!!

!

!

!

!

!

!

!

!

!

!

!

!

OPERATOR’S)MANUAL!

!

! ! ! ! ! ! ! ! ! ! ! !!!!!! ! ! ! ! !!!!"#"$%!&"!

! ! ! ! ! ! ! ! ! ! ! ! ! ! ! '()(**(*!&"!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

!!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

WerkMaster Grinders and Sanders Inc.

6932 Greenwood Street, Burnaby, BC V5A 1X8

tel: 604.629.8700 | toll free: 1.866.373.WERK | fax: 604.444.4231

www.werkmaster.com | email: info@werkmaster.com!

!!

LIABILITY LIMITATIONS

The remedies of the user set forth under provisions of warranty outlined at the

end of this manual are the exclusive and total liability of WerkMaster Grinders &

Sanders Inc. with the respect to their sale or the equipment and service furnished

hereunder, in connection with the performance or breach thereof, or from the

sale, delivery, installation, repair or technical direction covered by or furnished

under the sale, whether based on contract, warranty, negligence, indemnity, strict

liability, or otherwise shall not exceed the purchase price of the unit of equipment

upon which such liability is based.

WerkMaster will not in any event be liable to the user, any successors in interest

or any beneficiary or assignee relating to this sale for any consequential,

incidental, indirect, special or punitive damages arising out of this sale or any

breach thereof, or any defects on, or failure of, or malfunction of the equipment

under this sale based upon loss of use, lost profits or revenue, interest, lost

goodwill, work stoppage, impairment of other goods, loss by reason of shutdown

or non-operation, increased expenses of operation of the equipment, cost of

purchase or replacement power of claims of users or customers of the user for

service interruption whether or not such loss or damage is based on contract,

warranty, negligence, indemnity, strict liability, or otherwise.

WerkMaster reserves the right to modify, alter and improve any part or parts

without incurring any obligation to replace any part or parts previously sold

without such modified, altered or improved part or parts.

No person is authorized to give any other warranty or to assume any additional

obligation on WerkMaster’s behalf unless made in writing and signed by an

officer of WerkMaster.

USE ONLY GENUINE WERKMASTER PARTS AND ACCESSORIES FOR

YOUR OWN SAFETY, THE SAFETY OF OTHERS AND THE LIFE OF YOUR

MACHINE.

OPERATOR’S!MANUAL!!

+,-.!/!!

CONTENTS

Introduction!.....................................................................................................! 2!

Machine!Descriptions!........................................................................................!2!

Specifications!....................................................................................................!3!

Safety!Precautions!............................................................................................!4!

+.0123,4!+025.6578.!9:;7<=.35!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!?!

+@A176,4!,3B!C.35,4!D753.11!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!?!

*,E.!(<.0,573-!F715,36.!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!?!

+2G.0!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!?!

*,E.!(<.0,573-!'23B757231!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!?!

C2B7E76,57231!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!H!

Power!and!Connectivity!......................................................................................!5!

I.3.0,4!'233.657231!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!H!

*73-4.J+@,1.!52!"@0..J+@,1.!$B,<5.0!'20B!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!K!

+7-5,741!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!K!

*528.!,3B!F0A.0!$B,<5.0!+4;-1!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!K!

+2G.0!'20B!C737=;=!L.:;70.=.351!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!K!

I.3.0,520!C737=;=!L.:;70.=.351!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!K!

Introduction!to!the!Controls!................................................................................!7!

C,6@73.!'2350241!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!M!

NDF!'2350241!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!M!

Machine!Operation!...........................................................................................!8!

'@,3-73-!"2241OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO P!

9Q!R,S!5745!(<.0,5723!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!O>>T!

$BU;1573-!5@.!F;15!*S705!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!T!

$BU;1573-!5@.!V,3B4.!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/W!

#3757,4!*5,05!*.:;.36.!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/W!!

*.4.6573-!5@.!*5,0573-!*<..BOOOOOOOOOOOOOOOOOOOOOOOOOOO!>>//!

*5,0573-!5@.!C,6@73.OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO>>//!

$BU;1573-!5@.!*<..B!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/X!

*52<<73-!5@.!C,6@73.!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/X!

#315,4473-!,3B!L.=2873-!5@.!+,B!F078.0!!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/X!

L25,5723!+,55.03!2E!"22473-!+4,5.1!!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/X!

Checking!Usage!Time!.......................................................................................!13!

935.073-!5@.!+02-0,==73-!C.3;!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!OOOOO/Y!!

RA<,1173-!5@.!$66.11!'2B.!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/Y!

N7.G73-!5@.!"25,4!"7=.!93.0-7Z.B!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/?!

N7.G73-!5@.!"25,4!L;3!"7=.!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/?!

9[75!5@.!+02-0,==73-!C.3;!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!/H!

Vacuum!or!Water!Feature!.................................................................................!15!

Maintenance!....................................................................................................!16!

Troubleshooting!..............................................................................................!17!

VFD!Error!Screens!and!Codes!............................................................................!19!

Exploded!View!and!Parts!List!............................................................................!24!

"75,3!&"!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!X?!

'2421121!&"!>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>!XM!

Glossary!..........................................................................................................!30!

Warranty!Information!......................................................................................!31!

Operation!and!Safety!Guide!..............................................................................!33!

!

OPERATOR’S!MANUAL!!

+,-.!X!!

INTRODUCTION

Congratulations on your purchase of a WerkMaster machine. WerkMaster

machines allow professional surface prep, polishing, grinding, edging, buffing

and restoration of virtually any surface material, including concrete, terrazzo,

stone, and hardwood. This manual is provided to assist you in the operation and

maintenance of your WerkMaster machine.

!

!

!

MACHINE DESCRIPTIONS

WerkMaster machines include the Scarab, Termite, Viper XT, Raptor XT, TITAN

XT, COLOSSOS XT models. To see the complete family of WerkMaster

machines visit our website at www.werkmaster.com.

TITAN XT (230V / 380V / 460V)

• Most aggressive surface prep machine in its class, designed to exceed the

needs of the professional commercial, residential, and maintenance

contractor

• 7 Machines in 1 – grinds, sands, strips, polishes, buffs, burnishes, and edges

• Removes thinset, epoxy, glue, paint, mastic, and micro toppings; works on

spalled or rained out concrete

• Allows you to easily flatten a floor or follow a wavy floor with the same tool so

you can polish from cream to exposed aggregate

• Delivers deep, crisp, clear mirror finishes on concrete, marble, stone, granite

and terrazzo

• Runs wet or dry on concrete, stone, and terrazzo

• Features WerkMaster Octi-DiscTM Technology with 8 counter rotating heads

and the versatility of using our 6 ¾” (171 mm) ULTRA-FLEX Plug ‘N Go

tooling system

• Edges to within 1/8” (3 mm) of the wall

• Easy to use and operator friendly, the TITAN XT weighs only 600 lbs (273

kg), has a 20” (51 cm) footprint with a disc rotation speed range of 450 –

1800 RPM

• Runs on both single-phase 220V or three-phase 230V

• 380V / 460V runs in three-phase only in 380V or 460V mode

• The dual action wet/dry vacuum port allows for dry, dust-free pick up and can

be used with our optional water feature

• Has EZ Bak tilt and an adjustable, foldable handle for easy transport

!

!

!

!

!

!

!

!

OPERATOR’S!MANUAL!!

+,-.!Y!!

COLOSSOS XT (230V / 460V)

!

• Largest model in the WerkMaster family of machines, designed to exceed the

needs of the professional commercial, residential, and maintenance

contractors

• Available in 230V, 380V/460V and 460V models

• 7 Machines in 1 – grinds, sands, strips, polishes, buffs, burnishes, and edges

• Removes thinset, epoxy, glue, paint, mastic, and micro toppings; works on

spalled or rained out concrete.

• Allows you to easily flatten a floor or follow a wavy floor with the same tool, so

you can polish from cream to exposed aggregate

• Delivers deep, crisp, clear mirror finishes on concrete and terrazzo

• Runs wet or dry on concrete, stone and terrazzo

• Features WerkMaster Octi-DiscTM Technology with 8 counter rotating heads

and the versatility of using our 8” (203 mm) ULTRA-FLEX Plug ‘N Go tooling

system

• Edges to within 1/8” (3 mm) of the wall.

• Easy to use and operator friendly, the COLOSSOS XT weighs only 800 lbs

(364 kg), has a 24” (61 cm) footprint has an auto sensing dual voltage (230V

and 460V) 3 phase variable frequency drive with a disc rotation speed range

of 450 –1800 RPM. 380V models are NOT dual voltage

• The dual action wet/dry vacuum port allows for dry, dust-free pick up and can

be used with our optional water feature.

• Has EZ Bak tilt and an adjustable, foldable handle for easy transport.

SPECIFICATIONS

!

!

MODEL!

TITAN!XT!

COLOSSOS!XT!

F7=.317231!!!!!!!!!!!\4![!G!!73]!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!\4![!G!!6=]!

XW![!XW!

H/![!H/!

X?![!X?!

K/![!K/!

^.7-@5!!!!!!!!!!!!!!!!!!!\!4_1!`!S-]!

KWW!`!XMY!

PWW!`!YK?!

V201.<2G.0!!!!!!!!!!!!!!!!!\V+]!

+@,1.!

/W!

/a!`!Ya!

XW!

Ya!

D0.:;.36A!!!!!!!!!!!!!!!!!!!!!\VZ]!

HW!`!KW!

HW!`!KW!

N245,-.!!!!!!!!!!!!!!!!!!!!!!!!!!!!!\N]!

XYWNb!XWWJXYW!

?KWNb!YPWJ?KW!

XYWNb!XWWJXYW!

?KWNb!YPWJ?KW!

R0.,S.0!*7Z.!

XYWNb!HW!`!?KWNb!YW!

HW!

!

!

OPERATOR’S!MANUAL!!

+,-.!?!!

SAFETY PRECAUTIONS

!

!

Read this manual and all the safety precautions before attempting to

operate WerkMaster machines. Failure to follow the safety precautions may

result in severe personal injury or death. This machine is intended for

commercial use.

!

• Wear eye and ear protection at all times when operating WerkMaster

machines. Use only ANSI/OSHA-approved safety glasses to help prevent

eye injury.

• Wear appropriate clothing and footwear when operating WerkMaster

machines. Do not wear loose clothing or jewelry that may become entangled

in moving parts.

• Crystalline silica from bricks and concrete and other masonry products may

cause health problems. Risk of exposure varies depending on how often you

do this type of work. To reduce your risk, work in a well-ventilated area, use

a dust control system such as an industrial-style vacuum, and wear

approved personal safety equipment, such as a dust or particle respirator

designed to filter out microscopic particles.

• NEVER operate WerkMaster machines under the influence of drugs or

alcohol, when taking medications that impair the senses or reactions, or

when excessively tired or under stress.

• Only operate and maintain WerkMaster machines if you are in good physical

condition and mental health. You must be physically able to handle their

bulk, weight and power.

• WerkMaster machines are designed to be operated by one person at a time.

Maintain a safe operating distance to other personnel. Keep bystanders a

safe distance away during operation by blocking off the work area in all

directions with roping, safety netting, or other material. Failure to do so may

result in someone being injured by flying debris or being exposed to harmful

dust and noise.

• Maintain a safe operating distance from flammable materials. Sparks from the

cutting action of WerkMaster machines may ignite flammable materials or

vapors.

• Unplug the WerkMaster’s power cord when not in use and before servicing or

changing discs.

• Turn the WerkMaster off before disconnecting power.

• DO NOT disconnect power by pulling the cord. To disconnect power, grasp the

plug, not the cord. To remove twist-lock plugs, push in and turn clockwise to

engage, and turn counter-clockwise and pull to remove.

• DO NOT turn on the WerkMaster while it is tilted back. Any tooling fastened to

the WerkMaster may eject and become a lethal projectile.

