Pantec Engineering AG phone: +423/377 13 33 Dokumentnummer: UM-22031

Industriering 21 fax: +423/377 13 34 Dokumentrevision: D

9491 Ruggell mail: info@pantec.com Sprache: EN

Principality of Liechtenstein internet: www.pantec.com Freigabedatum: 14.05.2008

User Manual

Control Panel:

HT 400 / HT 400 RC

These operating instructions are part of the technical documentation of the UV Controller in compliance with EU

Machine Guidelines.

The operating instructions in hand correspond to the 'EC Directive 98/37/EC of the European Parliament and of

the Council on the approximation of the laws of the member states relating to machinery' (Machinery Directive),

Appendix I, Item 1.7.4.

The operating instructions in hand are aimed at the person in charge of the factory who must pass it on to the

personnel responsible for assembly, application and maintenance of the UV Controller.

The person in charge must make sure that the information contained in the Operating Instructions and in the

accompanying documents is read and understood.

The operating instructions must be kept in a known and easily accessible place and must be consulted for advice

whenever there is the slightest doubt.

The manufacturer does not accept any liability for injuries to persons or animals or for damage to goods, the UV

Controller or the system itself cause by improper use, nonobservance or insufficient observance of the safety

criteria listed in these assembly instructions, or caused by changes to the UV controller or use of non-suitable

replacement parts.

The copyright for these operating instructions is the exclusive property of

PANTEC Engineering AG

LI-9491 Ruggell

or its legal heirs.

The Operating Instructions in hand may be reproduced or passed on to third parties only when written consent

has been obtained. This applies also when only sections of the Operating Instructions are copied or passed on.

The same terms govern the transmission of the Operating Instructions in digital form.

PANTEC Engineering AG

Industriering 21

9491 Ruggell

Liechtenstein

http://www.pantec.com

Phone: +423 377 13 33

Fax: +423 377 13 34

Control Panel - User Manual

Table of contents

Doc.no.: UM-22031 Revision: D Page 3 of 30

Table of contents

1. Signs and symbols............................................................................................................... 4

2. Safety regulations ............................................................................................................... 5

2.1. Safety Test ........................................................................................................................................................... 5

2.2. Battery Precautionary Steps............................................................................................................................... 6

3. Technical description .......................................................................................................... 8

3.1. Correct use .......................................................................................................................................................... 8

3.2. Components HT 400 and HT 400 RC................................................................................................................... 9

3.3. Features and functions ..................................................................................................................................... 10

3.4. Connecting the control panel HT 400 ............................................................................................................... 11

3.5. Connecting the control panel HT 400 RC ......................................................................................................... 12

4. Control and display elements.............................................................................................13

5. Basic functions of the control panel ...................................................................................16

5.1. Powering up HT 400 RC..................................................................................................................................... 16

5.2. Switching on operating mode (mouse function or axial control).................................................................... 17

5.3. Moving/traversing axes..................................................................................................................................... 18

5.4. Aligning control panel with respect to measuring machine........................................................................... 19

5.5. Setting/changing rate........................................................................................................................................ 21

5.6. Switching on the power supply for the servo drives........................................................................................ 22

5.7. Special functions ............................................................................................................................................... 22

5.8. Battery charge control (HT 400 RC) ................................................................................................................. 22

5.9. Recharging battery (HT 400 RC) ....................................................................................................................... 23

5.10. Shutdown function of the HT 400 RC control panel......................................................................................... 23

5.11. Modified functions of the HT 400 Design control panel .................................................................................. 24

6. Maintenance of the control panel .......................................................................................26

7. Help with faults ..................................................................................................................27

8. Technical data ....................................................................................................................29

9. Versionsgeschichte ............................................................................................................30

10. Contact Pantec ...................................................................................................................30

Control Panel - User Manual

1 - Signs and symbols

Page 4 of 30 Revision: D Doc.no.: UM-22031

1. Signs and symbols

In addition to the key symbols, further signs and symbols appear in the manual.

They have the following significance:

WARNING

Warning of a danger point!

This symbol is to be found next to jobs, which could result in danger to life and

limb of personnel.

Important:

The text following this sign describes activities which should be carried out

in the specified sequence.

The text after this sign describes the result of an operation

NOTE !

After the word “Note” you will find instructions and useful tips for optimum

operation of the control panel.

