Page 1

FALL PROTECTION

PROTECCIÓN CONTRA CAÍDAS

USER INSTRUCTIONS

INSTRUCCIONES PARA EL USUARIO

D-BOLT ANCHORS

Complies with ANSI Z359.1-2007; OSHA 29 CFR 1910 and 1926

regulations.

ANCLAJES TIPO D-Bolt

Cumple con las normas ANSI Z359.1-2007; OSHA 29 CFR 1910 y 1926.

(This manual applies to D-Bolt anchors with model numbers starting A320)

(Este manual aplica a todos los anclajes tipo D-Bolt con números de

modelo que comienzan con A320

Werner Fall Protection 724-588-2000

93 Werner Rd. 888-523-3371 toll free/ llamada gratuita

Greenville, PA 16125 888-456-8458 fax

.)

Page 2

CAUTION!

If use of fall protection equipment is necessary then the work

environment is dangerous and potentially deadly. Werner Company

products are designed to eliminate as much of the hazard as possible

but can do that ONLY if they are used correctly. Use this equipment as

it was designed to be used, after appropriate training, under the direct

supervision of a competent person, according to the instructions

provided, and in accordance with OSHA and local safety regulations.

User MUST read and understand all cautions and instructions. Failure

to heed these guidelines could result in injury or even death. Please,

WORK SAFE! WORK SMART!

ENGLISH

Page 2

Page 3

D-BOLT ANCHORS

USER INSTRUCTIONS

Contents

I. BEFORE USING THE D-BOLT ANCHOR .......................................................... 4

a. Inspect ......................................................................................................................4

b. Compatibility ............................................................................................................5

c. Fall Protection Plan ..................................................................................................5

d. Training .....................................................................................................................8

II. D-BOLT ANCHOR INSTALLATION AND USE .................................................8

a. Making a Connection ...............................................................................................8

b. Anchorage Strength .............................................................................................. 10

c. Connector ...............................................................................................................10

d. Body Support ......................................................................................................... 11

e. Mounting Locations ...............................................................................................11

f. Installation ...............................................................................................................12

III. USE WARNINGS, RESTRICTIONS AND CAUTIONS ................................... 13

a. Purpose ..................................................................................................................13

b. Rated Capacity .......................................................................................................13

c. Dimensions.............................................................................................................13

d. Limitations..............................................................................................................14

e. Requirements .........................................................................................................14

IV. LABELS/IDENTIFICATION/INSPECTION RECORDS .................................. 15

V. EQUIPMENT RECORDS ................................................................................16

VI. INSPECTION RECORDS .............................................................................. 16

Page 3

ENGLISH

Page 4

WARNING!

This product is just one part of a personal fall arrest system. It must

be matched correctly with other components to form a complete and

functional system. The user must understand the function of each of

these components and follow the manufacturer’s instructions for use

for each. The user must be provided these instructions, should read

and follow them, and consult the competent person who will supervise

his work if he has any questions about any part of the instructions.

The employer must provide training in the proper use, inspection, and

maintenance of all components in the system, and these instructions

can be used as part of that training. The equipment should be used

ONLY in accordance with these instructions, local ordinances and

codes, the applicable OSHA and ANSI standards, and the employer’s

safety plan. Alterations or misuse of this product or failure to follow

instructions may result in serious injury or death.

IF YOU HAVE ANY QUESTIONS ABOUT ANYTHING IN THESE

INSTRUCTIONS, THE EQUIPMENT, OR PROPER USE OF THE

EQUIPMENT, CONTACT WERNER CO. FOR MORE INFORMATION.

I. Before Using the D-Bolt Anchor

Before using this equipment the user should take certain steps to

ensure that it is in suitable condition and safe for use. Users must

read and understand these instructions. It is the employer’s obligation

to ensure that all users have been trained in safe work procedures

as well as in the use and limitations of fall protection equipment. All

users should be aware of and comply with all applicable OSHA, ANSI

and local or regional regulations concerning fall protection equipment

and its use.

a. Inspect

Examine all equipment thoroughly, daily before use by the user,

and periodically by a competent person who is not the user.

1. Ensure that the D-Bolt Anchor is free from rust, corrosion and any

damage. Clean with warm soapy solution to prevent damaging

the D-Bolt Anchor or structure.

ENGLISH

2. Ensure that the nut is securely tightened and the Lock Washer

remains engaged. If the nut and lock washer become loose, re-

Page 4

Page 5

D-BOLT ANCHORS

USER INSTRUCTIONS

tighten the nut to the torque speci ed in section II.f.

3. Inspect the D-Bolt Anchor to ensure there are no cracks, dents

or marks on the anchorage.

4. Make sure labels are attached to the D-Bolt Anchor and are

legible.

5. Record the inspection date and results in the Inspection and

Maintenance Log.

6. If inspection reveals a defective condition or abnormalities in

any of these areas, remove unit from service immediately. A

competent person should be consulted to determine if that item

is safe for continued use or if it should be destroyed.

IMPORTANT: If this equipment has been subjected to forces

resulting from the arrest of a fall, it must be immediately removed

from service.

b. Compatibility

Werner Co. equipment is designed for use with Werner Co. approved

components and subsystems only. Substitutions or replacements

made with non-approved components or subsystems may

jeopardize compatibility of equipment and may affect the safety and

reliability of the complete system.

Connectors are considered to be compatible with connecting

elements when they have been designed to work together in such a

way that their sizes and shapes do not cause their gate mechanisms

to inadvertently open regardless of how they become oriented.

Contact Werner Co. if you have any questions about compatibility.

Connectors (hooks, carabiners, and D-rings) must be capable of

supporting at least 5,000 pounds (22.2kN). Connectors must be

compatible with the anchorage or other system components. Do not

use equipment that is not compatible. Non-compatible connectors

may unintentionally disengage. Connectors must be compatible in

size, shape, and strength. Self locking snap hooks and carabiners

are required by ANSI Z359 and OSHA.

c. Fall Protection Plan

Plan your fall arrest or restraint system before starting your work.

Take into consideration all factors affecting your safety at any

time during use. The following list gives some important points to

consider when planning your system:

Page 5

ENGLISH

Page 6

1. ANCHORAGE: Select a rigid anchorage point that is capable of

supporting the required loads. See section II.b.

The anchorage location must be carefully selected to reduce

possible free fall and swing fall hazards and to avoid striking an

object during a fall. For restraint systems the anchorage must be

located such that no vertical free fall is possible. For fall arrest

systems OSHA requires the anchorage be independent of the

means suspending or supporting the user.

2. FREE FALL: Do not work above the anchorage level; increased

fall distance will result. Personal fall arrest systems must be

rigged such that the potential free fall is never greater than 6

feet (1.83 m). Restraint systems must be rigged such that there

is no possible vertical free fall.

3. FALL ARREST FORCES: The assembled fall arrest system

must keep fall arrest forces below 1,800 pounds (8 kN) when

used with a full body harness. Do not use a body belt for fall

arrest.

