Page 1

Contents

Important User Information � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2

General �����������������������������������������2

Manufacturer �������������������������������������2

Intended Use �������������������������������������2

Warranty ����������������������������������������2

Before Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 2

Overview ����������������������������������������2

Before You Begin ���������������������������������2

Safety Precautions � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Required Tools� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Fastener Parts List � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Wall Fasteners - Not Supplied � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Layout Congurations � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Locker Options � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

Wall Mount Conguration Locker Components � � � � � � � � � � � � � � � 8

Island Mount Conguration Locker Components � � � � � � � � � � � � � 9

Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 10

Unpacking ���������������������������������������10

Leveling �����������������������������������������11

Connect All Locker Sides Together ��������������������14

Connect Locker Backs Together ����������������������16

Secure Lockers to Back Wall ������������������������17

Secure Island Mount Lockers ������������������������18

End Cover Panel Option � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 19

Assembly ����������������������������������������19

Single End Cover Attachment ������������������������20

Island End Cover Attachment ������������������������21

Helmet and Shoulder Pad Topper Option � � � � � � � � � � � � � � � � � � � 22

Finalize Installation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Care and Maintenance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

Replacement Parts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 24

Installation Instructions

Rival™ Athletic Locker

Visit gearboss.com/rival-lockers.php for detailed instructions and videos.

Note: Please read and understand these instructions before starting the installation�

Note: If you need additional information, contact Wenger Corporation using the information below�

©Wenger Corporation 2019 Printed in USA 2019-02 Part #243A242-01

Wenger Corporation, 555 Park Drive, P�O� Box 448, Owatonna, Minnesota 55060-0448

Questions? Call�����USA: (800) 4WENGER (493-6437) • Worldwide: +1-507-455-4100 • wengercorp�com

Page 2

Important User Information

General

Copyright © 2019 by Wenger Corporation

All rights reserved� No part of the contents of this manual may be reproduced, copied, or transmitted in any form

or by any means including graphic, electronic, or mechanical methods or photocopying, recording, or information

storage and retrieval systems without the written permission of the publisher, unless it is for the purchaser’s

personal use�

Printed and bound in the United States of America�

The information in this manual is subject to change without notice and does not represent a commitment on the

part of Wenger Corporation� Wenger Corporation does not assume any responsibility for any errors that may

appear in this manual�

In no event will Wenger Corporation be liable for technical or editorial omissions made herein, nor for direct, indirect,

special, incidental, or consequential damages resulting from the use or defect of this manual�

The information in this document is not intended to cover all possible conditions and situations that might occur�

The end user must exercise caution and common sense when assembling or installing Wenger Corporation

products� If any questions or problems arise, call Wenger Corporation at 1-800-887-7145�

Manufacturer

The GearBoss Rival™ Athletic Locker is manufactured by:

Wenger Corporation

555 Park Drive

Owatonna, MN 55060

(800) 4WENGER (493-6437) • +1 (507) 455-4100

www�wengercorp�com

Intended Use

· This product is intended for indoor use in normal ambient temperature and humidity conditions

— it must not be exposed to outside weather conditions�

· This product is intended to be installed only as described in these instructions�

Warranty

This product is guaranteed free of defects in materials and workmanship for ve full years from date of

shipment� A full warranty statement is available upon request�

Before Installation

Overview

· This system should be installed only by skilled technical persons, and only after carefully studying these

instructions�

· It is suggested that the lockers are setup in a space that is large enough to safely handle the cartons,

parts and accessories�

· Inspect the condition of the wall and oor where the lockers will be located.

If the wall is not straight, establish a reference line so that the fronts of all lockers will line up�

Also, determine the highest point on the oor, which will establish the leveled height of each

row of lockers�

Before You Begin

· Read the complete installation procedure before beginning�

· Hardware packs may contain extra fasteners that will not be required on your lockers�

