Page 1

FALL PROTECTION

PROTECCIÓN CONTRA CAÍDAS

USER INSTRUCTIONS

INSTRUCCIONES PARA EL USUARIO

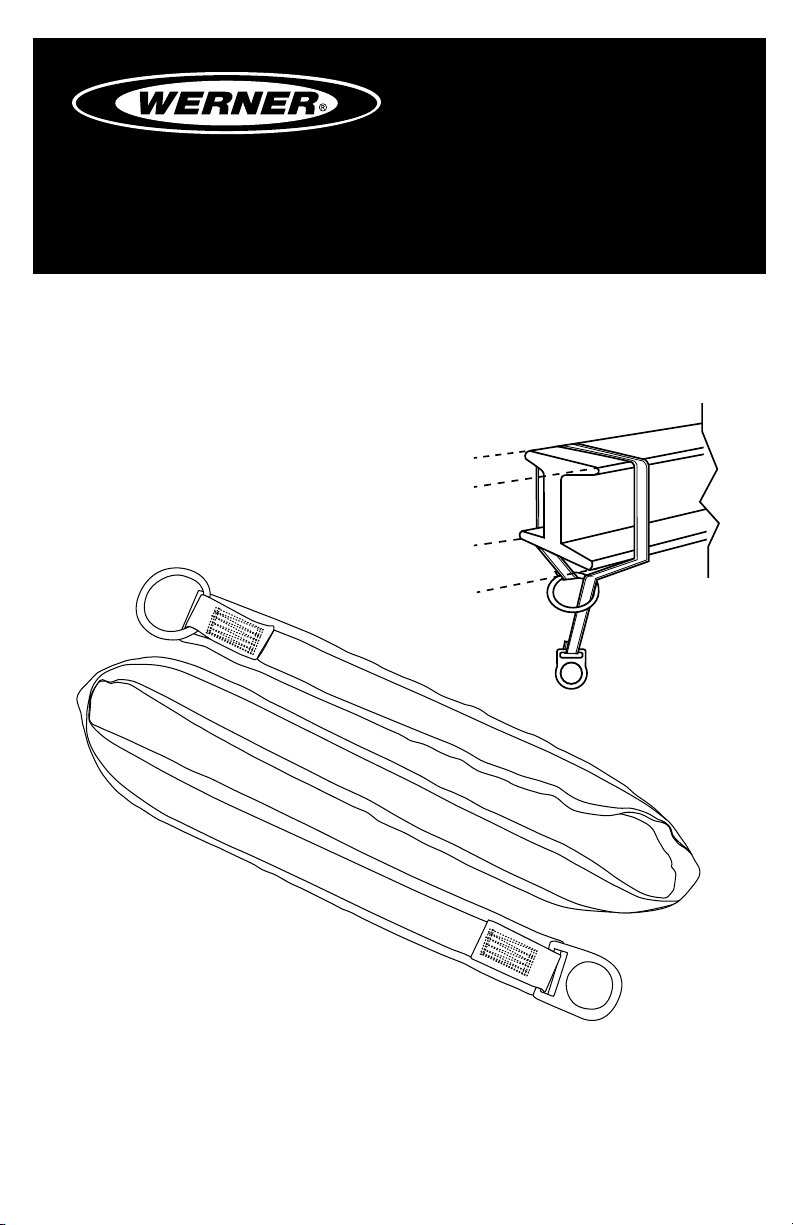

SOFT ANCHORAGE CONNECTOR

Complies with ANSI Z359.1-2007,

OSHA 1910 and 1926 requirements.

CONECTOR DE ANCLAJE FLEXIBLE

Cumple con las normas ANSI Z359.1-2007,

OSHA 1910 y 1926.

(See back page for specic model numbers.)

(Vea la página trasera para obtener los números de modelo especícos).

Werner Fall Protection 724-588-2000

93 Werner Rd. 888-523-3371 toll free/ llamada gratuita

Greenville, PA 16125 888-456-8458 fax

Page 2

CAUTION!

If use of fall protection equipment is necessary then the work

environment is dangerous and potentially deadly. Werner Company

products are designed to eliminate as much of the hazard as possible

but can do that ONLY if they are used correctly. Use this equipment as

it was designed to be used, after appropriate training, under the direct

supervision of a competent person, according to the instructions

provided, and in accordance with OSHA and local safety regulations.

User MUST read and understand all cautions and instructions. Failure

to heed these guidelines could result in injury or even death. Please,

WORK SAFE! WORK SMART!

ENGLISH

Page 2

Page 3

SOFT ANCHORAGE CONNECTOR

USER INSTRUCTIONS

Contents

I. BEFORE USING THE ANCHORAGE CONNECTOR ........................................ 4

a. Inspect ......................................................................................................................4

b. Compatibility ............................................................................................................6

c. Clearance ..................................................................................................................6

d. Rescue Plan .............................................................................................................6

e. Training .....................................................................................................................6

II. ANCHORAGE CONNECTOR INSTALLATION AND USE ................................ 6

a. Cable and Webbing Slings, Chokers and Cross-arm Straps ................................6

b. Anchorage Structure ...............................................................................................7

c. Cable Chokers ..........................................................................................................8

d. Cross-arm Straps / Webbing Chokers ....................................................................9

e. Cable Anchor Extensions ......................................................................................10

f. Pour-In Anchor Straps ...........................................................................................11

III. USE WARNINGS, RESTRICTIONS AND CAUTIONS ................................... 12

a. Fall Distance ..........................................................................................................12

b. Swing Fall Hazard ..................................................................................................13

c. Rated Capacity .......................................................................................................13

d. Environmental Hazards .........................................................................................13

e. Components/Subsystems .....................................................................................14

IV. LABELS/IDENTIFICATION/INSPECTION RECORDS .................................. 14

V. EQUIPMENT RECORDS ................................................................................18

VI. INSPECTION RECORDS .............................................................................. 18

ENGLISH

Page 3

Page 4

Warning:

This product is just one part of a personal fall arrest system. It must

be matched correctly with other components to form a complete and

functional system. The user must understand the function of each of

these components and follow the manufacturer’s instructions for use

for each. The user must be provided these instructions, should read

and follow them, and consult the competent person who will supervise

his work if he has any questions about any part of the instructions.

The employer must provide training in the proper use, inspection, and

maintenance of all components in the system, and these instructions

can be used as part of that training. The equipment should be used

ONLY in accordance with these instructions, local ordinances and

codes, the applicable OSHA and ANSI standards, and the employer’s

safety plan.

These devices are designed to provide an anchorage connection

between fall protection products and/or anchorages, for both fall

protection and fall restraint. They can accommodate attachment

options for a variety of fall protection products for fall protection or

rescue equipment that might be required, so long as the rated capacity

is not exceeded.

IF YOU HAVE ANY QUESTIONS ABOUT ANYTHING IN THESE

INSTRUCTIONS, THE EQUIPMENT, OR PROPER USE OF THE

EQUIPMENT, CONTACT WERNER CO. FOR MORE INFORMATION.

I. Before Using the Anchorage Connector

Before using this equipment the user should take certain steps to

ensure that it is in suitable condition and safe for use. Users must

read and understand these instructions. It is the employer’s obligation

to ensure that all users have been trained in safe work procedures as

well as in the use and limitations of fall protection equipment. All users

should be aware of and comply with all applicable OSHA, ANSI, CSA

and local or regional regulations concerning fall protection equipment

and its use.

a. Inspect

Examine all equipment thoroughly, daily before use by the user,

ENGLISH

Page 4

and periodically by a competent person who is not the user.

Page 5

SOFT ANCHORAGE CONNECTOR

USER INSTRUCTIONS

1. Verify the condition of each component. If any damage or

abnormalities are found the equipment should be removed from

service.

2. Check the webbing for cuts, abrasion, burns, welding spatter, or

discoloration that could be caused by chemical exposure.

3. For cable legs examine the entire length for any breaks, and the

swaged ttings for any irregularities.

