Page 1

Owner’s Manual

Trouper™and Stagehand

™

Platform Systems

T

ROUPER PLATFORM

SYSTEMS

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unpacking or Setting Up for the First Time . . . . . . . . . . . . . . . 5

Setting Up Individual Platform Units. . . . . . . . . . . . . . . . . . . . . 6

Same-Height Platform Systems

Connecting Same-Height Platforms . . . . . . . . . . . . . . . . . . . . 8

Installing Guard Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installing Drapery Enclosures. . . . . . . . . . . . . . . . . . . . . . . . 10

Installing the Stairway(s). . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installing a Backdrop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Riser Platform Systems

Typical Riser Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connecting Riser Sections . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installing Chair Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing Closure Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installing Guard Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Disassembling the Platform System. . . . . . . . . . . . . . . . . . . . 20

Loading the Storage Carts . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Unpacking or Setting Up for the First Time . . . . . . . . . . . . . . 35

Setting Up Individual Platform Units. . . . . . . . . . . . . . . . . . . . 36

Connecting Same-Height Platforms . . . . . . . . . . . . . . . . . . . . 37

Installing Guard Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Installing Drapery Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . 39

Installing the Stairway(s). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Installing a Backdrop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Disassembling the Platform System. . . . . . . . . . . . . . . . . . . . 42

Transporting and Storing Platform Units. . . . . . . . . . . . . . . . . 43

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

This publication includes complete Owner’s Manuals for both the Trouper and Stagehand Platform

Systems.

Please take a few minutes to read the appropriate sections and to familiarize yourself with Trouper

or Stagehand’s operating features. If you should need additional information, just write or call.

STAGEHAND

PLATFORM

SYSTEMS

©Wenger Corporation 2005 Printed in USA 09/05 Part #176A700-5

Wenger Corporation, 555 Park Drive, P.O. Box 448, Owatonna, Minnesota 55060-0448

Questions? Call.....USA: (800) 733-0393 • International (call collect): (507) 455-4100 • www.wengercorp.com

Page 2

2

Trouper Platform Systems

Page 3

3

SAFETY PRECAUTIONS

SETUP

Insist that anyone who assists with the set up of

the Trouper Platform System be familiar with

this manual.

GUARD RAILS

The guard rails are indicators of the perimeter of

the platform system, and are not intended as a

universal restraint. Excess weight or pressure

will cause them to collapse.

Never use the rails:

• As a crowd barrier

• As a perch

• As a tie-down.

PLATFORM STABILITY

All platform units must be locked together using

the unit-to-unit clamps beneath the stage

surface. These clamps are designed for use

only with one-level stage sets. Do not set up a

multilevel stage using Trouper units unless

adequate special clamping is provided to secure

the levels together. See “Connecting Riser

Sections” on page 14.

Trouper platforms are designed for level

surfaces only and contain no provision for

adjusting leg heights.

TRANSPORT/STORAGE CARTS

Never stack more than three platforms on a

3-Unit Cart, six platforms on an 6-Unit Cart,

eight platforms on an 8-Unit Cart, or twelve

platforms on a 12-Unit Cart.

Before moving or storing platforms on 6- or 8Unit Carts, always secure the units using the

unit lock assembly at the top of the cart. On a

12-Unit Cart, secure the units by slipping them

into the guides on the upright handle assembly.

See “Loading the Storage Carts” on page 21 for

more information.

Throughout this manual, you will find CAUTIONS and WARNINGS:

• WARNING means that if safety information is not followed someone could be seriously

injured or killed.

• CAUTION means that if safety information is not followed the platform could be damaged or

personal injury could result.

!

CAUTION

To avoid injury,

some setup steps

may require two

workers.

!

WARNING

Rails may collapse

if excess weight or

pressure applied.

!

WARNING

Platforms can fall

unless stacked and

secured properly

on the cart.

!

WARNING

Platforms are

unsafe if unit-tounit clamps are not

used as specified.

Page 4

WARRANTY

Wenger Trouper Platform Systems are guaranteed free of defects in

materials and workmanship for five full years.

Our guarantee assures you of either a full refund or repair or

replacement of the defective materials or workmanship without charge,

at the discretion of our Customer Service Department. Just call a

Customer Service Representative at 1-800-733-0393 and state the

reason you are dissatisfied. If a product return is necessary, your

Representative will issue a return authorization. This is your sole remedy

for breach of this warranty.

Should you have a question or problem with any Wenger product, don’t

hesitate to call, even if the product is past warranty. It’s important to us

that all our customers be satisfied.

This is the sole warranty made by Wenger. Wenger disclaims all other

warranties, including the warranties of merchantability and fitness for a

particular purpose, as well as all liability for incidental, consequential,

special, and indirect damage. Wenger liability for direct damages shall

be limited to the amount you paid for the product involved. Wenger

reserves the right to make product changes without obligation to

incorporate such changes into products previously sold.

Some states do not allow the exclusion or limitation of damages or

warranties, so the above may not apply to you. This warranty gives you

specific legal rights. You may also have other rights which vary from

state to state.

4

Page 5

5

INTRODUCTION

Trouper platform units are available in four sizes (4' x 8', 3' x 8', 4' x 6', and 3' x 6') and in four fixed

elevations (8", 16", 24", and 32"), as well as two dual-height options (16/24" and 24/32"). Platform

systems can be constructed with units that are all the same height (standard stage), or with units at

different heights (risers, or multi-level stage).

Do not set up a multilevel stage using Trouper units unless adequate special clamping is provided to

secure the levels together. See “Connecting Riser Sections” on page 14.

For efficient moving and storing of the platform units, several sizes of Wenger move-and-store carts are

available. See “Loading the Storage Carts” on page 21 for more information.

Easily attached 39" wide stairway units with double handrails are available in a 2-step version

(for 16" or 24" stage heights) and a 3-step version (for 24" or 32" stage heights).

Guard rail assemblies should be used with all stage elevations, and are available in 3', 4', 6' and 8'

lengths. The top rail on all guard rails is located 42" above the platform surface. The rail assemblies

include a chair stop rail.

To give the stage or risers a more formal, finished look, the following accessories are also

available from Wenger:

• drapery skirting

• drapery backdrops

• front and side closure panels.

UNPACKING OR SETTING UP FOR THE FIRST TIME

1. Remove all parts from their shipping cartons (refer to the packing list enclosed with the shipment).

Save the packaging materials at least until the stage system has been set up the first time.

2. Sort all platform units and accessories by size, leg length, etc.

3. Assemble all carts and stairways that are shipped disassembled - using the instructions supplied

with them.

4. If the stage or risers will be stored before being set up, see “Loading the Storage Carts” on page 21

and “Disassembling the Platform System” on page 20.

If the platform units will be set up immediately, see “Setting Up Individual Platform Units” on page 6.

IMPORTANT: Read this entire manual before starting to set up a platform system.

!

WARNING

Platforms are

unsafe if unit-tounit clamps are not

used as specified.

Page 6

SETTING UP INDIVIDUAL PLATFORM UNITS

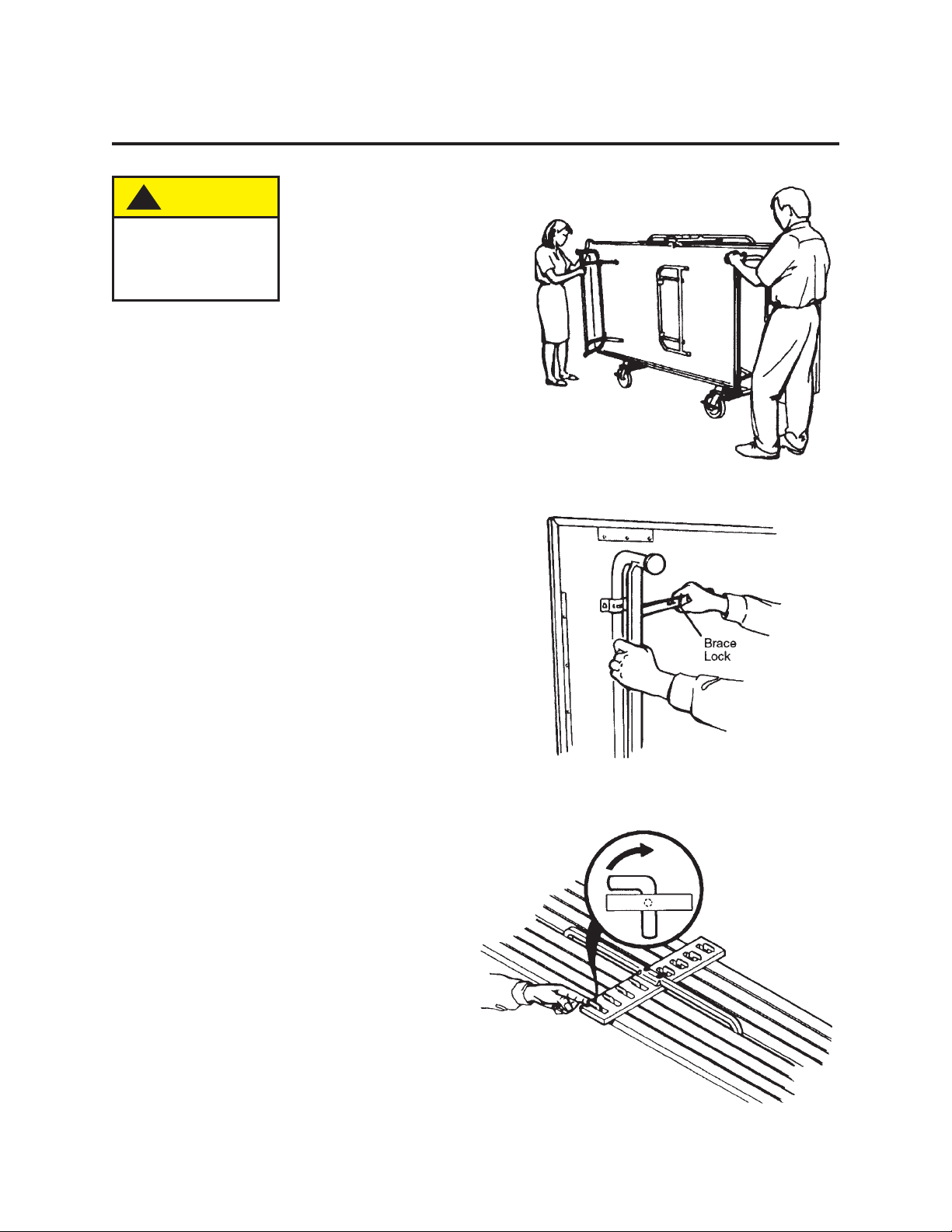

REMOVING THE PLATFORM UNITS

FROM THE

CART

1. Be sure the platform units are secured

to the cart before moving. Position the

cart near the set up area.