· At least two people are required to install the locker�

2

Page 3

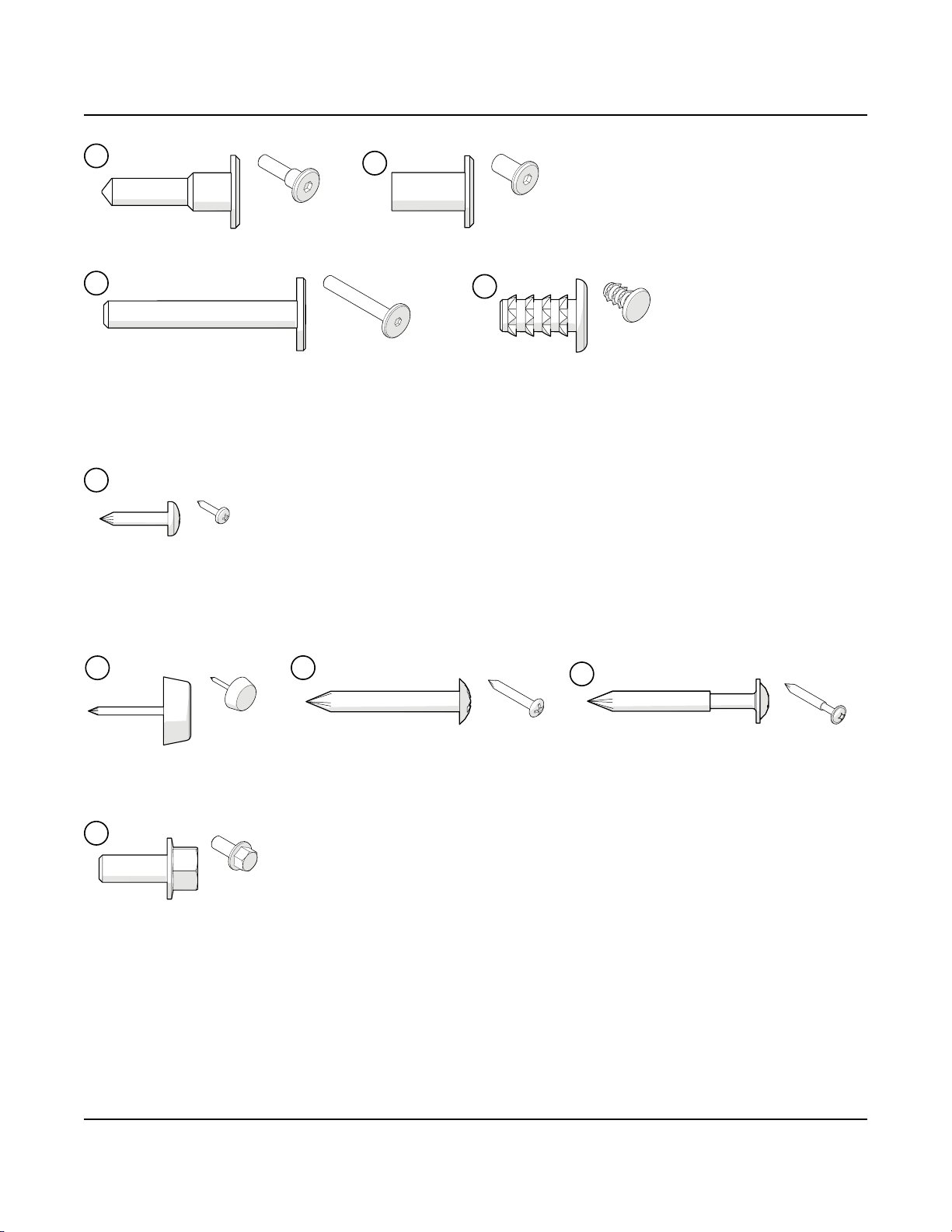

Safety Precautions

Throughout this document you may nd cautions and warnings which are dened as follows:

• WARNING: Failure to follow the instruction could result in serious injury or damage to property�

• CAUTION: Failure to follow the instruction could result in minor injury or damage to property�

Read all of these safety instructions before installation�

!

CAUTION

Make sure anyone installing

the lockers has read and

understands these instructions.

!

CAUTION

Make sure the lockers are

securely attached to walls

or adjoining lockers after

installation is complete.

Failure to comply with

Warnings and Cautions in this

document can result in damage

to property or serious injury.

Always wear safety glasses

and gloves when assembling

or installing the lockers.

Required Tools

· Power drill

· 1/4" Socket or insert bit

(to adjust levelers)

· 5/32" Hex key or insert bit

(to remove bottom shelf)

· 3/16" Hex key or insert bit

(to connect lockers and attach end cover panel)

· Phillips screwdriver or insert bit

(if attaching end cover panel)

!

CAUTION

!

CAUTION

!

CAUTION

To avoid damage and injury,

more than one person is

needed for installation.

!

CAUTION

Assemble and install the

lockers only on at, solid

surfaces.

· Box cutter

· Tape measure

· Carpenter’s level

· 5/32" Drill bit (if attaching end cover panel)

· Hammer or mallet (if attaching end cover panel)

· Hammer drill and bits (if anchoring to concrete)

· 9/16" Open end wrench

(if installing helmet and shoulder pad topper)

