Page 1

V1.2

OPERATION AND INSTRUCTION MANUAL

10,000-lbf (44kN)

Hybrid Swivel Anchor Model: A510002

IMPORTANT!!!

ALL PERSONS USING THIS EQUIPMENT MUST READ AND UNDERSTAND ALL INSTRUCTIONS.

FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY OR DEATH. USERS SHOULD BE FAMILIAR

WITH PERTINENT REGULATIONS GOVERNING THIS EQUIPMENT. ALL INDIVIDUALS WHO USE

THIS PRODUCT MUST BE PROPERLY INSTRUCTED ON HOW TO USE THIS DEVICE.

Page 2

Read This Instruction Manual Carefully Before Using This Equipment.

User Instructions must always be available to the user and are not to be removed except by the user of this equipment. For prop

User Instructions, or contact the manufacturer.

er use, see supervisor,

WARNING

Compliant fall protection and emergency rescue systems help prevent serious injury during fall arrest. Users and purchasers of this equipment must

read and understand the User Instructions provided for correct use and care of this product. All users of this equipment must understand the instructions, operation, limitations and consequences of improper use of this

1926.503 or applicable local standards. Misuse or failure to follow warnings and instructions may result in serious personal injury or death.

PURPOSE

The

A510002

access, or rescue system for the purpose of coupling the system to the anchorage. Any references to “anchorage connector” in this manual include, and

apply to, the

USE INSTRUCTIONS

1910.66 in the safe use of the system and its components.

2. Use only with ANSI/OSHA compliant personal fall arrest or restraint systems. The anchorage must have the strength capable

of supporting a static load, applied in the directions permitted by the system, of at least 10,000-lbf (44kN) in the

& opera

may result in serious personal injury or death.

4. The anchorage connector must be inspected prior to each use for wear, damage, and other deterioration. If defective

components are found the anchor connector must be immediately removed from service, in accordance with the requirements

of OSHA 29 CFR 1910.66 and 1926.502.

5. The complete fall protection system must be planned (including all components, calculating fall clearance, and swing fall)

before using.

6. A rescue plan, and the means at hand to implement it, must be in place that provides the prompt rescue of users in the

event of a fall, or assures that users are able to rescue themselves.

7. After a fall occurs, anchorage connector must be removed from service and destroyed immediately.

USE LIMITATIONS

system that will limit the maximum arrest force of the user to 1,800-lbf or less. The anchorage conn

maximum capacity of one 310-lbs (140kg) user including clothing, tools, etc. when used as part of an ANSI Z359 compliant fall

protection system.

2. The

3.

4. Do not expose the

5. Do not alter or modify this product in anyway.

6. Caution must be taken when using any component of a fall protection, work positioning, rope access, or rescue system

moving machinery, electrical hazards, sharp edges, or abrasive surfaces, as contact may cause equipment failure, personal

injury, or death.

7. Do not use/install equipment without proper training by a “competent person” as defined by OSHA 29 CFR 1926.32(f).

8. Do not remove the labeling from this product.

9. Additional requirements and limitations may apply depending on anchorage type and fastening option utilized for

personal injury or death.

COMPATIBILITY LIMITATIONS

All anchor connectors must only be coupled to compatible connectors. OSHA 29 CFR 1926.502 prohibits snaphooks from being engag

objects unless two requirements are met: it must be a locking type snaphook, and it must be “designed for” making such a connec

means that the manufacturer of the snaphook specifically designed the snaphook to be used to connect to the equipment listed. The following

connections must be avoided, because they can result in rollout* when a nonlocking snaphook is used:

• Direct connection of a snaphook to horizontal lifeline.

• Two (or more) snaphooks connected to one D-ring.

• Two snaphooks connected to each other.

• A snaphook connected back on its integral lanyard.

• A snaphook connected to a webbing loop or webbing lanyard.

• Improper dimensions of the D-ring, rebar, or other connection point in relation to the snaphook dimensions that would allow the

snaphook keeper to be depressed by a turning motion of the snaphook.

*Rollout: A process by which a snaphook or carabiner unintentionally disengages from another connector or object to which it is coupled.

(ANSI Z359.1-2007)

MAINTENANCE, CLEANING AND STORAGE

Cleaning periodically will prolong the life and proper functioning of the product. The frequency of cleaning should be determined by inspection and by

chemicals that could damage the product. Wipe all surfaces with a clean dry cloth and hang to dry, or use compressed air. When

age connectors in a cool, dry, clean environment, out of direct sunlight and free of corrosive or other degrading elements.

is an anchorage connector designed to function as an interface between the anchorage and a fall protection, work positioning,

A510002.