• Be sure all safety decals on the machine can be clearly read and understood.

Replace damaged or missing decals immediately.

• Maintain WerkMaster machines in safe operating condition with all guards in

place and secure, all mechanical fasteners tight, all controls in working order,

and the grinder configured for the job application, whether concrete, natural

stone, wood or other surfaces.

Personal Protective

Equipment

Physical and

Mental Fitness

Safe Operating Distance

Power

Safe Operating

Conditions

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !WARNING!

OPERATOR’S!MANUAL!!

+,-.!H!!

• To prevent damage to the grinder or severe personal injury, avoid protruding

slab inserts, nails, screws, Hilti anchors, rebar, embedded bolts or any other

debris, pipe extensions, machinery bases, or any objects that transmit

sudden shock to the grinding assembly.

• Inspect the tooling plates carefully before installing. Do not use any tooling

plates that exhibit signs of damage, as severe personal injury or damage to

the equipment could result.

• NEVER leave WerkMaster machines running unattended>!!

!

• Risk of Explosion: Floor sanding can result in an explosive mixture of fine dust

and air. Use floor-sanding machine only in well-ventilated area free from any

flame or match.

!

!

• DO NOT modify WerkMaster machines. Modifications will void the warranty

and may result in injury to persons and damage to the machine.

POWER AND CONNECTIVITY

All WerkMaster machines are outfitted with an X4 variable frequency drive (VFD)

that allows the desired grinding speed to be selected. Along with controlling the

speed of the machine, X4 VFD features include the following:

• Undervoltage protection (damages most single-phase motors)

• Overcurrent protection (prevents nuisance breaker tripping)

• 60 Hz and 50 Hz capability (international)

• Wide voltage range (200–230V +/- 15% for 230V models;

380–460V +/- 15% for 460V models)

• Soft start (smaller generator requirements)

• Monitor pad speed display

• Load display

!

!

WerkMaster machines come with a variety of different plug configurations. The

following table lists the plugs that are typically used.

!

!

MODEL!

!!!!!!!!!TITAN!XT!

230V!!!!!!!!!!!!!!!380V/!!460V!

!!!!COLOSSOS!XT!

!!!230V!!!!!!!!!!!!!380V/!460V!

N245,-.!

XYW!!!!!!!!!!!!!!!!!!!!!!!!!!!!?PW!

XYW!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!?PW!

R0.,S.0!F0,G!

YW!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!YW!

HW!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!YW!

+@,1.!'23E7-;0,5723!

/!<@,1.!!!!!!!!!!!!!!!!!!!Y!<@,1.!

Y!<@,1.!!!!!!!!!!!!!!!!!!!!!!Y!<@,1.!

'20B!93B!

?!<24.!Y!G70.!!!!!!!!?!<24.!Y!G70.!

5G715!426S!!!!!!!!!!!!!!5G715!426S!

?!<24.!Y!G70.!!!!!!!!!!!!?!<24.!Y!G70.!

5G715!426S!!!!!!!!!!!!!!!!!!5G715!426S!

!

!

!

!

!

!

!

!

!

Modifications

General Connections

OPERATOR’S!MANUAL!!

+,-.!K!!

WerkMaster machines come in a variety of voltage and phase configurations.

The TITAN XT is typically configured to operate on 208–230V three-phase

power. The TITAN XT is capable of operating on single-phase 208–230V power

with the use of the included adapter cord.

COLOSSOS XT is capable of operating with 230V three-phase to 460V threephase power with the use of the adapter cord. Runs on 230V or 460V auto

synching.

!

!

Pigtails are plug ends with unfinished bare wire on one end for hooking up to

panels. Pigtails are used when connectivity is unknown, when connecting to the

power grid of an unfinished building that has no power receptacles, or when

operating certain generators. Many pigtails are available or can be made up by

an electrician.

!

When using the TITAN XT in a residential environment, source power may be

hard to find. The use of stove and dryer adapter cords make it easier to connect

to single-phase source power. The adapter cords are outfitted with a 30 A 250 V

single-phase twist-lock cord end for dryers and 40A 250V single-phase twist-lock

cord end for stoves. The single-phase to three-phase adapter is used to connect

the stove or dryer adapter cord to the TITAN XT only.

!

The following table lists the minimum requirements for power cords.

!

!

MODEL

DISTANCE

MINIMUM REQUIREMENT

TITAN XT

Up to 300 ft

Over 300 ft

Single-phase minimum gauge of 10/3

Three-phase minimum gauge of 10/4

Single-phase minimum gauge of 8/3

Three-phase minimum gauge of 8/4

COLOSSOS XT

230V

Up to 100 ft

Over 100 ft

Three-phase minimum gauge of 8/4

Three-phase minimum gauge of 8/4

COLOSSOS XT

380V/460V

Up to 300 ft

Over 300 ft

Three-phase minimum gauge of 10/4

Three-phase minimum gauge of 8/4

!

"@.!E2442G73-!5,_4.!47151!5@.!=737=;=!0.:;70.=.351!E20!-.3.0,5201>!

!

!

MODEL

MINIMUM REQUIREMENT (KW)

TITAN XT

11

COLOSSOS XT

25

!

!

!

!

!

Exercise extreme caution at all times when working with electrical power.

WerkMaster strongly recommends that only certified electricians be permitted to

work with electrical power sources within customers’ facility or on their job site.

!

!

!

!

!

Single-Phase to

Three-Phase Adapter Cord

Pigtails

Stove and Dryer

Adapter Plugs

Power Cord

Minimum Requirements

Generator

Minimum Requirements

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !WARNING!

OPERATOR’S!MANUAL!!

+,-.!M!!

INTRODUCTION!TO!THE!CONTROLS!!

Starting the machine and changing the speed can only be done with the controls

on the handle.

USE THIS...

TO DO THIS...

Green Start

button

Start the machine.

Red Stop button

Stop the machine.

Speed control

knob

Control the speed of the pad drivers. You can set the speed

before the machine is turned on or adjust it while the machine is

running or unplugged. The speed control knob is analog and has

end points.

!

!

The TITAN XT and the COLOSSOS XT use a Vacon X4 Variable Frequency

Drive. The TITAN XT VFD allows the TITAN XT to be operated on either singlephase or three-phase power. To operate on single-phase power, a single-phase

to three-phase adapter is required. The machine can operate on either 50 Hz or

60 Hz frequencies. The VFD will automatically adjust for phase or frequency

input.

The COLOSSOS XT 230/460 Dual Volt VFD allows the COLOSSOS to run on

either 230V or 460V auto-sensing between 230 and 460V. The machine to be

operated on 230V, 380V or 460V except on 230V only or 460V only models.

An adapter (not included) is required to convert to 460V. The machine can

operate in 50 Hz or 60 Hz frequencies. The VFD will automatically adjust for

phase or frequency input.

!

!

!

!

NEVER!open!the!VFD!panel!while!plugged!in!or!immediately!after!unplugging!the!

power!cord.!Severe!injury!or!death!may!occur.!

!

!

"@.!"#"$%!&"!,3B!5@.!'()( * * (*!&"!=2B.41!7364;B.!NDF!62350241!4715.B!_.42G>!"@.!

E2442G73-!_;55231!,0.!426S.B!2;5!,1!5@.A!,0.!325!0.:;70.B!52!;1.!5@.1.!=,6@73.1b!

• D20G,0B!_;5523!\D^F]!

• L.8.01.!_;5523!\L9N]!

• c2-!_;5523!\c(I]!

• )26,4!`!0.=25.!_;5523!\)('`L9C]!

!

Machine Controls

VFD Controls

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !DANGER!

OPERATOR’S!MANUAL!!

+,-.!P!!

!

USE THIS...

TO DO THIS...

Stop button

(STOP)

Stop the machine. The machine will not perform any function

from the keypad other than stopping the machine.

The machine can be stopped with this stop button on the VFD

or with the stop button on the handle. The stop button on the

VFD cannot be locked out as it is a secondary safety stop. If

the stop button on the handle fails, the stop button on the VFD

can be used instead.

Program button

(PROG)

Enter level 1 programming. All programming parameters are

locked out by means of an access code. This is done to

prevent accidental parameter changes that can cause

machine malfunction or damage.

Shift button

(SHIFT)

Use with the program button to enter level 2 programming.

Also use to change parameter settings.

!

!

!

MACHINE OPERATION

!

!

!

Always turn off and disconnect power from the machine when performing any

operations to the bottom of the machine.

!

! ! ! ! ! ! ! $! ! ! ! ! ! !!!!!$! ! ! ! R! ! !

!

!

!

!

!

!

!

!

!!!!!!!!!!

! ! !!!!!!!!!!"75,3!&"! ! ! ! ! ! !!!!'2421121!&"! ! ! ! ! ! !!!!

! ! ! ! ! ! ! ! !!!!D7-!/!! ! ! ! ! ! ! ! ! !!!!D7-!X!

!

! ! !

Changing Tools

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !WARNING!

OPERATOR’S!MANUAL!!

+,-.!T!!

To change tooling:

1. Unplug the power cord from the twist lock inlet (A). Ensure the handle is in its

full upright position (Fig 1). Tilt the machine back (Fig 2). Choose the

appropriate tooling holder attachment – magnetic Plug ‘N Go plate (B) for

Metal Bond tools or Foam/Velcro Adapter plate for polishing resins. Insert

the two (2) shear pins into the rubber grommets. Attach the corresponding

tooling to the plate.

X> Return the machine to the upright position.!

!

For the TITAN XT:

!

! ! ! ! ! ! ! ! ! ! $! ! ! ! ! ! ! ! ! ! ! !!!!R!

! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! !

! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! !

!

!

!

! ! ! ! ! !!!!Fig 1

1. Unplug the power cord from the twist lock plug (A). Ensure the handle is in its

full upright position (Fig 1). Tilt the equipment back by removing the pull pin,

releasing and stepping on the step down plate (B) and pulling down on the

handle.

2. Slowly lift the equipment back to the upright position by using the step down

plate (B) to prevent the TITAN XT from hitting the floor.

3. Fold up and secure the step down plate (B); replace the pull pin.

For the COLOSSOS XT:!

! ! ! ! ! ! ! ! ! ! $! ! ! ! ! ! ! ! ! ! !!!!!!!!!!R!

!

!

!

!

!

!

! ! ! ! ! ! Fig 1

1. Unplug the power cord from the twist lock plug (A). Ensure the handle is in its

full upright position (Fig 1). Tilt the equipment back by releasing and

unfolding the step down plate (B). While stepping on the step down plate,

pull down on the handle.

2. Slowly lift the equipment back to the upright position by using the step down

plate (B) to prevent the COLOSSOS XT from hitting the floor.

3. Fold up and secure the step down plate (B); replace the pin.

!

!

The dust skirt serves as a seal for the bottom of the machine to act as a vacuum

chamber helping the dust stay contained under the machine. If the skirt is too far

from the ground, the dust containment is reduced.

EZ Bak Tilt Operation

Adjusting the Dust Skirt

OPERATOR’S!MANUAL!!

+,-.!/W!!

To adjust the dust skirt:

1. Pull one end of the skirt off of the machine until you reach the middle of the

skirt.

2. Position the skirt until it is barely touching the ground and repeat with the other

end.

Avoid positioning the dust skirt too low as it will drag against the ground, wearing

the skirt out prematurely and possibly preventing smooth machine movement.

!

To adjust the handle:

3. The handle on the TITAN XT is spring-loaded, pop the pin and adjust the

handle to the desired operating position.

4. On the COLOSSOS XT, pull the pin and adjust the handle to the desired

operating position.

!!

!

!

Failure to check the handle is fully engaged could result in damage to the

machine or personal injury as the handle could release unexpectedly when the

machine is being operated or tilted back.

!

!

!