4. Check all stitching for any broken threads.

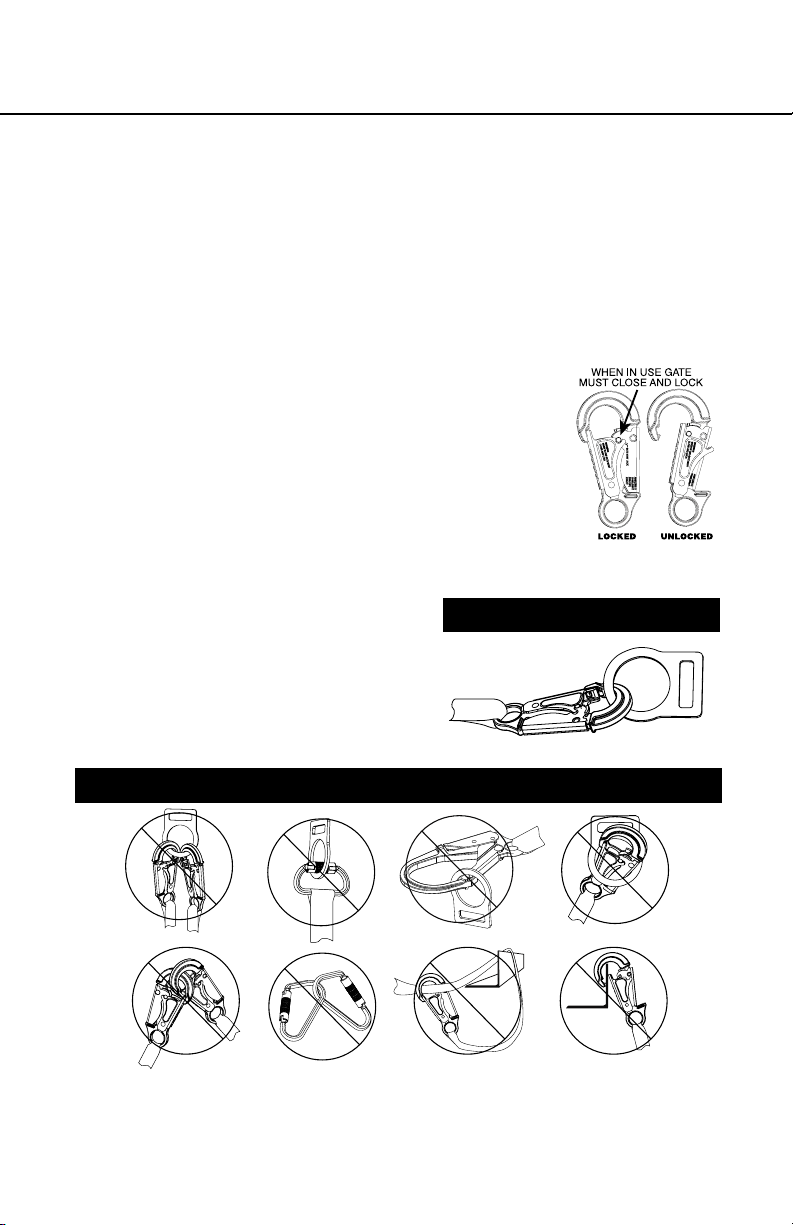

5. Check all hardware for cracks, bends,

irregularities, corrosion, or sharp edges.

Check the snap hook gates for proper

smooth operation. The engagement

release for the hook’s gate is visible for

inspectability. Ensure the mechanism is

undamaged and functioning correctly.

6. Verify that all labels are intact, in place, and legible.

If abnormalities are found in

any of these areas, then the

competent person should be

consulted to determine if that

item is safe for continued use

or if it should be removed from

service.

PROPER CONNECTIONS

INAPPROPRIATE CONNECTIONS

A. B.

NO! NO! NO! NO!

D. E. F.

C.

NO!NO!NO!NO!

ENGLISH

Page 5

Page 6

b. Compatibility

Verify compatibility of any subsystems being used. Werner

products connected to Werner products should be compatible, but

connection to other products should be veried by a competent

person for compatibility to ensure there is no accidental detachment

from side-loading, rollout, non-standard closures, etc.

c. Clearance.

Verify that adequate clearance exists below the work area and

there are no objects or obstructions below the work area that the

user could contact in the case of a fall.

d. Rescue Plan

If a worker falls and is forced to remain suspended for any length

of time, physical damage to the body or even death can result. For

this reason Werner, OSHA, ANSI, CSA and most local regulations

require that a rescue plan and the means to implement the rescue

plan are in place before use of this equipment.

e. Training

OSHA, ANSI, and most local ordinances require that workers using

this product receive adequate training before use of this product.

These instructions and their entire contents should be a part of that

training.

II. Anchorage Connector Installation and Use

a. Cable and Webbing Slings, Chokers and Cross-arm Straps

Also known as tie-off adapters, these devices are designed to

wrap around a structure which is the anchorage. They act as

a connector to that anchorage for attachment of a complete fall

protection system. All have D-rings, O-rings, or web loops and are

passed around the structure and then secured by being passed

back through the second O-ring, D-ring or web loop to “choke” the

anchorage.

Warning:

Webbing chokers and cross arm straps should not be left installed

permanently outdoors since prolonged exposure to the environment

and especially to UV in sunlight will degrade the webbing, reducing

ENGLISH

tensile strength.

Page 6

Page 7

SOFT ANCHORAGE CONNECTOR

USER INSTRUCTIONS

b. Anchorage Structure

Inspect the anchorage structure to ensure it is of adequate strength

and is sound, without sharp edges, corrosion, cracks or anything

else that could weaken the connection. The connectors can be

used vertically, but ensure that the choker has some stop so it will

not be able to move on the structure in the case of a fall.

1. For fall arrest, anchors need to have strength of either 5000

lbs per attached user (22.2kN), or be certied by a qualied

person to have strength of not less than 3600 lbs per attached

user (16kN).

2. For fall restraint (where there is no possibility of accidental

detachment), anchors need to withstand a static load of 3000

lbs per attached user (13.3 kN), or be certied by a qualied

person to be able to withstand two times the foreseeable force.

3. For positioning systems, the anchorage strength must be a

minimum of 3000 lbs per attached user (13.3 kN), or be certied

by a qualied person to have strength of twice the foreseeable

force.

4. For rescue systems, the anchorage should withstand a static

load of 3000 lbs per attached user (13.3kN) or be certied by a

qualied person for ve times the foreseeable load.

