Page 1

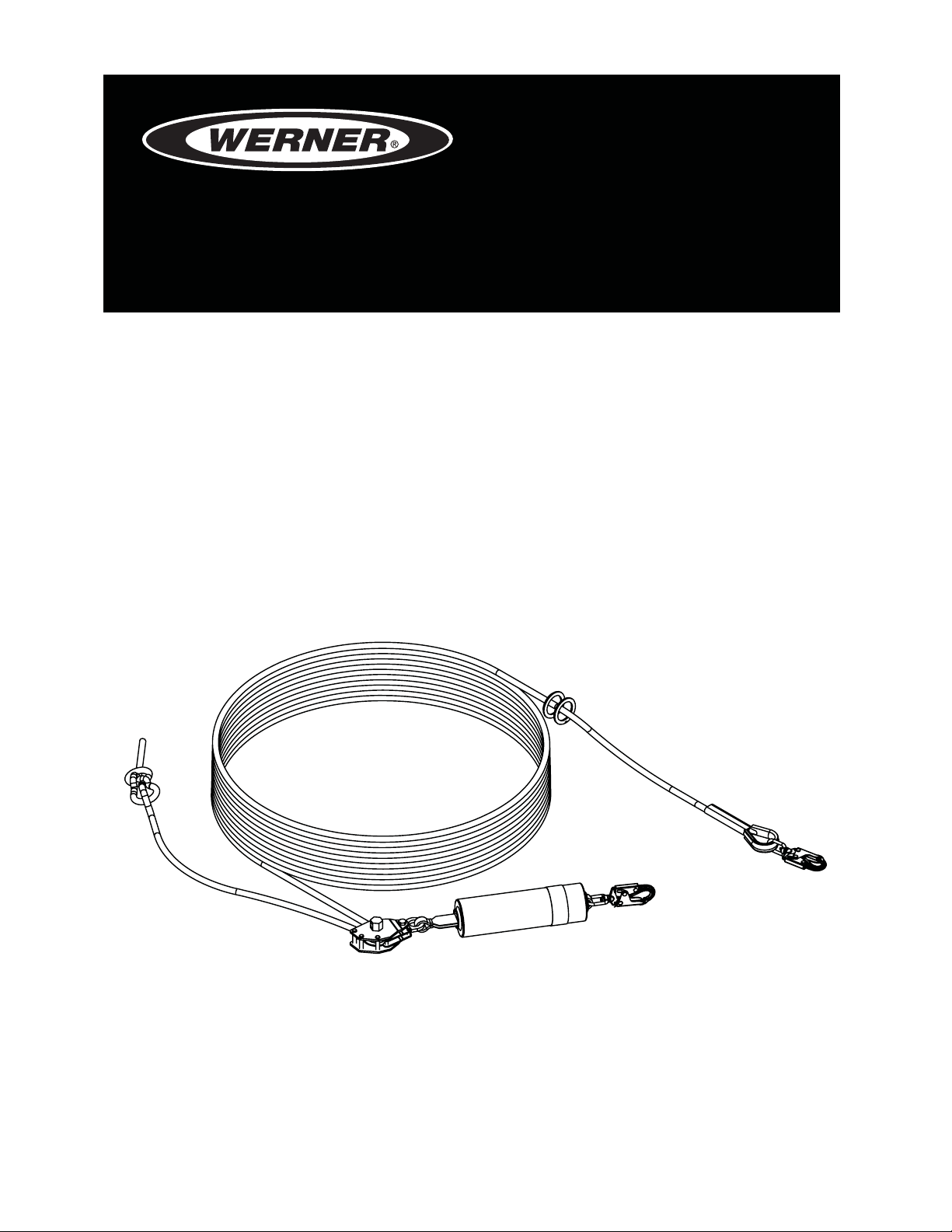

FALL PROTECTION

PROTECCIÓN CONTRA CAÍDAS

USER INSTRUCTIONS

INSTRUCCIONES PARA EL USUARIO

SYNTHETIC ROPE HORIZONTAL

LIFELINE

Complies with OSHA 29 CFR 1910 and 1926 regulations and requirements.

CUERDA SALVAVIDAS

HORIZONTAL SINTETICA

Cumple con los reglamentos y requisitos de OSHA 29 CFR 1910 y 1926

Models/Modelos: L100030, L100060, L100100, L102030, L102060, L102100,

L120030, L120060, L120100, L122030, L122060, L122100

Werner Co. Fall Protection 724-588-2000

93 Werner Rd. 888-523-3371 toll free/ llamada gratuita

Greenville, PA 16125 888-456-8458 fax

Page 2

WARNING!

Compliant fall protection equipment must only be used as it was designed.

Users MUST read and follow all user instructions provided with the product.

Before using a fall arrest system, users must be trained in the safe use of

the system, as required by OSHA 29 CFR 1910.66 and 1926.503, or local

safety regulations. Misuse or failure to heed these warnings and

instructions may result in injury or even death.

WORK SAFE! WORK SMART!

IF YOU HAVE ANY QUESTIONS ABOUT THE PROPER USE OF THE EQUIPMENT,

SEE YOUR SUPERVISOR, USER INSTRUCTIONS, OR CONTACT WERNER CO.

FOR MORE INFORMATION.

WARNING!

WARNING!

Over- or under-tensioning may cause excessive wear or damage to system

components and/or increased fall clearance requirements.

Never attach the unused leg of the lanyard back to the full body harness at

any location other than a lanyard keeper.

Never use combinations of components or subsystems that may affect, or

interfere with, the safe function of each other.

All components of the Synthetic Rope Horizontal Lifeline must be inspected

prior to each use in accordance with the requirements of OSHA 29 CFR

1910.66 and 1926.502.

If inspection reveals any defect, inadequate maintenance, or unsafe

condition, remove from service until a “quali ed” person, as de ned by

OSHA 29 CFR 1910.26(m), can determine the need for authorized repair or

disposal.

Any equipment that has been subjected to the forces of arresting a fall, or

that has a deployed load indicator, must be removed from service until a

“quali ed person” can determine the need for authorized repair or disposal.

ENGLISH

Page 2

Page 3

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

WARNING!

The installation height of the Synthetic Rope Horizontal Lifeline is

dependent on the type of connecting subsystem attached. See CLEARANCE

REQUIREMENTS.

When using SRLs as connecting devices, the Synthetic Rope Horizontal

Lifeline must be installed. The installation height of the Synthetic Rope

Horizontal Lifeline and type of connecting subsystem attached both directly

affect the fall clearance requirement.

When using SRLs, the increased potential for swing fall should be assessed

in addition to the required fall clearance. Longer Self Retracting Lifelines

(greater than 30 feet) may increase the potential for additional swing fall or

free fall.

USE INSTRUCTIONS AND LIMITATIONS

IMPORTANT

Before use, the user must read and understand these User Instructions. Keep

these User Instructions for reference.

PURPOSE

The Synthetic Rope Horizontal Lifeline is an engineered exible horizontal lifeline

system, designed to be used as part of a complete personal fall arrest system, to

provide horizontal mobility for up to two users and help limit the fall arrest forces

in the event of a fall.

USE INSTRUCTIONS

1. Failure to follow all instructions and limitations on the use of the Synthetic

Rope Horizontal Lifeline may result in serious personal injury or death.

2. Before using a personal fall arrest system, employees must be trained in

accordance with the requirements of OSHA 29 CFR 1910.66 in the safe use

of the system and its components.

3. Personal fall arrest systems, including the Synthetic Rope Horizontal

Lifeline, must be inspected prior to each use for wear, damage, and other

deterioration. Defective components must be immediately removed from

service, in accordance with the requirements of OSHA 29 CFR 1910.66 and

1926.502.

ENGLISH

Page 3

Page 4

4. The complete fall protection system must be planned (including all

components, calculating fall clearance, and swing fall) before using.

5. Users must have a rescue plan, and the means to implement it, that provides

for the prompt rescue of employees in the event of a fall, or assures that

employees are able to rescue themselves.

6. Store the Synthetic Rope Horizontal Lifeline in a cool, dry, clean environment

and out of direct sunlight when not in use.

7. After a fall occurs on the system, immediately remove from service until a

“quali ed person” can make the determination for reuse or disposal.

USE LIMITATIONS

1. CAPACITY: The Synthetic Rope Horizontal Lifeline is designed for up to two

users at one time, per system, with a capacity (including clothing, tools, etc.)

up to 400 pounds (181 kg) total working weight per user, in conjunction with

compatable connecting components.

2. SPAN: The Synthetic Rope Horizontal Lifeline can be adjusted from a

minimum of 10 feet (3.05m) to the maximum allowed by the included length

of rope.

3. SUPERVISION: In accordance with the requirements of OSHA 29 CFR

1910.66, and 1926.502, the Synthetic Rope Horizontal Lifeline must be

installed and used under the supervision of a “quali ed” person as de ned by

OSHA 29 CFR 1926.32(m).

4. EXTENDED SUSPENSION: The Synthetic Rope Horizontal Lifeline is not

intended for use in extended suspension applications.

5. CORROSION: Do not leave the Synthetic Rope Horizontal Lifeline in

environments where corrosion of metal parts could take place as a result

of vapors from organic materials. Use near seawater or other corrosive

environments may require more frequent inspections to ensure corrosion

damage is not affecting the performance of the product.

6. CHEMICAL HAZARDS: Solutions containing acids, alkali, or other caustic

chemicals, especially at elevated temperatures, may cause damage to the

Synthetic Rope Horizontal Lifeline. When working with such chemicals,

frequent inspection of this equipment must be performed. Contact Werner

Co. with any questions concerning the use of the Synthetic Rope Horizontal

Lifeline around chemical hazards.

7. EXTREME TEMPERATURE: The Synthetic Rope Horizontal Lifeline is

designed to be used in temperatures ranging from -40ºF to +130ºF (-40°C to

ENGLISH

Page 4

Page 5

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

+54°C). Protection should be provided for Synthetic Rope Horizontal Lifeline

when used near welding, metal cutting or similar activities. Contact Werner

Co. with any questions concerning high temperature environments.

8. ELECTRICAL HAZARDS: Use extreme caution when working near high

voltage power lines due to the possibility of electric current owing through

the Synthetic Rope Horizontal Lifeline or connecting components.

9. ANCHORAGES: The end anchorage must be capable of supporting loads

applied in all directions of 5,000 pounds (22.2kN), twice the maximum arrest

load.

10. COMPONENT COMPATIBILITY: Only components approved by Werner Co.

may be used with the Synthetic Rope Horizontal Lifeline.

11. SUBSYSTEMS: Only connecting subsystems that limit the maximum arrest

force to less than 1,800 pounds (8kN) may be used with the Synthetic Rope

Horizontal Lifeline.

12. HEALTH: Minors, pregnant women and anyone with a history of either back

or neck problems should not use this equipment.

13. TRAINING: Do not use or install the Synthetic Rope Horizontal Lifeline

without proper training from a “competent person” as de ned by OSHA’s 29

CFR 1926.32(f).

14. REPAIRS: Only Werner Co., or persons or entities authorized in writing by

Werner Co., may make repairs or alterations to the equipment.

ANCHORAGE REQUIREMENTS

ANCHORAGES

The Synthetic Rope Horizontal Lifeline incorporates an in-line energy absorber. It

is designed to limit the maximum arrest load to less than 2,500 pounds (11.1kN)

on the end anchorages. Therefore, the end anchorage must be rated at a

minimum strength of 5,000 pounds (22.2kN), twice the maximum arrest load.

All anchorages to which the Synthetic Rope Horizontal Lifeline attaches must

meet the requirements of ANSI Z359.1-2007 and OSHA 29 CFR 1910.66 and

1926.502.