Control Panel - User Manual

2 - Safety regulations

Doc.no.: UM-22031 Revision: D Page 5 of 30

2. Safety regulations

WARNING

For reasons of safety:

Independent modifications to the HT 400 (RC) control panel are prohibited.

Repair and troubleshooting

Repair work, trouble-shooting and fault rectification may only be car-ried out by

qualified technicians (e.g. an electrician).

It is essential that the connecting cable is separated from the control-ler before

the control panel is opened.

Plug connections may only be plugged in when the machine is switched off.

NOTE !

Do not move Joystick when switching on HT 400 (RC).

WARNING

During operations the antenna (only HT 400 RC) is not to be screened by a

hand or any object!

Disposal

Defective devices which cannot be repaired must be disposed of in an environmentally responsible way. Therefore separate the individual materials (plastic,

metal, electrics) and hand these over for recycling.

2.1. Safety Test

WARNING

For safety reasons, it is vital that the EMERGENCY STOP button on the

control panel is actuated at least once a week. It must be estab-lished

when pressing the EMERGENCY STOP button that the circuit has been

interrupted.

With the wireless variant, this EMERGENCY STOP button test needs to be

carried out at both the control panel and base station.

Control Panel - User Manual

2 - Safety regulations

Page 6 of 30 Revision: D Doc.no.: UM-22031

2.2. Battery Precautionary Steps

WARNING

The battery pack may explode and endanger life and limb of personel if not

properly handled!

Charging

Only charge this battery in the HT 400 RC or in a charger envisaged for this

purpose. This is to ensure that all charging parameters are kept and that optimum

efficiency is achieved.

Charging temperature: 0 - 45°C.

Discharging

Discharging temperature: Discharging in the .20 to 60°C range

Exhaustive discharge: Self-discharge can result in the cells discharging even when

the panel is switched off. This is why the battery needs to be regularly charged.

NOTE !

Battery capacity sinks to 80% after 350 to 400 charing/discharging cycles.

The battery is to be replaced after 500 charging/discharging cycles.

Storage

Storage temperature: Store at temperatures between .20 and 45°C. Ca-pacity

losses are noticeable given a lengthy period of storage at 60°C. Keep the battery

away from any flames !

Lengthy storage: The lower the state of charging the lower the reduction in

capacity. A lengthy period of storage is to be carried out at a 50% charge or at

around 3.7 V. Regularly re-charge the battery given storage in excess of one year.

Safety

Do not dismantle: Do not dismantle the battery pack. The battery pack is fitted with

safety cells. These cells not working properly could result in the battery leaking

and caustic liquids emerging. Furthermore the battery could overheat, ignite and

explode.

Do not short-circuit: Do not connect the positive (+) and negative (-) poles with a

conductive material. Do not transport or store the battery pack to-gether with

metal objects.

A short-circuit could result. This, in turn, might lead to overheating, electro-lyte

losses, smoke forming and to an explosion of the battery.

Keep away from flames: Keep the battery pack away from flames and do not ignite

it. The insulation could melt.

Safety cells could be destroyed, the electrolyte might ignite, the battery could leak,

overheat or explode.

Keep away from water: Do not submerge the battery or wet it. The safety cells

could be destroyed. The result could be unwanted chemical reactions. The battery

could leak, overheat or explode.

Control Panel - User Manual

2 - Safety regulations

Doc.no.: UM-22031 Revision: D Page 7 of 30

Do not drill through: Do not damage the battery pack with a nail or sharp object. Do

not drill through or hammer into it. The battery pack could be destroyed, could

leak, overheat and explode.

Not to be impacted or thrown: The safety cells could be destroyed. The result could

be unwanted chemical reactions. The battery could leak, over-heat or explode.

Not to be soldered on: The safety cells could be destroyed. The result could be

unwanted chemical reactions. The battery could leak, overheat and explode.

Control Panel - User Manual

3 - Technical description

Page 8 of 30 Revision: D Doc.no.: UM-22031

3. Technical description

3.1. Correct use

The HT 400 (RC) control panel can be connected to the controller of the following 3

coordinate measuring machines made by PANTEC ENGINEERING AG:

Measuring machines on air-bearings with motorised movement of the axes

(LH, LHF, LAF, LS systems)

Measuring machines on roller bearings with motorised movement of the

axes (RSplus, RSDplus, RAF, RAD etc.)

With the HT 400 (RC) control panel in conjunction with the 3-/4-axes WPC 20XX

contouring controller, the machine axes of a 3-coordinate measuring machine can

be manually translated (traversed). A joystick has been in-stalled for this purpose.