1. Before using a personal fall arrest system, user must be trained in accordance with the requirements of OSHA 29 CFR

tional characteristics of the selected installation location and system to be connected to this anchor. Improper use

1. Max Capacity: One user/worker maximum weight of 400-lbs when used as a single point anchorage connector in a fall arrest

anchorage connector

The Anchorage connector

may be pulled in any direction.

is designed to be used in temperatures ranging from -40ºF to +130ºF (-40°C to +54°C).

anchorage connector

equipment and be properly trained prior to use per OSHA 29 CFR 1910.66 and

rope

ural

ector has a capacity of

anchorage requirements in

chorage connector will have a

near

Improper use may result in serious

ed to certain

tion. “Designed for”

Do not use any corrosive

not in use, store anchor-

Werner co. / 93 Werner Rd., Greenville, PA 16125 / 1-(888)-523-3371 / www.wernerco.com

Page 3

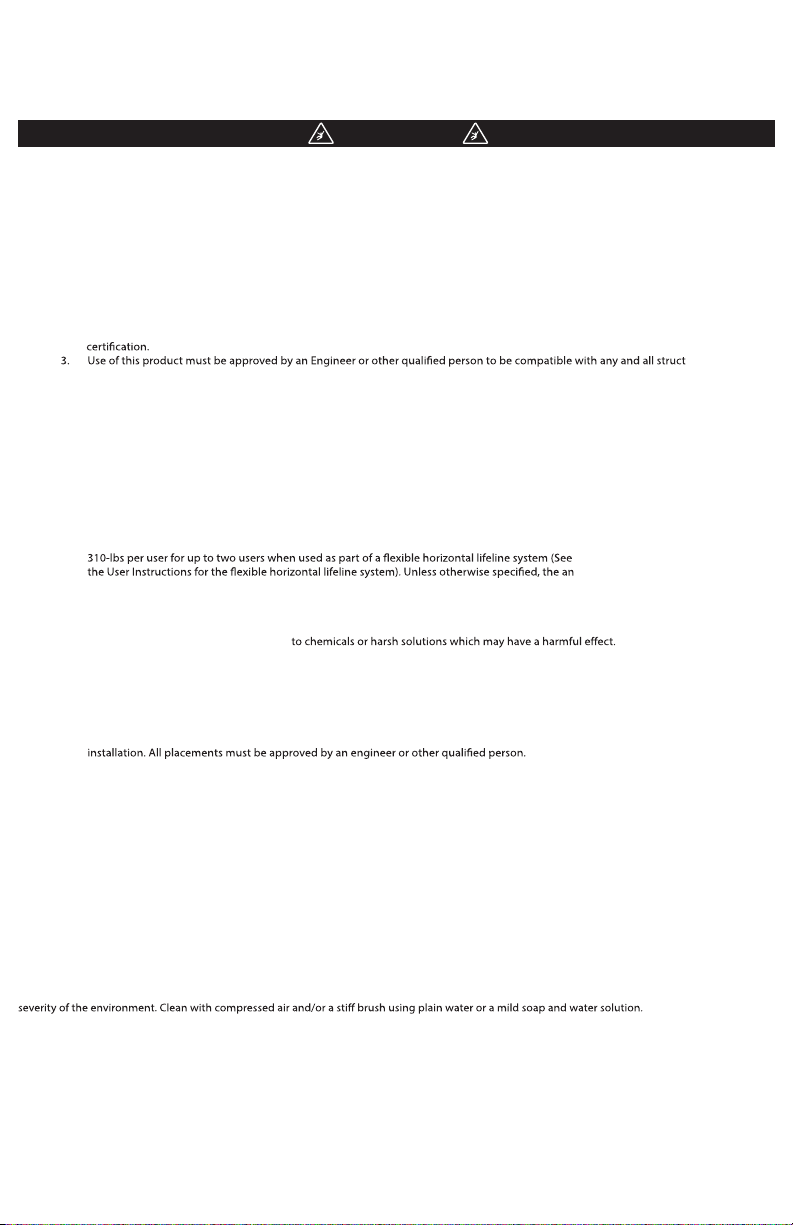

10k Hybrid Anchor

Zinc Plated Steel

Max Capacity:

(1) person 400-lbs

WARNING: All persons using this equipment must read,

understand and follow all instructions. Failure to do so may

result in serious injury or death.

COMPLIANCE: OSHA 1910.66 & 1926.502 ANSI Z359.1-07

Z359.7-11

(INSPECT BEFORE USE)

Tensile Strength (UTS): 10,000-lbf (44kN)

Maximum Capacity: See “Use Limitations”

Weight: 2.0-lbs (949g)

Regulatory Compliance

ANSI Z359.1-2007, ANSI Z359.7-2011

OSHA 1910.66 , 1926.502

Model: A510002

1-(888)-523-3371

2.25”ø

(57.15mm)

5.5”

(139.7mm)

3.0”

(76.2mm)

Compression Bushing: Polyethylene.

Retaining Bushing: Zinc Plated Steel.

Cone: Stainless Steel.

Spoons: Stainless Steel.

Compression

Bushing

Retaining

1.0”

(25.4mm)

Bushing

COMPONENT MATERIALS:

Bolt: Zinc Plated Steel.