OSHA states:

Anchorages used for attachment of personal fall arrest equipment shall be

independent of any anchorage being used to support or suspend platforms

ENGLISH

Page 5

Page 6

and capable of supporting at least 5,000 pounds (22.2 kN) per employee

attached, or shall be designed, installed, and used as part of a complete

personal fall arrest system which maintains a safety factor of at least two;

and under the supervision of a quali ed person.

ANSI Z359.1-2007 states that anchorages in a personal fall arrest system must

have a strength capable of sustaining static loads, applied in all permitted

directions by the system, of at least:

(a) two times the maximum arrest force permitted on the system when

certi cation exists, or

(b) 5,000 pounds (22.2kN) in the absence of certi cation

The strength in (a) and (b) must be multiplied by the number of personal fall

arrest systems attached to the anchorage, when more than one personal fall

arrest system is attached to the anchorage.

ANCHORAGE CONNECTORS

Anchorage connectors function as an interface between the anchorage and the

Synthetic Rope Horizontal Lifeline for the purpose of coupling the system to the

anchorage. The end anchorage connectors are designed to resist and transfer at

least twice the maximum arrest load to the end anchorages.

CONNECTION REQUIREMENTS

COMPATIBILITY LIMITATIONS

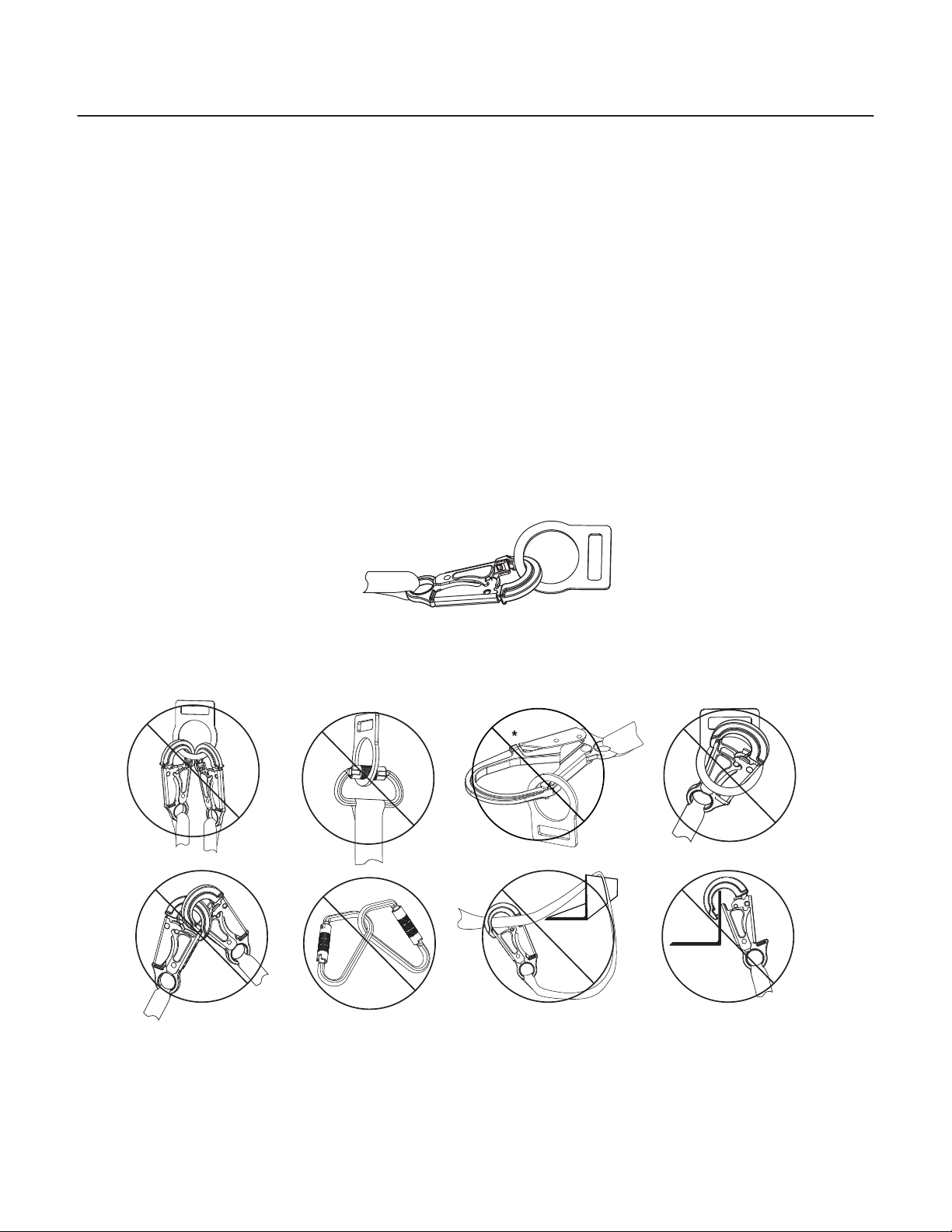

All connecting subsystems must only be coupled to compatible connectors.

OSHA 29 CFR 1926.502 prohibits snap hooks from being engaged to certain

objects unless two requirements are met: snap hook must be a locking type

and must be "designed for" making such a connection. Under OSHA 29

CFR 1926.502 "designed for" means that the manufacturer of the snap hook

speci cally designed the snap hook to be used to connect to the equipment in

question.

The following connections must be avoided, because they can result in rollout*

when a non locking snap hook is used:

ENGLISH

Page 6

Page 7

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

• Direct connection of a snap hook to horizontal lifeline.

• Two (or more) snap hooks connected to one D-ring.

• Two snap hooks connected to each other.

• A snap hook connected back on its integral lanyard.

• A snap hook connected to a webbing loop or webbing lanyard.

• Improper dimensions of the D-ring, rebar, or other connection point in

relation to the snap hook dimensions that would allow the snap hook

keeper to be depressed by a turning motion of the snap hook.

*Rollout: A process by which a snap hook or carabiner unintentionally

disengages from another connector or object to which it is coupled. (ANSI

Z359.0)

COMPATIBLE CONNECTIONS

INCOMPATIBLE CONNECTIONS

NO! NO! NO! NO!

SNAP HOOKS AND CARABINERS

Snap hooks and carabiners used in the Synthetic Rope Horizontal Lifeline,

marked with the ANSI Z359.1-07 or ANSI Z359.12-09 standard, are self-locking

with a minimum tensile break strength of 5,000 pounds (22.2kN), and a 3,600

pound (16kN) gate rating.

NO!NO!NO!NO!

ENGLISH

Page 7

Page 8

SYSTEM COMPONENTS

COMPATIBILITY LIMITATIONS

All components and subsystems used with the Synthetic Rope Horizontal Lifeline

have been tested as part of a pre-engineered exible horizontal lifeline system.

Only components and subsystems approved by Werner Co. are to be used with

the

Synthetic Rope Horizontal Lifeline.

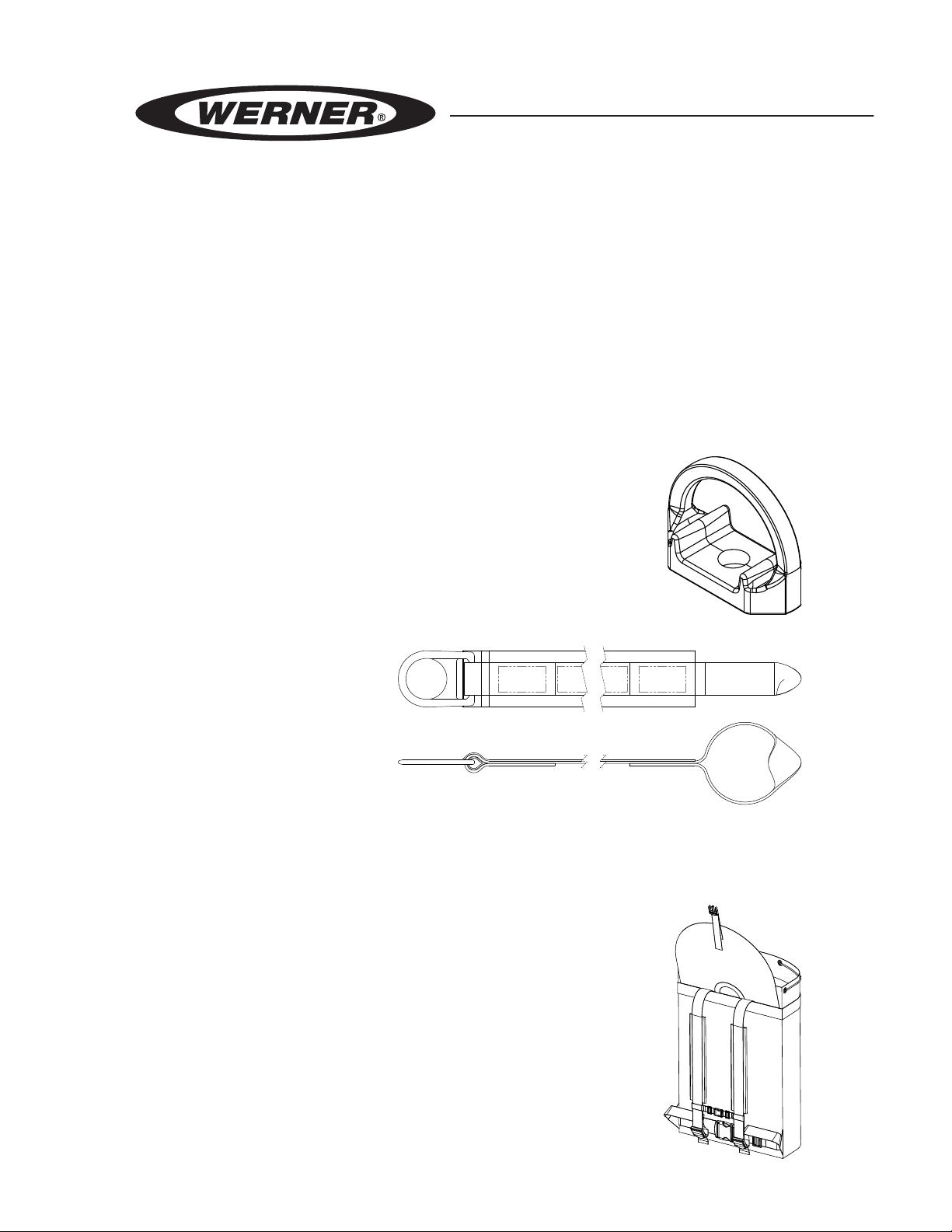

ANCHORAGE CONNECTORS

D-BOLT ANCHOR: A320001-WB

The 5,000 pound (22.2kN) anchorage connector made from high

tensile steel and attaches to anchor structure with a ⁄ inch -11

x 2¼ inch Grade 8 hex cap bolt, ⁄ inch-11 Grade 8 hex nut and

a ⁄ inch high alloy medium split lock washer. (A320001-WB

includes bolt, nut and lock washer)

CROSS ARM STRAP: A111104

Constructed with 1¾ inch

high strength polyester and 3

inch nylon, the 4 foot Cross

Arm Strap is designed to

wrap around a choke with the

12 inch soft loop to anchor

structures to creating a 5,000

pound

(22.2kN) anchor point.

ACCESSORIES

ACK PACK: K120004

B

The Back Pack is constructed of high strength polyester, with

a reinforced bottom to easily transport the

Horizontal Lifeline from job to job.