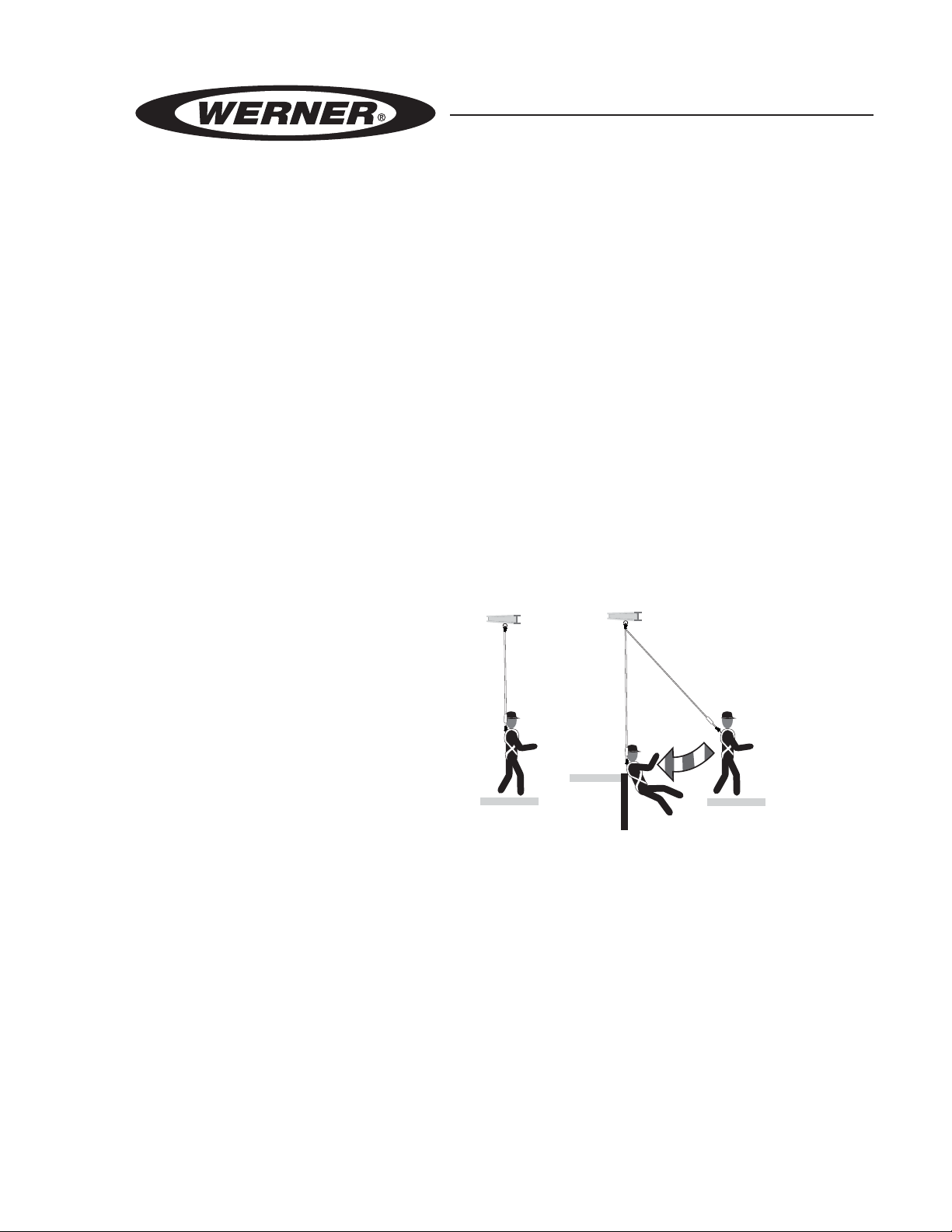

SWING FALL

4. SWING FALLS: Swing

falls occur when the

Anchorages

HAZARD

anchorage point is not

directly above the point

where a fall occurs. The

force of striking an object

in a swing fall may cause

serious injury or death.

Minimize swing falls by

working as close to the

Correct Incorrect

anchorage point as possible. Do not permit a swing fall if injury

could occur. Swing falls will signi cantly increase the clearance

required when a self-retracting lifeline or other variable length

connecting subsystem is used.

ENGLISH

Page 6

5. FALL CLEARANCE: Make certain enough clearance exists

in your fall path to prevent striking an object. The amount of

clearance needed is dependent upon the type of connecting

subsystem used and anchorage location. See connecting

subsystem user instructions for more information.

6. RESCUE: Should a fall occur, the user (employer) must have a

rescue plan. If a worker falls and is forced to remain suspended

for any length of time, physical damage to the body or even

death can result. For this reason Werner, OSHA, ANSI and

Page 7

D-BOLT ANCHORS

USER INSTRUCTIONS

most local regulations require that a rescue plan and the means

to implement the rescue plan are in place before use of this

equipment.

7. AFTER A FALL: Any equipment which has been subjected

to the force of arresting a fall must be removed from service

immediately.

WARNING!

Never connect more than one personal fall arrest or restraint system

to this device.

WARNING!

Follow manufacturer’s instructions for associated equipment used in

your fall protection or restraint system.

d. Training

OSHA, ANSI, and most local ordinances require that workers using

this product receive adequate training before use of this product.

These instructions and their entire contents should be a part of that

training.

II. D-Bolt Anchor Installation and Use

WARNING!

Do not alter or intentionally misuse this equipment. Consult with

Werner Co. if using this equipment with components or subsystems

other than those described in this manual. Some subsystem and

component combinations may interfere with the operation of this

equipment. Use caution when using this equipment around moving

machinery, electrical hazards, chemical hazards, and sharp edges.

WARNING!

Do not use this device if you are unable to tolerate the impact of

a fall arrest. Age and tness can seriously affect your ability to

withstand a fall. Pregnant women and minors must not use this

equipment.

