Page 1

FALL PROTECTION

PROTECCIÓN CONTRA CAÍDAS

USER INSTRUCTIONS

INSTRUCCIONES PARA EL USUARIO

MANUAL ROPE ADJUSTER

Complies with ANSI Z359.1-2007,

OSHA 1910 and 1926 requirements.

AJUSTADOR MANUAL PARA CUERDA

TRENZADA

Cumple con las normas ANSI Z359.1-2007,

OSHA 1910 y 1926.

(This manual applies to manual rope grabs L210100 and L210101.)

(Este manual aplica a ajustador manual para cuerda trenzada

L210100 y L210101.)

Werner Fall Protection 724-588-2000

93 Werner Rd. 888-523-3371 toll free/ llamada gratuita

Greenville, PA 16125 888-456-8458 fax

Page 2

CAUTION!

If use of fall protection equipment is necessary then the work

environment is dangerous and potentially deadly. Werner Company

products are designed to eliminate as much of the hazard as possible

but can do that ONLY if they are used correctly. Use this equipment as

it was designed to be used, after appropriate training, under the direct

supervision of a competent person, according to the instructions

provided, and in accordance with OSHA and local safety regulations.

User MUST read and understand all cautions and instructions. Failure

to heed these guidelines could result in injury or even death. Please,

WORK SAFE! WORK SMART!

ENGLISH

Page 2

Page 3

MANUAL ROPE ADJUSTER

USER INSTRUCTIONS

Contents

I. BEFORE USING THE ROPE GRAB .................................................................. 4

a. Inspect ......................................................................................................................4

b. Compatibility ............................................................................................................6

c. Fall Protection Plan ..................................................................................................6

d. Training .....................................................................................................................9

II. ANCHOR INSTALLATION AND USE ...............................................................9

a. Making a Connection .............................................................................................10

b. Anchorage Strength ..............................................................................................11

c. Lifelines ..................................................................................................................12

d. Lanyards .................................................................................................................13

e. Body Support .........................................................................................................13

f. Attaching Rope Grab to the Lifeline .....................................................................13

g. Positioning Rope Grab on the Lifeline .................................................................14

h. Connecting to Anchorage Connector or Anchorage Connector .......................14

i. Connecting to the Body Support ...........................................................................15

j. Connecting to the Rope Grab ................................................................................15

k. Use of LifeLines .....................................................................................................15

l. After Use ..................................................................................................................16

III. USE WARNINGS, RESTRICTIONS AND CAUTIONS ................................... 16

a. Purpose ..................................................................................................................16

b. Rated Capacity .......................................................................................................17

c. Limitations ..............................................................................................................17

d. Governing Requirements ......................................................................................18

IV. LABELS/IDENTIFICATION/INSPECTION RECORDS .................................. 18

V. EQUIPMENT RECORDS ................................................................................20

VI. INSPECTION RECORDS ..............................................................................20

ENGLISH

Page 3

Page 4

Warning:

This product is just one part of a personal fall arrest system. It must

be matched correctly with other components to form a complete and

functional system. The user must understand the function of each of

these components and follow the manufacturer’s instructions for use

for each. The user must be provided these instructions, should read

and follow them, and consult the competent person who will supervise

his work if he has any questions about any part of the instructions.

The employer must provide training in the proper use, inspection, and

maintenance of all components in the system, and these instructions

can be used as part of that training. The equipment should be used

ONLY in accordance with these instructions, local ordinances and

codes, the applicable OSHA and ANSI standards, and the employer’s

safety plan.

Alterations or misuse of this product or failure to follow instructions

may result in serious injury or death.

IF YOU HAVE ANY QUESTIONS ABOUT ANYTHING IN THESE

INSTRUCTIONS, THE EQUIPMENT, OR PROPER USE OF THE

EQUIPMENT, CONTACT WERNER CO. FOR MORE INFORMATION.

I. Before Using the Rope Adjuster

Before using this equipment the user should take certain steps to

ensure that it is in suitable condition and safe for use. Users must

read and understand these instructions. It is the employer’s obligation

to ensure that all users have been trained in safe work procedures as

well as in the use and limitations of fall protection equipment. All users

should be aware of and comply with all applicable OSHA, ANSI, CSA

and local or regional regulations concerning fall protection equipment

and its use.

a. Inspect

Examine all equipment thoroughly, daily before use by the user,

and periodically by a competent person who is not the user.

1. Before installation of this equipment, carefully inspect it to assure

it is in serviceable condition.

ENGLISH

2. The manual rope adjuster (manual rope grab) must be inspected

by a competent person other than the user at least annually.

Page 4

Page 5

MANUAL ROPE ADJUSTER

USER INSTRUCTIONS

Record the results of each formal inspection in the inspection

log.

3. Inspect the action of the lanyard connection handle for freedom

of motion. There should be no binding or sticking. The lanyard

connection handle is spring loaded and when raised the internal

cams should release from the lifeline allowing the rope grab to be

re-positioned. Releasing the spring loaded lanyard connection

handle should result in the internal cams binding onto the lifeline

preventing movement.

4. Inspect the rope channel for signs of rope wear. There should be

no dips or depressions worn into the rope channel. The internal

cams which come in contact with the lifeline should have a

visible serrated face.

5. Inspect each system component or subsystem per associated

manufacturer’s instructions.

6. Record the inspection date and results in the inspection log

7. INSPECTION STEPS FOR LIFELINE: (See the Lifeline User

Instruction Manual for complete details)

i. Lifeline hardware must not be damaged, broken, distorted,

or have any sharp edges, burrs, cracks, worn parts, or

corrosion. Ensure the connecting hooks work properly. Hook

gates must move freely and lock upon closing.

ii. Inspect the rope for concentrated wear. The material must be

free of frayed strands, broken yarns, cuts, abrasions, burns,

and discoloration. The rope must be free of knots, excessive

soiling, heavy paint buildup, and rust staining. Rope splices

must be tight, with ve full tucks, and thimbles must be

held by the splice. Cracked or distorted rope thimbles may

indicate that the lifeline has been impact loaded. Check for

chemical or heat damage (indicated by brown, discolored,

or brittle areas). Check for ultraviolet damage, indicated

by discoloration and the presence of splinters and slivers

on the rope surface. All of the above factors are known to

reduce rope strength. Damaged or questionable ropes must

be replaced.

iii. Inspect labels. All labels must be present and fully legible.

Replace labels if illegible or missing.

iv. Record the inspection date and results in the inspection log

found in the Lifeline User Instruction Manual.

Page 5

ENGLISH

Page 6

8. Verify that all labels are intact, in place, and legible.

9. If inspection reveals a defective condition or abnormalities in

any of these areas, remove unit from service immediately. A

competent person should be consulted to determine if that item

is safe for continued use or if it should be destroyed.

IMPORTANT: If this equipment has been subjected to forces

resulting from the arrest of a fall, it must be immediately

removed from service.

IMPORTANT: Do not attempt to alter, repair, or make substitutions

to the rope grab or rope grab parts. Equipment found to be

in defective condition must be removed from service. Repairs

may only be performed by Werner Co. or those authorized in

writing to do so.

b. Compatibility

Werner Co. equipment is designed for use with Werner Co. approved

components and subsystems only. Substitutions or replacements

made with non-approved components or subsystems may

jeopardize compatibility of equipment and may affect the safety and

reliability of the complete system.

Connectors are considered to be compatible with connecting

elements when they have been designed to work together in

such a way that their sizes and shapes do not cause their gate

mechanisms to inadvertently open regardless of how they become

oriented. Contact Werner Co. if you have any questions about

compatibility. Connectors (hooks, carabiners, and D-rings) must be

capable of supporting at least 5,000 lbs. (22.2kN). Connectors must

be compatible with the anchorage or other system components.

Do not use equipment that is not compatible. Non-compatible

connectors may unintentionally disengage. Connectors must be

compatible in size, shape, and strength. Self locking snap hooks

and carabiners are required by ANSI Z359 and OSHA.

ENGLISH

Page 6

c. Fall Protection Plan

Plan your fall arrest or restraint system before starting your work.

Take into consideration all factors affecting your safety at any

time during use. The following list gives some important points to

consider when planning your system:

Page 7

MANUAL ROPE ADJUSTER

USER INSTRUCTIONS

1. ANCHORAGE: Select a rigid anchorage point that is capable of

supporting the required loads. See section II.b.

The anchorage location must be carefully selected to reduce

possible free fall and swing fall hazards and to avoid striking an

object during a fall. For restraint systems the anchorage must be

located such that no vertical free fall is possible. For fall arrest

systems OSHA requires the anchorage be independent of the

means suspending or supporting the user.

2. FREE FALL: Do not work above the anchorage level, increased

fall distance will result. Personal fall arrest systems must be

rigged such that the potential free fall is never greater than six

feet. Restraint systems must be rigged such that there is no

possible vertical free fall.

3. FALL ARREST FORCES: The assembled fall arrest system

must keep fall arrest forces below 1,800 lbs. when used with a

full body harness. Do not use a body belt for fall arrest.

