Page 1

Assembly/Operating Instructions

StageTek™Guardrail

Basic Instructions only!

For Replacement Parts and more detailed product information,

refer to the StageTek

™

Owner’s Manual 280A099.

!

CAUTION

Make sure anyone assembling

or installing the StageTek

component has read and

understands the instructions.

!

CAUTION

Always comply with Warnings

or Cautions in the instructions

or posted on the equipment.

Guardrails are recommended

for instances where the deck

height is 12” (30 cm) or more.

!

CAUTION

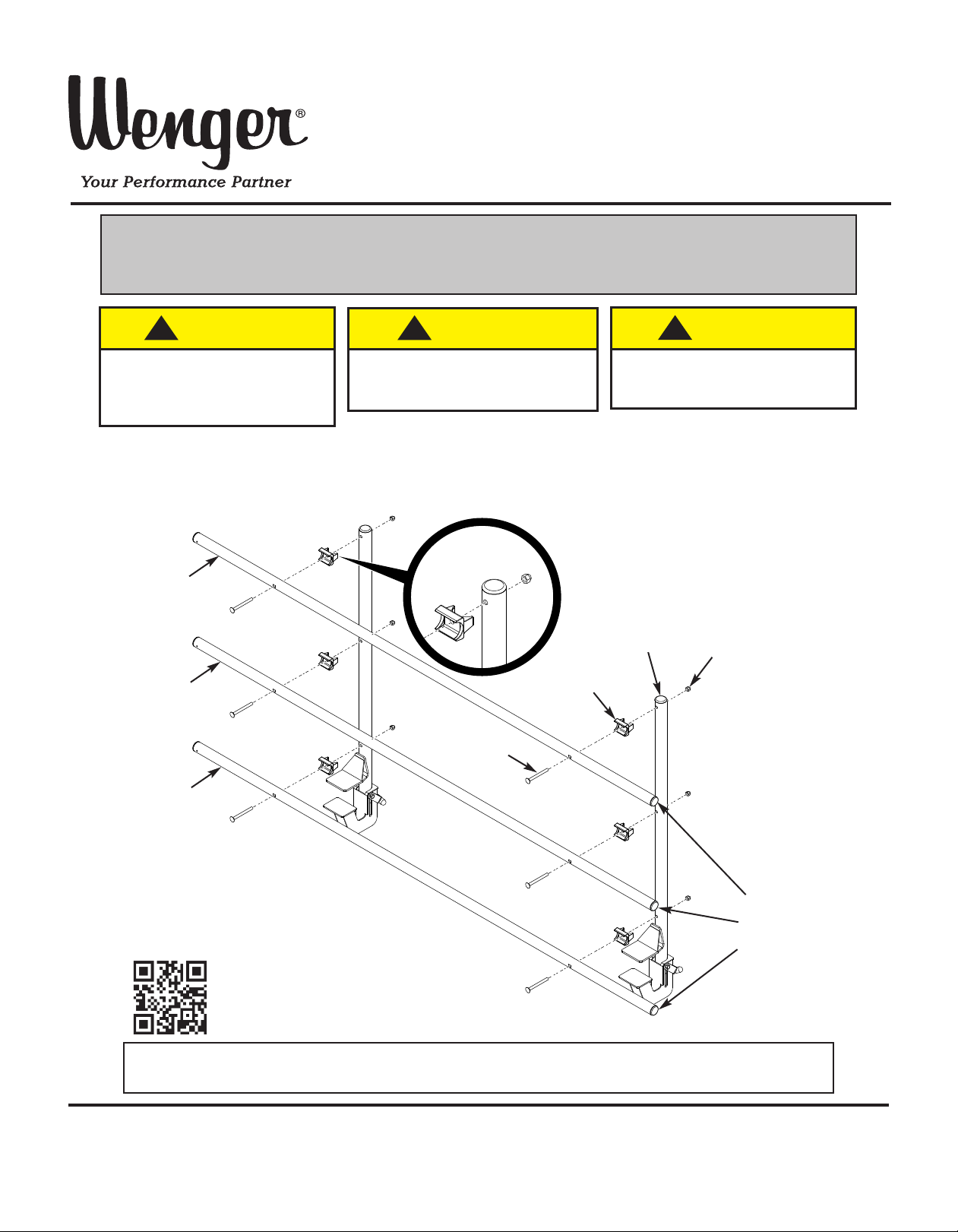

ASSEMBLY WITHOUT OPTIONAL INFILL PANELS

To assemble the Guardrail without the optional Infill Panels, attach Rails to the top, middle and

bottom positions of both Upright Weldments using 3/8-16 x 3-3/4” Carriage Bolts, Tube Saddles

and 3/8-16 Acorn Nuts as shown.