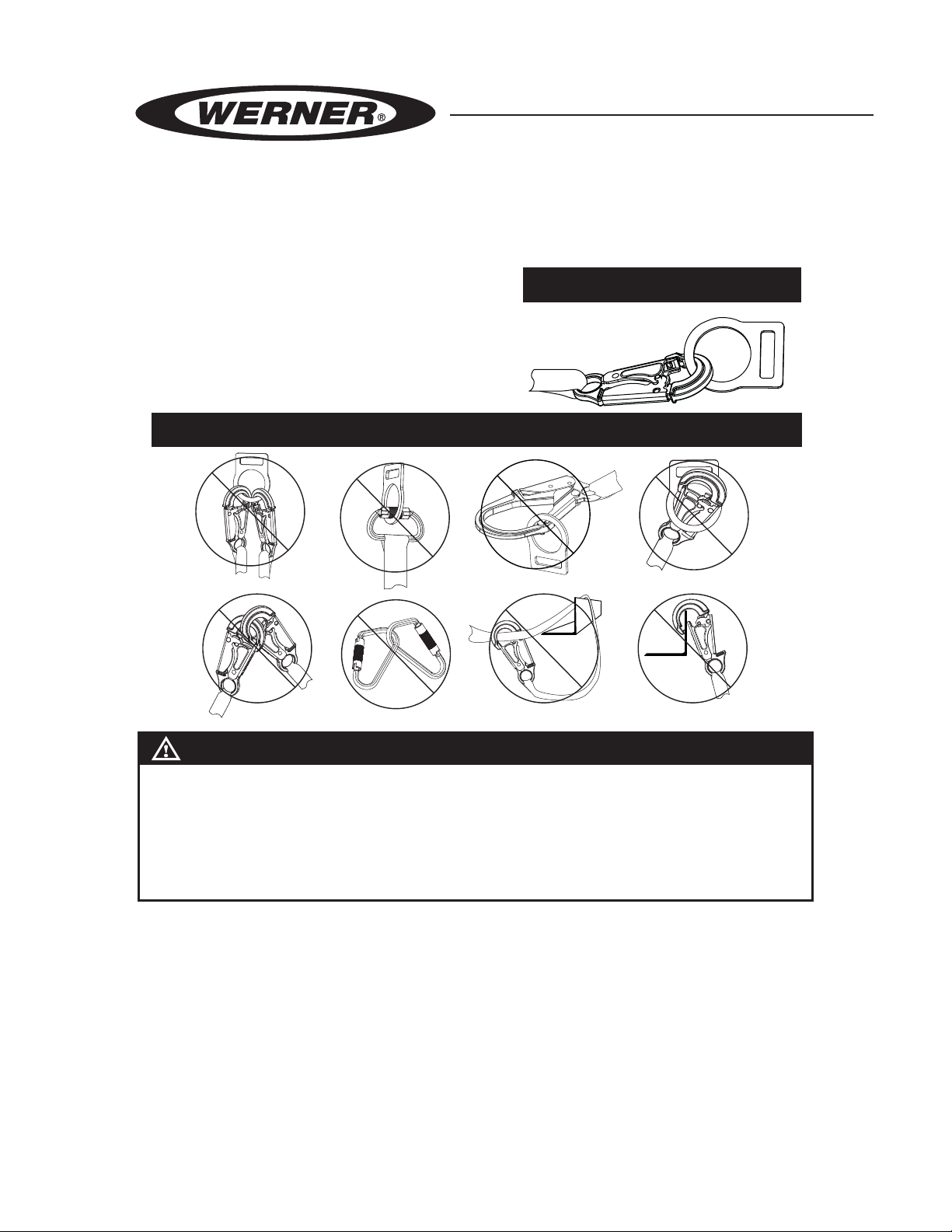

a. Making Connections

1. Only use self-locking snap hooks and carabiners with this

equipment. Only use connectors that are suitable to each

Page 7

ENGLISH

Page 8

application. Ensure all connections are compatible in size, shape

and strength. Do not use equipment that is not compatible.

Ensure all connectors are fully closed and locked.

2. Werner Co. connectors (snap

hooks and carabiners) are

designed to be used only as

speci ed in each product’s

user’s instructions. See

inappropriate connections.

INAPPROPRIATE CONNECTIONS

NO! NO! NO! NO!

PROPER CONNECTION

NO!NO!NO!NO!

WARNING!

Large throat opening snap hooks should not be connected to

standard size D-rings or similar objects which will result in a load

on the gate if the hook or D-ring twists or rotates. Large throat snap

hooks are designed for use on xed structural elements such as

rebar or cross members that are not shaped in a way that can capture

the gate of the hook.

Werner Co. snap hooks and carabiners should NOT be

connected:

i. to a D-ring to which another connector is attached.

ii. in a manner that would result in a load on the gate. If the

connecting element that a snap hook or carabiner attaches

to is undersized or irregular in shape, a situation could occur

where the connecting element applies a force to the gate of

the snap hook or carabiner. This force may cause the gate

ENGLISH

(of either a self-locking or a non-locking snap hook) to open,

allowing the snap hook or carabiner to disengage from the

Page 8

connecting point.

Page 9

D-BOLT ANCHORS

USER INSTRUCTIONS

iii. in a false engagement, where features that protrude from

the snap hook or carabiner catch on the anchor and without

visual con rmation seems to be fully engaged to the anchor

point.

iv. to each other.

v. directly to webbing or rope lanyard or tie-back (unless

the manufacturer’s instructions for both the lanyard and

connector speci cally allow such a connection).

vi. to any object which is shaped or dimensioned such that the

snap hook or carabiner will not close and lock, or that rollout could occur.

3. When using an energy-absorbing lanyard, connect the energy

absorber “pack” end to the harness.

b. Anchorage Strength

Depending on the application, the anchorage to which the D-Bolt

Anchor is installed must meet strengths as given below:

1. FALL ARREST: Anchorages selected for personal fall arrest

systems (PFAS) shall have a strength capable of sustaining

static loads, applied in the directions permitted by the PFAS, of

at least; (A) 3,600 pounds (16kN) when certi cation exists (see

ANSI Z359.1 for certi cation de nition), or (B) 5,000 pounds

(22kN) in the absence of certi cation. When more than one

PFAS is attached to an anchorage, the anchorage strengths

set forth in (A) and (B) above shall be multiplied by the number

of personal fall arrest systems attached to the anchorage. Per

OSHA 29 CFR 1926.500 and 1910.66; Anchorages used for

attachment of PFAS shall be independent of any anchorage

being used to support or suspend platforms, and capable of

supporting at least 5,000 pounds (22kN) per user attached, or be

designed, installed, and used as part of a complete PFAS which

maintains a safety factory of at least two, and is supervised by

a quali ed person.

2. RESTRAINT: Anchors selected for restraint applications must be

attached to a roof member capable of sustaining a static load of

at least 3,000 pounds (13 kN) applied in any direction permitted

by the restraint system when in use. Each roof member anchor

installation must be independently capable of sustaining this

load.

Page 9

ENGLISH

Page 10

WARNING!

Restraint anchorages may only be used where there is no possible

vertical free fall. Restraint anchorages do not have sufficient strength

for fall arrest. Do not connect personal fall arrest systems to restraint

anchorages.

c. Connector

For fall arrest systems Werner Co. recommends using energy

absorbing lanyards incorporating self locking snap hooks or selfretracting lifelines. Lanyards labeled ANSI A10.14 Type II must

not be used for fall arrest applications. All lanyards must have a

minimum breaking strength of 5,000 pounds (22kN).

NOTE: Applications such as working near high voltage may require

special lifeline materials, consult Werner Co. before using such

lifelines.

d. Body Support

The recommended body support for fall arrest applications is a full

body harness. For restraint applications a body belt may be used.

e. Mounting location

The D-Bolt Anchor should be positioned on the mounting surface

ENGLISH

so that the attached connector will never be subjected to dynamic

loading on the keeper system . Werner D-Bolt Anchors may

be installed on overhead horizontal or vertical surfaces. Other

installation applications must be approved by Werner Co.

1. The entire base of the D-Bolt Anchor must be ush with the

mounting surface.

2. The area of the mounting surface for the D-Bolt Anchor must

be such that no dynamic forces get applied to the attached

connector’s keeper system.

Page 10

Page 11

D-BOLT ANCHORS

USER INSTRUCTIONS

Minimum load

bearing surface to

extend entire length

of anchorage and

snap hook.

Minimum load

bearing surface

DOES NOT extend

entire length of

anchorage and snap

hook.

Minimum load

bearing surface

DOES NOT extend

entire length of

anchorage hook.

f. Installation

Install the D-Bolt Anchor at the correct mounting locations in the

following manner:

1. D-Bolt A320001 and A320001-WB:

i. Pre-drill a 21/32 inch (16.7 mm) hole into the desired structure,

using a suitable drill bit for penetration. Remove any burred

edges from the structure to ensure that the xed anchorage

point sits ush against the mounting surface. The location of

the drilled hole must be suitable to take the forces de ned

in Section II.b.

ii. Use only Werner approved bolts and fasteners with this

anchor. User must supply an approved 5/8 inch (16 mm)

grade 8 bolt for use with D-Bolt A320001. Fasteners are

included with D-Bolt A320001-WB.

iii. Insert the bolt through the D-Bolt and the pre-drilled hole.

