Page 1

Assembly Instructions

Corner Cabinet and Options

Note: Please read and understand these instructions before assembling the parts.

Note: Assemble the Corner Cabinet in the room that it will be used in.

The assembled Corner Cabinet is typically too large to fit through a doorway.

Note: Assembly requires two people.

Note: Remove all items from the shipping cartons and arrange them in a convenient location.

Refer to the illustrations on the following pages.

If you need additional information, contact Wenger Corporation using the information below.

©Wenger Corporation 2014 Printed in USA 08/14 Part #250A893-05

Wenger Corporation, 555 Park Drive, P.O. Box 448, Owatonna, Minnesota 55060-0448

Questions? Call.....USA: 1-800-4WENGER (493-6437) • Worldwide: 1-507-455-4100 • www.wengercorp.com

CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Corner Cabinet Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Shelf/Hanger Bar Option Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Revolving Shelf Option Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Page 2

GENERAL

Copyright© 2014 by Wenger Corporation

All rights reserved. No part of the contents of this manual may be reproduced, copied, or transmitted in

any form or by any means including graphic, electronic, or mechanical methods or photocopying,

recording, or information storage and retrieval systems without the written permission of the publisher,

unless it is for the purchaser's personal use.

Printed and bound in the United States of America.

The information in this manual is subject to change without notice and does not represent a commitment

on the part of Wenger Corporation. Wenger Corporation does not assume any responsibility for any

errors that may appear in this manual.

In no event will Wenger Corporation be liable for technical or editorial omissions made herein, nor for

direct, indirect, special, incidental, or consequential damages resulting from the use or defect of this

manual.

The information in this document is not intended to cover all possible conditions and situations that might

occur. The end user must exercise caution and common sense when assembling or installing Wenger

Corporation products. If any questions or problems arise, call Wenger Corporation at 1-800-887-7145.

MANUFACTURER

The Corner Cabinet is manufactured by:

Wenger Corporation

555 Park Drive

Owatonna, MN 55060

1-507-455-4100 • 1-800-733-0393

www.wengercorp.com

WARRANTY

This product is guaranteed free of defects in materials and workmanship for ten full years from

date of shipment. A full warranty statement is available upon request.

2

SAFETY

Throughout this manual you will find Cautions and Warnings which are defined as follows.

• Warning means that failure to follow the instruction may result in serious injury or death.

•Caution means that failure to follow the instruction may result in injury or damage to property.

Read and understand the following safety instructions before installing the Cover Panel.

GENERAL

INSTALLATION

Always observe and comply

with Warnings and Cautions

posted on the system

equipment.

Always wear safety glasses

when assembling the Corner

Cabinet.

Make sure that anyone who

helps assemble the Corner

Cabinet has read and

understands this manual.

!

CAUTION

Installation and use of the

Corner Cabinet must always

comply with the information

contained in this manual.

!

CAUTION

!

CAUTION

!

CAUTION

IMPORTANT USER INFORMATION

Page 3

3

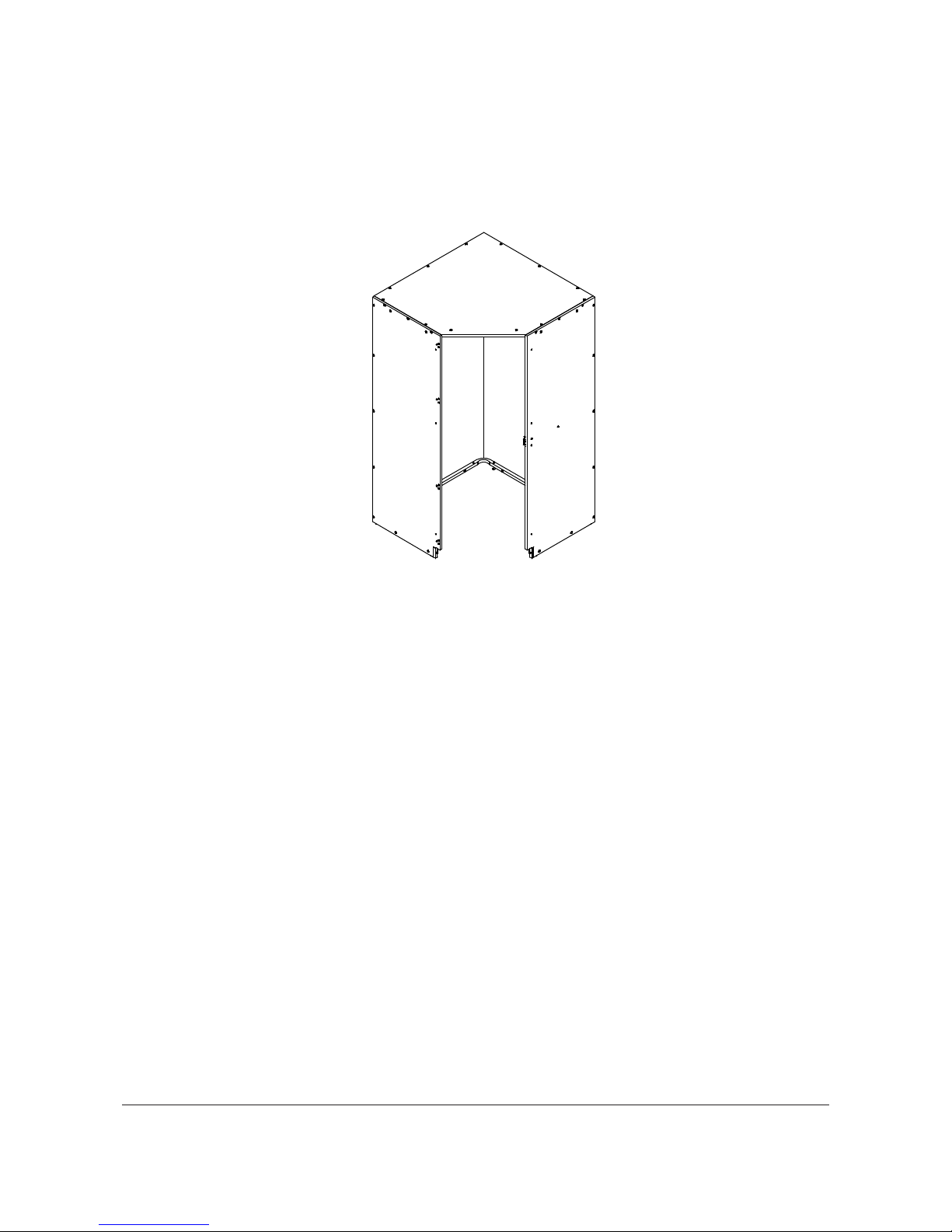

Corner Cabinet Assembly Instructions

CONTENTS

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Corner Cabinet Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Corner Cabinet Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Corner Cabinet Fasteners Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Corner Cabinet Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Level the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Assemble Cabinet Connector Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Door Assembly Fasteners Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Door Assembly Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Door Assembly Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Wood Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Grille Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Page 4