Page 7

ENGLISH

Page 8

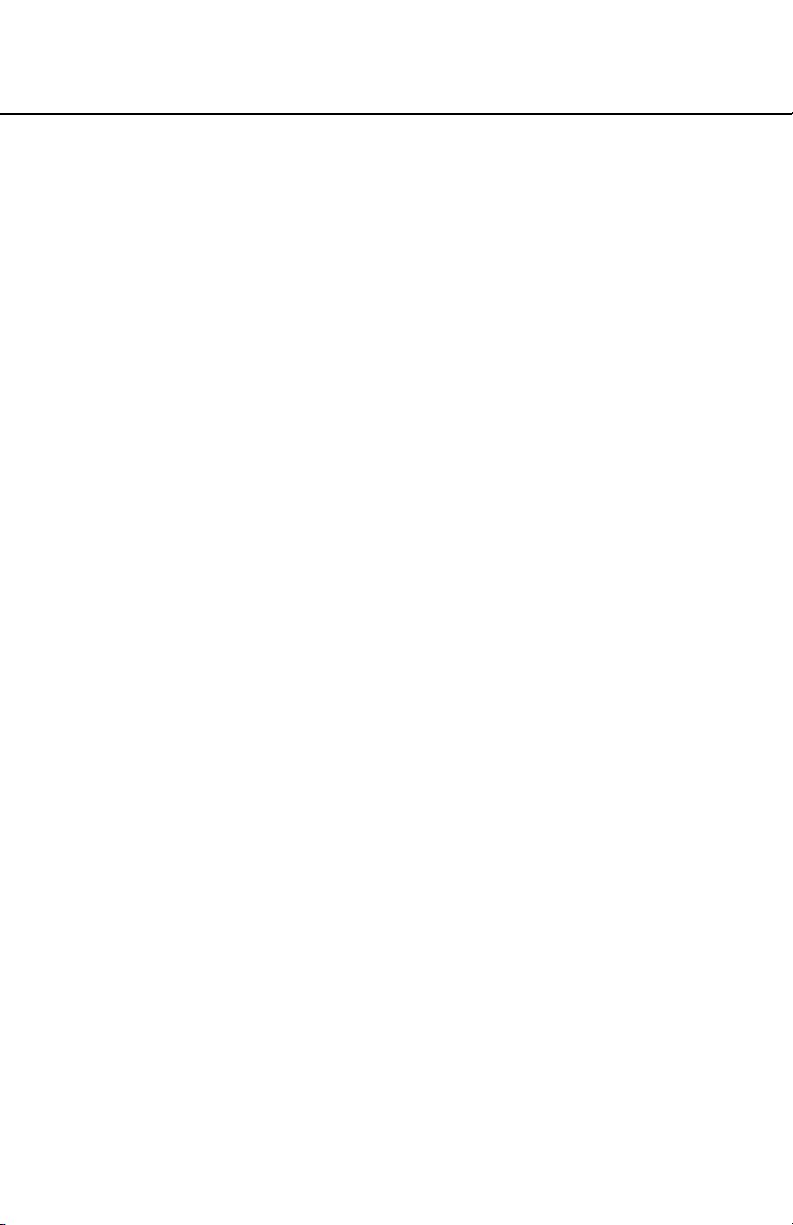

c. Cable Chokers

Cable chokers are used when the anchorage

they are being connected to will not be

damaged by the cable in the case of a fall,

such as structural I-beams, or when the

choker will be left in place and subjected to the

environment for an extended period of time.

Installing Cable Chokers

1. Pass cable over structure with choker ends

dangling on either side. Pass the small

O-ring on one end through the larger O-ring

on the other end. Pull small O-ring to tighten

(choke) the structure.

2. Continue to pass the extended cable end

around the beam or other anchor until

there is not enough length left to make

another complete revolution. Then “choke”

the anchor by passing the smaller O-ring

through the larger. The small O-ring will

become the anchorage point for a complete

fall protection system.

While it is preferable to make several

turns of the cabling around the anchorage

before “choking” it, in cases where a lower

anchorage connection is needed the

connector can be choked with only one turn

around the beam before passing the small

O-ring through the larger O-ring. This is

also a convenient way to adjust the length

of the choker slightly.

3. Connect fall protection system to the small O-ring.

ENGLISH

Page 8

Page 9

SOFT ANCHORAGE CONNECTOR

USER INSTRUCTIONS

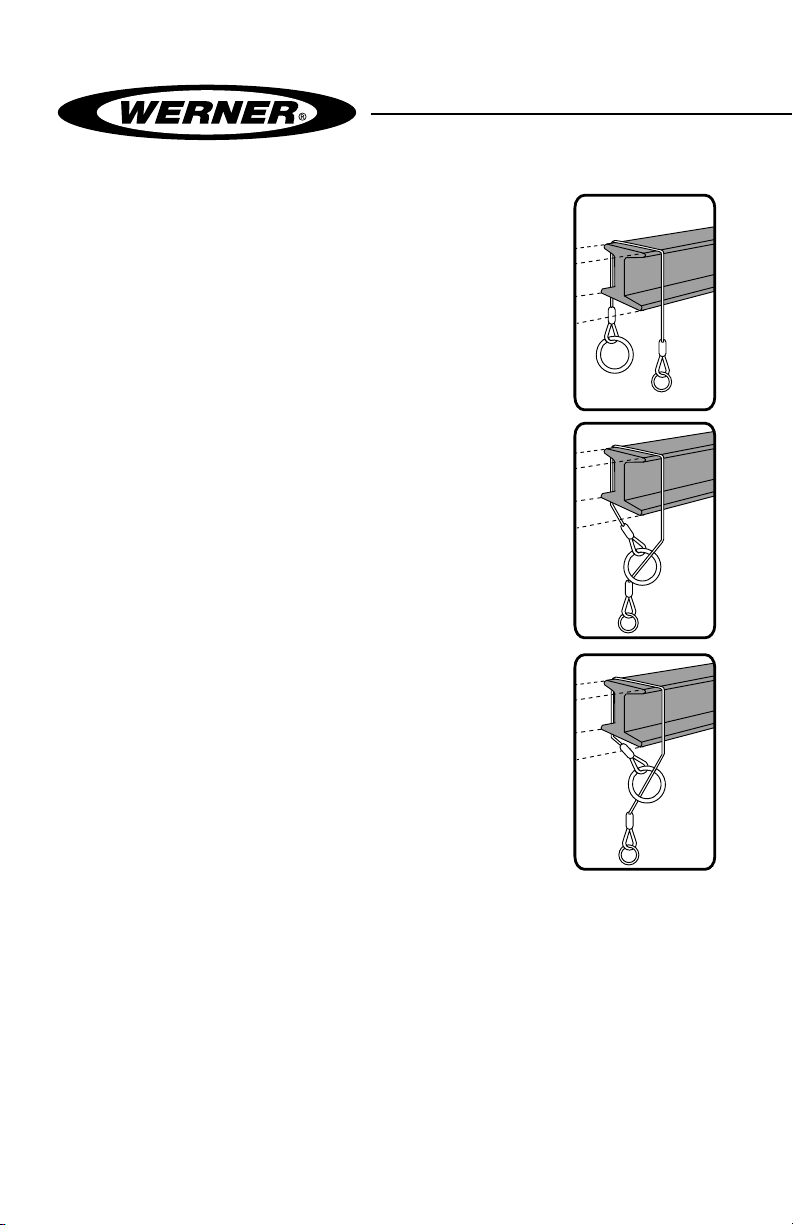

d. Cross-arm Straps / Webbing Chokers

Web chokers work the same as cable chokers,

but the wider surface of the webbing means that

the impact in the case of a fall will be spread over

a larger area considerably reducing the impact

per square inch.

Installing Cross-arm Straps

1. With labels on outward facing surface of strap.

Pass web over structure with choker ends

dangling on either side. Pass the small D-ring

or O-ring on one end through the larger

D-ring, O-ring or web loop on the other end.

Pull small D-ring or O-ring to tighten (choke)

the structure.

2. Continue to pass the extended web end

around the beam or other anchor until there

is not enough length left to make another

complete revolution, then “choke” the anchor

by passing the smaller O-ring or D-ring

through the larger O-ring or web loop. The

small D-ring will become the anchorage point

for a complete fall protection system.

It’s preferable but not necessary to make

several turns of the webbing around the anchorage before

“choking” by passing the small D-ring or O-ring through the

larger O-ring or web loop. This is also a convenient way to adjust

the length of the cross arm strap slightly.