3

Page 4

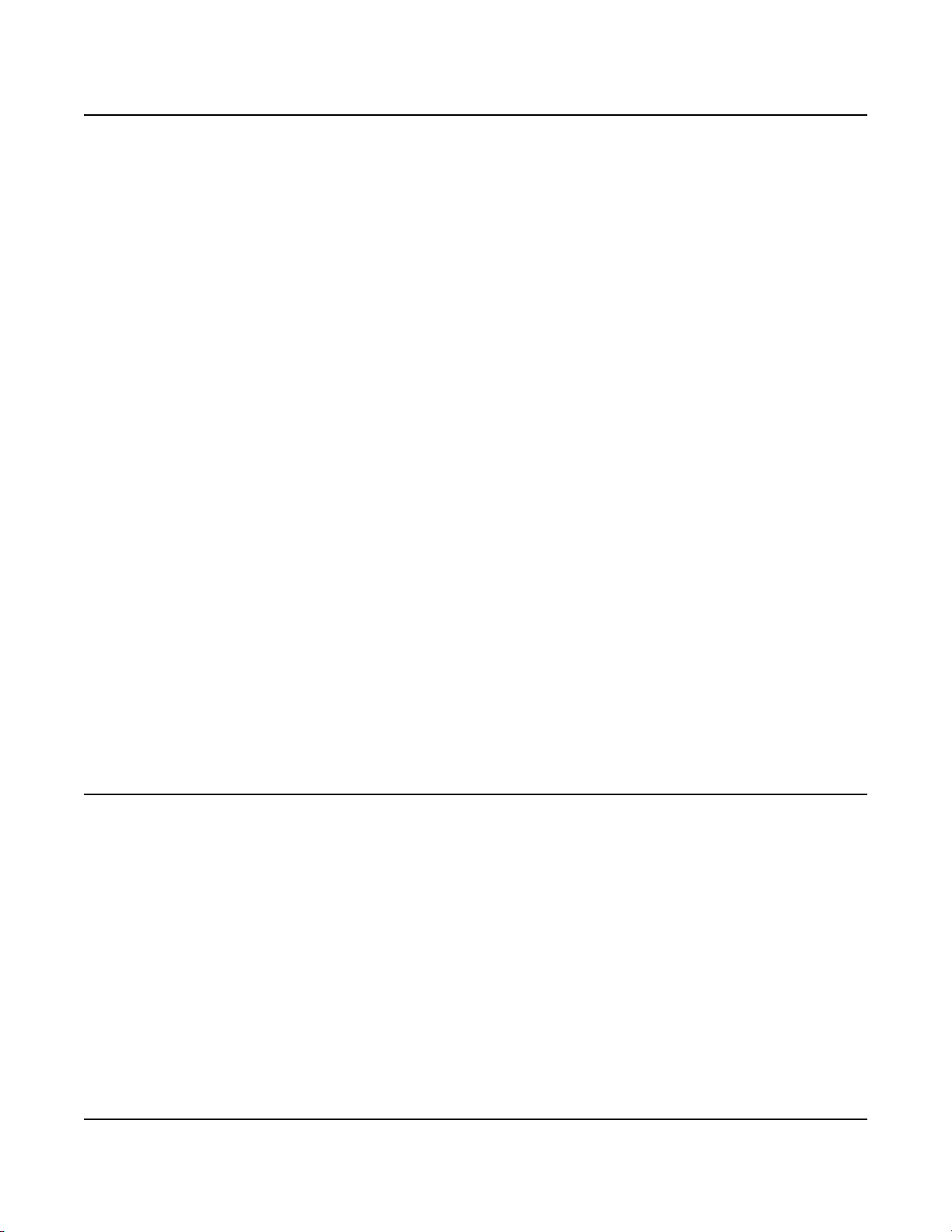

Fastener Parts List

Locker Connection Fasteners*

3

4

1/4-20 x 1.181"

Connector Bolt

10

1/4-20 x 1.77"

Machine Screw

Wall or Floor Bracket Fasteners*

14

#8 x 5/8"

Pan Head Screw

End Cover Panel Accessory Fasteners*

6

8

1/4-20

Cap Nut

11

1/4-20

Insert Nut

9

#8 x 1-1/4"

Tack Glide

Truss Head Screw

Helmet and Shoulder Pad Topper Accessory Fasteners*

20

3/8-16 x 3/4"

Flange Bolt

*Depending on conguration, not all fasteners may be used.

4

#8 x 1-3/8"

Wood Screw

Page 5

Fasteners - Not Supplied

Because materials and construction of oors and walls can vary, fasteners for attaching the locker

to the structure are not provided�

The installer must choose the appropriate fastener and follow the manufacturer’s instructions�

!

WARNING

Inferior or improperly installed fasteners

could cause the lockers to tip over.

Determine the construction of the walls and/or oor.

If the lockers will be attached to the wall, no attachment to the oor is required.

If the lockers will be installed back-to-back in the middle of a room, attachment to the oor is required.

Locker Fastener Guidelines:

· If the oor is wood construction, attachment should be by sheet metal or lag screws (#10 minimum).

· If the oor is concrete, attachment should be by concrete screw (Tapcon), or sheet metal screws

(#10 minimum) into metal or plastic inserts�

· If the wall is wood stud-and-drywall construction, attachment should be by lag screws

(1/4" minimum) into every stud�

· If the wall is metal stud-and-drywall construction, attachment should be by toggle bolt

(1/4" minimum) into every stud�

· If the wall is concrete block construction, attachment should be by concrete screw (Tapcon) or

toggle bolt (1/4" minimum), spaced no more than 16" apart�

· If the wall is poured concrete construction, attachment should be by Concrete screw (Tapcon) or

wedge-type concrete anchors, spaced no more than 24" apart�

Note: Each wall and oor connection must be rated for a minimum of 500 lb of tension.

