Page 1

FALL PROTECTION

PROTECCIÓN CONTRA CAÍDAS

useR instRuctions

instRucciones PARA eL usuARio

Positioning LAnYARDs

Complies with ANSI Z359.3-2007

OSHA 1910 and 1926 regulations and requirements.

cueRDAs sALvAviDAs De

PosicionAMiento

Cumplen con los requisitos y normas ANSI Z359.3-2007,

OSHA 1910 y 1926.

(See back pages for specic model numbers.)

(Vea las páginas traseras para obtener los números de modelo especícos).

Werner Co. Fall Protection 724-588-2000

93 Werner Rd. 888-523-3371 llamada gratuita

Greenville, PA 16125 888-456-8458 fax

Page 2

CAUTION!

If use of fall protection equipment is necessary then the work

environment is dangerous and potentially deadly. Werner Co. products

are designed to eliminate as much of the hazard only as possible but

can do that ONLY if they are used correctly. Use this equipment as it

was designed to be used, after appropriate training, under the direct

supervision of a competent person, according to the instructions

provided, and in accordance with OSHA and local safety regulations.

User MUST read and understand all cautions and instructions. Failure

to heed these guidelines could result in injury or even death. WORK

SAFE! WORK SMART!

ENGLISH

Page 2

Page 3

Contents

WARNINGS ...........................................................................................................4

I. BEFORE USING LANYARDS

a. Inspect ......................................................................................................................4

b. Compatibility ............................................................................................................6

c. Anchorage Strength .................................................................................................6

d. Clearances ................................................................................................................7

e. Rescue Plan..............................................................................................................7

f. Training ......................................................................................................................7

II. LANYARD DESCRIPTIONS

a. Fall Restraint or Positioning Lanyards ..................................................................7

b. Rebar Positioning Lanyards ...................................................................................8

III.CONNECTIONS

a. Connecting to Harness - Standard Positioning Lanyard .....................................8

b. Connecting to a Harness - Rebar Positioning Lanyard ........................................8

c. Connecting to an Anchorage - Standard Positioning Lanyard ............................8

d. Connect to an Anchorage - Rebar Positioning Lanyard ......................................9

IV. USE WARNINGS, RESTRICTIONS AND CAUTIONS

a. Adequate anchorages ..............................................................................................9

b. Fall Distance ............................................................................................................9

c. Swing Fall .................................................................................................................9

d. Capacity ....................................................................................................................9

e. Environmental Hazards ...........................................................................................9

f. Components/Subsystems ...................................................................................... 10

g. Care and Storage ................................................................................................... 10

V. LABELS/IDENTIFICATION/INSPECTION RECORDS ................................... 11

VI. EQUIPMENT RECORDS ............................................................................... 14

VII. INSPECTION RECORD ................................................................................14

ENGLISH

Page 3

Page 4

Warning:

This product is just one part of a personal fall arrest, work positioning,

travel restraint, climbing or rescue system. It must be matched

correctly with other components to form a complete and functional

system. The user must understand the function of each of these

components and follow the manufacturer’s instructions for use for

each. ANSI and OSHA standards require that training in the use of

these products be provided by a competent person. The user must be

provided these instructions, should read and follow them, and then

consult the competent person who will supervise his work if he has

any questions about any part of the instructions. The employer must

provide training in the proper use, inspection, and maintenance of all

components in the system, and these instructions can be used as part

of that training. The equipment should be used ONLY in accordance

with these instructions, local ordinances and codes, the applicable

OSHA and ANSI standards, and the employer’s safety plan.

IF YOU HAVE ANY QUESTIONS ABOUT ANYTHING IN THESE

INSTRUCTIONS, THE EQUIPMENT, OR PROPER USE OF THE

EQUIPMENT, CONTACT WERNER CO. FOR MORE INFORMATION.

I. Before Using the Lanyard

Before using this equipment the user should take certain steps to

ensure that it is in good condition and safe for use. Some lanyards are

manufactured with an exclusive Werner Co. WebAlert Inspectable

Webbing that is designed to make these inspections easier. The

WebAlert Webbing has a contrasting internal color that will make cuts

or abrasions more visible. Any appearance of the internal WebAlert

color indicates that product should receive further examination by

a competent person before continued use. If a competent person

determines that the affected webbing or component has lost strength

then that product should be immediately removed from service.

a. Inspect

ENGLISH

Page 4

Examine all equipment thoroughly, daily before use, and periodically

by a competent person who is not the user. Verify the condition of

each component. If any damage, abnormalities or excessive wear

are found, the lanyard should be removed from service.

Page 5

1. Check the webbing for cuts, abrasion, burns, welding spatter,

or discoloration that could be caused by chemical exposure.

The WebAlert feature of the webbing on some models is

intended to make these much easier to spot. If any abnormality

is noted check further by bending the webbing to expose the

irregularity to determine severity.

2. For cable legs, examine the entire length for any breaks and

the swaged ttings for any irregularities.