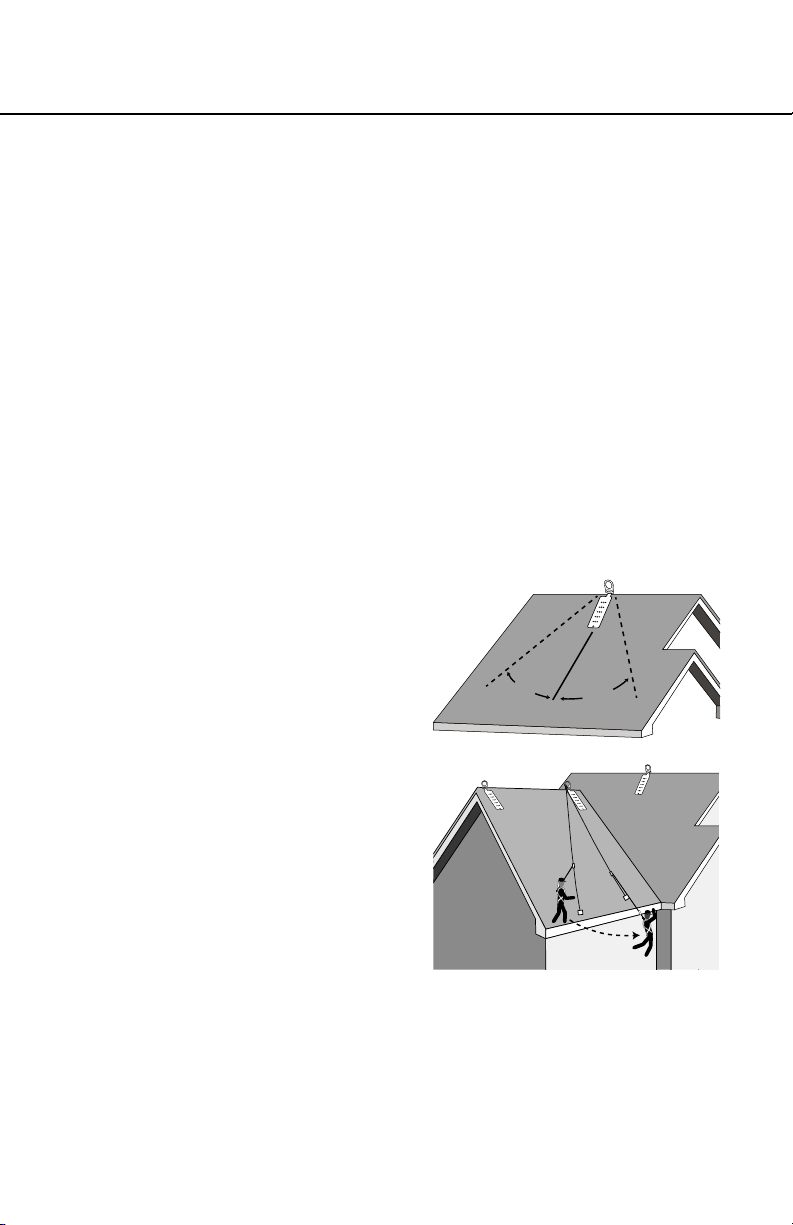

4. SWING FALLS: Swing falls

occur when the anchor is

not directly above the point

where a fall occurs. The

force of striking an object

while swinging can be great

and cause serious injury.

Minimize swing falls by

working as directly below the

anchorage as possible (the

worker must be positioned

within 30 degrees of the

roof anchor). It is acceptable

to captivate a lifeline (i.e.

rope grab system) to an

anchorage close to the work

area with a carabiner. Do

not captivate the lifeline of a

self retracting lifeline as this may affect the performance of its

internal braking.

30°

Working Range

Roof Anchor

30°

5. FALL CLEARANCE: Make certain enough clearance exists

in your fall path to prevent striking an object. The amount of

clearance needed is dependent upon the type of connecting

subsystem used and anchorage location.

Page 7

ENGLISH

Page 8

6. SHARP EDGES: Avoid working where parts of the system will

be in contact with, or abrade against, unprotected sharp edges.

7. RESCUE: Should a fall occur, the user (employer) must have a

rescue plan. If a worker falls and is forced to remain suspended

for any length of time, physical damage to the body or even

death can result. For this reason Werner, OSHA, ANSI, CSA

and most local regulations require that a rescue plan and the

means to implement the rescue plan are in place before use of

this equipment.

8. AFTER A FALL: Any equipment which has been subjected

to the force of arresting a fall must be removed from service

immediately.

9. GENERAL USE CONSIDERATIONS: Avoid working where

lifeline may cross or tangle with that of another worker. Do not

allow the lanyard to pass under arms or between legs. Do not

clamp, tie, or otherwise prevent the rope grab lanyard connection

handle from moving freely into the “locked” position.

10. SLOPED ROOFS: Provisions must be made (warning lines,

monitors, guardrails) to prevent swing falls from unprotected roof

edges or corners. The rope grab should be connected to the

body support using a locking carabiner (direct connection) or

a short lanyard. If a lanyard is used for connecting to the rope

grab, keep the length as short as possible, and never greater

than three feet. The lifeline must be protected from contact with

sharp or abrasive edges and surfaces. The rope grab locking

operation must not be hindered by interference with the roof or

objects on the roof surface.

11. UNSTABLE SURFACES: The rope grab is not suitable for use

on unstable or slowly shifting materials, such as sand or grain.

Warning:

Never connect more than one personal fall arrest or restraint system

to a single lifeline or rope grab.

Warning:

Follow manufacturer’s instructions for associated equipment used in

your fall protection or restraint system.

d. Training

ENGLISH

OSHA, ANSI, and most local ordinances require that workers using

this product receive adequate training before use of this product.

Page 8

Page 9

MANUAL ROPE ADJUSTER

USER INSTRUCTIONS

These instructions and their entire contents should be a part of that

training.

II. Rope Adjuster Installation and Use

Warning:

Do not alter or intentionally misuse this equipment. Consult with

Werner Co. if using this equipment with components or subsystems

other than those described in this manual. Some subsystem and

component combinations may interfere with the operation of this

equipment. Use caution when using this equipment around moving

machinery, electrical hazards, chemical hazards, and sharp edges.

Warning:

Do not use this system if you are unable to tolerate the impact of

a fall arrest. Age and tness can seriously affect your ability to

withstand a fall. Pregnant women and minors must not use this

equipment.

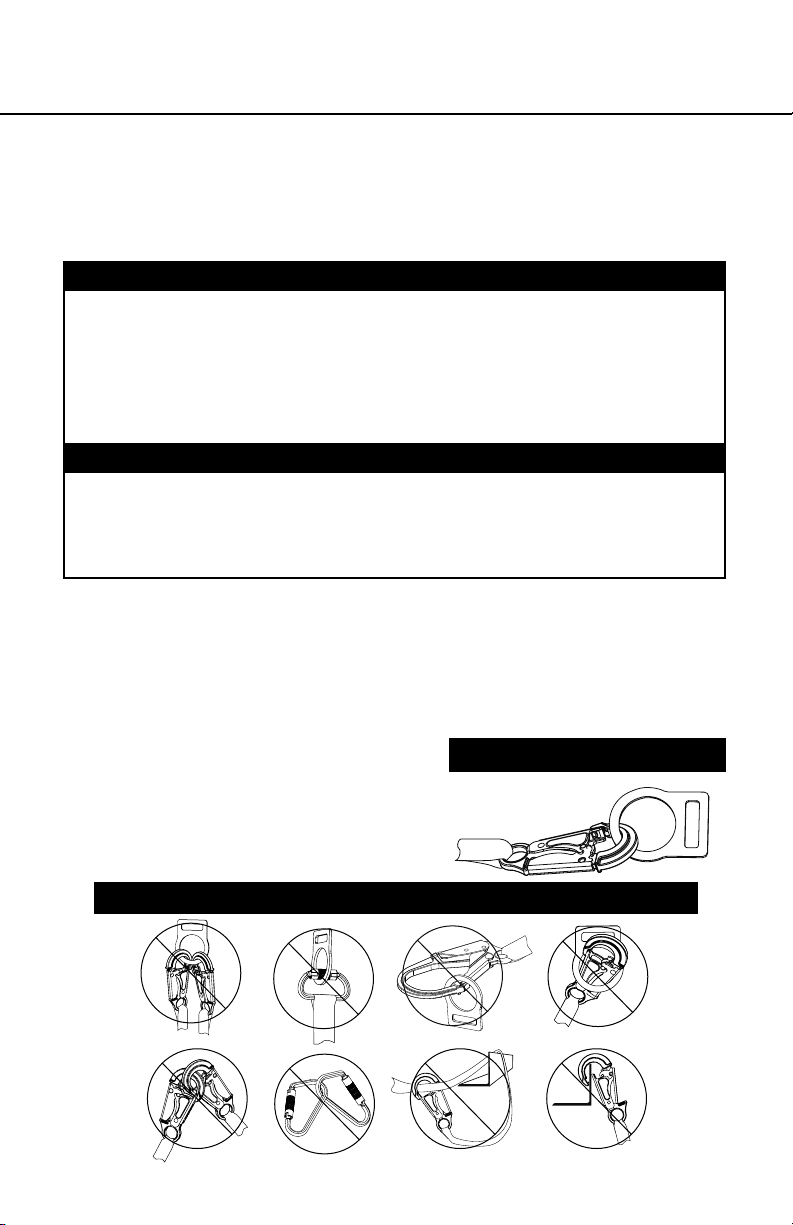

a. Making Connections

1. Only use self-locking snap hooks and carabiners with this

equipment. Only use connectors that are suitable to each

application. Ensure all connections are compatible in size, shape

and strength. Do not use equipment that is not compatible.

Ensure all connectors are fully closed and locked.

2. Werner Co. connectors (snap

hooks and carabiners) are

designed to be used only as

specied in each product’s

user’s instructions. See

inappropriate connections.

INAPPROPRIATE CONNECTIONS

A. B.

PROPER CONNECTIONS

C.

NO! NO! NO! NO!