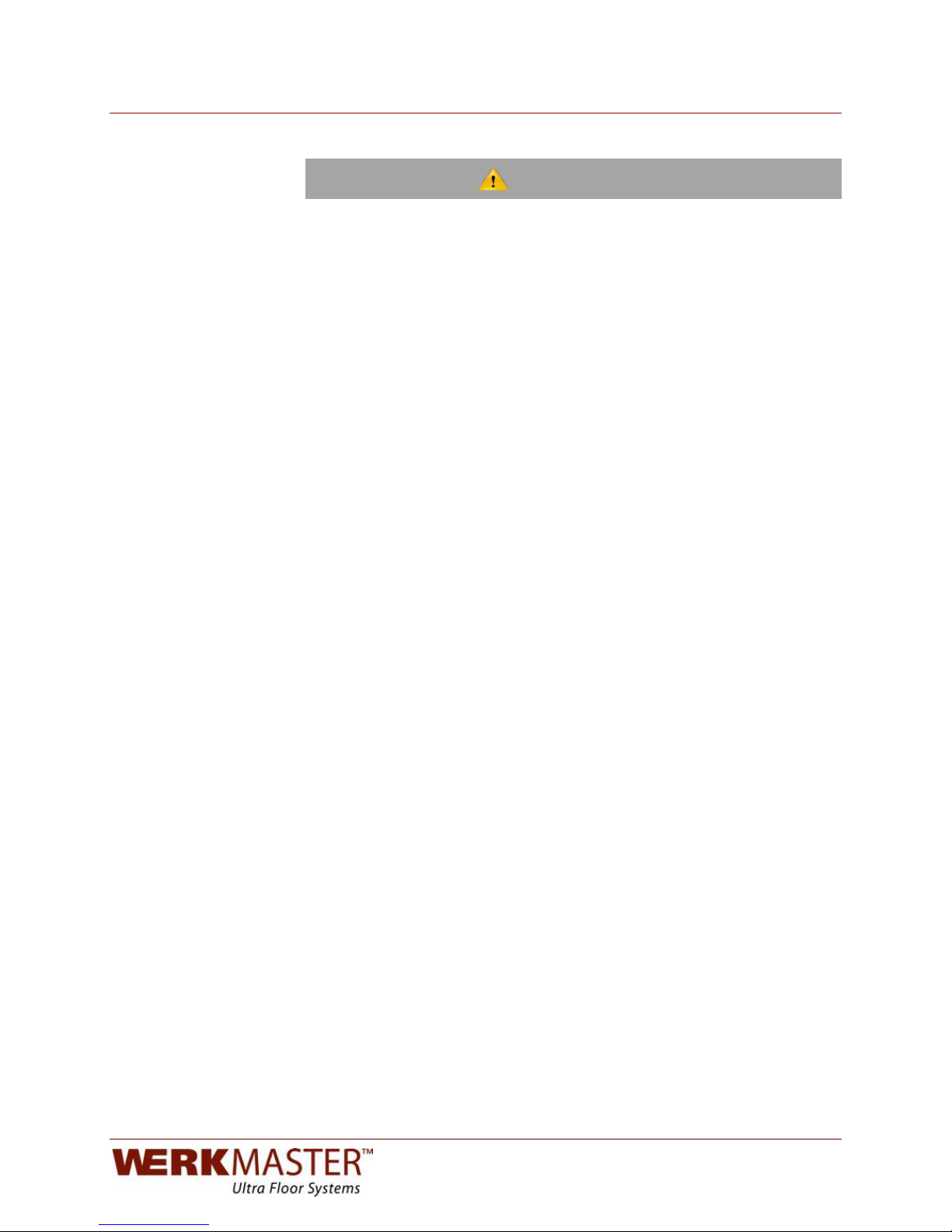

When the machine is first plugged in, the following start-up screen will appear

showing the model of the VFD and the software version.

!

!

!

After the machine runs through its initial start-up sequence, the screen will show

the VFD status, pad driver speed in revolutions per minute (RPM), and percent of

motor load.

!

Adjusting the Handle

Initial Start Sequence

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !WARNING!

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !WARNING!

OPERATOR’S!MANUAL!!

+,-.!//!!

!

!

!

!

!

!

!

!

!

!

!

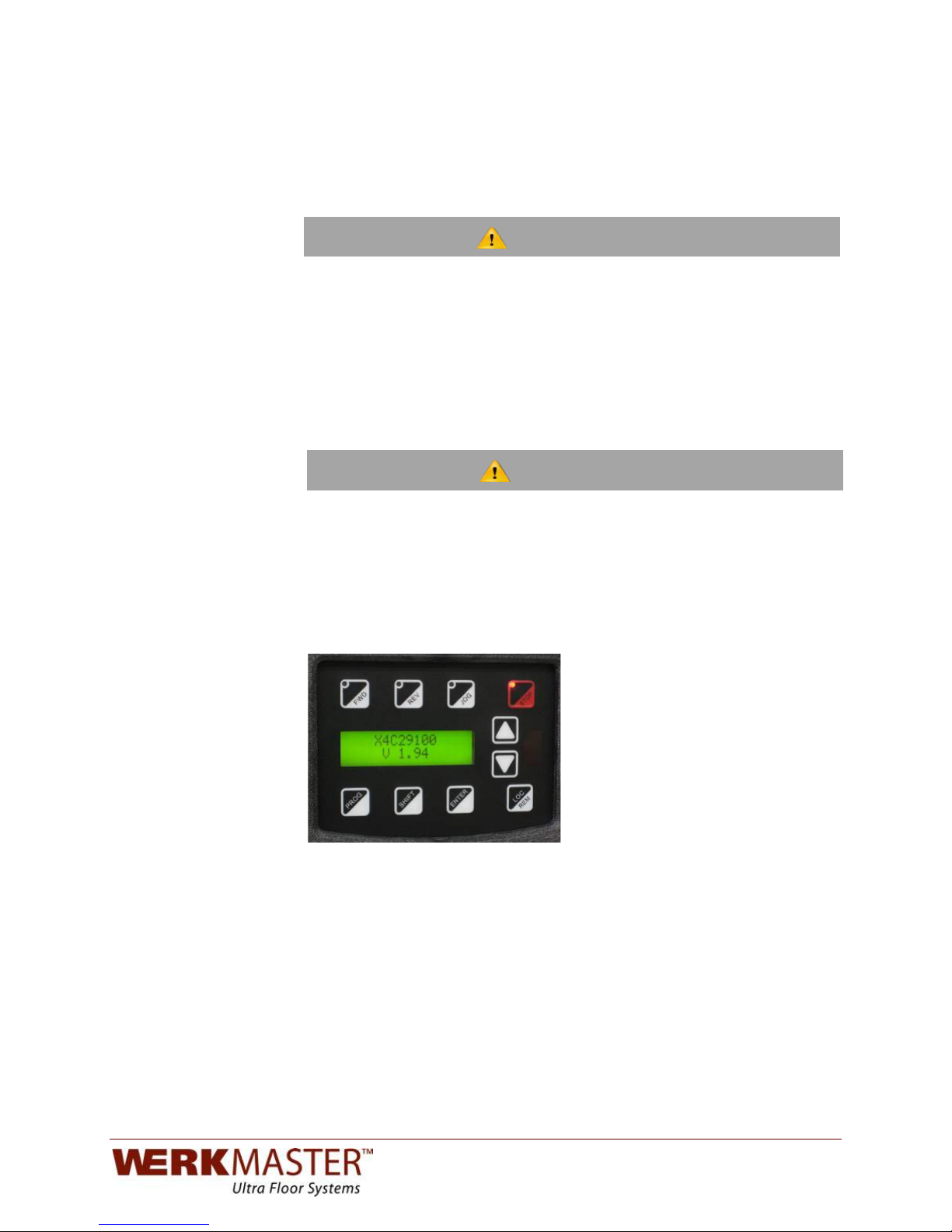

Using the speed control knob on the handle, turn the speed all the way down to

450 RPM.

!

!

!

!

!

!

!

!

!

!

!

!

Selecting the Starting Speed

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !WARNING!

OPERATOR’S!MANUAL!!

+,-.!/X!!

Do not lift the machine off the ground while starting it. Doing so could cause

the diamonds to release from the machine, resulting in damage to the floor or

personal injury.

To start the machine:

1. Apply downward pressure on the handle to alleviate some pressure off the

diamonds; press the green start button.

2. The status on the screen will change from stopped to forward acceleration.

The load will increase as indicated by the percentage at the bottom right.

3. Once the machine starts, gently release the downward pressure and start

grinding.

4. Use the Speed Control Knob to select desired speed.

5. Once the machine reaches the desired speed, the following screen will

appear. The speed will remain constant as long as the load applied remains

below 100%. If the machine is running at speed and the load begins to

exceed 100%, the machine will reduce its speed as a protective measure to

try and alleviate the outstanding load. This happens under demanding

conditions and is normal.

!

!

!

The speed of the machine can be adjusted when the machine is running or

stopped. To adjust the speed, rotate the speed control knob on the handle

counterclockwise to slow it down or clockwise to speed it up.

!

!

To stop the machine, push the stop button on the handle or the STOP button on

the VFD.

!

!

!

NEVER open the VFD panel while plugged in or immediately after unplugging

the power cord. Severe injury or death may occur.!

!

To install and remove the pad driver on the bottom of the machine, you will need

a 9/16” (14 mm) socket wrench, a soft face mallet, and some medium-strength

thread locker (blue Loctite 243 or equivalent).

To remove the pad driver:

1. Slip the 9/16”(14 mm) socket wrench over the pad driver bolt and strike the

wrench with the soft face mallet in a counter-clockwise direction.

2. When installing a new pad driver or re-installing an existing one, apply a

generous amount of thread locker compound to the end of the bolt and fit it

through the hole in the pad driver. Reapply thread locking compound every

time a pad driver is removed.

3. Line up the bolt to the threaded end of the shaft and start the first couple of

threads.

4. Once the bolt is engaged, make sure that the drive shaft tongue is properly

seated within the pad driver’s slot before tightening the bolt all the way.

!

!

Starting the Machine

Adjusting the Speed

Stopping the Machine

Installing and Removing

the Pad Driver

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !DANGER!

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !CAUTION!

OPERATOR’S!MANUAL!!

+,-.!/Y!!

Failure to seat the pad driver could result in the pad driver slot being stripped out,

the threads in the shaft being stripped, the machine leaving heavy tool marks,

and the tooling overheating.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Bottom!of!WerkMaster!with!numbered!discs!and!clockwise!and!counter\clockwise!labeling!

