Page 1

Assembly/Installation Instructions

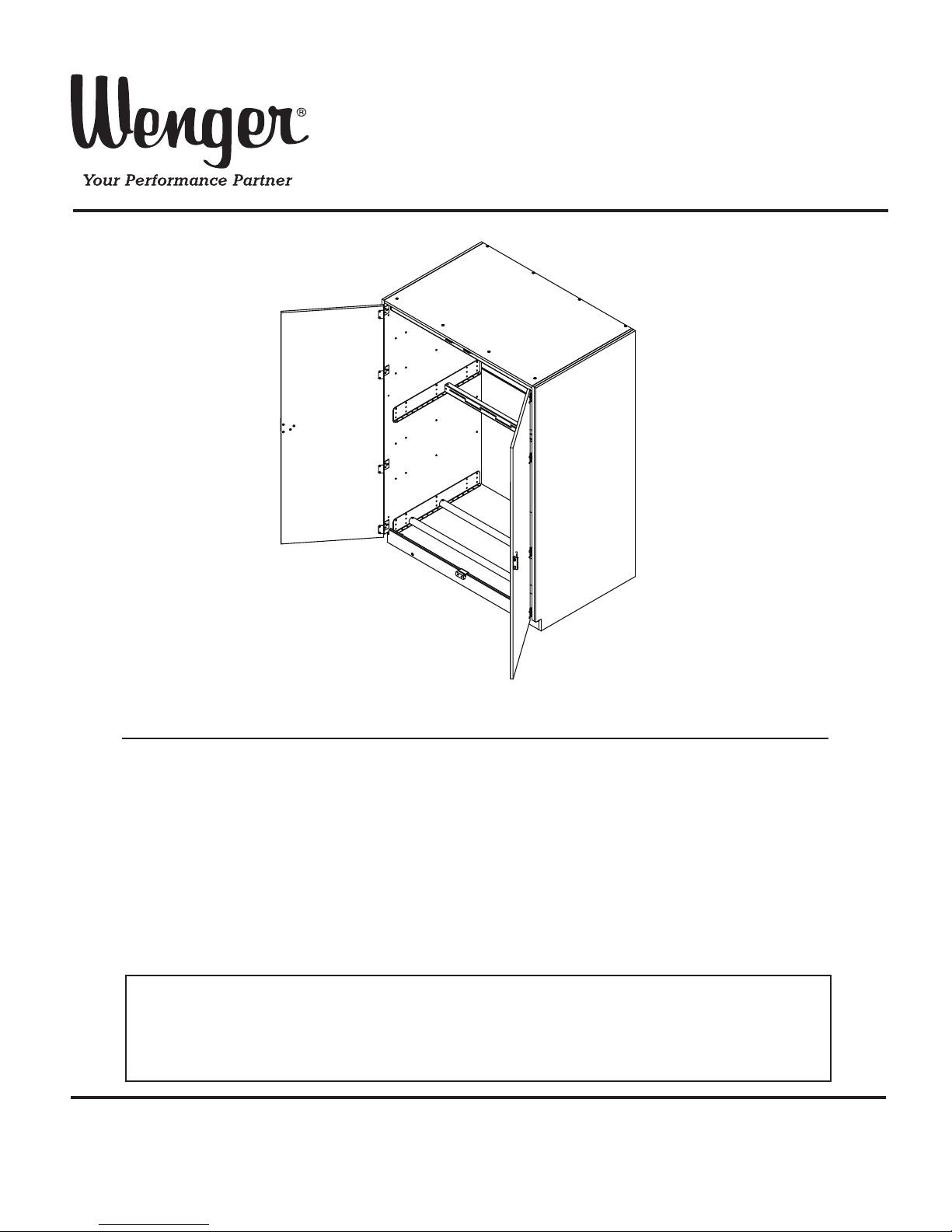

Stringed Instrument

Storage Cabinet (#42)

Note: Please read and understand these instructions before assembling the parts.

Note: Remove all items from the shipping cartons and arrange them in a convenient location.

Refer to the illustrations on the following pages.

If you need additional information, contact Wenger Corporation using the information below.

CONTENTS

©Wenger Corporation 2014 Printed in USA 08/14 Part #250A700-03

Wenger Corporation, 555 Park Drive, P.O. Box 448, Owatonna, Minnesota 55060-0448

Questions? Call.....USA: 1-800-4WENGER (493-6437) • Worldwide: 1-507-455-4100 • www.wengercorp.com

Important User Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Intended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Fastener Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

To Level Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

To Attach Full-Length Wood Doors. . . . . . . . . . . . . . . . . . . . . 10

To Attach Full-Length Grille Doors . . . . . . . . . . . . . . . . . . . . . 11

To Secure Cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

To Secure Cabinets Together. . . . . . . . . . . . . . . . . . . . . 12

To Secure Cabinets to the Back Wall. . . . . . . . . . . . . . . 13

To Secure Cabinets Back to Back . . . . . . . . . . . . . . . . . 14

AcoustiCabinet Backing Attachment. . . . . . . . . . . . . . . . . . . . 15

To Secure the AcoustiCabinet . . . . . . . . . . . . . . . . . . . . . . . . 15

To Secure AcoustiCabinets Together . . . . . . . . . . . . . . . 16

To Install Cover Panels. . . . . . . . . . . . . . . . . . . . . . . . . . 17

To Secure Cabinets to the Wall . . . . . . . . . . . . . . . . . . . 20

Storage Cabinet Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 24

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 2

2

IMPORTANT USER INFORMATION

GENERAL

Copyright © 2014 by Wenger Corporation

All rights reserved. No part of the contents of this manual may be reproduced, copied, or transmitted in

any form or by any means including graphic, electronic, or mechanical methods or photocopying,

recording, or information storage and retrieval systems without the written permission of the publisher,

unless it is for the purchaser's personal use.

Printed and bound in the United States of America.

The information in this manual is subject to change without notice and does not represent a commitment

on the part of Wenger Corporation. Wenger Corporation does not assume any responsibility for any

errors that may appear in this manual.

In no event will Wenger Corporation be liable for technical or editorial omissions made herein, nor for

direct, indirect, special, incidental, or consequential damages resulting from the use or defect of this

manual.

The information in this document is not intended to cover all possible conditions and situations that might

occur. The end user must exercise caution and common sense when assembling or installing Wenger

Corporation products. If any questions or problems arise, call Wenger Corporation at 1-800-887-7145.