4

IMPORTANT USER INFORMATION

INSTALLATION

• The Wenger Corner Cabinet installation must comply with local building regulations and codes.

• Personnel installing the Wenger Corner Cabinet must comply with the Warnings and Cautions in

the Safety Section.

INTENDED USE

• The Wenger Corner Cabinet is intended for indoor use in normal ambient temperature and humidity

conditions — it must not be exposed to prolonged outside weather conditions.

• The Wenger Corner Cabinet is intended to be permanently installed only as described in this manual.

CORNER CABINET REQUIRED TOOLS

• 6-foot Ladder

• Carpenters Level

• Tape Rule

• Carpenters Square

• Variable Speed Drill

• Mallet

• Philips Screwdriver

•

7

/8” Open End Wrench

• Hex Insert Bit

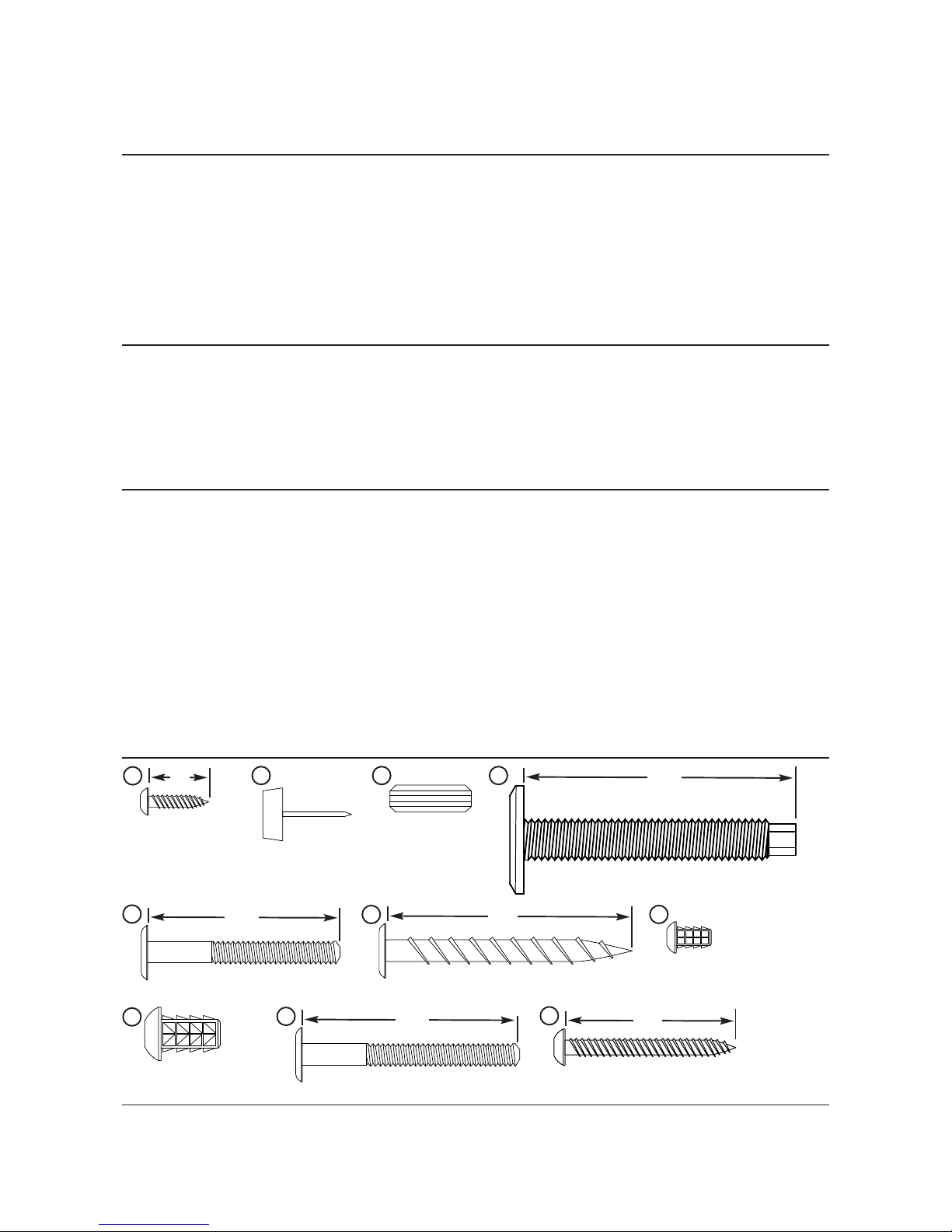

CORNER CABINET PARTS LIST

Item Description Part Number Item Description Part Number

1 Pan Head Screw X000045 12 Plastic Extrusion Trim Strip 145L460

2

Tube Plug, 11/8Square, 16 gauge

X001605 13

Hex Insert Bit, 5/32"

X001962

3 Tack Glide X001757 14 Bracket Connector, Cabinet 145A288

4 Wood Dowel X002540 15 Side Panel, RH, Corner Cabinet 250A145._

5

Leveler Glide, 3/8-16 x 21/2"

X002561 16 Side Panel, LH, Corner Cabinet 250A144._

6 Hex Socket Machine Screw 1.57" (40mm) 145L193 17 Back Panel, RH, Corner Cabinet 250A294._

7 Hex Socket Lag Screw 145R472 18 Back Panel, LH, Corner Cabinet 250A293._

8

Screw Insert, 8-32x7/16"