Tube Saddle

Orientation

Top

Rail

3/8-16

Acorn

Nut

Middle

Rail

Upright

Weldment

Tube

Saddle

3/8-16 x 3-3/4”

Carriage Bolt

Bottom

Rail

End Caps

may need to

be installed

in Rail Ends

Visit the StageTek web page at www.wengercorp.com

for detailed instructions and videos.

Note: Please read and understand the instructions before starting the assembly or installation.

Note: If you need additional information, contact Wenger Corporation using the information below.

©Wenger Corporation 2013 Printed in USA 04/13 Part #281A442-03

Wenger Corporation, 555 Park Drive, P.O. Box 448, Owatonna, Minnesota 55060-0448

Questions? Call.....USA: 800-4WENGER (493-6437) • Worldwide: 1-507-455-4100 • www.wengercorp.com

Page 2

ASSEMBLY WITH OPTIONAL INFILL PANELS

To assemble the Guardrail with the Optional Infill Panels:

1. Attach a Rail to both the top and bottom positions of both Upright Weldments using

3/8-16 x 3-3/4” Carriage Bolts, Tube Saddles and 3/8-16 Acorn Nuts as described on

the previous page.

Do not attach the Middle Rail yet.

2. With the vertical wires facing outward, center an Infill Panel to fit into the channel of both attached

Tube Saddles behind both the Top and Bottom Rails.

3. Place a Tube Saddle between the Top and Bottom Infill Panels at both ends to align with the

pre-drilled middle hole in the Upright Weldments.

4. Push the Tube Saddles and Infill Panels inward to be flush with the Upright Weldments.

Top

Rail

Tube

Saddle

Tube

Saddle

Infill

Panels

(Vertical Wires Facing Out)

Infill Panels

Tube

Saddle

Bottom

Rail

2

Page 3

ASSEMBLY WITH OPTIONAL INFILL PANELS (CONTINUED)

5. Attach the Middle Rail to both

Upright Weldments using

Tube

Saddle

a 3/8-16 x 3-3/4” Carriage Bolt

through the Tube Saddle

and an 3/8-16 Acorn Nut as

previously described.

Middle

Rail

3/8-16 x 3-3/4”

Carriage Bolt

6. Secure the Top and Bottom Infill Panels to the Rails using

evenly distributed Spacers and Nylon Ties as shown.

3/8-16

Acorn Nut

a. Orient the Nylon Tie

with the head towards

the bottom of the assembly.

b. After the Nylon Tie has

been tightened, trim off

any excess to be flush

with the head.