3. Check all stitching for any broken threads.

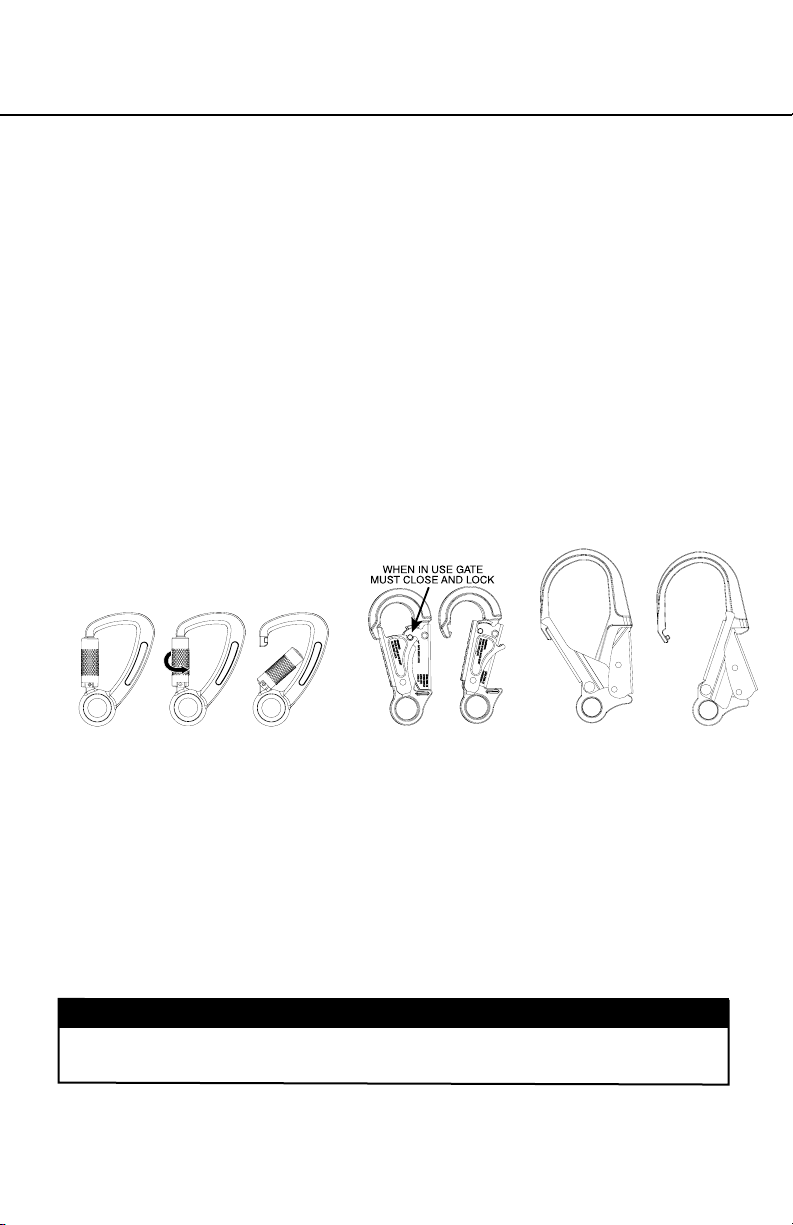

4. Check all hardware for cracks, bends, irregularities, corrosion,

or sharp edges. Check the snap hook gates for proper smooth

operation. The engagement release for the hook’s gate is

visible for inspectability. Ensure the mechanism is undamaged

and functioning correctly.

LOCKED UNLOCKEDTWIST

LOCKED UNLOCKED LOCKED UNLOCKED

5. Check all plastic parts for damage or cracks. If any

abnormalities are found, the product should be removed from

service.

6. Verify that all labels are in place and legible. Examples of

the labels can be found in section IV of these instructions.

If abnormalities are found in any of these areas then the

competent person should be consulted to determine if that item

is safe for continued use or if it should be removed from service.

Warning:

No alteration or modication of any fall protection equipment

is permitted for any reason unless authorized in writing by Werner Co.