D. E. F.

ENGLISH

NO!NO!NO!NO!

Page 9

Page 10

Werner Co. snap hooks and carabiners should NOT be

connected:

i. to a D-ring to which another connector is attached.

ii. in a manner that would result in a load on the gate. If the

connecting element that a snaphook or carabiner attaches

to is undersized or irregular in shape, a situation could occur

where the connecting element applies a force to the gate of

the snaphook or carabiner. This force may cause the gate

(of either a self-locking or a non-locking snaphook) to open,

allowing the snaphook or carabiner to disengage from the

connecting point.

NOTE: Large throat opening snap hooks should not be

connected to standard size D-rings or similar objects which

will result in a load on the gate if the hook or D-ring twists

or rotates. Large throat snap hooks are designed for use on

xed structural elements such as rebar or cross members

that are not shaped in a way that can capture the gate of

the hook.

iii. in a false engagement, where features that protrude from

the snap hook or carabiner catch on the anchor and without

visual conrmation seems to be fully engaged to the anchor

point.

iv. to each other.

v. directly to webbing or rope lanyard or tie-back (unless

the manufacturer’s instructions for both the lanyard and

connector specically allow such a connection).

vi. to any object which is shaped or dimensioned such that the

snap hook or carabiner will not close and lock, or that roll-

out could occur.

3. Do not pass the lanyard or lifeline through the roof anchor D-ring

and hook back into the lanyard or lifeline. When connecting,

make sure the connections are fully closed and locked.

4. When using an energy-absorbing lanyard, connect the energy

absorber “pack” end to the harness.

ENGLISH

Page 10

b. Anchorage Strength

Depending on the application, the anchorage to which the roof

anchor is installed must meet strengths as given below:

Page 11

MANUAL ROPE ADJUSTER

USER INSTRUCTIONS

1. FALL ARREST: Anchorages selected for personal fall arrest

systems (PFAS) shall have a strength capable of sustaining

static loads, applied in the directions permitted by the PFAS, of

at least; (A) 3,600 lbs. (16kN) when certication exists (see ANSI

Z359.1 for certication denition), or (B) 5,000 lbs. (22kN) in the

absence of certication. When more than one PFAS is attached

to an anchorage, the anchorage strengths set forth in (A) and

(B) above shall be multiplied by the number of personal fall

arrest systems attached to the anchorage. Per OSHA 1926.500

and 1910.66; Anchorages used for attachment of PFAS shall

be independent of any anchorage being used to support or

suspend platforms, and capable of supporting at least 5,000 lbs.

(22kN) per user attached, or be designed, installed, and used as

part of a complete PFAS which maintains a safety factory of at

least two, and is supervised by a qualied person.

2. RESTRAINT: Roof anchors installed for restraint applications

must be attached to a roof member capable of sustaining a static

load of at least 3,000 lbs. applied in any direction permitted by

the restraint system when in use. Each roof anchor installation

must be independently capable of sustaining this load.

Warning:

Restraint anchorages may only be used where there is no possible

vertical free fall. Restraint anchorages do not have sufficient

strength for fall arrest. Do not connect personal fall arrest systems

to restraint anchorages.

c. Lifelines

Werner Co. rope grabs are to be used with Werner Co. lifelines and

lifeline subsystems.

1. SIZE: This device is designed to be used on 5/8-inch (16mm)

diameter lifeline. Undersized rope may not allow the rope grab

to lock properly and may cause excessive stopping distances.

Oversized rope may impede rope grab mobility on the lifeline.

It is recommended that lifeline diameter be 5/8 inch, ±1/32 inch

(0.8mm).

2. CONSTRUCTION: Three-strand lay rope constructions are

recommended, but other constructions may also be acceptable.

Consult Werner Co. if you are considering using this equipment

with other lifeline constructions. Braided, double braided, hollow

Page 11

ENGLISH

Page 12

braided, or other types of rope constructions must not be used.

When selecting the lifeline, choose a rope with a rm lay. Inspect

the lay of the rope by grasping it several feet from the end

between the thumb and index nger. You should not be able to

easily squeeze or atten the rope. Untwisting should be difficult

and the rope should spring back to its original shape.

3. MATERIAL: Werner Co. recommends selecting lifeline ropes

made from polyester bers. Polyester has less stretch and less

swelling due to moisture absorption than nylon. Ropes made

solely of polypropylene, polyethylenes, or other olens must not

be used. Ropes made from cotton, sisal, hemp, abaca (manila),

or other plant/animal bers must not be used. ANSI Z359.1

requires rope used in vertical lifelines to be made of virgin

synthetic materials having strength, aging resistance, abrasion

resistance, and heat resistance characteristics equivalent or

superior to polyamides.

4. STRENGTH: Select a lifeline which, when terminated and

installed, will retain a minimum strength of 5,000 lbs. (22kN)

per ANSI Z359.1. Selection must account for strength reduction

factors, such as sharp edges and degrading factors (i.e.

chemicals).

Note: Per ANSI Z359.1; Knots shall not be used for load bearing

end terminations, but may be an acceptable means of securing

the free end of the lifeline at ground level.

d. Lanyard

ENGLISH

Page 12

For fall arrest systems Werner Co. recommends using energy

absorbing lanyards incorporating self locking snap hooks. Lanyards

labeled ANSI A10.14 Type II must not be used for fall arrest

applications. All lanyards must have a minimum breaking strength

of 5,000 lbs.

e. Body Support

The recommended body support for fall arrest applications is a full

body harness. For restraint applications a body belt may be used.

IMPORTANT: Only lifeline ropes which meet the size, construction,

and material properties required for compatible use with this rope

grab may be used.

Page 13

MANUAL ROPE ADJUSTER

UP

USER INSTRUCTIONS

Note: Applications such as working near high voltage may require

special lifeline materials, consult Werner Co. before using such

lifelines.

f. Attaching the Rope Grab to the Lifeline

1. Ensure the rope grab is in the “UP”

position as indicated on the device.

The “UP” end of the rope grab must be

oriented towards the anchorage when

installed onto the lifeline.

2. Raise the lanyard connection handle to

full “UP” position. Insert the lifeline into

the rope grab.

3. Attach approved shock-absorbing lanyard. Connection to the

rope grab must be compatible.

Note: Some rope grab models have lanyards sewn directly to the

lanyard connection handle.

4. Test the operation of the rope grab by pulling down on the

lanyard. You must not be able to pull the rope grab down the

lifeline or adjust it without raising the lanyard connection handle.

g. Positioning the Rope Grab on the Lifeline

1. Squeeze the lanyard connection handle to release the rope

grab from its current position on the lifeline. Release the lanyard

connection handle to the desired new position and tug on the

lanyard to ensure it locks on the lifeline. Keep a minimum of 6 ft.

of rope below the rope grab for rope grab locking distance and

fall clearance.

Note: Werner Co. recommends terminating the bottom of the lifeline

after the rope grab is installed.

Warning:

The rope grab should be positioned to limit potential free fall to the

shortest possible distance, but in no case more than 6’ per ANSI Z359

and OSHA requirements.

Page 13

ENGLISH

Page 14

h.

Connecting to Anchorage or Anchorage Connector

When attaching the lifeline or lifeline

subsystem to the anchorage or anchorage

connector, ensure the connector used (self

locking snap hook) is fully engaged and

locked onto the connection point. Ensure

connections are compatible in size, shape,

and strength.

Refer to manufacturer’s instructions for the

anchorage connector and lifeline for further

information.

i. Connecting to the Body Support

For fall arrest applications, connect to the

dorsal D-ring located between the shoulders

on the back of the full body harness. For

restraint applications, the dorsal or frontal

harness attachment may be used. If using a

body belt for restraint applications connect

to the D-ring opposite the restraining load.

Ensure connections are compatible in size,

shape, and strength. Refer to the body support manufacturer’s

instructions for more information on making connections.

ENGLISH

Page 14

j. Connecting to the Rope Grab

When connecting an energy absorbing lanyard to the rope grab,

attach the lanyard end (vs. the energy absorber end) to the rope

grab to reduce possible interference with the operation of the rope

grab by the energy absorber “pack”. Some rope grab models may be

supplied with a permanently attached lanyard or energy absorber.

Do not attempt to attach additional lanyards or connectors to these

subsystems. If using a carabiner to connect directly to the rope

grab, ensure the carabiner will not interfere with the operation of the

rope grab. Carabiners must be of the self closing/self locking type.

Ensure connections are compatible in size, shape, and strength.

Ensure the connector attached to the rope grab allows the handle

to rotate freely, and does not interfere with the rope grab operation.

Page 15

MANUAL ROPE ADJUSTER

USER INSTRUCTIONS

k. Use of Lifelines

(See Lifeline User Instruction Manual for complete details)

1. Always protect the lifeline if passing over or around sharp

edges. Sharp edges can reduce rope strength by 70% or more.

2. Keep lifelines clean.

3. Avoid twisting or kinking lifelines when coiling or uncoiling

4. Avoid using lifelines near acids or alkalines. If the lifeline is

used around any chemical or compound, watch for signs of

deterioration.

5. Never use a knotted lifeline, knots can reduce rope strength

by 50%.

6. Store lifelines properly.

l. After Use

After use of the rope grab and its subsystem components, return it

for cleaning or storage as described below:

1. Clean the rope grab and lifeline with water and a mild soap

solution. Wipe off hardware with a clean, dry cloth, and hang

to air dry. Do not force dry with heat. Apply a thin coat of an oil

based lubricant if desired. An excessive buildup of dirt, paint,

etc. may prevent the rope grab or lifeline from working properly,

and in severe cases degrade the rope grab or rope to a point

where it has weakened and should be removed from service.