2. Open all legs on the outside platform

unit before removing from the cart.

3. Straighten the hinged brace on each

leg. If necessary, push in on the brace

lock until it engages.

4. With a 6 or 8-Unit Cart, release the first

platform unit by pushing the unit lock to

the right.

!

CAUTION

To avoid injury, two

people should set

up the platforms.

6

Page 7

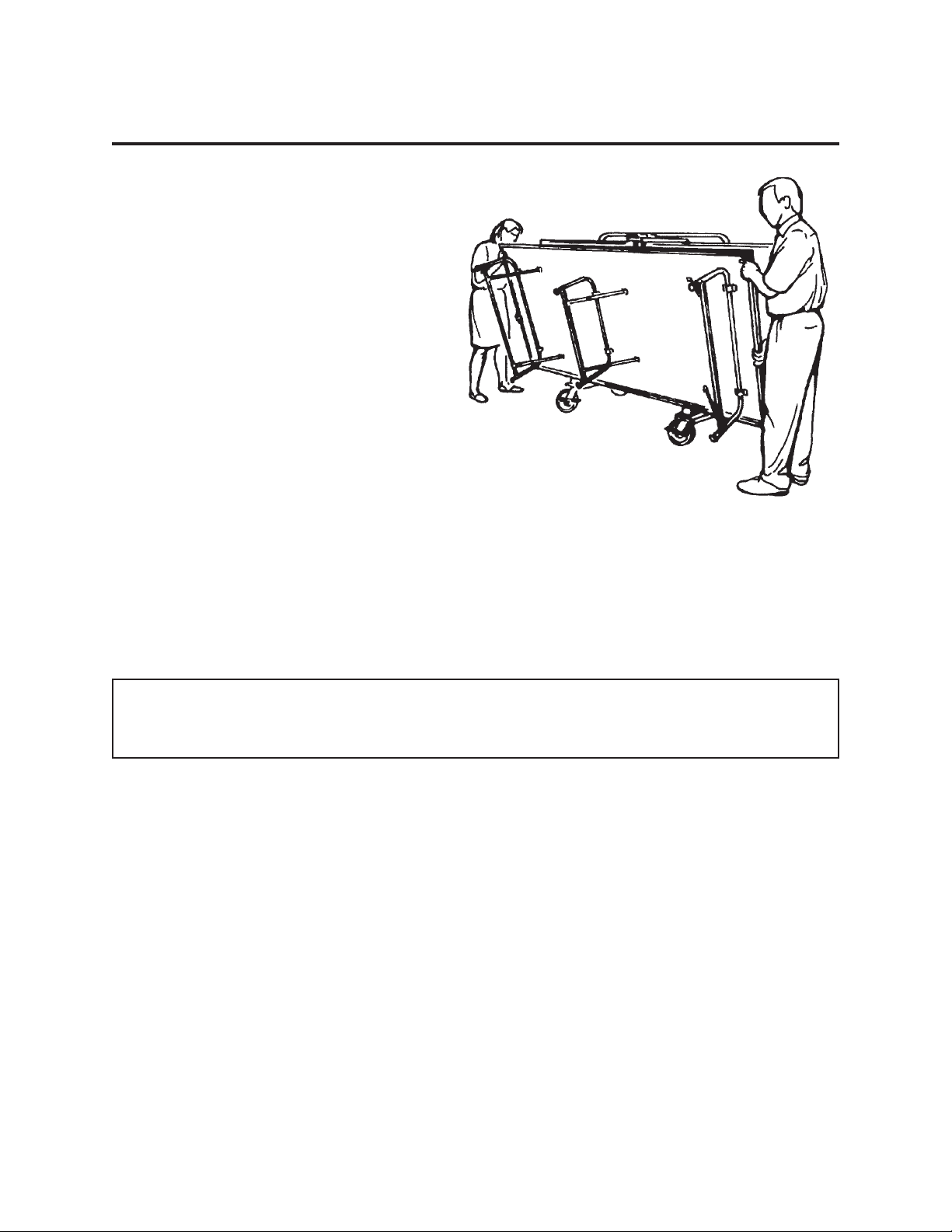

SETTING UP INDIVIDUAL PLATFORM UNITS (CONTINUED)

5. Rotate the platform unit off the cart and set it upright on its legs.

6. Repeat steps 2 - 5 for the remaining platform units.

If all of the platform units being set up are same-height platforms, go to page 8.

If setting up platform units as riser systems or as a multilevel stage, go to page 13.

7

Page 8

8

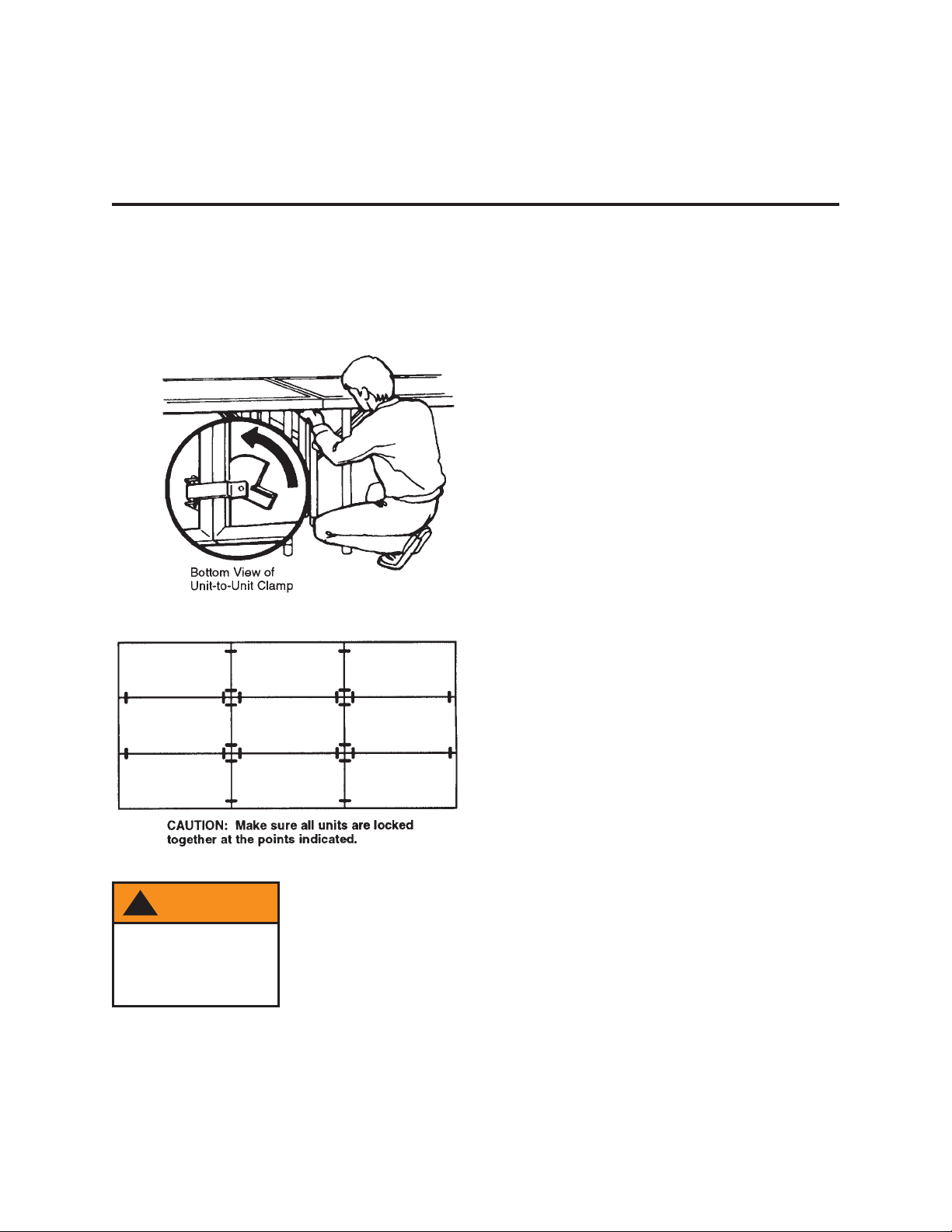

TROUPER SAME-HEIGHT PLATFORM SYSTEMS

CONNECTING SAME-HEIGHT PLATFORMS

1. Position the first two platform units at their desired stage location (at the rear center of the stage).

2. Attach them together in at least two places, using the unit-to-unit clamps beneath the platform

surface.

3. Attach the remaining platform units together in the same way.

!

WARNING

Platforms are

unsafe if unit-tounit clamps are not

used as specified.