Warning:

3. Connect fall protection system to the smaller D-ring or O-ring.

ENGLISH

Page 9

Page 10

ENGLISH

Page 10

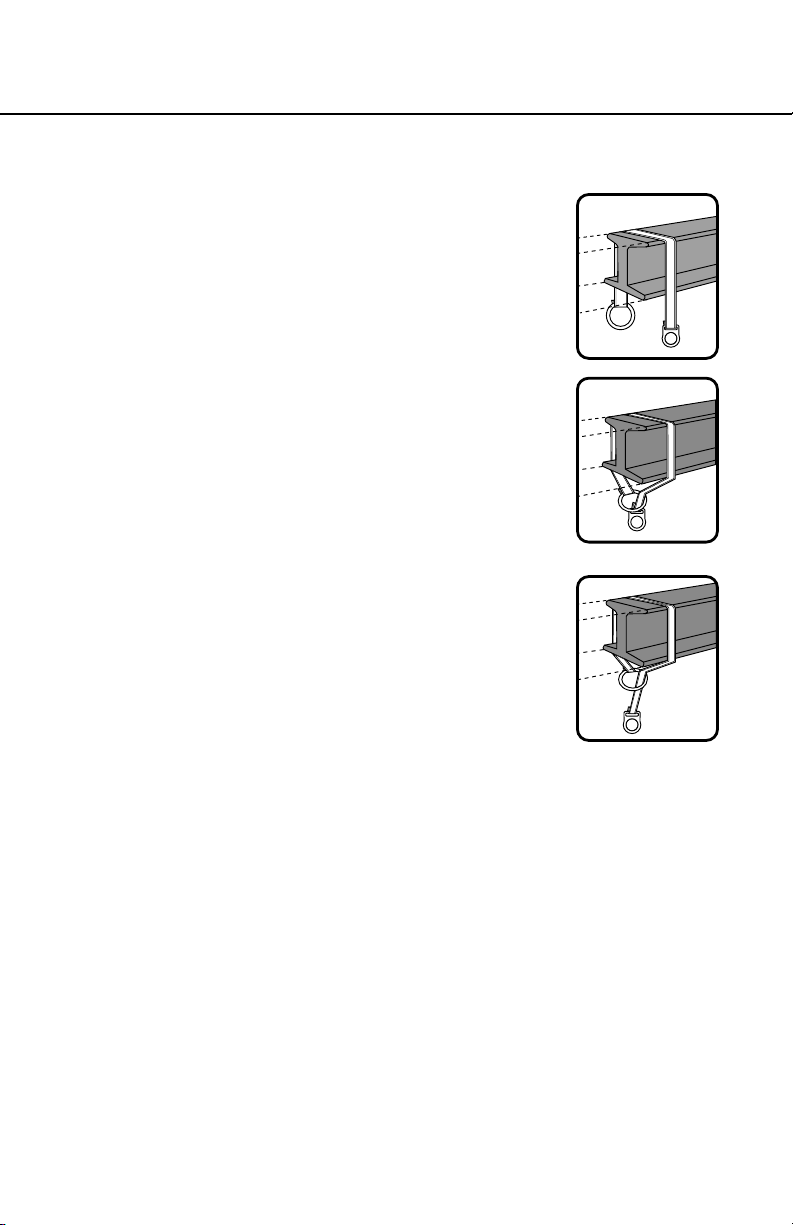

e. Cable Anchor Extensions

Cable anchor extensions come in various

standard lengths. They differ from cable

chokers because they are intended

to extend the position of an existing

anchorage connector to within reach of a

user, so the extensions have a snap-hook on one end to connect

to the existing anchorage connector, and an O-ring on the other, to

provide the new extended anchorage connection for the user.

Installing a Cable Anchor Extension

1. Calculate the needed extension length considering the worker’s

needs and the available fall distance to be sure there will not be

any contact with any object in the fall path. Connect the snap

hook to the existing fall protection anchorage. Connect ONLY

with the snap hook and NEVER loop the extender around the

anchorage as you would a choker.

2. The user should connect to the extender’s O-ring as he would to

any other suitable anchorage.

CAUTION:

Anchor extensions are not cable

chokers and should not be used

as such. The ONLY approved

fall protection attachment

point is to the O-ring. NEVER

connect two snap hooks to

one O-ring or the snap hook

to the cable. Connect it ONLY

to the existing anchorage.

The Anchorage Extenders are

not anchorages themselves.

They are only extensions of

an existing anchorage. ONLY

connect the Anchor Extensions

to an overhead anchor and

never in any position that could

increase the user’s fall distance

beyond the allowable free fall

distance of 6 feet.

Page 11

SOFT ANCHORAGE CONNECTOR

USER INSTRUCTIONS

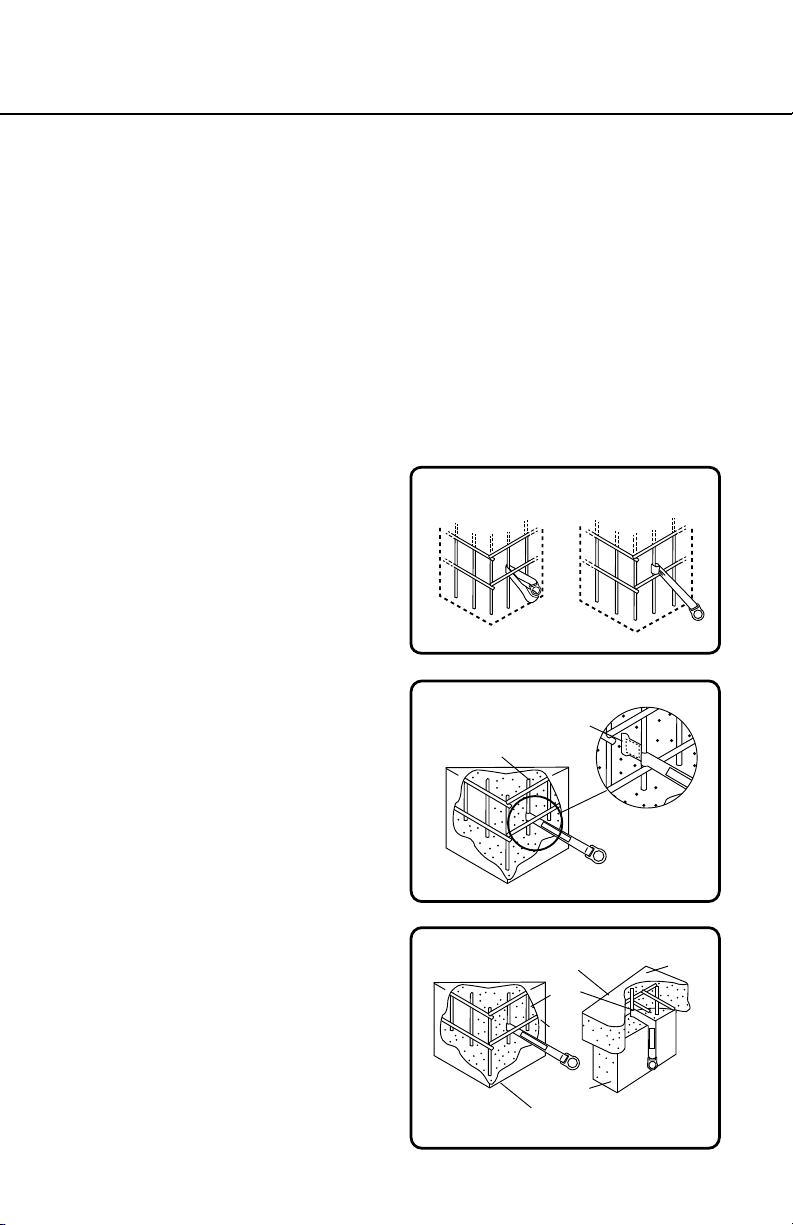

f. Pour-In Anchor Straps

Pour-in-place anchors are actually simplied standard web chokers

that have been modied to continue functioning as an anchorage

connector after being partially embedded in concrete. As such they

conform to most of the same instructions and warnings contained

in the previous Cross arm strap/ webbing choker section. All Werner

Pour-In anchors are for one-time use only.

Installing a Pour-In Anchor Strap

1. Select a location with required anchorage strength and

unobstructed fall clearance. Either place the strap’s loop end

over the rebar or use the

loop to “choke” it. To choke

it, loop strap around

the re-bar and pull the

exposed end (with loop

or D-ring) through the end

loop. Tighten the choke

on the rebar. Position the

exposed end with the

other loop or D-ring at

least six inches outside

the form. Secure the strap

so that it can not be pulled

inside when the concrete

is poured. Position the

strap’s wear protector so

it will be partly embedded

in the poured concrete

and partly exposed. It’s

important that the wear

protector is positioned

to protect the main loadbearing webbing from

contact with the sharp

edge of the poured

concrete.