Sleeve: Zinc Plated Steel.

Return Wire: Aircraft Cable.

Swivel: Zinc plated steel.

(15.88cm)

Cable

6-1/4”

Bolt

Sleeve

Spoon

Cone

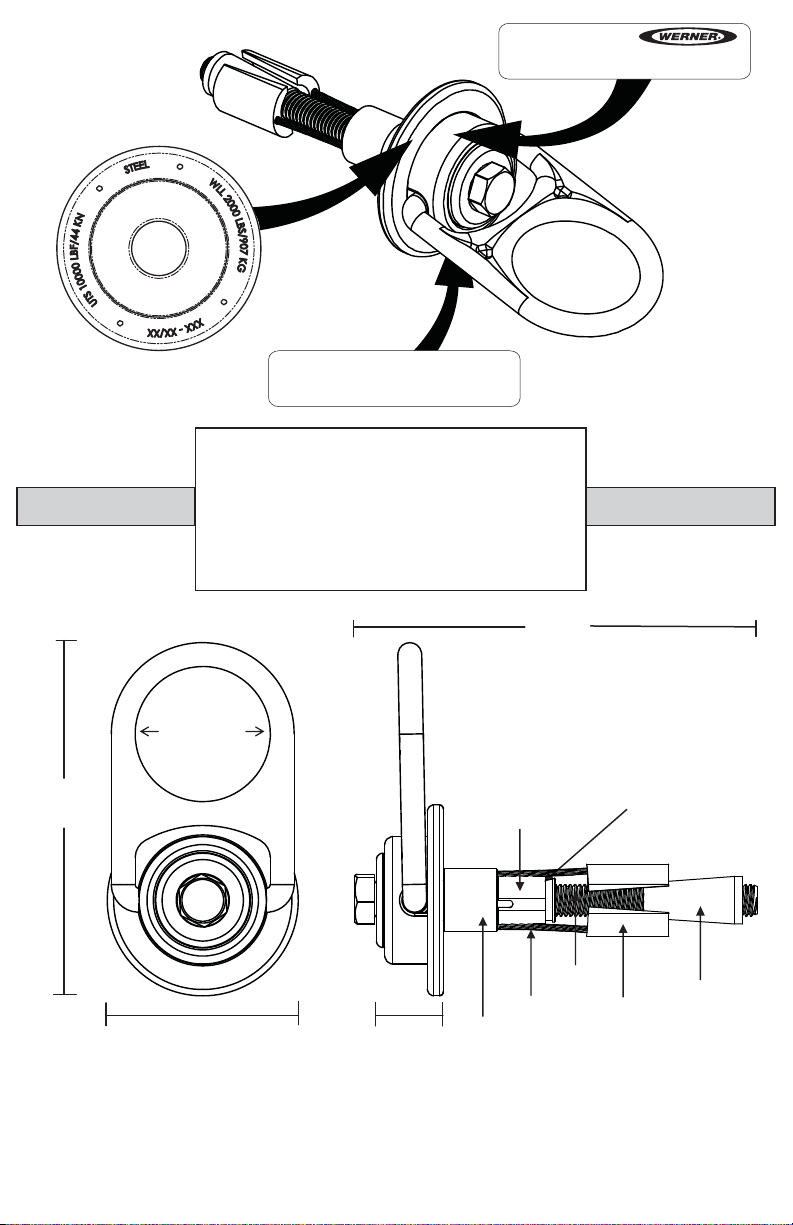

Page 4

8.0”ø

180°

(203.2mm)

360°

LOADING CONDITIONS DIAGRAM

LOAD

LOAD

ACCEPTABLE ACCEPTABLE

LOAD

LOAD

IMPROPERACCEPTABLE

DRILLING :

1. Use a hammer drill (SDS), drill a 1” (25mm) diameter hole at least 5” (127mm) deep.

The drilled hole must be straight and perpendicular to the surface. Make sure the hole

is of uniform diameter and free of peaks and valleys on the inner wall. See diagram

below

2. Blow hole clean with compressed air.

3. Refer to the diagram below for hole location and requirements.

4. Always inspect the hole carefully when reusing a previously drilled hole.

Hole to Edge:

min

10”

(25.4cm)

rom any ed

f

e

g

6”min

(15.24cm)

Section View:

Drill 1ӯ

(2.54cm)

1”min

(2.54cm)

5” min

depth

(12.7cm)

Page 5

Check for kinked

or frayed cables.

Look for signs

of wear on

spoons.

INSPECT BEFORE USE

Check for deformation

of cone.