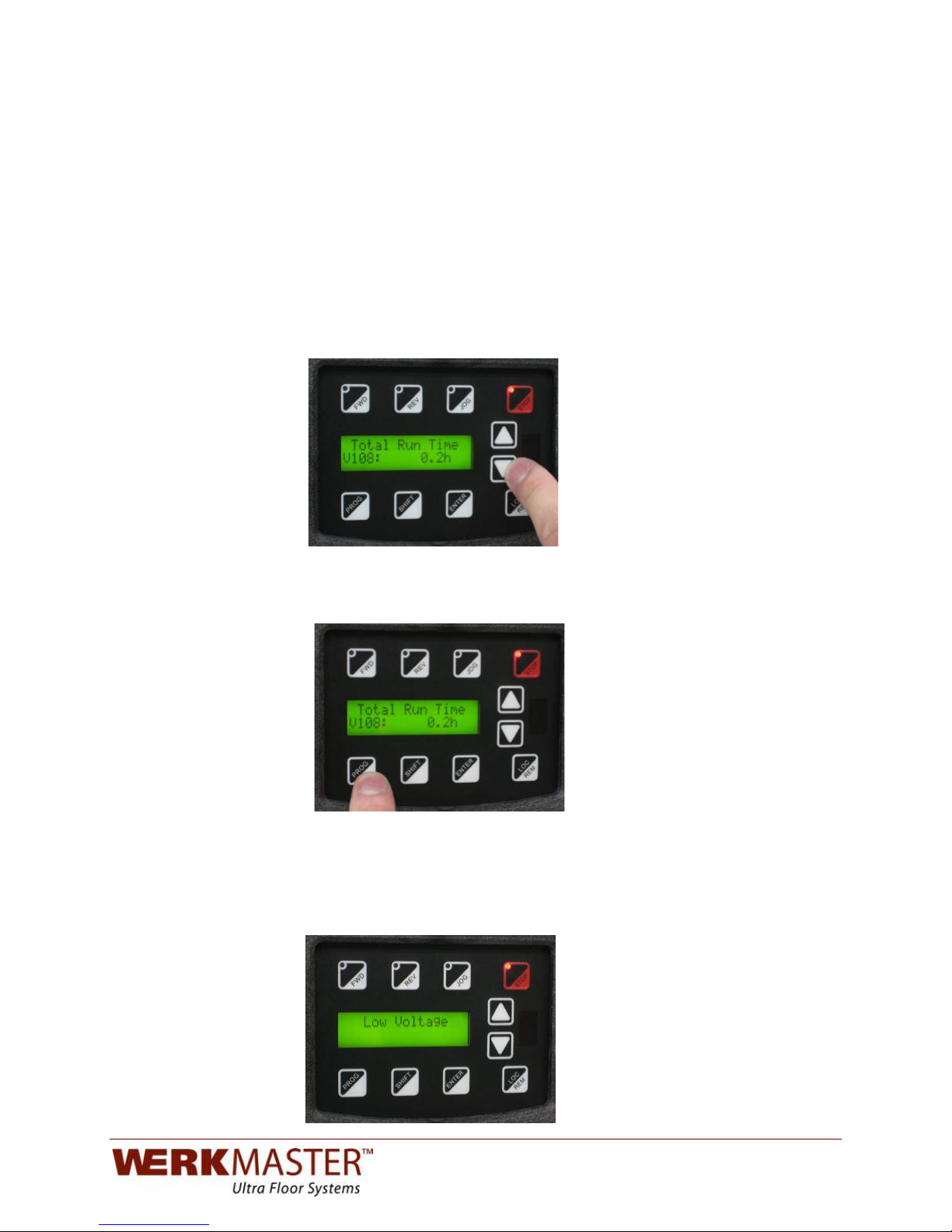

CHECKING(USAGE(TIME!

The X4 VFD has some options you can select to determine the total time the

machine has been energized or the total run time, or view various other

parameters. To view these screens, enter the programming menu by pressing

and holding the SHIFT button and pressing the program (PROG) button once.

!

!

!

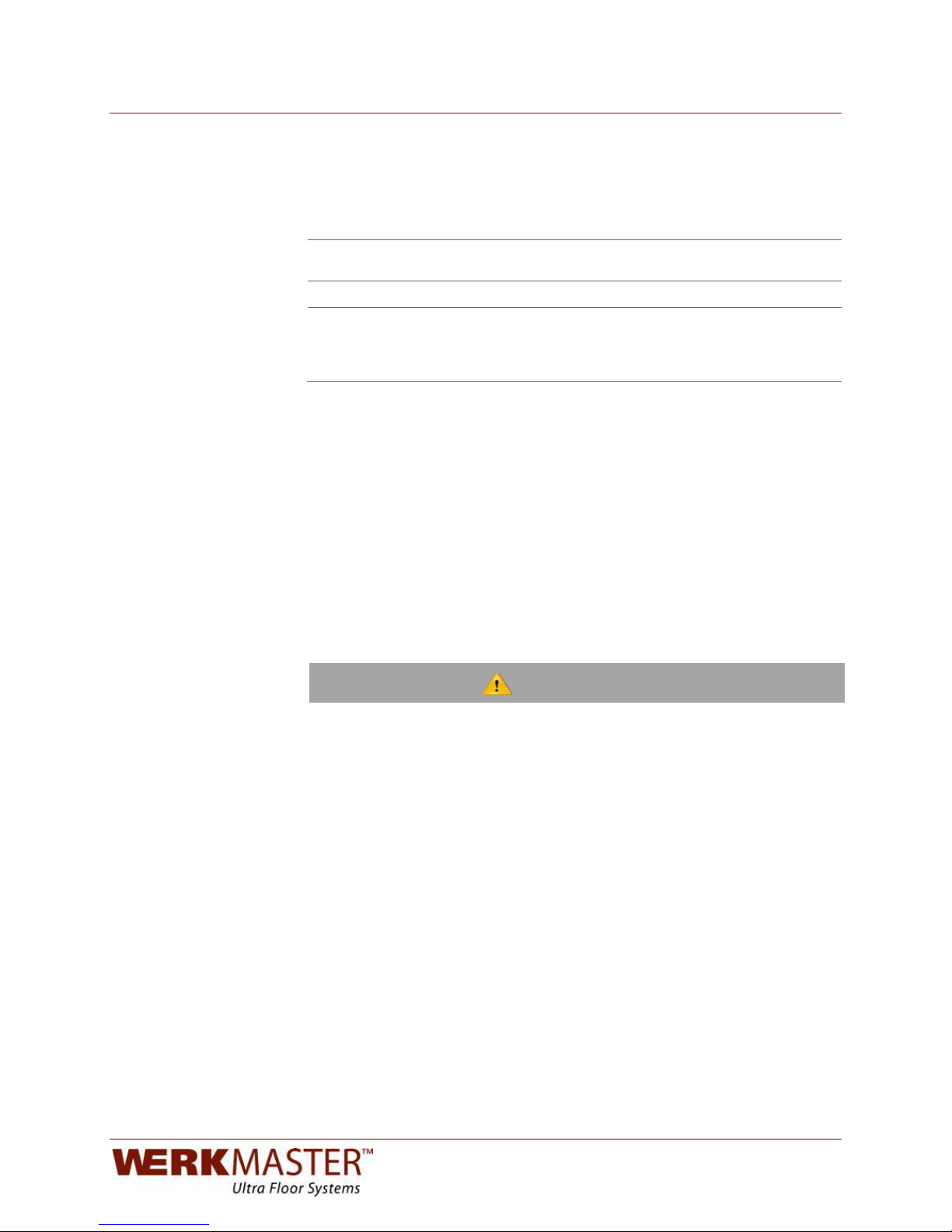

!

The machine is set with an access code to prevent accidental parameter

changes that could cause the machine to behave unpredictably, run less

efficiently, or cause irreparable damage. The following screen will appear.

For your protection and to protect the machines, the access code is not provided.

There is no reason to change the programming of the machine as the machine is

optimized from the factory to provide maximum performance.

Rotation Pattern of

Tooling Plates

Entering the

Programming Menu

Bypassing the Access

Code

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !!!!NOTE!

OPERATOR’S!MANUAL!!

+,-.!/?!!

!

!

!

To bypass the access code screen and enter the programming menu, press the

ENTER button. Any attempt to enter an access code will be ignored by the VFD

!

!

!

!

!

!

!

!

!

!

!

After the access code screen, the following screen will appear>!!

!

!

!

!

!

!

The number 201 has a “V” before it. All parameter numbers that have a V before

them can only be viewed. Any number with a “P” before it can be changed. If you

notice a parameter with a P before it, contact customer service as this is a fault

that may cause problems.

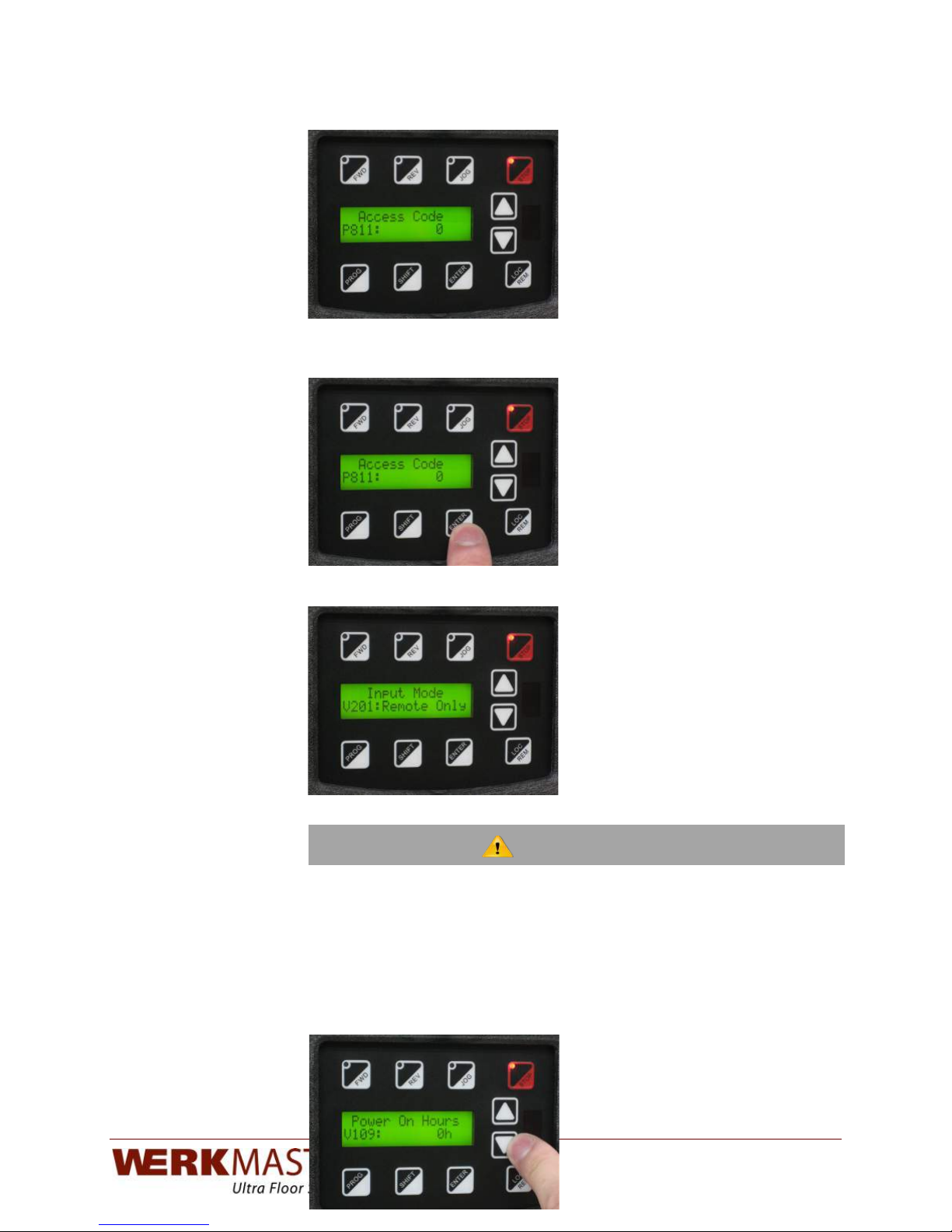

Using the arrow button, scroll down until you reach parameter 109. This

parameter displays the total time the machine has been in plugged in. You

cannot reset this parameter.

!

!

!

!

!

!

Viewing the Total Time

Energized

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !!!!NOTE!

OPERATOR’S!MANUAL!!

+,-.!/H!!

!

!

!

!

!

!

!

!

Using the arrow button, scroll down to parameter 108. This parameter displays

the total time that the machine has actually been running. This is useful if you

want to compare the total run time to the total plugged in time. This parameter is

also used for assessing warranty information.

!

!

!

!

!

!

!

!

!

!

!

!

!

To exit the programming menu, press the program (PROG) button. The main

operation screen will appear.

!

!

!

!

!

!

!

!

!

!

!

!

!

When you unplug the machine, the screen will stay lit for a few seconds. As the

VFD drains the power from its internal capacitors, it will display “Low Voltage”

until it turns off. This is normal.