ENGLISH

Page 8

Synthetic Rope

Page 9

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

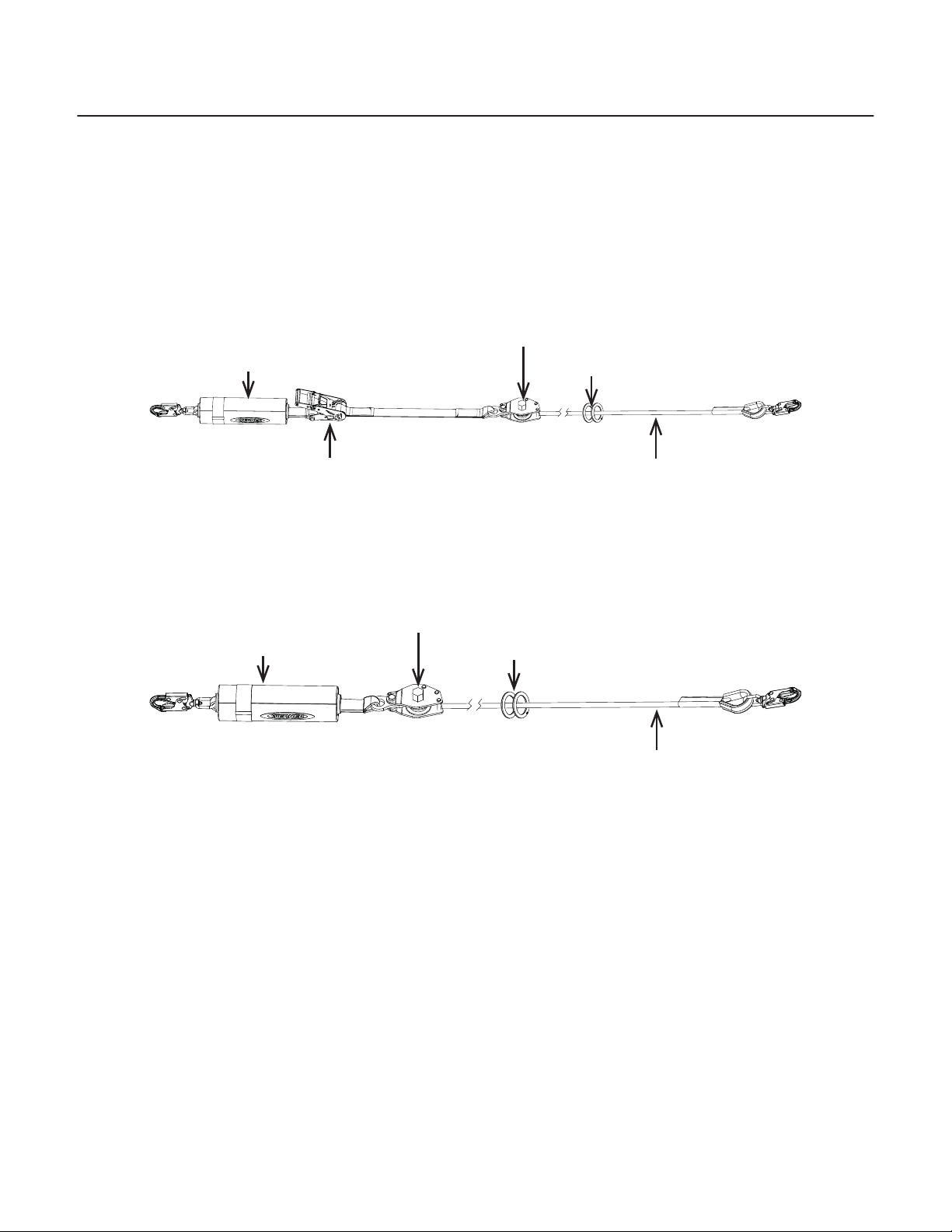

LIFELINE ASSEMBLY

SYSTEMS WITH TENSION-INDICATING RATCHET

L102030, L102060, L102100, L122030, L122060, L122100

Rope Tensioner

Shock Pack

O-Rings

Tension-Indicating

Ratchet

Rope

SYSTEMS WITHOUT TENSION-INDICATING RATCHET

L100030, L100060, L100100, L120030, L120060, L120100

Rope Tensioner

Shock Pack

O-Rings

Rope

SHOCK PACK

The shock pack is designed to limit the maximum arrest load to less than 2,500

lbf (11.1kN) on the end anchorages. The shock pack is constructed with polyester

web and tear web with a polyester cover that includes the labels with a protective

cover.

TENSION-INDICATING RATCHET

The Tension-Indicating Ratchet is constructed from high tensile steel and has a

10,000 pound

of the Tension-Indicating Ratchet is engineered to bend indicating when the

Synthetic Rope Horizontal Lifeline is properly tensioned. The Tension-Indicating

Ratchet includes high strength 1¾ inch (44.45mm) polyester webbing for 18

inches (0.45m) of adjustability.

(44.5kN) minimum breaking strength. The spring loaded handle

Page 9

ENGLISH

Page 10

LIFELINE ASSEMBLY CONTINUED

ROPE TENSIONER

The Rope Tensioner is used for coarse adjustment of the rope on systems

incorporating the Tension-Indicating Ratchet. For systems that do not incorporate

the Tension-Indicating Ratchet, the Rope Tensioner is designed to achieve

proper tension of the

constructed with high tensile steel.

Synthetic Rope Horizontal Lifeline. The Rope Tensioner is

ROPE

The low stretch ⁄ inch (15.9mm) Kernmantle rope is constructed with a nylon

strand core and a polyester jacket, providing a 10,000 pound

breaking strength. The abrasion-resistant jacket is designed to show damage

before the load carrying core becomes damaged. The rope should be removed

from service if the outer sheath is damaged. The rope comes with one end

nished (thimble and stitched) with a snap hook, and the other end is knotted to

prevent the rope from passing back through the Rope Tensioner.

(44.5kN) minimum

O-RINGS

The 2 inch (50.8mm) O-rings are made from high tensile steel and marked to

ANSI Z359.1-2007 and/or ANSI Z359.12-2012 with a minimum breaking strength

of 5,000 pounds

(22.2kN).

INSTALLATION

WARNING!

All components of the Synthetic Rope Horizontal Lifeline

must be inspected prior to each use in accordance with

the requirements of OSHA 29 CFR 1910.66 and 1926.502.

BEFORE EACH USE

Users must have a rescue plan, and the means to implement it, that provides for

the prompt rescue of employees in the event of a fall or assures that employees

are able to rescue themselves.

The user must read and understand these User Instructions, as well as the

User Instructions for every component and subsystem of the personal fall arrest

system.

ENGLISH

Page 10

Page 11

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

The entire Synthetic Rope Horizontal Lifeline, and its subsystems, must be

inspected prior to each use. See INSPECTION.

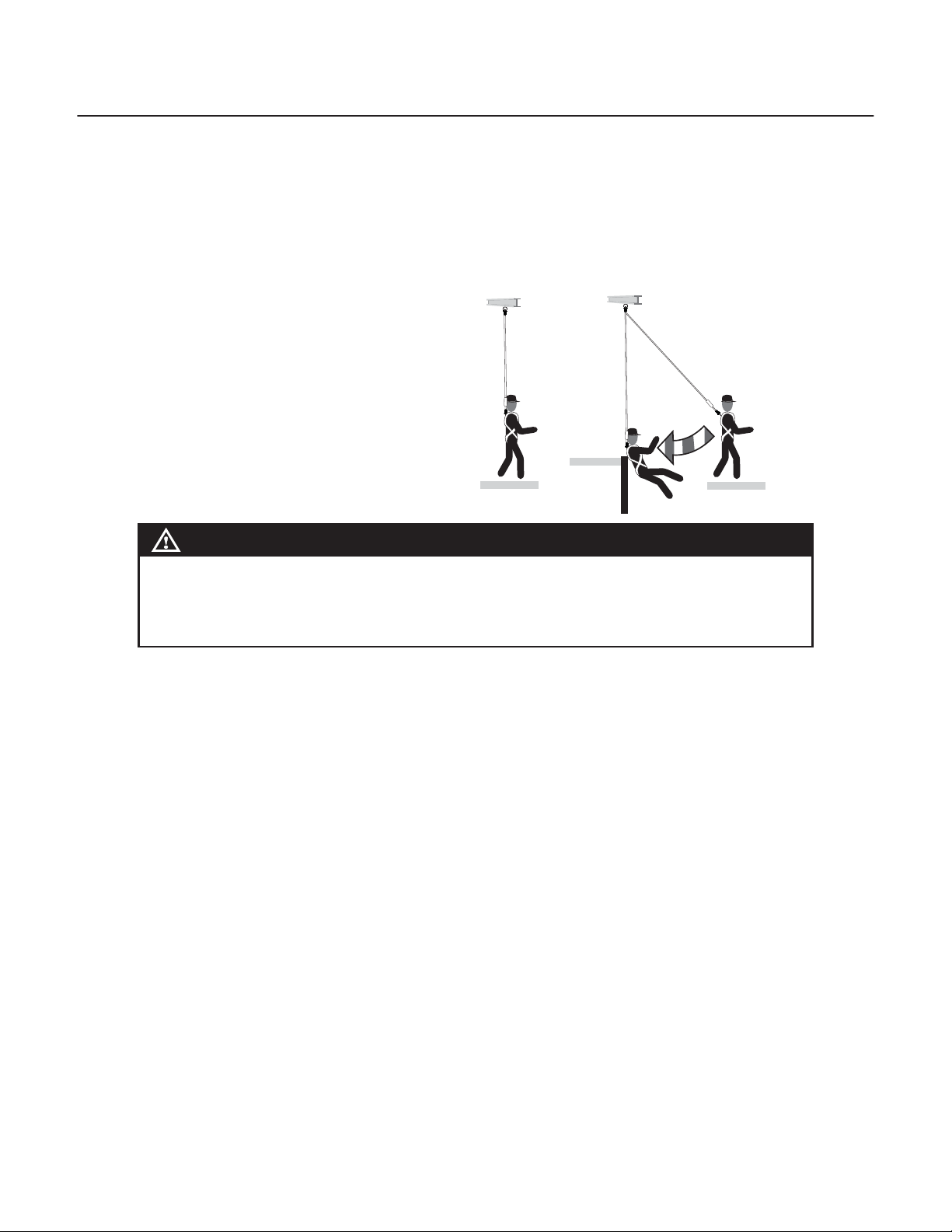

SWING FALLS

To minimize the possibility of a swing

fall, work as directly under or adjacent

to the Synthetic Rope Horizontal

Lifeline as possible. Striking objects

horizontally, due to the pendulum

affect, may cause serious injury. Swing

falls also increase the vertical fall

distance of a worker, compared to a

fall directly below the connection point.

See CLEARANCE REQUIREMENTS.

WARNING!

Anchorages

Correct Incorrect

SWING FALL

HAZARD

The installation height of the Synthetic Rope Horizontal

Lifeline is dependent on the type of connecting

subsystem attached. See CLEARANCE REQUIREMENTS.

STEP 1A: INSTALL CROSS ARM STRAP ANCHORAGE CONNECTOR

With labels on the outward facing surface of the Cross Arm Strap wrap web

around the anchorage

the web loop on the other end. Wrap as many times as necessary to achieve

desired length. Pull small D-ring to tighten (choke) the anchorage. The small

D-ring is the anchorage connector at the connection point.

structure and pass the small D-ring on one end through

STEP 1B: INSTALL D-BOLT ANCHORAGE CONNECTOR

Drill a ⁄ inch (17mm) hole where needed in the anchorage structure using a

suitable drill bit for penetration. Remove any burred edges from the structure.

Attach the D-Bolt Anchorage Connector using supplied 5⁄8 inch -11 x 2 inch

Grade 8 steel bolt, nut and lock washer. Insert supplied bolt through D-Bolt and

pre-drilled hole. Ensure bolt is pushed through completely and back surface

of the D-Bolt is ush against the anchorage structure. Slide the supplied lock

washer over the threads of the bolt until the washer is against the surface of the

anchorage structure. Thread nut onto bolt until it meets washer. Ensure D-Bolt is

oriented correctly and torque to 125 lbf-ft (17.3kgf-m).