Ensure that the bolt is pushed through completely, and the

back surface of the D-ring is ush against the structure.

iv. Slide a lock washer over the threads of the bolt until the

washer is ush against the surface of the structure.

v. Thread the nut onto the bolt until it meets the washer. Ensure

the D-ring is oriented correctly and then torque the nut

Page 11

ENGLISH

Page 12

tight. Recommended torque is 125 ft-lbs (169.5 N-m). Once

tightened, at least one full thread must extend beyond the

nut. Do not overtighten.

vi. Inspect the D-Bolt Anchor to ensure that it is not loose and

sits ush against the structure.

2. D-Bolt A320002:

i. Pre-drill a 17/32 inch (13.5 mm) hole into the desired structure,

using a suitable drill bit for penetration. Remove any burred

edges from the structure to ensure that the xed anchorage

point sits ush against the mounting surface. The location of

the drilled hole must be suitable to take the forces de ned

in Section II.b.

ii. Insert the D-Bolt through the pre-drilled hole. Ensure that the

bolt is pushed through completely, and the back surface of

the D-ring is ush against the structure.

iii. Slide the lock washer over the threads of the D-Bolt until the

washer is ush against the surface of the structure.

iv. Thread the nut onto the D-Bolt until it meets the washer.

Ensure the D-ring is oriented correctly and then torque the

nut tight. Recommended torque range is 45-55 ft-lbs (61

- 74.5 N-m). Once tightened, at least one full thread must

extend beyond the nut. Do not overtighten.

v. Inspect the D-Bolt Anchor to ensure that it is not loose and

sits ush against the structure.

III. Use Warnings, Restrictions and Cautions

a. Purpose

Werner Co. D-Bolt Anchors provide a permanent or semipermanent

anchorage point for personal fall arrest systems where anchorage

on a surface is required. The D-Bolt Anchor’s vertical anchor area

will accommodate all of Werner Co. snap hooks and carabiners.

b. Rated Capacity

Refer to connecting device or subsystem instructions for limitations

of worker weight and number of workers.

NOTE: No more than one connection may be attached to this device.

ENGLISH

Page 12

See c. Limitations.

Page 13

D-BOLT ANCHORS

USER INSTRUCTIONS

c. Limitations

The following application limitations must be recognized and

considered before using this product:

1. FREE FALL: Restraint systems must be rigged such that there is

no possible vertical free fall. Personal fall arrest systems must be

rigged in such a way to limit the free fall to 6 feet (1.83 m) (ANSI

Z359.1). See associated connecting subsystem manufacturer’s

instructions for further information.

2. FALL CLEARANCE: Make certain that enough clearance exists

in your fall path to prevent striking an object. The amount of

clearance required is dependent upon the type of connecting

subsystem used (lanyard, lifeline), the anchorage location, and

the amount of stretch in the lifeline. See section I.c for more

information on determining fall clearance.

3. ENVIRONMENTAL HAZARDS: Use of this equipment in areas

with environmental hazards may require additional precautions

to prevent injury to the user or damage to the equipment.

Hazards may include, but are not limited to: heat, chemicals,

corrosive environments, high voltage power lines, gases, moving

machinery, and sharp edges.

4. TRAINING: This equipment is to be used by persons who have

been properly trained in its correct application and use.

d. Requirements

Refer to applicable local, state, and federal (OSHA) regulations

governing this equipment for more information on anchorages

and associated system components, including; ANSI Z359.1, and

OSHA 29 CFR 1910.66, appendix C.

Page 13

ENGLISH

Page 14

IV. Labels/Identi cation/Inspection Records

a. All products should be inspected by the user thoroughly before

each use. Additional inspections by a competent person other than

the user should be conducted at least annually. That interval should

be shortened any time the product is used in a harsh environment

or is exposed to conditions such as chemicals, abrasion, heat or

any other factor that could affect the strength of any of the materials

or components.

b. This manual should always accompany the product, or be on le

with the employer for access when needed. Record the identi cation

details for the anchor and record the inspections in the inspection

log. It is important to keep this log current, complete, and available

as needed.

ID / Warning Label

ENGLISH

WARNING

Read User Manual and understand

all instructions and warnings. Refer

to the instruction manual for stability

and compatibility limitations. If user

manual is missing contact Werner

Co. for a replacement copy. The blue

wear sleeve must protrude past the

edge of the concrete after installation.

Product must be inspected prior to

each use according to instructions in

manual, then periodically by a

competent person who is not the user.

User repairs or alterations are NOT

permitted. Avoid exposure to sharp

edges, chemicals, machinery and

environmental hazards that could

weaken the materials. Verify that

connectors are compatible (see

instruction manual). OSHA, CSA and

local regulations require that workers

receive training in the proper use and

limitations of fall restraint equipment.

FAILURE TO READ AND HEED ALL

WARNINGS COULD RESULT IN INJURY

OR DEATH!

93 Werner Road, Greenville, PA 16125

888-523-3370 • www.wernerladder.com

Page 14

Page 15

D-BOLT ANCHORS

USER INSTRUCTIONS

Standards/Estándares

ANSI Z359.1-2007, OSHA 1910-1926

Model/Modelo:

Material

Materiales:

Maximum Capacity:

Capacidad máxima:

Year of Manufacture:

Año de la fabricación:

Greenville, PA 16125 • 888-523-3371

310 lb./141 kg

2016

Minimum Breaking Strength:

Resistencia a Ruptura Mínima:

5,000lbs / 22.2 kN

Model / Modelo:

A320001-WB

Materials:

Materiales:

Steel / Acero

Date of

Manufacture:

Fecha de

la Fabricación:

Serial Number:

Número de Serie:

XX/XX

xxxxxx

Max Capacity

(user with tools):

Capacidad Máxima

(usuario con las

herramientas):

Assembled in:

Ensemblado en:

400 lb

181 kg

US

Inspection Log/Registro de Inspección

Yea r

Yea r

Yea r

Yea r

Año

1

2

Año

3

Año

Año

Yea r

4

5

Año

1

2

3

4

5

6

7

8

9

10

11

12

Standards/Estándares

ANSI Z359.1-2007, OSHA 29 CFR 1910, 1926

93 Werner Road, Greenville, PA 16125

1-888-523-3371 • www.wernerco.com

© 2016 Werner Co.

P/N 110643-01 Rev A 8/16

Warning: User must follow manufacturer’s instructions

included with the equipment at the time of shipment

from the manufacturer. Refer to the instruction manual

for proper installation and stability and compatibility

limitations. Inspect prior to use.

Page 15

ENGLISH

Page 16

V. Equipment Record

PART NUMBER

SERIAL NUMBER

DATE

MANUFACTURED

PURCHASE DATE

ASSIGNED TO

SPECIFICATIONS

Werner D-Bolt Anchor

Certi ed to meet the ANSI Z359.1-2007 standard and OSHA 29 CFR

1910 and 1926 regulations for the subsystem components of a complete

personal fall arrest system.

Individually bar coded model and serial numbers, location and date of

manufacture are on product label.