MANUFACTURER

The Stringed Instrument Storage Cabinet (#42) is manufactured by:

Wenger Corporation

555 Park Drive

Owatonna, MN 55060

1-800-4WENGER (493-6437) • 1-507-455-4100

www.wengercorp.com

INTENDED USE

• This product is intended for indoor use in normal ambient temperature and humidity conditions —

it must not be exposed to prolonged outside weather conditions.

• This product is intended to be assembled and used only as described in these instructions.

WARRANTY

This product is guaranteed free of defects in materials and workmanship for ten full years from

date of shipment. A full warranty statement is available upon request.

Page 3

3

SAFETY PRECAUTIONS

Make sure anyone working

on the Storage Cabinets has

read and understands this

manual.

!

CAUTION

Failure to comply with

Warnings and Cautions in

this document can result in

damage to property or

serious injury.

!

CAUTION

Always observe and comply

with the Warnings and

Cautions posted on the

system equipment.

!

CAUTION

It is unsafe for only one

person to assemble or move

the Storage Cabinets.

!

CAUTION

Make sure the Cabinets are

securely attached to walls or

floor after assembly is

complete.

!

CAUTION

Throughout this manual you may find CAUTIONS and WARNINGS they are defined as follows:

• WARNING; failure to follow the instruction may result in serious injury or death.

• CAUTION; failure to follow the instruction may result in serious injury or damage to property.

Read all of these safety instructions before assembling and installing the Storage Cabinets.

OVERVIEW

It is suggested that the Storage Cabinets are set up in a space that is large enough (approximately 25' x 25')

to safely handle the cartons, pieces, finished cabinets, and dunnage.

Inspect the condition of the wall and floor where the cabinets will be located. If the wall is not straight,

establish a reference line so the fronts of all cabinets will line up. Also, determine the highest point on

the floor, which will establish the leveled height of each row of cabinets.

Build only one cabinet at a time, to avoid intermixing parts. Build each according to the instructions in

this manual for the specific model. Do not start installing doors until all cabinets are assembled and in

their final location, leveled, and bolted to adjacent walls and cabinets.

After all cabinets are in place, distribute the door cartons and door hardware sets to each cabinet.

Assemble and hang the doors one at a time according to the instructions. Then clean off any

fingerprints, dirt, and dust, using a clean rag and Fantastic (or comparable) spray cleaner or acetone.

BEFORE YOU BEGIN

Keep the Storage Cabinet Packing List with the cabinet, use for reference until the unit is completely

assembled.

• Read the complete assembly procedure before beginning to assemble the cabinet.

• Hardware packs may contain extra fasteners that will not be required on your cabinet.

• Because of the variety of possible wall surfaces, they are not included.

Have your maintenance personnel recommend an appropriate type for safe, secure attachment

and have the fasteners available before assembling the cabinet.

• At least two people (preferably four) are required to assemble the cabinet and set it upright.

BEFORE INSTALLATION

Page 4

4

• Plastic Mallet

• Phillips Head Screwdriver

• Standard Screwdriver

• Open-End Wrench,

7/16

"

• Open-End Wrench,

3

/8"

• Open-End Wrench,

1

/2"

• Allen Wrench,

5

/

3

2

"

• Open-End Wrench,

1

/4" or 1/4" socket

• 4-mm Hex Drive for Drill (supplied)

• Carpenter’s Level

• Tape Measure

• Carpenter’s Square

• Variable Speed Electric Drill (to drive Hex Socket

Screws)

• Utility Knife

NOTE: To save assembly time, it is recommended to

have more than one of each ty

pe of

screwdriver on hand.