!

!

!

!

!

!

!

!

!

!

!

!

Viewing the Total Run

Time

Exiting the

Programming Menu

OPERATOR’S!MANUAL!!

+,-.!/K!!

VACUUM OR WATER FEATURE

1. Use a 2” vacuum hose between the vacuum port to fit a standard 2” vacuum

hose.

2. Run the vacuum only while dry grinding.

3. Always refer to vacuum manual.

1. Insert water feature plug into the vacuum port.

2. Ensure the blue flow control valve is in the OFF position.

3. Attach a ¾” male (standard garden hose) to the ¾” female end of water

feature. Secure tightly with a new washer to prevent leaks.

4. Turn on water supply. Adjust the blue flow control valve as wet grinding

process requires.

!

!

!

ALWAYS refer to the variable speed grinder/polisher manual prior to using the

water feature.

!

MAINTENANCE

!

!

!

Disconnect power before performing any maintenance, cleaning, or repairs to

your machine.

!

• Wipe down the machine after every job.

• Check grommets and pad drivers for wear.

• Check pins for wear.

• Vacuum, wash and thoroughly dry the underside of the machine.

• Inspect the plug ends for signs of carbon deposits and arcing.

• Check all fasteners and tighten if necessary.

!

• Inspect the handle wires for damage.

• Blow off the VFD heat sink with compressed air.

• Blow out the VFD cooling fin fans with low-pressure compressed air (30 psi or

less). Cleaning the fan prevents fan failure and potential VFD overheating.

• Blow off the motor fan with compressed air.

• Re-install the pad drivers using blue thread locking compound.

• Using a soft scrub pad, remove any excess dirt build-up from the bottom plate

and back side of the pad drivers.

!

!

DO NOT over-speed the fans with compressed air.

Vacuum

Water Feature

Daily

Weekly

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !WARNING!

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !WARNING!

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !CAUTION!

OPERATOR’S!MANUAL!!

+,-.!/M!!

After wet operation, wash bottom of machine thoroughly, failure to do so may

result in damaged bearing seals.!

DO NOT use any sharp object or abrasive pad to clean the bearing shields. This

can compromise the bearing seal.

!

!

• Check all strain reliefs and make sure they are tight. (Strain reliefs are the

plastic nuts that secure the wires that come out of the handle and VFD.)

• Remove the pad drivers and inspect the threads to make sure there are no

signs of cross-threading or stripping. Remove excess thread locking

compound from bolts using a wire brush or by washing the bolts in a solvent.

• Clean and lubricate wheels.

• Using an extremely light abrasive pad, remove any topical rust from the shafts.

TROUBLESHOOTING

!

ISSUE

TEST

SOLUTIONS

Machine will not turn on.

Check all power connections. Make sure

the source power meets the machine’s

minimum power requirements (see

Power Cord Minimum Requirements

p. 5).

• Plug in the machine.

• Check to see if any breakers or fuses are tripped or blown.

• Check to see the handle activation lever is not depressed.

• Have a qualified electrician test the source power to see if it meets

the machine’s minimum power requirements.

Machine turns on but will not

start.

Check the VFD display for error codes

(see Appendix p. p.19).

• If no error code is displayed, check if the handle wire is plugged

into the machine.

• If the VFD error code is “voltage range,” have a qualified

electrician test the source power and make the necessary

adjustments to the wiring to supply the machine with its required

input power.

Machine runs for a short time

and then shuts down.

Check the circuit breaker to see if it is

tripped or the fuse if it is blown.

• Check to make sure that the power source has the appropriately

sized breaker or fuse to meet the machine’s minimum power

requirements.

• Make sure the generator meets the machine’s minimum power

requirements.

• Have an electrician perform a voltage test while the machine is

under load to see if the voltage drops below the machine’s

minimum power requirements.

Pad drivers are not turning or

only one pad driver is

turning.

Disconnect the power and tilt the

machine back. Spin one pad by hand.

• If the pad turns independently, replace the secondary belt. Go to

www.werkmaster.com/support.

• If all pad drivers turn but the motor fan does not turn, replace the

primary belt. Contact technical support: 866.373.9375.

Not all discs are grinding the

floor.

Disconnect the power and tilt the

machine back. Visually inspect each pad

driver height against the adjacent pad

driver.

• Make sure all pad drivers are seated properly on the shafts.

• Make sure grinding / polishing / sanding media is seated properly

on the pad drivers.

• Make sure grinding / polishing / sanding media is worn evenly and

change out any media if uneven.

Monthly

OPERATOR’S!MANUAL!!

+,-.!/P!!

ISSUE

TEST

SOLUTIONS

Excessive noise or vibration

is felt or heard while running

the machine.

Disconnect the power and tilt the

machine back. Spin one pad by hand.

Listen for a clicking sound or grit-like

feeling.

• Check that all tooling is in the correct pin holes on the pad drivers.

• Replace the bearings. Contact technical support: 866.373.9375 for

instructions.

Tooling becomes dislodged

from the machine while

operating.

Disconnect the power and tilt the

machine back. Remove and inspect all

tooling. This includes the pins, tooling

plates, and pad drivers.

• If the pin holes are excessively damaged, replace the pad drivers.

• If the grommets/bumpers on the pad drivers are damaged, replace

the damaged parts.

• If the pins on the diamonds or tooling plates are damaged or

missing, replace the pins.

The machine handle

malfunctions.

Check the handle plug to see if it has

come loose.

• Secure the handle plug. If the handle controls are still

malfunctioning, contact customer service for instructions.

VFD makes popping noise

and starts to smoke.

***Disconnect power

immediately!***

Wait for 1–2 hours, then remove the

VFD cover and check electronic

components for discoloration, scorching,

or swelling.

• Contact a dealer or technical support: 866.373.9375.

VFD screen displays error

message or unusual screen

display.

Look up the message in the Appendix.

• Contact technical support: 866.373.9375.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

OPERATOR’S!MANUAL!!

+,-.!/T!!

VFD ERROR SCREENS AND CODES

Voltage!Range!Error!

"@.!NDF!71!6,<,_4.!2E!@,3B473-!,!G7B.!0,3-.!2E!73<;5!<2G.0>!"@.!8245,-.!0,3-.!71b!

• XYWN!=2B.41b!XWWdXYWN!e`J/Wf!\/PWdXHYN]!!

• ?KWN!=2B.41b!YPWd?KWN!e`J/Wf!\Y?XdHWKN]!

!

#E!73<;5!12;06.!<2G.0!71!2;517B.!2E!5@.1.!0,3-.1g!5@.!.0020!23!5@.!E2442G73-!160..3!G744!

,<<.,0>!"@.!NDF!71!<025.65.B!E02=!8245,-.!E4;65;,57231!G75@73!5@.!1<.67E7.B!8245,-.!

0,3-.>!

!

!

!

#E!,!=,6@73.!71!<4;--.B!7352 !, !< 2 G.0!12;06.!5@,5!71!,_28.!5@ . !=,6@73.h1!=,[7=;=!

8245,-.!6,<,_7475A!\E20!.[,=<4.g!XYWN!=2B.4!<4;--.B!7352!,!?KWN!-.3.0,520]g!5@71!G744!

B,=,-.!5@.!NDF!,3B!827B!5@.!G,00,35A>!!!

!

!

Cooling!Fan!Error!

"@.!&?!NDF1!,0.!.:;7<<.B!G75@!23.!20!5G2!.4.65076!E,31!=2;35.B!23!5@.!_,6S!2E!5@.!

NDFh1!622473-!E731!\@.,5!173S!d!V*]>!^@.3!5@.!NDF!71!<4;--.B!73g!75!G744!0;3!,!1.4EJ

B7,-321576!52!=,S.!1;0.!,44!735.03,4!62=<23.351!,0.!2<.0,5723,4!,3B!52!6@.6S!5@.!

622473-!E,31>!#E!5@.!E,31!E,74!52!1<73g!5@.!.0020!23!5@.!E2442G73-!160..3!G744!,<<.,0>!"@71!

62;4B!@,<<.3!_.6,;1.!2E!B._071!U,==73-!5@.!E,3!_4,B.1g!@.,8A!6235,=73,5723g!20!G,5.0!

73@7_7573-!5@.!<2G.0!5@,5!5@.!E,3!3..B1!52!0;3>!#3!5@.!.8.35!2 E!,!622 473- !E, 3!. 0020g!

;3<4;-!5@.!=,6@73.!,3B!731<.65g!64.,3g!,3B!6@.6S!E20!E0..!=28.=.35!2E!5@.!E,3!_4,B.>!!

!

!

!

VFD Error Screens

OPERATOR’S!MANUAL!!

+,-.!XW!!

"@.!E2442G73-!5,_4.!1@2G1!5@.!E,;45!62B.1!5@,5!=,A!_.!B71<4,A.B!B;073-!&?!$'!B078.!

2<.0,5723g!,423-!G75@!1;--.157231!E20!0.628.073-!E02=!5@.!E,;45!623B75723>!!

!

!

!

*@,B.B!E,;451!,0.!,;52J0.1.55,_4.g!.[6.<5!G@.0.!325.B>!!

!

CODE!

FAULT!

DISPLAY!

DESCRIPTION!

ADV.!FAULT!

CODE!

EXPLANATION!

SUGGESTIONS!FOR!RECOVERY!

/!

*A15.=!!

*A15.=!E,;45!!

Wg/gX!

#35.03,4!=7602<026.1120!<02_4.=>!!

'231;45!5@.!E,6520A!E20!0.<,70!20!

0.<4,6.=.35>!!

Y!

"@.0=71520!<02E74.!71!736200.65>!!

'231;45!5@.!E,6520A!E20!0.<,70!20!

0.<4,6.=.35>!!

W!

C.=20A!<02_4.=!G@.3!0.E4,1@73-!5@.!

B078.h1!=.=20A>!!

L.1.5!5@.!B078.!52!E,6520A!1.5573-1>!

'231;45!5@.!E,6520A>!!

/gXgY!

'23E4765!73!5@.!B078.h1!=.=20A>!!

L.1.5!5@.!B078.!52!E,6520A!1.5573-1>!

'231;45!5@.!E,6520A>!!

X!

99!'@.6S1;=!!

'@.6S1;=!.0020!!

?!

i3,_4.!52!G075.!,3!99!<,0,=.5.0!,E5.0!,!

<,0,=.5.0!@,1!_..3!6@,3-.B!5@02;-@!

5@.!S.A<,B!20!*#(>!!

L.1.5!5@.!B078.!52!E,6520A!1.5573-1>!

'231;45!5@.!E,6520A>!!

H!

"@.!B078.!71!0.6.7873-!99!G075.!0.:;.151!

E,15.0!5@,3!5@.A!6,3!_.!<026.11.B>!"@71!

G2;4B!5A<76,44A!_.!6,;1.B!_A!G07573-!

<,0,=.5.01!522!E0.:;.354A!5@02;-@!

C2B_;1>!!

*42G!B2G3!5@.!E0.:;.36A!2E!5@.!C2B_;1!

G075.1>!!

Y!

';00!',47_0!

';00.35!

6,47_0,5723!E,;45!

W!

';00.35!6,47_0,5723!E,;45!23!<@,1.!"/`i>!

'@.6S!5@.!=2520!6233.657231!52!5@.!

5.0=73,4!1507<!2E!5@.!B078.!,3B!,5!5@.!

=2520>!V,8.!=2520!6@.6S.B>!'231;45!5@.!

E,6520A!E20!0.<,70!20!0.<4,6.=.35!2E!

B078.>!

/!

';00.35!6,47_0,5723!E,;45!23!<@,1.!"X`N>!

X!

';00.35!6,47_0,5723!E,;45!23!<@,1.!

"Y`^>!

?!

+2G.0!*;<<!!