Page 11

ENGLISH

Page 12

STEP 2: CONNECT SNAP HOOK END OF ROPE

Attach the snap hook that is connected to the end of the rope to the D-ring of the

Cross Arm Strap or the D-Bolt anchorage connector. This end of the system is the

dead-end of the Synthetic Rope Horizontal Lifeline system.

STEP 3: CONNECT SNAP HOOK ON SHOCK PACK

Connect the swivel snap hook attached to the shock pack to the remaining

anchorage connector (D-ring of the cross arm strap or the D-Bolt). This end of

the system is the live end of the Synthetic Rope Horizontal Lifeline system. Pull

the end of the rope through the Rope Tensioner by hand until the slack has been

removed from the system. Rotate the shock pack so the rope has as little twist as

possible.

STEP 4A: TENSION SYSTEM WITH TENSION-INDICATING RATCHET

Use the Tension-Indicating Ratchet to tension the system. When the handle of

the ratchet bends backward, nish the next click to apply the correct tension, then

close the ratchet to engage the safety lock.

STEP 4B: TENSION SYSTEM WITH ROPE TENSIONER

For systems that do not include a Tension-Indicating Ratchet, use a torque

wrench with 1⁄ inch socket to apply 60 lbf-ft (8.3 kgf-m) of torque to the lug.

Push pawl lever toward the body of the tensioner to prevent accidental tension

release.

STEP 5: TIE KNOT IN EXCESS ROPE

Using the excess rope, tie an overhand knot close to the rope tensioner, as

indicated by the label.

WARNING!

Over- or under-tensioning may cause excessive wear

or damage to system components and/or increased fall

clearance requirements.

ENGLISH

Page 12

Page 13

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

CONNECTION

UMBER OF USERS

N

The Synthetic Rope Horizontal Lifeline is designed for up to two users at one

time, per system, with a capacity (including clothing, tools, etc.) up to 400 pounds

(181 kg) total working weight per user, in conjunction with compatible connecting

components.

CAUTION!

When two users are connected to the same Synthetic

Rope Horizontal Lifeline, a single fall may result in

pulling the second person off the work surface, causing

a secondary fall

When two users are connected to the same Synthetic Rope Horizontal Lifeline, a

single fall may result in pulling the second person off the work surface, causing a

secondary fall. Precautions should be taken to reduce the risk of secondary falls,

including limiting each Synthetic Rope Horizontal Lifeline to a single user when

and where possible or rigging the lifeline for restraint to reduce the risk of any

users falling.

.

ENERGY ABSORBING LANYARDS (EALS)

Only energy absorbing lanyards that limit the fall arrest forces to less than 1,800

pounds (8kN) may be used with the Synthetic Rope Horizontal Lifeline. Energy

absorbing lanyards must be connected with the energy absorbing end of the

lanyard connected to the dorsal D-ring of the full body harness. The opposing

end of the lanyard is to be connected to the O-ring on the rope of the Synthetic

Rope Horizontal Lifeline.

TWIN LEG LANYARDS

Twin leg lanyards are designed for single person use only and must be connected

with the energy absorbing end of the lanyard connected to the dorsal D-ring

of the full body harness. Do not connect the energy absorbing end of the

lanyard to the O-ring on the Synthetic Rope Horizontal Lifeline. Attach

one leg of the twin leg lanyard to the O-ring and the unused lanyard leg to an

approved lanyard keeper on the full body harness.

Page 13

ENGLISH

Page 14

WARNING!

Never attach the unused leg of the lanyard back to the

full body harness at any location other than a lanyard

keeper.

When using twin leg lanyards to move between fall arrest systems, attach the

unused leg of the lanyard to the new location before disconnecting the rst

lanyard leg. Connection of both lanyard legs to separate anchorage connectors

while transitioning between systems is acceptable.

SELF-RETRACTING LIFELINES (SRLS)

Attach the housing connector of the self-retracting lifeline to the O-ring of the

Synthetic Rope Horizontal Lifeline. The opposing end is connected to the dorsal

D-ring of the full body harness. Never attach an additional energy absorbing

lanyard or self-retracting lifeline to lengthen the lifeline.

WARNING!

Never use combinations of components or subsystems

that may affect, or interfere with, the safe function of

each other.

HOUSING OF THE SRL TO HARNESS

Lighter weight self-retracting lifelines may be attached by the housing connector

directly to the dorsal D-ring of the full body harness. The opposing end is

connected to the O-ring of the Synthetic Rope Horizontal Lifeline.

PERSONAL SRLS AND TWIN LEG SRLS

There are many different ways Personal SRLs and Twin Leg SRLs attach to the

full body harness. Follow User Instructions supplied with the product.

WARNING!

Never attach the unused leg of the lanyard back to the

full body harness at any location other than a lanyard

keeper.

ENGLISH

Page 14

Page 15

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

INSPECTION AND MAINTENANCE

WARNING!

If inspection reveals any defect, inadequate

maintenance, or unsafe condition, remove from service

until a “quali ed person”, as de ned by OSHA 29 CFR

1910.26(m), can determine the need for authorized repair

or disposal.

CAUTION!

Proper Personal Protective Equipment must be

worn when performing Inspection and Maintenance

procedures.

FREQUENCY

All components of the Synthetic Rope Horizontal Lifeline must be inspected

prior to each use, and annually by an OSHA de ned “competent person” other

than the user. Local, state, governmental and jurisdictional agencies governing

occupational safety may require the user to conduct more frequent or mandatory

inspections.

CRITERIA

WARNING!

Any equipment that has been subjected to the forces

of arresting a fall, or that has a deployed load indicator,

must be removed from service until a “quali ed person”

can make the determination for reuse or disposal.

The tension of the system must be checked and adjusted. The Tension-Indicating

Ratchet can be used to check the tension by the same method as used during

installation. See step 4A. Systems without the Tension-Indicating Ratchet can be

checked and adjusted through the use of a torque wrench. See step 4B.

All components and subsystems of the Synthetic Rope Horizontal Lifeline must

be inspected.

Page 15

ENGLISH

Page 16

All markings must be legible and attached to the product.

All equipment must be free of corrosion, chemical attack, alteration, excessive

heating or wear.

To inspect webbing, bend a 6-8 inch (15.2 - 20.3cm) portion of the webbing into

an upsidedown ‘U’ shape and continue along all webbing.

All webbing and rope must be inspected for tears, cuts, fraying, abrasion,

discoloration, burns, holes, glazing, mold, kinking or hockling, pulled or broken

stitches, or other signs of wear and damage. Core from the center of the rope

must not be exposed. Sewn terminations should be secure, complete, and not

visibly damaged.

The rope must be inspected for any damage which exposes the white inner core.

If the core is exposed, the rope must be removed from service.

All snap hooks and carabiners must be able to self-close and lock. All hardware

must be free of cracks, sharp edges, deformation, corrosion, or any evidence of

defect.

All components of the full body harness, self retracting lanyard, and/or energy

absorbing lanyard must be inspected. See user instructions supplied with the

product.

UNINSTALLATION

R

EMOVAL OF SYSTEM

When work is complete, the system should be removed from the job site and

stored.

To remove the system:

For systems with Tension-Limiting Ratchet: The ratchet can be released by opening the ratchet and pulling the release handle to push the ratchet open fully. This

may cause an abrupt unloading of the system tension.

For systems without Tension-Limiting Ratchet: The rope adjuster release lever

must be opened fully by hand, then a screwdriver inserted under the lever to pull

it fully upward, releasing the system tension.

ENGLISH

Page 16

Page 17

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

The rope should be stored properly to avoid damage to the rope during storage or

kinking of the rope when taking it out of storage.

CLEANING AND STORAGE

C

LEANING

Cleaning maintenance may be performed by the user. The Synthetic Rope

Horizontal Lifeline may be wiped down with a mild detergent and clean water

solution, and rinsed with a dampened clean cloth to remove detergent. The

hardware can also be wiped down to remove grease, or dirt with a clean dry cloth.

STORAGE

The Synthetic Rope Horizontal Lifeline should be stored in a cool, dry place out of

direct sunlight when not in use. Do not store where damage from environmental

factors such as heat, light, excessive moisture, oil, chemicals and their vapors, or

other degrading elements may be present.

Do not store damaged equipment or equipment in need of maintenance in the

same area as product approved for use. Equipment that has been stored for an

extended period must be inspected as de ned in these User Instructions prior to

use.

CLEARANCE REQUIREMENTS

LEARANCE CHARTS

C

The following clearance charts show the required distance that must remain

clear of obstructions between the working surface to the lower level or nearest

obstruction below.

The clearance requirements include the following in the total fall distance: the

deection of anchorage connectors and lifeline, the elongation of the full body

harness and the user, the vertical component of any swing fall, and a clearance

safety margin of 2 feet (0.61m). The clearance requirements account for

performance of the system and the number of users on the system.

Page 17

ENGLISH

Page 18

SELF RETRACTING LIFELINES - ANSI Z359.14 CLASS A

Fall clearance required for attaching with self retracting lifelines marked with ANSI

Z359.14 Class A, and rigged for 310 pound (141 kg) users and the Synthetic

Rope Horizontal Lifeline installed above the user. All SRL fall clearances are

measured from the work platform to the next obstruction below the work platform.

The below clearances are for AutoCoil 2 SRL Model Numbers: R230007,

R230011, R230018, R210010.

WARNING!

When using SRLs, the Synthetic Rope Horizontal

lifeline must ALWAYS be installed above the user. The

installation height of the Synthetic Rope Horizontal

Lifeline and type of connecting subsystem attached

directly affect the fall clearance requirement.

WARNING!

When using SRLs, the increased potential for swing

fall should be assessed in addition to the required fall

clearance. Longer Self Retracting Lifelines (greater than

30 feet (9.1m)) may increase the potential for additional

swing fall or free fall.

SPAN (UP TO...) ONE USER TWO USERS

10ft (3m) 7' 2" (2.2m) 7' 10" (2.4m)

20ft (6.1m) 8' 11" (2.7m) 10' 2" (3.1m)

30ft (9.1m) 10' 7" (3.2m) 12' 6" (3.8m)

40ft (12.2m) 12' 4" (3.7m) 14' 10" (4.5m)

50ft (15.25m) 14' 0" (4.3m) 17' 4" (5.3m)

60ft (18.3m) 15' 8" (4.8m) 19' 8" (6m)

70ft (21.3m) 17' 5" (5.3m) 22' 2" (6.8m)

80ft (24.4m) 19' 0" (5.8m) 24' 7" (7.5m)

90ft (27.4m) 20' 8" (6.3m) 27' 0" (8.2m)

ENGLISH

100ft (30.5m) 22' 4" (6.8m) 29' 5" (9m)

Page 18

Page 19

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

SELF RETRACTING LIFELINES - ANSI Z359.14 CLASS B

Fall clearance required for attaching with self retracting lifelines marked with ANSI

Z359.14 Class B, and rigged for 310 pound (141 kg) users and the Synthetic

Rope Horizontal Lifeline installed above the user. All SRL fall clearances are

measured from the work platform to the next obstruction below the work platform.

The below clearances are for AutoCoil2 SRL Model Numbers: R230050,

R210020, R210030, R210060, R213030, R213060

WARNING!

When using SRLs, the Synthetic Rope Horizontal

lifeline must ALWAYS be installed above the user. The

installation height of the Synthetic Rope Horizontal

Lifeline and type of connecting subsystem attached

directly affect the fall clearance requirement.

WARNING!

When using SRLs, the increased potential for swing

fall should be assessed in addition to the required fall

clearance. Longer Self Retracting Lifelines (greater than

30 feet 9.1m)) may increase the potential for additional

swing fall or free fall.