Other fasteners may be used if the connection strength requirement is met�

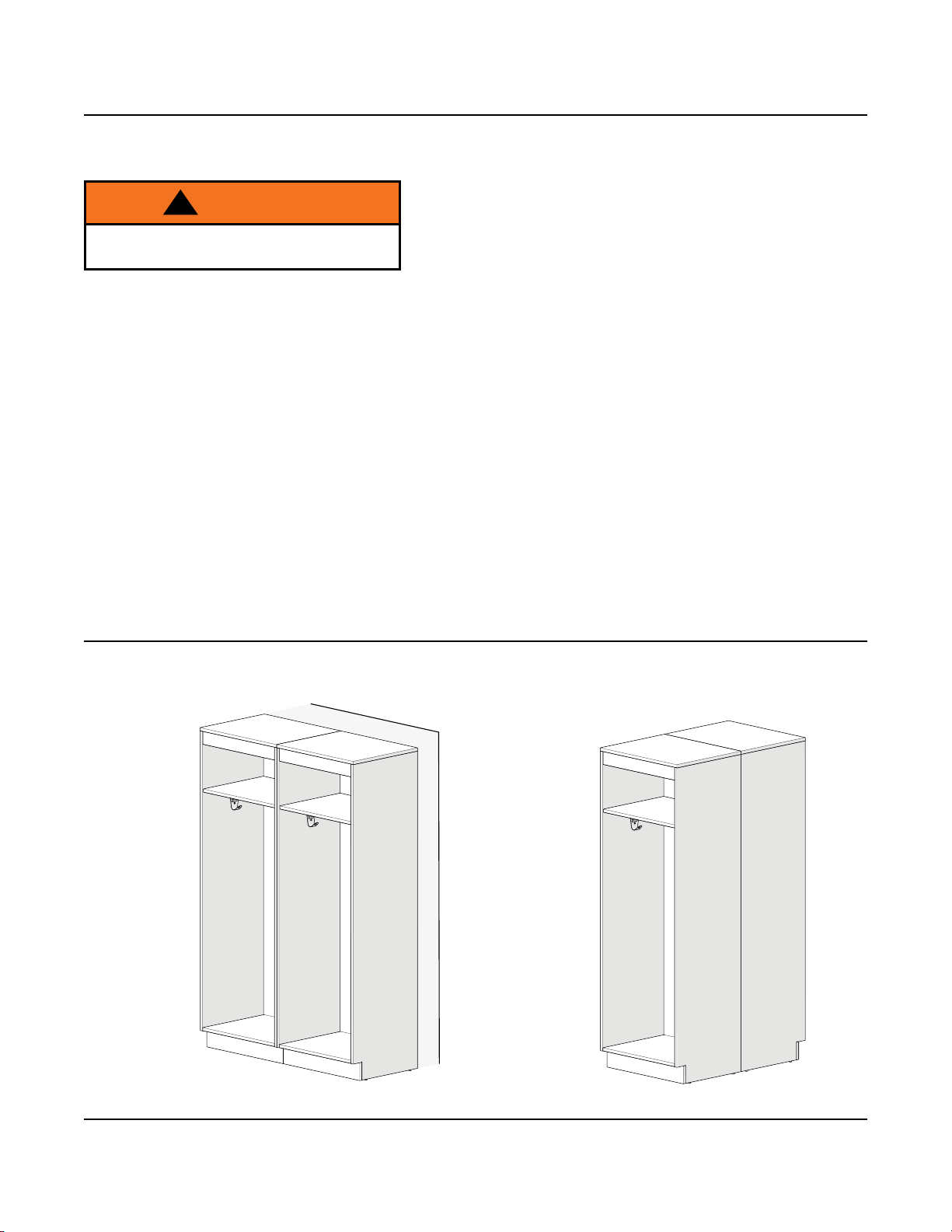

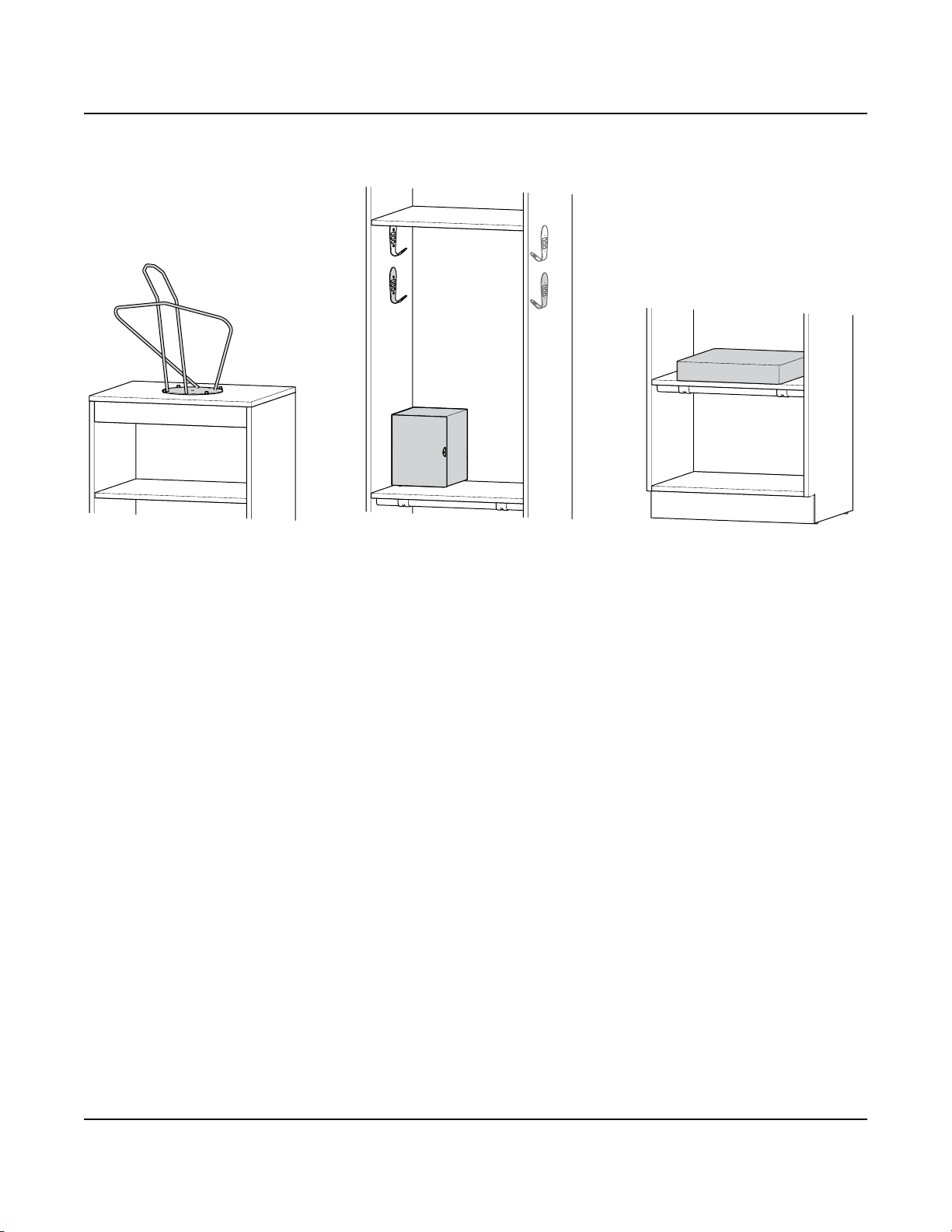

Layout Congurations

Lockers can be installed in wall mount or island mount congurations.