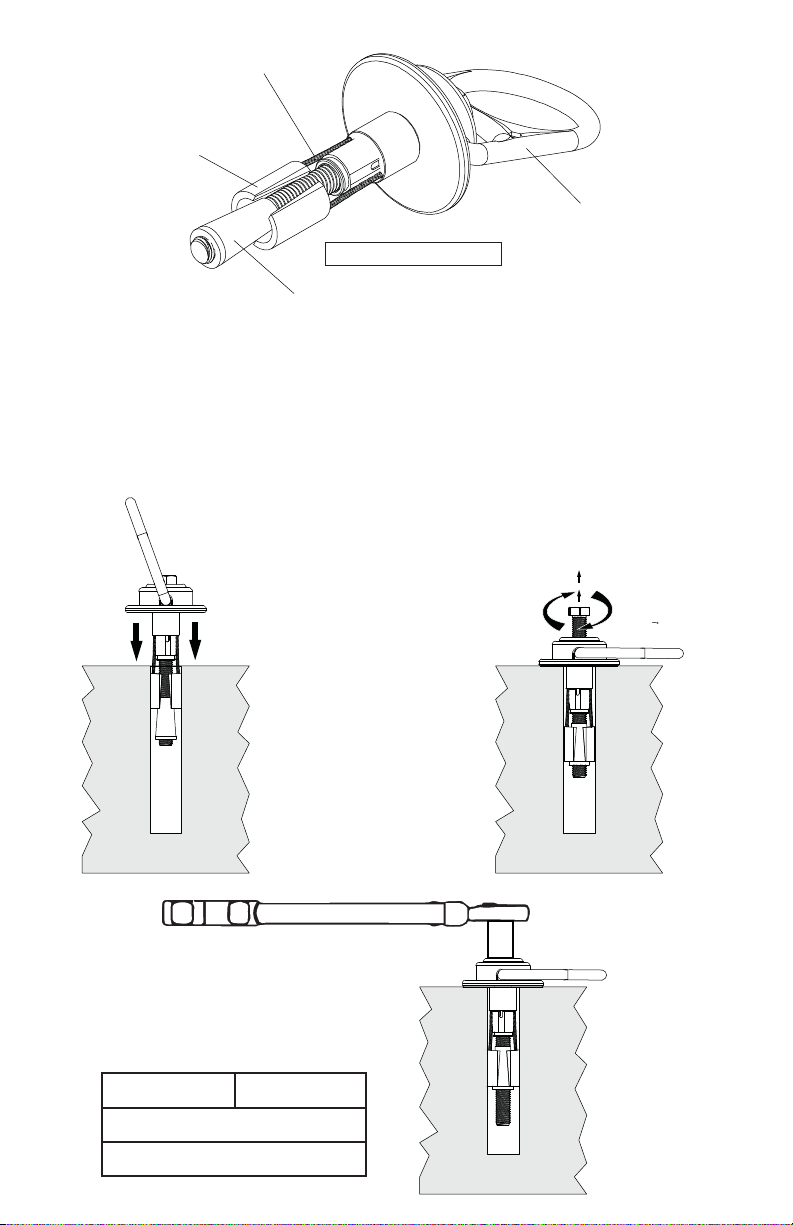

INSTALLATION:

1. Before installing make sure the

cone is below the spoons. Insert

the anchor into hole so the base

plate rest at on the concrete

surface.

Drop In

Swivel should

move freely.

2. Pull up on the bolt while holding

swivel ush with the concrete.

Tighten the bolt by turning it

clockwise by hand until bolt is

fastened ush to swivel.

Step 1.

3. Use a torque wrench to set the

pretension on the bolt for the

loading situation required for

the application.

LOAD: BOLT TORQUE:

10,000-lbf

(44 kN)

5,000-lbf

(22 kN)

85-ft-lbs

(9.60 Nm)

30-ft-lbs

(3.38 Nm)

Step 3.

Pull Up

Bolt &

Step 2.

Twist

Clockwise

Page 6

REMOVAL:

1. Loosen bolt so that at least 3/4”

(1.9cm) of threads are exposed.

Unscrew

min of

3/4”

(1.9cm)

2. Use a hammer to tap down bolt

and disengage cone from the

spoons.

Step 1.

TAP!!!

Step 2.

3. Pull the anchor from the hole.

Pull UP

Step 3.