VI. Inspection Record

ENGLISH

Page 16

INSPECTION RECORD

DATE INSPECTOR PASS/FAILDATE INSPECTOR PASS/FAIL

Page 17

ANCLAJES TIPO D-BOLT

INSTRUCCIONES PARA EL USUARIO

Advertencia:

Si el uso de equipos de protección contra caídas es necesario,

entonces el ambiente de trabajo es peligroso y potencialmente

mortal. Los productos Werner Company están diseñados para

eliminar peligros tanto como sea posible, pero SÓLO si estos

productos se utilizan correctamente. Utilice este equipo tal como

fue diseñado para usarse, después de una capacitación apropiada,

bajo la supervisión directa de una persona cali cada, de acuerdo con

las instrucciones suministradas, y de acuerdo con las regulaciones

OSHA y las regulaciones de seguridad locales. El usuario DEBE leer y

entender todas las precauciones e instrucciones. No tener en cuenta

estas directrices podría resultar en lesiones o incluso la muerte.

Por favor, ¡TRABAJE DE MANERA SEGURA! ¡TRABAJE DE MANERA

INTELIGENTE!

Página 17

ESPAÑOL

Page 18

Contenido

I. INSTRUCCIONES PARA EL USUARIO ..........................................................17

a. Inspeccione ............................................................................................................19

b. Compatibilidad .......................................................................................................20

c. Plan de protección contra caídas .........................................................................20

d. Capacitación ..........................................................................................................23

II. INSTALACIÓN Y USO DEL ANCLAJE TIPO D-BOLT .................................... 23

a. Realización de una conexión ................................................................................23

b. Resistencia del anclaje..........................................................................................25

c. Conector .................................................................................................................25

d. Soporte del cuerpo ................................................................................................26

e. Ubicaciones de montaje ........................................................................................26

f. Instalación ..............................................................................................................27

III. TENGA EN CUENTA LAS ADVERTENCIAS,

RESTRICCIONES Y PRECAUCIONES .........................................................28

a. Propósito ..............................................................................................................28

b. Capacidad nominal ................................................................................................28

c. Dimensiones...........................................................................................................28

d. Limitaciones ...........................................................................................................29

c. Requisitos ..............................................................................................................29

IV. ETIQUETAS/IDENTIFICACIÓN/REGISTROS DE INSPECCIÓN .................. 29

V. REGISTROS DE EQUIPOS ............................................................................31

VI. REGISTROS DE INSPECCIÓN ..................................................................... 31

ESPAÑOL

Página 18

Page 19

ANCLAJES TIPO D-BOLT

INSTRUCCIONES PARA EL USUARIO

Advertencia:

Este producto es sólo una parte de un sistema personal de detención de

caídas. Éste debe combinarse correctamente con otros componentes para

conformar un sistema completo y funcional. El usuario debe entender la

función de cada uno de estos componentes y seguir las instrucciones del

fabricante para el uso de cada componente. El usuario debe recibir estas

instrucciones, debe leerlas y seguirlas, y consultar a la persona cali cada que

supervisará su trabajo si tiene alguna pregunta acerca de cualquier parte de

las instrucciones. El empleador debe proporcionar capacitación sobre el uso

apropiado, inspección y mantenimiento de todos los componentes del sistema,

y estas instrucciones pueden utilizarse como parte de esa capacitación. El

equipo SÓLO debe utilizarse de acuerdo con estas instrucciones, ordenanzas

y códigos locales, las normas OSHA y ANSI aplicables, y el plan de seguridad

del empleador. Las alteraciones o uso incorrecto de este producto, o no

seguir estas instrucciones, podría resultar en lesiones graves o la muerte.

SI USTED TIENE ALGUNA PREGUNTA ACERCA DE ALGO DE ESTAS

INSTRUCCIONES, EL EQUIPO O EL USO APROPIADO DEL EQUIPO,

COMUNÍQUESE CON WERNER CO. PARA OBTENER MÁS INFORMACIÓN.

I. Antes de utilizar el anclaje tipo D-Bolt

Antes de utilizar este equipo, el usuario debe realizar ciertos pasos para

garantizar que éste está en condiciones apropiadas y es seguro para su uso.

Los usuarios deben leer y entender estas instrucciones. Es obligación del

empleador garantizar que todos los usuarios hayan recibido capacitación

sobre los procedimientos de trabajo seguros y también sobre el uso y

limitaciones de los equipos de protección contra caídas. Todos los usuarios

deben estar informados acerca de y cumplir todas las normas OSHA, ANSI

aplicables y las normas locales o regionales relacionadas con los equipos

de protección contra caídas y su uso.

a. Inspeccione

Todo el equipo debe ser examinado completamente, diariamente antes

del uso, por parte del usuario; y periódicamente por parte de una persona

cali cada que no sea el usuario.

1. Veri que que el anclaje tipo D-Bolt no tiene óxido, corrosión ni ningún

daño. Limpie con una solución jabonosa tibia para evitar dañar el

anclaje tipo D-Bolt o la estructura.

2. Veri que que la tuerca está apretada rmemente y que la arandela

de seguridad permanece enganchada. Si la tuerca y la arandela de

seguridad están ojas, re-apriete la tuerca.

Página 19

ESPAÑOL

Page 20

3. Inspeccione el anclaje tipo D-Bolt para garantizar que no hay grietas,

abolladuras o marcas en el anclaje.

4. Veri que que las etiquetas están sujetadas al anclaje tipo D-Bolt y que

están legibles.

5. Registre la fecha y resultados de la inspección en el registro de

inspección y mantenimiento.

6. Si la inspección revela una condición defectuosa o anormalidades en

cualquiera de estas áreas, retire inmediatamente del servicio la unidad.

Debe consultarse a una persona capacitada para determinar si ese

elemento es seguro para uso continuado o si debe destruirse.

IMPORTANTE: Si este equipo ha sido sometido a las fuerzas resultantes

de una detención de caída, éste debe retirarse inmediatamente del

servicio.

b. Compatibilidad

Los equipos Werner Co. están diseñados para uso sólo con componentes

y subsistemas aprobados por Werner Co. Las sustituciones o reemplazos

realizados con componentes o subsistemas no aprobados podrían

arriesgar la compatibilidad del equipo y podrían afectar la seguridad y

con abilidad del sistema completo.

ESPAÑOL

Los conectores se consideran compatibles con los elementos conectivos

cuando éstos han sido diseñados para trabajar en conjunto de tal manera

que sus tamaños y formas no causen que sus mecanismos de cierre

se abran inadvertidamente sin importar la manera como se orienten.

Comuníquese con Werner Co. si usted tiene alguna pregunta acerca

de la compatibilidad. Los conectores (ganchos, argollas rectangulares

metálicas y los anillos en ‘D’) deben ser capaces de soportar 22,2kN

(5000 lbs). Los conectores deben ser compatibles con el ancladero u otros

componentes del sistema. No utilice equipos que no sean compatibles.

Los conectores no compatibles podrían desengancharse accidentalmente.

Vea las conexiones inapropiadas. Los conectores deben ser compatibles

en tamaño, forma y resistencia. Las normas ANSI Z359 y OSHA

requieren argollas rectangulares metálicas y ganchos de cierre resortado

autoasegurables.

c. Plan de protección contra caídas

Planee su sistema de detención o evitamiento de caídas antes de iniciar

su trabajo. Tenga en cuenta todos los factores que afectan su seguridad en

cualquier momento durante el uso. La siguiente lista proporciona algunos

puntos importantes que deben considerarse al planear su sistema:

Página 20

Page 21

ANCLAJES TIPO D-BOLT

INSTRUCCIONES PARA EL USUARIO

1. ANCLADERO: Seleccione un punto de anclaje rígido que sea capaz

de soportar las cargas requeridas. Vea la sección II.b. La ubicación del

anclaje debe seleccionarse cuidadosamente para reducir la posibilidad

de peligros por caída libre o por caída tipo columpio y para evitar

golpear un objeto durante una caída. Para los sistemas de evitamiento

de caídas, el anclaje debe ubicarse de modo que no sea posible

una caída libre vertical. Para los sistemas de detención de caídas,

OSHA exige que el anclaje sea independiente de los elementos que

suspenden o soportan el usuario.