250A506._ 19 Top Panel, Corner Cabinet 250A214._

9 Screw Insert, 1/4-20 x 5/8" 146B507 20 Bottom Frame, Corner Cabinet 145R750

10 Hex Socket Machine Screw, 1.77" (45mm) 145L458 21 Upper Frame, Corner Cabinet 145R753

11

Pan Head Screw, oyster, 1-1/4" long

215B564 22 Filler Strips (one long, one short) 250A350._

23 Deflector Panel (use on Revolving Option) 250A284._

Screw Insert, 1/4-20 x 5/8”

Hex Socket Lag Screw

2”

7

Leveler Glide, 3/8-16 x 21/2”

21/2”

5

Pan Head Screw

5

/8”

1

Wood Dowel

4

9

Tack Glide

3

Pan Head Screw

11/4”

11

Hex Socket Machine Screw

1.77”

10

Screw Insert, 8-32 x 7/16”

(oyster)

8

Hex Socket Machine Screw

1.57”

6

FASTENERS PARTS LIST

The following tools must be supplied by the installer to install the Wenger Corner Cabinet:

Page 5

5

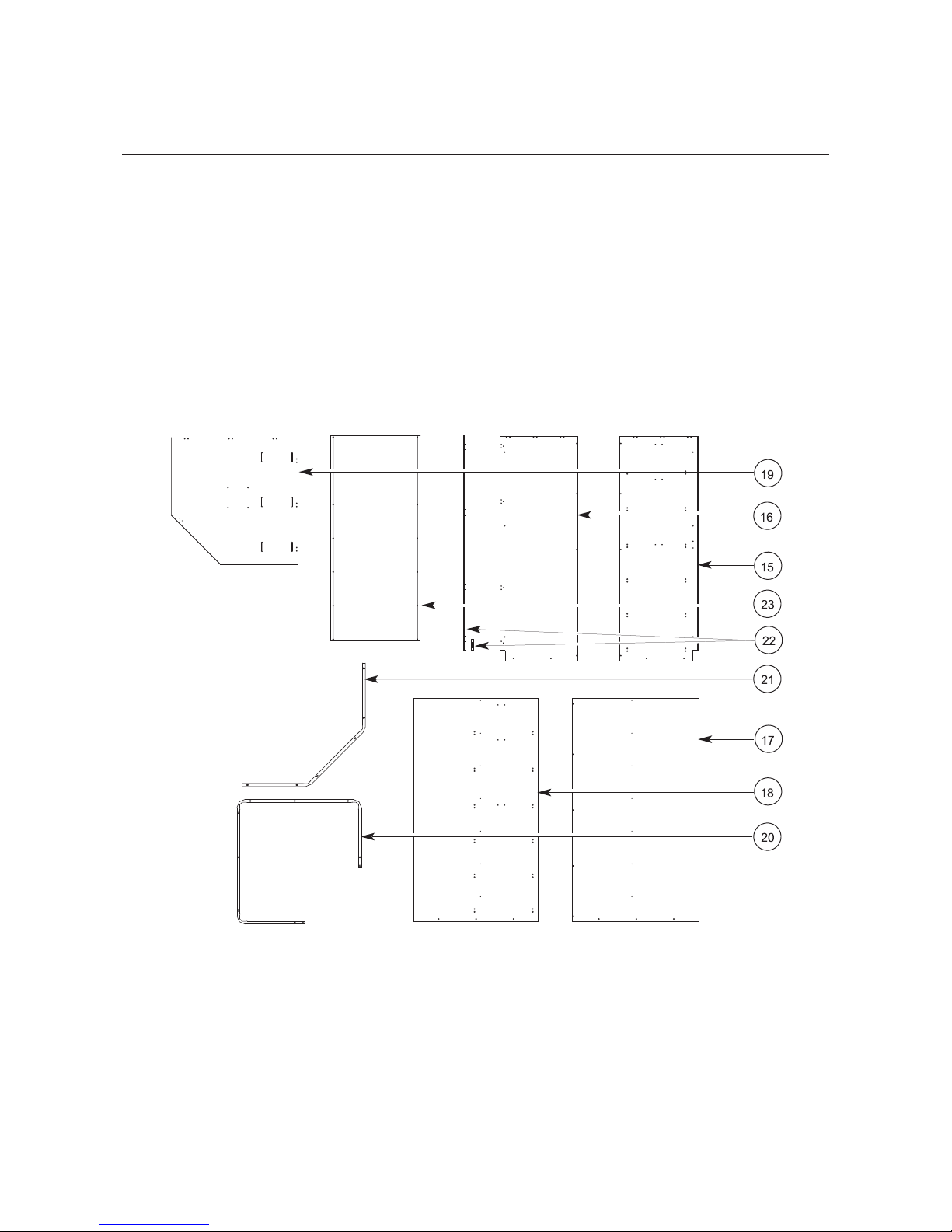

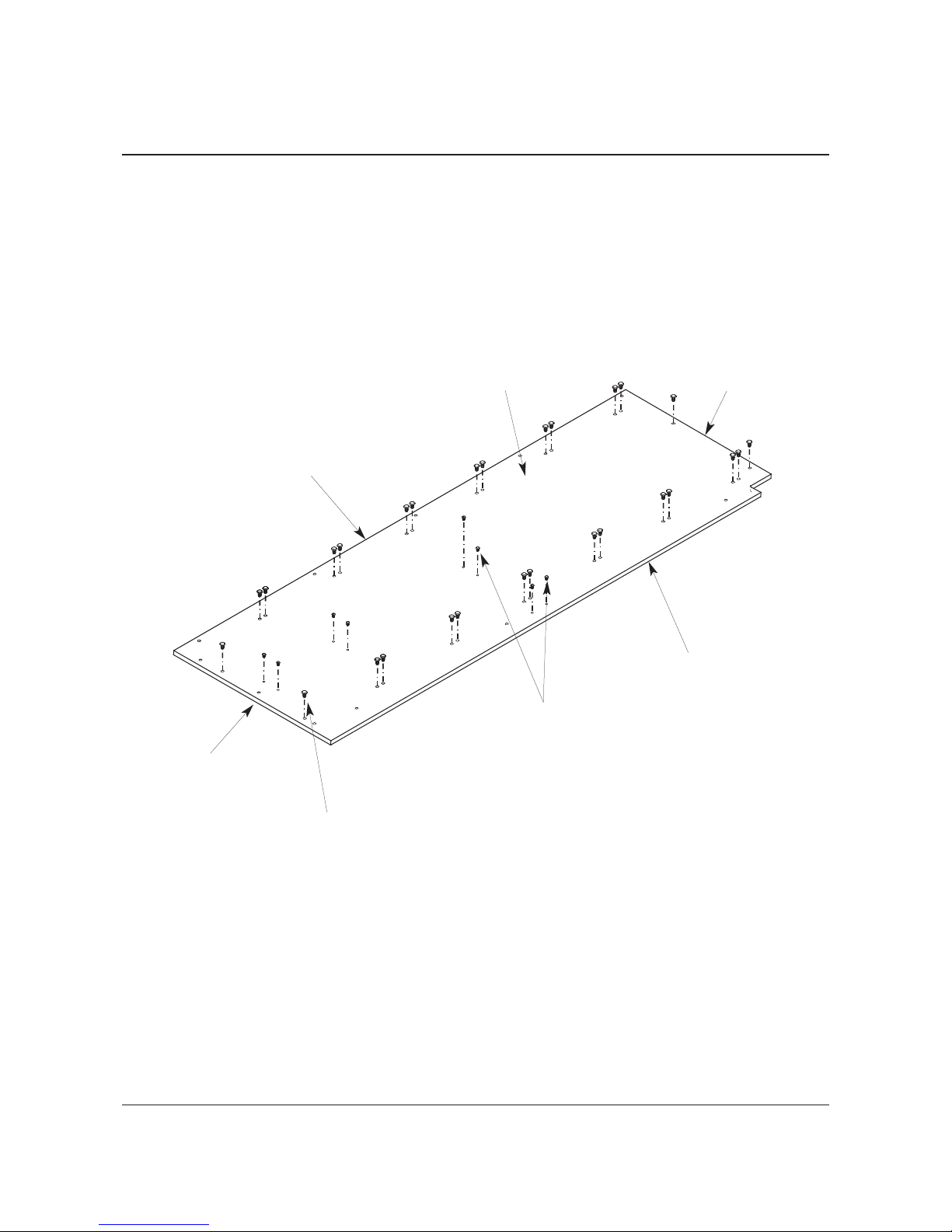

Before starting the Corner Cabinet assembly, do the

following.

1. Read and understand this assembly instruction.

2. Remove all items from the shipping carton and

arrange the parts as shown in the diagram below.

Make sure that all parts are present. Item

numbers refer to the Parts List on page 4 and the

table at the right.

3. Inventory the hardware package and make sure

that all required hardware is present. Discard any

items not used during the assembly.

Item Description

15 Right Hand Side Panel

16 Left Hand Side Panel

17 Right Hand Back Panel

18 Left Hand Back Panel

19 Top Panel

20 Bottom Frame

21 Upper Frame

22 Filler Strips

(one long/one short)

23 Deflector Panel*

* Use only with Revolving Options

CORNER CABINET ASSEMBLY

NOTE: Depending on Corner Cabinet configuration, hole positioning in the individual panels may vary.