Be sure to follow the appropriate installation instructions on the following pages�

Back Wall

Wall Mount

Configuration

Island Mount

Configuration

5

Page 6

Locker Options

Customer Installed Options

The following options are installed during the locker installation�

Helmet and Shoulder Pad Topper

(see page 22)

Includes two additional Garment Hooks

ADA Compliant Locker

(see separate installation instructions)

Padded Seat Cushion

Available for

Fixed or Hinged Seats

(see separate installation instructions)

6

Page 7

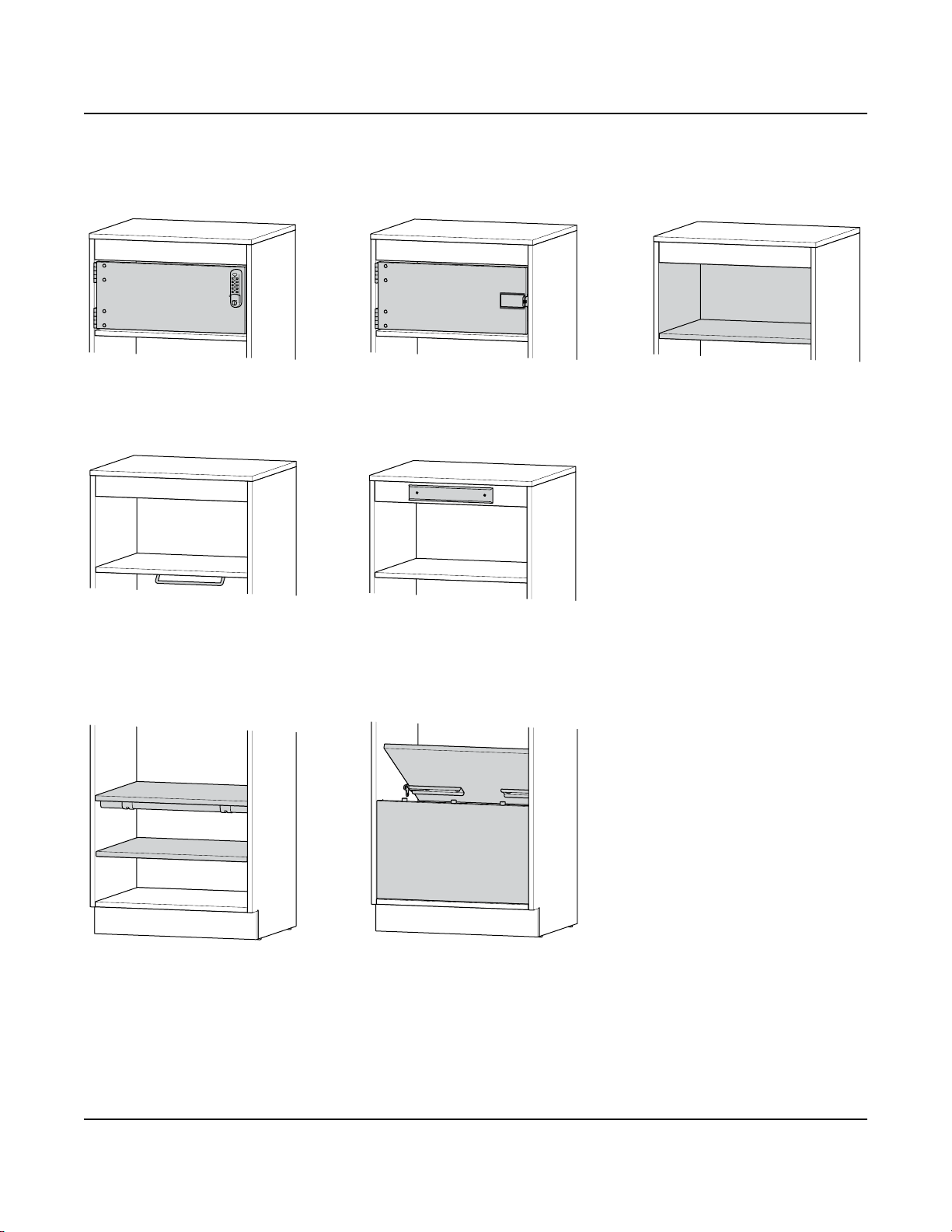

Locker Options (continued)

Pre-installed Options

The following options may be installed on the locker prior to shipping with no assembly required�

Cubby Compartment with

Programmable Digital Lock

Flip-down

Garment Bar

Cubby Compartment with

Hasp Lock

Nameplate

Housing

Cubby Compartment with

No Door

Fixed Seat with

Open Foot Locker

Shelf is available for

Open Foot Locker

Hinged Seat with

Enclosed Foot Locker

7

Page 8

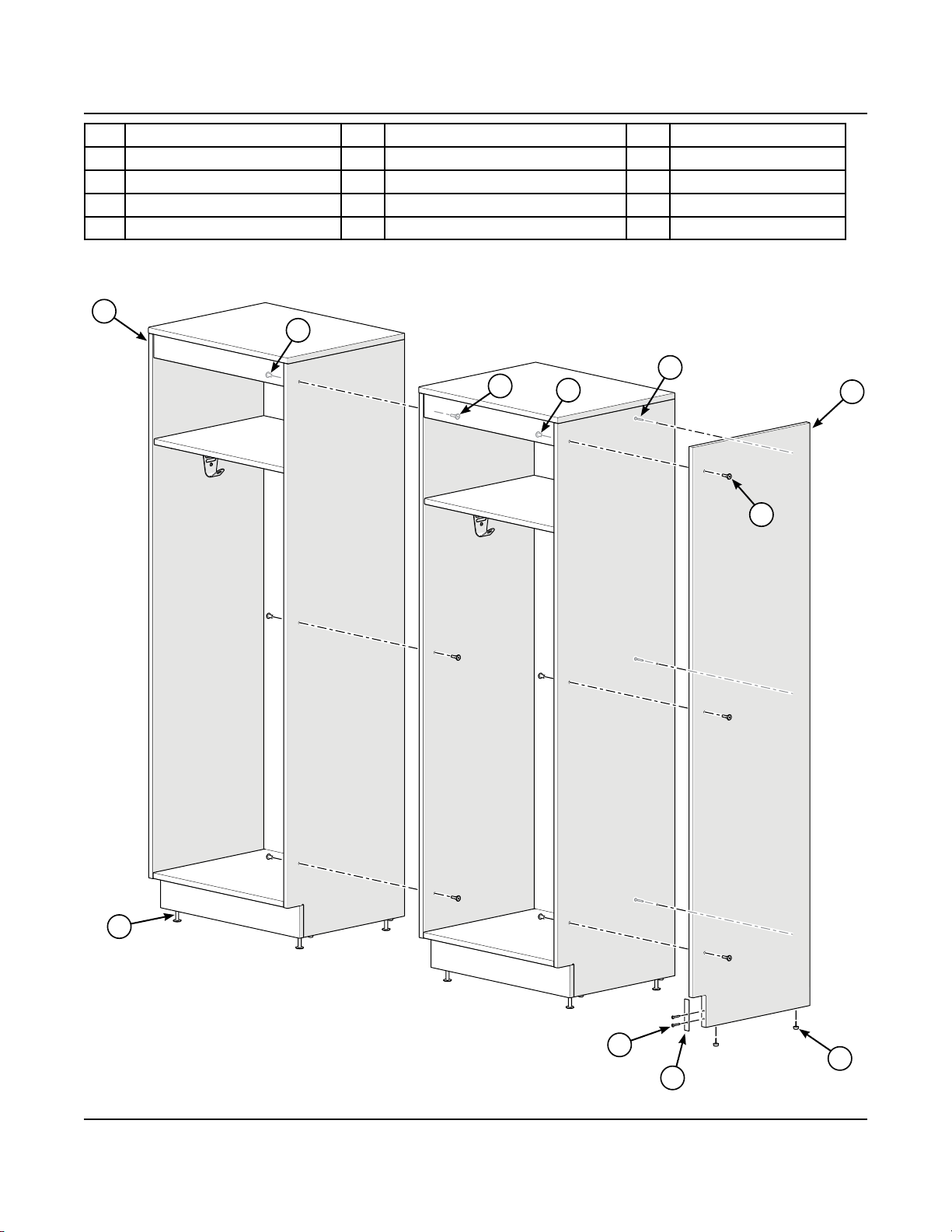

Wall Mount Conguration Locker Components

Item Description Item Description Item Description

1 Locker Unit 5 Single End Cover Panel (Optional) 9 #8 x 1-3/8" Wood Screw

2 Leveler 6 Tack Glide

3 1/4-20 x 1�181" Connector Bolt 7 Toe Kick Cover Plate

4 1/4-20 Cap Nut 8 #8-15 x 1-1/4" Truss Head Screw

1

4

9

3

4

3

5

2

8

7

6

8

Page 9

Island Mount Conguration Locker Components

Item Description Item Description Item Description

1 Locker Unit 6 Tack Glide 11 1/4-20 Insert Nut

2 Leveler 7 Toe Kick Cover Plate 12 Island End Cover Panel (Optional)

3 1/4-20 x 1�181" Connector Bolt 8 #8-15 x 1-1/4" Truss Head Screw

4 1/4-20 Cap Nut 10 1/4-20 x 1�77" Machine Screw

3

12

3

4

1

10

10

11

4

11

8

7

6

2

9

Page 10

Installation

Unpacking

1� Unpack each individual locker unit�

Use more than one person and take care to avoid damage�

!

CAUTION

More than one person is needed

to unpack the lockers.

2� Set each locker unit upright�

10

Page 11

Installation

Leveling

The lockers must be leveled to each other before attaching them together�

1� The bottom shelf must be removed to access the

levelers�

a� Remove the two screws that secure the shelf

to the locker�

b� Pull the shelf out�

c� Set the shelf and screws aside to reattach

later�

Do not reattach the bottom shelf until the

lockers are attached to the structure.

2� Move the lockers to be within a few inches of their

nal location according to the layout drawings.

3� Turn the levelers to adjust the height at each

corner�

Continued on the next page.

Turn to

adjust height

Remove

screws

Pull

shelf out

11

Page 12

Installation (continued)

Leveling (continued)

4. a. Check the level of the entire oor where

the lockers will be installed�

b. Determine the highest point of the oor in

that area�

c� The locker installed at this highest location

will be the reference for all other lockers

to be leveled against�

5� Adjust the levelers on one side

until the front edges of the

locker side panels

are plumb

(side-to-side)�

6� Measure A and B and adjust

the front levelers until

A=B (+1/32 inch)�

12

Page 13

Installation (continued)

Leveling (continued)

7� Adjust both front levelers equally until the front

edges of the locker are plumb (front-to-back)�

9� Adjust the levelers on the adjacent locker so it will

line up with the top of the highest locker�

Conrm that adjacent lockers are level using a

wall bracket or carpenter’s level across the tops�

Adjacent lockers must be

level along tops

Wall bracket or

carpenter’s level

8� Recheck that A=B�

Readjust if necessary

(repeat steps 4-6)�

10� Repeat steps 5-9 for the remaining lockers�

13

Page 14

Installation (continued)

This procedure is for securing the sides of adjacent lockers.

STOP

Island mount lockers will require additional steps on the next pages.

For standard installations only, see separate seismic instructions if required.

Connect All Locker Sides Together

There are three holes at the front of the side panels for securing adjacent lockers together�

See Detail A1. All adjacent locker sides must be connected together.