Installing on Completed Cage

Anchorage Connector Installed

Steel

Re-bar

Concrete

Column

Anchorage Connector Installed

4” min

Steel

Re-bar

Shear

Wall

Web Cut

Line

Poured

Concrete

Floor

Concrete

Column

Imbedded Concrete

Anchor Strap

ENGLISH

Page 11

Page 12

2. The user should connect to the Pour-In Anchor’s D-ring or loop

as he would to any other suitable anchorage.

When connecting to a web loop use ONLY a carabiner, NEVER

a snaphook. Never connect two users to the same anchorage.

Never connect two snap hooks or carabiners to the same

connector.

3. Cut off and discard exposed portion of anchor strap after use.

III. Use Warnings, Restrictions and Cautions

a. Fall Distance

Equipment is designed for a maximum free fall of 6 feet. Contact

with a lower level can occur even when this equipment is in perfect

operating condition if there is any object in the path of the fall or

if the height of the anchorage being used is inadequate. The fall

distance can vary according to the connecting subsystem used. The

following diagrams indicate typical clearance calculations for shock

absorbing lanyards and self-retracting lifelines. While these are

typical situations, the authorized/competent person on site should

make these determinations for each work situation depending on

the site-specic conditions.

Fall distance for shock absorbing lanyards

Energy

Free Fall

Absorbing

Lanyard

Working Level

Length of Anchorage Connector

6 ft.

Length of Lanyard

4 ft.

Deceleration Free Fall Distance

1 ft. Harness Stretch

(Free Fall +

Deceleration)

Total Fall

Distance

11 ft.

Total Estimated

Fall Distance

18 ft.

ENGLISH

Page 12

Lower Level or Obstruction

5 ft.

To Worker’s Back D-Ring

2 ft.

Safety Factor

Page 13

SOFT ANCHORAGE CONNECTOR

USER INSTRUCTIONS

Fall distance for self-retracting lifeline

Self Retracting

Lifeline

Working Level

Lower Level or Obstruction

Swing Fall Hazard

Bottom of Retractable Lifeline

2 ft.

Maximum Free Fall

2.5 ft.

Maximum Deceleration

1 ft. Harness Stretch

5 ft.

To Worker’s Back D-Ring

2 ft.

Safety Factor

Maximum Arrest

Distance (per ANSI)

4.5 ft.

Anchorages

Total Estimated

Fall Distance

12.5 ft.

Position the worker below the

anchorage so if a fall occurs the

worker will not swing into an object

below the work surface.

c. Rated Capacity.

Correct Incorrect

1. Capacity: 310 lbs., including tools and equipment (one person)

2. Strength: For fall arrest OSHA requires a static tensile strength of

5000 lbs. This connector satises the OSHA and ANSI strength

requirements when used in accordance with OSHA, ANSI, CSA

standards, local regulations and the manufacturer’s instructions.

3. These anchors are for fall protection, fall restraint and rescue

use only. They are not designed to hang, support, or lift materials

or equipment.

b .

SWING FALL

HAZARD

d. Environmental Hazards.

This equipment is to be used only under the direct supervision of

a competent person who is able to identify hazards that must be

avoided. These include electricity, chemicals, machinery or moving

objects, sharp edges, damaged anchorages or structures, or any

other element that could damage this equipment or prevent it from

operating as intended.

Page 13

ENGLISH

Page 14

e. Components/Subsystems

Before rst use a qualied person should inspect and determine that

all components and subsystems are compatible and will perform

correctly when combined into a complete personal fall protection

system. Consult the information in these instructions, and if any

additional information is needed contact Werner Co. directly.

IV. Labels/Identication/Inspection Records

a. All products should be inspected by the user thoroughly before

each use. Additional inspections by a competent person other than

the user should be conducted at intervals of no less than one year.

That interval should be shortened any time the product is used in a

harsh environment or is exposed to conditions such as chemicals,

abrasion, heat or any other factor that could affect the strength of

any of the materials or components.

b. The product labels provide an inspection grid to record these

inspections by a competent person. Use a punch or permanent

marker to record those dates.

c. This manual should always accompany the product, or be on le

with the employer for access when needed. Record the identication

details for the anchor and record the inspections in the inspection

log, on page 18. It is important to keep this log current, complete,

and available as needed.

ENGLISH

Page 14

Page 15

SOFT ANCHORAGE CONNECTOR

USER INSTRUCTIONS

front back

Id label

ENGLISH

Page 15

Page 16

ENGLISH

Page 16

front back

Warning label Chokes & Extensions

Page 17

SOFT ANCHORAGE CONNECTOR

USER INSTRUCTIONS

front back

Warning Label Pour-In anchors

ENGLISH

Page 17

Page 18

V. Equipment Record

PART NUMBER

SERIAL NUMBER

DATE

MANUFACTURED

PURCHASE DATE

ASSIGNED TO

SPECIFICATIONS

Werner SOFT ANCHORAGE

Certied to meet ANSI Z359.1-2007, and OSHA 1910 and 1926

standards and regulations for the lanyard component of a

complete personal fall arrest system. All hardware certied to

5000 lb. breaking strength, 100 percent proof tested to 3600 lbs.

Individually bar coded model and serial numbers, location and date of

manufacture are on product label.

VI. Inspection Record

INSPECTION RECORD

DAT E INSPECTOR PASS/FAILDAT E INSPECTOR PASS/FAIL

ENGLISH

Page 18

Page 19

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

¡PRECAUCIÓN!

Si el uso de equipos de protección contra caídas es necesario, entonces el

ambiente de trabajo es peligroso y potencialmente mortal. Los productos

Werner Company están diseñados para eliminar peligros tanto como sea

posible, pero SÓLO si estos productos se utilizan correctamente. Utilice este

equipo ya que éste fue diseñado para usarse, utilice este equipo después

de una capacitación apropiada, bajo la supervisión directa de una persona

calicada, de acuerdo con las instrucciones suministradas, y de acuerdo con

las regulaciones OSHA y las regulaciones de seguridad locales. El usuario

DEBE leer y entender todas las precauciones e instrucciones. No tener en

cuenta estas directrices podría resultar en lesiones o incluso la muerte. Por

favor, ¡TRABAJE DE MANERA SEGURA! ¡TRABAJE DE MANERA INTELIGENTE!

Página 2

ESPAÑOL

Page 20

Contenido

I. ANTES DE UTILIZAR EL CONECTOR DE ANCLAJE ..................................... 4

a. Inspeccione .............................................................................................................4

b. Compatibilidad ........................................................................................................6

c. Espacio libre ...........................................................................................................6

d. Plan de rescate .......................................................................................................6

e. Capacitación ...........................................................................................................6

II. INSTALACIÓN Y USO DEL CONECTOR DE ANCLAJE .................................6

a. Eslingas de correa tejida y de cable, correas de estrangulación y

correas de cruzar ....................................................................................................6

b. Estructura del anclaje.............................................................................................7

c. Cables de estrangulación ......................................................................................8

d. Correas tejidas de estrangulación / correas de cruzar .......................................9

e. Extensiones de anclajes de cable .......................................................................10

f. Correas de anclaje instalables durante el vertido de concreto

III. TENGA EN CUENTA LAS ADVERTENCIAS, RESTRICCIONES

Y PRECAUCIONES ................................................................................... 12

a. Distancia de caída..................................................................................................12

b. Peligro de caída tipo columpio ............................................................................13

c. Capacidad nominal ................................................................................................13

d. Peligros ambientales .............................................................................................13

e. Componentes/Subsistemas ..................................................................................14

IV. ETIQUETAS/IDENTIFICACIÓN/REGISTROS DE INSPECCIÓN .................. 14

V. REGISTROS DE EQUIPOS ............................................................................ 18

........................11

VI. REGISTROS DE INSPECCIÓN ..................................................................... 18

ESPAÑOL

Página 3

Page 21

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

Advertencia:

Este producto es sólo una parte del sistema personal de detención de

caídas. Éste debe combinarse correctamente con otros componentes para

conformar un sistema completo y funcional. El usuario debe entender la

función de cada uno de estos componentes y seguir las instrucciones del

fabricante para el uso de cada componente. El usuario debe recibir estas

instrucciones, debe leerlas y seguirlas, y consultar a la persona calicada que

supervisará su trabajo si tiene alguna pregunta acerca de cualquier parte de

las instrucciones. El empleador debe proporcionar capacitación sobre el uso

apropiado, inspección y mantenimiento de todos los componentes del sistema,

y estas instrucciones pueden utilizarse como parte de esa capacitación. El

equipo SÓLO debe utilizarse de acuerdo con estas instrucciones, ordenanzas

y códigos locales, las normas OSHA y ANSI aplicables, y el plan de seguridad

del empleador.