+2G.0!1;<<4A!

E,;45!!

W!

H!N!1;<<4A!71!_.42G!?!NF'!E20!=20.!

5@,3!/WW!=1>!!

#360.,1.!0.1715,36.!_.5G..3!L9D!,3B!

,3,42-!73<;51>!'@.6S!5@.!G7073-!52!L9D!

5.0=73,41>!'231;45!5@.!E,6520A>!!

K!

#('!"07<!!

#315,35,3.2;1!

28.06;00.35!507<!!

W!

*@205!6706;75!G,1!B.5.65.B!23!<2G.0J

;<>!!

L.=28.!5@.!1@205!E02=!5@.!<2G.0!G7073-!!

'@.6S!E20!,!1@205.B!=2520>!'231;45!5@.!

E,6520A>!!

/!

*@205!6706;75!G,1!B.5.65.B!B;073-!

2<.0,5723>!!

M!

C()!!

C()!6235,65!

E,;45!!

W!

C()!B7-75,4!73<;5!G,1!,6578,5.Bg!

B.<.3B73-!23!<;44J;<!20!<;44JB2G3!

42-76!623E7-;0,5723>!

L.1.5!5@.!C()!6235,65!20!0.=28.!5@.!

623B75723!6,;173-!5@.!C()!6235,65!

,6578,5723>!

P!

C2B.4!#F!!

#F!j!2;5!2E!

0,3-.!!

Wg/gX!

'235024!_2,0B!71!325!0.,B73-!5@.!B078.!

#F!<02<.04A>!!

'231;45!5@.!E,6520A!E20!0.<,70!20!

0.<4,6.=.35>!!

/W!

L.1!)26S2;5!!

L.15,05!426S2;5!!

W!

"@.!3;=_.0!2E!E,;45!0.15,051!71!-0.,5.0!

5@,3!5@.!47=75!B.E73.B!73!5@.!6;152=.0!

<,0,=.5.0>!

'@.6S!5@.!,65;,4!E,;45!73!5@.!E,;45!42-!,3B!

;1.!5@.!,<<02<07,5.!0.=.BA>!

//!

I02;3B!!

I02;3B!E,;45!!

W!

"@.!B078.!B.5.65.B!,!6;00.35!7=_,4,36.!

_.5G..3!2;5<;5!<@,1.1>!#=_,4,36.!

B.5.0=73.B!52!_.!6;00.35!E42G!52!

-02;3B>!!

'@.6S!E20!;3_,4,36.B!6;00.351>!'@.6S!

E20!-02;3B.B!=2520!4.,B1!20!=2520>!

'231;45!5@.!E,6520A>!!

/X!

N,6!#=_436.!!

#3<;5!8245,-.!

7=_,4,36.!!

W!

"@.!B078.!B.5.65.B!,!173-4.J<@,1.!

623B75723!20!,!8245,-.!7=_,4,36.!

2;517B.!5@.!B078.h1!0,573-!G@74.!0;3373-!

,!42,B!5@,5!62;4B!_.!B,=,-73-!52!5@.!

B078.>!!

'@.6S!73<;5!8245,-.!,3B!6;00.35!E20!

7=_,4,36.g!,3B!6200.65>!!

VFD Error Codes

! ! ! !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! !!!!!NOTE!

OPERATOR’S!MANUAL!!

+,-.!X/!!

CODE!

FAULT!

DISPLAY!

DESCRIPTION!

ADV.!FAULT!

CODE!

EXPLANATION!

SUGGESTIONS!FOR!RECOVERY!

/Y!

(8.0N245,-.!

(8.08245,-.!

623B75723!

W!

"@.!B078.!B.5.65.B!,3!28.08245,-.!

623B75723!B;073-!<2G.0J;<!!"#$%&'$#(

)*+*$$&,-*.>!

N.07EA!5@,5!7362=73-!473.!<2G.0!71!G75@73!

5@.!B078.h1!1<.67E76,57231>!$BB!,!0.,6520!

20!50,31E20=.0!52!6200.65>!

/gY!

"@.!B078.!B.5.65.B!,3!28.08245,-.!

623B75723!B;073-!,!0;3373-!623B75723>!!

N.07EA!7362=73-!473.!<2G.0!,3B!6@.6S!E20!

0.-.3.0,578.!42,B>!L.B;6.!L.-.3!42,B!20!

,BB!BA3,=76!_0,S73-!0.1715201>!L.-.3!

';00.35!)7=75!=,A!@.4<k!6231;45!5@.!

E,6520A>!!

X!

"@.!B078.!B.5.65.B!,3!28.08245,-.!

623B75723!23!<2G.0J;<!23!5@.!42,B!17B.>!

N.07EA!5@,5!7362=73-!473.!<2G.0!71!G75@73!

5@.!B078.h1!1<.67E76,57231>!$BB!,!0.,6520!

20!50,31E20=.0!52!6200.65>!

/H!

FA3!R0,S.!

FA3,=76!_0,S.!

28.042,B!

W!

FR!6706;75!71!,6578.!23!<2G.0J;<!!"#$%

&'$#()*+*$$&,-*.%!

'@.6S!E20!,!E,74.B!_0,S73-!50,3171520>!

'231;45!5@.!E,6520A>!!

/!

FR!6706;75!71!_.73-!,6578,5.B!E20!522!

423-g!<2117_4A!6,;173-!5@.!0.171520!52!

28.0@.,5!20!E,74>!!

L.B;6.!5@.!_0,S73-!6A64.!20!7360.,1.!

6,<,675A>!$6578,5.!5@.!6;00.35!47=75k!

6231;45!5@.!E,6520A>!!

X!

FR!6706;75!71!28.042,B.B!_.6,;1.!2E!522!

4,0-.!,!0.-.3.0,578.!42,B>!

L.B;6.!5@.!_0,S73-!6A64.!20!7360.,1.!

6,<,675A>!$6578,5.!5@.!6;00.35!47=75k!

6231;45!5@.!E,6520A>!

Yg?gH!

FR!6706;75!71!E,;45A!23!<2G.0J;<!!"#$%

&'$#()*+*$$&,-*./%!

!

/P!

(8.0';00.35!

(8.06;00.35!

623B75723!

W!

"@.!B078.!B.5.65.B!,3!28.06;00.35!

623B75723!23!<2G.0J;<!!"#$%&'$#(

)*+*$$&,-*.>!!

'@.6S!E20!,!E,74.B!2;5<;5!<2G.0!B.876.!20!

1@205.B!=2520>!!

/!

"@.!B078.!B.5.65.B!,3!28.06;00.35!

623B75723!B;073-!2<.0,5723>!"@.!6;00.35!

@,1!.[6..B.B!5@.!1,E.!2<.0,5723!<2735!

2E!<2G.0!B.876.1>!!

L.B;6.!5@.!42,B!23!5@.!=2520>!N.07EA!

5@,5!C2520!D)$!71!<02-0,==.B!

6200.654A>!'@.6S!E20!=.6@,376,4!_73B73-!

,3B!1@26S!42,B73->!!

/T!

(8.0!".=<!

(8.0J!

5.=<.0,5;0.!

623B75723!

W!

"@.!5.=<.0,5;0.!2E!5@.!@.,5!173S!

.[6..B.B!,!5.=<.0,5;0.!47=75>!!

'@.6S!5@,5!,=_7.35!5.=<.0,5;0.!B2.1!

325!.[6..B!5@.!B078.h1!0,573->!'@.6S!E,3!

2<.0,5723!\7E!5@.!B078.!@,1!E,31!7315,44.B]>!!

/!

"@.!5.=<.0,5;0.!2E!5@.!6235024!_2,0B!

.[6..B.B!,!5.=<.0,5;0.!47=75>!!

'@.6S!5@,5!,=_7.35!5.=<.0,5;0.!B2.1!

325!.[6..B!5@.!B078.h1!0,573->!'@.6S!E,3!

2<.0,5723!\7E!5@.!B078.!@,1!E,31!7315,44.B]>!!

X!

"@.!B078.!B.5.65.B!5@,5!5@.!@.,5!173S!

5@.0=71520!1.3120!71!E,;45A!20!325!

6233.65.B!<02<.04A>!!

'@.6S!5@.!5@.0=71520!6233.657231!20!

0.<4,6.>!'231;45!5@.!E,6520A>!!

Y!

"@.!B078.!B.5.65.B!5@,5!5@.!6235024!

_2,0B!5@.0=71520!1.3120!71!E,;45A!20!325!

6233.65.B!<02<.04A>!

'@.6S!5@.!5@.0=71520!6233.657231!20!

0.<4,6.>!'231;45!5@.!E,6520A>!!

XW!

C2520!"()!!

C2520!57=.B!

28.042,B!507<!!

W!

"@.!B078.!B.5.65.B!,3!28.042,B!5@,5!

.[6..B1!5@.!6;152=.0h1!B.E73.B!

28.042,B!1.5573->!!

'@.6S!42,B!6;00.35!B.=,3B>!N.07EA!5@,5!

C2520!D)$!71!<02-0,==.B!52!5@.!6200.65!

8,4;.>!N.07EA!5@,5!"()!6@,0,65.071576!71!

6200.65!E20!5@.!,<<476,5723>!!

X/!

)2G!".=<!!

)2G!

5.=<.0,5;0.!!

W!

"@.!5.=<.0,5;0.!2E!5@.!@.,5!173S!E.44!

_.42G!J/Wl!'>!!

N.07EA!5@,5!,=_7.35!5.=<.0,5;0.!71!

G75@73!5@.!B078.h1!1<.67E76,57231k!7360.,1.!

5@.!,=_7.35!5.=<.0,5;0.!7E!3.6.11,0A>!!

XX!

L.E!)211!!

*<..B!0.E.0.36.!

4211!!

W!

"@.!B078.!B.5.65.B!5@,5!5@.!,3,42-!

73<;5!G,1!623E7-;0.B!52!E,;45!7E!5@.!

73<;5!6;00.35!G.35!_.42G!5@.!4.8.4!

1<.67E7.B!_A!6;152=.0!<,0,=.5.01>!!

'@.6S!5@.!<@A176,4!6233.657231!E20!,!

0.E.0.36.!17-3,4>!'@.6S!5@,5!5@.!

<02-0,==73-!E20!,!?dXW!=$!17-3,4!71!

6200.65>!N.07EA!5@,5!5@.!17-3,4!52!5@.!B078.!

71!6200.65>!!

OPERATOR’S!MANUAL!!

+,-.!XX!!

CODE!

FAULT!

DISPLAY!

DESCRIPTION!

ADV.!FAULT!

CODE!

EXPLANATION!

SUGGESTIONS!FOR!RECOVERY!

XY!

R0S!^70.!!

R02S.3!G70.!

B.5.65723!!

W!

"@.!B078.!B.5.65.B!5@,5!5@.!

<25.3572=.5.0!6706;75!G7073-!2<.3.B!

,3B!-.3.0,5.B!,!E,;45>!!

'@.6S!5@.!G7073-!E20!4211!2E!6233.65723!

52!6235024!5.0=73,41>!'@.6S!5@,5!,!

<25.3572=.5.0!2E!5@.!<02<.0!8,4;.!71!

7315,44.B>!!

X?!

m.A<,B!)211!

m.A<,B!4211!

W!

+02_4.=!G75@!5@.!S.A<,B!20!,!S.A<,B!

6233.65723>!"@.!B078.!B.5.65.B!5@,5!75!

62;4B!325!0.,B!,3A!S.A!<0.11.1>!

'@.6S!5@.!6233.65723!E02=!5@.!S.A<,B!

52!5@.!6235024!_2,0B>!%25.!5@,5!5@.!

S.A<,B!71!325!B.17-3.B!E20!0.=25.!

=2;3573->!!

/!

+02_4.=!G75@!5@.!S.A<,B!20!,!S.A<,B!