REQUIRED TOOLS

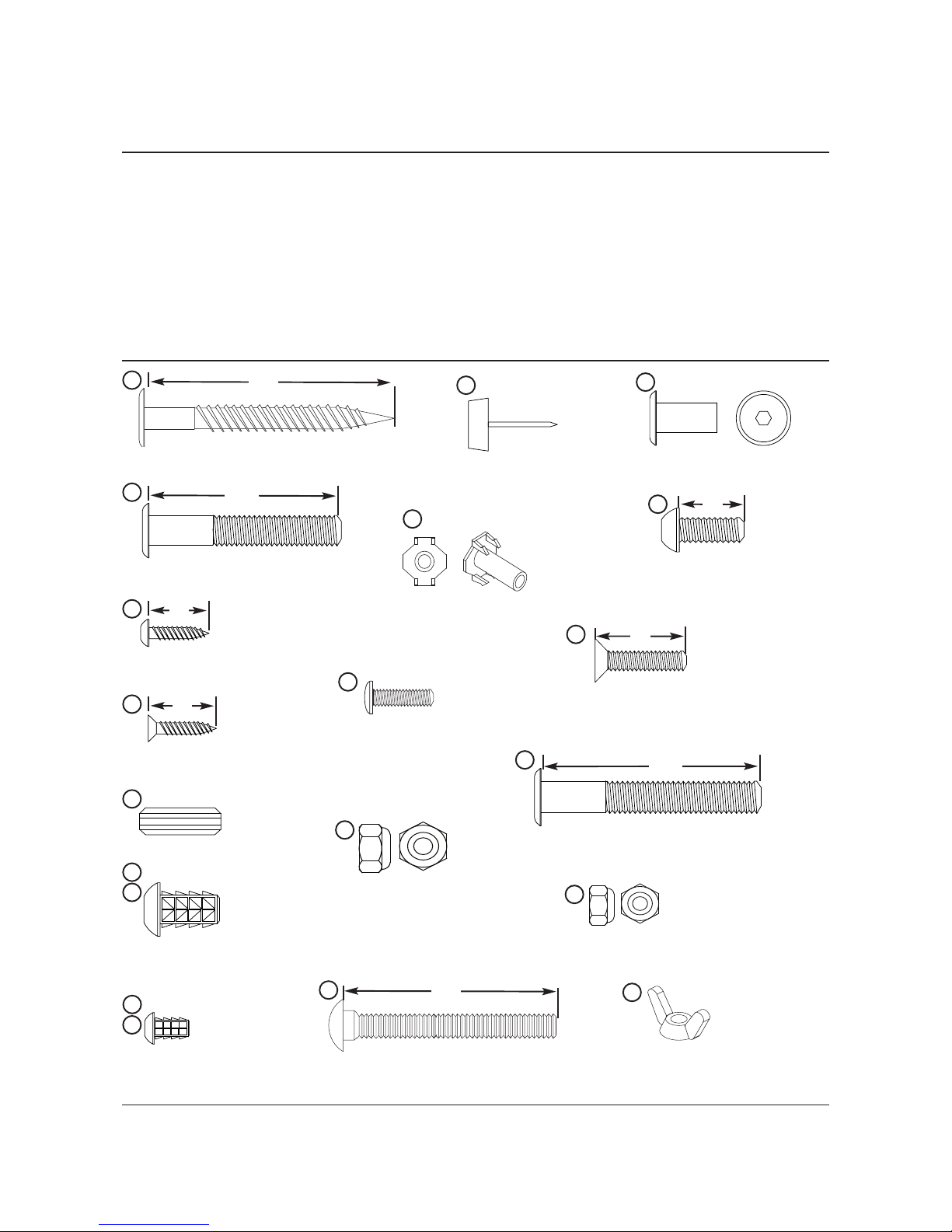

FASTENER PARTS LIST

Screw Insert, 1/4-20x5/8”

Hex Socket Machine Screw

1.57”

3

Wood Dowel

6

9

Hex Socket Lag Screw

2”

2

Hex Cap Insert Nut

41

49

3

/4”

Flat Head Screw (Painted)

Hex Socket Machine Screw

1.77”

56

67

Carriage Bolt

Nylock Nut - 1/4”

Round Head Screw

#10-24x

3

/4”

Crimp Lock Tee Nut (assembled)

Pan Head Screw

5

/8”

4

Flat Head Screw (Painted)

5

/8”

5

11

Screw Insert, 8-32x7/16”

(Oyster or colored)

10

Tack Glide

13

24

26

31

21/2”

32

Hex Socket Button Head Screw

5

/8”

46

Nylock Nut - #10

8

Wing Nut, 1/4”

68

Page 5

5

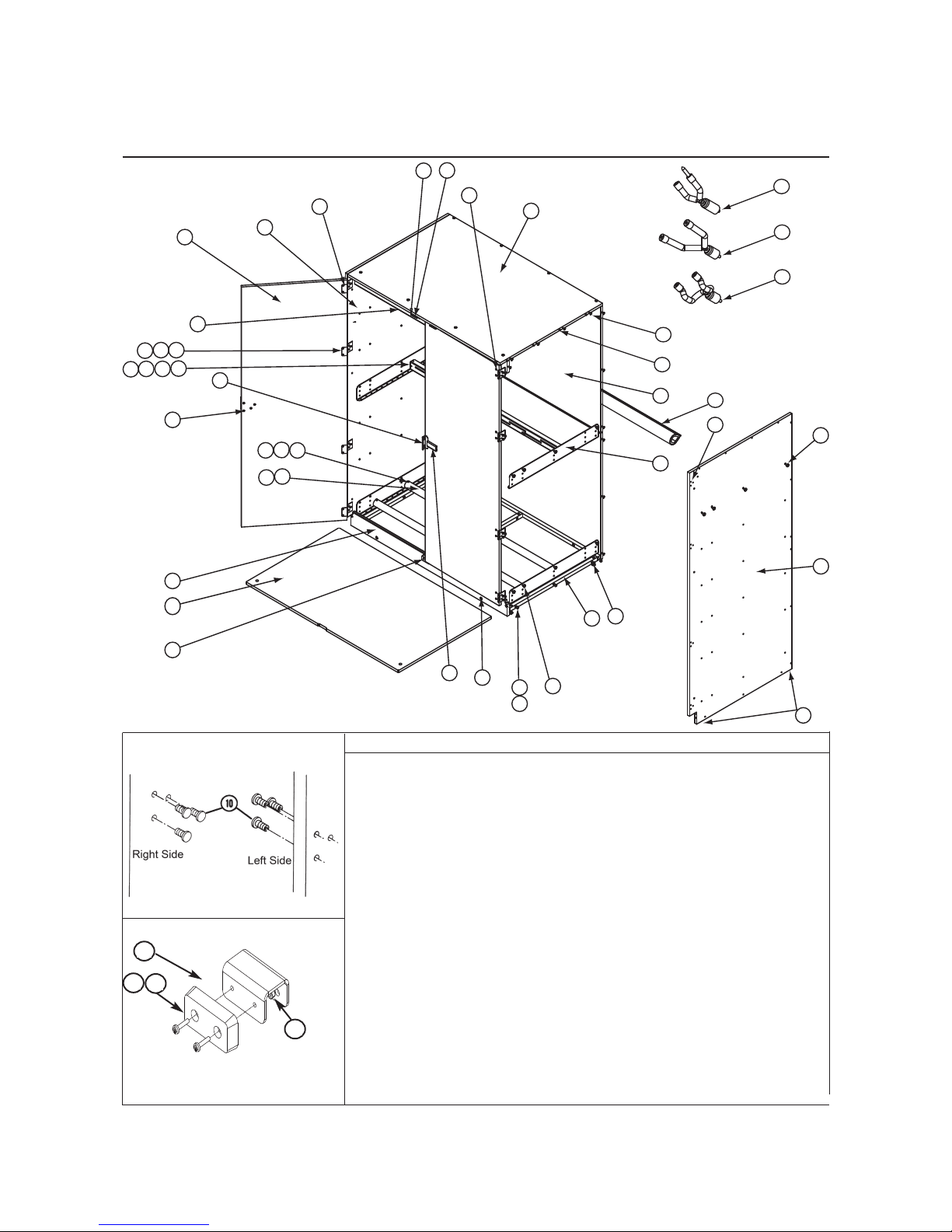

ASSEMBLY

23

49

48

37

33

11

20

13

24

55

68

15

29

50

49

28

46

53

41

34

68

51

32

35

6

21

22

2

4346

4

5

7

58

59

5

25

45

3

9

8

10

25

31

31

Item Description

2 screw, hex-socket lag

3 screw, hex-socket, 40 mm (oyster)

4 screw, pan-head, 5/8"

5 screw, flat-head, 5/8"

6 dowel, wood

8 insert, screw, 1/4"-20 (coordinated color)

9 insert, screw, 1/4"-20 (oyster)

10 insert, screw, 8-32 (oyster)

11 insert, screw, 8-32 (coordinated color)

13 glide, tack

14 screw, painted pan-head, 11/4"

15 rubber bumper

20 panel, top

21 panel, back

22 panel, right-hand side

23 panel, left-hand side

24 crimp-lock tee nut (installed)

25 support tube pad

26 screw, round-head, #10-24

28 instrument support tube

29 floor, cabinet

31 nylon insert lock-nut

Item Description

32 carriage bolt, 1/4"-20x 2.5

33 door

34 handle (wood door only)

35 hinge

37 door catch

41 nut, cap, hex socket

43 upper bar, support

44 trim strip (see page 12)

45 bracket, angle

46 screw, hex-socket button-head

48 panel, top front stretcher

49 screw, painted flat-head, 3/4"

50 panel, bottom front stretcher

51 leveler

53 card holder

55 frame assembly

57 violin / viola / vihuela yoke

58 bass / cello yoke

59 guitar / guitarron yoke

67 nylock nut - #10

68 wing nut, 1/4"

Detail A

Inserts for hinge screws

Screw insert color is oyster.