Estos dispositivos están diseñados para proporcionar una conexión de

anclaje entre los productos de protección contra caídas y/o los anclajes, para

protección contra caídas y evitamiento de caídas. Éstos pueden incorporar

opciones de sujeción para una variedad de productos de protección contra

caídas para equipos de protección contra caídas o de rescate que pudieran

requerirse, siempre y cuando no se exceda la capacidad nominal.

SI USTED TIENE ALGUNA PREGUNTA ACERCA DE ALGO DE ESTAS

INSTRUCCIONES, EL EQUIPO O EL USO APROPIADO DEL EQUIPO,

COMUNÍQUESE CON WERNER CO. PARA OBTENER MÁS INFORMACIÓN.

I. Antes de utilizar el conector de anclaje

Antes de utilizar este equipo, el usuario debe realizar ciertos pasos para

garantizar que éste está en condiciones apropiadas y es seguro para su uso.

Los usuarios deben leer y entender estas instrucciones. Es obligación del

empleador garantizar que todos los usuarios hayan recibido capacitación

sobre los procedimientos de trabajo seguros y también sobre el uso y

limitaciones de los equipos de protección contra caídas. Todos los usuarios

deben estar informados acerca de y cumplir todas las normas OSHA, ANSI,

CSA y las normas locales o regionales relacionadas con los equipos de

protección contra caídas y su uso.

a. Inspeccione

Todo el equipo debe ser examinado completamente, diariamente antes

del uso, por parte del usuario; y periódicamente por parte de una persona

calicada que no sea el usuario.

Página 4

ESPAÑOL

Page 22

1. Verique la condición de cada componente. Si se encuentra cualquier

daño o anormalidad, el equipo debe retirarse del servicio.

2. Revise las correas tejidas en busca de cortaduras, abrasión,

quemaduras, salpicadura de soldadura, o decoloración que pudiera

haberse causado por exposición a productos químicos.

3. Para los tramos de cuerda/cable, examine toda la longitud en busca de

cualquier rotura y examine los acoples forjados en busca de cualquier

irregularidad.

4. Revise todas las costuras en busca de hilos

rotos.

CUANDO ESTÁ EN USO,

EL CIERRE DEBE QUEDAR

CERRADO Y ASEGURADO

5. Revise todos los herrajes en busca de grietas,

dobladuras, irregularidades, corrosión o bordes

losos. Revise los ganchos de cierre resortado

para vericar el funcionamiento sin problemas.

El liberador de enganche del cierre del gancho

es visible para inspeccionabilidad. Verique

ASEGURADO

DESASEGURADO

que el mecanismo no tiene daños y está funcionando correctamente.

6. Verique que todas las etiquetas están intactas, en su sitio, y son legibles.

Si se encuentran anormalidades

en alguna de estas áreas,

CONEXIONES APROPIADAS

entonces debe consultarse a la

persona capacitada para que

determine si ese elemento es

seguro para continuar su uso o si

debe retirarse del servicio.

CONEXIONES INAPROPIADAS

A. B.

NO! NO! NO! NO!

D. E. F.

ESPAÑOL

Página 5

C.

NO!NO!NO!NO!

Page 23

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

b. Compatibilidad

Verique la compatibilidad de todos los subsistemas que se están

utilizando. Los productos Werner conectados con productos Werner son

compatibles, pero la conexión con otros productos debe ser vericada,

por una persona capacitada, en cuanto a compatibilidad para garantizar

que no haya desconexión accidental por carga lateral, rodaje, cierres noestándares, etc.

c. Espacio libre.

Verique que existe una altura libre adecuada debajo del área de trabajo y

que no hay objetos ni obstrucciones debajo del área trabajo que el usuario

pudiera contactar en caso de una caída.

d. Plan de rescate

Si un trabajador cae y queda obligado a permanecer suspendido durante

cualquier período de tiempo, podría producirse daño físico o incluso la

muerte. Por este motivo, Werner, las regulaciones de OSHA, ANSI, CSA,

y la mayoría de las regulaciones locales exigen la existencia de un plan

de rescate y los medios para ejecutar un plan de rescate, antes del uso

de este equipo.

e. Capacitación

Las regulaciones OSHA, ANSI, y la mayoría de las regulaciones locales

exigen que los trabajadores que utilizan este producto reciban capacitación

adecuada antes del uso de este producto. Estas instrucciones y su

contenido completo deben ser parte de esa capacitación.

II. Instalación y uso del conector de anclaje

a. Eslingas de correa tejida y de cable, correas de estrangulación y

correas de cruzar

También conocidas como adaptadores de amarre, estos dispositivos

están diseñados para envolverse alrededor de una estructura que es el

anclaje. Éstas actúan como conector para ese anclaje para la sujeción de

un sistema completo de protección contra caídas. Todas tienen anillos en

“D”, anillos en “O”, o lazos tejidos, y se pasan alrededor de una estructura

y luego se aseguran pasándose de regreso a través del segundo anillo en

“O”, anillo en “D” o lazo tejido para “estrangular” el anclaje.

Advertencia:

Las correas tejidas de estrangulación y las correas de cruzar no deben

dejarse instaladas de manera permanente en exteriores ya que la exposición

prolongada al ambiente y especialmente a la luz ultravioleta de la luz solar

degradarán la correa tejida, reduciendo la resistencia a la tracción.

Página 6

ESPAÑOL

Page 24

b. Estructura del anclaje

Inspeccione la estructura del anclaje para garantizar que tiene la

resistencia adecuada y es sólido, sin bordes losos, corrosión, grietas ni

nada que pudiera debilitar la conexión. Los conectores pueden utilizarse

verticalmente, pero verique que el estrangulador tiene algún tope de

modo que éste no podrá moverse sobre la estructura en caso de una

caída.

1. Para la detención de caídas, los anclajes deben tener una resistencia

de 5000 lbs por cada usuario conectado (22.2kN), o ser certicados

por una persona calicada indicando que tienen una resistencia no

inferior a 3600 lbs. por cada usuario conectado (16kN).

2. Para el evitamiento de caídas (donde no hay posibilidad de desconexión

accidental), los anclajes deben soportar una carga estática de 3000

lbs por cada usuario conectado (13.3kN), o ser certicados por una

persona calicada para poder soportar dos veces la fuerza previsible.

3. Para los sistemas de puesta en posición, la resistencia mínima de los

anclajes debe ser de 3000 lbs por cada usuario conectado (13.3 kN), o

ser certicados por una persona calicada para una resistencia de dos

veces la fuerza previsible.

4. Para los sistemas de rescate, los anclajes deben soportar una carga

estática de 3000 lbs por cada usuario conectado (13.3kN) o ser

certicados por una persona calicada para cinco veces la carga

previsible.

ESPAÑOL

Página 7

Page 25

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

c. Cables de estrangulación

Los cables de estrangulación se utilizan cuando

el anclaje al cual se está conectando no será

dañado por el cable en caso de una caída, tal como

vigas en “I” estructurales, o cuando el cable de

estrangulación se dejará en sitio y se expondrá al

ambiente durante un período de tiempo prolongado.

Instalación de cables de estrangulación

1. Pase el cable sobre la estructura con los

extremos del cable de estrangulación colgando

sobre cualquier lado. Pase el anillo en “O”

pequeño de un extremo a través del anillo en

“O” más grande del otro extremo. Hale el anillo

en “O” pequeño para apretar (estrangular) la

estructura.