If you have any questions concerning the condition of the

rope grab or lifeline, or have any doubt about putting them into

service, contact Werner Co. See the Lifeline User Instruction

Manual for specic maintenance details.

2. Additional maintenance and servicing procedures (replacement

parts) must be completed by a factory authorized service center.

Authorization must be in writing. Do not attempt to disassemble

the unit.

3. Store the rope grab and lifeline in a cool, dry, clean environment

out of direct sunlight. Avoid areas where chemical vapors may

exist. Thoroughly inspect the rope grab and lifeline after any

period of extended storage.

Page 15

ENGLISH

Page 16

III. Use Warnings, Restrictions and Cautions

a. Purpose

Werner Co. rope grab fall arresters are intended to be used as part

of a personal fall arrest or restraint system. Applications for this type

of product include inspection work, construction and demolition,

maintenance, oil production, window washing, and other activities

where there exists the need for fall arrest or restraint. The following

denitions describe these applications:

1. FALL ARREST: The rope grab is used as part of a complete fall

arrest system. Such systems generally include a lifeline, rope

grab, lanyard, and full body harness (body support). Applications

include: protection of a worker on scaffolding, powered platforms,

or riding a boatswain’s chair. Maximum permissible free fall is six

feet.

2. RESTRAINT: The rope grab is used in combination with a

lifeline, lanyard or connector, and body support to restrain the

user from reaching a hazard (sloped or leading edge roof work).

No vertical free fall possible.

b. Rated Capacity

Capacity: 310 lbs. This equipment is designed for use by persons

with a combined weight (person, clothing, tools, etc.) of no more

than 310 lbs.

ENGLISH

Page 16

Note: No more than one person may be attached to a single lifeline.

See c. Limitations

c. Limitations

The following application limitations must be recognized and

considered before using this product:

1. FREE FALL: Restraint systems must be rigged such that there

is no possible vertical free fall. Personal fall arrest systems must

be rigged in such a way to limit the free fall to six feet (ANSI

Z359.1). See associated connecting subsystem manufacturer’s

instructions for further information.

2. FALL CLEARANCE: Make certain that enough clearance exists

in your fall path to prevent striking an object. The amount of

clearance required is dependent upon the type of connecting

subsystem used (lanyard, lifeline), the anchorage location, and

Page 17

MANUAL ROPE ADJUSTER

USER INSTRUCTIONS

the amount of stretch in the lifeline. See section I.c for more

information on determining fall clearance.

3. CORROSION: Do not leave this equipment for long periods in

environments where corrosion of metal parts could take place as

a result of vapors from organic materials. Sewage and fertilizer

plants, for example, have high concentrations of ammonia. Use

near seawater or other corrosive environments may require

more frequent inspections or servicing to ensure corrosion

damage is not affecting the performance of the product.

4. CHEMICAL HAZARDS: Solutions containing acids, alkali, or

other caustic chemicals, especially at elevated temperatures,

may cause damage to this equipment. When working with

such chemicals, frequent inspection of this equipment must be

performed. Consult Werner Co. if doubt exists concerning using

this equipment around chemical hazards.

5. HEAT: This equipment is not designed for use in high temperature

environments. Protection should be provided for this equipment

when used near welding, metal cutting, or similar activities. Hot

sparks may burn or damage this equipment. Consult Werner

Co. for details on high temperature environments.

6. ELECTRICAL HAZARDS: Due to the possibility of electric current

owing through this equipment or connecting components, use

extreme caution when working near high voltage power lines.

7. COMPONENT COMPATIBILITY: The rope grab addressed by

these instructions is intended for use with Werner Co. lifelines

and lifeline subsystems only. Consult Werner Co. if you are

considering using this equipment with other lifelines or lifeline

subsystems. See section I.b.

8. TRAINING: This equipment is to be used by persons who have

been properly trained in its correct application and use.

d. Governing Requirements

Refer to applicable local, state, and federal (OSHA) requirements

governing this equipment for more information on rope grabs and

associated system components, including; ANSI Z359.1, and

OSHA 1910.66, appendix C.

Page 17

ENGLISH

Page 18

IV. Labels/Identication/Inspection Records

a. All products should be inspected by the user thoroughly before

each use. Additional inspections by a competent person other than

the user should be conducted at intervals of no less than one year.

That interval should be shortened any time the product is used in a

harsh environment or is exposed to conditions such as chemicals,

abrasion, heat or any other factor that could affect the strength of

any of the materials or components

b. The product labels provide an inspection grid to record these

inspections by a competent person. Use a punch or permanent

marker to record those dates.

c. This manual should always accompany the product, or be on le

with the employer for access when needed. Record the identication

details for the anchor and record the inspections in the inspection

log, on page 20. It is important to keep this log current, complete,

and available as needed.

ENGLISH

Page 18

Page 19

MANUAL ROPE ADJUSTER

USER INSTRUCTIONS

Id label front / back

ENGLISH

Page 19

Page 20

V. Equipment Record

PART NUMBER

SERIAL NUMBER

DATE

MANUFACTURED

PURCHASE DATE

ASSIGNED TO

SPECIFICATIONS

Werner Manual Rope Adjuster

Certied to meet ANSI Z359.1-2007, and OSHA 1910 and 1926 standards

and regulations for the subsystem components of a complete personal

fall arrest system.

Individually bar coded model and serial numbers, location and date of

manufacture are on product label.

VI. Inspection Record

INSPECTION RECORD

DATE INSPECTOR PASS/FAILDATE INSPECTOR PASS/FAIL

ENGLISH

Page 20

Page 21

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

¡PRECAUCIÓN!

Si el uso de equipos de protección contra caídas es necesario,

entonces el ambiente de trabajo es peligroso y potencialmente

mortal. Los productos Werner Company están diseñados para

eliminar peligros tanto como sea posible, pero SÓLO si estos

productos se utilizan correctamente. Utilice este equipo tal como

fue diseñado para usarse, después de una capacitación apropiada,

bajo la supervisión directa de una persona calicada, de acuerdo con

las instrucciones suministradas, y de acuerdo con las regulaciones

OSHA y las regulaciones de seguridad locales. El usuario DEBE leer y

entender todas las precauciones e instrucciones. No tener en cuenta

estas directrices podría resultar en lesiones o incluso la muerte.

Por favor, ¡TRABAJE DE MANERA SEGURA! ¡TRABAJE DE MANERA

INTELIGENTE!

ESPAÑOL

Página 21

Page 22

Contenido

I. ANTES DE UTILIZAR EL DISPOSITIVO DE AGARRE

PARA CUERDA TRENZADA ............................................................................23

a. Inspeccione ............................................................................................................23

b. Compatibilidad .......................................................................................................25

c. Plan de protección contra caídas .........................................................................25

d. Capacitación ..........................................................................................................28

II. INSTALACIÓN Y USO DEL ANCLAJE ........................................................... 28

a. Realización de una conexión ................................................................................29

b. Resistencia del anclaje..........................................................................................30

c. Cuerdas salvavidas................................................................................................31

d. Cuerdas ..................................................................................................................32

e. Soporte del cuerpo ................................................................................................32

f. Soporte del cuerpo ................................................................................................32

g. Posicionamiento del dispositivo de agarre sobre la cuerda salvavidas ..........33

h. Conexión al conector de anclaje ..........................................................................33

i. Conexión al soporte de cuerpo .............................................................................34

j. Conexión al dispositivo de agarre .........................................................................34

k. Uso de cuerdas salvavidas ...................................................................................34

l. Después del uso .....................................................................................................35

III. TENGA EN CUENTA LAS ADVERTENCIAS,

RESTRICCIONES Y PRECAUCIONES .......................................................... 35

a. Propósito ..............................................................................................................35

b. Capacidad nominal ................................................................................................36

c. Limitaciones ...........................................................................................................36

d. Requisitos regidores .............................................................................................37

IV. ETIQUETAS/IDENTIFICACIÓN/ REGISTROS DE INSPECCIÓN .................37

V. REGISTROS DE EQUIPOS ............................................................................ 39

VI. REGISTROS DE INSPECCIÓN ..................................................................... 39

ESPAÑOL

Página 22

Page 23

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

Advertencia:

Este producto es sólo una parte de un sistema personal de detención de caídas. Éste

debe combinarse correctamente con otros componentes para conformar un sistema

completo y funcional. El usuario debe entender la función de cada uno de estos

componentes y seguir las instrucciones del fabricante para el uso de cada componente.

El usuario debe recibir estas instrucciones, debe leerlas y seguirlas, y consultar a

la persona calicada que supervisará su trabajo si tiene alguna pregunta acerca de

cualquier parte de las instrucciones. El empleador debe proporcionar capacitación

sobre el uso apropiado, inspección y mantenimiento de todos los componentes del

sistema, y estas instrucciones pueden utilizarse como parte de esa capacitación. El

equipo SÓLO debe utilizarse de acuerdo con estas instrucciones, ordenanzas y códigos

locales, las normas OSHA y ANSI aplicables, y el plan de seguridad del empleador.

Las alteraciones o uso incorrecto de este producto, o no seguir estas instrucciones,

podría resultar en lesiones graves o la muerte.

SI USTED TIENE ALGUNA PREGUNTA ACERCA DE ALGO DE ESTAS

INSTRUCCIONES, EL EQUIPO O EL USO APROPIADO DEL EQUIPO,

COMUNÍQUESE CON WERNER CO. PARA OBTENER MÁS INFORMACIÓN.