Detail B

Rubber

Bumper

67

15

9

26

Page 6

6

ASSEMBLY (CONTINUED)

NOTE: Tighten screws snugly, but do not over tighten (use special care with a power screwdriver).

NOTE: Where colored hardware is called out, use the color coordinated to the laminate.

PREASSEMBLE MISCELLANEOUS PARTS

NOTE: The side panels have a notch in the bottom front corner.

1. If Two Full-Length Cabinet Doors will be installed:

Side Panels - (#22 and #23)

a. Lay the side panels (#22 and 23) flat, with their outside

surface up. Note: The outside surface has the largest

part of the crimp lock nut showing.

b. See Detail A. Use a plastic mallet to pound 8-32 screw inserts (#10 oyster) into the twelve holes (four sets of

three holes) located approximately 19/

3

2

" and 1 3/8" from the front edge of both panels. The inserts will be used

later for hinge screws. Refer to pages 10-11

c. Insert 1/4" screw inserts (#9) into the larger holes along the bottom notched edge of both panels.

Front Bottom Stretcher (#50)

a. Lay the front bottom stretcher (#50) flat, with the recessed holes side up.

b. Insert 1/4" screw inserts (#8 coordinated color) into the four larger holes. Note: Two of the holes are recessed.

Back Panel (#21)

a. Insert 1/4" screw inserts (#9) into the three larger holes along the top edge of one of the back panels.

NOTE: The panels are large and hard to keep aligned when you attach them together with screws. Because of this, in

several of the following steps you will be told to “peg” the parts first by inserting wood dowels (#6). These

dowels fit snugly into existing

5

/16"-diameter holes in the panels, and may have to be tapped into place.

2. Insert wood dowels into the side edges of the top panel (#20), the top edge of the top front stretcher panel (#48), and

in the notched out area of the side panels (#22 and 23).

ASSEMBLE THE MAIN PANELS

3. Turn the side panels on edge, with their front edges down. Using the wood dowels, peg the side panels to the top

panel. Then attach the side panels to the side edges of the top panel and the ends of the top front stretcher panel with

2"hex-socket screws (#2 oyster). Tighten the screws using the allen wrench or bit packed with these instructions.

4. With the screw inserts to the inside and edge banding to the middle of the cabinet, peg the two back panels (#21)

together. Attach the back panels to the side and top panels, using the 2" hex-socket screws (#2 oyster).

5. Insert

1

/4" screw inserts (#9) into the three larger holes along the bottom back panel. Attach the back panel using hex

socket machine screw (#3).

6. Attach the frame assembly (#55) to the inside of the side and rear panels with the weldnuts facing down towards the

bottom of cabinet, using 40 mm hex-socket screws (#3 oyster) inside the cabinet and

1

/4" screw inserts (#9 oyster)

outside. Do not tighten the screws.

ATTACH THE GLIDES AND LEVELERS

7. To protect corners and edges while moving the cabinet into place, push or hammer plastic tack glides (#13, not shown)

into the bottom edge of the side panels, about 2" from the corners.

8. Screw the four short levelers (#51) into the frame assembly.

NOTE: If the floor is excessively uneven longer levelers have been included and may be substituted as needed. Full

thread engagement is required on all levelers when installed.

SET THE CABINET UPRIGHT

9. Set the assembled cabinet upright.

10. Attach the bottom front stretcher (#50) to the side panel using the hex-socket screws (#2), hex-socket screw, then use

the 40 mm (#3) and screw insert (#9) to attach the side panel.

11. See Detail B. Attached the rubber bumper (#15) to the bottom front stretcher (#50).

12. Tighten all screws in the cabinet.

INSTALL THE SUPPORT GROUP

13. Refer to operation instructions on pages 7-8.

LEVEL THE CABINET AND MAKE FINAL ADJUSTMENTS

14. Move the cabinet to its intended location, and level it by using a 1/4" socket or screwdriver before putting the floor in

the cabinet. Refer to the leveling procedure on page 9. Insert the floor with the cutout forward.

15. To attach doors, refer to pages 10-11. To attach two or more cabinets together, and to secure the cabinet(s) to the

back wall, refer to pages 12-13.

16. If the cabinet is to be free-standing, it is advisable to use suitable floor-anchoring fasteners to hold the side panels

stationary. Be sure that the cabinet is square and plumb before anchoring.