Page 5

ENGLISH

Page 6

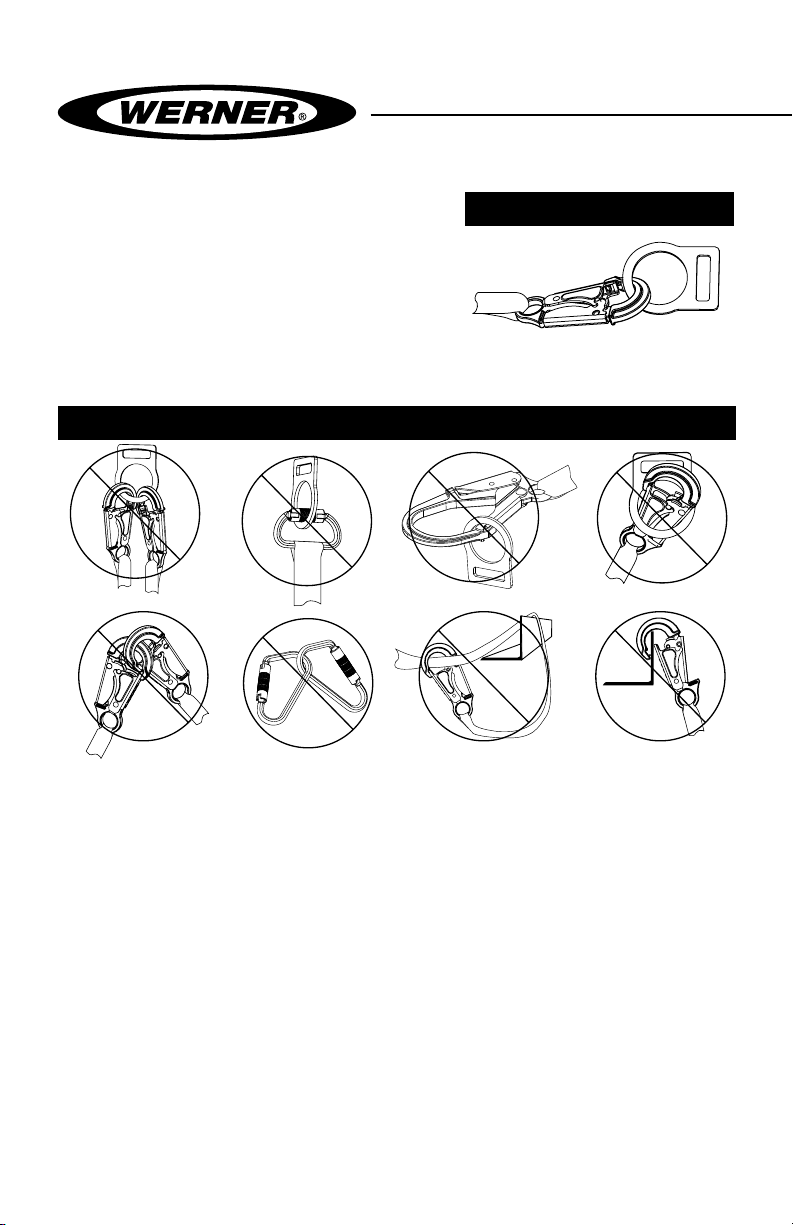

b. Compatibility.

PROPER CONNECTIONS

Verify compatibility of all subsystems

being used. Werner products

connected to Werner products

should be compatible, but connection

to other products should be veried

for compatibility to ensure there is no possibility of accidental

detachment from side-loading, rollout, non-standard closures, etc.

INAPPROPRIATE CONNECTIONS

A. B.

NO! NO! NO! NO!

D. E. F.

c. Anchorage Strength

C.

NO!NO!NO!NO!

ENGLISH

Page 6

Verify that Chosen Anchorages are Appropriate.

1. For fall restraint (where there is no possibility of accidental

detachment), anchors need to withstand a static load of 3000

lbs per attached user (13.3kN), or be certied by a qualied

person to be able to withstand two times the foreseeable force.

2. For positioning systems, the anchorage strength must be a

minimum of 3000 lbs per attached user (13.3 kN), or be certied

by a qualied person to have strength of twice the foreseeable

force.

3. For rescue systems, the anchorage should withstand a static

load of 3000 lbs per attached user (13.3kN) or be certied by a

qualied person for ve times the foreseeable load.

Page 7

d. Clearance

1. Verify that adequate clearance exists below the work area, and

there are no objects or obstructions below the work area that

the user could contact in the case of a fall.

2. For positioning applications, lanyards must be rigged to limit

free fall to no more than two feet. For situations where free

fall may exceed two feet, a backup fall arrest system should

be used. A fall arrest system is recommended to be used in

conjunction with rebar positioning lanyards to protect the user

in the event the positioning system becomes disengaged from

the anchorage point.

e. Rescue Plan

If a worker falls and is forced to remain suspended for any length of

time, physical damage to the body or even death can result. For this

reason Werner Co., OSHA, ANSI, CSA and most local regulations

require that a rescue plan and the means to implement the rescue

plan are in place before use of this equipment.

f. Training

OSHA, ANSI, and most local ordinances require that workers using

this product receive adequate training by a competent person

before use of this product. These instructions and their entire

contents should be a part of that training.

II. Lanyard Descriptions

Lanyards have a variety of attachment hardware types and types of

lanyard legs depending on their intended use. Use the lanyard type

that is appropriate for the work being done.

a. Fall Restraint or Positioning Lanyards

With no shock pack or other provision for energy absorption, these

lanyards fall outside the dynamic performance requirements of

OSHA and ANSI standards for energy absorbing lanyards. Without

energy absorption these lanyards are to be used only for

positioning/fall restraint either when there is no possibility of

a fall or to prevent workers from reaching a fall hazard.

ENGLISH

Page 7

Page 8

Werner Co. lanyards can be had with a variety of different connectors,

according to the intended use. The different lanyard types are:

1. We b

WebAlert inspectable webbing with red internal bers.

i. Standard length. 2',3',4',5' and 6' lengths.

ii. Adjustable length with adjuster buckle added enabling

reduction in total lanyard length in situations of reduced

clearances.

2. Cable

Cable is resistant to welding spatter, and vinyl coating provides

abrasion resistance and facilitates inspection of damaged

areas. Check for damage, kinks or broken strands. Available in

2',3',4' and 6' lengths.

b. Rebar Positioning Lanyards

These lanyards are intended to be used as part of a work positioning

system that supports the user at a work location in applications

such as concrete rebar assembly. They are designed to have one

leg attached to each side/hip D-ring on a user’s harness, and the

third leg attached to a suitable work positioning anchorage. The

lanyards are available in either web or chain materials.

III. Connections

a. Connecting to Harness - Standard Positioning Lanyard

Connect the lanyard to the rear D-ring for general fall arrest. The

end of the lanyard with labels should be attached to the harness

rear D-ring.

b. Connecting to a Harness - Rebar Positioning Lanyard

Connect each of the standard snap hooks to each of the side/hip

D-rings on the harness.

c. Connecting to an Anchorage - Standard Positioning Lanyard

Connect the opposite end of the lanyard to an anchor or anchor connector

ENGLISH

Page 8

ensuring the connection is made with compatible components.