Page 7

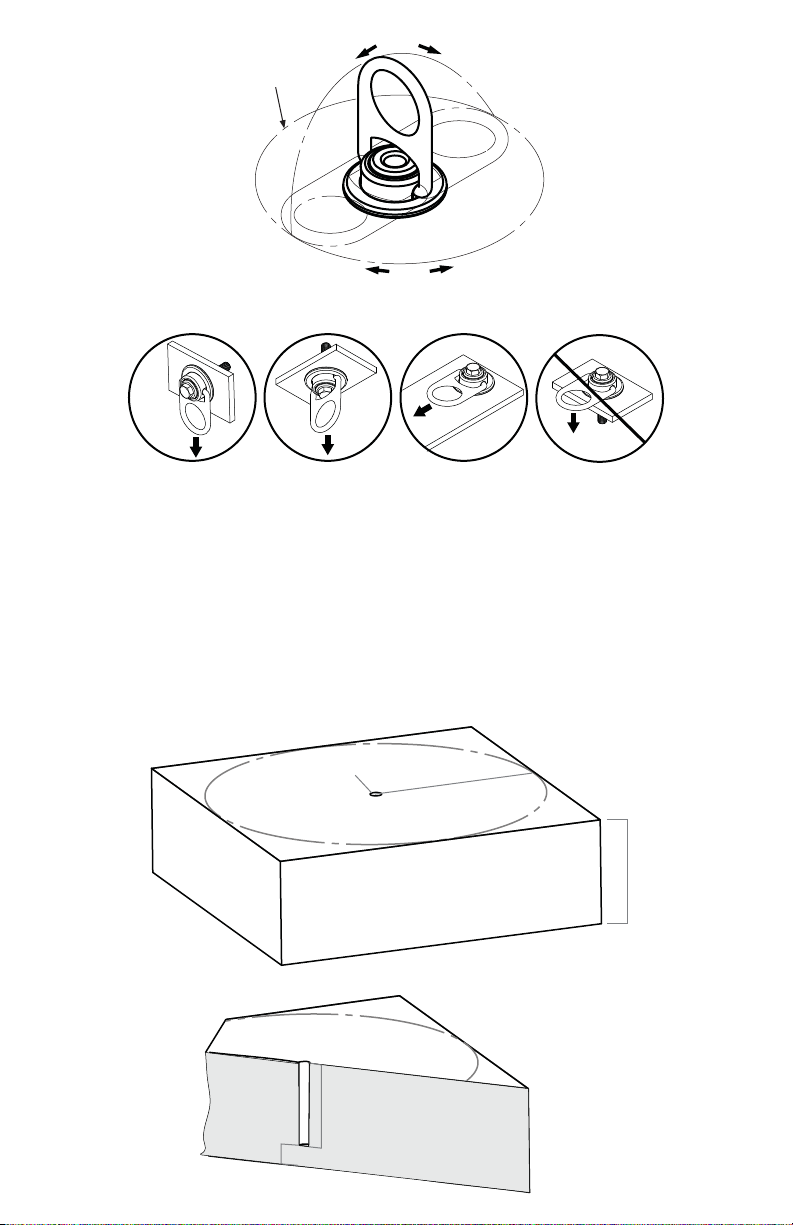

May be used as a anchoring point for a leading

edge restraint system. Examples are of optional

anchoring point locations. The use of two anchors

is for illustration purposes only and

is not required for leading edge restraint systems

OPTIONAL

(ANCHOR POINTS)

WORK SURFACE

(ANCHOR POINT)

The concrete must be

3000-psi or higher and

fully cured. Installation

location to be approved

WORK SURFACE

Free fall distance (limit) must

not exceed 6’ ft (1.8 m). Refer

to connecting device

documentation for proper

usage and limitations.

MINIMUM CLEARANCE 3ft (1m)

DECK/FLOOR/GROUND LEVEL

All products subjected to fall arresting forces should be removed

from service immediately!

WARNING!!! SWING FALLS CAN OCCUR WHEN THE WORKER IS NOT DIRECTLY UNDER ANCHOR POINT.

PN200417 ©2013 Werner Co. 10/13

Page 8

INSPECTION AND MAINTAINANCE LOG

MODEL NUMBER:

DATE OF MANUFACTURE:

Dat e

s

m

muN tr

aP

reb

C

tnem

o

Inspector Name

Inspection:

conditions exist then inspections must be carried out more frequently. All inspection

results must be logged in the space provided above.

1.

2.

3. Inspect anchoring system for signs of damage or wear to spoons or cone.

4. Make sure the unit can rotate 360°

5. When reusing a previously drilled hole, inspect for for debris or wallowing.

6. Record inspection results in the space provide above.

unsafe conditions are found, proper disposal is required. The anchor connector

must be rendered unusable and then properly discarded.

Page 9

V1.2

MANUAL DE OPERACIÓN E INSTRUCCIONES

10.000-lbf (44kN.)

Anclaje giratorio híbrido, Modelo: A510002

¡IMPORTANTE!!!

TODAS LAS PERSONAS QUE UTILIZAN ESTE EQUIPO DEBEN LEER Y ENTENDER TODAS LAS

INSTRUCCIONES. NO HACERLO ASÍ PODRÍA RESULTAR EN LESIONES GRAVES O LA MUERTE.

LOS USUARIOS DEBEN FAMILIARIZARSE CON LAS NORMAS PERTINENTES QUE REGULAN

ESTE EQUIPO. TODAS LAS PERSONAS QUE UTILIZAN ESTE PRODUCTO DEBEN RECIBIR

INSTRUCCIONES APROPIADAS SOBRE CÓMO UTILIZAR ESTE DISPOSITIVO.

Page 10

Antes de utilizar este equipo, lea cuidadosamente este manual de instrucciones

Las Instrucciones para el Usuario siempre deben estar disponibles para el usuario y no deben removerse excepto por el usuario de este

equipo. Para conocer el uso apropiado, hable con su supervisor, vea las Instrucciones para el Usuario, o comuníquese con el fabricante.