Page 7

7

OPERATION

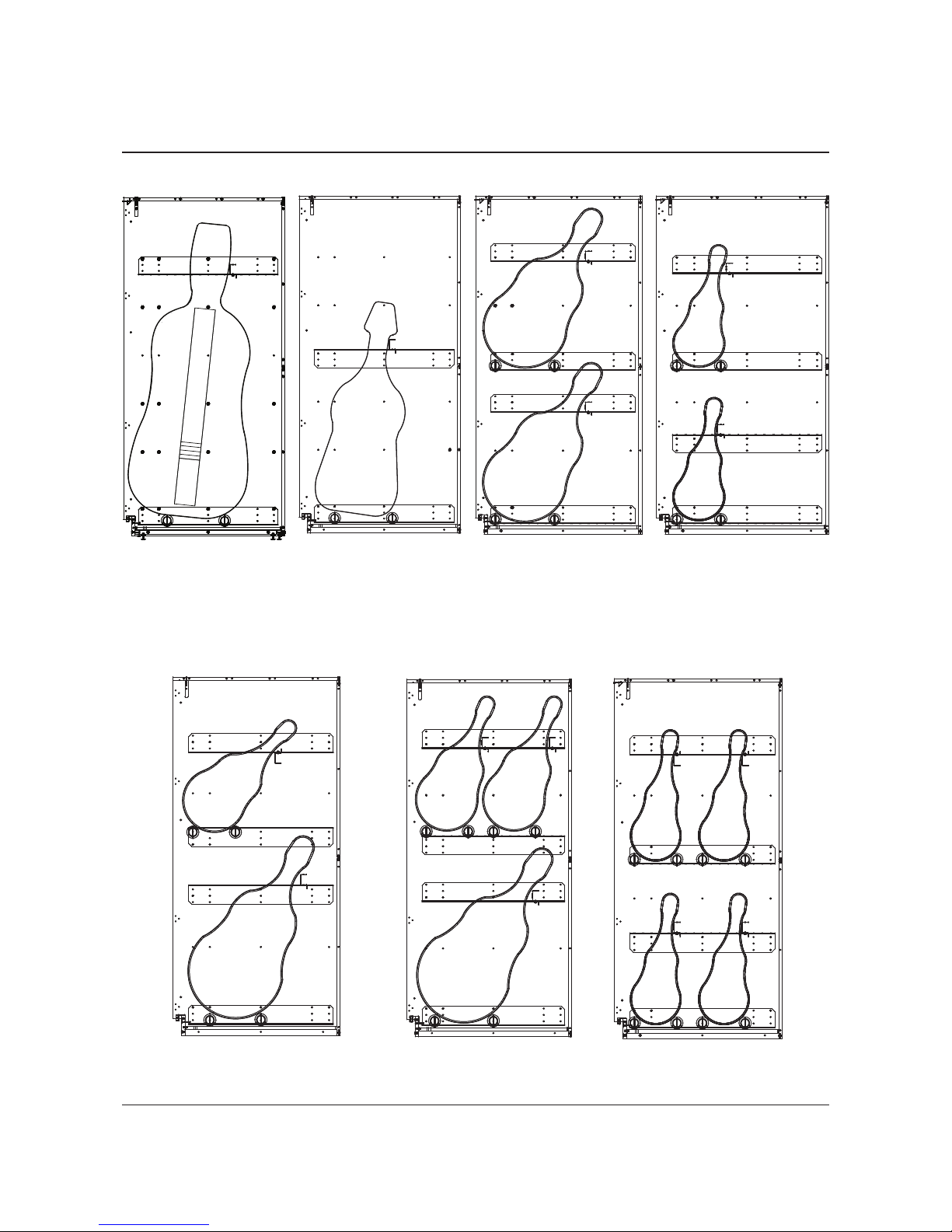

SUPPORT GROUP ARRANGEMENTS

Bass

Cello / Guitarron

Guitar Violin / Viola / Vihuela

Combination - Cello / Guitarron

& Violin / Viola / Vihuela

Cello / Guitarron &

Violin / Viola / Vihuela

Violin / Viola / Vihuela

Combination

High- Pack

Options

Page 8

8

OPERATION (CONTINUED)

The basic support group consists of 4 side brackets, 2 padded instrument support tubes and 1 upper

support bar. From the sketches above and on page 7, select the approximate arrangement desired.

1. Place 2 side brackets onto the cabinet side panels at the same level and with the same orientation

(flange up or down) to receive the instrument support tubes. Note: Four 1/4”-20 x 5/8” button head

fasteners (#46) are required per side bracket.

2. Install the support tube pad onto the instrument support tube with the seam of the pad on the flat

edge of the tube.

3. Loosely lay one instrument support tube on the brackets in the desired position and insert the

required hardware (#31 and 32) to determine if there is adequate clearance to continue assembly.

4. To get an approximate instrument support tube to instrument support tube spacing, place them side

by side on the floor. Using a common instrument case or instrument securely held, move the

instrument support tubes apart or together until they fit and support the bottom of the instrument

case or instrument reclined at the desired angle.

Note: This is the dimension to the nearest hole location on the side bracket. It should be used to

locate the instrument support tubes with respect to each other onto the side brackets.

5. Place the instrument support tubes, with the flat side and support tube pad seam down, in the

desired location(s), confirm they are evenly spaced and parallel to the back of the cabinet. Then

tighten all bracket and support tube fasteners.

6. Place a common instrument case or instrument and lean it back at the desired angle. Note where

the upper support bar would be best positioned to contact the neck of the instrument and hold it

securely.

7. Install the side brackets onto the cabinet side panels using

1

/4”-20 x 5/8” button head fasteners (#46)

at the same level and with the same orientation to receive the upper support bar.

8. Install the upper support bar using 1/4”-20 x 5/8” button head fasteners (#46) and lock-nut (#31). Wing

nut (#68) may be used in place of the nylock nut (#31) if frequent adjustment is required. Nylock

nuts (#31) are recommended for a more secure upper support bar mounting. Tighten all fasteners

securely.

Note: The upper support rail can be mounted above or below the flange for increased versatility

instrument cases or instruments should not be installed so upright that they would tip off the support

rails. A reclining angle of 30 to 45 degrees is recommended. Instrument cases or instruments

should be placed on the support tubes and rails to be parallel with the side panels of the cabinet so

the instrument case or instrument does not fall to one side or the other

It is highly recommended that instruments stored in the cabinet, without cases, use neck supports

for best security. The neck supports are available in 3 different sizes based on the type of

instrument and mount onto the upper support rail. The upper support rail can be located up and

down or near and far. The individual neck supports can be located side to side. Two flat washers

are provided and are to be placed in front and in back of the upper support bar slot on the

1

/4”-20

threaded rod of the neck support. This allows the washers to clamp and hold the neck support on

the upper support bar.

9 Insert and remove all instruments carefully to avoid damage and avoid knocking over other

instruments.

SUPPORT GROUP ARRANGEMENTS INSTRUCTION:

Page 9

9

1. Check the level of the

entire floor where the

cabinets will be

installed. Determine

the highest point of

the floor in that area.

Extend all levelers

until the bottom of the

cabinet will be higher

than the highest point

in the floor.

2. Adjust the levelers on

one side until the front

edges of the cabinet

side panels are plumb

(side-to-side).

3. Measure A and B with a tape

and adjust the front levelers

until A=B (+1/32inch).

4. Adjust both front levelers

equally until the front

edges of the cabinet are

plumb (front-to-back).

5. Recheck that A=B.

Readjust if necessary

(repeat steps 2-4).

6. Adjust the levelers on the next cabinet so it

will line up with the top of the first cabinet.

7. Repeat steps 2-5 for the second cabinet.

8. Continue in the same manner until all cabinets

are leveled.