This permits the drives of the axes to be infinitely adjusted.

NOTE !

With a CNC measuring machine, the joystick controller and other HT 400

(RC) functions are blocked when an automatic CNC pro-gram is running.

In addition to controlling the axes, the control panel can also be used as a normal

PC mouse, with which you can for example operate the evaluation software,

providing this function has been activated in the PC.

Control Panel - User Manual

3 - Technical description

Doc.no.: UM-22031 Revision: D Page 9 of 30

3.2. Components HT 400 and HT 400 RC

Picture 1 – Components of the HT400 (RC)

1. Switch-on button (only HT 400 RC) 2. EMERGENCY-STOP button

3. Antenna (only HT 400 RC) 4. Joystick

5. Knob for speed-attitude 6. Charge connector (only HT 400 RC)

7. Diaphragm keyboard 8. Knurled thumb screw for battery

locker (only HT 400 RC)

9. Connecting cable (not for HT 400 RC)

Control Panel - User Manual

3 - Technical description

Page 10 of 30 Revision: D Doc.no.: UM-22031

3.3. Features and functions

In conjunction with the controller, the control panel has the following fea-tures and

functions:

Two operating modes:

o axial control

o mouse function (using the control panel as PC mouse for the applied

software)

Infinite adjustment of up to four axes with the aid of the joystick

Safety shutdown: If any axis has not been moved within a period of 30 secs,

the axial controller is automatically shut down.

EMERGENCY STOP button: is also functional when an automatic CNC

program is running

Adjustment/alteration of the traverse rate by the operator

The alignment of the control panel in respect to the measuring machine can

be adjusted depending on the operator’s position

Auto-switch-off: To save battery power system will switch off after 30 min of

inactivity (HT 400 RC).

LED for Joystick-mode

LED for CNC-mode

LED for battery charge control (HT 400 RC).

Control Panel - User Manual

3 - Technical description

Doc.no.: UM-22031 Revision: D Page 11 of 30

3.4. Connecting the control panel HT 400

The control panel must be connected to the 25 pin terminal connection of the

controller.

The mouse function can only be used, if the hook-up from the terminal con-nection

to the mouse interface (e.g. COM 1) is plugged into the PC.

Picture 2 – Schematic diagram of connections HT 400

Control Panel - User Manual

3 - Technical description

Page 12 of 30 Revision: D Doc.no.: UM-22031

3.5. Connecting the control panel HT 400 RC

The basis station must be connected to the 25 pin terminal connection of the

controller.

The mouse function can only be used, if the hook-up from the terminal con-nection

to the mouse interface (e.g. COM 1) is plugged into the PC.

Picture 3 – Schematic diagram of connections HT 400 RC

Adjustment of the Country Code

The differing international regulations mean that an adaptation is needed in some

countries (France). Consult your Wenzel representative office on this.

Control Panel - User Manual

4 - Control and display elements

Doc.no.: UM-22031 Revision: D Page 13 of 30

4. Control and display elements

EMERGENCY STOP button

The axis drives can be shut down in emergencies with this pushbutton. All

movements are stopped immediately and the power supply for the servo drives is

cut off. This applies even when an automatic CNC program is run-ning.

NOTE !

Do not use the EMERGENCY STOP button for routinely switching off the axis

drives!

Resetting the EMERGENCY STOP:

Remedy the problem which lead to the button being pressed.

Release the EMERGENCY STOP button.

Switch on the power supply for the servo drives (Servo-ON key).

If necessary, acknowledge fault messages in the software.

The control panel is now ready for operation again.