Page 6

6

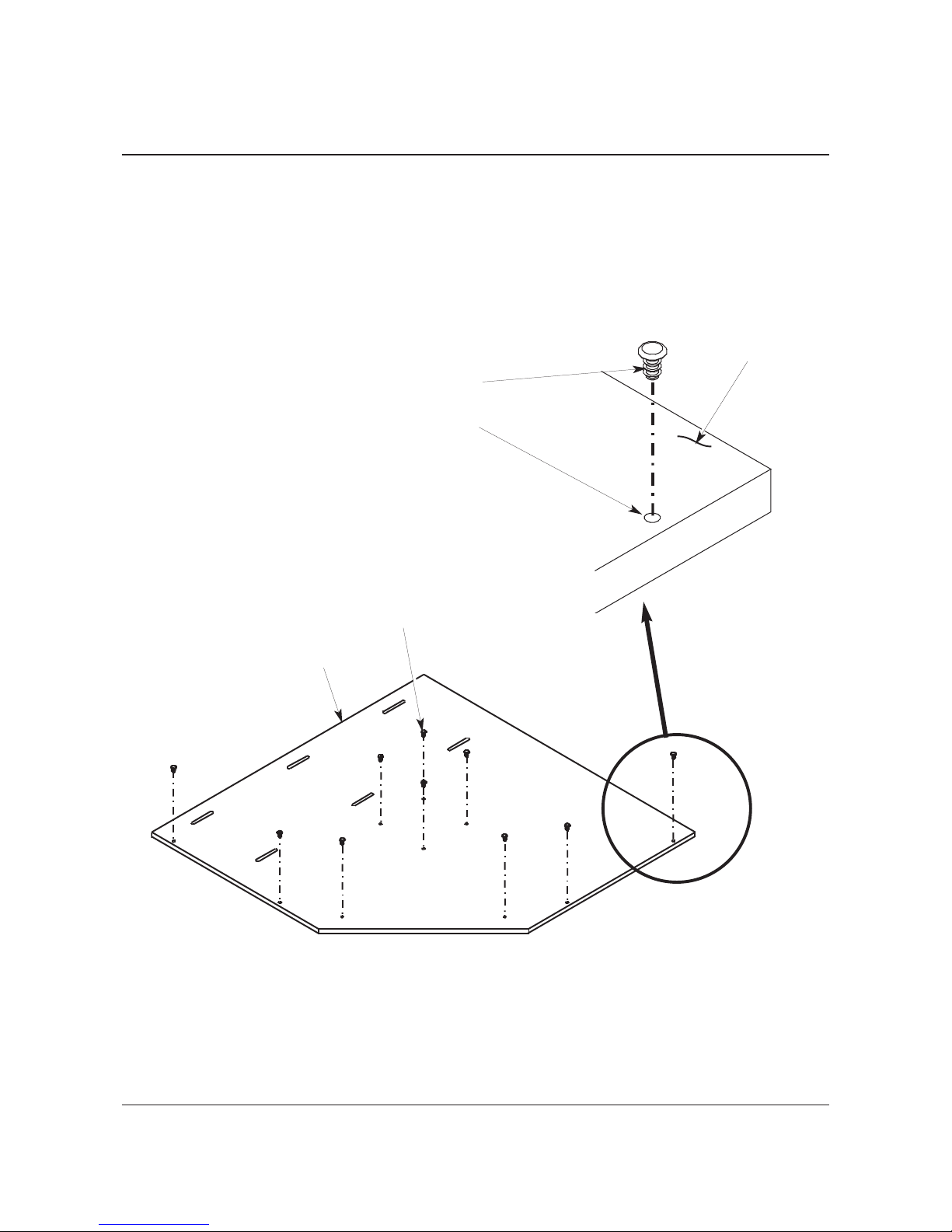

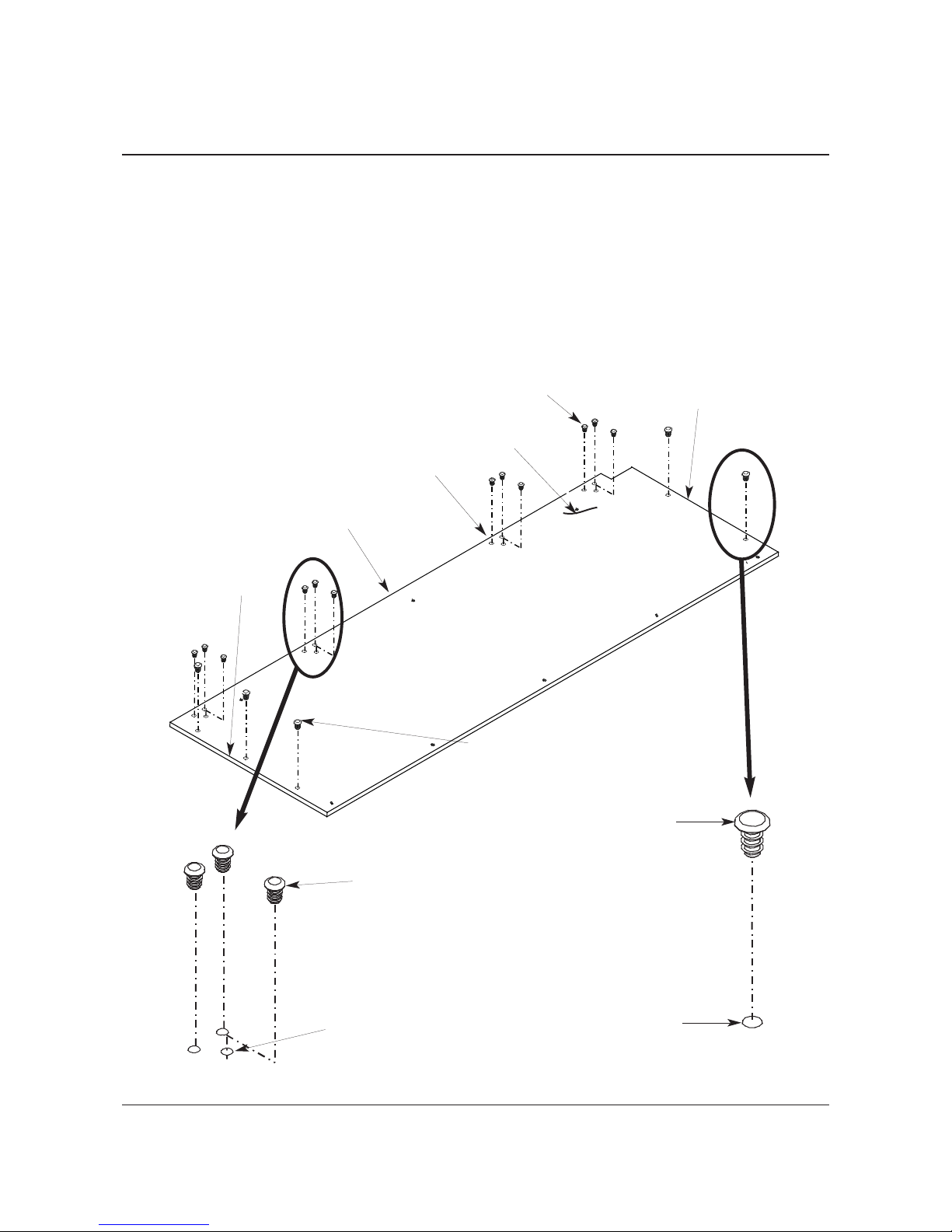

4. Place the Top Panel (19) flat on the floor with the inside surface facing downward (dowel holes do

not go through and are visible only on the inside surface).

IMPORTANT: Dowel holes should not be visible when inside surface is facing down.

5. Using a mallet, drive the Screw Inserts (9) into the clearance holes on the outside surface of the

Top Panel (19).

NOTE: Numerical notations that follow part names in this document refer to part list item numbers

on pages 4 and 5.

Top Panel (19)

Screw Insert, 1/4-20 x 5/8" (9)

Clearance Hole

Screw Insert, 1/4-20 x 5/8" (9)

(Install these only with Revolving Shelf Option)

Outside Surface

CORNER CABINET ASSEMBLY CONTINUED

NOTE: Depending on Corner Cabinet configuration, hole positioning in the individual panels may vary.