ADVERTENCIA

Los sistemas de protección contra caídas y de rescate de emergencia que cumplen las normas ayudan a evitar lesiones graves durante la detención de

caída. Los usuarios y compradores de este equipo deben leer y entender las Instrucciones para el Usuario suministradas para el uso y cuidado correctos

de este producto. Todos los usuarios de este equipo deben entender las instrucciones, operación, limitaciones y consecuencias del uso inapropiado de

este equipo, y deben recibir capacitación apropiada antes de su uso según las normas OSHA 29 CFR 1910.66 y 1926.503 o las normas locales aplicables.

El uso incorrecto o no seguir las advertencias e instrucciones podrían resultar en lesiones personales graves o la muerte.

PROPÓSITO

El A510002 es un conector de ancladero diseñado para funcionar como interconexión entre el ancladero y un sistema de protección contra caídas, de

posicionamiento de trabajo, de acceso mediante cuerda, o de rescate, con el n de acoplar el sistema al ancladero. Cualquier referencia al “conector

de ancladero” en este manual incluye, y se aplica a, el A510002.

INSTRUCCIONES DE USO

1. Antes de utilizar un sistema personal de detención de caídas, el usuario debe recibir capacitación, según los requisitos de

OSHA 29 CFR 1910.66, sobre el uso seguro del sistema y sus componentes.

2. Sólo utilice con sistemas personales de detención o evitamiento de caídas que cumplan con ANSI/OSHA. El ancladero debe tener

una resistencia capaz de soportar una carga estática, aplicada en las direcciones permitidas por el sistema, de al menos

10.000 lbf (44 kN) en ausencia de certicación.

3. El uso de este producto debe ser aprobado, por un Ingeniero u otra persona calicada, indicando que es compatible con

cualquiera y todas las características estructurales y operativas de la ubicación de instalación seleccionada y del sistema que se

conectará a este anclaje. El uso inapropiado podría resultar en lesiones personales graves o la muerte.

4. El conector de ancladero se debe inspeccionar antes de cada uso en cuanto a desgaste, daño y otro deterioro. Si se encuentran

componentes defectuosos, el conector de ancladero debe retirarse inmediatamente del servicio, de acuerdo con los requisitos

de OSHA 29 CFR 1910.66 y 1926.502.

5. Antes de utilizar, se debe planear el sistema completo de protección contra caídas (incluyendo todos los componentes,

calculando el espacio libre de caída y la caída tipo columpio).

6. Se debe tener un plan de rescate, y los medios disponibles para implementarlo, que permita el rescate rápido de los usuarios en

caso de una caída, o que garantice que los usuarios pueden rescatarse ellos mismos.

7. Después que ocurra una caída, el conector de ancladero se debe retirar del servicio y destruirse inmediatamente.

LIMITACIONES DE USO

1. Capacidad máx.: Un (1) trabajador/usuario con peso máximo de 181 kg (400 lbs) cuando se utiliza como conector de ancladero

de punto único para un sistema personal de detención de caídas que limitará la fuerza de detención máxima del usuario a

1.800 lbf o menos. El conector de ancladero tiene una capacidad de 140 kg (310 lbs) por usuario para hasta dos usuarios cuando

se utiliza como parte de un sistema de cuerda salvavidas horizontal exible). A menos que se indique de otra manera, el conector

de ancladero tendrá una capacidad máxima de un (1) usuario de 310 lbs (140 kg) incluyendo la ropa, herramientas, etc. cuando

se utiliza como parte de un sistema de protección contra caídas que cumple la norma ANSI Z359.

2. El conector de ancladero se puede halar en cualquier dirección.

3. El conector de ancladero está diseñado para utilizarse en temperaturas que varían desde -40ºF a +130ºF (-40°C a +54°C).

4. No exponga el conector de ancladero a productos químicos o soluciones agresivas que pudieran tener un efecto perjudicial.

5. No altere ni modique de ninguna manera este producto.

6. Debe tenerse cuidado al utilizar cualquier componente de un sistema de protección contra caídas, de posicionamiento de

trabajo, de acceso mediante cuerda, o de rescate, cerca de máquinas en movimiento, peligros eléctricos, bordes losos, o

supercies abrasivas, ya que el contacto podría causar la falla del equipo, lesiones personales o la muerte.

7. No utilice ni instale el equipo sin capacitación apropiada por parte de una “persona competente” según lo denido por

OSHA 29 CFR 1926.32(f).

8. No remueva las etiquetas de este producto.

9. Se podrían aplicar requisitos y limitaciones adicionales dependiendo del tipo de anclaje y opción de sujeción utilizada para la

instalación. Todas las ubicaciones deben ser aprobadas por un ingeniero u otra persona calicada. El uso inapropiado

podría resultar en lesiones personales graves o la muerte.