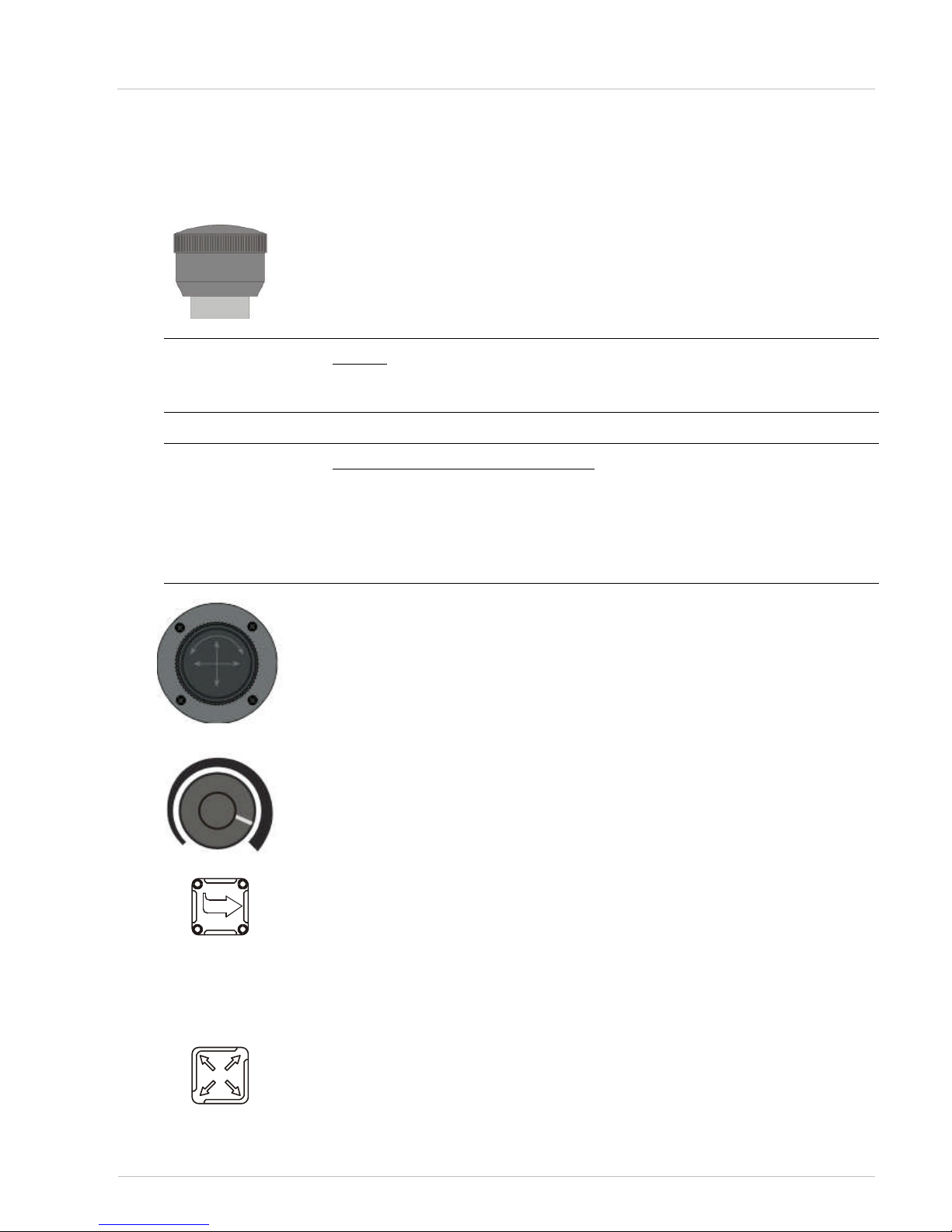

Joystick

The functioning of the joystick depends on which operating mode is switched on:

With axial control You can traverse a previously activated axis with the

joystick.

With mouse function You can move the mouse pointer on the screen with the

joystick.

Speed control

When the axial control is switched on, moving speed of the machine-axis can be

varied (0-100%).

Changing the alignment and Alignment display

The LEDs shows the orientation of the control panel with respect to the 3

coordinate measuring machine (also refer to Fig. 4.2).

With this pushbutton, you can change the alignment of the control panel with

respect to the 3 coordinate measuring machine independently of the operator’s

workstation. Each time the button is pressed, the alignment is shifted by 90° in the

clockwise direction (also see Chap. 4.4).

Active key

With this key you can switch the axial control on and off. When the axial control is

switched on (the LED Joy shines), you can activate and deacti-vate individual axes

with the aid of the activation keys ("X", "Y", "Z" or "C").

Control Panel - User Manual

4 - Control and display elements

Page 14 of 30 Revision: D Doc.no.: UM-22031

Servo ON

If you press the Servo-ON key, the power supply for the servo drives is switched on.

NOTE !

Extra functions are determined by the respective software adjustment.

Shift key

Pressing this key is the prerequisite for the following functions:

Pressing shift-key and function keys activates second functions.

Activation of brakes ( X, Y, Z, C) depending on Software-

setup.

Left-hand mouse key

The key is always functional even when the axial control is switched on.

The properties/functions of the key (e.g. clicking menus and buttons) de-pend on

the key configuration in the system controller of the PC.