Page 9

9

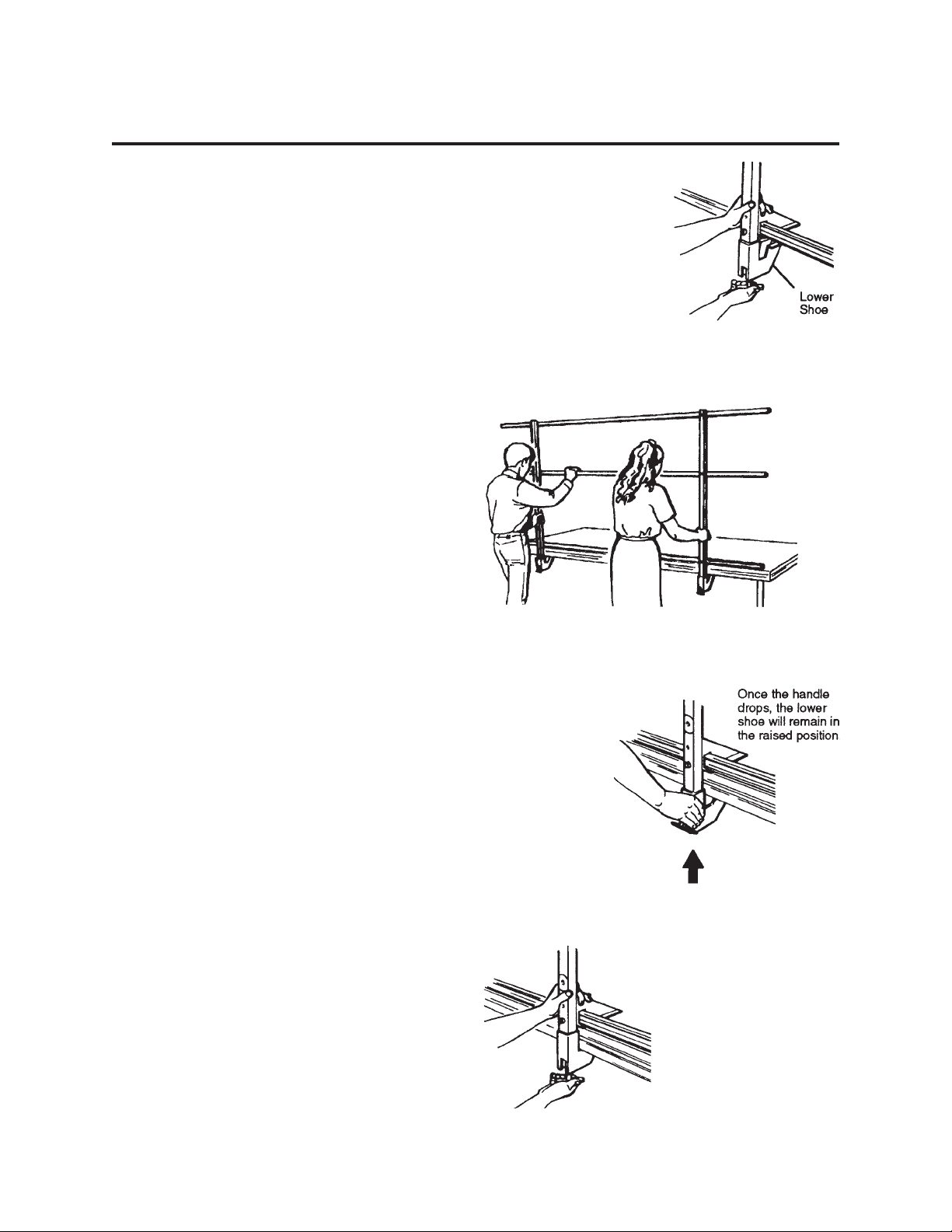

INSTALLING GUARD RAILS

To attach each guard rail assembly to the platform

system:

1. Unscrew the handle at the bottom of each

upright, just until pulling the handle outward

allows the lower shoe to drop. Don’t unscrew

all the way.

2. Set the guard rail on the platform, with the

lower shoe on each upright positioned below

the deck surface. Center the rail side-to-side

on the platform section.

3. Lift the lower shoe on each upright until the

handle drops.

4. Slide the Rail against the platform deckand

turn the handle until the lower shoe is tight

against the platform deck.

Page 10

10

INSTALLING DRAPERY ENCLOSURES

Draperies are often used to close off the lower portion of the stage, for better appearance. They can be

attached to the stage even where stairways or back/side rails are used.

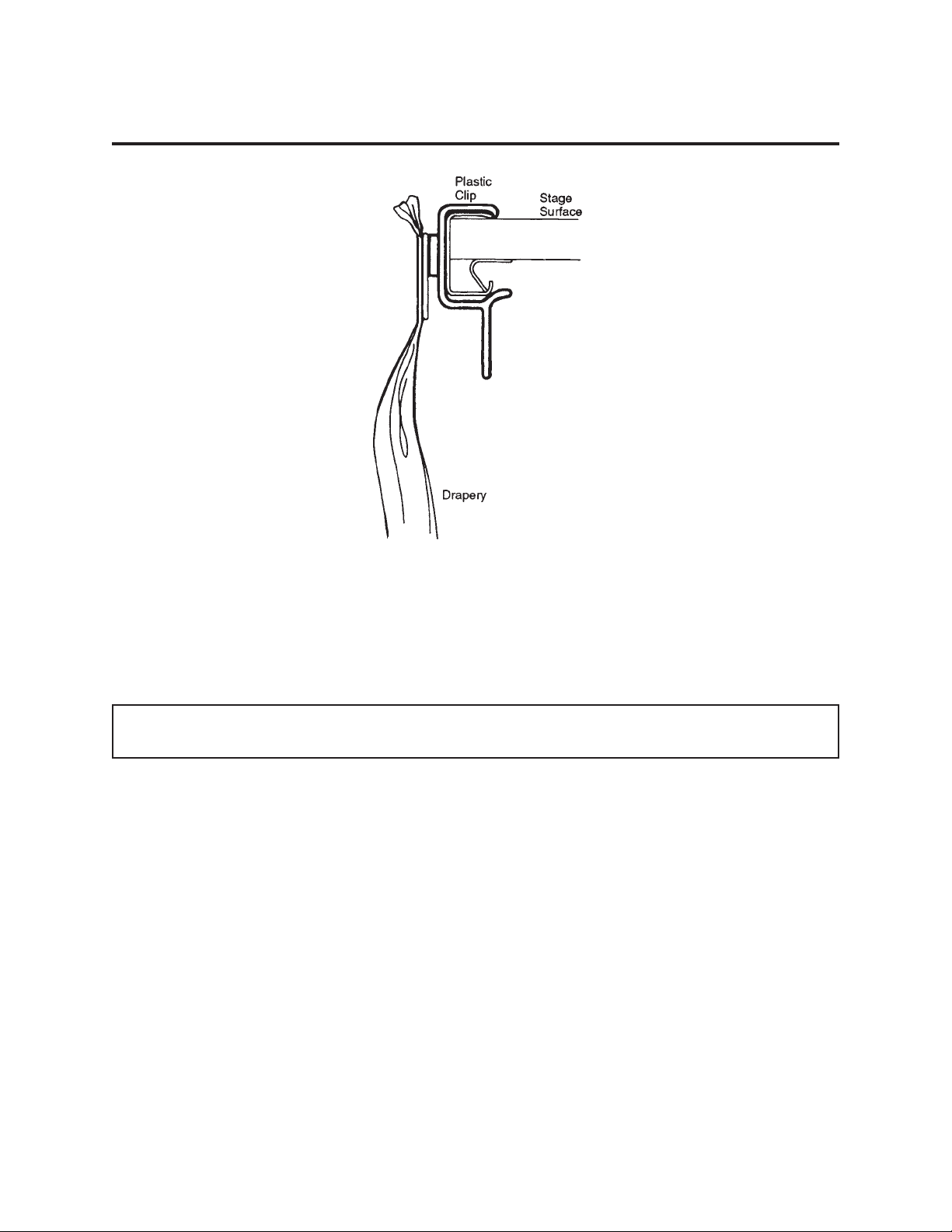

The draperies are secured to the stage using plastic clips fitted with a hook tab that connects to a loop

fastener on the drapery.

Drapery enclosures must be attached after guard rails are installed, and before stairways.

To attach the draperies:

1. Install clips along the stage perimeter wherever drapery is desired (about 12" apart).

2. Beginning at a corner of the stage, press the drapery onto the clips.

3. Continue attaching the drapery to the clips until the section is completely installed.

4. Repeat the above procedure with the remaining drapery sections.

Page 11

11

INSTALLING THE STAIRWAY(S)

The 2-step and 3-step stairways supplied with

Trouper Platform Systems can be adapted to

several staging models and heights.

The hook tube assemblies that slip into

guides on each side of the stairway frame

have a notched plate which can be

interchanged to match the framework on the

bottom of the staging. The illustration shows

the appropriate notched plate properly

mounted for use with Trouper Platform

Systems.

Each stairway model can be adjusted for two

platform heights:

• The 2-step stairway can be adjusted for

16" or 24" platform heights

• The 3-step stairway can be adjusted for

24" or 32" platform heights.

When the snap button on the hook tube

assembly is in the matching hole in the guide,

the stairway can be connected to the higher

platform. When the hook tube assembly is all

the way down in the guide, the stairway can

be connected to the lower platform.

The notched plates must be on the outside of

the tubes, extending away from the stairway

frame.

To attach the stairway:

1. Be sure that the stairway has the correct

hook tube assemblies (see above).

2. Adjust the hooks to the proper height for

the stage.

3. Tip the stairway into place.

4. Check that the notch in the hook tube is

secured to the stage framework, and that

the stairway feet are flat on the floor.

5. Tuck the top edge of drapery enclosures

under the lip of the stage at stairway

locations.