2. Continúe pasando el extremo del cable extendido

alrededor de la viga u otro anclaje hasta que

no quede suciente longitud para realizar otra

revolución completa. Luego “estrangule” el

anclaje pasando el anillo en “O” más pequeño

a través del anillo en “O” más grande. El anillo

en “O” pequeño se convertirá en el punto de

anclaje para un sistema completo de protección

contra caídas.

Aunque es preferible realizar varios giros

del cable alrededor del anclaje antes de

“estrangularlo”, en casos donde se necesita

una conexión de anclaje más baja, el conector

puede estrangularse con sólo una vuelta

alrededor de la viga antes de pasar el anillo en

“O” pequeño a través del anillo en “O” más grande. Ésta también es

una manera conveniente de ajustar levemente la longitud del cable de

estrangulación.

3. Conecte el sistema de protección contra caídas al anillo en “O” pequeño.

Página 8

ESPAÑOL

Page 26

d. Correas tejidas de estrangulación / correas de

cruzar

Las correas tejidas de estrangulación funcionan igual

a los cables de estrangulación, pero la supercie

más ancha del tejido signica que el impacto en

caso de una caída será distribuido sobre una área

mayor reduciendo considerablemente el impacto por

pulgada cuadrada.

Instalación de las correas

1. Con las etiquetas en la supercie dirigida hacia

afuera de la correa. Pase la correa tejida sobre

la estructura con los extremos de la correa tejida

de estrangulación colgando sobre cualquier lado.

Pase el anillo en “D” o anillo en “O” pequeño de

un extremo a través del anillo en “D”, anillo en “O”

o lazo tejido más grande del otro extremo. Hale el

anillo en “D” o anillo en “O” pequeño para apretar

(estrangular) la estructura.

2. Continúe pasando el extremo tejido extendido

alrededor de la viga u otro anclaje hasta que

no quede suciente longitud para realizar otra

revolución completa, luego “estrangule” el anclaje

pasando el anillo en “O” o anillo en “D” más

pequeño a través del anillo en “O” o lazo tejido

más grande. El anillo en “D” pequeño se convertirá

en el punto de anclaje para un sistema completo de protección contra

caídas.

ESPAÑOL

Página 9

Es preferible pero no necesario realizar varios giros de la correa tejida

alrededor del anclaje antes de “estrangular” pasando el anillo en “D”

o anillo en “O” pequeño a través del anillo en “O” o lazo tejido más

grande. Ésta también es una manera conveniente de ajustar levemente

la longitud de la correa.

3. Conecte el sistema de protección contra caídas al anillo en “D” o anillo

en “O” más pequeño.ing:

Page 27

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

e. Extensiones de anclaje de cable

Las extensiones de anclaje de cable vienen

en diferentes longitudes estándares. Éstas

son diferentes de los cables de estrangulación

porque éstas están diseñadas para extender

la posición de un conector de anclaje existente

hasta dentro del alcance de un usuario, así que

las extensiones tienen un gancho de cierre resortado en un extremo para

conectar con el conector de anclaje existente, y un anillo en “O” en el otro

extremo, para proporcionar la nueva conexión de anclaje extendida para el

usuario.

Instalación de una extensión de anclaje de cable

1. Calcule la longitud de extensión necesaria considerando las necesidades del

trabajador y la distancia de caída disponible para garantizar que no habrá

ningún contacto con ningún objeto en la trayectoria de caída. Conecte el

gancho de cierre resortado al anclaje de protección contra caídas existente.

SÓLO conecte con el gancho de cierre resortado y NUNCA envuelva el

extensor alrededor del anclaje como usted lo haría con un estrangulador.

2. El usuario debe conectarse al anillo en “O” del extensor tal como lo haría con

cualquier otro anclaje apropiado.

PRECAUCIÓN:

Las extensiones de anclaje no

son cables de estrangulación y

no deben utilizarse como tales.

El ÚNICO punto de sujeción

de protección contra caídas

aprobado es con el anillo en “O”.

Nunca conecte dos ganchos de

cierre resortado con un (1) anillo

en “O” ni el gancho de cierre

resortado con el cable. Conéctelo

ÚNICAMENTE al anclaje existente.

Los extendedores de anclaje

no son anclajes por sí mismos.

Estos sólo son extensiones de un

anclaje existente. SÓLO conecte

las Extensiones de Anclaje a un

anclaje elevado y nunca en una

posición que pudiera aumentar

la distancia de caída del usuario

más allá de la distancia de caída

libre permisible de 1.8 m (6 pies).

Anillo en “O”

Cuerda salvavidas horizontal

en anclaje elevado

Gancho de cierre

resortado

Extensión de anclaje

Anillo en “O”

Argolla metálica

Cuerda salvavidas auto-

retráctil

Anillo en “D” Dorsal

Anclaje elevado

Gancho de cierre

resortado

Extensión de anclaje

Anillo en “O”

Anillo en “D” Dorsal

ESPAÑOL

Página 10

Page 28

f. Correas de anclaje instalables durante el

vertido de concreto

Los anclajes instalables durante el vertido

de concreto son realmente correas tejidas

de estrangulación estándares simplicadas

que han sido modicadas para continuar

funcionando como conector de anclaje

después de ser empotradas parcialmente

dentro de concreto. Como tal, éstas siguen

la mayoría de las mismas instrucciones

y advertencias contenidas en la anterior

sección “Correa tejida de estrangulación

/ correa de cruzar”. Todos los anclajes

instalables durante el vertido de concreto

de Werner sólo son para un (1) uso.

Instalación de una correa de anclaje

instalable durante el vertido de

concreto

1. S eleccione un lugar que tenga la

resistencia de anclaje requerida

y un espacio libre de caída sin

obstrucciones. Coloque el extremo

de lazo de la correa sobre la barra

de refuerzo o utilice el lazo para

“estrangularla”. Para estrangular la

barra de refuerzo, envuelva la correa

alrededor de la barra de refuerzo y

hale el extremo expuesto (con lazo

o anillo en “D”) a través del lazo de

extremo. Apriete el estrangulador

sobre la barra de refuerzo. Coloque

el extremo expuesto con el otro lazo

o anillo en “D” a al menos 6 pulgadas

afuera del molde/encofrado. Asegure

la correa de modo que ésta no pueda

halarse adentro cuando se vierta el

concreto. Coloque el protector de

desgaste de la correa de modo que

este protector quedará parcialmente

empotrado en el concreto vertido y

parcialmente expuesto. Es importante

colocar el protector de desgaste para

proteger el tejido de soporte de carga

ESPAÑOL

principal contra el contacto con el

borde loso del concreto vertido.

Installing on Completed Cage

Instalación en jaula completa

Anchorage Connector Installed

Conector de anclaje, instalado

Barra de refuerzo

Steel

de acero

Re-bar

Columna de

Concrete

Column

Conector de anclaje, instalado

Anchorage Connector Installed

Re-bar

Pared en

de concreto

Correa de anclaje

Imbedded Concrete

empotrada en concreto

Anchor Strap

Línea de

Web Cut

corte del

tejido

concreto

4” min

Barra de

Steel

refuerzo

de acero

Shear

corte

Wall

Concrete

Columna

Column

Line

Piso de

Poured

concreto

Concrete

vertido

Floor

Página 11

Page 29

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

2. El usuario debe conectarse al anillo en “D” o lazo del anclaje instalable

durante el vertido de concreto tal como lo haría con cualquier otro anclaje

apropiado. Al conectarse con un lazo tejido, SÓLO utilice una argolla

metálica (carabiner), NUNCA un gancho de cierre resortado. Nunca

conecte dos usuarios al mismo anclaje. Nunca conecte dos ganchos de

cierre resortado al mismo conector.

3. Corte y deseche la porción expuesta de la correa de anclaje después del

uso.