Right-hand mouse key

The key is always functional even when the axial control is switched on.

The properties/functions of the key (e.g. calling up context menus) depend on the

key configuration in the system controller of the PC.

Activation of the X axis

The key is only functional when the axial control is switched on (the LED Joy

shines).

When you press this key, the X-axis is activated. The orange LED at the top right of

the pushbutton now lights up.

Press the key again to deactivate the axis. The LED now goes out.

Pressing shift key and activation key of the X .axis, the respective axis-brake is

switched.

NOTE !

Availability depends on Software-setup.

Activation of the Y axis

The key is only functional when the axial control is switched on (the LED Joy

shines).

When you press this key, the Y-axis is activated. The orange LED at the top right of

the pushbutton now lights up.

Press the key again to deactivate the axis. The LED now goes out.

Pressing shift key and activation key of the Y .axis, the respective axis-brake is

switched.

NOTE !

Availability depends on Software-setup.

Control Panel - User Manual

4 - Control and display elements

Doc.no.: UM-22031 Revision: D Page 15 of 30

Activation of the Z-axis

The key is only functional when the axial control is switched on (the LED Joy

shines).

When you press this key, the Z-axis is activated. The orange LED at the top right of

the pushbutton now lights up (see Chap. 4.2).

Press the key again to deactivate the axis. The LED now goes out.

Pressing shift key and activation key of the Z .axis, the respective axis-brake is

switched.

NOTE !

Availability depends on Software-setup.

Activation of the C-axis (turntable = option)

The key is only functional when the axial control is switched on.

When you press this key, the C-axis is activated. The orange LED at the top right of

the pushbutton now lights up (see Chap. 4.2).

Press the key again to deactivate the axis. The LED now goes out.

Slow/fast – key

With this key you can change over between rapid and crawl traverse rate:

Rapid traverse rate (= LED next to the hare lights up)

Crawl traverse rate (= LED next to the turtle lights up)

NOTE !

The LEDs of the fast/slow button (symbols: hare, turtle) blink when the

base station is connected to the control part and the data packages have

been sent. The blinking rate reflects the quality of connection (i.e. high

blinking rate -> high connection quality; low blinking rate -> poor connection

quality).

-

F1 - F12 key

The functions F1 to F12 depend on the measuring software used in each case.

You can select the previously assigned functions in the software with these keys.

Battery status (HT 400 RC)

3 LEDs indicate energy status of lithium accumulator.

Control Panel - User Manual

5 - Basic functions of the control panel

Page 16 of 30 Revision: D Doc.no.: UM-22031

5. Basic functions of the control panel

The basic functions described here can only be carried out when the con-troller

has been initialised.

Basic setting

When the controller is switched on, the control panel has the following initial

setting:

Axial control is switched off

Rapid traverse rate is switched on

Alignment of the control panel to the measuring machine: Operating position

= facing the Z-axis (also see Fig. 4.2)

NOTE !

Speed-setup (see Chapter 4) must be done manually.

5.1. Powering up HT 400 RC

Switch-on: Press switch-on button.

Battery mode: On-off switch position 1

24 V - Mains: On-off switch position 0

For charging battery or cable use plug in powercable from base-station or external

power-supply.

NOTE !

Base-station is active when WPC 20XX is powered up. With HT 400 RC

switched on, system is .negotiating. to set up a proper link. This will take

approx. 30 sec. And is indicated by a blinking LED of F1-key.

Control Panel - User Manual

5 - Basic functions of the control panel

Doc.no.: UM-22031 Revision: D Page 17 of 30

5.2. Switching on operating mode (mouse function or axial control)

You can change between two operating modes:

axial control (= prerequisite for translating the axes)

mouse function

Switching on axial

control

If you wish to translate/traverse an axis with the joystick, the axial control must

have been previously switched on.

This is how to switch on the axial control::

Press "active key".

The LED Joy shines

NOTE !

If you do not move the joystick for 30 seconds, the axial control is

automatically switched off.

NOTE !

Buttons, menu titles etc. can also be clicked with the mouse keys, when the

axial control is switched on. In this case, the mouse pointer must be moved

to the required button, before the axial control is switched on.

Switching on the

mouse function

Whenever the axial control is switched off, the mouse function is switched on.

When the mouse function is switched on, you can move the mouse pointer around

the screen.

This is how to switch over from the axial control to the mouse

function:

Press "active key".