I. Antes de utilizar el ajustador para cuerda trenzada

Antes de utilizar este equipo, el usuario debe realizar ciertos pasos para

garantizar que éste está en condiciones apropiadas y es seguro para su uso.

Los usuarios deben leer y entender estas instrucciones. Es obligación del

empleador garantizar que todos los usuarios hayan recibido capacitación

sobre los procedimientos de trabajo seguros y también sobre el uso y

limitaciones de los equipos de protección contra caídas. Todos los usuarios

deben estar informados acerca de y cumplir todas las normas OSHA, ANSI,

CSA y las normas locales o regionales relacionadas con los equipos de

protección contra caídas y su uso.

a. Inspeccione

Todo el equipo debe ser examinado completamente, diariamente antes

del uso, por parte del usuario; y periódicamente por parte de una

persona calicada que no sea el usuario.

1. Antes de instalar este equipo, inspecciónelo cuidadosamente para

garantizar que está en buenas condiciones para ser utilizado.

2. El ajustador manual para cuerda trenzada (dispositivo manual de

agarre para cuerda trenzada) debe ser inspeccionado por una persona

capacitada diferente al usuario, anualmente como mínimo. Registre los

resultados de cada inspección formal en el registro de inspección.

Página 23

ESPAÑOL

Page 24

ESPAÑOL

Página 24

3. Inspeccione el funcionamiento de la manija de conexión a cuerda

en cuanto a la libertad de movimiento. No debe haber atoramiento ni

adhesión. La manija de conexión a cuerda tiene un resorte y cuando

se levanta, las levas internas deben liberarse de la cuerda salvavidas

permitiendo que el dispositivo de agarre para cuerda trenzada se

reposicione. Al soltar la manija de conexión a cuerda se debe producir

la sujeción de las levas internas sobre la cuerda salvavidas evitando el

movimiento.

4. Inspeccione el canal de cuerda en cuanto a señales de desgaste de

la cuerda. No debe haber sitios hundidos ni depresiones desgastados

en el canal de cuerda. Las levas internas que hacen contacto con la

cuerda salvavidas deben tener una cara dentada visible.

5. Inspeccione cada componente del sistema o subsistema según las

instrucciones del fabricante respectivo.

6. Registre la fecha y resultados de la inspección en el registro de

inspección.

7. PASOS DE INSPECCIÓN PARA CUERDAS SALVAVIDAS: (Vea el

manual de instrucciones para usuario de la cuerda salvavidas, para

obtener los detalles completos)

i. Los herrajes de la cuerda salvavidas no deben estar dañados,

rotos, deformados ni tener bordes losos, rebabas, grietas, piezas

desgastadas, ni corrosión. Verique que los ganchos conectivos funcionan

apropiadamente. Los cierres de los ganchos deben moverse libremente y

asegurar al momento de cerrar.

ii. Inspeccione la cuerda en busca de desgaste focalizado. El material no

debe tener trenzas deshilachadas, hilos rotos, cortaduras, raspaduras,

quemaduras ni decoloración. La cuerda no debe tener nudos, suciedad

excesiva, acumulación excesiva de pintura, ni manchas de óxido.

Los empalmes de cuerda deben estar apretados, con cinco pliegues

completos, y los guardacabos deben estar sostenidos por el empalme.

Los guardacabos de cuerda agrietados o deformados podrían indicar que

la cuerda salvavidas ha recibido una carga de impacto. Revise en busca

de daño por sustancias químicas o calor (lo cual se indica por áreas

color café, decoloradas o quebradizas). Revise en busca de daño por luz

ultravioleta; lo cual se indica por decoloración y la presencia de astillas y

pedacitos sobre la supercie de la cuerda. Se sabe que todos los factores

anteriores reducen la resistencia de la cuerda. Las cuerdas dañadas o con

posibles daños deben reemplazarse.

iii. Inspeccione las etiquetas. Todas las etiquetas deben estar presentes y

totalmente legibles. Reemplace las etiquetas si están ilegibles o colóquelas

si están faltando.

iv. Registre la fecha de inspección y sus resultados en el registro de

inspección mostrado en el manual de instrucciones para el usuario de la

cuerda salvavidas.

Page 25

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

8. Verique que todas las etiquetas están intactas, en su sitio, y son

legibles.

9. Si la inspección revela una condición defectuosa o anormalidades

en cualquiera de estas áreas, retire inmediatamente del servicio la

unidad. Debe consultarse a una persona capacitada para determinar

si ese elemento es seguro para uso continuado o si debe destruirse.

IMPORTANTE: Si este equipo ha sido sometido a las fuerzas resultantes

de una detención de caída, éste debe retirarse inmediatamente del

servicio.

IMPORTANTE: No intente modicar, reparar o realizar sustituciones

al dispositivo de agarre o a las piezas del dispositivo de agarre. El

equipo que se encuentre en condiciones defectuosas debe retirarse

del servicio. Las reparaciones sólo pueden ser realizadas por Werner

Co. o quienes estén autorizados por escrito para hacerlo.

b. Compatibilidad

Los equipos Werner Co. están diseñados para uso sólo con componentes

y subsistemas aprobados por Werner Co. Las sustituciones o reemplazos

realizados con componentes o subsistemas no aprobados podrían

arriesgar la compatibilidad del equipo y podrían afectar la seguridad y

conabilidad del sistema completo.

Los conectores se consideran compatibles con los elementos conectivos

cuando éstos han sido diseñados para trabajar en conjunto de tal manera

que sus tamaños y formas no causen que sus mecanismos de cierre

se abran inadvertidamente sin importar la manera como se orienten.

Comuníquese con Werner Co. si usted tiene alguna pregunta acerca de la

compatibilidad. Los conectores (ganchos, argollas rectangulares metálicas

y los anillos en ‘D’) deben ser capaces de soportar 5.000 lbs. (22,2kN). Los

conectores deben ser compatibles con el ancladero u otros componentes

del sistema. No utilice equipos que no sean compatibles. Los conectores

no compatibles podrían desengancharse accidentalmente. Los conectores

deben ser compatibles en tamaño, forma y resistencia. Las normas ANSI

Z359 y OSHA requieren argollas rectangulares metálicas y ganchos de

cierre resortado auto-asegurables.

c. Plan de protección contra caídas

Planee su sistema de detención o evitamiento de caídas antes de iniciar

su trabajo. Tenga en cuenta todos los factores que afectan su seguridad en

cualquier momento durante el uso. La siguiente lista proporciona algunos

puntos importantes que deben considerarse al planear su sistema:

1. ANCLADERO: Seleccione un punto de anclaje rígido que sea capaz de

soportar las cargas requeridas. Vea la sección II.b.

Página 25

ESPAÑOL

Page 26

La ubicación del anclaje debe seleccionarse cuidadosamente para

reducir la posibilidad de peligros por caída libre o por caída tipo

columpio y para evitar golpear un objeto durante una caída. Para

los sistemas de evitamiento de caídas, el anclaje debe ubicarse de

modo que no sea posible una caída libre vertical. Para los sistemas de

detención de caídas, OSHA exige que el anclaje sea independiente de

los elementos que suspenden o soportan el usuario.

2. CAÍDA LIBRE: No trabaje encima del nivel del anclaje porque existirá

una mayor distancia de caída. Los sistemas personales de detención de

caídas deben instalarse de modo que la posible caída libre nunca sea

superior a 1.83 m (6 pies). Deben instalarse sistemas de evitamiento de

caídas de modo que no haya posibilidad de una caída libre vertical.

3. FUERZAS DE DETENCIÓN DE CAÍDAS: El sistema de detención de

caídas ensamblado debe mantener las fuerzas de detención de caídas

por debajo de 1.800 lbs. cuando se utiliza con un arnés de cuerpo

completo. No utilice un cinturón de cuerpo para las aplicaciones de

detención de caídas.

Anclaje en techo

4. CAÍDAS TIPO COLUMPIO:

Las caídas tipo columpio

ocurren cuando el anclaje

no está directamente encima

del punto donde ocurre una

caída. La fuerza de golpear

30°

Rango de trabajo

30°

un objeto mientras sucede un

movimiento pendular puede

ser grande y causar lesiones

graves. Minimice las caídas

tipo columpio trabajando tan

directamente debajo del anclaje

como sea posible (el trabajador

debe colocarse dentro de 30

grados del anclaje instalado

en techo). Es aceptable sujetar

una cuerda salvavidas (es decir,

sistema de dispositivo de agarre) a un anclaje cercano al área de

trabajo mediante una argolla rectangular metálica. No sujete la cuerda

de una cuerda salvavidas auto-retráctil ya que esto podría afectar el

funcionamiento de su frenado interno.

ESPAÑOL

Página 26

5. ESPACIO LIBRE DE CAÍDA: Verique que existe suciente espacio

libre en la trayectoria de caída para evitar golpear un objeto. La cantidad

de espacio libre necesario depende del tipo de subsistema conectivo

utilizado y de la ubicación del anclaje.

Page 27

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

6. BORDES FILOSOS: Evite trabajar en lugares donde las piezas del

sistema harán contacto con, o se desgastarán contra, bordes losos

expuestos.

7. RESCATE: Si ocurre una caída, el usuario (empleador) debe tener un

plan de rescate. Si un trabajador cae y queda obligado a permanecer

suspendido durante cualquier período de tiempo, podría producirse

daño físico o incluso la muerte. Por este motivo; Werner, las regulaciones

de OSHA, ANSI, CSA, y la mayoría de las regulaciones locales exigen

la existencia de un plan de rescate y los medios para ejecutar un plan

de rescate, antes del uso de este equipo.