2. CAÍDA LIBRE: No trabaje encima del nivel del anclaje porque existirá

una mayor distancia de caída. Los sistemas personales de detención de

caídas deben instalarse de modo que la posible caída libre nunca sea

superior a 1,83 m (6 pies). Deben instalarse sistemas de evitamiento

de caídas de modo que no haya posibilidad de caídas libres verticales.

3. FUERZAS DE DETENCIÓN DE CAÍDAS: El sistema de detención de

caídas ensamblado debe mantener las fuerzas de detención de caídas

por debajo de 8 kN (1800 lbs) cuando se utiliza con un arnés de cuerpo

completo. No utilice un cinturón de cuerpo para las aplicaciones de

detención de caídas.

4. CAÍDAS TIPO COLUMPIO:

Peligro de caída

tipo columpio

Las caídas tipo columpio

ocurren cuando el punto de

Anclajes

anclaje no está directamente

encima del punto donde

ocurre una caída. La fuerza

al golpear un objeto en una

caída tipo columpio podría

causar lesiones graves o la

muerte. Minimice las caídas

Correcto Incorrecto

tipo columpio trabajando lo

más cerca posible del punto de anclaje. No permita una caída tipo

columpio si hay posibilidad de ocurrencia de lesiones. Las caídas tipo

columpio aumentarán signi cativamente el espacio libre requerido

cuando se utiliza una cuerda salvavidas autoretráctil u otro subsistema

de conexión de longitud variable.

5. ESPACIO LIBRE DE CAÍDA: Veri que que existe su ciente espacio

libre en la trayectoria de caída para evitar golpear un objeto. La cantidad

de espacio libre necesario depende del tipo de subsistema conectivo

utilizado y de la ubicación del anclaje. Vea las tablas de distancia

de caída para las cuerdas absorbedoras de impacto o la distancia

de caída para las cuerdas salvavidas autoretráctiles para calcular el

espacio libre de caída.

Página 21

ESPAÑOL

Page 22

6. RESCATE: Si ocurre una caída, el usuario (empleador) debe

tener un plan de rescate. Si un trabajador cae y queda obligado a

permanecer suspendido durante cualquier período de tiempo, podría

producirse daño físico o incluso la muerte. Por este motivo; Werner, las

regulaciones de OSHA, ANSI y la mayoría de las regulaciones locales

exigen la existencia de un plan de rescate y los medios para ejecutar

un plan de rescate, antes del uso de este equipo.

7. DESPUÉS DE UNA CAÍDA: Cualquier equipo que ha sido sometido a

una fuerza de detención de caída debe retirarse inmediatamente del

servicio.

Advertencia:

Nunca conecte más de un sistema personal de detención o evitamiento

decaídas a un solo anclaje tipo D-Bolt.

Advertencia:

Siga las instrucciones del fabricante para el equipo respectivo utilizado en su

sistema de protección contra caídas o de evitamiento de caídas.

d. Capacitación

Las regulaciones OSHA, ANSI, y la mayoría de las regulaciones locales

exigen que los trabajadores que utilicen este producto deben recibir

capacitación adecuada antes del uso de este producto. Estas instrucciones

y su contenido completo deben ser parte de esa capacitación.

II. Instalación y uso del anclaje tipo D-Bolt

Advertencia:

No altere ni utilice incorrectamente intencionalmente este equipo. Consulte

con Werner Co. si este equipo se utilizará con componentes o subsistemas

diferentes a los descritos en este manual. Algunos subsistemas y

combinaciones de componentes podrían interferir con la operación de este

equipo. Tenga precaución al utilizar este equipo alrededor de máquinas en

movimiento, peligros eléctricos, peligros químicos y bordes losos.

Advertencia:

No utilice este dispositivo si usted no puede tolerar el impacto de una

detención de caída. La edad y la condición física pueden afectar seriamente

su capacidad para soportar una caída. Las mujeres embarazadas y los

menores de edad no deben utilizar este equipo.

a. Realización de las conexiones

ESPAÑOL

Página 22

1. Con este equipo, sólo utilice argollas rectangulares metálicas y ganchos

de cierre resortado auto-asegurables. Sólo utilice conectores que sean

Page 23

ANCLAJES TIPO D-BOLT

INSTRUCCIONES PARA EL USUARIO

apropiados para cada aplicación. Veri que que todas las conexiones

son compatibles en tamaño, forma y resistencia. No utilice equipos que

no sean compatibles. Veri que que todos conectores están totalmente

cerrados y asegurados.

2. Los conectores Werner Co.

(ganchos de cierre resortado y

argollas rectangulares metálicas)

están diseñados para utilizarse

únicamente según se especi ca

en las instrucciones para

usuario de cada producto. Vea

las conexiones inapropiadas.

CONEXIONES INAPROPIADAS

NO! NO! NO! NO!

CONEXIONES APROPIADAS

NO!NO!NO!NO!

Advertencia:

Los ganchos de cierre resortado que se abren hasta una garganta grande no

deben conectarse a anillos en ‘D’ de tamaño estándar u objetos similares, lo

cual resultará en una carga sobre el cierre si el gancho o anillo en ‘D’ gira o

rota. Los ganchos de cierre resortado de garganta grande están diseñados

para uso en elementos estructurales jos tales como barras de refuerzo o

travesaños que no tengan una forma que pueda atrapar el cierre del gancho.

Los ganchos de cierre resortado y las argollas rectangulares metálicas de

Werner Co. NO deben conectarse:

i. a un anillo en ‘D’ al cual está sujetado otro conector.

ii. de tal manera que se produzca carga sobre el cierre. Si el elemento

conectivo al cual se sujeta un gancho de cierre resortado o una

argolla rectangular metálica es de tamaño inferior o tiene forma

irregular, podría ocurrir un problema cuando el elemento conectivo

Página 23

ESPAÑOL

Page 24

aplique una fuerza al cierre del gancho de cierre resortado o la argolla

rectangular metálica. Esta fuerza podría causar que se abra el cierre

(de un gancho de cierre resortado auto-asegurable o no-asegurable),

permitiendo que el gancho de cierre resortado o la argolla rectangular

metálica se desenganche del punto de conexión.

iii. en un enganche falso, donde las características que sobresalen

del gancho de cierre resortado o la argolla rectangular metálica se

agarran al anclaje, y sin con rmación visual parece estar totalmente

enganchado al punto de anclaje.

iv. uno al otro.

v. directamente a una correa tejida o cuerda de bras trenzadas o

amarre sobre sí mismo (a menos que las instrucciones del fabricante

de la cuerda y el conector permitan especí camente dicha conexión).

vi. a cualquier objeto que tenga una forma o dimensiones tales que el

gancho de cierre resortado o la argolla rectangular metálica no se

cierren ni aseguren, y que pudiera ocurrir rodaje.