LED JOY goes out. Axial traverse is switched off and the mouse func-tion is

simultaneously switched on.

Control Panel - User Manual

5 - Basic functions of the control panel

Page 18 of 30 Revision: D Doc.no.: UM-22031

5.3. Moving/traversing axes

This is how to traverse the axes with the control panel:

Switch on the axial control

Activate the required axes: Press the keys for the axes

which you want to traverse ("X", "Y", "Z" or "C").

If an axis is activated, the LED at the top right of the appropriate pushbutton

lights up.

NOTE !

Up to three axes can be simultaneously activated, including either the Zaxis or the C-axis, but not both at the same time. If you switch on a fourth

axis (the C-axis) then the Z-axis will be automatically deactivated. If the Caxis is activated and the Z-axis is switched on, the C-axis is then

automatically deactivated.

NOTE !

If you do not move the joystick for 30 seconds, the axial control is

automatically switched off for safety reasons. In order to traverse the axes,

the axial control must first be restarted.

This is how to control the axis with the joystick:

Traversing X-axis: Deflect joystick to the left/right or forward/reverse

(depending on the measuring machine system).

Traversing Y-axis: Deflect joystick to the left/right or forward/reverse

(depending on the measuring machine system).

Traversing Z-axis: Turn joystick.

o If you turn the joystick clockwise, the axis is moved in a negative Z-

direction (downwards).

o If you turn the joystick anti-clockwise, the axis is moved in a positive Z-

direction (upwards).

Control Panel - User Manual

5 - Basic functions of the control panel

Doc.no.: UM-22031 Revision: D Page 19 of 30

Picture 4 – Traversing Z-axis

Traversing C-axis: Turn joystick.

o If you turn the joystick clockwise, the axis (turntable) also turns

clockwise.

o If you turn the joystick anti-clockwise, the C-axis (turntable) is also

moved anti-clockwise

5.4. Aligning control panel with respect to measuring machine

It is easier to traverse the axes of the measuring machine and thus the measuring

probe, if the joystick and measuring probe move in parallel. For example: If you

move the joystick to the left, the measuring probe also trav-els to the left.

To make this also possible at different operating positions, the alignment of the

control panel with respect to the measuring machine can be changed.

Control Panel - User Manual

5 - Basic functions of the control panel

Page 20 of 30 Revision: D Doc.no.: UM-22031

This is how to change the alignment (taking an LH measuring

machine as an example):

Stand with the HT 400 (RC) control panel at the location, from where you

wish to operate the 3-axis coordinate measuring machine.

Find "your" location in Picture 5

Picture 5 – Alignment of the control panel

This is how to traverse the axes with the control panel:

Keep pressing “Change the alignment” key until the “alignment

display” agrees with “your” position in the diagram.

Check if the axial control is switched on, switch on if necessary.

Activate X- and Y-axes.

Check if the measuring probe moves in the X- or Y-direction, in which

the joystick is deflected.

If the joystick and measuring probe movement agree, then the control panel

alignment has been optimised.

Control Panel - User Manual

5 - Basic functions of the control panel

Doc.no.: UM-22031 Revision: D Page 21 of 30

5.5. Setting/changing rate

The traverse rate of the axes can be set/changed as follows:

Changing over between two basic traverse rates:

o rapid traverse rate

o crawl traverse rate (20% of the rapid traverse rate)

Infinite fine adjustment of the rapid traverse rate. Speed is varied by speed-

control knob.

NOTE !

The traverse rate setting affects all axes.

NOTE !

The traverse rate setting can also be changed while an automatic CNC

program is running. A reduction of the traverse rate is a good idea when

testing a new program, for example. In this case, the CNC traverse rate is

overridden by the traverse rate set at the control panel (traverse rate

override).

This is how to switch over between rapid and crawl traverse rate:

Check the existing setting on the "fast-/slow" key:

o LED next to the hare lights up → Rapid traverse rate is switched on.

o LED next to the turtle lights up → Crawl traverse rate is switched on.

To switch over, press the "fast-/slow" key.

You have now changed the basic traverse rate.

How to change max. traverse-speed:

Faster: Turn knob cw

Slow: Turn ccw

NOTE !

There is an superposition with other speed-settings (hare, turtle, softwaresettings)

The setting is still retained even if:

- the EMERGENCY STOP button is pressed

- the power supply for the servo drives is switched off

Control Panel - User Manual

5 - Basic functions of the control panel

Page 22 of 30 Revision: D Doc.no.: UM-22031

5.6. Switching on the power supply for the servo drives

The power supply for the servo drives can be switched on at the HT 400 (RC)

control panel (= same function as pushbutton at the front panel of the controller).