Page 9

d. Connect to an Anchorage - Rebar Positioning Lanyard

Full Body Harness

Connecting

Anchorage Connector

Anchorage

FALL ARREST

Full Body Harness

Full Arrest System

Anchorage Connector

Anchorage

Connector

Restraint

Lanyard

Anchorage

Anchorage

WORK POSITION

Full Body Harness

Cable

Cable Sleeve

Ladder

CLIMBING

Full Body Harness

Seat Board

Full Arrest System

Anchorage Connector

Anchorage

Connector

Suspension Lin

e

Anchorage

Anchorage

PERSONNEL RIDING

Full Body Harness

Restraint Lanyard

Anchorage Connector

Anchorage

RESTRAINT

Connect the hook on the rebar lanyard

to the intersection of the horizontal and

vertical rebar.

IV. Use Warnings, Restrictions and Cautions

a. Adequate Anchorages

For positioning operations, OSHA requires anchor strengths of

3000 lbs or twice the maximum expected load if the anchorage has

been certied by a qualied person. Use of any anchorage that is of

inadequate strength could result in injury or death.

b. Fall Distance

For work positioning applications, the potential fall distance cannot

be more than two feet. If there is a possibility of a fall of more than

two feet occurring, a back up fall arrest system should be used.

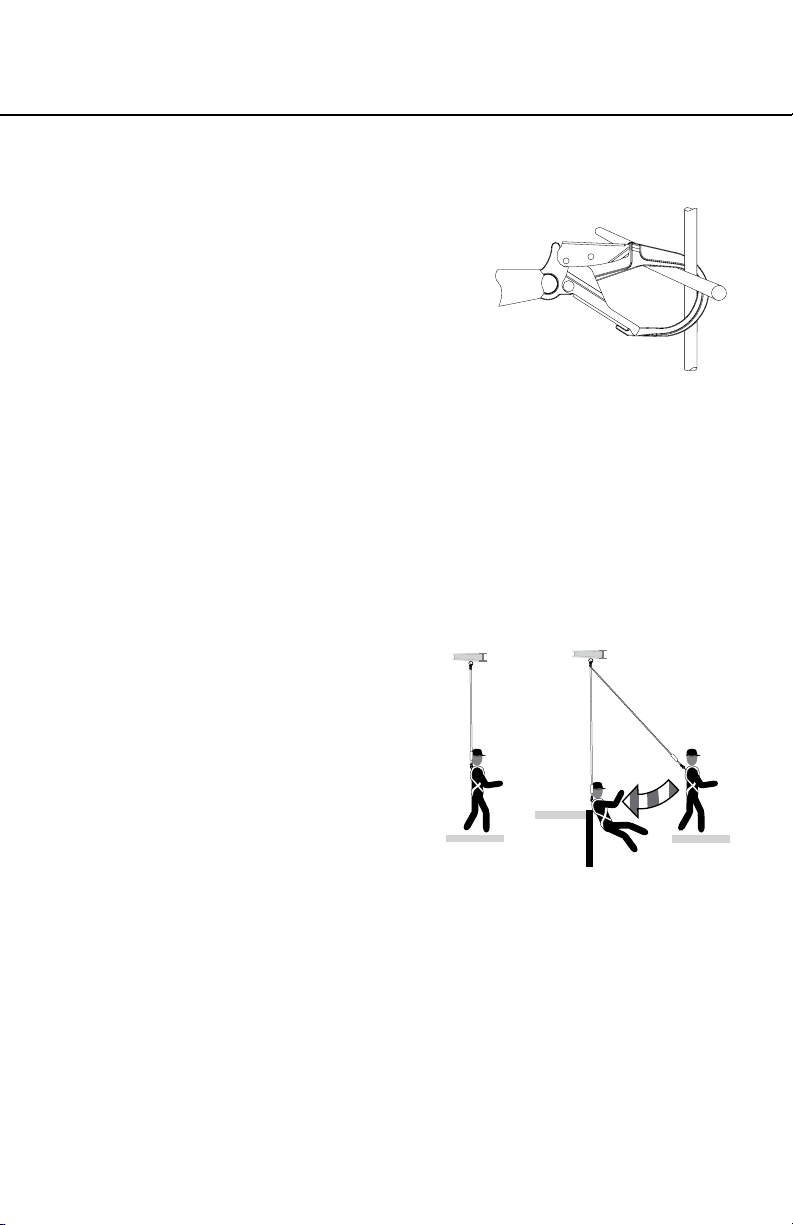

c. Swing Falls

possibility of a swing-fall impact.

Swing falls occur when the user is

not directly below the anchorage,

Ensure that there will be no

so if he falls his swing could

produce an impact with an object.

d. Capacity

Maximum capacity for all Werner lanyards is 310 lbs (140.6 kg) for

the combined weight of a worker and all tools. For any weight over

310 lbs (140.6 kg) contact Werner Co. for more information. The

employer should ensure that all other elements of the fall protection

system are adequate to support any higher weights.

Anchorages

CorrectIncorrect

SWING FALL

HAZARD

e. Environmental Hazards

This equipment is used only under the direct supervision of a

competent person who is able to identify hazards that must be

avoided, including electrical and chemicals, machinery or other

moving objects, sharp edges, damaged anchorages or structures,

Page 9

ENGLISH

Page 10

or any other workplace element that could damage this equipment

or prevent it from operating as intended.

f. Components/Subsystems

Before rst use, a qualied person should inspect and determine that

all components and subsystems are compatible and will perform

correctly when combined into a complete personal fall protection

system. Consult the information in these instructions, and if any

additional information is needed contact Werner Co. directly.

g. Care and Storage

Product can be cleaned using a mild laundry detergent in warm or

cold water and air or machine dried at the lowest heat level. Store in

a cool, dry place, protected from exposure to any direct light.

V. Labels/Identication/Inspection Records

a. All products should be inspected by the user thoroughly before

each use. Additional inspections by a competent person other than

the user should be conducted at intervals of no less than one year.