Page 12

12

INSTALLING A BACKDROP

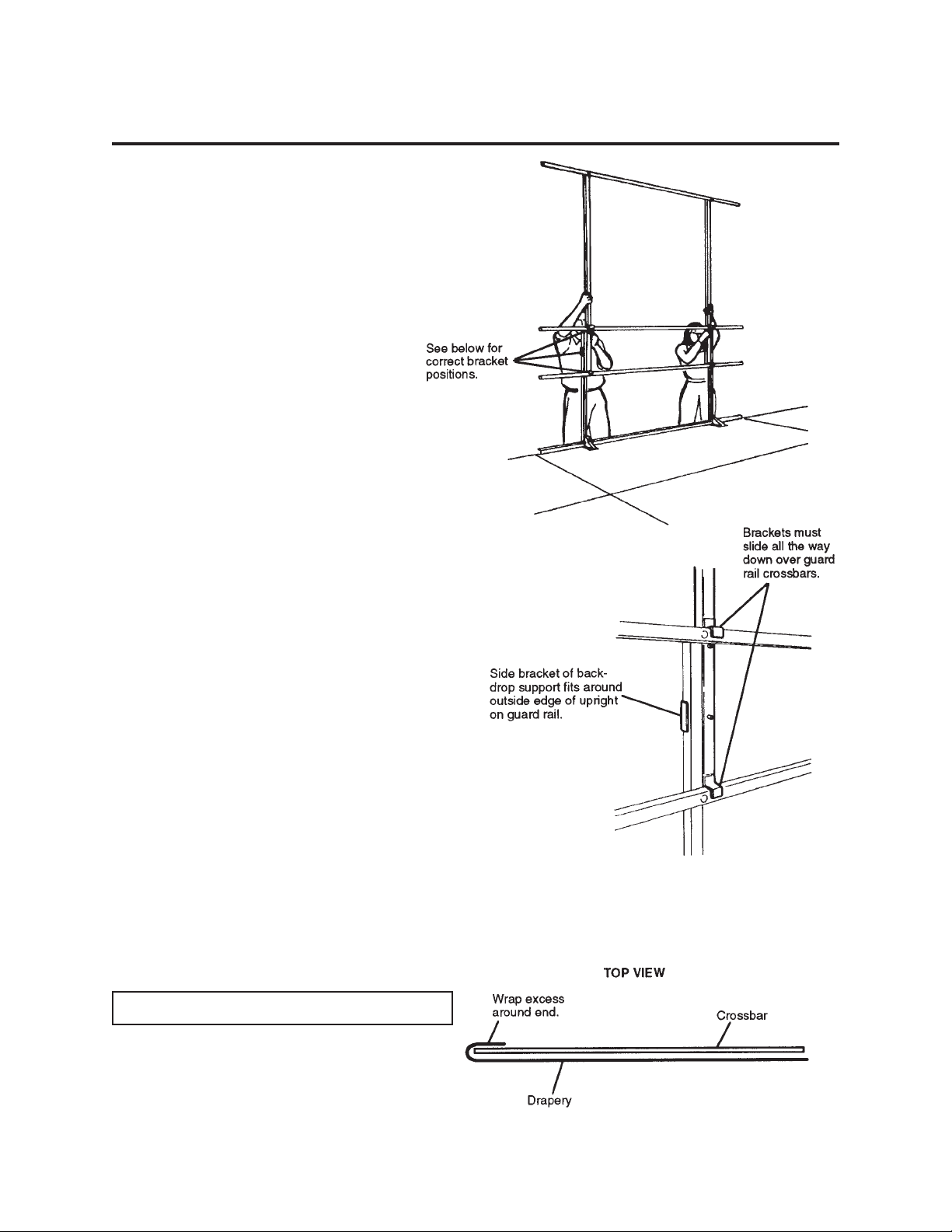

NOTE: Two people are required to install the

backdrop support.

1. Unfold each backdrop support and set it on

a guard rail as shown.

2. Hook-and-loop tape is attached to both

surfaces so that drapery sections can be

secured to the crossbar of the backdrop

support.

Use a ladder to attach the drapery. Wrap

any excess drapery around the end of the

crossbar.

For disassembly instructions, see page 20.

Page 13

13

TROUPER RISER PLATFORM SYSTEMS

TYPICAL RISER LAYOUTS

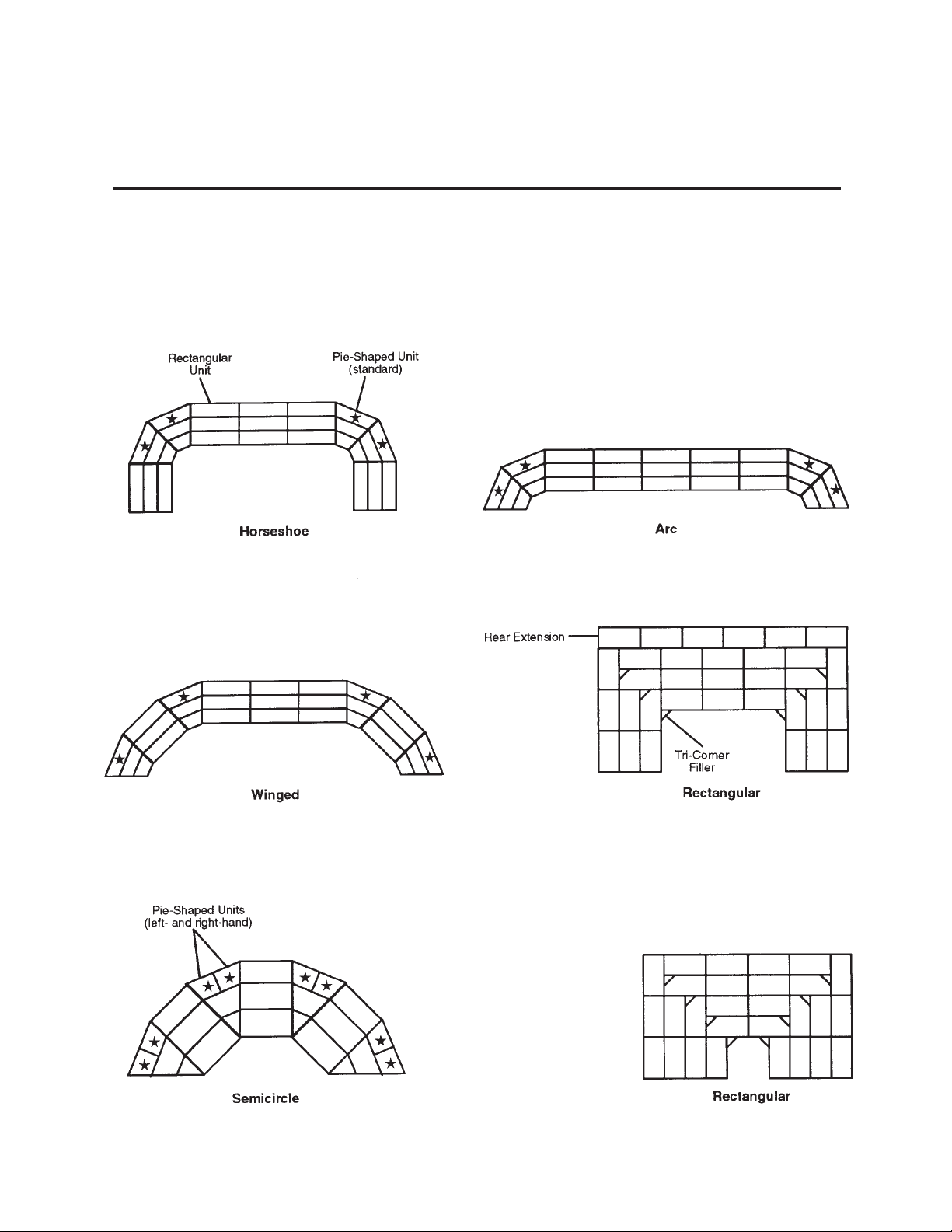

Use rectangular and pie-shaped units as shown.

At the third elevation of pie-shaped locations:

-Choral risers have a single unit

-Band risers have two units, one left-hand and one right-hand. If a fourth elevation has been

supplied, both choral and band risers will have two units, one left-hand and one right-hand.

Page 14

14

CONNECTING RISER SECTIONS

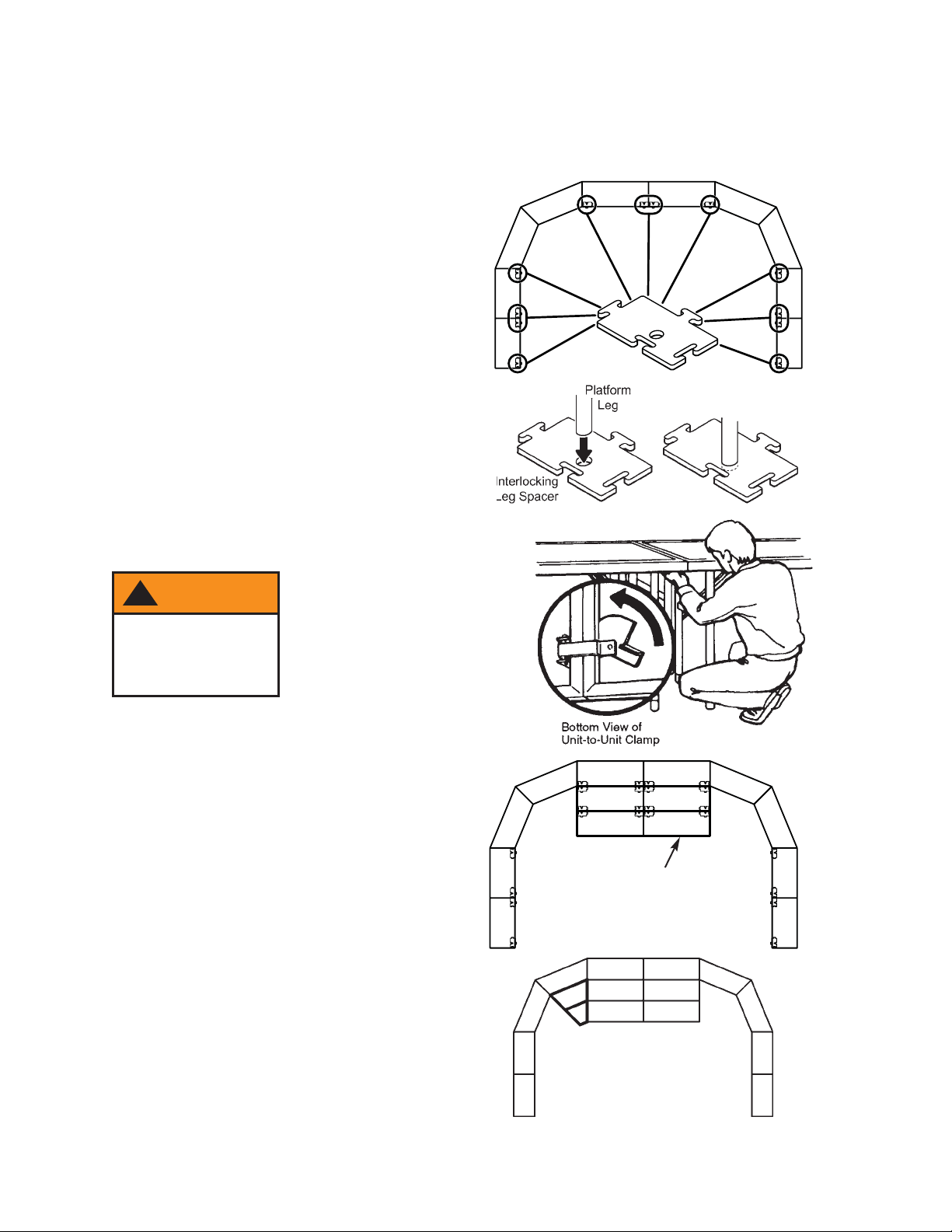

1. Set up the back row of platforms (including

any rear extensions), to verify that there is

enough space for the full riser set. Do not

lock these units together until the

remaining units are positioned.