SPAN (UP TO...) ONE USER TWO USERS

10ft (3m) 8' 6" (2.6m) 9' 2" (2.8m)

20ft (6.1m) 10' 1" (3.1m) 11' 6" (3.5m)

30ft (9.1m) 11' 10" (3.6m) 14' 0" (4.3m)

40ft (12.2m) 13' 5" (4.1m) 16' 7" (5.1m)

50ft (15.25m) 15' 1" (4.6m) 19' 1" (5.8m)

60ft (18.3m) 16' 8" (5.1m) 21' 7" (6.6m)

70ft (21.3m) 18' 4" (5.6m) 24' 0" (7.3m)

80ft (24.4m) 20' 0" (6.1m) 26' 6" (8.1m)

90ft (27.4m) 21' 7" (6.6m) 28' 11" (8.8m)

100ft (30.5m) 23' 2" (7.1m) 31' 5" (9.6m)

Page 19

ENGLISH

Page 20

6 FOOT FREE FALL ENERGY ABSORBING LANYARDS

Fall clearance required for attaching with 6 foot (1.8m) energy absorbing

lanyards, and rigged for 310 pound (141 kg) users and a 6 foot (1.8m) rst user

free fall. These fall clearances are measured from the work platform to the next

obstruction below the platform.

WARNING!

The Synthetic Rope Horizontal Lifeline must be installed

to limit free fall of the rst user to 6 feet (1.8m) or less.

The installation height of the Synthetic Rope Horizontal

Lifeline and type of connecting subsystem attached

directly affect the fall clearance requirement.

SPAN (UP TO...) ONE USER TWO USERS

10ft (3m) 20' 4" (6.2m) 21' 0" (6.4m)

20ft (6.1m) 22' 0" (6.7m) 23' 4" (7.1m)

30ft (9.1m) 23' 7" (7.2m) 25' 8" (7.8m)

40ft (12.2m) 25' 4" (7.7m) 28' 2" (8.6m)

50ft (15.25m) 26' 11" (8.2m) 30' 10" (9.4m)

60ft (18.3m) 28' 7" (8.7m) 33' 4" (10.1m)

70ft (21.3m) 30' 2" (9.2m) 35' 10" (10.9m)

80ft (24.4m) 31' 10" (9.7m) 38' 4" (11.7m)

90ft (27.4m) 33' 6" (10.2m) 40' 8" (12.4m)

100ft (30.5m) 35' 1" (10.7m) 43' 2" (13.2m)

ENGLISH

Page 20

Page 21

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

LABELS

Synthetic Rope

Horizontal Lifeline

Cuerda Salvavidas

Horizontal Sintética

Model / Modelo:

Mark Number

Número de Calicación

Max. System Length:

Longitud Máxima

del Sistema:

Serial Number:

Número de Serie:

1

Inspection Log/Registro de Inspección

Yea r

Yea r

Yea r

Yea r

Año

1

2

Año

Año

Yea r

3

4

5

Año

Año

1

2

3

4

5

6

7

8

9

10

11

12

Date of

Manufacture:

Fecha de

Fabricación:

Maximum Users:

Usarios Máximo :

Max. Capacity

per User:

Capacidad Máx.

por Usario :

Minimum Anchorage Strength:

Resistencia Mínima del Ancladero:

2

400 lb

181 kg

5,000lbs / 22.2 kN

See instructions for fall

clearance requirements

Vea las instrucciones para

conocer los requisitos de

espacio libre de caída.

Only connecting subsystems that

limit the maximum arrest force to

less than 1,800 pounds (8 kN) are

approved for use with this system.

Para uso con este sistema, sólo

están aprobados los subsistemas

conectores que limitan la fuerza de

detención máxima a menos de

1.800 libras (8 kN).

Standards/Estándares

OSHA 29 CFR 1910, 1926

93 Werner Road, Greenville, PA 16125

1-888-523-3371

www.wernerco.com

© 2016 Werner Co.

P/N 109395-01 Rev A 8/16

Werner Fall Protection

Follow All

Instructions

5/8" Diameter Static Kernmantle Blue

Min Break Strength: Snap Hook: 5,000 lbs (22.2 kN)

Min Break Strength: Rope/Termination: 10,000 lbs (44.5 kN)

Part # 109045-01

Lot No: xxxx

Mfg. by Pelican Rope

Mfg. Date: mm/dd/yyyy

© 2016 Werner Co.

P/N109397-01 Rev A 6/16

ENGLISH

Page 21

Page 22

LABELS

E

WARNING

Compliant fall protection equipment

must only be used as it was designed.

Users MUST read and follow all user

instructions provided with the product.

Before using a fall arrest system, users

must be trained in the safe use of the

system, as required by OSHA 29 CFR

1910.66 and 1926.503, or local safety

regulations. Product must be inspected

prior to each use according to the user

instructions, and additionally by a

competent person who is not the user,

at intervals of no more than one year.

Only make compatible connections.

User repairs and alterations are NOT

permitted. Avoid physical and

environmental hazards such as thermal,

exposure to sharp edges and abrasive

surfaces, machinery, and electrical and

chemicals sources. For proper use see

supervisor, user instructions, or

contact Werner Co.

This system is only to be used by

Authorized Persons.

Any equipment that has been subjected

to the forces of arresting a fall, or that

has a deployed load indicator, must be

removed from service until a “qualied

person” can make the determination

for reuse or disposal.

ADVERTENCIA

El equipo de protección contra caídas

que cumple las normas sólo se puede

utilizar según se diseñó. Los usuarios

DEBEN leer y seguir todas las

instrucciones del usuario suministradas

con el producto. Antes de utilizar un

sistema de detención de caídas, los

usuarios deben recibir capacitación

acerca del uso seguro del sistema,

según lo requerido por OSHA 29 CFS

1910.66 y 1926.503, o los reglamentos

de seguridad locales. Antes de cada

uso, el producto debe ser inspeccionado

de acuerdo con las instrucciones del

usuario, y adicionalmente, por una

persona competente que no sea el

usuario, en intervalos no superiores a

un (1) año. Sólo realice conexiones

compatibles. NO se permiten

reparaciones y alteraciones por parte

del usuario. Evite los peligros físicos y

medioambientales tales como los

peligros térmicos, exposición a bordes

losos y supercies abrasivas,

maquinaria, y fuentes eléctricas y

químicas. Para conocer el uso

apropiado, hable con su supervisor,

vea las instrucciones del usuario, o

omuníquese con Werner Co.

Este sistema sólo es utilizado por

Personas Autorizadas.

Cualquier equipo que haya sido

sometido a las fuerzas de detención

de una caída, o que tenga un indicador

de carga desplegado, debe ser retirado

del servicio hasta que una "persona

calicada" pueda determinar reutilizar

o desecho.

TIE KNOT ADJACENT

HACER UN NUDO AYACENT

INSPECT!

™

TO THIS EDGE

A ESTE LADO

© 2016 Werner Co.

P/N 110253-01 Rev A 8/16

ENGLISH

Page 22

93 Werner Road, Greenville, PA 16125

888-523-3371 • www.wernerco.com

© 2016 Werner Co. P/N 109396-01 Rev A 8/16

Page 23

SYNTHETIC ROPE HORIZONTAL LIFELINE

USER INSTRUCTIONS

EQUIPMENT RECORD

MODEL NUMBER

SERIAL NUMBER

DATE

MANUFACTURED

PURCHASE DATE

ASSIGNED TO

SPECIFICATION

WERNER CO. SYNTHETIC ROPE HORIZONTAL LIFELINE

This product meets OSHA 29 CFR 1910.66 and 1926.502 regulations for the

horizontal lifeline component of a complete personal fall arrest system.

Individually bar coded model and serial numbers, location and date of

manufacture are on product label.

INSPECTION RECORD

DATE INSPECTOR PASS/FAIL DATE INSPECTOR PASS/FAIL

Page 23

ENGLISH

Page 24

¡ADVERTENCIA!

El equipo de protección contra caídas que cumple las normas sólo se

puede utilizar según se diseñó. Los usuarios DEBEN leer y seguir todas las

instrucciones del usuario suministradas con el producto. Antes de utilizar

un sistema de detención de caídas, los usuarios deben recibir capacitación

acerca del uso seguro del sistema, según lo requerido por OSHA 29 CFR

1910.66 y 1926.503, o los reglamentos de seguridad locales. El uso

incorrecto o no tener en cuenta estas advertencias e instrucciones

podría resultar en lesiones o incluso la muerte.

¡TRABAJE DE MANERA SEGURA! ¡TRABAJE DE MANERA INTELIGENTE!

SI TIENE ALGUNA PREGUNTA ACERCA DEL USO APROPIADO DEL EQUIPO,

CONSULTE A SU SUPERVISOR, VEA LAS INSTRUCCIONES DEL USUARIO, O

COMUNÍQUESE CON WERNER CO. PARA OBTENER MÁS INFORMACIÓN.

¡ADVERTENCIA!

¡ADVERTENCIA!

El tensado excesivo o de ciente podría causar desgaste excesivo o daño

de los componentes del sistema y/o mayores requisitos de espacio libre de

caída.

Nunca sujete la pata no utilizada de la correa de seguridad de regreso al

arnés de cuerpo completo en ningún lugar que no sea el retenedor de la

correa de seguridad.

Nunca utilice combinaciones de componentes o subsistemas que pudieran

afectar, o interferir con, la función segura del uno con respecto al otro.

Todos los componentes de la Cuerda Salvavidas Horizontal Sintética se

deben inspeccionar antes de cada uso de acuerdo con los requisitos de

OSHA 29 CFR 1910.66 y 1926.502.

Si la inspección revela algún defecto, mantenimiento inadecuado, o

condición insegura, saque del servicio hasta que una persona “cali cada”,

según lo de nido por OSHA 29 CFR 1910.26(m), pueda determinar la

necesidad de reparación autorizada o desecho.

Cualquier equipo que haya sido sometido a las fuerzas de detención de una

caída, o que tenga un indicador de carga desplegado, debe ser retirado del

servicio hasta que una “persona cali cada” pueda determinar la necesidad

ESPAÑOL

de reparación autorizada o desecho.

Página 24

Page 25

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

¡ADVERTENCIA!

La altura de instalación de la Cuerda Salvavidas Horizontal Sintética

depende del tipo de subsistema asociado sujetado. (Vea los “REQUISITOS

DE ESPACIO LIBRE”)

Cuando se utilizan Cuerdas Salvavidas Auto-retráctiles (SRL) como

dispositivos asociados, se debe instalar la Cuerda Salvavidas Horizontal

Sintética. La altura de instalación de la Cuerda Salvavidas Horizontal

Sintética y el tipo de subsistema asociado sujetado afectan directamente el

requisito de espacio libre de caída.

Cuando se utilizan Cuerdas Salvavidas Auto-retráctiles (SRL), se debe

evaluar la mayor posibilidad de caída tipo columpio adicionalmente al

espacio libre de caída requerido. Las Cuerdas Salvavidas Auto-retráctiles

más largas (con longitud superior a 9,1 m (30 pies)) podrían aumentar la

posibilidad de caída tipo columpio o caída libre adicionales.

INSTRUCCIONES DE USO Y LIMITACIONES

IMPORTANTE

Antes de utilizar, el usuario debe leer y entender estas Instrucciones del Usuario.

Guarde estas Instrucciones del Usuario para consulta.

PROPÓSITO

La Cuerda Salvavidas Horizontal Sintética es un sistema de cuerda salvavidas

horizontal exible, diseñado para utilizarse como parte de un sistema personal

de detención de caídas completo, para proporcionar movilidad horizontal para

un máximo de dos usuarios y para ayudar a limitar las fuerzas de detención de

caídas en caso de una caída.

INSTRUCCIONES DE USO

1. No seguir las instrucciones y limitaciones en el uso de la Cuerda Salvavidas

Horizontal Sintética podría resultar en lesiones personales graves o la

muerte.