That interval should be shortened any time the product is used in a

harsh environment or is exposed to conditions such as chemicals,

abrasion, heat or any other factor that could affect the strength of

any of the materials or components.

b. The lanyard labels provide an inspection grid to record these

inspections by a competent person. Use a punch or permanent

marker to record those dates.

ENGLISH

Page 10

c. This manual should always accompany the product or be on le with

the employer for access when needed. Record the identication

details for the lanyard and record the inspections in the inspection

log, on page 13. It is important to keep this log current, complete,

and available as needed.

Page 11

front back

Id label

ENGLISH

Page 11

Page 12

front back

Inspect label

ENGLISH

Page 12

Warning label front / back

Page 13

VI. Equipment Record

PART NUMBER

SERIAL NUMBER

DATE

MANUFACTURED

PURCHASE DATE

ASSIGNED TO

SPECIFICATIONS

Werner Co. POSITIONING LANYARDS

Certied to meet ANSI Z359.3-2007, and OSHA 1910 and 1926

standards and regulations for the lanyard component of a

complete personal fall arrest system. Lanyard webbing certied

minimum 6000 lb. breaking strength, all hardware certied to

5000 lb. breaking strength, 100 percent proof tested to 3600 lbs.

Individually bar coded model and serial numbers, location and date of

manufacture are on product label.

VII. Inspection Record

INSPECTION RECORD

DATE INSPECTOR PASS/FAILDATE INSPECTOR PASS/FAIL

Page 13

ENGLISH

Page 14

NOTES

Page 15

cueRDAs De PosicionAMiento

INSTRUCCIONES PARA EL USUARIO

¡PRECAUCIÓN!

Si el uso de equipos de protección contra caídas es necesario, entonces el

ambiente de trabajo es peligroso y potencialmente mortal. Los productos

Werner Co. están diseñados para eliminar peligros tanto como sea posible

pero SÓLO si estos productos se utilizan correctamente. Utilice este equipo

ya que éste fue diseñado para usarse, utilice este equipo después de una

capacitación apropiada, bajo la supervisión directa de una persona calicada,

de acuerdo con las instrucciones suministradas, y de acuerdo con las

regulaciones OSHA y las regulaciones de seguridad locales. El usuario DEBE

leer y entender todas las precauciones e instrucciones. No tener en cuenta

estas directrices podría resultar en lesiones o incluso la muerte. ¡TRABAJE

DE MANERA SEGURA! ¡TRABAJE DE MANERA INTELIGENTE!

Página 2

ESPAÑOL

Page 16

Contenido

ADVERTENCIAS .................................................................................................. 4

I. ANTES DE UTILIZAR LAS CUERDAS SALVAVIDAS

a. Inspeccione .............................................................................................................4

b. Compatibilidad ........................................................................................................6

c. Resistencia del anclaje ..........................................................................................6

d. Alturas libres ...........................................................................................................7

e. Plan de rescate .......................................................................................................7

f. Capacitación ...........................................................................................................7

II. DESCRIPCIONES DE LAS CUERDAS SALVAVIDAS

a. Cuerdas salvavidas para el evitamiento de caídas o

cuerdas salvavidas de posicionamiento ..............................................................7

b. Cuerdas salvavidas de posicionamiento en barras de refuerzo ........................8

III.CONEXIONES

a. Conexión con un arnés - Cuerda de posicionamiento estándar ........................8

b. Conexión con un arnés - Cuerda de posicionamiento en barra de refuerzo ....8

c. Conexión con un anclaje - Cuerda de posicionamiento estándar .....................8

d. Conexión con un anclaje - Cuerda de posicionamiento en barra de refuerzo ..9

IV. TENGA EN CUENTA LAS ADVERTENCIAS, RESTRICCIONES Y

PRECAUCIONES

a. Anclajes adecuados ...............................................................................................9

b. Distancia de caída ..................................................................................................9

c. Caída tipo columpio ...............................................................................................9

d. Capacidad ...............................................................................................................9

e. Peligros ambientales ..............................................................................................9

f. Componentes/Subsistemas .................................................................................10

g. Cuidado y almacenamiento .................................................................................10

V. ETIQUETAS/IDENTIFICACIÓN/REGISTROS DE INSPECCIÓN ................... 11

VI. REGISTROS DE EQUIPOS ........................................................................... 14

VII. REGISTRO DE INSPECCIÓN ...................................................................... 14

ESPAÑOL

Página 3

Page 17

cueRDAs De PosicionAMiento

INSTRUCCIONES PARA EL USUARIO

Advertencia:

Este producto es sólo una parte de un sistema personal de detención de caídas,

posicionamiento para el trabajo, limitación de recorrido, ascenso o rescate.

Éste debe combinarse correctamente con otros componentes para conformar

un sistema completo y funcional. El usuario debe entender la función de

cada uno de estos componentes y seguir las instrucciones del fabricante

para el uso de cada componente. Las normas ANSI y OSHA exigen que una

persona calicada suministre capacitación sobre el uso de estos productos. El

usuario debe recibir estas instrucciones, debe leerlas y seguirlas, y luego debe

consultar a la persona calicada que supervisará su trabajo si tiene alguna

pregunta acerca de cualquier parte de las instrucciones. El empleador debe

proporcionar capacitación sobre el uso apropiado, inspección y mantenimiento

de todos los componentes del sistema, y estas instrucciones pueden utilizarse

como parte de esa capacitación. El equipo SÓLO debe utilizarse de acuerdo

con estas instrucciones, ordenanzas y códigos locales, las normas OSHA y ANSI

aplicables, y el plan de seguridad del empleador.