Head of

Nylon Tie

Head Towards

Botttom

and Trim Off

Excess

Nylon

Tie

Spacer

3

Page 4

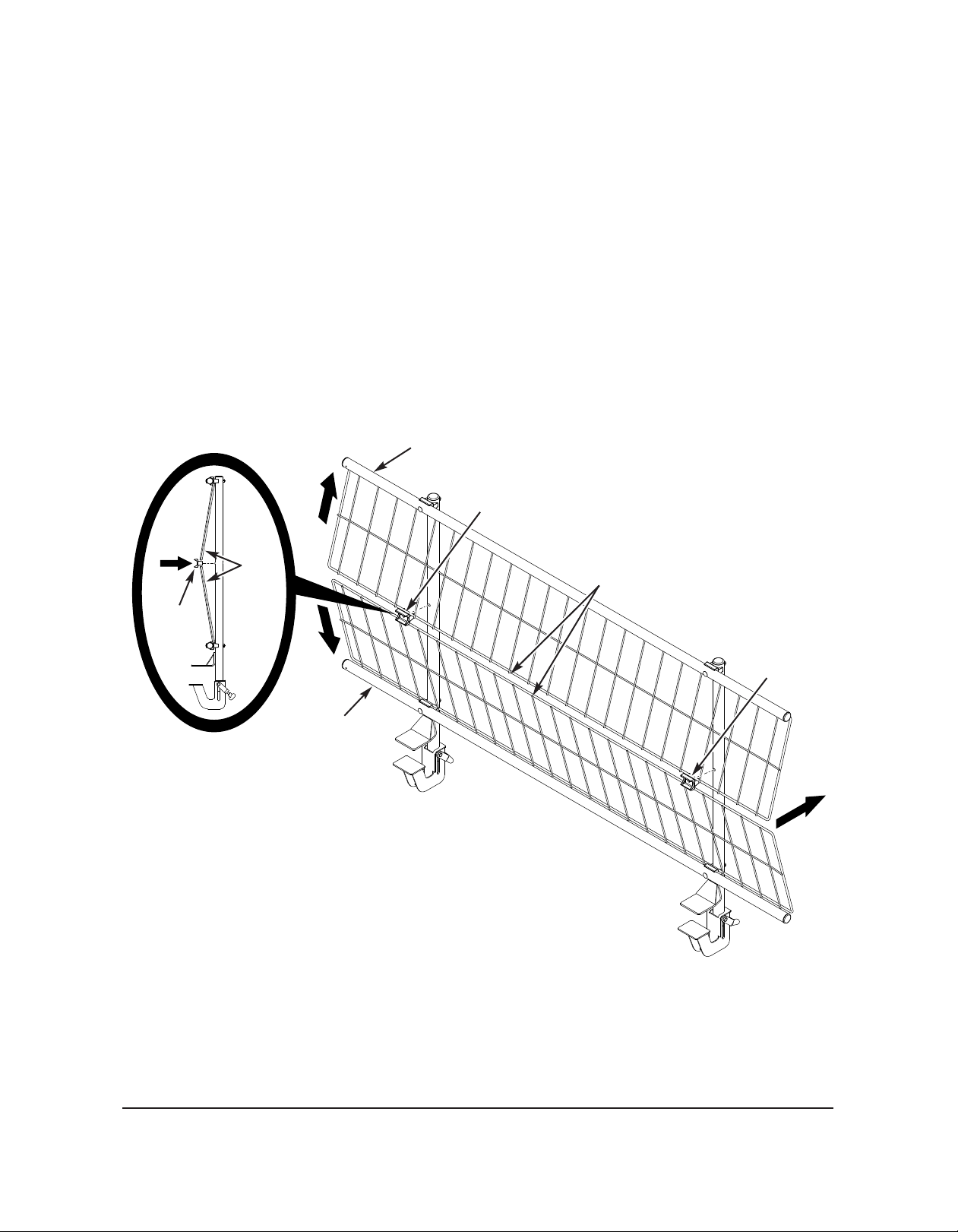

OPERATION

To attach the Guardrail to the stage deck:

1. Be sure that the Lower Slide at the base of both Upright Weldments

are in the Open Position.

To move the Lower Slide to the Open Position:

a. Loosen the Knob.

b. Rotate the Pivot Lock back from the Lower Slide.

c. Move the Lower Slide down to the Open Position.

2. Using two people, lift the Guardrail Assembly to rest on the stage deck as shown.

The Lower Slides should fit under the edge of the stage deck and be tight against the

bottom of the stage deck when in the closed position.

!

CAUTION

Two people are required to lift the

Guardrail Assembly onto the stage deck.

3. Move the Lower Slides to the Closed Position:

a. Move the Lower Slide up to the Closed Position.

b. Rotate the Pivot Lock over the Lower Slide.

c. Tighten the Knob.

Lower Slide

Closed Position

Lower Slide

Open Position

Knob

4” (10 cm)

Maximum Gap

Pivot

Lock

!

WARNING

The Guardrail Assembly is not secure

until it is locked into the Closed

Position on the stage deck as specified.

If multiple Guardrail Assemblies with Optional Infill Panels are being attached,

the gap between them can be no more than 4” (10 cm) apart as shown.

4

Loading...

Loading...