Page 7

7

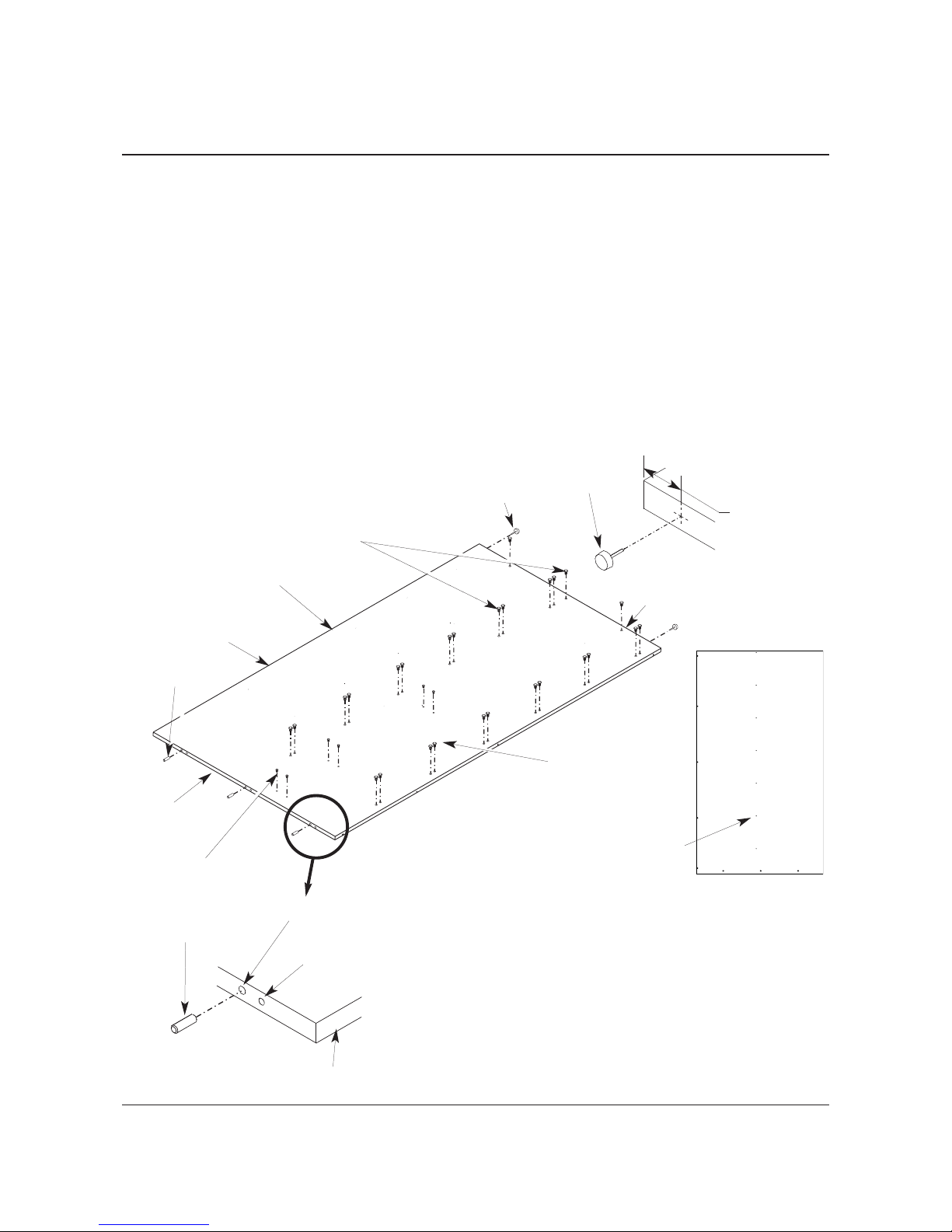

6. Place the Left Hand Back Panel (18) flat on the floor with the inside surface down.

IMPORTANT:

Shelf/Hanger Bar option - when the inside surface is facing down, the outside surface has most of

the clearance holes to the right and the 3 Dowel holes at the top of the panel are visible when

viewing it from the top edge (see the illustration below).

Rotating Shelf option - when the inside surface is facing down, the row of pilot holes at the center of

the panel will also be facing down (see the illustration below).

7. Using a mallet, drive 27 Screw Inserts (3 for the Rotating Shelf option) (9) into the 3/8” clearance

holes in the left Hand Back Panel (18) as shown below.

8. Using a mallet, drive 6 Screw Inserts (8) into the 1/4” clearance holes in the Left Hand Back Panel

(18) as shown below (Shelf/Hanger Bar option only).

9. Using the mallet, drive three Wood Dowels (4) into the three pilot holes on the top edge of the Panel.

10. Using the mallet, drive two Tack Glides (3) into the bottom surface of the Left Hand Back Panel (18)

as shown below. Each Tack Glide (3) should be about 11/2" from the corner.

NOTE: Depending on Corner Cabinet configuration, hole positioning in the individual panels may vary.

Screw Insert, 1/4-20 x 5/8" (9)

Left Hand Back Panel (18)

Bottom Surface of Panel

Left Hand Edge of Panel

Outside surface

Wood Dowel (4)

5

/16" Pilot Hole

Pilot Hole for Lag

Screw (to be inserted

at a later step

Wood Dowel (4)

Screw Insert, 8-32 x 7/16" (8)

Right Hand

Edge of Panel

Top Edge of

Panel

Tack Glide (3)

Drive Glide into

bottom surface

about 1” to 11/2"

from corner edge

Tack

Glide (3)