2. Place interlocking leg spacers on the floor

under the inside legs of the rectangular

units as shown in the illustration. Platform

legs fit into the hole in the center of the

spacer.

Note: Interlocking leg spacers are used

only to connect rectangular platform units

together. Use metal spacer assemblies to

connect pie-shaped platform units together

as decribed on the following page.

3. Attach adjoining units together in at least

two places, using the unit-to-unit clamps

beneath the platform surface.

4. Position the remaining units for the center

section — first the middle elevation (16"),

then the front (8"). Repeat the pattern for

the interlocking leg spacers on the

rectangular units.

5. Assemble the next section (pie-shaped

units) to the left of the completed section,

again starting with the highest elevation

and working down to the lowest elevation.

!

WARNING

Platforms are

unsafe if unit-tounit clamps are not

used as specified.

Position the remaining

center units next

Page 15

15

CONNECTING RISER SECTIONS (CONTINUED)

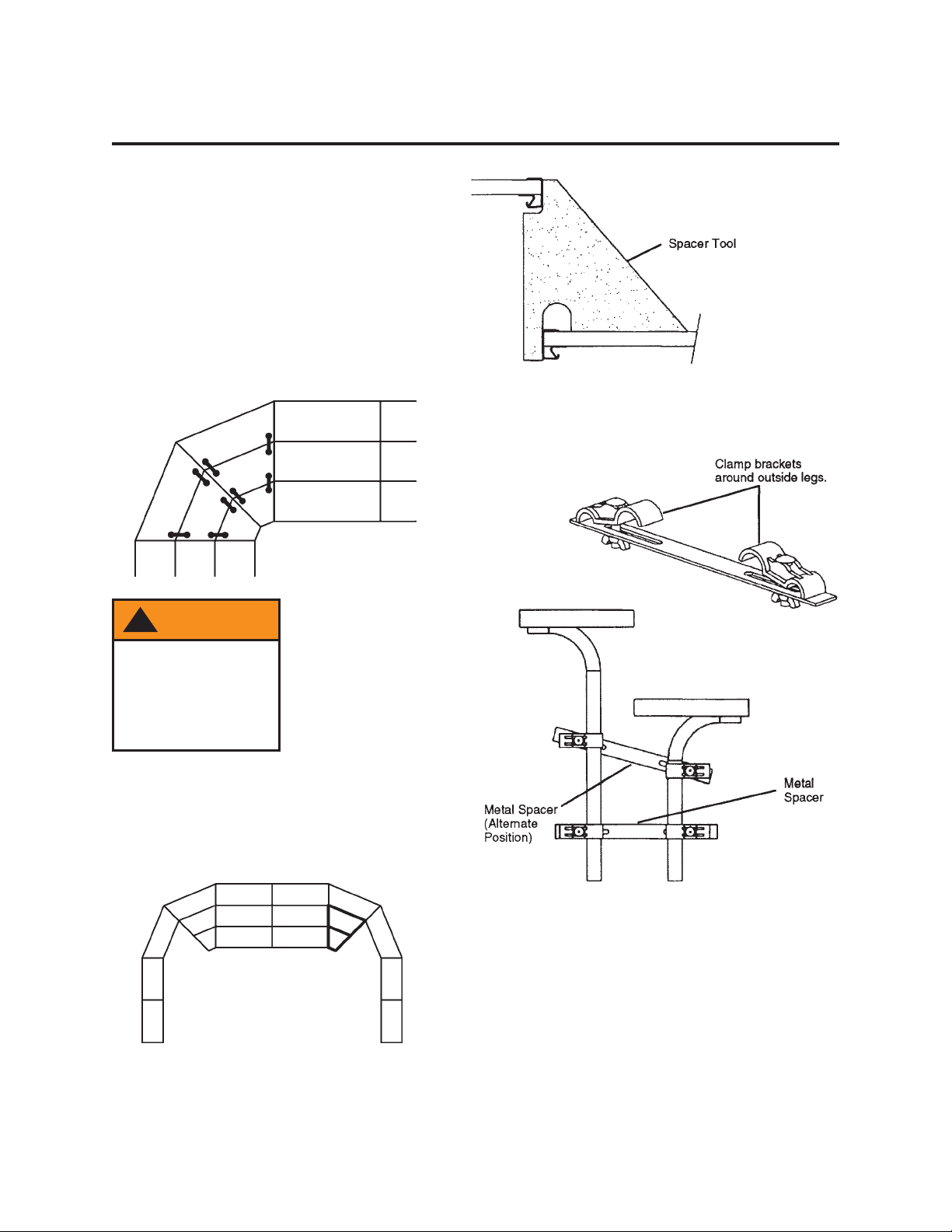

6. Use the riser spacer tool to align the

edges of the pie-shaped units vertically.

Make sure the corners of the decks are

aligned.

7. Connect all matching height units together

using the unit-to-unit clamps.

8. Connect different height pie-shaped units

together using metal spacer assemblies.

9. Assemble the next section ( pie-shaped

units) to the right of the completed

sections, again repeating steps 6 - 8 and

connecting same-height sections with the

unit-to-unit clamps.

9. Continue until all sections are installed.

!

WARNING

Always install all leg

spacers, and secure

each section with

unit-to-unit clamps,

before beginning a

new section.

Page 16

16

CONNECTING RISER SECTIONS (CONTINUED)

I

NSTALL TRI-CORNER FILLERS (IF USED)

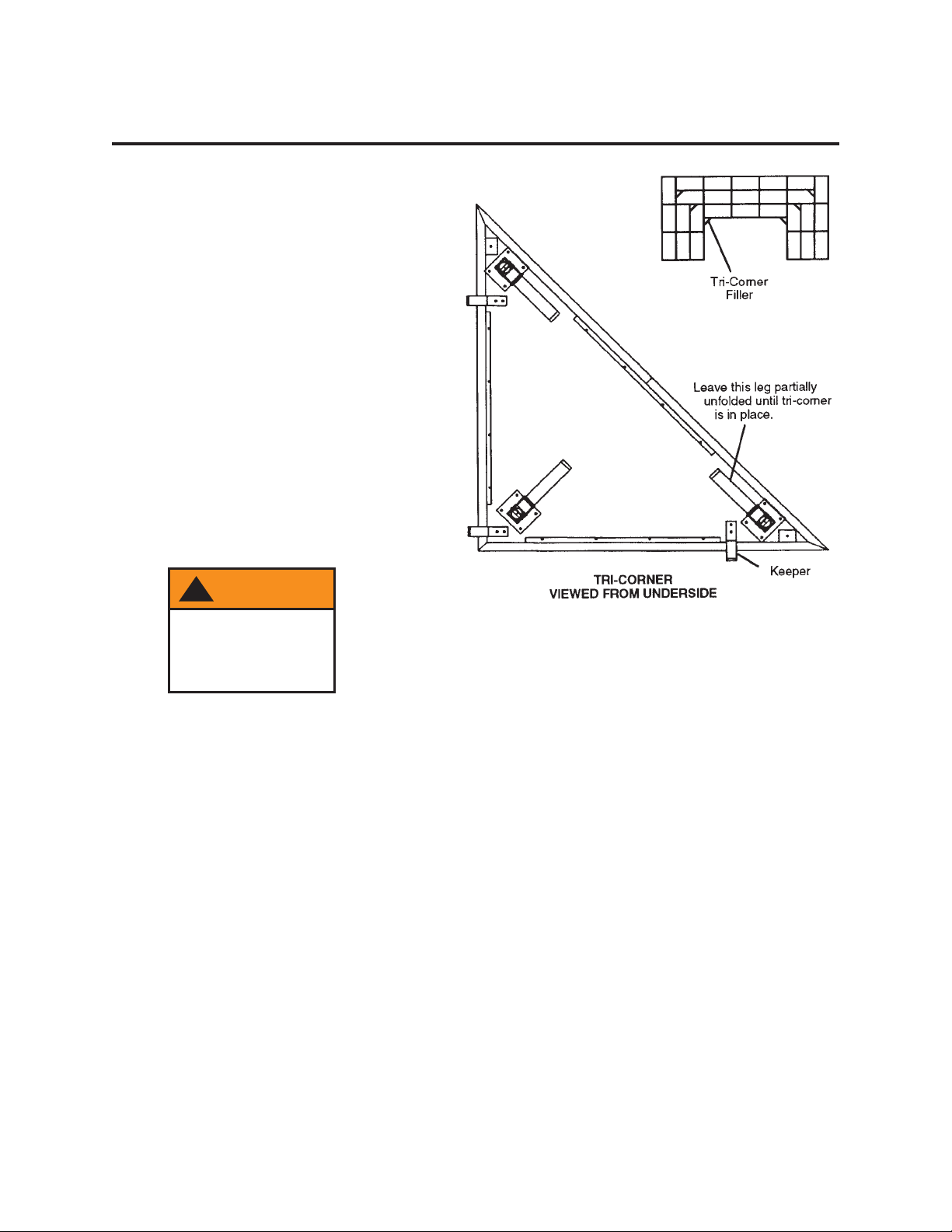

10. Tri-corner fillers are used to fill corner voids in

rectangular configurations. To install them:

a. Unfold the two legs on the side that has

two keepers, until they lock in place.