8. DESPUÉS DE UNA CAÍDA: Cualquier equipo que ha sido sometido a

una fuerza de detención de caída debe retirarse inmediatamente del

servicio.

9. CONSIDERACIONES GENERALES DE USO: Evite trabajar donde la

cuerda salvavidas pudiera atravesarse o enredarse con la cuerda de

otro trabajador. No permita que la cuerda pase debajo de sus brazos

o entre las piernas. No sujete, amarre, ni evite de ninguna manera que

la manija de conexión a cuerda del dispositivo de agarre se mueva

libremente hacia la posición “asegurada”.

10. TECHOS INCLINADOS: Deben suministrarse elementos (cuerdas de

advertencia, monitores, barandillas) para evitar caídas tipo columpio

desde esquinas o bordes de techo no protegidos. El dispositivo de

agarre para cuerdas trenzadas debe conectarse al soporte de cuerpo

utilizando una argolla rectangular metálica asegurable (conexión

directa) o una cuerda corta. Si se utiliza una cuerda para conectar

al dispositivo de agarre, mantenga la longitud lo más corta posible, y

nunca superior a 0.91 m (3 pies). La cuerda salvavidas debe protegerse

contra el contacto con bordes y supercies losos o abrasivos. La

operación de aseguramiento/jación/bloqueo del dispositivo de agarre

no debe ser impedida por interferencia con el techo u objetos sobre la

supercie del techo.

11. SUPERFICIES INESTABLES: El dispositivo de agarre para cuerda

trenzada no es apropiado para uso en materiales inestables o de

desplazamiento lento, tal como arena o grano.

ADVERTENCIA:

Nunca conecte más de un sistema personal de detención o evitamiento

de caídas a una sola cuerda salvavidas o dispositivo de agarre.

ADVERTENCIA:

Siga las instrucciones del fabricante para el equipo respectivo

utilizado en su sistema de protección contra caídas o de evitamiento

de caídas.

d. Capacitación

Las regulaciones OSHA, ANSI, y la mayoría de las regulaciones locales

exigen que los trabajadores que utilicen este producto deben recibir

capacitación adecuada antes del uso de este producto. Estas instrucciones

y su contenido completo deben ser parte de esa capacitación.

Página 27

ESPAÑOL

Page 28

II. Instalación y uso del ajustador para cuerda trenzada

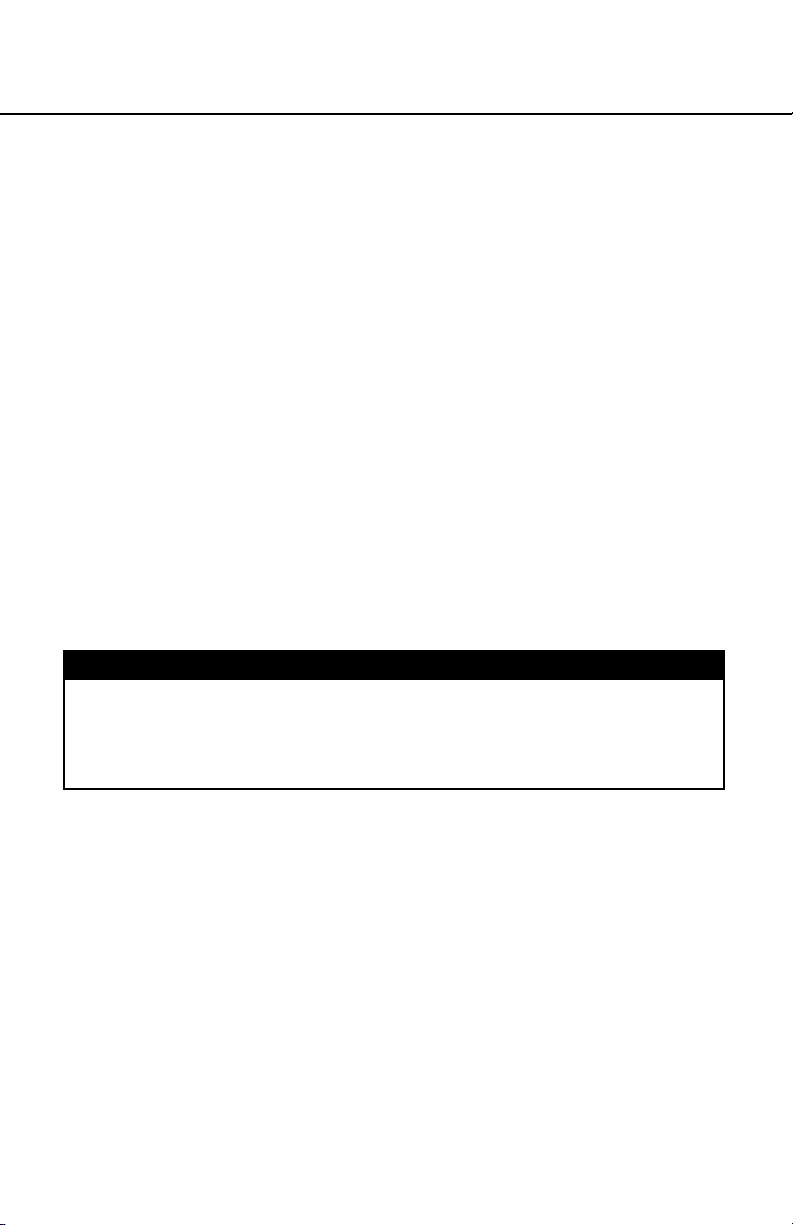

A. B.

C.

D. E. F.

NO! NO! NO! NO!

NO!NO!NO!NO!

Advertencia:

No altere ni utilice incorrectamente intencionalmente este equipo. Consulte

con Werner Co. si este equipo se utilizará con componentes o subsistemas

diferentes a los descritos en este manual. Algunos subsistemas y

combinaciones de componentes podrían interferir con la operación de este

equipo. Tenga precaución al utilizar este equipo alrededor de máquinas en

movimiento, peligros eléctricos, peligros químicos y bordes losos.

Advertencia:

No utilice este sistema si usted no puede tolerar el impacto de una

detención de caída. La edad y la condición física pueden afectar

seriamente su capacidad para soportar una caída. Las mujeres

embarazadas y los menores de edad no deben utilizar este equipo.

a. Realización de las conexiones

1. Con este equipo, sólo utilice argollas rectangulares metálicas y ganchos

de cierre resortado auto-asegurables. Sólo utilice conectores que sean

apropiados para cada aplicación. Verique que todas las conexiones

son compatibles en tamaño, forma y resistencia. No utilice equipos que

no sean compatibles. Verique que todos conectores están totalmente

cerrados y asegurados.

2. Los conectores Werner Co.

(ganchos de cierre resortado y

argollas rectangulares metálicas)

están diseñados para utilizarse

únicamente según se especica

en las instrucciones para usuario

de cada producto. Vea las

conexiones inapropiadas.

CONEXIONES INAPROPIADAS

CONEXIONES APROPIADAS

ESPAÑOL

Página 28

Page 29

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

Los ganchos de cierre resortado y las argollas rectangulares metálicas de

Werner Co. NO deben conectarse:

i. a un anillo en ‘D’ al cual está sujetado otro conector.

ii. de tal manera que se produzca carga sobre el cierre. Si el elemento

conectivo al cual se sujeta un gancho de cierre resortado o una argolla

rectangular metálica es de tamaño inferior o tiene forma irregular,

podría ocurrir un problema cuando el elemento conectivo aplique una

fuerza al cierre del gancho de cierre resortado o la argolla rectangular

metálica. Esta fuerza podría causar que se abra el cierre (de un gancho

de cierre resortado auto-asegurable o no-asegurable), permitiendo

que el gancho de cierre resortado o la argolla rectangular metálica se

desenganche del punto de conexión.

NOTA: Los ganchos de cierre resortado que se abren hasta una garganta

grande no deben conectarse a anillos en ‘D’ de tamaño estándar u

objetos similares, lo cual resultará en una carga sobre el cierre si el

gancho o anillo en ‘D’ gira o rota. Los ganchos de cierre resortado de

garganta grande están diseñados para uso en elementos estructurales

jos tales como barras de refuerzo o travesaños que no tengan una

forma que pueda atrapar el cierre del gancho.

iii. en un enganche falso, donde las características que sobresalen

del gancho de cierre resortado o la argolla rectangular metálica se

agarran al anclaje, y sin conrmación visual parece estar totalmente

enganchado al punto de anclaje.

iv. uno al otro.

v. directamente a una correa tejida o cuerda de bras trenzadas o amarre

sobre sí mismo (a menos que las instrucciones del fabricante de la

cuerda y el conector permitan especícamente dicha conexión).

vi. a cualquier objeto que tenga una forma o dimensiones tales que el

gancho de cierre resortado o la argolla rectangular metálica no se

cierren ni aseguren, y que pudiera ocurrir rodaje.

3. No pase la cuerda o cuerda salvavidas a través del anillo en ‘D’

del anclaje en techo y enganche de regreso en la cuerda o cuerda

salvavidas. Al conectar, verique que las conexiones están totalmente

cerradas y aseguradas.