This is how to switch the power supply:

Press the „Servo-on key“.

The power supply for the servo drives in now switched on.

5.7. Special functions

Press the „Shift key“.plus „Activating-key“

This combination can launch a special function depending on front end

software used. on.

5.8. Battery charge control (HT 400 RC)

Green LED.

100% power.

LED on the right blinks green.

Battery „is being charged“

Yellow LED.

50% power.

Red LED.

10% power.

Red LED blinking.

Approx 0% power..

NOTE !

Red LED blinking will cause an emergency-stop. Charge or replace battery.

Control Panel - User Manual

5 - Basic functions of the control panel

Doc.no.: UM-22031 Revision: D Page 23 of 30

5.9. Recharging battery (HT 400 RC)

Charging of the battery begins as soon as the charging cable is plugged to the

manual terminal. It does not matter whether the appliance is on or not.

Charging takes 6 hours. When the appliance is on the green battery LED blinks

during charging.

NOTE !

Battery capacity sinks to 80% after 350 to 400 charging/discharging cycles.

The battery is to be replaced after 500 charging/discharging cycles.

NOTE !

After a long battery stand-still period (roughly 6 months), the bat-tery

should be subject to 2 charging cycles. Pull out the charging cable after the

1st cycle and then refit -> the 2nd charging cycle then starts.

5.10. Shutdown function of the HT 400 RC control panel

To keep demands down on the battery when not being used for a while, the manual

terminal is automatically shutdown after 30 minutes. The switch-on button must

be pressed before the control panel can be re-operated. With the connection

restored (F1 stops blinking), operations can proceed anew.

NOTE !

While executing a CNC-program this function is deactivated! When ever HT

400 RC is switched off (manually or automati-cally) an error-message

.Emergency-stop. is reported on the screen.

This is the way to switch off the control panel using the sheetcovered keyboard:

Press “Shift key” and then “Servo-on” button in addition.

Control panel is switched off

Control Panel - User Manual

5 - Basic functions of the control panel

Page 24 of 30 Revision: D Doc.no.: UM-22031

5.11. Modified functions of the HT 400 Design control panel

Adjusting mill cutter speed

Only when the mill cutter is active can its speed be changed.

Press the “Active key” to change to the Joy-mode

Press “C” button

Orange LED, top right in the key zone, lights up mill cutter active

Turn the speed adjustment knop to set the speed required

Operating drive coupling and axial brakes.

WARNING

Ensure that the joystick is not extended before pressing the “Servo-on”

button. Otherwise the axes could move in an uncontrolled fashion.

Press “Servo-on” button

The supply voltage for the servo-drives is switched on.

Use the application software (CM) to start the joystick mode.

The X, Y and Z axes are activated (LEDs at the top right in the appro-priate

key zone are illuminated).

The axle drives are engaged and the X, Y and Z brakes are not being applied.

Deactivate the required axies: Press the buttons for the

appropriate axies..

Drive coupling is not applied and the brake of the axis in question is active

(locked). The LED in the respective axis button blinks.

Press the “Shift key” and then the required axis button

as well.

The respective brake is activated and the LED is extinguished.

Control Panel - User Manual

5 - Basic functions of the control panel

Doc.no.: UM-22031 Revision: D Page 25 of 30

This is how to activate the required axis drives:

Press the button for the corresponding axis.

Drives are connected, brakes released and the LEDs light up.

NOTE !

Activating one axis always means an activation of all axes.

Control Panel - User Manual

6 - Maintenance of the control panel

Page 26 of 30 Revision: D Doc.no.: UM-22031

6. Maintenance of the control panel

Wipe the control panel with a slightly damp cloth once a month

- or –

use an anti-static cloth.

Never use benzene or other solvents.

Control Panel - User Manual

7 - Help with faults

Doc.no.: UM-22031 Revision: D Page 27 of 30

7. Help with faults

Fault/malfunction Possible cause Countermeasure/remedy

LED on servo-on button

blinks on power-on. No

activation of servo drives

possible.

Defective Semiconductor. Repair of HT 400 (RC) by

Pantec Engineering AG.

Control panel not

function-ing: LED in

alignment display does

not light up.

Measuring machine controller is not switched on..