Partially unfold the third leg (don’t lock

it).

b. Set the tri-corner approximately in place,

and raise the corner with the unfolded leg

until the two keepers will slide under the

edging of the opposite riser. Push the tricorner tight against that riser.

Lower the corner until the single keeper

will slide under the edging of the adjacent

riser. Slide the tri-corner until it contacts

the riser.

Raise the corner. Lower and lock the third

leg.

Make sure that all legs are locked in their

open position.

!

WARNING

Tri-corner fillers

can easily tip if not

properly secured.

Page 17

17

INSTALLING CLOSURE PANELS

There are two styles of closure panels:

• Those that go between the different levels

of units (elevation closures). They have

positioning brackets along the top edge.

• Those that touch the floor (along the front

of the bottom row, and the side closure

panels). They have clips along the top

edge to snap the closure onto the unit.

To simplify installation, the closures are

labeled (on the back side) by a letter that

indicates their length and position. See the

illustration.

Note: On some rectangular riser sets, there

may also be various odd-length closure

panels that are not labeled.

It is suggested that you install any 8' and 6'

closures first. This will make it easier to

identify where the smaller closures mount.

INSTALLING CHAIR STOPS

The riser was shipped with enough chair stops

to span the back of all elevations on the risers,

plus the sides of end units that are 16" or

higher.

Chair stops cannot be installed where closure

panels or guard rails are used.

Any excess chair stop may be discarded.

To install chair stops:

1. Snap chair stop clips onto every unit,

where appropriate, at approximately 24"

intervals.

Note: Side closures must be installed after

the clips, but before the chair stops are

installed. See “Installing Closure Panels”

above.

2. Install the chair stops into the clips, with the

grooved side up.

Page 18

18

INSTALLING CLOSURE PANELS (CONTINUED)

FRONT FLOOR-LEVEL CLOSURES

1. Interlocking leg spacers must be installed

on the front row of platform legs to provide

a backstop for the front floor closure panels.

2. Snap the panels onto the riser unit. Inside

edge should be flush with interlocking leg

spacer for support.

ELEVATION CLOSURES

Install the panels from the middle of the riser

set, and then work your way toward the ends.

This will even out any gaps between the

elevation closures and the side closure panels.

1. Hook the lower clips onto the lower

elevation units at the same intervals as the

positioning brackets that came installed on

the closure panel.

2. Set the closure panel onto the clips, then

push the closure panel down and rotate it

until the positioning brackets catch the

upper elevation unit.

S

IDE CLOSURES

Snap the panels onto the sides of the riser set

(in the same way as the front floor-level

closures).

Note: Chair stop clips must be installed before

the side closures; chair stops must be installed

after the side closures. See “Installing Chair

Stops” on page 17.

Page 19

19

INSTALLING GUARD RAILS

To attach each guard rail assembly to the platform

system:

1. Unscrew the handle at the bottom of each

upright, just until pulling the handle outward

allows the lower shoe to drop. Don’t unscrew

all the way.

2. Set the guard rail on the platform, with the

lower shoe on each upright positioned below

the deck surface. Center the rail side-to-side

on the platform section.

3. Lift the lower shoe on each upright until the

handle drops.

4. Slide the Rail against the platform deckand

turn the handle until the lower shoe is tight

against the platform deck.

Page 20

20

DISASSEMBLING THE PLATFORM SYSTEM

1. To remove the drapery from a backdrop:

a. “Peel” the drapery away from the crossbar.

b. Fold the drapery carefully to minimize

wrinkling in storage.

An optional carrying case can be purchased

from Wenger to store the drapery.

c. Press the release button on each upright,

and lift the backdrop support from the guard rail.

2. Remove any stairways by lifting the outer end

(lowest step) until the hook tube assembly is

free of the stage.

3. Remove any drapery enclosures by reversing

the installation procedure. See “Installing

Drapery Enclusures” on page 10.

Don’t remove the clips from the drapery

unless they have to be relocated. Keeping

the clips on the drapery prevents lossing

them and eliminates the need to store separately.

If the clips remain attached to the platform

frame they will interfere with storage of the

platform units.

Carefully fold the drapery to minimize wrinkling. Special drapery hangers are available from Wenger.

4. Remove any guard rails by unscrewing the handles. Store the guard rails on the (optional) guard rail

storage cart.

5. Remove all closure panels.

6. Remove all chair stops.

IMPORTANT: Two people are recommended for the following step.

7. Release the unit-to-unit clamps on the underside of adjacent same-height platforms.

See “Connecting Same-Height Platforms” on page 8.

8. Pull the first platform section away from the stage or riser and place near the storage cart.

Tilt the section onto the cart.

9. Return the legs to their shorter position (if extended on dual-height models).

10. To fold the legs:

a. On each leg brace, slide the brace lock away from the deck,

and use the heel of your other hand to unlock the brace.

b. Fold the legs against the deck.

11. Be sure the platform units are positioned securely on

the cart:

a. On 12-Unit Carts, slide the end of the platform units

all the way into the guides on the handle end.

b. On 6- or 8-Unit Carts, secure each platform unit

with the unit lock.

c. On 3-Unit Carts, the platform units rest against the

diagonal brace.

10. Repeat steps 8 through 11 for the remaining sections.

Page 21

21

LOADING THE STORAGE CARTS

Wenger storage carts are available to store and transport 3, 6, 8, or 12 platform units. All cart models

store the platform units vertically, so that they can be tipped off the cart directly into their setup position.

See “Setting Up Individual Platform Units” on page 6).

• On the 3-Unit Cart, platform units rest against the diagonal brace.

• On the 6 and 8-Unit Carts, platform units are secured by the latches of the unit lock assembly at the

top of the cart.

Note that the height of the top cross tube on 6- and 8-Unit Carts can be adjusted to fit platform units

that are either 3' or 4' wide.

• On the 12-Unit Cart, platform units are secured by slipping them into the guides on the upright

handle assembly.

!

WARNING

Always use unit

locks when moving

or storing.

Page 22

22

MAINTENANCE

STAGE

SURFACE

Trouper platform units are available with the following surfaces:

• hardboard

• skid-resistant

• carpeted.

Clean and protect hardboard surfaces as you would any normal flooring. Clean skid-resistant surfaces by

sweeping with a broom. Spot-clean carpeting, keeping it as dry as possible — never saturate the carpet.

DRAPERY ENCLOSURES AND BACKDROPS

Drapery sections may be washed or dry-cleaned. Remove all drapery clips prior to cleaning.

Machine-wash at 120° F or lower using mild detergent. Remove immediately after the wash cycle is

completed.

Tumble-dry at “permanent-press” or lower temperature. Remove and hang immediately to prevent

wrinkling. Excessive heat or drying time will detract from the permanent-press characteristics of the

fabric.

Little or no ironing is required.

When dry-cleaning, tumble-dry on the lowest heat cycle and remove immediately when dry.

OTHER PREVENTIVE MAINTENANCE

Inspect all bolts on the stage and accessories every six months, and tighten as necessary.

Replace any worn, bent, or broken parts promptly to prevent injury.

REPLACEMENT PARTS LIST

Replacement parts for your Trouper Platform System can be ordered from Wenger Corporation by:

Phone: USA, (800) 733-0393

International, (507) 455-4100 collect

Fax: (507) 455-4258

Mail: The Wenger Corporation

P.O. Box 448

555 Park Drive

Owatonna, Minnesota, USA 55060-0448

When ordering replacement parts, always indicate the product name and model.

Items not shown on the following pages:

When ordering additional backdrop or enclosure draperies, indicate height, width, and color.

Replacement parts are not available for the basic platform units: order complete new units.

Page 23

23

REPLACEMENT PARTS LIST (CONTINUED)

P

LATFORM DECK

Item Qty Description

2 2 Leg assembly, outside

3 1 Leg assembly, inside

9 6 Bracket, leg pivot

10 6 Plug, leg tip, fixed-height

10 6 Plug, leg tip, dual-height

11 3 Screw, Phillips pan-head, 8 - 18 x 1/2"

12 4 Lock assembly, unit-to-unit

16 6 Lock, brace

17 6 Spring, compression

Page 24

24

REPLACEMENT PARTS LIST (CONTINUED)

2 AND 3-STEP STAIRWAYS

3-STEP MODEL

SHOWN

Item Qty

2-Step

Qty

3-Step

Description

1 2 3 Step assembly

2 2 2 Frame assembly, hand-rail

3 2 2 Tube, hook (with notched plate)

4 1 1 Brace, cross

5 2 2 Wheel assembly

6 12 16 Nut, hex, 5/16 - 18

7 12 16 Bolt, carriage, 5/16 - 18 x 1-1/2"

8 4 4 Screw, self-tapping, 1/4" x 3/4"

9 12 16 Washer, lock, 5/16”

Page 25

25

REPLACEMENT PARTS LIST (CONTINUED)

3-UNIT STORAGE CART

Item Qty Description Item Qty Description

1 1 Channel, caster, right-hand (with decal) 10 1 Tube, back frame

2 1 Channel, caster, left-hand 11 2 Bracket, pivot

3 2 Caster, swivel 12 6 Bolt, carriage, 5/16 - 18 x 2"

4 2 Caster, rigid 13 2 Strap, brace

5 12 Bolt, carriage, 5/16 - 18 x 5/8" 14 2 Angle, brace

6 30 Nut, lock, 5/16 - 18 15 4 Capscrew, 5/16 - 18 x 1"

7 2 Post assembly, upright 16 12 Washer, flat, 5/16"

8 1 Tube, cross 17 4 Capscrew, 5/16 - 18 x 1-3/4"

9 4 Capscrew, 5/16 - 18 x 2 - 1/4"

Page 26

26

REPLACEMENT PARTS LIST (CONTINUED)