2. Antes de utilizar un sistema personal de detención de caídas, los empleados

deben recibir capacitación, según los requisitos de OSHA 29 CFR 1910.66,

sobre el uso seguro del sistema y sus componentes.

3. Los sistemas personales de detención de caídas, incluyendo la Cuerda

Salvavidas Horizontal Sintética, se deben inspeccionar antes de cada uso en

busca de desgaste, daño y otro deterioro. Los componentes defectuosos se

deben retirar inmediatamente del servicio, de acuerdo con los requisitos de

OSHA 29 CFR 1910.66 y 1926.502.

ESPAÑOL

Página 25

Page 26

4. Antes de utilizar, se debe planear el sistema completo de protección contra

caídas (incluyendo todos los componentes, calculando el espacio libre de

caída y la caída tipo columpio).

5. Los usuarios deben tener un plan de rescate, y los medios para

implementarlo, que permita el rescate rápido de los empleados en caso

de una caída, o que garantice que los empleados pueden rescatarse ellos

mismos.

6. Guarde la Cuerda Salvavidas Horizontal Sintética en un ambiente fresco,

seco y limpio y alejado de la luz solar directa cuando no esté en uso.

7. Después que ocurra una caída en el sistema, saque inmediatamente del

servicio hasta que una “persona cali cada” pueda tomar la determinación

para reuso o desecho.

LIMITACIONES DE USO

1. CAPACIDAD: La Cuerda Salvavidas Horizontal Sintética está diseñada para

un máximo de dos usuarios a la vez, por cada sistema, con una capacidad

máxima (incluyendo ropa, herramientas, etc.) de 181 kg (400 libras) de

peso de trabajo total por cada usuario, en conjunto con los componentes

asociados compatibles.

2. TRAMO: La Cuerda Salvavidas Horizontal Sintética se puede ajustar desde

un mínimo de 3.05 m (10 pies) hasta el máximo permitido por la longitud de

cuerda incluida.

3. SUPERVISIÓN: De acuerdo con los requisitos de OSHA 29 CFR 1910.66,

y 1926.502, la Cuerda Salvavidas Horizontal Sintética se debe instalar y

utilizar bajo la supervisión de una persona “cali cada” según lo de nido por

OSHA 29 CFR 1926.32(m).

4. SUSPENSIÓN EXTENDIDA: La Cuerda Salvavidas Horizontal Sintética no

está diseñada para uso en aplicaciones de suspensión extendida.

5. CORROSIÓN: No deje la Cuerda Salvavidas Horizontal Sintética en

ambientes donde pudiera ocurrir corrosión de las piezas metálicas como

resultado de vapores procedentes de materiales orgánicos. El uso cerca del

agua de mar u otros ambientes corrosivos podría requerir inspecciones más

frecuentes para garantizar que el daño por corrosión no está afectando el

funcionamiento del producto.

6. PELIGROS POR SUSTANCIAS QUÍMICAS: Las soluciones que contienen

ácidos, álcali, u otras sustancias cáusticas, especialmente a temperaturas

elevadas, podrían causar daño a la Cuerda Salvavidas Horizontal Sintética.

Al trabajar con dichos productos químicos, se debe realizar una inspección

frecuente de estos equipos. Comuníquese con Werner Co. con cualquier

pregunta relacionada con el uso de la Cuerda Salvavidas Horizontal

Sintética alrededor de peligros químicos.

7. TEMPERATURA EXTREMA: La Cuerda Salvavidas Horizontal Sintética está

ESPAÑOL

diseñada para utilizarse en temperaturas que varían desde -40°C a +54°C

(-40ºF a +130ºF). Debe suministrarse protección para la Cuerda Salvavidas

Página 26

Page 27

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

Horizontal Sintética al utilizar cerca de actividades de soldadura, corte de

metales o actividades similares. Comuníquese con Werner Co. con cualquier

pregunta relacionada con los ambientes de alta temperatura.

8. PELIGROS ELÉCTRICOS: Tenga mucho cuidado al trabajar cerca de

cables de energía de alto voltaje debido a la posibilidad de que la corriente

eléctrica uya a través de la Cuerda Salvavidas Horizontal Sintética o los

componentes asociados.

9. ANCLADEROS: El ancladero de extremo debe ser capaz de soportar cargas

aplicadas en todas las direcciones de 22,2 kN (5.000 libras), dos veces la

capacidad de detención máxima.

10. COMPATIBILIDAD DE LOS COMPONENTES: Con la Cuerda Salvavidas

Horizontal Sintética, sólo se pueden utilizar componentes aprobados por

Werner Co.

11. SUBSISTEMAS: Con la Cuerda Salvavidas Horizontal Sintética, sólo se

pueden utilizar subsistemas asociados que limitan la fuerza de detención

máxima a menos de 8 kN (1.800 libras).

12. SALUD: Los menores de edad, mujeres embarazadas y cualquier persona

con una historia de problemas de espalda o cuello no deberían utilizar este

equipo.

13. CAPACITACIÓN: No utilice ni instale la Cuerda Salvavidas Horizontal

Sintética sin la capacitación apropiada suministrada por una “persona

competente” según lo de nido por la norma 29 CFR 1926.32(f) de OSHA.

14. REPARACIONES: Sólo Werner Co., o personas o entidades autorizadas por

escrito por Werner Co., pueden realizar reparaciones o modi caciones al

equipo.

REQUISITOS DE LOS ANCLADEROS

ANCLADEROS

La Cuerda Salvavidas Horizontal Sintética incorpora un absorbedor de energía

en línea. Está diseñada para limitar la carga de detención máxima a menos de

11,1 kN (2.500 libras) en los ancladeros de extremo. Por lo tanto, el ancladero de

extremo debe tener una resistencia mínima de 22,2 kN (5.000 libras), dos veces

la carga de detención máxima.

Todos los ancladeros a los cuales se sujeta la Cuerda Salvavidas Horizontal

Sintética deben cumplir los requisitos de ANSI Z359.1-2007 y OSHA 29 CFR

1910.66 y 1926.502.

OSHA estipula:

Los ancladeros utilizados para la sujeción de equipo personal de detención

de caídas deberán ser independientes de cualquier ancladero que se esté

Página 27

ESPAÑOL

Page 28

utilizando para soportar o suspender plataformas, y deberán ser capaces

de soportar al menos 22,2 kN (5.000 libras) por cada empleado sujetado, o

deberá diseñarse, instalarse y utilizarse como parte de un sistema personal

completo de detención de caídas que mantenga un factor de seguridad de

dos como mínimo, y estar bajo la supervisión de una persona capacitada.

ANSI Z359.1-2007 estipula que los ancladeros en un sistema personal de

detención de caídas deben tener una resistencia capaz de soportar cargas

estáticas, aplicadas en todas direcciones permitidas por el sistema, de al menos:

(a) dos veces la fuerza de detención máxima permitida en el sistema, cuando

existe certi cado, o

(b) 22,2 kN (5.000 libras) en ausencia de certi cado

La resistencia en (a) y (b) se debe multiplicar por el número de sistemas

personales de detención de caídas sujetados al ancladero, cuando más de un (1)

sistema personal de detención de caídas está sujetado al ancladero.

CONECTORES DE ANCLADERO

Los conectores de ancladero funcionan como una interconexión entre el

ancladero y la Cuerda Salvavidas Horizontal Sintética para el propósito de

acoplar el sistema al ancladero. Los conectores de ancladero de extremo están

diseñados para resistir y transferir al menos dos veces la carga de detención

máxima a los ancladeros de extremo.

REQUISITOS DE CONEXIÓN

LIMITACIONES DE COMPATIBILIDAD

Todos los subsistemas asociados sólo se deben acoplar a conectores

compatibles. La norma OSHA 29 CFR 1926.502 prohíbe enganchar los ganchos

de cierre resortado a ciertos objetos a menos que se cumplan dos requisitos:

el gancho de cierre resortado debe ser del tipo que se asegura o bloquea y

debe estar "diseñado para" realizar dicha conexión. Según la norma OSHA 29

CFR 1926.502, “diseñado para” signi ca que el fabricante del gancho de cierre

resortado diseñó especí camente el gancho de cierre resortado para conectarse

al equipo en cuestión.

Las siguientes conexiones se deben evitar, porque éstas pueden resultar en

desenganche accidental* cuando se utiliza un gancho de cierre resortado no

bloqueable:

ESPAÑOL

Página 28

Page 29

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

• Conexión directa de un gancho de cierre resortado a una cuerda

salvavidas horizontal.

• Dos (o más) ganchos de cierre resortado conectados a un (1) anillo en “D”.

• Dos ganchos de cierre resortado conectados entre sí.

• Un gancho de cierre resortado conectado de regreso sobre su correa de

seguridad integral.

• Un gancho de cierre resortado conectado a un lazo tejido o una correa de

seguridad tejida.

• Las dimensiones inapropiadas del anillo en “D”, barra de refuerzo u

otro punto de conexión en relación con las dimensiones del gancho de

cierre resortado que podrían permitir que el jador del gancho de cierre

resortado sea presionado por un movimiento giratorio del gancho de cierre

resortado.

*Desenganche accidental: Un proceso mediante el cual un gancho de cierre

resortado o argolla rectangular metálica se desengancha accidentalmente de

otro conector u objeto al cual está acoplado. (ANSI Z359.0)

CONEXIONES COMPATIBLES

CONEXIONES INCOMPATIBLES

NO! NO! NO! NO!

NO!NO!NO!NO!

GANCHOS DE CIERRE RESORTADO Y ARGOLLAS RECTANGULARES

METÁLICAS

Los ganchos de cierre resortado y mosquetones utilizados en la Cuerda

Salvavidas Horizontal Sintética, marcados con la norma ANSI Z359.1-07 o ANSI

Z359.12-09, son auto-bloqueables (auto-asegurables) con una resistencia a la

tracción mínima de 22,2 kN (5.000 libras), y una capacidad del cierre resortado

de 16 kN (3.600 libras).

ESPAÑOL

Página 29

Page 30

COMPONENTES DEL SISTEMA

LIMITACIONES DE COMPATIBILIDAD

Todos los componentes y subsistemas utilizados con la Cuerda Salvavidas

Horizontal Sintética

salvavidas horizontal exible pre-diseñado. Sólo se deben utilizar los

componentes y subsistemas aprobados por Werner Co. con la

Horizontal Sintética

han sido probados como parte de un sistema de cuerda

Cuerda Salvavidas

.

CONECTORES DE ANCLADERO

ANCLAJE DEL TIPO D-BOLT: A320001-WB

El conector de ancladero de 22,2 kN (5.000 libras) hecho de

acero de alta resistencia se sujeta a una estructura de anclaje

mediante un perno de cabeza hexagonal de ⁄ pulgadas

-11 x 2¼ Grado 8, tuerca hexagonal de ⁄ pulgadas-11 Grado

8 y una arandela dividida de seguridad de alta aleación de

⁄ pulgadas (El A320001-WB incluye perno, tuerca y arandela

de seguridad)

CORREA DE ENVOLVER:

A111104

Construida con poliéster

de alta resistencia de

1- ¾ pulgadas y nylon de

3 pulgadas, la Correa de

Envolver de 1,2 m (4 pies)

está diseñada para envolverse

alrededor de un cuello de botella con un lazo suave de 30 cm (12 pulgadas) a

estructuras de anclaje para crear un punto de anclaje de

22,2 kN (5.000 libras).

ACCESORIOS

ORRAL: K120004

M

El morral está construido de poliéster de alta resistencia, con

una parte inferior reforzada para fácil transporte de la

Salvavidas Horizontal Sintética de un trabajo a otro.