See Detail A2. Island mount lockers must also be connected together at the back in addition to

the sides.

!

CAUTION

All adjacent locker sides must

be connected together.

Wall

Side Locker

Connections

Back Locker

Connections

Detail A1 - Top View of Wall Mounted Lockers

Side Locker

Connections

Back Locker

Connections

Side Locker

Connections

Detail A2 - Top View of Island Mounted Lockers

Back Locker

Connections

14

Page 15

Installation (continued)

Connect All Locker Sides Together (continued)

1� Check that each locker is level vertically and adjacent lockers are level along the tops�

Make any necessary leveling adjustments before connecting the locker sides together�

2� Be sure that the front pilot holes in the end panels are aligned and connect the locker units

together using 1/4-20 x 1�181" connector bolts (3) and 1/4-20 cap nuts (4)�

Each locker must be

level vertically and

adjacent lockers must be

level along the tops

1/4-20

Cap Nut

(4)

1/4-20 x 1.181"

Connector Bolt

(3)

3� If installing island mounted lockers continue to the next page�

If installing wall mounted lockers skip to page 17�

15

Page 16

Installation (continued)

This procedure is for securing the backs of adjacent island mount lockers.

STOP

The sides of the lockers must already be connected as described on the previous page.

This instruction is for standard installation only.

For seismic installation, see the instructions included with the Seismic Island Kit 243A028.

!

CAUTION

In an island conguration, the adjacent locker backs must

also be connected in addition to the sides of the lockers.

Connect Locker Backs Together (island mount lockers only)

NOTE: If lockers are installed in a back-to-back conguration, two holes must be drilled through

both lockers to secure the adjacent backs together�

NOTE: Make sure the locker sides are secured together before attaching them back-to-back�

1� From inside one locker, drill two 3/8" holes 3" down

from the top of the inside through the backs of both lockers�

These holes should be a minimum of 4" in from

the sides of the locker�

2� Use a plastic mallet to pound

1/4-20 insert nuts (11) from the inside

of one of the lockers and install

1/4-20 x 1�77" machine screws (10)

from the other side and tighten�

3� Skip to page 18�

1/4-20 x 1.77"

Machine Screw

(10)

Drill through

both lockers

1/4-20

Insert Nut

(11)

3" Down from

inside top

Minimum of

4" from

inside edges

16

Page 17

Installation (continued)

This procedure is for securing wall mount lockers to the structure.

STOP

See the next page for securing island mount lockers to the structure.

This instruction is for standard installation only.

For seismic installation, see the instructions included with the Seismic Wall Kit 243A024.

!

CAUTION

In addition to the sides of the lockers being secured,

the locker backs must also be attached to a back wall.

Inferior or improperly installed fasteners

could cause the lockers to tip over.

!

WARNING

Secure Lockers to Back Wall (wall mount lockers only)

Because materials and construction of walls can vary, fasteners for attaching the lockers to the structure

are not provided� The installer must choose the appropriate fastener and follow the manufacturer’s instructions�

See “Fasteners - Not Supplied" on page 5 for more information�

NOTE: At least every 2nd locker must be secured to the back wall�

NOTE: Make sure all adjacent locker sides are

secured together before attaching them

to the back wall�

1� Place the wall bracket (13) onto the top

of the locker and position it to be ush

with the back wall�

The brackets have extra holes for the

best t on the top of the locker.

2� Secure the bracket to the locker

using a minimum of two

#8 x 5/8" pan head screws (14)�

3� Secure the wall bracket to the wall

using the appropriate fasteners�

4� Reattach the bottom shelves

in the lockers�

Wall Bracket

(13)

Attach to the

locker using

a minimum of two

#8 x 5/8"

Pan Head Screws

(14)

Reattach

screws

Slide

shelf in

5� Install any optional equipment

as shown on the following pages

before continuing to

“Finalize Installation" on page 23�

17

Page 18

Installation (continued)

This procedure is for securing island mount lockers to the structure.

STOP

See the previous page for securing wall mount lockers.

This instruction is for standard installation only.

For seismic installation, see the instructions included with the Seismic Island Kit 243A028.

!

CAUTION

In addition to the sides and backs of the lockers being

secured, the lockers must also be attached to the oor.

Inferior or improperly installed fasteners

could cause the lockers to tip over.

!

WARNING

Secure Island Mount Lockers

Because materials and construction of walls can vary, fasteners for attaching the lockers to the structure

are not provided� The installer must choose the appropriate fastener and follow the manufacturer’s instructions�

See “Fasteners - Not Supplied" on page 5 for more information�

NOTE: The end of every locker bank must be secured to the oor.

NOTE: Make sure all the lockers are secured together before

attaching them to the oor.

1� At the ends of the locker bank, attach one

wall bracket (13) to the bottom inside of

each locker using

#8 x 5/8" pan head screws (14)�

The brackets have extra holes for the

best t.

2� Secure the bracket to the locker

using #8 x 5/8" pan head screws (14)�

3. Secure the bracket to the oor using

the appropriate fasteners�

4� Reattach the bottom shelves in the

lockers�

Reattach

screws

Slide

shelf in

5� Install any optional equipment

as shown on the following pages

before continuing to

“Finalize Installation" on page 23�

Wall

Bracket

(14)

Attach to the

locker using

#8 x 5/8"

Pan Head Screws

(14)

18

Page 19

End Cover Panel Option

End cover panels may be attached to cover exposed ends of locker formations.

STOP

For Single End Cover Panel attachment, see page 20.

For Island End Cover Panel attachment, see page 21.