LIMITACIONES DE COMPATIBILIDAD

Todos los conectores de ancladero sólo se deben acoplar a conectores compatibles. OSHA 29 CFR 1926.502 prohíbe enganchar los ganchos de cierre

resortado a ciertos objetos a menos que se cumplan dos requisitos: éste debe ser un gancho de cierre resortado del tipo con seguro, y éste debe

estar “diseñado para” realizar dicha conexión. “Diseñado para” signica que el fabricante del gancho de cierre resortado diseñó especícamente el

gancho de cierre resortado para utilizarse para conectar al equipo indicado. Las siguientes conexiones se deben evitar, porque éstas pueden resultar

en desenganche accidental* cuando se utiliza un gancho de cierre resortado sin seguro:

• Conexión directa de un gancho de cierre resortado a una cuerda salvavidas horizontal.

• Dos (o más) ganchos de cierre resortado conectados a un (1) anillo en “D”.

• Dos ganchos de cierre resortado conectados entre sí.

• Un gancho de cierre resortado conectado de regreso sobre su correa sujetadora integral.

• Un gancho de cierre resortado conectado a un lazo tejido o correa sujetadora tejida.

• Las dimensiones inapropiadas del anillo en “D”, barra de refuerzo u otro punto de conexión en relación con las dimensiones del gancho

de cierre resortado que podrían permitir que el jador del gancho de cierre resortado sea presionado por un movimiento giratorio del gancho

de cierre resortado.

*Desenganche accidental: Un proceso mediante el cual un gancho de cierre resortado o argolla rectangular metálica se desengancha accidentalmente de

otro conector u objeto al cual está acoplado. (ANSI Z359.1-2007)

MANTENIMIENTO, LIMPIEZA Y ALMACENAMIENTO

La limpieza periódica alargará la vida útil y funcionamiento apropiado del producto. La frecuencia de la limpieza debe ser determinada por la

inspección y según la severidad del medio ambiente. Limpie con aire comprimido y/o un cepillo de cerdas rígidas utilizando agua común o una

solución suave de agua y jabón. No utilice ningún producto químico corrosivo que pudiera dañar el producto. Limpie frotando todas las supercies

con un trapo seco limpio, y cuelgue para secar; o utilice aire comprimido. Cuando no están en uso, almacene los conectores de ancladero en un

ambiente fresco, seco y limpio, fuera de la luz solar directa y libre de elementos corrosivos u otros elementos dañinos.

Werner co. / 93 Werner Rd., Greenville, PA 16125 / 1-(888)-523-3371 / www.wernerco.com

Page 11

Anclaje híbrido 10k

Acero enchapado en zinc

Capacidad máx.:

(1) persona 181kg (400-lbs)

ADVERTENCIA: Todas las personas que utilizan este equipo

deben leer, entender y seguir todas las instrucciones. No

hacerlo así podría resultar en lesiones graves o la muerte.

(INSPECCIONE ANTES DE UTILIZAR).

CUMPLIMIENTO: OSHA 1910.66 Y 1926.502 ANSI Z359.1-2007

Z359.7-2011 CE 0321 / EN 795:1996 (+A1:2000) Clase B

Resistencia a la tracción estática (UTS):

10,000-lbf (44kN)

Capacidad máxima: See “Use Limitations”

Peso: 2.0-lbs (949g)

Cumplimiento de normas:

ANSI Z359.1-2007, ANSI Z359.7-2011

Modelo: A510002

1-(888)-523-3371

2.25”ø

(57.15mm)

5.5”

(139.7mm)

3.0”

(76.2mm)

COMPONENT MATERIALS:

Buje de compresión: Polietileno

buje de retención: Acero enchapado en zinc

Cono: Acero inoxidable

Cuchara: Acero inoxidable

1.0”

(25.4mm)

6-1/4”

(15.88cm)

Perno

Manguito

Cuchara

Cono

Buje de

compresión

Cable

Buje de

retención

Perno: Acero enchapado en zinc

Manguito: Acero enchapado en zinc

Cable: Cable de avión

Pieza giratoria: Acero enchapado en zinc

Page 12

8.0”ø

180°

(203.2mm)

360°

CONDICIONES DE CARGA DIAGRAMA

Carga

ADMISIBLE

Carga

ADMISIBLE

Carga

ADMISIBLE

Carga

INCORRECTO

TALADRADO:

1. Utilice un taladro percutor (SDS), taladre un oricio de 1” (25 mm) de diámetro con una profundi

dad mínima de 5” (127 mm).

El oricio taladrado debe ser recto y perpendicular a la supercie. Verique que el oricio tiene

un diámetro uniforme y está libre

de picos y valles en la pared interior. Vea el siguiente diagrama de distancia del oricio al borde

2. Limpie soplando el oricio con aire comprimido.

3. Consulte el siguiente diagrama de distancia del oricio al borde para ubicación del oricio y

requisitos.