4. Al utilizar una cuerda absorbedora de energía;, conecte el extremo,

con “paquete” absorbedor de energía, al arnés.

b. Resistencia del anclaje

Dependiendo de la aplicación, el ancladero al cual se instala el

anclaje en techo debe cumplir las resistencias según se indican a

continuación:

Página 29

ESPAÑOL

Page 30

1. DETENCIÓN DE CAÍDAS: Los ancladeros seleccionados para los

Sistemas Personales de Detención de Caídas (SPDC) deberán tener

una resistencia capaz de sostener cargas estáticas, aplicadas en las

direcciones permitidas por el SPDC, de al menos; (A) 3.600 lbs. (16kN)

cuando existe certicación (vea la norma ANSI Z359.1 para obtener

la denición de certicación), ó (B) 5.000 lbs. (22kN) en ausencia de

certicación. Cuando se sujeta más de un (1) SPDC a un ancladero, las

resistencias del ancladero establecidas en (A) y (B) anteriores deberán

multiplicarse por el número de sistemas personales de detención de

caídas sujetados al ancladero. Según las normas OSHA 1926.500 y

1910.66; los ancladeros utilizados para sujeción de los SPDC deberán

ser independientes de cualquier ancladero que se esté utilizando para

soportar o suspender plataformas, y capaces de soportar al menos

5.000 lbs. (22kN) por cada usuario sujetado, o diseñarse, instalarse y

utilizarse como parte de un sistema completo personal de detención de

caídas que mantenga un factor de seguridad de dos como mínimo, y

sea supervisado por una persona capacitada.

2. EVITAMIENTO DE CAÍDAS: Los anclajes en techo instalados para

aplicaciones de evitamiento de caídas debe sujetarse a un componente

de techo capaz de soportar como mínimo una carga estática de

3.000 lbs. aplicada en cualquier dirección permitida por el sistema

de evitamiento de caídas cuando está en uso. Cada instalación de

anclaje en techo debe ser capaz de soportar esta carga de manera

independiente.

Advertencia:

Los anclajes para evitamiento de caídas sólo pueden utilizarse donde no existe

la posibilidad de una caída libre vertical. Los anclajes para evitamiento de caídas

no tienen suciente resistencia para detener una caída. No conecte los sistemas

personales de detención de caídas a anclajes para evitamiento de caídas.

c. Cuerdas salvavidas

Los dispositivos de agarre Werner Co. deben utilizarse con cuerdas

salvavidas y subsistemas de cuerdas salvavidas Werner Co.

1. TAMAÑO: Este dispositivo está diseñado para utilizarse en cuerda

salvavidas con diámetro de 5/8 pulgadas (16 mm). Las cuerdas con

diámetro inferior podrían no permitir que el dispositivo de agarre se je

apropiadamente y podrían causar distancias de detención excesivas.

Las cuerdas con diámetro superior podrían impedir la movilidad del

dispositivo de agarre sobre la cuerda salvavidas. Se recomienda que el

diámetro de la cuerda salvavidas sea de 5/8 pulgadas, ±1/32 pulgadas

(0.8mm).

2. CONSTRUCCIÓN: Se recomiendan las construcciones de cuerda de

tres trenzas, pero otras construcciones también podrían ser aceptables.

Consulte a Werner Co. si usted está considerando utilizar este equipo

con otras construcciones de cuerdas salvavidas. No deben utilizarse

las construcciones del tipo entrelazada, doble entrelazado, hueca

ESPAÑOL

Página 30

Page 31

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

entrelazada, u otros tipos de construcciones de cuerda. Al seleccionar

la cuerda salvavidas, elija una cuerda con una conguración rme.

Inspeccione la conguración de la cuerda agarrándola a varios pies

de distancia del extremo entre el dedo pulgar y el dedo índice. Usted

no debería poder comprimir ni aplanar fácilmente la cuerda. Debe ser

difícil desenroscar la cuerda y la cuerda debe regresar a su forma

original.

3. MATERIAL: Werner Co. recomienda seleccionar cuerdas salvavidas

trenzadas hechas de bras de poliéster. El poliéster tiene menos

alargamiento y menos hinchamiento por absorción de humedad que el

nylon. No deben usarse cuerdas hechas únicamente de polipropileno,

polietileno u otros oleonos. No deben utilizarse cuerdas hechas de

algodón, sisal (pita), cáñamo, abaca (manila), u otras bras vegetales/

animales. ANSI Z359.1 exige que la cuerda utilizada en cuerdas

salvavidas verticales esté hecha de materiales sintéticos vírgenes que

tengan características de resistencia, resistencia al envejecimiento,

resistencia a la abrasión, y resistencia al calor equivalentes o superiores

a las poliamidas.

4. RESISTENCIA: Seleccione una cuerda salvavidas que, cuando esté

terminada e instalada, mantendrá una resistencia mínima de 5.000

lbs. (22kN) según la norma ANSI Z359.1. La selección debe tener en

cuenta los factores de reducción de resistencia, tales como bordes

losos y factores de degradación (es decir, productos químicos).

NOTA: Según la norma ANSI Z359.1; no deben utilizarse nudos para

realizar terminaciones de extremo de soporte de carga, pero puede

ser un medio aceptable para asegurar el extremo libre de la cuerda

salvavidas al nivel del suelo.

d. Cuerda

Para los sistemas de detención de caídas, Werner Co. recomienda

utilizar cuerdas absorbedoras de energía que tengan ganchos de cierre

resortados auto-asegurables. Las cuerdas con etiqueta ANSI A10.14 tipo

II no deben utilizarse para aplicaciones de detención de caídas. Todas las

cuerdas deben tener una resistencia mínima a la rotura de 5.000 lbs.

e. Soporte del cuerpo

El soporte de cuerpo recomendado para todas las aplicaciones de

detención de caídas es un arnés de cuerpo completo. Para las aplicaciones

de evitamiento de caídas, puede utilizarse un cinturón de cuerpo.

IMPORTANTE: Sólo pueden usarse cuerdas salvavidas que cumplan las

propiedades de tamaño, construcción y material requeridas para el uso

compatible con este dispositivo de agarre para cuerda trenzada.

Página 31

ESPAÑOL

Page 32

NOTA: Las aplicaciones tales como trabajar cerca de cables de alto voltaje

UP

podrían requerir materiales especiales de cuerda salvavidas, consulte a

Werner Co. antes de utilizar dichas cuerdas salvavidas.

f. Sujeción del dispositivo de agarre a la cuerda

salvavidas

1. Verique que dispositivo de agarre para

cuerda trenzada está en la posición “UP”

(ARRIBA) según se indica en el dispositivo.

El extremo “UP” del dispositivo de agarre

debe estar orientado hacia el anclaje cuando

está instalado sobre la cuerda salvavidas.

2. Levante la manija de conexión a cuerda hasta

la posición “UP” completa. Inserte la cuerda

salvavidas en el dispositivo de agarre.

3. Sujete una cuerda absorbedora de impacto aprobada. La conexión al

dispositivo de agarre debe ser compatible.

NOTA: Algunos modelos de dispositivo de agarre tienen cuerdas cosidas

directamente a la manija de conexión a cuerda.

4. Pruebe el funcionamiento del dispositivo de agarre halando hacia

abajo sobre la cuerda. Usted no debe poder halar el dispositivo de

agarre hacia abajo por la cuerda salvavidas ni ajustarla sin levantar la

manija de conexión a cuerda.

g. Posicionamiento del dispositivo de agarre sobre la cuerda salvavidas

1. Apriete la manija de conexión a cuerda para liberar el dispositivo de

agarre de su posición actual en la cuerda salvavidas. Suelte la manija

de conexión a cuerda hasta la nueva posición deseada y hale la cuerda

para garantizar que ésta se ja sobre la cuerda salvavidas. Mantenga

un mínimo de 1.83 m (6 pies) de cuerda debajo del dispositivo de

agarre para permitir una distancia de jación del dispositivo de agarre

y espacio libre de caída.

NOTA: Werner Co. recomienda colocar un terminal a la parte inferior de la

cuerda salvavidas después de instalar el dispositivo de agarre.

Advertencia:

El dispositivo de agarre debe posicionarse para limitar una posible

caída libre a la distancia más corta posible, pero en ningún caso

superior a 1.83m (6 pies) según la norma ANSI Z359 y los requisitos

OSHA.

ESPAÑOL

Página 32

Page 33

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

h.

Conexión a un anclaje o conector de anclaje

Al sujetar la cuerda salvavidas o el subsistema

de cuerda salvavidas al anclaje o conector

de anclaje, verique que el conector utilizado

(gancho de cierre resortado auto-asegurable)

esté totalmente enganchado y asegurado en el

punto de conexión. Verique que las conexiones

son compatibles en tamaño, forma y resistencia.

Consulte las instrucciones del fabricante para el

conector de anclaje y la cuerda salvavidas para

obtener información adicional.

i. Conexión al soporte de cuerpo

Para las aplicaciones de detención de caídas, conecte al anillo en ‘D’ dorsal

ubicado entre los hombros en la parte trasera del

arnés de cuerpo completo. Para las aplicaciones

de evitamiento de caídas, puede utilizarse la

sujeción dorsal o frontal del arnés. Si se utiliza

un cinturón de cuerpo para las aplicaciones de

evitamiento de caídas, conecte al anillo en ‘D’

opuesto a la carga de evitamiento de caídas.