CORNER CABINET ASSEMBLY CONTINUED

Row of

Pilot Holes

Inside Surface of Left

Hand Back Panel

Page 8

8

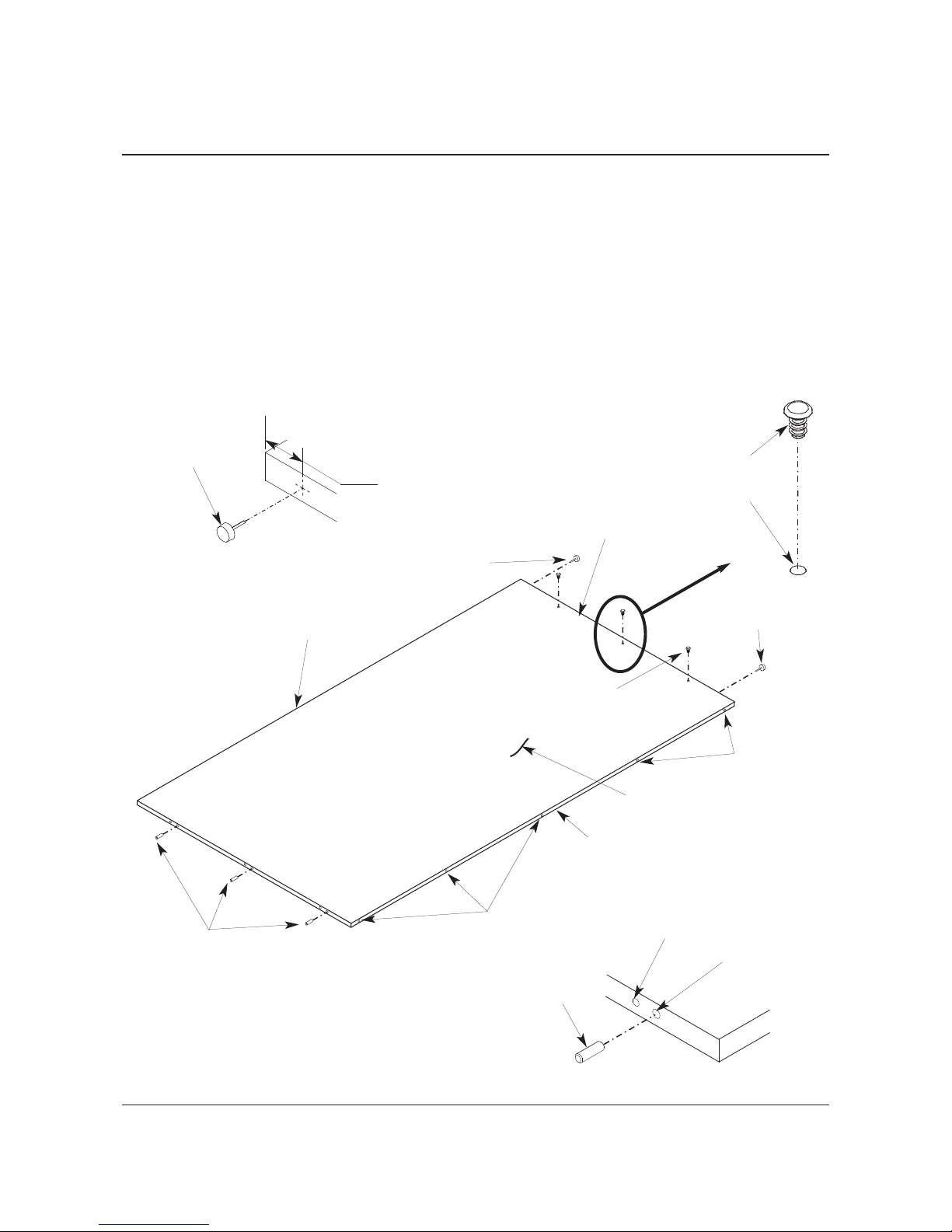

11. Place the Right Hand Back Panel (17) flat on the floor with the inside surface facing down.

IMPORTANT:

When the Right Hand Back Panel has the inside surface facing down, there are five pilot holes on

the right hand edge and the three Dowel holes at the top of the panel are visible when viewing it

from the top edge (refer to the illustration below).

12. Using the mallet, drive three Screw Inserts (9) into the three 3/8” diameter pilot holes at the bottom of

the Panel.

13. Drive three Wood Dowels (4) into the three 5/16” diameter pilot holes on the top edge of the Panel.

Refer to the illustration below.

14. Using the mallet, drive two Tack Glides (3) into the bottom surface of the Right Hand Back Panel

(17) about 11/2” from each bottom corner as shown below.

Right Hand Back Panel (17)

3

/8" Pilot Hole

Bottom Edge of Panel

Left Hand Edge

of Panel

Outside Surface

Wood

Dowel (4)

5

/16" Pilot Hole

3

/16" Pilot Hole for Lag

Screw (to be inserted

at a later step

Wood Dowel (4)

Pilot

Holes

Screw Insert, 1/4-20 x 5/8" (9)

Screw Insert, 1/4-20 x 5/8" (9)

Tack Glide (3)

Drive Glide into bottom surface

about 1” to 11/2" from corner

edge

Tack Glide (3)

Tack Glide (3)

CORNER CABINET ASSEMBLY CONTINUED

Pilot Holes

Page 9

9

15. Place the Right Hand Side Panel (15) flat on the floor with the inside surface down and outside

surface facing upward.

IMPORTANT:

When the inside surface is facing down, the dowel holes on the inside surface will not be visible

(see the illustration below).

16. Using a mallet, drive the Screw Inserts (9) into the

3

/8” clearance holes in the left Right Hand Side

Panel (15) as shown below (Shelf/Hanger Bar option shown).

17. Using a mallet, drive the Screw Inserts (8) into the 1/4” clearance holes in the Right Hand Side Panel

(15) as shown below (Shelf/Hanger Bar option shown).

NOTE: Depending on Corner Cabinet configuration, hole positioning in the individual panels may vary.

Screw Insert, 8-32 x 7/16" (8)

Screw Insert, 1/4-20 x 5/8" (9)

Right Hand Side Panel (15)

Top Edge of Panel

Left Hand Edge of Panel

Bottom Edge of Panel

Outside Surface

CORNER CABINET ASSEMBLY CONTINUED

Page 10

10

18. Turn the Right Hand Side Panel (15) over so that the outside surface is facing down (dowel holes

will now be visible).

19. Using a mallet, drive three Wood Dowels (4) into the three 5/

1

6

” diameter pilot holes close to the top

edge of the Right Hand Side Panel (15).

NOTE: The dowel holes do not go all the way through and are on the inside surface of the Side Panel.

20. Using the mallet, drive two Tack Glides (3) into the bottom surface of the Right Hand Side Panel

(15) about 11/2” from each bottom corner as shown below.

NOTE: Depending on Corner Cabinet configuration, hole positioning in the individual panels may vary.

