

Overreaching, walking, twisting excessively or moving the ladder while on the ladder are all

D. Twisting excessively while on ladder

B. Overreaching C. Walking or moving the ladder while on it

7. Which of the following are common mistakes with stepladder and extension ladder use? Circle all that apply.

Storing other materials on top of a ladder may damage it.

B. False

6. It is okay to store other materials on top of a ladder.

Remember that it is important to secure your ladder tightly to your vehicle during transit to prevent any vibration.

D. Do not drop a ladder when loading or unloading it from a vehicle.

C. Do not carry an extension ladder in its extended position.

A. Do not drag it across the ground.

5. When handling a ladder, it is important to remember which of the following? Circle all that apply.

It is important that you inspect your ladder for wear, damage and missing or loose components prior to every use.

D. Prior to every use

4. How often should you inspect your ladder for wear, damage, and missing or loose components?

A person’s maximum safe reaching height is approximately four feet higher than the height of the ladder.

B. False

3. A person’s maximum safe reaching height is approximately eight feet higher than the height of the ladder.

weight of any tools, building materials and the weight of the worker’s clothing.

To stay within the duty rating of a ladder, you must take into account not only the worker’s weight but also the

C. Weight of clothing

A. Worker’s weight B. Weight of any tools and material

2. Duty rating must take into account which of the following? Circle all that apply.

All four considerations are important when selecting a ladder.

C. Duty rating D. Material

A. Style B. Size

1. Which of the following are important to consider when selecting a ladder? Circle all that apply.

KNOWLEDGE CHECK - ANSWER KEY

Page 40

GM7693 Rev A ©2020 Werner Co. 3/20

GLOBAL HEADQUARTERS

Werner Co.

555 Pierce Road • Suite 300

Itasca, IL 60143

To contact us, please visit:

wernerco.com

Loading...

Loading...