3. Al utilizar una cuerda absorbedora de energía, conecte el extremo, con

“paquete” absorbedor de energía, al arnés.

b. Resistencia del anclaje

ESPAÑOL

Dependiendo de la aplicación, el ancladero al cual se instala el anclaje tipo

D-Bolt debe cumplir las resistencias según se indican a continuación:

1. DETENCIÓN DE CAÍDAS: Los ancladeros seleccionados para los Sistemas

Personales de Detención de Caídas (SPDC) deberán tener una resistencia

capaz de sostener cargas estáticas, aplicadas en las direcciones permitidas

por el SPDC, de al menos; (A) 16kN (3600 lbs) cuando existe certi cación

(vea la norma ANSI Z359.1 para obtener la de nición de certi cación), ó

(B) 22 kN (5000 lbs) en ausencia de certi cación. Cuando se sujeta más

de un (1) SPDC a un ancladero, las resistencias del ancladero establecidas

en (A) y (B) anteriores deberán multiplicarse por el número de sistemas

personales de detención de caídas sujetados al ancladero. Según las

normas OSHA 1926.500 y 1910.66; los ancladeros utilizados para sujeción

de los SPDC deberán ser independientes de cualquier ancladero que

se esté utilizando para soportar o suspender plataformas, y capaces de

soportar al menos 22 kN (5000 lbs) por cada usuario sujetado, o diseñarse,

instalarse y utilizarse como parte de un sistema completo personal de

detención de caídas que mantenga un factor de seguridad de dos como

mínimo, y sea supervisado por una persona capacitada.

2. EVITAMIENTO DE CAÍDAS: Los anclajes tipo D-Bolt instalados para

aplicaciones de evitamiento de caídas deben sujetarse a un componente

de techo capaz de soportar como mínimo una carga estática de 13 kN

(3000 lbs) aplicada en cualquier dirección permitida por el sistema de

evitamiento de caídas cuando está en uso.

Página 24

Page 25

ANCLAJES TIPO D-BOLT

INSTRUCCIONES PARA EL USUARIO

Advertencia:

Los anclajes para evitamiento de caídas sólo pueden utilizarse donde no existe

la posibilidad de una caída libre vertical. Los anclajes para evitamiento de caídas

no tienen su ciente resistencia para detener una caída. No conecte sistemas

personales de detención de caídas a anclajes para evitamiento de caídas.

c. Conector

Para los sistemas de detención de caídas, Werner Co. recomienda

utilizar cuerdas absorbedoras de energía que tengan ganchos de cierre

resortados auto-asegurables. Las cuerdas con etiqueta ANSI A10.14 tipo

II no deben utilizarse para aplicaciones de detención de caídas. Todas las

cuerdas deben tener una resistencia mínima a la rotura de 22 kN (5000

lbs).

NOTA: Las aplicaciones tales como trabajar cerca de cables de alto

voltaje podrían requerir materiales especiales de cuerda salvavidas,

consulte a Werner Co. antes de utilizar dichas cuerdas salvavidas.

d. Soporte del cuerpo

El soporte de cuerpo recomendado para todas las aplicaciones de

detención de caídas es un arnés de cuerpo completo. Para las aplicaciones

de evitamiento de caídas, puede utilizarse un cinturón de cuerpo.

e. Ubicación de montaje

El anclaje tipo D-Bolt debe colocarse en una supericie de montaje

de modo que el conector sujetado nunca será sometido a cargas

dinámicas sobre el sistema de cierre. Los anclajes tipo D-Bolt de

Werner pueden instalarse en supericies elevadas horizontales o

verticales. Otras aplicaciones de instalación deben ser aprobadas

por Werner Co.

1. Toda la base del anclaje tipo D-Bolt debe estar al ras con la supericie

de montaje.

2. El área de la supericie de montaje para el anclaje tipo D-Bolt debe ser

tal que no se aplique ninguna fuerza dinámica al sistema de cierre del

conector sujetado.

Página 25

ESPAÑOL

Page 26

La super cie

minima de apoyo

de carga debe

extenderse a lo

largo de toda la

longitud del anclaje

y del gancho.

f. Instalación

Instale el anclaje tipo D-Bolt en las ubicaciones de montaje correctas, de

la siguiente manera:

1. D-Bolt A320001 y A320001-WB:

i. Pre-taladre un ori cio de 16.7 mm (21/32 pulgadas) en la estructura

deseada, utilizando una broca apropiada para penetración. Elimine

cualquier borde con rebaba de la estructura para garantizar que

el punto de anclaje jo se asienta al ras contra la supericie de

montaje. La ubicación del ori cio taladrado debe ser apropiada

para recibir las fuerzas deinidas en la Sección II.b.

La super cie minima

de apoyo de carga

NO se extende a

lo largo de toda la

longitud del anclaje y

del gancho.

La super cie

minima de apoyo

de carga NO se

extende a lo largo

de toda la longitud

del anclaje.

ESPAÑOL

Página 26

ii. Con este anclaje, sólo utilice pernos y sujetadores aprobados por

Werner. El usuario debe suministrar un perno de 16 mm (5/8

pulgadas) grado 8 aprobado para uso con el D-Bolt A320001.

Tornillos de jaciónestán incluidos con D-Bolt A320001-WB.

iii. Inserte el perno a través del anclaje tipo D-Bolt y del ori cio pre-

taladrado. Veri que que el perno está insertado completamente,

y que la supericie trasera del D-Bolt está al ras con respecto a la

estructura.

iv. Deslice sobre las roscas del perno hasta que la arandela esté al ras

con respecto a la supericie de la estructura.

v. Enrosque la tuerca sobre el perno hasta que ésta se encuentre con

Page 27

ANCLAJES TIPO D-BOLT

INSTRUCCIONES PARA EL USUARIO

la arandela. Veri que que el D-Bolt está orientado correctamente y

luego apriete la tuerca. El torque de apriete recomendado es 169.5

N-m(125 libras-pie). Una vez apretado, al menos una (1) rosca

completa debe extenderse más allá de la tuerca.

vi. Inspeccione el anclaje tipo D-Bolt para garantizar que no está lojo

y que está asentado al ras con respecto a la estructura.

2. D-Bolt A320002:

i. Pre-taladre un ori cio de 13.5 mm (17/32 pulgadas) en la estructura

deseada, utilizando una broca apropiada para penetración. Elimine

cualquier borde con rebaba de la estructura para garantizar que

el punto de anclaje jo se asienta al ras contra la supericie de

montaje. La ubicación del ori cio taladrado debe ser apropiada

para recibir las fuerzas deinidas en la Sección II.b.

ii. Inserte el D-Bolt a través del ori cio pre-taladrado. Veri que que el

perno está insertado completamente, y que la supericie trasera

del D-Bolt está al ras con respecto a la estructura.

iii. Deslice la arandela de seguridad sobre las roscas del D-Bolt

hasta que la arandela esté al ras con respecto a la supericie de la

estructura.

iv. Enrosque la tuerca sobre el D-Bolt hasta que ésta se encuentre

con la arandela. Veri que que el anillo en ‘D’ está orientado

correctamente y luego apriete la tuerca. El rango de apriete

recomendado es 61 a 74.5 N-m (45 a 55 libras-pie). Una vez

apretado, al menos una (1) rosca completa debe extenderse más

allá de la tuerca.

v. Inspeccione el anclaje tipo D-Bolt para garantizar que no está ojo y

que está asentado al ras con respecto a la estructura.