6233.65723g!20!G023-!S.A<,B!G,1!;1.B>!

m.A<,B!#F!E20!,3!&?!62;4B!325!_.!0.,B>!!

X!

+02_4.=!G75@!5@.!S.A<,B!20!,!S.A<,B!

6233.65723>!"@.!B078.!B.5.65.B!5@,5!75!

62;4B!325!G075.!52!5@.!)'F>!

XH!

'2==!)211!!

'2==;376,5723!

4211!!

W!

"@.!B078.!71!73!,!1.07,4!473S!6235024!<,5@!

,3B!5@.!,=2;35!2E!57=.!1736.!5@.!4,15!

C2B_;1!62==>!.[6..B.B!5@.!57=.!1.5!

73!<,0,=.5.0!TWY!\*#(!"7=.0]>!!

'@.6S!5@.!6233.657231!52!5@.!C2B_;1!

<205>!$BU;15!5@.!8,4;.!2E!<,0,=.5.0!TWY!

\*#(!"7=.0]!,1!3..B.B>!!

XK!

L.-.3!"7=.!!

L.-.3!57=.2;5!!

W!

"@.!B078.!522S!=20.!57=.!52!B.6.4.0,5.!

52!,!152<!5@,3!71!,442G.B>!"@.!57=.2;5!

71!B.5.0=73.B!_A!5@.!423-.15!

B.6.4.0,5723!0,=<!57=.!\F.6.4/!20!

F.6.4X]!<4;1!5@.!L.-.3!57=.2;5!

<,0,=.5.0>!

L.B;6.!5@.!,=2;35!2E!0.-.3.0,578.!

.3.0-A!20!7360.,1.!5@.!L.-.3!57=.2;5!

<,0,=.5.0>!!

XM!

+G0!R07B-.!!

+2G.0!_07B-.!

E,;45!!

Wg/gX!

"@.!B078.!B.5.65.B!,!E,74;0.!73!5@.!

2;5<;5!<2G.0!B.876.1>!!

'@.6S!E20!,!E,74.B!73<;5!<2G.0!B.876.>!!

XP!

F078.!"()!!

F078.!57=.B!

28.042,B!!

W!

"@.!B078.!B.5.65.B!,3!28.042,B!5@,5!

.[6..B.B!5@.!B078.!0,573->!!

'@.6S!5@,5!42,B!623B757231!B2!325!

.[6..B!5@.!B078.h1!0,573-!\/XWf!E20!

KW!1.623B1!E02=!3,=.<4,5.!6;00.35!

0,573-!E20!320=,4!B;5A!,3B!/HWf!20!0,5.B!

6;00.35!E20!KW!1.623B1!@.,8A!B;5A]>!

XT!

*5;6S!m.A!!

*5;6S!S.A!.0020!!

W!

m.A!<0.11!G,1!B.5.65.B!;<23!<2G.0J

;<>!"@71!G2;4B!266;0!_.6,;1.!2E!,!

B.E.6578.!S.A<,B!20!_.6,;1.!12=.23.!

G,1!@24B73-!B2G3!,!S.A!G@.3!

<2G.073-!;<!5@.!B078.>!!

'@.6S!E20!,!15;6S!S.A<,B!,3B!0.<,70!20!

0.<4,6.>!'231;45!5@.!E,6520A>!!

YW!

+,0,=!L,3-.!!

+,0,=.5.0!2;5!

2E!0,3-.!!

W!

(3.!2E!5@.!6;152=.0!<,0,=.5.01!71!2;5!

2E!0,3-.>!!

'@.6S!E20!,!<,0,=.5.0!8,4;.!1,8.B!2;5!2E!

5@.!15,3B,0B!0,3-.>!L.1.5!<,0,=.5.01!52!

5@.!E,6520A!B.E,;45>!'231;45!5@.!E,6520A>!!

Y/!

+G0!^7073-!

+2G.0!G7073-!

.0020!

W!

+02_4.=!G75@!5@.!B078.!G7073->!!

'@.6S!5@,5!73<;5!<2G.0!G7073-!71!325!

6233.65.B!52!42,B!<2G.0!5.0=73,41>!

'231;45!5@.!E,6520A>!

/!

#('!E,;45!G,1!B.5.65.B!B;073-!5@.!

<2G.0!G7073-!5.15>!

YX!

)2G!N245,-.!!

)2G!8245,-.!507<!!

W!

+2G.0!B7<!266;00.B!G@.3!5@.!B078.!G,1!

2<.0,573-g!,3B!5@.!B078.!G,1!325!,_4.!52!

07B.!5@02;-@!5@.!<2G.0!B7<!_.E20.!

1@;5573-!2EE!2;5<;51>!!

N.07EA!5@,5!73<;5!473.!<2G.0!71!G75@73!5@.!

B078.h1!1<.67E76,57231>!$BB!,!50,31E20=.0!

20!0.B;6.!B.=,3B1!52!5@.!<2G.0!E..B>!

'231;45!5@.!E,6520A>!!

YY!

/+@!(8.042,B!!

/+@!28.042,B!!

W!

R;1!8245,-.!07<<4.!G,1!2;517B.!5@.!47=75!

2E!5@.!B078.!\G@.3!<,0,=.5.0!H/M!

*73-4.J+@,1.!71!623E7-;0.B!E20!173-4.J

<@,1.!2<.0,5723]>!!

'@.6S!5@,5!73<;5!<2G.0!B.=,3B!B2.1!

325!.[6..B!5@.!B078.h1!6,<,675A!E20!

173-4.J<@,1.!2<.0,5723>!'231;45!5@.!

E,6520A>!!

Y?!

L*!C.,1>!D,74!!

*5,520!

0.1715,36.!

=.,1;0.=.35!

E,74.B!!

W!

"@.!B078.!62;4B!325!=.,1;0.!5@.!15,520!

0.1715,36.!<02<.04A>!!

"0A!5@.!02;573.!,-,73!,3B!7E!5@.!E,;45!

266;01!5G76.g!6231;45!5@.!E,6520A>!!

OPERATOR’S!MANUAL!!

+,-.!XY!!

CODE!

FAULT!

DISPLAY!

DESCRIPTION!

ADV.!FAULT!

CODE!

EXPLANATION!

SUGGESTIONS!FOR!RECOVERY!

YH!

D,3!)211!

)211!2E!E,3!

6235024!20!

2<.0,5723!

W!

+02_4.=!G75@!5@.!@.,5!173S!E,3>!!

'231;45!5@.!E,6520A>!!

/!

+02_4.=!G75@!5@.!735.03,4!E,3>!"@71!

266;01!234A!23!*7Z.!?!,3B!H!=2B.41>!$44!

25@.0!=2B.41!B71<4,A!,!E,3!.0020!

G,0373->!%25.!5@,5!5@71!71!4,6S!2E!E,3!

6235024g!12!5@.!E,3!6,3!_.!1<73373-!,3B!

5@71!E,;45!G744!15744!266;0>!"@71!6,3!

@,<<.3!7E!5@.!E,3!71!23!,3B!1@2;4B!325!

_.g!20!7E!5@.!E,3!E..B_,6S!17-3,41!,0.!

2_150;65.B!E02=!-.5573-!52!5@.!6235024!

_2,0B>!!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

OPERATOR’S!MANUAL!!

+,-.!X?!!

EXPLODED VIEW AND PARTS LIST – TITAN XT

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

OPERATOR’S!MANUAL!!

+,-.!XH!!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

ITEM

QTY

PART NUMBER

DESCRIPTION TITAN XT

!!!

!

1 1 110-0088-00

Vacuum Tube Assembly

2 1 100-0631-00

Cover 3 1

100-0625-00

Drive Train, Lower Plate

4

17

500-0013-00

Bearing

5 8 550-0022-00

Key 6 8

500-0254-00

Sprocket

7 8 500-0255-00

Bushing

8 7 100-0578-01

Drive, Short Shaft

9 1 550-0007-00

Key Stock

10 1 500-0248-00

Bushing

11 1 500-0252-00

Sprocket

12 1 100-0577-03

Drive, Long Shaft

13 1 500-0256-00

Sprocket

14 2 500-0006-00

Bearing

15 1 100-0628-00

Idler Shaft Spacer

16 1 100-0627-00

Offset Idler Shaft

17 1 520-0041-00

Belt

18 1 100-0626-00

Drive Train, Upper Plate

19 1 100-0585-01

Bearing Plate

20 8 100-0629-00

Drive Train Spacer

21 8 590-0120-00

Fastener

22 1 100-0651-00

Idler Wrench

23 1 590-0245-00

Fastener

24 3 590-0169-00

Fastener

25 1 008-0343-00

Weather Strip

26 1 590-0260-00

Fastener

27 1 590-0261-00

Lock Nut

28 9 590-0142-00

Lock Washer

29 1 100-0635-00

Belt Check Mounting Plate

30 9 590-0114-00

Fastener

31 8 590-0124-00

Fastener

32 4 540-0151-00

Vibration Dampener

33 1 540-0133-00

VFD

34 2 540-0156-00

Strain Relief

35 1 540-0072-00

Strain Relief

36 2 590-0047-00

Washers

37 1 540-0073-00

Strain Relief

38 1 540-0002-00

Mating Receptacle

39 1 540-0068-00

Strain Relief

40 1 540-0069-00

Strain Relief

41 1 540-0218-00

Conduit

42 1 540-0008-00

Cable

43 1 540-0268-00

Cable Retainer

44 1 540-0060-00

Plug

45 1 520-0042-00

Belt

46 1 530-0005-00

Motor

47 1 550-0021-00

Key Stock

48 1 500-0066-00

Bushing

49 1 500-0253-00

Sprocket

50 1 120-0002-02

Motor Shroud Assembly

51 7 590-0115-00

Fastener

52 1 130-0091-00

Handle

53 1 130-0093-00

Handle Assembly

54 1 540-0005-00

Start Button

55 1 540-0006-00

Stop Button

56 4 540-0179-00

Threaded Bumper

57 1 540-0117-00

Potentiometer

58 1 540-0116-00

Potentiometer

59 2 580-0122-00

Handle Grip

60 1 580-0089-00

T-Handle Assembly

OPERATOR’S!MANUAL!!

+,-.!XK!!

!

ITEM

QTY

PART NUMBER

DESCRPTION TITAN XT

61 1 540-0003-00

Cords

62 1 100-0188-01

Handle Junction Box

63 1 540-0144-00

Strain Relief

64 2 590-0232-00

Washer

65 1 590-0237-00

Fastener

66 1 130-0094-00

Handle Assembly

67 2 540-0240-00

Bumper

68 1 100-0650-00

Handle Protection Plate

69 1 580-0070-00

Quick Release Pin

70 2 580-0095-00

Wheel

71 2 590-0234-00

Washer

72 2 590-0263-00

Fastener

73 2 590-0192-00

Fastener

74 2 590-0159-00

Fastener

75 1 100-0454-01

Motor Mounting Plate

76 4 590-0134-00

Fastener

77

16

008-0208-00

Bumper

78 2 008-0154-00

Bumper

79

16

008-0189-00

Shear Pin Grommet

80

12

590-0128-00

Fastener

81 8 008-0363-01

Pad Driver

82 1 008-0357-00

Velcro Loop

83 1 008-0358-00

Dust Skirt

84 4 590-0009-00

Fastener

85 4 590-0063-00

Washer

86

48

580-0033-00

Magnet

87

48

590-0182-00

Fastener

88 8 008-0362-00

Plate

89

16

008-0142-03

Shear Pins

90

16

590-0019-00

Fastener

91 1 580-0104-00

Chain

92 8 008-0354-01

Pad Driver Plate Assembly

93 8 008-0361-00

Plate Assembly

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

OPERATOR’S!MANUAL!!

+,-.!XM!!