SI USTED TIENE ALGUNA PREGUNTA ACERCA DE ALGO DE ESTAS

INSTRUCCIONES, EL EQUIPO O EL USO APROPIADO DEL EQUIPO,

COMUNÍQUESE CON WERNER CO. PARA OBTENER MÁS INFORMACIÓN.

I. Antes de utilizar la cuerda

Antes de utilizar este equipo, el usuario debe realizar ciertos pasos para

garantizar que éste está en buenas condiciones y es seguro para su uso.

Algunas cuerdas salvavidas se fabrican con Correa Tejida Inspeccionable

WebAlert exclusiva de Werner Co. que está diseñada para facilitar estas

inspecciones. La correa tejida WebAlert tiene un color interno contrastante

que hará más visibles las cortaduras o desgastes. La aparición del color

interno de la WebAlert indica que el producto debe recibir una inspección

adicional por parte de una persona calicada antes de continuar su uso. Si la

persona calicada determina que el componente o correa tejida afectada ha

perdido resistencia, entonces ese producto debe retirarse inmediatamente del

servicio.

a. Inspeccione

Examine completamente todo el equipo, diariamente antes del uso, y

periódicamente por parte de una persona calicada que no sea el usuario.

Verique la condición de cada componente. Si se encuentra cualquier daño,

anormalidad o desgaste excesivo, la cuerda debe retirarse del servicio.

1. Revise las correas tejidas en busca de cortaduras, abrasión,

quemaduras, salpicadura de soldadura, o decoloración que

pudiera haberse causado por exposición a productos químicos. La

característica WebAlert de las correas tejidas, en algunos modelos,

ESPAÑOL

Página 4

Page 18

está diseñada para facilitar la detección de estos daños. Si se

observa cualquier anormalidad, revise adicionalmente doblando la

correa tejida para exponer la irregularidad y determinar la gravedad

de la anormalidad.

2. Para los tramos de cuerda/cable, examine toda la longitud en busca

de cualquier rotura y examine los acoples forjados en busca de

cualquier irregularidad.

3. Revise toda la costura en busca de hilos rotos.

4. Revise todos los herrajes en busca de grietas, dobladuras,

irregularidades, corrosión o bordes losos. Revise los ganchos de

cierre resortado para vericar el funcionamiento sin problemas.

El liberador de enganche del cierre del gancho es visible para

inspeccionabilidad. Verique que el mecanismo no tiene daños y está

funcionando correctamente.

CUANDO ESTÁ EN USO,

EL CIERRE DEBE QUEDAR

CERRADO Y ASEGURADO

LOCKED UNLOCKEDTWIST

ASEGURADO GIRE DESASEGURADO ASEGURADO DESASEGURADO ASEGURADO DESASEGURADO

LOCKED UNLOCKED LOCKED UNLOCKED

5. Revise todas las piezas plásticas en cuanto a daños o grietas. Si

se encuentra cualquier anormalidad, el producto debe retirarse del

servicio.

6. Verique que todas las etiquetas están en su sitio y son legibles.

Pueden encontrarse ejemplos de etiquetas en la sección IV de estas

instrucciones.

Si se encuentran anormalidades en alguna de estas áreas, entonces

debe consultarse a la persona capacitada para que determine si ese

elemento es seguro para continuar su uso o si debe retirarse del servicio.

Advertencia:

No se permite ninguna alteración ni modicación de ningún equipo de

protección contra caídas, por ningún motivo, a menos que sea autorizado por

escrito por Werner Co.

ESPAÑOL

Página 5

Page 19

cueRDAs De PosicionAMiento

INSTRUCCIONES PARA EL USUARIO

b. Compatibilidad

Verique la compatibilidad de todos los

subsistemas que se están utilizando.

Los productos Werner conectados con

productos Werner son compatibles, pero

la conexión con otros productos debe

vericarse en cuanto a compatibilidad

para garantizar que no hay posibilidad de desconexión accidental por carga

lateral, rodaje, cierres no-estándares, etc.

CONEXIONES INAPROPIADAS

A. B.

NO! NO! NO! NO!

D. E. F.

c. Resistencia del anclaje

CONEXIONES APROPIADAS

C.

NO!NO!NO!NO!

Verique que los anclajes elegidos son apropiados.

1. Para el evitamiento de caídas (donde no hay posibilidad de desconexión

accidental), los anclajes deben soportar una carga estática de 3000

lbs por cada usuario conectado (13.3kN), o ser certicados por una

persona calicada para poder soportar dos veces la fuerza previsible.

2. Para los sistemas de puesta en posición, la resistencia mínima de los

anclajes debe ser de 3000 lbs por cada usuario conectado (13.3 kN), o

ser certicados por una persona calicada para una resistencia de dos

veces la fuerza previsible.

3. Para los sistemas de rescate, los anclajes deben soportar una carga

estática de 3000 lbs por cada usuario conectado (13.3kN) o ser

certicados por una persona calicada para cinco veces la carga

previsible.

ESPAÑOL

Página 6

Page 20

d. Altura libre

1. Verique que existe una altura libre adecuada debajo del área de

trabajo, y que no hay objetos ni obstrucciones debajo del área trabajo

que el usuario pudiera contactar en caso de una caída.

2. Para las aplicaciones de posicionamiento, las cuerdas salvavidas

deben instalarse para limitar la caída libre a no más de 61 cm (2 pies).