III. Tenga en cuenta las advertencias, restricciones y precauciones

a. Distancia de caída

El equipo está diseñado para una caída libre máxima de 1.8 m (6 pies). Aún

cuando este equipo esté en perfectas condiciones de funcionamiento podría

ocurrir contacto con un nivel inferior si hay algún objeto en la trayectoria de

la caída o si es inadecuada la altura del anclaje que se está utilizando. La

distancia de caída puede variar de acuerdo con el subsistema conectivo

utilizado. Los siguientes diagramas indican los cálculos de espacio libre

típico para cuerdas absorbedoras de impacto y cuerdas salvavidas autoretráctiles. Aunque éstas son situaciones típicas, la persona autorizada/

calicada en sitio debe realizar estas decisiones para cada situación de

trabajo dependiendo de las condiciones especícas del sitio.

Distancia de caída para las cuerdas absorbedoras de impacto

Cuerda

Energy

absorbedora

Caída libre

Free Fall

Absorbing

de energía

Lanyard

Nivel de trabajo

Working Level

Nivel inferior u obstrucción

Lower Level or Obstruction

Longitud del conector del anclaje

Length of Anchorage Connector

6 ft.

1.8 m (6 pies)

Length of Lanyard

Longitud de la cuerda

1.2 m (4 pies)

4 ft.

Distancia de caída libre con

Deceleration Free Fall Distance

desaceleración

1 ft. Harness Stretch

0.31 m (1 pie) de alargamiento del arnés

1.5 m (5 pies)

5 ft.

To Worker’s Back D-Ring

al anillo en “D” de espalda del trabajador

0.6 m (2 pies)

2 ft.

Safety Factor

Factor de seguridad

Distancia

Total Fall

total de caída

Distance

(caída libre +

(Free Fall +

desaceleración)

Deceleration)

3.4 m

11 ft.

(11 pies)

Distancia de caída

Total Estimated

estimada total

Fall Distance

5.5 m (18 pies)

18 ft.

Página 12

ESPAÑOL

Page 30

ESPAÑOL

Distancia de caída para cuerda salvavidas auto-retráctil

Cuerda

Self Retracting

salvavidas

Lifeline

auto-retráctil

Working Level

Nivel de trabajo

Nivel inferior u obstrucción

Lower Level or Obstruction

b. Peligro de caída tipo columpio

Posicione el trabajador debajo del

anclaje de modo que si ocurre una

caída, el trabajador no se columpiará

hacia un objeto debajo de la supercie

de trabajo.

c. Capacidad nominal.

1. Capacidad: 310 lbs., incluyendo las

herramientas y equipos (1 persona)

2. Resistencia: Para la detención de caídas, OSHA exige una resistencia

estática a la tracción de 5000 lbs. Este conector satisface los requisitos

de resistencia de OSHA y ANSI cuando se utiliza de acuerdo con las

normas OSHA, ANSI, CSA, las regulaciones locales y las instrucciones

del fabricante.

3. Estos anclajes sólo son para protección contra caídas, evitamiento

de caídas y uso para rescate. Estos no están diseñados para colgar,

soportar o levantar materiales o equipos.

d. Peligros ambientales.

Este equipo sólo debe utilizarse bajo la supervisión directa de una persona

competente que pueda identicar los peligros que deben evitarse. Éstos

incluyen la electricidad, productos químicos, máquinas u objetos en

movimiento, bordes losos, estructuras o anclajes dañados, o cualquier

otro elemento que pudiera dañar este equipo o que evite que funcione

según se pretende.

Parte inferior de la unidad de cuerda salvavidas retráctil

Bottom of Retractable Lifeline

0.6 m (2 pies)

2 ft.

Caída libre máxima

Maximum Free Fall

0.8 m (2.5 pies)

2.5 ft.

Desaceleración máxima

Maximum Deceleration

1 ft. Harness Stretch

0.31 m (1 pie) de alargamiento del arnés

5 ft.

1.5 m (5 pies)

To Worker’s Back D-Ring

al anillo en “D” de espalda del trabajador

0.6 m (2 pies)

2 ft.

Factor de seguridad

Safety Factor

Distancia máxima

Maximum Arrest

para detención

Distance (per ANSI)

(según ANSI)

4.5 ft.

1.4 m (4.5 pies)

Anclajes

Anchorages

Correct Incorrect

Correcto

Distancia de caída

Total Estimated

estimada total

Fall Distance

3.8 m (12.5 pies)

12.5 ft.

Incorrecto

PELIGRO DE

SWING FALL

CAÍDA TIPO

HAZARD

COLUMPIO

Página 13

Page 31

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

e. Componentes/Subsistemas

Antes del primer uso, una persona calicada debe inspeccionar y decidir que

todos los componentes y subsistemas son compatibles y que funcionarán

correctamente en combinación con un sistema personal completo de

protección contra caídas. Consulte la información en estas instrucciones, y

si se requiere cualquier información adicional, comuníquese directamente

con Werner Co.

IV. Etiquetas/Identicación/Registros de inspección

a. Todos los productos deben ser inspeccionados completamente por el

usuario antes de cada uso. Una persona calicada, diferente al usuario,

debe realizar inspecciones adicionales en intervalos no inferiores a un (1)

año. Ese intervalo debe acortarse cada vez que el producto se utiliza en

un ambiente agresivo o se expone a condiciones tales como productos

químicos, abrasión, calor o cualquier otro factor que pudiera afectar la

resistencia de cualquiera de los materiales o componentes.

b. Las etiquetas del producto proporcionan una tabla de inspección para que

una persona calicada registre estas inspecciones. Utilice un punzón o

marcador permanente para registrar estos datos.

c. Este manual siempre debe acompañar el producto o estar en los archivos

del empleador para consultarlo cuando se requiera. Registre los detalles

de identicación para el anclaje y registre las inspecciones en el registro

de inspección mostrado en la página 18. Es importante mantener este

registro actualizado, completo y disponible según se requiera.

Página 14

ESPAÑOL

Page 32

ESPAÑOL

Página 15

parte delantera

Etiqueta de identicación

parte trasera

Page 33

CONECTOR DE ANCLAJE FLEXIBLE

INSTRUCCIONES PARA EL USUARIO

parte delantera parte trasera

Etiqueta de advertencia para los

estranguladores y extensiones

ESPAÑOL

Página 16

Page 34

ESPAÑOL

Página 17

front back

Etiqueta de advertencia para los anclajes

instalables durante el vertido de concreto

Page 35

V. Registro del equipo

NÚMERO DE

PIEZA

NÚMERO DE SERIE

FECHA DE

FABRICACIÓN

FECHA DE COMPRA

ASIGNADO A

ESPECIFICACIONES

ANCLAJE FLEXIBLE de Werner

Certicado para cumplir las regulaciones y normas ANSI Z359.1-2007

y OSHA 1910 y 1926 para los componentes de cuerdas de sistemas

personales completos de detención de caídas. Como mínimo, todos

los herrajes están certicados para una resistencia a la rotura de 5000

lb., 100% probados para 3600 lbs.

Los números de modelo y números de serie, sitio y fecha de fabricación,

con código de barras individual, están en la etiqueta del producto.

VI. Registro de inspección

REGISTRO DE INSPECCIÓN

FECHA INSPECTOR APROBADO/

NO-APROBADO

FECHA INSPECTOR APROBADO/

NO-APROBADO

Page 36

Werner Soft Anchorage Model Numbers Included

Se incluyen los números de modelo de anclajes

exibles de Werner

A111002

A111003

A111004

A111006

A111008

A 11110 2

A 11110 3

A 11110 4

A 11110 6

A 11110 8

A112002

A112003

A112004

A112006

A112008

A113002

A113003

A113004

A113006

A113008

A211002

A211003

A211004

A211103

A211104

A211106

A211006

Werner Co. Fall Protection

93 Werner Rd. Greenville, PA 16125

724-588-2000 • 888-523-3371 toll free/ llamada gratuita • 888-456-8458 fax

PN103774-01 ©2012 Werner Co. Rev C 2/14

Loading...

Loading...