TO LEVEL CABINETS

NOTE: Do not try to level the cabinets to match soffits.

Do not try to plumb the cabinet to match adjacent walls.

For proper door alignment, follow these instructions carefully.

Page 10

10

NOTE: The cabinet must be properly leveled first, or the doors will not fit properly. See page 9

1. Lay the door (#33) flat. Use a plastic mallet to pound 8-32 screw inserts (#11) into the eight holes (four pairs)

near one edge of each door (install inserts into the front

face of the door). Note: There are pilot holes started

on the front face of the door.

2. Attach four hinges (#35) to the inside (back face) of each door, using flat-head 3/4" screws

(#49 matches hinge color) into the inserts installed in step 1.

3. See Detail G. Hold a door in position on the cabinet. Attach the hinges to the side panel,

using three flat-head screws (#49 matches hinge color) into each set of screw inserts.

A screw may be inserted into the rear-most hole of the cabinet and the door may be hung from it by placing the

slotted hole in the hinge onto the screw and moving the hinge forward until the other two screw inserts are

exposed. Tighten the three screws in each hinge. Repeat with the other door.

Four sets of screw inserts (#10 oyster) were previously installed in the left and right side panels for the door

hinges. See Detail A on the cabinet assembly instructions.

4. Secure each hinge to the edge of the door, using flat-head

5

/8" screws (#5 matches hinge color) into the

predrilled hole.

5. See Detail H. Insert a card holder housing (#70) into the two inner holes in the front face of the left

door as

shown. Insert the other card holder housing to the inner holes in the right

door. Insert hex-socket cap nuts (#41

matches hinge color) into the holes in the back face of the door and tighten them.

6. Insert the handle (#34 matches hinge color) into the remaining two holes in each door. Install and tighten the

cap nuts.

Closing the doors align holes in the handles for installing a padlock.

7. See Detail L. Attach the door catches (#37) to the holes in the underside of the top panel, where the

doors meet, using

5

/8" pan-head screws (#4) into the predrilled holes.

TO ATTACH FULL-LENGTH WOOD DOORS

Detail G

Left side hinge installation

To identify the front

and back faces of

the door, see also

Detail G on page 50

Detail H

Card Holder & Handle Installation

Detail L

Door catch installation

Item Description

4 screw, pan-head, 5/8"

5 screw, painted flat-head, 5/8" (matches hinge color)

10 insert, screw, 8-32 (oyster)

11 insert, screw, 8-32

33 door

34 handle (matches hinge color)

35 hinge

37 catch, door

41 nut, cap, hex-socket (matches hinge color)

49 screw, painted flat-head,

3

/4" (matches hinge color)

53 holder, card

70 housing, card holder

Page 11

11

NOTE: The cabinet must be properly leveled first, or the doors will not fit properly. See page 9.

1. Four sets of screw inserts (#10 oyster) were previously installed in the left and right side panels

for the door hinges. See Detail A on the cabinet assembly instructions.

2. See Detail G. Four hinges are welded to full-length grille doors at the factory. Hold a door (#33) in

position on the cabinet. Attach the hinges to the side panel, using three pan-head screws (#8) into

each set of screw inserts. A screw may be inserted into the rear-most hole of the cabinet and the door

may be hung from it by placing the slotted hole in the hinge onto the screw and moving the hinge

forward until the other two screw inserts are exposed. Tighten the three screws in each hinge.

Repeat with the other door.

3. Closing the doors will align holes in the two lock housing for installing a padlock.

4. See Detail L. Attach the door catches (#37) to the holes in the underside of the top panel, where the

doors meet, using 5/8" pan-head screws (#4) into the predrilled holes.

TO ATTACH FULL-LENGTH GRILLE DOORS

Detail G

Left side hinge installation

Detail L

Door catch installation

Item Description

4 screw, pan-head, 5/8"

10 insert, screw, 8-32 (oyster)

33 door

37 catch, door

49 screw, painted flat-head,

3

/4"

(matches hinge color)

Page 12

NOTE: The following instructions are for standard installations.

- For seismic installation instructions, see 145R422.

- For AcoustiCabinet refer to pages 14-21.

TO SECURE CABINETS TOGETHER

NOTE: Make sure the cabinets are in position and level before you secure them together.

1. See Detail M. Install two trim strips (I-shaped plastic strips) (#44) on the side panel of one of the two

mating cabinets. Install the longer strip

1

/8" back from the front edge and install the shorter strip

at the bottom 2

3

/4" back from the front edge.

The top of the longer strip should be flush with the top of the cabinet.

The end of the strip, with the hole, goes to the top.

To attach, peel the paper from the pressure-adhesive tape and press the strip into place.

This will hold the strips in position until the cabinets are bolted together in step 2.

2. There are three holes predrilled in the side panels for securing the cabinets together.

These holes are located

1

13

/16" back from the front edge of the cabinet, and 6", 33 1/2", and 75" down from the top.

With a plastic mallet, pound three

1

/4-20 screw inserts (#9 oyster) from one side of each hole,

Install 1.77" (45 mm) hex-socket screws (#56) through the other side, and tighten.

TO SECURE CABINETS

12

Securing cabinets together

Detail M

Installing

trim strips

Item Description

9 insert, screw, 1/4-20 (oyster)

44 trim strip

56 screw, hex-socket, 45 mm

Cabinets are unsafe unless

secured as specified.

!

WARNING

Use methods appropriate to

your wall surfaces.

!

WARNING

Front of Cabinets

Top View

1/8”

2-3/4”

Shorter

Trim Strip

Longer

Trim Strip

Page 13

13

NOTE: The following instructions are for standard installations. For seismic installation instructions,

see 145R422.

TO SECURE CABINETS TO THE BACK WALL

There are L-shaped brackets (#45) in the hardware bag for attaching the cabinets to your wall surface.

Because of the variety of possible wall surfaces, fasteners are not included. Have your maintenance

people recommend an appropriate type for safe, secure attachment.

NOTE: Make sure all the cabinets are secured together before you attach them to the back wall.

1. See Detail N. Using the L-shaped brackets, you can tie cabinets together and to the wall surface at

the top. The brackets have extra holes: if the cabinets can’t be positioned tight against the wall, you

can slide the bracket back as much as 2" until it is tight against the wall surface.

2. Use the necessary fasteners suggested by your maintenance people to secure the cabinets to the

wall. At least every 5th cabinet must be attached to the back wall surface.