Verique que las conexiones son compatibles

en tamaño, forma y resistencia. Consulte las

instrucciones del fabricante del soporte de

cuerpo para obtener más información sobre la

realización de conexiones.

j. Conexión al dispositivo de agarre

Al conectar una cuerda absorbedora de energía al dispositivo de agarre,

sujete el extremo de la cuerda (vs. el extremo absorbedor de energía)

al dispositivo de agarre para reducir la posibilidad de interferencia con

el funcionamiento del dispositivo de agarre por parte del “paquete”

absorbedor de energía. Algunos modelos de dispositivo de agarre podrían

estar equipados con una cuerda o un absorbedor de energía sujetados

permanentemente. No intente sujetar conectores o cuerdas adicionales

a estos subsistemas. Si se utiliza una argolla rectangular metálica para

conectar directamente al dispositivo de agarre, verique que la argolla

rectangular metálica no interferirá con el funcionamiento del dispositivo de

agarre. Las argollas rectangulares metálicas deben ser del tipo de autocierre / auto-aseguramiento. Verique que las conexiones son compatibles

en tamaño, forma y resistencia. Verique que el conector sujetado al

dispositivo de agarre permite que la manija gire libremente, y no interere

con el funcionamiento del dispositivo de agarre.

Página 33

ESPAÑOL

Page 34

k. Uso de cuerdas salvavidas

(Vea el manual de instrucciones para usuario de la cuerda salvavidas,

para obtener la información completa)

1. Siempre proteja la cuerda salvavidas si pasa sobre o alrededor de bordes

losos. Los bordes losos pueden reducir la resistencia de la cuerda en 70% ó

más.

2. Mantenga limpias las cuerdas salvavidas.

3. Evite retorcer o doblar las cuerdas salvavidas al enrollar o desenrollar

4. Evite utilizar cuerdas salvavidas cerca de sustancias ácidas o alcalinas. Si

la cuerda salvavidas se utiliza alrededor de cualquier compuesto o producto

químico, revise en busca de signos de deterioro.

5. Nunca utilice una cuerda salvavidas con nudos, los nudos pueden reducir la

resistencia de la cuerda en 50%.

6. Guarde apropiadamente las cuerdas salvavidas.

l. Después del uso

Después del uso del dispositivo de agarre y sus componentes de

subsistema, devuélvalo para limpieza o almacenamiento según se

describe a continuación:

1. Limpie el dispositivo de agarre y la cuerda salvavidas con agua

y una solución de jabón suave. Seque los herrajes con un trapo

limpio y seco, y cuelgue para secar al aire. No fuerce el secado con

calor. Si desea, aplique una capa delgada de lubricante a base de

aceite. Una acumulación excesiva de suciedad, pintura, etc. podría

evitar que el dispositivo de agarre o la cuerda salvavidas funcionen

apropiadamente, y en casos graves, podría degradar el dispositivo de

agarre o la cuerda hasta un punto donde se debilite y deba retirarse del

servicio. Si usted tiene preguntas acerca de la condición del dispositivo

de agarre o de la cuerda salvavidas, o tiene alguna duda acerca de

colocarlas en servicio, comuníquese con Werner Co. Vea el manual

de instrucciones para el usuario de la cuerda salvavidas para obtener

detalles de mantenimiento especícos.

ESPAÑOL

Página 34

2. Los procedimientos adicionales de mantenimiento y servicio (piezas de

repuesto) deben ser realizados por un centro de servicio autorizado por

fábrica. La autorización debe ser por escrito. No intente desensamblar

la unidad.

3. Guarde el dispositivo de agarre y la cuerda salvavidas en un ambiente

fresco, seco y limpio, alejado de la luz solar directa. Evite los lugares

donde pudieran existir vapores de productos químicos. Inspeccione

detalladamente el dispositivo de agarre y la cuerda salvavidas después

de cualquier periodo de almacenamiento prolongado.

Page 35

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

III. Tenga en cuenta las advertencias,

restricciones y precauciones

a. Propósito

Los detenedores de caídas del dispositivo de agarre Werner Co. están

diseñados para utilizarse como parte de un sistema personal de detención o

evitamiento de caídas. Las aplicaciones para este tipo de producto incluyen

trabajos de inspección, construcción y demolición, mantenimiento, producción

de petróleo, lavado de ventanas, y otras actividades donde exista la necesidad

de equipos para detención o evitamiento de caídas. Las siguientes deniciones

describen estas aplicaciones:

1. DETENCIÓN DE CAÍDAS: El dispositivo de agarre para cuerda trenzada se

utiliza como parte de un sistema completo de detención de caídas. Dichos

sistemas generalmente incluyen una cuerda salvavidas, un dispositivo de

agarre para cuerda trenzada, una cuerda, y un arnés de cuerpo completo

(soporte de cuerpo). Las aplicaciones incluyen: protección de trabajadores

sobre andamios, plataformas motorizadas, o al montar en una silla de

contramaestre. La caída libre máxima permisible es de 1.83 m (6 pies).

2. EVITAMIENTO DE CAÍDAS: El dispositivo de agarre para cuerda trenzada

se utiliza en combinación con una cuerda salvavidas, una cuerda o

conector, y un soporte de cuerpo para evitar que el usuario se acerque

a un peligro (trabajo en techos inclinados o de borde delantero). La caída

libre vertical no es posible.

b. Capacidad nominal

Capacidad: 310 lbs. Este equipo está diseñado para uso por personas con

un peso combinado (persona, ropa, herramientas, etc.) no superior a 310

lbs.

NOTA: No puede sujetarse más de una (1) persona a una (1) cuerda

salvavidas. Vea el numeral c. Limitaciones

c. Limitaciones

Las siguientes limitaciones de aplicación deben reconocerse y tenerse en

cuenta antes de utilizar este producto:

1. CAÍDA LIBRE: Deben instalarse sistemas de evitamiento de caídas de

modo que no haya posibilidad de caídas libres verticales. Los sistemas

personales de detención de caídas deben instalarse de tal manera

que limiten una caída libre a 1.83 m (6 pies) (ANSI Z359.1). Vea las

instrucciones del fabricante del subsistema conectivo asociado para

obtener información adicional.

2. ESPACIO LIBRE DE CAÍDA: Verique que existe suciente espacio

libre en la trayectoria de caída para evitar golpes con un objeto. La

cantidad de espacio libre requerida depende del tipo de subsistema

conectivo utilizado (cuerda, cuerda salvavidas), de la ubicación del

anclaje, y de la cantidad de alargamiento de la cuerda salvavidas. Vea

la sección I.c para obtener más información sobre la determinación del

espacio libre de caída.

Página 35

ESPAÑOL

Page 36

3. CORROSIÓN: No deje este equipo durante períodos largos en

ambientes donde pudiera ocurrir corrosión de las piezas metálicas

como resultado de vapores procedentes de materiales orgánicos.

Los alcantarillados y fábricas de fertilizantes, por ejemplo tienen altas

concentraciones de amoniaco. El uso cerca del agua de mar u otros

ambientes corrosivos podría requerir inspecciones más frecuentes o

servicio de mantenimiento para garantizar que el daño por corrosión

no está afectando el funcionamiento del producto.

4. PELIGROS POR SUSTANCIAS QUÍMICAS: Las soluciones que

contienen ácidos, álcali, u otras sustancias cáusticas, especialmente a

temperaturas elevadas, podrían causar daño a este equipo. Al trabajar

con dichos productos químicos, debe realizarse una inspección

frecuente de estos equipos. Consulte a Werner Co. si existen dudas

relacionadas con el uso de este equipo alrededor de peligros por

productos químicos.

5. CALOR: Este equipo no está diseñado para usarse en ambientes a

temperaturas altas. Debe suministrarse protección para este equipo

al utilizar cerca de actividades de soldadura, corte de metales o

actividades similares. Las chispas calientes podrían quemar o dañar

este equipo. Consulte con Werner Co. para obtener detalles sobre los

ambientes de alta temperatura.

6. PELIGROS ELÉCTRICOS: Debido a la posibilidad de ujo de corriente

eléctrica a través de este equipo o los componentes conectivos, tenga

extremo cuidado al trabajar cerca de cables de energía de alto voltaje.

7. COMPATIBILIDAD DE LOS COMPONENTES: El dispositivo de

agarre para cuerda trenzada mencionado en estas instrucciones

está diseñado sólo para uso con cuerdas salvavidas y subsistemas

de cuerda salvavidas Werner Co. Consulte a Werner Co. si usted está

considerando utilizar este equipo con otras cuerdas salvavidas o

subsistemas de cuerdas salvavidas. Vea la sección I.b.

8. CAPACITACIÓN: Este equipo de ser utilizado por personas que han

sido capacitadas apropiadamente en cuanto a su aplicación y uso

correctos.

d. Requisitos regidores

Consulte los requisitos (OSHA) locales, estatales y federales aplicables

que rigen este equipo para obtener más información sobre los dispositivos

de agarre para cuerda trenzada y los componentes de sistema asociados,

incluyendo; ANSI Z359.1, y OSHA 1910.66, anexo C.

ESPAÑOL

Página 36

Page 37

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

IV. Etiquetas/Identicación/Registros de inspección

a. Todos los productos deben ser inspeccionados completamente por

el usuario antes de cada uso. Una persona calicada, diferente

al usuario, debe realizar inspecciones adicionales en intervalos

no inferiores a un (1) año. Ese intervalo debe acortarse cada vez

que el producto se utiliza en un ambiente agresivo o se expone

a condiciones tales como productos químicos, abrasión, calor o

cualquier otro factor que pudiera afectar la resistencia de cualquiera

de los materiales o componentes.

b. Las etiquetas del producto proporcionan una tabla de inspección

para que una persona calicada registre estas inspecciones. Utilice

un punzón o marcador permanente para registrar estos datos.

c. Este manual siempre debe acompañar el producto o estar en

los archivos del empleador para consultarlo cuando se requiera.

Registre los detalles de identicación para el anclaje y registre las

inspecciones en el registro de inspección mostrado en la página

39. Es importante mantener este registro actualizado, completo y

disponible según se requiera.

Página 37

ESPAÑOL