III. Tenga en cuenta las advertencias, restricciones y

precauciones

a. Propósito

Los anclajes tipo D-Bolt de Werner Co. proporcionan un punto de

anclaje permanente o semipermanente para los sistemas personales

de detención de caídas donde se requiere un anclaje sobre una

supericie. El área de anclaje vertical del anclaje tipo D-Bolt alojará todos

los ganchos de cierre resortado y argollas rectangulares metálicas de

Werner Co.

Página 27

ESPAÑOL

Page 28

b. Capacidad nominal

Re érase a las instrucciones de conexión dispositivos o subsistemas para

las limitaciones de peso del trabajador y número de trabajadores.

NOTA: No puede sujetarse más de una (1) persona a este dispositivo. Vea el

numeral c. Limitaciones.

c. Limitaciones

Las siguientes limitaciones de aplicación deben reconocerse y tenerse en

cuenta antes de utilizar este producto:

1. CAÍDA LIBRE: Deben instalarse sistemas de evitamiento de caídas de

modo que no haya posibilidad de caídas libres verticales. Los sistemas

personales de detención de caídas deben instalarse de tal manera

que limiten una caída libre a 1.83 m (6 pies) (ANSI Z359.1). Vea las

instrucciones del fabricante del subsistema conectivo asociado para

obtener información adicional.

2. ESPACIO LIBRE DE CAÍDA: Veri que que existe su ciente espacio

libre en la trayectoria de caída para evitar golpear un objeto. La cantidad

de espacio libre necesario depende del tipo de subsistema conectivo

utilizado y de la ubicación del anclaje. Vea las instrucciones para el

usuario del subsistema conectivo para mas información.

3. RIESGOS AMBIENTALES: El uso de este equipo en lugares con

peligros ambientales podría requerir precauciones adicionales para

evitar lesiones al usuario o daño al equipo. Los peligros podrían ser,

entre otros, los siguientes: calor, productos químicos, ambientes

corrosivos, cables de energía de alto voltaje, gases, maquinaria en

movimiento y bordes ilosos.

4. CAPACITACIÓN: Este equipo de ser utilizado por personas que han

sido capacitadas apropiadamente en cuanto a su aplicación y uso

correctos.

d. Requisitos

Consulte los requisitos (OSHA) locales, estatales y federales aplicables

que rigen este equipo para obtener más información sobre los anclajes

y los componentes de sistema asociados, incluyendo; ANSI Z359.1, y

OSHA 29 CFR1910.66, anexo C.

IV. Etiquetas/Identi cación/Registros de inspección

a. Todos los productos deben ser inspeccionados completamente por el

ESPAÑOL

Página 28

Page 29

ANCLAJES TIPO D-BOLT

INSTRUCCIONES PARA EL USUARIO

usuario antes de cada uso. Una persona capacitada diferente al usuario

debe realizar inspecciones adicionales, al menos anualmente. Ese intervalo

debe acortarse cada vez que el producto se utiliza en un ambiente agresivo

o se expone a condiciones tales como productos químicos, abrasión, calor

o cualquier otro factor que pudiera afectar la resistencia de cualquiera de

los materiales o componentes.

b. Este manual siempre debe acompañar el producto o estar en los archivos

del empleador para consultarlo cuando se requiera. Registre los detalles

de identi cación para el anclaje y registre las inspecciones en el registro de

inspección mostrado. Es importante mantener este registro actualizado,

completo y disponible según se requiera.

Etiqueta de identiicación/ advertencia

ADVERTENCIA

Debe leer el manual del usuario y

entender todas las instrucciones y

advertencias. Reera al manual de la

instrucción para las limitaciones de la

estabilidad y de la compatibilidad.

Si el manual del usuario está faltando,

comuníquese con Werner Co. para

obtener una copia de reemplazo. La

manga azul debe sobresalir del borde

de concreto despues de su instalacion

Antes de cada uso, el producto debe

inspeccionarse de acuerdo con las

instrucciones del manual, luego debe

ser inspeccionado periódicamente por

una persona capacitada que no sea

el usuario. NO se permiten

reparaciones o alteraciones por parte

del usuario. Verique que los

conectores sean compatibles (véase

el manual de la instrucción). El OSHA,

CSA y las regulaciones locales

requieren que los trabajadores reciban

el entrenamiento en el uso y las

limitaciones apropiados del equipo

del alojamiento de la caída.

¡NO LEER Y NO TENER EN CUENTA

TODAS LAS ADVERTENCIAS PODRÍA

RESULTAR EN LESIONES O LA MUERTE!

© 2011 Werner Co.

PN104277-02 RevB 12/11

ESPAÑOL

Página 29

Page 30

Minimum Breaking Strength:

Resistencia a Ruptura Mínima:

5,000lbs / 22.2 kN

Model / Modelo:

A320001-WB

Materials:

Materiales:

Steel / Acero

Date of

Manufacture:

Fecha de

la Fabricación:

XX/XX

Inspection Log/Registro de Inspección

Yea r

Yea r

Yea r

Yea r

Año

1

2

Año

3

Año

Año

Yea r

4

5

Año

10

11

12

Standards/Estándares

ANSI Z359.1-2007, OSHA 1910-1926

Model/Modelo:

Material

Materiales:

Maximum Capacity:

Capacidad máxima:

Year of Manufacture:

Año de la fabricación:

Greenville, PA 16125 • 888-523-3371

310 lb./141 kg

2016

1

2

3

4

5

6

7

8

9

Warning: User must follow manufacturer’s instructions

included with the equipment at the time of shipment

from the manufacturer. Refer to the instruction manual

for proper installation and stability and compatibility

limitations. Inspect prior to use.

Serial Number:

Número de Serie:

Max Capacity

(user with tools):

Capacidad Máxima

(usuario con las

herramientas):

Assembled in:

Ensemblado en:

ESPAÑOL

Página 30

xxxxxx

400 lb

181 kg

US

Standards/Estándares

ANSI Z359.1-2007, OSHA 29 CFR 1910, 1926

93 Werner Road, Greenville, PA 16125

1-888-523-3371 • www.wernerco.com

© 2016 Werner Co.

P/N 110643-01 Rev A 8/16

Page 31

V. Registro del equipo

ANCLAJES TIPO D-BOLT

INSTRUCCIONES PARA EL USUARIO

NÚMERO DE

PIEZA

NÚMERO DE SERIE

FECHA DE

FABRICACIÓN

FECHA DE COMPRA

ESPECIFICACIONES

Anclajes tipo D-Bolt de Werner Co.

Certi cada para cumplir las regulaciones y normas ANSI Z359.1-2007, OSHA

1910 y 1926.

Los números de modelo y números de serie, sitio y fecha de fabricación, con

código de barras individual, están en la etiqueta del producto.

VI. Registro de inspección

ASIGNADO A

REGISTRO DE INSPECCIÓN

FECHA INSPECTOR APROBADO/

NO-APROBADO

FECHA INSPECTOR APROBADO/

NO-APROBADO

ESPAÑOL

Página 31

Page 32

Werner Co. Fall Protection

93 Werner Rd. Greenville, PA 16125

724-588-2000 • 888-523-3371 toll free/ llamada gratuita • 888-456-8458 fax

PN104676-01 ©2016 Werner Co. Rev B 8/16

Loading...

Loading...