TO SECURE CABINETS (CONTINUED)

Detail N

Installing wall brackets

Item Description

4 screw, pan-socket, 5/8”

45 bracket, L-shaped

Page 14

14

TO SECURE CABINETS (CONTINUED)

TO SECURE CABINETS BACK TO BACK

If cabinets are installed back-to-back in a “island” or “peninsula” formation, you must drill holes through

the back of each cabinet and secure the backs of the cabinets together.

NOTE: Make sure the cabinets are in position and level before you secure them together.

1. Using a 3/8" drill, make holes 2 5/8" down from the top (inside) on the back of the cabinets that are

back-to-back. These holes should be no closer than 4" from the side of the cabinet. Drill through the

back of the opposite cabinet. You may also need to make holes 2 1/2" up from the bottom of the cabinets.

2. With a plastic mallet, pound 1/4-20 screw inserts (#9 oyster) from the inside of one of the cabinets.

Have someone inside the opposite cabinet install 1.77" hex-socket screws (#56) and tighten.

Item Description

9 insert, screw, 1/4-20

(oyster)

56 screw, hex-socket, 50 mm

Connecting Holes

(sides of cabinets — see page 9)

Connecting Holes

(backs of cabinets)

Page 15

15

ACOUSTICABINET BACKING ATTACHMENT

Detail O

Flip-Stix

®

To attach the sound absorptive material to the back of the AcoustiCabinets:

1. See Detail 0. Flip-Stix®(#80) are used to hold the sound absorptive material in place.

The Flip-Stix®are already attached to the rear stretcher panels on the back of all AcoustiCabinets

to attach the sound absorptive material. The quantity of Flip-Stix®installed on the cabinet will vary

by cabinet design.

On each Flip-Stix®, pull the top tab out approximately 11/2”.

2. See Detail P. Attach the sound absorptive material (#81) to the back of the cabinet by placing it

over all of the Flip-Stix®approximately 2” above the desired final location with the white (printed)

plastic barrier facing away from the cabinet back.

3. Pull down on the sound absorptive material to secure it into place on the Flip-Stix®and pulling it level.

The Flip-Stix® are intended to penetrate the gray plastic and the insulation only, not the white

(printed) plastic barrier.

Item Description

80 Flip-Stix

®

81 sound absorptive material

Detail P

Attach sound absorptive material

Note: AcoustiCabinets shown on the next few pages are for

illustration purposes only. They do not reflect the exact

cabinet dimensions.

Holes in Upper Panel

21

21

Holes in Lower Panel

80

80

6

1½”

81

81

Page 16

16

TO SECURE CABINETS TOGETHER

NOTE: Make sure the cabinets are in position and level before you secure them together.

1. See Detail Q. Install two trim strips (I-shaped plastic strips) (#44) on the side panel of

one of the two mating cabinets.

Install the longer strip 1/8" back from the front edge and install the shorter strip at the bottom 2 3/4"

back from the front edge.

The top of the longer strip should be flush with the top of the cabinet.

The end of the strip that has a hole goes to the top.

To attach, peel the paper from the pressure-adhesive tape and press the strip into place.

This will hold the strips in position until the cabinets are bolted together in step 2.

2. a. See Detail R. For flush back mounting (recommended): There are three holes predrilled in

the side panels for securing the cabinets together. These holes are located 113/16" back from

the front edge of the cabinet, and 6", 33 1/2", and 75" down from the top.

b. For flush front mounting: Align the cabinets to be flush in the front.

Use the three predrilled holes in the shallowest cabinet as the template for the remaining

cabinet. Using the 3/8” drill bit, drill new holes into the side panel of the adjacent cabinet.

3. With a plastic mallet, pound three 1/4-20 screw inserts (#9 oyster) from one side of each hole,

Install 1.77" (45 mm) hex-socket screws (#56) through the other side, and tighten.

TO SECURE THE ACOUSTICABINET

Detail R

Securing cabinets together

Detail Q

Installing

trim strips

Item Description

9 insert, screw, 1/4-20 (oyster)

44 trim strip

56 screw, hex-socket, 45 mm

Cabinets are unsafe unless

secured as specified.

!

WARNING

Use methods appropriate to

your wall surfaces.

!

WARNING

Front of Cabinets

Top View

1/8”

2-3/4”

Shorter

Trim Strip

Longer

Trim Strip

Page 17

17

TO SECURE THE ACOUSTICABINET (CONTINUED)

TO INSTALL COVER PANELS

1. See Detail S. Insert two plastic guide tacks (#84) into the bottom of each cover Panel (#85),

centered and 2-3” from each end.

2. See Detail T. Lift the cover panel to a vertical position and fit it into place over the exposed

hardware. Use the plastic guide tacks to protect the bottom of the cover panel.

The cover panel should fit flush against the front side of the cabinet and overhang the back side by

2

1

/2”. If it does not, check to see if it is a left hand cover panel on the left side of the cabinet (or right

hand on the right side).

3. Lay the cover panel back down onto the packaging.

84

85

84

Detail T

Securing cabinets together

Detail S

Installing guide tacks

Item Description

84 guide tack

85 cover panel

NOTE: Cabinet side is not

shown for clarity.

Page 18

TO INSTALL COVER PANELS (C

ONTINUED

)

4. See Detail U. Using the 3/

1

6

” drill bit, drill 12 holes (9 holes for 68” tall cabinets) into the side panel of

the cabinet to be covered:

Top Row

NOTE: Do not drill into a shelf or cross member. Measure before drilling so that the hole is

1-2” from the nearest horizontal surface to allow clearance for tools.

a. Drill a hole 2-3” down from the top and 2-3” back from the front of the cabinet.

b. Drill the second hole 2-3” down from the top and 24-26” (14-16” for 191/4” deep cabinets)

from the front of the cabinet.

c. Drill a third hole 2-3” down from the top and evenly spaced horizontally between the first

two holes.

Bottom Row

NOTE: Do not drill into a shelf or cross member.

Measure before drilling so that the hole

is 1-2” from the nearest horizontal

surface to allow clearance for tools.

d. Drill a hole 7-8” up from the bottom

and 2-3” back from the front of the

cabinet.

e. Drill the second hole 7-8” up from

the bottom and 24-26” (14-16” for

19

1

/4” deep cabinets) from the front

of the cabinet.

f. Drill a third hole 7-8” up from the

bottom and evenly spaced

horizontally between the first

two holes.