Para situaciones donde la caída libre pudiera exceder 61 cm (2 pies),

debe utilizarse un sistema de detención de caídas como respaldo. Se

recomienda utilizar un sistema de detención de caídas en conjunto

con las cuerdas salvavidas de posicionamiento en barra de refuerzo

para proteger el usuario en caso que el sistema de posicionamiento se

desenganche del punto de anclaje.

e. Plan de rescate

Si un trabajador cae y queda obligado a permanecer suspendido durante

cualquier período de tiempo, podría producirse daño físico o incluso la

muerte. Por este motivo, Werner Co., las regulaciones de OSHA, ANSI, CSA,

y la mayoría de las regulaciones locales exigen la existencia de un plan de

rescate y los medios para ejecutar un plan de rescate, antes del uso de este

equipo.

f. Capacitación

Las regulaciones OSHA, ANSI, y la mayoría de las regulaciones locales

exigen que los trabajadores que utilizan este producto reciban capacitación

adecuada por parte de una persona calicada, antes del uso de este

producto. Estas instrucciones y su contenido completo deben ser parte de

esa capacitación.

II. Descripciones de las cuerdas salvavidas

Las cuerdas salvavidas tienen una variedad de tipos de herrajes de conexión

y tipos de tramos de cuerda dependiendo de su uso pretendido. Utilice el tipo

de cuerda que sea apropiado para el trabajo que se realizará.

a. Cuerdas salvavidas para el evitamiento de caídas o cuerdas salvavidas

de posicionamiento

Sin ningún elemento contra choque ni otro mecanismo para la absorción

de energía, estas cuerdas salvavidas no quedan incluidas en los requisitos

de desempeño dinámico de las normas OSHA y ANSI para las cuerdas

salvavidas absorbedoras de energía. Sin absorción de energía, estas

cuerdas salvavidas sólo deben utilizarse para posicionamiento/

ESPAÑOL

Página 7

evitamiento de caídas, ya sea cuando no hay posibilidad de caída o

para evitar que los trabajadores lleguen a tener un peligro de caída.

Page 21

cueRDAs De PosicionAMiento

INSTRUCCIONES PARA EL USUARIO

Las cuerdas salvavidas Werner Co. pueden tenerse con una variedad de

conectores diferentes, de acuerdo con el uso pretendido. Los diferentes tipos

de cuerdas salvavidas son:

1. Correa tejida

Correa tejida inspeccionable WebAlertcon bras internas rojas.

i. Longitud estándar. Longitudes de 2', 3', 4', 5' y 6' (0.61 m, 0.91 m,

1.22 m, 1.5 m y 1.83 m).

ii. Longitud ajustable con hebilla ajustadora adicional que hace posible

la reducción de la longitud total de la cuerda en situaciones con

alturas libres reducidas.

2. Cable

El cable es resistente a la salpicadura de soldadura, y el recubrimiento

de vinilo proporciona resistencia a la abrasión y facilita la inspección

de áreas dañadas. Revise en busca de daño, retorcimientos o hilos

rotos. Disponible en longitudes de 2', 3', 4' y 6' (0.61 m, 0.91 m, 1.22 m

y 1.83 m)

b. Cuerdas salvavidas de posicionamiento en barras de refuerzo

Estas cuerdas salvavidas están diseñadas para utilizarse como parte de un

sistema de posicionamiento de trabajo que soporta el usuario en un lugar

de trabajo en aplicaciones tales como conjuntos de barras de refuerzo de

concreto. Éstas están diseñadas para tener un (1) tramo sujetado a cada

lado/anillo “D” de cadera de un arnés de usuario, y el tercer tramo sujetado a

un anclaje de posicionamiento de trabajo apropiado. Las cuerdas salvavidas

están disponibles en correa tejida o materiales de cadena.

III. Conexiones

a. Conexión con un arnés - Cuerda de posicionamiento estándar

Conecte la cuerda al anillo en “D” trasero para detención de caída general. El

extremo de la cuerda con etiquetas debe conectarse al anillo en “D” trasero

del arnés.

b. Conexión con un arnés - Cuerda de posicionamiento en barra de

refuerzo

Conecte cada uno de los ganchos de cierre resortado estándares con cada

uno de los anillos en “D” de cadera/laterales del arnés.

c. Conexión con un anclaje - Cuerda de posicionamiento estándar

Conecte el extremo opuesto de la cuerda con un anclaje o conector de anclaje

vericando que la conexión se realice con componentes compatibles.

ESPAÑOL

Página 8

Page 22

d. Conexión con un anclaje - Cuerda de

Full Body Harness

Connecting

Anchorage Connector

Anchorage

FALL ARREST

Full Body Harness

Full Arrest System

Anchorage Connector

Anchorage

Connector

Restraint

Lanyard

Anchorage

Anchorage

WORK POSITION

Full Body Harness

Cable

Cable Sleeve

Ladder

CLIMBING

Full Body Harness

Seat Board

Full Arrest System

Anchorage Connector

Anchorage

Connector

Suspension Lin

e

Anchorage

Anchorage

PERSONNEL RIDING

Full Body Harness

Restraint Lanyard

Anchorage Connector

Anchorage

RESTRAINT

posicionamiento en barra de refuerzo

Conecte el gancho de la cuerda para barras

de refuerzo con la intersección de la barra de

refuerzo horizontal y vertical.

IV. Tenga en cuenta las advertencias,

restricciones y precauciones

a. Anclajes adecuados

Para las operaciones de posicionamiento, OSHA exige resistencias de

anclaje de 3000 lbs o dos veces la carga esperada máxima si el anclaje

ha sido certicado por una persona calicada. El uso de algún anclaje que

tenga una resistencia inadecuada podría resultar en lesiones o la muerte.