ESPAÑOL

Cuerda

Página 30

Page 31

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

CONJUNTO DE CUERDA SALVAVIDAS

SISTEMAS CON TRINQUETE INDICADOR DE TENSIÓN

L102030, L102060, L102100, L122030, L122060, L122100

Tensor de cuerda

Paquete contra impacto

Trinquete

indicador de tensión

Anillos "O"

Cuerda

SISTEMAS SIN TRINQUETE INDICADOR DE TENSIÓN

L100030, L100060, L100100, L120030, L120060, L120100

Tensor de cuerda

Paquete contra impacto

Anillos "O"

Cuerda

PAQUETE CONTRA IMPACTO

El paquete contra impacto está diseñado para limitar la carga de detención

máxima a menos de 11,1kN (2.500 lbf) en los ancladeros de extremo. El paquete

contra impacto está construido con tejido de poliéster y tejido de rotura con una

cubierta de poliéster que incluye las etiquetas con una cubierta protectora.

TRINQUETE INDICADOR DE TENSIÓN

El trinquete indicador de tensión está construido de acero de alta resistencia y

tiene una resistencia a la rotura mínima de

resortada del Trinquete Indicador de Tensión está diseñada para exionarse lo

cual indica el momento cuando la

tensada apropiadamente.

poliéster de alta resistencia de 44,45 mm (1¾ pulgadas) para 0,45m

(18 pulgadas) de ajustabilidad.

El Trinquete Indicador de Tensión incluye tejido de

Cuerda Salvavidas Horizontal Sintética está

44,5kN (10.000 libras) . La manija

Página 31

ESPAÑOL

Page 32

CONJUNTO DE CUERDA SALVAVIDAS, CONTINUACIÓN

TENSOR DE CUERDA

El Tensor de Cuerda se utiliza para el ajuste aproximado de la cuerda en los

sistemas que incorporan el Trinquete Indicador de Tensión. Para los sistemas

que no incorporan el Trinquete Indicador de Tensión, el Tensor de Cuerda está

diseñado para lograr la tensión apropiada de la

Sintética.

El Tensor de Cuerda está construido con acero de alta resistencia.

Cuerda Salvavidas Horizontal

CUERDA

La cuerda Kernmantle de bajo estiramiento de 15.9 mm (⁄ pulgadas) está

construida con un núcleo de trenzas de nylon y una funda de poliéster,

proporcionando una resistencia a la rotura mínima de

La funda resistente a la abrasión está diseñada para mostrar daño antes que

se dañe el núcleo soportador de carga. La cuerda se debe retirar del servicio

si la funda exterior está dañada. La cuerda viene con un extremo terminado

(guardacabo y cosido) con un gancho de cierre resortado, y el otro extremo

está anudado para evitar que la cuerda pase de regreso a través del Tensor de

Cuerda.

44,5kN (10.000 libras) .

ANILLOS "O"

Los anillos "O" de 50,8mm (2 pulgadas) están hechos de acero de alta

resistencia y están marcados según ANSI Z359.1-2007 y/o ANSI Z359.12-2012

con una resistencia a la rotura mínima de

22,2kN (5.000 libras).

INSTALACIÓN

¡ADVERTENCIA!

Todos los componentes de la Cuerda Salvavidas

Horizontal Sintética se deben inspeccionar antes de

cada uso de acuerdo con los requisitos de OSHA 29

CFR 1910.66 y 1926.502.

ANTES DE CADA USO

Los usuarios deben tener un plan de rescate, y los medios para implementarlo,

que permita el rescate rápido de los empleados en caso de una caída, o que

garantice que los empleados pueden rescatarse ellos mismos.

El usuario debe leer y entender estas Instrucciones del Usuario, y también

las Instrucciones del Usuario de cada componente y subsistema del sistema

ESPAÑOL

personal de detención de caídas.

Página 32

Page 33

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

Toda la Cuerda Salvavidas Horizontal Sintética, y sus subsistemas, se deben

inspeccionar antes de cada uso. Vea INSPECCIÓN.

CAÍDAS TIPO COLUMPIO

Para minimizar la posibilidad de

una caída tipo columpio, trabaje

lo más directamente debajo o

adyacente posible de la Cuerda

Salvavidas Horizontal Sintética.

Golpear objetos de manera

horizontal, debido al efecto

péndulo, podría causar lesiones

graves. Las caídas tipo columpio

también aumentan la distancia de

caída vertical de un trabajador, en comparación con una caída directamente

debajo del punto de conexión. Vea REQUISITOS DE ESPACIO LIBRE.

¡ADVERTENCIA!

Ancladeros

Correcto Incorrecto

PELIGRO DE CAÍDA

TIPO COLUMPIO

La altura de instalación de la Cuerda Salvavidas

Horizontal Sintética depende del tipo de subsistema

asociado sujetado. Vea REQUISITOS DE ESPACIO

LIBRE.

PASO 1A: INSTALE EL CONECTOR DE ANCLADERO DE CORREA DE

NVOLVER

E

Con las etiquetas en la super cie dirigida hacia afuera de la Correa de Envolver,

envuelva el elemento tejido alrededor de la

pequeño anillo en forma de "D" de un extremo a través del lazo tejido en el otro

extremo. Envuelva tantas veces como sea necesario hasta lograr la longitud

deseada. Hale el pequeño anillo en “D” para apretar (estrangular) el ancladero. El

pequeño anillo en "D" es el conector de ancladero en el punto de conexión.

estructura de ancladero y pase el

PASO 1B: INSTALE EL CONECTOR DE ANCLADERO DE D-BOLT

Taladre un ori cio de 17 mm (⁄ pulgadas) donde sea necesario en la estructura

de ancladero utilizando una broca apropiada para la penetración. Remueva

cualquier borde con rebaba de la estructura. Sujete el Conector de Ancladero

de D-Bolt utilizando el perno de acero de 5⁄8 pulgadas -11 x 2 pulgadas Grado 8,

la tuerca y arandela de seguridad suministrados. Inserte el perno suministrado

a través del D-Bolt y del ori cio pre-taladrado. Veri que que el perno está

insertado completamente, y que la super cie trasera del D-Bolt está a ras contra

la estructura de ancladero. Deslice la arandela de seguridad suministrada

sobre las roscas del perno hasta que la arandela esté contra la super cie de la

estructura de ancladero. Enrosque la tuerca sobre el perno hasta que ésta haga

ESPAÑOL

Página 33

Page 34

contacto con la arandela. Veri que que el D-Bolt está orientado correctamente y

apriete hasta 17,3 kgf-m (125 lbf-pie).

PASO 2: CONECTE EL EXTREMO DE CUERDA QUE TIENE EL

GANCHO DE CIERRE RESORTADO

Sujete el gancho de cierre resortado, que está conectado al extremo de la

cuerda, al anillo en "D" de la Cuerda de Envolver o al conector de ancladero de

D-Bolt. Este extremo del sistema es el extremo inactivo del sistema de Cuerda

Salvavidas Horizontal Sintética .

PASO 3: CONECTE EL GANCHO DE CIERRE RESORTADO QUE ESTÁ

SUJETADO AL PAQUETE CONTRA IMPACTO

Conecte el gancho de cierre resortado giratorio, que está sujetado al paquete

contra impacto, al conector de ancladero restante (anillo en "D" de la correa de

envolver o del

de Cuerda Salvavidas Horizontal Sintético. Hale a mano el extremo de la cuerda

a través del Tensor de Cuerda hasta eliminar la ojedad del sistema. Gire el

paquete contra impacto de modo que la cuerda tenga tan poco torcimiento como

sea posible.

D-Bolt). Este extremo del sistema es el extremo activo del sistema

PASO 4A: SISTEMA DE TENSIÓN CON TRINQUETE INDICADOR DE

T

ENSIÓN

Utilice el Trinquete Indicador de Tensión para tensar el sistema. Cuando la manija

del trinquete se exione hacia atrás, nalice con el siguiente clic para aplicar la

tensión correcta, luego cierre el trinquete para enganchar el cerrojo de seguridad.

PASO 4B: SISTEMA DE TENSIÓN CON TENSOR DE CUERDA

Para los sistemas que no incluyen el Trinquete Indicador de Tensión, utilice una

llave de torsión (llave dinamométrica) con copa de 1⁄ pulgadas para aplicar 8,3

kgf-m (60 lbf-pie) de apriete a la orejeta. Empuje la palanca de trinquete hacia el

cuerpo del tensor para evitar la liberación accidental de la tensión.

PASO 5: ATE UN NUDO EN LA CUERDA EN LA CUERDA SOBRANTE

Utilizando la cuerda sobrante, realize un nudo sencillo cerca del tensor de

cuerda, según se indica en la etiqueta.

¡ADVERTENCIA!

El tensado excesivo o de ciente podría causar desgaste

excesivo o daño de los componentes del sistema y/o

mayores requisitos de espacio libre de caída.

ESPAÑOL

Página 34

Page 35

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

CONEXIÓN

ÚMERO DE USUARIOS

N

La Cuerda Salvavidas Horizontal Sintética está diseñada para un máximo de

dos usuarios a la vez, por cada sistema, con una capacidad máxima (incluyendo

ropa, herramientas, etc.) de 181 kg (400 libras) de peso de trabajo total por cada

usuario, en conjunto con los componentes asociados compatibles.

¡PRECAUCIÓN!

Cuando dos usuarios están conectados a la misma Cuerda

Salvavidas Horizontal Sintética, la caída de uno de los

usuarios podría halar la segunda persona fuera de la

super cie de trabajo, causando una caída secundaria.

Cuando dos usuarios están conectados a la misma Cuerda Salvavidas Horizontal

Sintética, la caída de uno de los usuarios podría halar la segunda persona fuera

de la super cie de trabajo, causando una caída secundaria. Se deben tomar

precauciones para reducir el riesgo de caídas secundarias, incluyendo la de

limitar cada Cuerda Salvavidas Horizontal Sintética a un solo usuario cuando y

donde sea posible, o la de instalar la cuerda salvavidas para reducir el riesgo de

caída de cualquiera de los usuarios.

CORREAS DE SEGURIDAD ABSORBEDORAS DE ENERGÍA (EALS)

Con la Cuerda Salvavidas Horizontal Sintética, sólo se pueden utilizar correas

de seguridad absorbedoras de energía que limiten las fuerzas de detención de

caída a menos de 1.800 libras (8 kN) . El extremo absorbedor de energía de

las correas de seguridad absorbedoras de energía se deben conectar al anillo

en "D" dorsal del arnés de cuerpo completo. El extremo opuesto de la correa

de seguridad se debe conectar al Anillo "O" de la Cuerda Salvavidas Horizontal

Sintética.

CORREAS DE SEGURIDAD DE DOBLE PATA

Las correas de seguridad de doble pata están diseñadas para uso por una sola

persona y sólo se deben conectar, con el extremo absorbedor de energía de la

correa de seguridad, al anillo en "D" dorsal del arnés de cuerpo completo. No

conecte el extremo absorbedor de energía de la correa de seguridad al

anillo "O" de la Cuerda Salvavidas Horizontal Sintética. Sujete una pata

de la correa de seguridad de pata doble al anillo "O" y la pata no utilizada de la

correa seguridad a un retenedor aprobado de la correa de seguridad ubicado en

el arnés de cuerpo completo.

Página 35

ESPAÑOL

Page 36

¡ADVERTENCIA!

Nunca sujete la pata no utilizada de la correa de

Seguridad de regreso al arnés de cuerpo completo en

ningún lugar que no sea el retenedor de la correa de

seguridad.

Al utilizar correas de seguridad de pata doble para moverse entre sistemas

de detención de caídas, sujete la pata no utilizada de la correa de seguridad

al nuevo lugar antes desconectar la primera pata de la correa seguridad. Es

aceptable la conexión de ambas patas de la correa de seguridad a conectores de

ancladero separados mientras se realiza la transición entre sistemas.