6 AND

8-UNIT STORAGE CART

Item Qty Description Item Qty Description

1 2 Caster, swivel 8 1 Lock assembly, unit

2 2 Channel, caster 9 1 Tube, cross

3 16 Bolt, carriage, 5/16 -18 x 3/4" 10 2 Upright assembly

4 28 Nut, lock, 5/16 - 18 11 2 Caster, rigid

5 8 Bolt, carriage, 5/16 - 18 x 2-1/4" 12 2 Brace, center

6 4 Capscrew, 5/16 - 18 x 2" 13 16 Washer, lock, 5/16"

7 2 Washer, flat, 5/16"

Page 27

27

REPLACEMENT PARTS LIST (CONTINUED)

12-UNIT STORAGE CART

Item Qty Description

1 4 Capscrew, 3/8-16 x 2-1/4"

2 10 Nut, lock, 3/8 - 16

3 1 Bracket assembly, end

4 1 Frame assembly, base

5 2 Caster, swivel

6 2 Caster, rigid

7 6 Capscrew, 3/8 - 16 x 1"

Page 28

28

GUARD RAILS

Item Qty Description Item Qty Description

1 2 Upright Weldment4 9 4 Bolt, carriage, 5/16 - 18 x 3-1/4"

2 2 Lower Bracket Weldment 10 6 Nut, lock, 5/16 - 18

3 2 Bolt, tab, 3/8-16 11 1 Rail, chair [*]

4 2 Handle, tee 12 2 Rail, guard [*]

5 2 Plug, 1-1/2" square 13 1 Railing, In-Fill Panel

8 2 Capscrew, 5/16 - 18 x 3-1/2"

[*] Indicates rail length on order.

REPLACEMENT PARTS LIST (CONTINUED)

Page 29

29

G

UARD RAIL S

TORAGE TRUCK

Item Qty Description Item Qty Description

1 2 Channel, caster 8 12 Bolt, carriage, round-head, 5/16 - 18 x 2"

2 2 Brace, center (specify 6- or 8-unit) 9 2 Capscrew, 5/16 - 18 x 2"

3 2 Upright weldment 10 1 Rack assembly

4 2 Caster, swivel, 6" 11 4 Bracket, stabilizer

5 2 Caster, rigid, 6" 12 16 Bolt, carriage, 5/16 - 18 x 1"

6 6 Plug, 1-1/4" square 15 16 Washer, flat, 1/4"

7 30 Nut, lock, 5/16 - 18 16 2 Tube weldment, upright support

REPLACEMENT PARTS LIST (CONTINUED)

Page 30

30

D

RAPERY BACKDROP

SUPPORT

Item Qty Description

1 2 Upright Weldment

2 1 Tube, support

3 2 Bracket

4 4 Plug, 1-1/2" square

5 2 Plug, 1-1/4" square

6 2 Capscrew, 5/16 - 18 x 2"

7 2 Capscrew, 5/16 - 18 x 3-1/2"

8 4 Nut, lock, 5/16 - 18

9 2 Washer, flat, nylon, 5/16" I.D.

10 - Hook-and-loop strip, 101" long

REPLACEMENT PARTS LIST (CONTINUED)

Page 31

31

Page 32

32

Stagehand Platform Systems

Page 33

33

SAFETY PRECAUTIONS

SETUP

Insist that anyone who assists with the set up

the Stagehand Platform System be familiar with

this manual.

GUARD

RAILS

The guard rails are indicators of the perimeter of

the platform system, and are not intended as a

universal restraint. Excess weight or pressure

will cause them to collapse.

Never use the rails:

• As a crowd barrier

• As a perch

• As a tie-down.

PLATFORM STABILITY

All platform units must be locked together using

the unit-to-unit clamps beneath the stage

surface. These clamps are designed for onelevel stage sets. Do not set up a multilevel

stage using Stagehand units.

Stagehand platforms are designed for level

surfaces only and contain no provision for

leveling adjustments.

GAS SPRINGS

If you suspect that the gas springs on the cart

are not operating properly, contact the Customer

Service department at Wenger Corporation

immediately. NEVER use a platform that has

faulty springs!

!

CAUTION

To avoid injury,

some setup steps

may require two

workers.

!

WARNING

Cart is unsafe if gas

springs are not

operating properly.

Throughout this manual, you will find CAUTIONS and WARNINGS:

• WARNING means that if safety information is not followed someone could be seriously

injured or killed.

• CAUTION means that if safety information is not followed the platform could be damaged or

personal injury could result.

!

WARNING

Rails may collapse

if excess weight or

pressure applied.

!

WARNING

Platforms are

unsafe if unit-tounit clamps are not

used as specified.

Page 34

34

WARRANTY

Wenger Trouper Platform Systems are guaranteed free of defects in

materials and workmanship for five full years.

Our guarantee assures you of either a full refund or repair or

replacement of the defective materials or workmanship without charge,

at the discretion of our Customer Service Department. Just call a

Customer Service Representative at 1-800-733-0393 and state the

reason you are dissatisfied. If a product return is necessary, your

Representative will issue a return authorization. This is your sole remedy

for breach of this warranty.

Should you have a question or problem with any Wenger product, don’t

hesitate to call, even if the product is past warranty. It’s important to us

that all our customers be satisfied.

This is the sole warranty made by Wenger. Wenger disclaims all other

warranties, including the warranties of merchantability and fitness for a

particular purpose, as well as all liability for incidental, consequential,

special, and indirect damage. Wenger liability for direct damages shall

be limited to the amount you paid for the product involved. Wenger

reserves the right to make product changes without obligation to

incorporate such changes into products previously sold.

Some states do not allow the exclusion or limitation of damages or

warranties, so the above may not apply to you. This warranty gives you

specific legal rights. You may also have other rights which vary from

state to state.

Page 35

35

INTRODUCTION

Stagehand platform units are available in two fixed elevations (16" and 24"), as well as two dual-height

options (16/24" and 24/32").

Easily-attached 39" wide stairway units with double handrails are available in a 2-step version (for 16" or

24" stage heights) and a 3-step version (for 24" or 32" stage heights).

Guard rail assemblies should be used with all stage elevations, and are available in 3', 4', 6' and 8'

lengths. The to rail on all guard rails is located 42" above the platform surface. The rail assemblies

include a chair stop rail.

To give the stage a more formal, finished look, drapery skirting and drapery backdrops are also available

from Wenger.

UNPACKING OR SETTING UP FOR THE FIRST TIME

1. Remove all parts from their shipping cartons (refer to the packing list enclosed with the shipment).

Save the packaging materials at least until the stage system has been set up the first time.

2. Sort all platform units and accessories by size, leg length, etc.

3. Assemble all carts and stairways that are shipped disassembled - using the instructions supplied

with them.

4. If the platform units will be stored before being set up, see “Transporting and Storing Platform Units”

on page 43 and “Disassembling the Platform System” on page 42.

If the platform units will be set up immediately, see “Setting Up Individual Platform Units” on page 36.

IMPORTANT: Read this entire manual before you start to set up a platform system.

!

WARNING

Do not set up a

multilevel stage

using Stagehand

units.

Page 36

36

SETTING UP INDIVIDUAL PLATFORM UNITS

1. Bring the platform units to the set up area.

2. Open all legs on the platform units.

3. Straighten the hinged brace on each leg.

Pull the brace until the lock engages.

4. Dual-Height Models.

Adjust the legs to the desired height:

a. Pull the lower leg body out until the

locking tabs are visible (A).

b. Rotate the lower leg a quarter-turn (B).

c. Engage the locking tabs and lock them

into the upper leg body (C).

5. Depress the foot pedal with your left foot,

and gently push the unit down to the floor.

To keep the platform from rolling, maintain

firm pressure on the pedal.

Note: Units can be moved into their final

position by releasing the pedal just before

the legs rest on the floor. Once the unit is in

the desired location, depress the pedal

again and gently push the unit down until it

sets firmly in place. Lock the caster brakes.

Note: Stagehand platforms have locking

gas springs that are actuated only when the

pedal is fully depressed. If the pedal is

releasedl while raising or lowering the deck,

the gas springs lock and the deck won’t

move further up or down.

6. Repeat steps 2 - 5 for the remaining

platform units.

Page 37

37

CONNECTING SAME-HEIGHT PLATFORMS

1. Position the first two platform units in their desired stage location (in the rear center of the stage).

Attach them together in at least two places, using the unit-to-unit clamps beneath the platform deck.

2. Attach the remaining units together in the same way.

!

WARNING

Platforms are

unsafe if unit-tounit clamps are not

used as specified.

Page 38

INSTALLING GUARD RAILS

To attach each guard rail assembly to the platform

system:

1. Unscrew the handle at the bottom of each

upright, just until pulling the handle outward

allows the lower shoe to drop. Don’t unscrew

all the way.

2. Set the guard rail on the platform, with the

lower shoe on each upright positioned below

the deck surface. Center the rail side-to-side

on the platform section.

3. Lift the lower shoe on each upright until the

handle drops.

4. Slide the Rail against the platform deckand

turn the handle until the lower shoe is tight

against the platform deck.

38

Page 39

INSTALLING DRAPERY ENCLOSURES

39

Draperies are often used to close off the lower portion of the stage, for better appearance. They can be

attached to the stage even where stairways or back/side rails are used.

The draperies are secured to the stage using plastic clips fitted with a hook tab that connects to a loop

fastener on the drapery.

Drapery enclosures must be attached after guard rails are installed, and before stairways.

To attach the draperies:

1. Install clips along the stage perimeter wherever drapery is desired (about 12" apart).

2. Beginning at a corner of the stage, press the drapery onto the clips.

3. Continue attaching the drapery to the clips until the section is completely installed.

4. Repeat the above procedure with the remaining drapery sections.

Page 40

INSTALLING THE STAIRWAY(S)

The 2-step and 3-step stairways supplied with

Stagehand Platform Systems can be adapted

to several platform system models and

heights.

The hook tube assemblies that slip into guides

on each side of the stairway frame have a

notched plate which can be reversed to match

the framework on the bottom of the platform

deck. Select the hook tube assemblies that

have the notched plate in the illustration, and

install them as shown.