Middle Rows

NOTE: Do not drill into a shelf or

cross member. Measure before

drilling so that the hole is 1-2” from

the nearest horizontal surface to

allow clearance for tools.

g. Drill two rows (1 row for 68” tall

cabinets) evenly spaced

between the top and bottom rows.

Use the same vertical spacing as

the top and bottom rows.

18

TO SECURE THE ACOUSTICABINET (CONTINUED)

Detail U

Drill holes in

side panel

Page 19

TO INSTALL COVER PANELS (CONTINUED)

5. See Detail V. Place the cover panel into position covering the cabinet side panel and flush

with the front edge as in Step 2.

6. Clamp securely in position using at least two non-marring padded clamps.

7. Insert all twelve of the wood screws (#82).

Do not over-torque or strip out the screws. Tighten securely and remove the clamps.

19

TO SECURE THE ACOUSTICABINET (CONTINUED)

Detail V

Install cover panel

NOTE: Cabinet side is not

shown for clarity.

Page 20

20

NOTE: The following instructions are for standard installations. For seismic installation instructions,

contact the Wenger Corporation.

TO SECURE CABINETS TO THE WALL

There are three methods for attaching AcoustiCabinets to a wall surface:

• 21/2” from wall (recommended)

• Greater than 21/2” from wall

• Flush with the wall.

CABINETS 21/2” FROM WALL (RECOMMENDED)

There are wall brackets (#45) for attaching the cabinets to your wall surface. Because of the variety

of possible wall surfaces, fasteners are not included. Have your maintenance people recommend an

appropriate type for safe, secure attachment.

NOTE: Make sure all the cabinets are secured together before you attach them to the wall.

1. See Detail W. Attach the wider tabbed surface of the mounting bracket to the top edge

at the back of the cabinet using four 5/8” pan head screws (#68) in the front four holes.

The tabs should be flush with the cabinet and all open areas at the top of the cabinet should be

covered by the mounting bracket (see the following page for cabinets that are a different size

than the mounting bracket).

2. Position the cabinets with the mounting brackets against the wall. Using the wall brackets,

attach the cabinets to the wall surface.

The brackets allow the recommended 21/2” spacing between the cabinet and the wall surface.

3. Use the necessary fasteners suggested by your maintenance people to secure the cabinets to the

wall. Every AcoustiCabinet must be attached to the back wall surface.

TO SECURE THE ACOUSTICABINET (CONTINUED)

2½”

Cabinet Top

Back Wall

4

Tab

82

Detail W

Installing

wall brackets

Item Description

4 screw, pan-socket, 5/8”

82 bracket, wall

Page 21

21

DIFFERENT SIZE CABINETS

1. See Detail X. Flatten the tab on the mounting bracket at the side that will be closest to and overlap

the wider cabinet or trim the mounting bracket to fit if preferred.

2. Overlap the mounting bracket from the narrower cabinet with the mounting bracket for the wider

cabinet.

Full width cabinets should always be on the on the outside run of cabinets.

3. See Detail Y on previous page. Attach the wider tabbed surface of the mounting brackets to the

top edge at the back of the cabinets using 5/8” pan head screws (#68).

The tabs should be flush with the cabinet and all open areas at the top of the cabinet should be

covered by the mounting bracket.

4. Position the cabinets with the mounting brackets against the wall. Using the wall brackets,

attach the cabinets to the wall surface.

The brackets allow the recommended 21/2” spacing between the cabinet and the wall surface.

5. Use the necessary fasteners suggested by your maintenance people to secure the cabinets to the

wall. Every AcoustiCabinet must be attached to the back wall surface.

TO SECURE THE ACOUSTICABINET (CONTINUED)

60”

Cabinet

Flatten Tab

Overlap

Mounting Bracket

Detail X

Page 22

22

TO SECURE THE ACOUSTICABINET (CONTINUED)

CABINETS GREATER THAN 21/2” FROM WALL

1. See Detail W. Flatten the tabs on the mounting bracket.

2. Attach the mounting bracket to the back of the cabinet, over the sound absorptive material.

3. Mount a stud to the wall using the necessary fasteners suggested by your maintenance people.

4. Attach the closure panel to the top of the mounting bracket and wall stud.

3. Refer to the “Cabinet Closure Kits Assembly Instructions” that accompanies the optional

closure panels for more detailed instructions.

Wall

Closure

Panel

Mounting

Bracket

Sound Absorbtive M at er ial

Wall

Stud

Detail Y

Installing closure panels

Page 23

23

CABINETS FLUSH WITH WALL (NOT RECOMMENDED)

1. See Detail Z. Flatten the tabs on the wider tabbed surface of the mounting bracket.

2. Position the mounting bracket to extend between 1/4” to 21/2” beyond the back of the cabinet.

Overlap mounting brackets for different size cabinets as indicated under “Different Size Cabinets”

on the previous page.

3. Attach the mounting bracket to the top edge at the back of the cabinet using four 5/8” pan head

screws (#68) in the front four holes.

4. Trim the end cover panels to extend between 1/4” and 21/2” beyond the back of the cabinets.

5. Position the cabinets against the wall. Using the wall brackets, attach the cabinets to the wall

surface.

6. Use the necessary fasteners suggested by your maintenance people to secure the cabinets to

the wall. Every AcoustiCabinet must be attached to the back wall surface.

TO SECURE THE ACOUSTICABINET (CONTINUED)

Cabinet Top

Back Wall

4

Flatten

tab

82

¼” min

Detail Z

Installing

flush to

wall

Item Description

4 screw, pan-socket, 5/8”

82 bracket, wall

Page 24

24

CLEANING

For removal of mild stains and mild scuff marks, the polyester wood panels and polyester shelves may

be cleaned using an all-purpose household cleaner (409, Fantastic, or similar), or just simple mild soap

and water.

For heavier scuff marks, ink stains, felt pen and magic marker stains, or other tough stains; use a nonabrasive cleaner (Soft Scrub or similar), or an industrial all-purpose cleaner (Acetone or similar).

Ammoniated or vinegar-based glass cleaners also work well for these stains.

Do not use harsh abrasive cleaners, as permanent damage could occur to the panel surface. Be sure to

quickly remove all cleanser residues with water and wipe dry with a soft cloth.

HUMIDITY CONTROL

To insure longevity of panel performance, maintain the relative humidity between 25% - 55% at the

permanent installation site.

STORAGE CABINET MAINTENANCE

Loading...

Loading...