CUERDAS SALVAVIDAS AUTO-RETRÁCTILES (SRLS)

Sujete el conector de carcasa de la cuerda salvavidas auto-retráctil al anillo "O"

de la Cuerda Salvavidas Horizontal Sintética. El extremo opuesto se conecta al

anillo "D" dorsal del arnés de cuerpo completo. Nunca sujete una correa de

seguridad absorbedora de energía o una cuerda salvavidas auto-retráctil

adicionales para alargar la cuerda salvavidas.

¡ADVERTENCIA!

Nunca utilice combinaciones de componentes o subsistemas

que pudieran afectar, o interferir con, la función segura del

uno con respecto al otro.

CONEXIÓN DE LA CUERDA SALVAVIDAS AUTO-RETRÁCTIL AL

ARNÉS

Las Cuerdas Salvavidas Auto-retráctiles (SRL) más livianas se puede conectar

mediante el conector de carcasa directamente al anillo "D" dorsal del arnés de

cuerpo completo. El extremo opuesto se conecta al anillo "O" de la Cuerda

Salvavidas Horizontal Sintética.

CUERDAS SRL PERSONALES Y CUERDAS SRL DE PATA DOBLE

Hay muchas diferentes maneras como las cuerdas SRL personales y las

cuerdas SRL de pata doble se sujetan al arnés de cuerpo completo. Siga las

Instrucciones de Usuario suministradas con el producto.

¡ADVERTENCIA!

Nunca sujete la pata no utilizada de la correa de seguridad de

regreso al arnés de cuerpo completo en ningún lugar que no

sea el retenedor de la correa de seguridad.

ESPAÑOL

Página 36

Page 37

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

INSPECCIÓN Y MANTENIMIENTO

¡ADVERTENCIA!

Si la inspección revela algún defecto, mantenimiento

inadecuado, o condición insegura, saque del servicio

hasta que una persona “cali cada”, según lo de nido

por OSHA 29 CFR 1910.26(m), pueda determinar la

necesidad de reparación autorizada o desecho.

¡PRECAUCIÓN!

Se debe utilizar Equipo Protector Personal apropiado al

realizar procedimientos de Inspección y Mantenimiento.

FRECUENCIA

Todos los componentes de la Cuerda Salvavidas Horizontal Sintética se deben

inspeccionar antes de cada uso, y anualmente por una "persona competente"

de nida por OSHA, diferente al usuario. Las agencias locales, estatales,

gubernamentales y jurisdiccionales que reglamentan la seguridad ocupacional

podrían exigir que el usuario realice inspecciones más frecuentes y obligatorias.

CRITERIOS

¡ADVERTENCIA!

Cualquier equipo que haya sido sometido a las fuerzas de

detención de una caída, o que tenga un indicador de carga

desplegado, debe ser retirado del servicio hasta que una

“persona cali cada” pueda tomar la decisión para re-uso o

desecho.

La tensión del sistema se debe revisar y ajustar. El Trinquete Indicador de

Tensión se puede utilizar para revisar la tensión mediante el mismo método

utilizado durante la instalación. Vea el Paso 4A. Los sistemas sin el Trinquete

Indicador de Tensión se pueden revisar y ajustar mediante el uso de una llave de

torsión (llave dinamométrica). Vea el Paso 4B.

Todos los componentes y subsistemas de la Cuerda Salvavidas Horizontal

Sintética se deben inspeccionar.

Página 37

ESPAÑOL

Page 38

Todas las marcas deben estar legibles y sujetadas al producto.

Todos los equipos deben estar sin corrosión, ataque químico, modi cación,

calentamiento o desgaste excesivos.

Para inspeccionar el tejido, pliegue una porción de 15.2 a 20.3 cm

(6 a 8 pulgadas) del tejido en forma de ‘U’ boca-abajo y continúe a lo largo de

todo el tejido.

Se debe inspeccionar todo el tejido y la cuerda en busca de roturas, cortes,

deshilachamiento, abrasión, decoloración, quemaduras, ori cios, acristalamiento,

moho, retorcimiento, costuras estiradas o rotas, u otros signos de desgaste

y daño. El núcleo del centro de la cuerda no debe estar expuesto. Las

terminaciones cosidas deben estar rmes, completas y sin daños visibles.

La cuerda se debe inspeccionar en busca de daño que exponga el núcleo interior

blanco. Si el núcleo está expuesto, la cuerda se debe retirar del servicio.

Todos los ganchos de cierre resortado y las argollas metálicas rectangulares

deben tener la capacidad de auto-cierre y bloqueo. Todos los herrajes deben

estar sin grietas, bordes losos, deformación, corrosión, o cualquier evidencia de

defecto.

Se deben inspeccionar todos los componentes del arnés de cuerpo completo,

la correa de seguridad auto-retráctil, y/o la correa de seguridad absorbedora de

energía. Vea las Instrucciones del Usuario suministradas con el producto.

DESINSTALACIÓN

ESMONTAJE DEL SISTEMA

D

Después de nalizar el trabajo, el sistema se debe retirar el sitio de trabajo y se

debe guardar.

Para desmontar el sistema:

Para los sistemas con Trinquete Limitador de Tensión: El trinquete se puede

liberar abriendo el trinquete y halando la manija de liberación para empujar y

abrir completamente el trinquete. Esto puede causar una descarga repentina de

la tensión del sistema.

Para los sistemas sin Trinquete Limitador de Tensión: La palanca de liberación

del ajustador de cuerda se debe abrir completamente a mano, luego se debe

ESPAÑOL

insertar un destornillador debajo de la palanca para halarla completamente hacia

Página 38

Page 39

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

arriba, liberando la tensión del sistema.

La cuerda se debe guardar apropiadamente para evitar dañar la cuerda durante

el almacenamiento o para evitar retorcimiento o enredos de la cuerda al sacarla

del almacenamiento.

LIMPIEZA Y ALMACENAMIENTO

L

IMPIEZA

El usuario puede realizar la limpieza de mantenimiento. La Cuerda Salvavidas

Horizontal Sintética se puede limpiar con trapo con una solución de agua limpia

y detergente suave, y enjuagarse con un trapo limpio humedecido para remover

el detergente. Los herrajes también se pueden limpiar con un trapo limpio y seco

para remover la grasa o la suciedad.

ALMACENAMIENTO

La Cuerda Salvavidas Horizontal Sintética se debe guardar en un lugar fresco y

seco alejado de la luz solar directa, cuando no está en uso. No almacene donde

pudiera ocurrir daño por factores del medio ambiente tales como calor, luz,

humedad excesiva, aceite, productos químicos y sus vapores, o otros elementos

dañinos.

No almacene equipos dañados o equipos que necesiten mantenimiento en el

mismo lugar de los productos aprobados para uso. Los equipos que han sido

almacenados durante un periodo extendido de tiempo se deben inspeccionar

según lo de nido en estas Instrucciones del Usuario antes de su uso.

REQUISITOS DE ESPACIO LIBRE

T

ABLAS DE ESPACIOS LIBRES

Las siguientes tablas de espacios libres muestran la distancia requerida que

debe permanecer libre de obstrucciones entre la super cie de trabajo y el nivel

inferior o la obstrucción abajo más cercana.

Los requisitos de espacio libre incluyen lo siguiente en la distancia de caída

total: la de exión de los conectores de ancladero y la cuerda salvavidas, el

alargamiento del arnés de cuerpo completo y el usuario, el componente vertical

de cualquier caída tipo columpio, y un margen de seguridad de espacio libre de

0.61 m (2 pies). Los requisitos de espacio libre tienen en cuenta el desempeño

del sistema y el número de usuarios en el sistema.

Página 39

ESPAÑOL

Page 40

CUERDAS SALVAVIDAS AUTO-RETRÁCTILES - ANSI Z359.14

LASE A

C

Espacio libre de caída requerido para sujetar con cuerdas salvavidas auto-retráctiles

marcadas con ANSI Z359.14 Clase A, e instaladas para usuarios de 141 kg (310 libras) y la

Cuerda Salvavidas Horizontal Sintética instalada sobre el usuario. Todos los espacios libres

de caída de las Cuerdas Salvavidas Auto-retráctiles (SRLs) se miden desde la plataforma

de trabajo hasta la siguiente obstrucción debajo de la plataforma de trabajo.

Los siguientes espacios libres son para los Números de Modelo de cuerda SRL

AutoCoil 2: R230007, R230011, R230018, R210010.

¡ADVERTENCIA!

Al utilizar cuerdas SRL, la Cuerda Salvavidas Horizontal

Sintética SIEMPRE debe estar instalada sobre el usuario.

La altura de instalación de la Cuerda Salvavidas Horizontal

Sintética y el tipo de subsistema asociado sujetado afectan

directamente el requisito de espacio libre de caída.

¡ADVERTENCIA!

Cuando se utilizan Cuerdas Salvavidas Auto-retráctiles (SRL),

se debe evaluar la mayor posibilidad de caída tipo columpio

adicionalmente al espacio libre de caída requerido. Las Cuerdas

Salvavidas Auto-retráctiles más largas (con longitud superior a 9,1

m (30 pies)) podrían aumentar la posibilidad de caída tipo columpio

o caída libre adicionales.

TRAMO (HASTA...) UN (1) USUARIO DOS (2) USUARIOS

3 m (10 pies) 2,2 m (7' 2") 2,4 m (7' 10")

6,1 m (20 pies) 2,7 m (8' 11") 3,1 m (10' 2")

9,1 m (30 pies) 3,2 m (10' 7") 3,8 m (12' 6")

12,2 m (40 pies) 3,7 m (12' 4") 4,5 m (14' 10")

15,25 m (50 pies) 4,3 m (14' 0") 5,3 m (17' 4")

18,3 m (60 pies) 4,8 m (15' 8") 6 m (19' 8")

21,3 m (70 pies) 5,3 m (17' 5") 6,8 m (22' 2")

24,4 m (80 pies) 5,8 m (19' 0") 7,5 m (24' 7")

27,4 m (90 pies) 6,3 m (20' 8") 8,2 m (27' 0")

ESPAÑOL

30,5 m (100 pies) 6,8 m (22' 4") 9 m (29' 5")

Página 40

Page 41

CUERDA SALVAVIDAS HORIZONTAL SINTÉTICA

INSTRUCCIONES PARA EL USUARIO

CUERDAS SALVAVIDAS AUTO-RETRÁCTILES - ANSI Z359.14

LASE B

C

Espacio libre de caída requerido para sujetar con cuerdas salvavidas auto-retráctiles

marcadas con ANSI Z359.14 Clase B, e instaladas para usuarios de 141 kg (310 libras) y la

Cuerda Salvavidas Horizontal Sintética instalada sobre el usuario. Todos los espacios libres

de caída de las Cuerdas Salvavidas Auto-retráctiles (SRLs) se miden desde la plataforma

de trabajo hasta la siguiente obstrucción debajo de la plataforma de trabajo.

Los siguientes espacios libres son para los Números de Modelo de cuerda SRL

AutoCoil2: R230050, R210020, R210030, R210060, R213030, R213060

¡ADVERTENCIA!

Al utilizar cuerdas SRL, la Cuerda Salvavidas Horizontal

Sintética SIEMPRE debe estar instalada sobre el usuario.

La altura de instalación de la Cuerda Salvavidas Horizontal

Sintética y el tipo de subsistema asociado sujetado afectan

directamente el requisito de espacio libre de caída.

¡ADVERTENCIA!

Cuando se utilizan Cuerdas Salvavidas Auto-retráctiles (SRL),

se debe evaluar la mayor posibilidad de caída tipo columpio

adicionalmente al espacio libre de caída requerido. Las Cuerdas

Salvavidas Auto-retráctiles más largas (con longitud superior a 9,1

m (30 pies)) podrían aumentar la posibilidad de caída tipo columpio

o caída libre adicionales.

TRAMO (HASTA...) UN (1) USUARIO DOS (2) USUARIOS