ESPAÑOL

b. Distancia de caída

Para las aplicaciones de posicionamiento para trabajo, la distancia de caída

posible no puede ser superior a 61 cm (dos pies). Si existe la posibilidad

de una caída superior a 61 cm (dos pies), debe utilizarse un sistema de

detención de caídas como respaldo.

c. Caídas tipo columpio

Verique que no existe la posibilidad

de un impacto por caída tipo columpio.

Las caídas tipo columpio ocurren

cuando el usuario no está directamente

debajo del anclaje, de modo que si

el usuario cae, su balanceo podría

producir un impacto con un objeto.

d. Capacidad

La capacidad máxima para todas las

cuerdas salvavidas Werner es 310 lbs

(140.6 kg) para el peso combinado de un trabajador y todas las herramientas.

Para cualquier peso superior a 310 lbs (140.6 kg), comuníquese con Werner

Co. para obtener más información. El empleador debe garantizar que todos

los otros elementos del sistema de protección contra caídas son apropiados

para soportar cualquier peso superior.

e. Peligros ambientales

Este equipo sólo debe utilizarse bajo la supervisión directa de una persona

capacitada que pueda identicar los peligros que deben evitarse, incluyendo

los elementos eléctricos y productos químicos, maquinaria y otros objetos

móviles, bordes losos, estructuras o anclajes dañados o cualquier otro

elemento en el sitio de trabajo que pudiera dañar este equipo o evitar que

funcione según lo previsto.

Anchorages

Anclajes

Correcto Incorrecto

CorrectIncorrect

PELIGRO DE CAÍDA

SWING FALL

TIPO COLUMPIO

HAZARD

Página 9

Page 23

cueRDAs De PosicionAMiento

INSTRUCCIONES PARA EL USUARIO

f. Componentes/Subsistemas

Antes del primer uso, una persona calicada debe inspeccionar y decidir que

todos los componentes y subsistemas son compatibles y que funcionarán

correctamente en combinación con un sistema personal completo de

protección contra caídas. Consulte la información en estas instrucciones, y

si se requiere cualquier información adicional, comuníquese directamente

con Werner Co.

g. Cuidado y almacenamiento

El producto puede limpiarse utilizando un detergente suave de lavado de

ropa en agua tibia o fría y secarse al aire o en máquina al nivel de calor más

bajo. Guarde en un lugar fresco y seco protegido de la exposición a cualquier

luz directa.

V. Etiquetas/Identicación/Registros de inspección

a. Todos los productos deben ser inspeccionados completamente por el

usuario antes de cada uso. Una persona calicada, diferente al usuario,

debe realizar inspecciones adicionales en intervalos no inferiores a un (1)

año. Ese intervalo debe acortarse cada vez que el producto se utiliza en

un ambiente agresivo o se expone a condiciones tales como productos

químicos, abrasión, calor o cualquier otro factor que pudiera afectar la

resistencia de cualquiera de los materiales o componentes.

b. Las etiquetas de las cuerdas salvavidas proporcionan una tabla de inspección

para registrar estas inspecciones por parte una persona calicada. Utilice un

punzón o marcador permanente para registrar estos datos.

c. Este manual siempre debe acompañar el producto o estar en los archivos

del empleador para consultarlo cuando se requiera. Registre los detalles

de identicación para la cuerda y registre las inspecciones en el registro de

inspección mostrado en la página 13. Es importante mantener este registro

actualizado, completo y disponible según se requiera.

Página 10

ESPAÑOL

Page 24

ESPAÑOL

Página 11

parte delantera parte trasera

Etiqueta de identicación

Page 25

cueRDAs De PosicionAMiento

INSTRUCCIONES PARA EL USUARIO

Etiqueta de

inspección

parte delantera parte trasera

Parte delantera / trasera de

etiqueta de advertencia

ESPAÑOL

Página 12

Page 26

VI. Registro de equipos

NÚMERO DE

PIEZA

NÚMERO DE SERIE

FECHA DE

FABRICACIÓN

FECHA DE COMPRA

ASIGNADO A

ESPECIFICACIONES

CUERDAS DE POSICIONAMIENTO de Werner Co.

Certicadas para cumplir las regulaciones y normas Z359.3-2007 y OSHA

1910 y 1926 para los componentes de cuerdas de sistemas personales

completos de detención de caídas. La correa tejida de la cuerda está

certicada para una resistencia a la rotura de 6000 lb. como mínimo, todos

los herrajes están certicados para una resistencia a la rotura de 5000 lb.,

100% probados para 3600 lbs.

Los números de modelo y números de serie, sitio y fecha de fabricación, con

código de barras individual, están en la etiqueta del producto.

VII. Registro de inspección

REGISTRO DE INSPECCIÓN

FECHA INSPECTOR APROBADO/

NO-APROBADO

FECHA INSPECTOR APROBADO/

NO-APROBADO

ESPAÑOL

Página 13

Page 27

NOTAS

Page 28

Lanyard Model Numbers Included

Se incluyen los números de modelo de arneses

C111102

C111103

C111104

C111105

C111106

C111203

C111204

C161102

C161103

C161104

C161106

C191203

C191204

C111206

C111506

C113106

724-588-2000 • 888-523-3371 toll free • 888-456-8458 fax

PN103764-01 ©2011 Werner Co. 11/11

Werner Fall Protection

93 Werner Rd. Greenville, PA 16125

Loading...

Loading...