EXPLODED VIEW AND PARTS LIST – COLOSSOS XT

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

SCALE 0.06/1

1

2

COLOSSOS XT

(001-0068-00)

19

21

57

17

15

16

56

20

21

27

100

101

48

98

68

38

67

36

33

37

64

52

28

21

58

59

63

4

29

9

18

55

51

2

62

61

39

10

8

30

5

6

94

92

82

91

8

86

11

73571

70

77

72

76

33

50

87

96

75

77

89

88

95

69 81 74 808283

78

79

54

53

9

4

31

12

13

33534

17

45

41

44

22

49

47

93

97

8 10

46

84

85

99

43

102

60 25 26

103 8

6566

23

42

24

14

32

5

6

40

90

OPERATOR’S!MANUAL!!

+,-.!XP!!

ITEM

QTY

PART NUMBER

DESCRIPTION COLOSSOS XT

!!!

!

1 1 530-0007-01

Motor

2 1 500-0079-00

Bushing

3 1 540-0078-00

VFD

4 5 590-0144-00

Lock Washer

5

12

590-0142-00

Lock Washer

6 8 590-0124-00

Fastener

7 1 120-0003-02

Motor Shroud Assembly

8

10

590-0114-00

Fastener

9 8 590-0159-00

Fastener

10

13

590-0140-00

Fastener

11 2 590-0166-00

Fastener

12 4 590-0050-00

Lock Washer

13 4 590-0217-00

Fastener

14 8 100-0176-00

Drive Spacer

15 2 500-0197-00

Bearing

16 1 500-0247-00

Idler Sprocket

17 1 100-0609-02

Offset Idler Shaft

18 8 590-0120-00

Fastener

19 1 500-0267-00

Sprocket

20 7 500-0266-00

Sprocket

21

17

500-0013-00

Bearing

22 1 540-0069-00

Strain Relief

23 1 540-0073-00

Strain Relief

24 1 100-0120-01

Drive, Idler Shaft Spacer

25 1 500-0248-00

Bushing

26 1 550-0007-00

Key Stock

27 1 100-0573-01

Drive Train, Lower Plate

28 1 100-0572-01

Drive Train, Upper Plate

29 1 110-0072-01

Cover Assembly

30 1 100-0115-01

Belt Check Plate Cover

31 1 100-0137-03

Motor Mounting Plate

32 1 100-0216-03

Lifting Lug, Motor Mounting Plate

33

12

590-0128-00

Fastener

34 8 540-0152-00

Vibration Dampener

35 8 590-0133-00

Fastener

36

24

008-0154-00

Bumper

37

16

008-0143-03

Shear Pins

38

16

008-0189-00

Shear Pin Grommet

39 2 110-0073-00

Vacuum Tube Assembly

40 2 540-0156-00

Strain Relief

41 1 540-0002-00

Mating Receptacle

42 1 540-0072-00

Strain Relief

43 2 590-0047-00

Reducing Washer

44 1 540-0268-00

Strain Relief

45 1 540-0319-00

Cable

46 2 540-0268-00

Cable Retainer

47 1 540-0066-00

Plug

48 1 008-0319-00

Weather Strip

49 1 540-0266-00

Conduit

50 8 590-0115-00

Fastener

51 1 550-0009-00

Key Stock

52

16

590-0055-00

Fastener

53 1 008-0309-01

Dust Skirt

54 1 008-0320-00

Velcro Loop

55 1 590-0244-00

Fastener

56 1 100-0611-00

Idler Wrench

57 1 590-0193-00

Fastener

58 1 100-0585-01

Bearing Plate

59 3 590-0169-00

Fastener

60 1 500-0252-00

Sprocket

61 1 520-0042-00

Belt

!

!

OPERATOR’S!MANUAL!!

+,-.!XT!!

!

62 1 500-0253-00

Sprocket COLOSSOS XT

63 8 590-0258-00

Fastener

64 8 008-0360-00

Plate, Plug ‘N Go

65

48

580-0033-00

Magnet

66

48

590-0182-00

Fastener

67

16

008-0208-00

Bumper

68 8 008-0359-02

Pad Driver

69 1 580-0070-00

Quick Release Pin

70 2 580-0095-00

Wheel

71 2 500-0198-00

Bearing

72 2 590-0132-00

Fastener

73 4 590-0135-00

Fastener

74 2 590-0230-00

Flat Washer

75 1 590-0237-00

Fastener

76 2 590-0000-00

Flat Washer

77 4 590-0232-00

Washer

78 1 130-0071-02

Handle, Main Frame

79 2 130-0073-02

Handle, Extender Assembly

80 2 100-0555-01

Hitch

81 2 580-0098-00

Retaining Ring

82 4 540-0179-00

Threaded Bumper

83 2 590-0147-00

Flat Washer

84 2 540-0240-00

Bumper

85 2 130-0076-02

Handle Assembly

86 1 100-0226-02

Handle, Wheel Axle

87 1 100-0558-01

Protection Plate

88 1 540-0116-00

Potentiometer

89 1 540-0117-00

Potentiometer Knob

90 1 100-0215-01

Handle Cover Plate

91 1 540-0006-00

Stop Button, Red

92 1 540-0005-00

Start Button, Green

93 2 540-0003-00

Cord

94 2 580-0122-00

Handle Grip

95 1 540-0144-00

Strain Relief

96 2 590-0192-00

Fastener

97 1 580-0190-00

Quick Release Pin

98 1 520-0041-00

Belt

99 1 580-0104-00

Chain

100 8 008-0368-00

Plate Assembly

101 8 008-0367-00

Pad Driver Plate Assembly

102 8 008-0310-01

Compression Foam

103 1 540-0308-00

Grounding Wire Assembly

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

OPERATOR’S!MANUAL!!

+,-.!YW!!

!

GLOSSARY

!

This is the voltage of a power source when it has no load applied to it. It can also be called

“nominal voltage” as the voltage expressed is usually a guideline voltage.

This is the voltage of a power source when a load has been applied to it. As a load is applied to the

power source, the resistance of the line is easier to examine. When a voltage-measuring device

such as a multimeter is used during operation of the machine, you can clearly see that the voltage

drops as soon as a load is applied and rises back when the load is taken off.

Pigtails are plug ends with unfinished bare wire on one end used for hooking up to panels. Pigtails

are used when the source power is unknown, when connecting to the power grid of an unfinished

building that has no power receptacles, and when running certain generators. Many pigtails are

available or can be made up by an electrician.

Rear pivoting assembly.

Vinyl composition tile.

A variable frequency drive (VFD) is a system for controlling the rotational speed of an alternating

current electric motor by controlling the frequency of the electrical power supplied to the motor. A

variable frequency drive is a specific type of adjustable-speed drive. Variable frequency drives are

also known as adjustable-frequency drives (AFD), variable-speed drives (VSD), AC drives,

microdrives, or inverter drives. Because the voltage is varied along with frequency, these are

sometimes also called variable voltage variable frequency (VVVF) drives.

!

Line Voltage

Load Voltage

Pigtail

RPA

VCT

VFD

OPERATOR’S!MANUAL!!

+,-.!Y/!!

WARRANTY!INFORMATION!!

!

WerkMaster Grinders & Sanders Inc.,herein referred to as WerkMaster, warrants

that each new machine, manufactured by WerkMaster to be free from defects in

material and workmanship in normal use and service for a period of three (3)

years from date of shipment to the original Purchaser or Distributor.

WerkMaster will, at its option, repair or replace, at the WerkMaster factory or at a

point designated by WerkMaster, any part which shall appear to the satisfaction

of WerkMaster inspection to have been defective in material or workmanship.

WerkMaster reserves the right to modify, alter and improve any part or parts

without incurring any obligation to replace any part or parts previously sold

without such modified, altered or improved part or parts.

This warranty is in lieu of and excludes all other warranties, expressed, implied,

statutory, or otherwise created under applicable law including, but not limited to

the warranty of merchantability and the warranty of fitness for a particular

purpose. In no event shall the Seller or the Manufacturer of the product be liable

for special, incidental, or consequential damages, including loss of profits,

whether or not caused by or resulting from the negligence of Seller and/or the

Manufacturer of the product unless specifically provided herein.

In addition, this warranty shall not apply to any products or portions thereof

which, at WerkMaster’s discretion, have been subjected to abuse, misuse,

improper installation, maintenance, or operation, electrical failure or abnormal

conditions, and to products which have been tampered with, altered, modified,

repaired, reworked by anyone not approved by the Seller, or used in any manner

inconsistent with the provisions of the above or any instructions or specifications

provided with or for the product.

Except for conditions or warranties which may not be excluded by law, the Seller

makes no warranty of its own on any item warranted by WerkMaster, and makes

no warranty on other items unless it delivers to the Purchaser a separate written

warranty document specifically warranting the item. The Seller has no authority

to make any representation or promise on behalf of WerkMaster or to modify the

terms or limitations of this warranty in any way.

Seller shall use reasonable efforts to attempt to cause the Products to be

delivered as provided for in these Terms & Conditions. Delivery to the initial

common carrier shall constitute the delivery to the Purchaser. Seller’s

responsibility, in so far as transportation risks are concerned, ceases upon the

delivery of the Products in good condition to such carrier at the F.O.B. point and

all the Products shall be shipped at the Purchaser’s risk. Seller shall not be

responsible or liable for any loss of income and/or profits, or incidental, special,

consequential damages resulting from Seller’s delayed performance in shipment

and delivery.

Defective or failed material shall be held at the Purchaser’s premises until

authorization has been granted by Seller to return or dispose of Products.

Products that are to be returned for final inspection must be returned Freight

Prepaid in the most economical way. Credit will be issued for material found to

be defective upon Seller’s inspection based on prices at time of purchase.

Delivery, Damages,

Shortages

Return of Defective

Products

Terms & Conditions

OPERATOR’S!MANUAL!!

+,-.!YX!!

WARRANTY continued

!

!

Seller’s obligation hereunder are subject to, and Seller shall not be held

responsible for, any delay or failure to make delivery of all or any part of the

Product due to labor difficulties, fires, casualties, accidents, acts of the elements,

acts of God, transportation difficulties, delays by a common carrier, inability to

obtain Product, materials or components or qualified labor sufficient to timely

perform part of or all of the obligations contained in these terms and conditions,

governmental regulations or actions, strikes, damage to or destruction in whole

or part of manufacturing plant, riots, terrorist attacks or incidents, civil

commotions, warlike conditions, flood, tidal waves, typhoon, hurricane,

earthquake, lightning, explosion or any other causes, contingencies or

circumstances within CANADA not subject to the Seller’s control which prevent

or hinder the manufacture or delivery of the Products or make the fulfillment of

these terms and conditions impracticable. In the event of the occurrence of any

of the foregoing, at the option of Seller, Seller shall be excused from the

performance under these Terms and Conditions, or the performance of the Seller

shall be correspondingly extended. This document sets forth the terms and

conditions pursuant to which the purchaser(“Purchaser”) will purchase and

WerkMaster (“Seller”) will sell the products, accessories, attachments

(collectively “the Products”) ordered by the Purchaser. These terms and

conditions shall govern and apply to the sale of Seller’s Products to Purchaser,

regardless of any terms and conditions appearing on any purchase order or other

forms submitted by Purchaser to Seller, or the inconsistency of any terms therein

and herein.

!

!

!

!

!

To get the best protection from your WerkMaster Warranty be sure to register

your product(s) online at www.werkmaster.com/warranty.

!

!

!

! !

!

!

!

!

!

!

!

!

!

!

!

WerkMaster Grinders and Sanders Inc.

6932 Greenwood Street, Burnaby, BC V5A 1X8

tel: 604.629.8700 | toll free: 1.866.373.WERK | fax: 604.444.4231

www.werkmaster.com | email: info@werkmaster.com

! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! ! 1G=`WP`/M!

FORCE MAJEURE

OPERATOR’S!MANUAL!!

+,-.!YY!!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!