4. Al reutilizar un oricio taladrado previamente, siempre inspeccione cuidadosamente el oricio.

Distancia del oricio al borde:

Oricio 1ӯ

(2.54cm)

10”

(25.4cm)

min. desde cualquier bor

e

d

6”min

(15.24cm)

Vista en sección:

1”min

(2.54cm)

5” de profundidad

min.

(12.7cm)

Page 13

Revise en busca de cables

retorcidos o deshilachados.

Busque indicios de

desgaste en las

cucharas.

INSPECCIONE ANTES DE UTILIZAR

Revise en busca de

deformación del cono.

INSTALACIÓN:

1. Antes de realizar la instalación, verique que el cono

está debajo de las cucharas según se muestra en el el

diagrama de instalación. Inserte el anclaje dentro del

oricio de modo que la placa de base quede apoyada

de manera plana sobre la supercie de concreto.

Inserte

Verique que la

pieza giratoria se

pueda mover

libremente.

2. Hale hacia arriba el perno mientras

sostiene la pieza giratoria a ras con el

concreto. Apriete el perno girándolo en

sentido horario con sus dedos hasta que

el perno quede atornillado todo el

recorrido a mano.

Hale hacia

arriba el

perno y

Gire en

sentido

horario

Paso 1.

3. Utilice una llave de torsión (llave

dinamométrica) para aplicar la

pretensión del perno para la situación

de carga requerida para la aplicación.

CARGA:

10,000-lbf

(44 kN)

5,000-lbf

(22 kN)

APRIETE DEL PERNO:

85 lbs-pie

(9.60 Nm)

30 lbs-pie

(3.38 Nm)

Paso 2.

Paso 3.

Page 14

Destornille

un mínimo de

REMOCIÓN:

1. Aoja el perno de modo que se

exponga una longitud mínima de 3/4”

(1.9 cm) de roscas.

3/4”

(1,9cm)

2. Utilice un martillo para golpear

hacia abajo el perno y desenganchar el

cono fuera de las cucharas.

¡GOLPEE

SUAVEMENTE!!!

Paso 2.

Paso 1.

3. El anclaje debe poderse halar hacia

afuera del oricio. Vea el diagrama de

remoción.

Hale hacia

arriba

Paso 3.

Page 15

Se puede utilizar como punto de anclaje para un sistema

de evitamiento de caídas de borde delantero. Ejemplos

son las ubicaciones de puntos de anclaje opcionales. El

uso de dos anclajes es sólo para propósitos de ilustración

y no se requieren para los sistemas de evitamiento de

caídas de borde delantero a menos que sea especicado

de otra manera por el fabricante).

OPCIONAL

(PUNTOS DE ANCLAJE)

SUPERFICIE DE TRABAJO

(PUNTO DE ANCLAJE)

El concreto debe tener una

resistencia de 3000 psi o

superior, y estar totalmente

curado. La ubicación de

instalación debe ser

aprobada por una persona

calicada.

SUPERFICIE DE TRABAJO

La distancia (límite) de caída libre no

debe superior a 6 pies (1,8 m).

Consulte los documentos del

dispositivo conector para conocer

el uso apropiado y limitaciones.

DISTANCIA MÍNIMA SOBRE EL SUELO: 3 pies (1 m)

NIVEL DE PLATAFORMA/PISO/SUELO

¡Todos los productos sometidos a fuerzas de detención de caída

deben retirarse del servicio inmediatamente

¡ADVERTENCIA!!! LAS CAÍDAS TIPO COLUMPIO PUEDEN OCURRIR CUANDO EL TRABAJADOR NO ESTÁ DIRECTAMENTE DEBAJO DEL PUNTO DE ANCLAJE.

PN200417 ©2013 Werner Co. 10/13

Page 16

REGISTRO DE INSPECCIÓN Y MANTENIMIENTO

NÚMERO DE MODELO:

FECHA DE FABRICACIÓN:

Número de pieza

Comentarios

Nombre del

inspector

Se debe realizar una inspección periódica ocial al menos anualmente. La inspección

debe ser realizada por una persona calicada diferente al usuario previsto. Si existen

condiciones climáticas severas, entonces las inspecciones se deben realizar más

frecuentemente. Todos los resultados de la inspección se deben registrar en el espacio

suministrado arriba.

1. Inspeccione la pieza giratoria para vericar que está a ras con la supercie de montaje.

2. Verique que las etiquetas están jadas a la unidad.

3. Inspeccione el sistema de anclaje en busca de señales de daño o desgaste de las

cucharas o el cono.

4. Verique que la unidad puede girar 360° y que el anillo en “D” puede girar de lado a lado.

5. Al reutilizar un oricio previamente taladrado, inspeccione en busca de residuos u oricio

desgastado (rodado).

6. Registre los resultados de la inspección en el espacio suministrado arriba.

*Si encuentra algún daño que pudiera afectar la resistencia o funcionamiento del dispositivo,

o condiciones inseguras, se requiere desechar apropiadamente el dispositivo. El conector de

ancladero se debe inutilizar y luego desechar de manera apropiada.

Loading...

Loading...