Each stairway model can be adjusted for two

platform heights:

• The 2-step stairway can be adjusted for

16" or 24" platform heights

• The 3-step stairway can be adjusted for

24" or 32" platform heights.

When the snap button on the hook tube

assembly is in the matching hole in the guide,

the stairway can be connected to the higher

platform. When the hook tube assembly is all

the way down in the guide, the stairway can

be connected to the lower platform.

The notched plates must be on the outside of

the tubes, extending forward from the stairway

frame.

To attach the stairway:

1. Be sure that the stairway has the correct

hook tube assemblies (see above).

2. Adjust the hook tube assemblies to the

proper height for the stage (see above).

3. Tip the stairway into place.

4. Check that the notch in the hook tube is

secured to the stage framework, and that

the stairway feet are flat on the floor.

5. Tuck the top edge of drapery enclosures

under the lip of the stage at stairway

locations.

40

Page 41

41

INSTALLING A BACKDROP

NOTE: Two people are required to install the

backdrop support.

1. Unfold each backdrop support and set it on a

guard rail as shown.

2. Hook-and-loop tape is attached to both surfaces

so that drapery sections can be secured to the

crossbar of the backdrop support.

Use a ladder to attach the drapery. Wrap any

excess drapery around the end of the crossbar.

Page 42

42

DISASSEMBLING THE PLATFORM SYSTEM

1. To remove the drapery from a backdrop:

a. “Peel” the drapery away from the crossbar.

b. Fold the drapery carefully to minimize

wrinkling in storage.

An optional carrying case can be purchased

from Wenger to store the drapery.

c. Press the release button on each upright,

and lift the backdrop support from the guard

rail.

2. Remove any stairways by lifting the outer end

(lowest step) until the hook tube assembly is

free of the stage.

3. Remove any drapery enclosures by reversing

the installation procedure. See “Installing

Drapery Enclusures” on page 39.

Don’t remove the clips from the drapery

unless they have to be relocated. Keeping

the clips on the drapery prevents lossing

them and eliminates the need to store

separately.

If the clips remain attached to the platform

frame they will interfere with storage of the

platform units.

Carefully fold the drapery to minimize wrinkling.

Special drapery hangers are available from

Wenger.

4. Remove any guard rails by unscrewing the

handles.

Store the guard rails on the (optional) guard rail

storage cart.

5. Release the unit-to-unit clamps on the

underside of adjacent same-height platforms.

See “Setting up Individual Platform Units” on

page 36.

6. Depress the foot pedal with your left foot, and

lift the deck to its vertical position. Be sure it is

resting in both saddles, then release the pedal.

Unlock the caster brakes.

Do not pull up on the deck too quickly, or the

unit could overturn.

!

CAUTION

Unit can overturn if

pedal is released

before deck rests in

saddles.

!

CAUTION

Unit can overturn if

deck is lifted too

quickly.

Page 43

43

DISASSEMBLING THE PLATFORM SYSTEM (CONTINUED)

7. Return the legs to their shorter position (if extended

on dual-height models).

8. To fold the legs:

a. One each leg brace, slide the brace lock away

from the deck, then use the heel of your other

hand to unlock the brace.

b. Fold the legs against the deck.

9. Repeat steps 5 to 8 for the remaining sections.

TRANSPORTING AND STORING PLATFORM UNITS

TRANSPORTING

To transport platform units to the storage area, roll them by pushing from the end.

If necessary, units can also be safely lifted and carried when in the transport position. For safe handling,

two people are required. Grasp the ends of the deck — not the cart.

STORING

The platform units will nest together for compact storage.

Page 44

44

MAINTENANCE

STAGE

SURFACE

Stagehand platform units are available with the following surfaces:

• hardboard

• skid-resistant

• carpeted.

Clean and protect hardboard surfaces as you would any normal flooring. Clean skid-resistant surface by

sweeping with a broom. Spot-clean carpeting, keeping it as dry as possible — never saturate the carpet.

DRAPERY

ENCLOSURES AND BACKDROPS

Drapery sections may be washed or dry-cleaned. Remove all drapery clips prior to cleaning.

Machine-wash at 120° F or lower using mild detergent. Remove immediately after the wash cycle is

completed.

Tumble-dry at “permanent-press” or lower temperature. Remove and hang immediately to prevent

wrinkling. Excessive heat or drying time will detract from the permanent-press characteristics of the

fabric.

Little or no ironing is required.

When dry-cleaning, tumble-dry on the lowest heat cycle and remove immediately when dry.

GAS SPRINGS

If you suspect that the gas springs on the cart are not operating properly, contact the Customer Service

department at Wenger Corporation immediately. NEVER use the platforms that have faulty springs!

O

THER PREVENTIVE

MAINTENANCE

Inspect all bolts on the stage and accessories every six months, and tighten as necessary.

Replace any worn, bent, or broken parts promptly to prevent injury.

REPLACEMENT PARTS LIST

Replacement parts for your Trouper Platform System can be ordered from Wenger Corporation by:

Phone: USA, (800) 733-0393

International, (507) 455-4100 collect

Fax: (507) 455-4258

Mail: The Wenger Corporation

P.O. Box 448

555 Park Drive

Owatonna, Minnesota, USA 55060-0448

When ordering replacement parts, always indicate the product name and model.

Items not shown on the following pages:

When ordering additional backdrop or enclosure draperies, indicate height, width, and color.

Replacement parts are not available for the basic platform units: order complete new units.

Page 45

45

REPLACEMENT PARTS LIST (CONTINUED)

PLATFORM

DECK

Item Qty Description

2 2 Leg assembly, outside

3 1 Leg assembly, inside

9 6 Bracket, leg pivot

10 6 Plug, leg tip, fixed-height

10 6 Plug, leg tip, dual-height

11 3 Screw, Phillips pan-head, 8 - 18 x 1/2"

12 4 Lock assembly, unit-to-unit

16 6 Lock, brace

17 6 Spring, compression

Page 46

46

REPLACEMENT PARTS LIST (CONTINUED)

P

LATFORM CART

Item Qty Description Item Qty Description

1 1

Cart Weldment

16 2

Spring, torsion

2 2

Arm, swing

17 1

Sleeve, foam

3 4

Spacer, short

18 2

Capscrew, 1/4 - 20 x 1-3/4"

4 2

Capscrew, 1/2 - 13 x 3"

19 2

Capscrew, 5/16 - 18 x 3-3/4"

5 2

Nut, lock, 1/2 - 13

20 2

U-channel, extruded rubber

6 1

Crosstube Weldment

21 2

Pad, rubber, saddle

7 4

Capscrew, 1/4 - 20 x 3/4"

23 6

Plug, plastic, 1" x 1-1/2"

8 6

Nut, lock, 1/4 - 20

24 2

Bushing, nylon

9 2

Caster, swivel, 4" dia.

25 2

Capscrew, 5/16 - 18 x 3-1/2"

10 2

Spring, gas, locking

26 4

Nut, lock, 5/16 - 18

11 2

Clevis, gas spring

27 2

Bracket, channel

12 2

Plate, pivot, gas spring

28 2

Capscrew, 1/4 - 20 x 3"

13 4

Nut, hex, M10 x 1

29 16

Screw, Phillips pan-head, #10 x 3/4"

14 2

Cam, pedal bar

30 2

Caster, braked, 4" dia.

15 1

Tube, pedal

Page 47

47

REPLACEMENT PARTS LIST (CONTINUED)

2- AND

3-STEP STAIRWAYS

3-Step Model Shown

Item Qty

2-Step

Qty

3-Step

Description

1 2 3 Step assembly

2 2 2 Frame assembly, hand-rail

3 2 2 Tube, hook (with notched plate)

4 1 1 Brace, cross

5 2 2 Wheel assembly

6 12 16 Nut, hex, 5/16 - 18

7 12 16 Bolt, carriage, 5/16 - 18 x 1-1/2"

8 4 4 Screw, self-tapping, 1/4" x 3/4"

9 12 16 Washer, lock, 5/16”

Page 48

REPLACEMENT PARTS LIST (CONTINUED)

GUARD RAILS

48

Item Qty Description Item Qty Description

1 2 Upright Weldment 9 4 Bolt, carriage, 5/16 - 18 x 3-1/4"

2 2 Lower Bracket Weldment 10 6 Nut, lock, 5/16 - 18

3 2 Bolt, tab, 3/8-16 11 1 Rail, chair [*]

4 2 Handle, tee 12 2 Rail, guard [*]

5 2 Plug, 1-1/2" square 13 1 Railing, In-Fill Panel

8 2 Capscrew, 5/16 - 18 x 3-1/2" 14 4 Plug, 1-1/8" square

[*] Indicates rail length on order.

Page 49

49

REPLACEMENT PARTS LIST (CONTINUED)

GUARD RAIL STORAGE TRUCK

Item Qty Description Item Qty Description

1 2 Channel, caster 8 12 Bolt, carriage, round-head, 5/16 - 18 x 2"

2 2 Brace, center (specify 6- or 8-unit) 9 2 Capscrew, 5/16 - 18 x 2"

3 2 Upright weldment 10 1 Rack assembly

4 2 Caster, swivel, 6" 11 4 Bracket, stabilizer

5 2 Caster, rigid, 6" 12 16 Bolt, carriage, 5/16 - 18 x 1"

6 6 Plug, 1-1/4" square 15 16 Washer, flat, 1/4"

7 30 Nut, lock, 5/16 - 18 16 2 Tube weldment, upright support

Page 50

REPLACEMENT PARTS LIST (CONTINUED)

DRAPERY BACKDROP SUPPORT

50

Item Qty Description

1 2 Upright Weldment

2 1 Tube, support

3 2 Bracket

4 4 Plug, 1-1/2" square

5 2 Plug, 1-1/4" square

6 2 Capscrew, 5/16 - 18 x 2"

7 2 Capscrew, 5/16 - 18 x 3-1/2"

8 4 Nut, lock, 5/16 - 18

9 2 Washer, flat, nylon, 5/16" I.D.

10 - Hook-and-loop strip, 101" long

Page 51

51

Loading...

Loading...