Switch on controller

Link between joystick and

controller is faulty.

Check if the plug is connected, connect correctly

if necessary.

Axes (all) cannot be

manually

moved/traversed with the

joystick.

EMERGENCY STOP

button is pressed.

Reset the EMERGENCY

STOP button.

Power supply for servo

drives is not switched on.

Switch on servo drives:

Press "SERVO ON" but-

ton on WPC 20XX.

CNC program is being

executed. The LED Joy

shines.

Wait until the CNC pro-

gram is completed or in-

terrupt it.

The axes have not been

moved for 30 seconds →

device switches the axial

control off (= safety shutdown).

Switch on axial control

again: Press "active key".

Axial control is not

switched on.

Switch on the axial con-

trol: Press "active key".

Knob for seed-attitude is

at the left end. Speed is

near 0.

Knob for seed-attitude

turn to the right.

A particular axis cannot

be manually traversed

with the joystick.

Axis is not activated. Activate the required axis.

Direction of movement of

measuring probe and

joystick do not coincide

(are not parallel)

Operating panel is not

optimally aligned to the

measuring machine..

Change alignment (see

Chap. 4.4).

F1 blinks permanently No link

WPC 20XX switched off Switch on WPC 20XX

Wrong addresses of HT

400 RC and base-station

WP-service must do the

proper setup

HT 400 RC out of range Reduce distance to 2m

Antenna damaged or not

fixed

Repair by Pantec

Engineering AG

The antenna is screened

by a hand or an object..

Stop the screening.

Red LED is blinking, message .Emergency-stop.

appears

Battery low.

Recharge / replace

Plug in cable

Control Panel - User Manual

7 - Help with faults

Page 28 of 30 Revision: D Doc.no.: UM-22031

Fault/malfunction Possible cause Countermeasure/remedy

Mouse pointer cannot be

moved.

The axial control is

switched on.

Switch off axial control →

Mouse function is automatically switched on.

Cable between terminal

socket on the controller

and the mouse socket at

the PC is not plugged in.

Connect the cable.

Mouse is not configured

in the operating system.

Configure mouse and

configure keys as required.

Table 1 – Malfunction table

If you cannot remedy the fault/malfunction with the aid of the malfunction table,

read the notes on faults in the operating manual for the measuring machine or in

the description of the controller.

If you cannot find any help there get in contact with Pantec Engineering AG

customer service. For this purpose, use the ready prepared fault report. This has

been appended the operating manual supplied with your measur-ing machine.

Control Panel - User Manual

8 - Technical data

Doc.no.: UM-22031 Revision: D Page 29 of 30

8. Technical data

HT 400 (Cable

version)

Power supply/DC 24V

Power intake 25 W

Length of the connecting cable: 7 m

Connecting plug 25 pin, socket

Working temperature range +5 … +40 °C

Dimensions (l x B xH) approx. 260 x 115 x 115 mm

Weight (with connecting cable) approx. 1060 g

Table 2 – Technical data on HT 400 control panel

HT 400 RC

(Wireless version)

Power supply/DC 5 / 24V

Power intake max. 6 W

Working temperature range +5 … +40 °C

Dimensions (l x B xH) approx. 260 x 115 x 115 mm

Weight (with battery) approx. 600 g

Range (sith visual contact) max. 10 m

Table 3 – Technical specifications – Control panel HT 400 RC

Base station

Power supply/DC 24V

Power intake 2.5 W

Length of the connecting cable 3 m

Connecting plug 25 pin, socket

Working temperature range +5 … +40 °C

Dimensions (l x B xH) approx. 185 x 105 x 45 mm

Weight (with connecting cable) approx. 1250 g

Table 4 – Technical specifications – Base station HT 400 RC

Control Panel - User Manual

9 - Versionsgeschichte

Page 30 of 30 Revision: D Doc.no.: UM-22031

9. Versionsgeschichte

Version Datum Visum Bemerkungen

A 07.01.02 JORE Building

B 22.04.03 HULO Extensions

C 17.07.03 HULO Extensions

D 18.06.08 HEAN English Version

10. Contact Pantec

With unsolvable Problems, please contact the Pantec Customer Care Service.

PANTEC Engineering AG

Support CMM

Industriering 21

9491 Ruggell

Liechtenstein

mailto: support.cmm@pantec.com

http://www.pantec.com

Phone: +423 377 13 33

Fax: +423 377 13 34

Loading...

Loading...