Assembly

1� Carefully remove the end cover panel from the package�

2� Pound two plastic tack glides (6) into the bottom edge, centered and 2"-3" from each end�

3� Attach one toe kick cover plate (7) to the bottom notched edges of the end cover panel using

two #8-15 x 1-1/4" truss head screws (8)�

Single end cover panels (5) use one cover plate.

Island end cover panels (12) use two cover plates.

4� If attaching a single end cover panel, go to the next page�

If attaching an island end cover panel, skip to page 22�

Single End

Cover Panel

(5)

2"-3"

Pound in

Tack Glides

Tack

Glides

(6)

Island End

Cover Panel

(12)

Toe Kick

Cover Plate

(7)

#8 x 1-1/4"

Truss Head Screws

(8)

19

Page 20

End Cover Panel Option (continued)

Single End Cover Panel Attachment

1� To further secure the single end cover panel, screws must be installed through the rear of the end locker�

a� From the outside of the locker at the end of the locker formation, measure and mark for three holes�

These holes should be parallel with the existing holes in the front of the locker and 2-1/2"-3" in

from the back of the locker as shown�

b� Drill three 5/32" holes completely through the locker�

2. Raise the single end cover panel into position covering the cabinet side and ush with the front edge.

Be sure that the front holes in the single end cover panel (5) are aligned with the front holes in the locker�

3� Attach the front of the single end cover panel to the locker using

three 1/4-20 x 1�181" connector bolts (3) and 1/4-20 cap nuts (4)�

4� Attach the back of the end cover panel using three #8 x 1-3/8" wood screws (9)

through the locker holes drilled in Step 1 and into the end cover panel�

Single End

Cover Panel

(5)

End of

locker formation

2-1/2"-3"

Existing

hole

Existing

hole

5/32" hole

5/32" hole

Drill new

Drill new

End of

locker formation

No

existing

hole

Existing

hole

New drilled

hole

Existing

hole

Existing

hole

Drill new

5/32" hole

2-1/2"-3"

#8 x 1-3/8"

Wood Screw

(9)

20

1/4-20 x 1.181

1/4-20

Cap Nut

(4)

!

CAUTION

Connector Bolt

Overtightening the screws could

cause them to poke through the

outside of the end cover panel.

(3)

Page 21

End Cover Panel Option (continued)

Island End Cover Panel Attachment

1. Raise the single end cover panel into position covering the cabinet side and ush with both edges.

Be sure that both sets of pilot holes in the island end cover panel (12) are aligned with the

pilot holes in both lockers at the end of the formation�

2� Attach both edges of the island end cover panel to both lockers using

six 1/4-20 x 1�181" connector bolts (3) and 1/4-20 cap nuts (4)�

Island End

Cover Panel

(12)

1/4-20

Cap Nuts

(4)

1/4-20 x 1.181"

Connector Bolts

(3)

21

Page 22

Helmet and Shoulder Pad Topper Option

A helmet and shoulder pad topper option can be installed on top of the locker�

1� Place the helmet and shoulder pad topper (19) to be centered over the four holes on top of the locker�

2. Secure the helmet and shoulder pad topper to the top of the locker using four 3/8-16 x 3/4" ange bolts (20)

into the already installed insert nuts�

NOTE: The lips of the ange bolts hold it in place as shown.

Helmet and

Shoulder Pad Topper

Insert

Nuts

(19)

3/8-16 x 3/4"

Flange Bolt

(20)

Lips of the ange bolts hold

the helmet and shoulder

pad topper in place

22

Page 23

Finalize Installation

Plug Empty Holes

Any unlled holes in the locker sides can be plugged by

either pushing in 1/4-20 Insert Nuts (11)

or glueing in 1/4-20 Cap Nuts (4)�

Tighten All Fasteners

Check to see that all fasteners used for the installation are tight�

Tighten All

Fasteners

Push-in 1/4-20 Insert Nuts (11)

or

Glue-in 1/4-20 Cap Nuts (4)

1/4-20

Cap Nut

(4)

Care and Maintenance

Electronic Lock

If the locker has an electronic lock, the default user code is 2244�

Contact Wenger for information about updating the codes�

Cleaning

For removal of mild stains and mild scu marks, panels and

shelves may be cleaned using an all-purpose household cleaner

or just simple mild soap and water�

For heavier scu marks, ink stains, felt pen and magic marker

stains, or other tough stains; use a nonabrasive cleaner,

or an industrial all-purpose cleaner�

Ammoniated or vinegar-based glass cleaners also work well

for these stains�

Do not use harsh abrasive cleaners, as permanent damage

could occur to the panel surface�

Be sure to quickly remove all cleanser residues with water

and wipe dry with a soft cloth�

1/4-20

Insert Nut

or

(11)

Tighten All

Fasteners

Check

fasteners

Check

fasteners

Humidity Control

To insure longevity of panel performance, maintain the relative

humidity between 25% - 55% at the permanent installation site�

Fasteners

Check fasteners after each season to ensure

that they are not loose or dislodged�

23

Page 24

Replacement Parts

Item Description Item Description Item Description Item Description

1 Hook Bracket 6 Nameplate* 11 Padded Seat Cushion* 16 Top Shelf

2 Garment Bar* 7 Cubby Door* 12 Left Side Panel 17 Back Panel

3 Fixed Seat* 8 Hasp Lock* 13 Marquee Panel 18 Bottom Shelf

4 Foot Locker Shelf* 9 Hinged Seat* 14 Top Panel 19 Toe Kick Panel

5 Helmet and Shoulder

Pad Topper*

*Optional component

10 Digital Lock* 15 Right Side Panel 20 End Cover Panel

5

14

6

16

7

8

1

2

3

4

9

17

13

12

10

15

11

18

20

24

19

Loading...

Loading...