Right Hand Side Panel (15) with

inside surface facing up

Wood Dowel (4)

Top Edge

Top Edge

Wood Dowel (4)

5

/16" Clearance Hole

7

/16" Deep

3

/16" Pilot Hole through

Inside Surface

Bottom Edge

Drive Glide into bottom surface

about 1” to 11/2" from corner

edge

Tack Glide (3)

Tack Glide (3)

CORNER CABINET ASSEMBLY CONTINUED

Page 11

11

21. Place the Left Hand Side Panel (16) flat on the floor with the inside surface down and outside

surface facing upward

IMPORTANT:

When the inside surface is facing down, the dowel holes on the inside surface will not be visible

(see the illustration below).

22. Using a mallet, drive four Screw Inserts (9) into the

3

/8” clearance holes in the Left Hand Side Panel

(16) as shown below.

23. Using a mallet, drive twelve Screw Inserts (8) into the 1/4” clearance holes in the Left Hand Side

Panel (16) as shown below.

NOTE: Depending on Corner Cabinet configuration, hole positioning in the individual panels may vary.

Screw Insert, 1/4-20 x 5/8" (9)

3

/8" Clearance Hole

Left Hand Side Panel (16)

Top Edge of Panel

Left Hand Edge of Panel

Bottom Edge of Panel

Outside Surface

Screw Insert, 1/4-20 x 5/8" (9)

Screw Insert, 8-32 x 7/16" (8)

1

/4" Clearance Hole

Screw Insert, 8-32 x 7/16" (8)

CORNER CABINET ASSEMBLY CONTINUED

Page 12

12

24. Turn the Left Hand Side Panel (16) over so that the outside surface is facing down. (dowel holes will

now be visible).

25 . Using a mallet, drive three Wood Dowels (4) into the three 5/16” diameter pilot holes close to the top

edge of the Left Hand Side Panel (16).

NOTE: The dowel holes do not go all the way through and are on the inside surface of the Side Panel.

26. Using the mallet, drive two Tack Glides (3) into the bottom surface of the Left Hand Side Panel (16)

about 11/2” from each bottom corner as shown below.

NOTE: Depending on Corner Cabinet configuration, hole positioning in the individual panels may vary.

Left Hand Side Panel (16) with inside

surface facing up

Wood Dowel (4)

Top Edge

Top Edge

Wood Dowel (4)

5

/16" Pilot Hole

7

/16" Deep

3

/16" Clearance

Through-Hole

Inside Surface

Bottom Edge

Drive Glide into bottom surface

about 1” to 11/2" from corner

edge

Tack Glide (3)

CORNER CABINET ASSEMBLY CONTINUED

Page 13

13

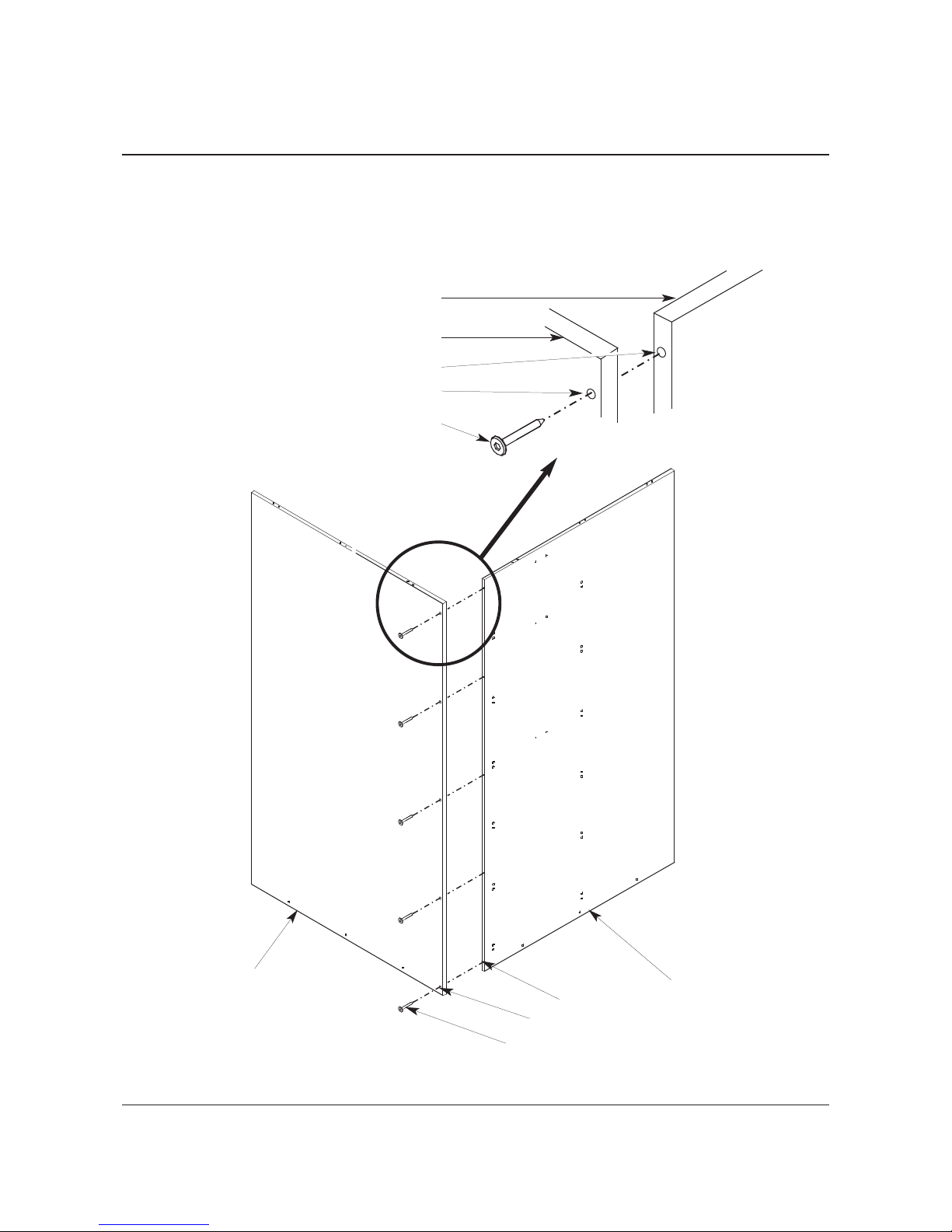

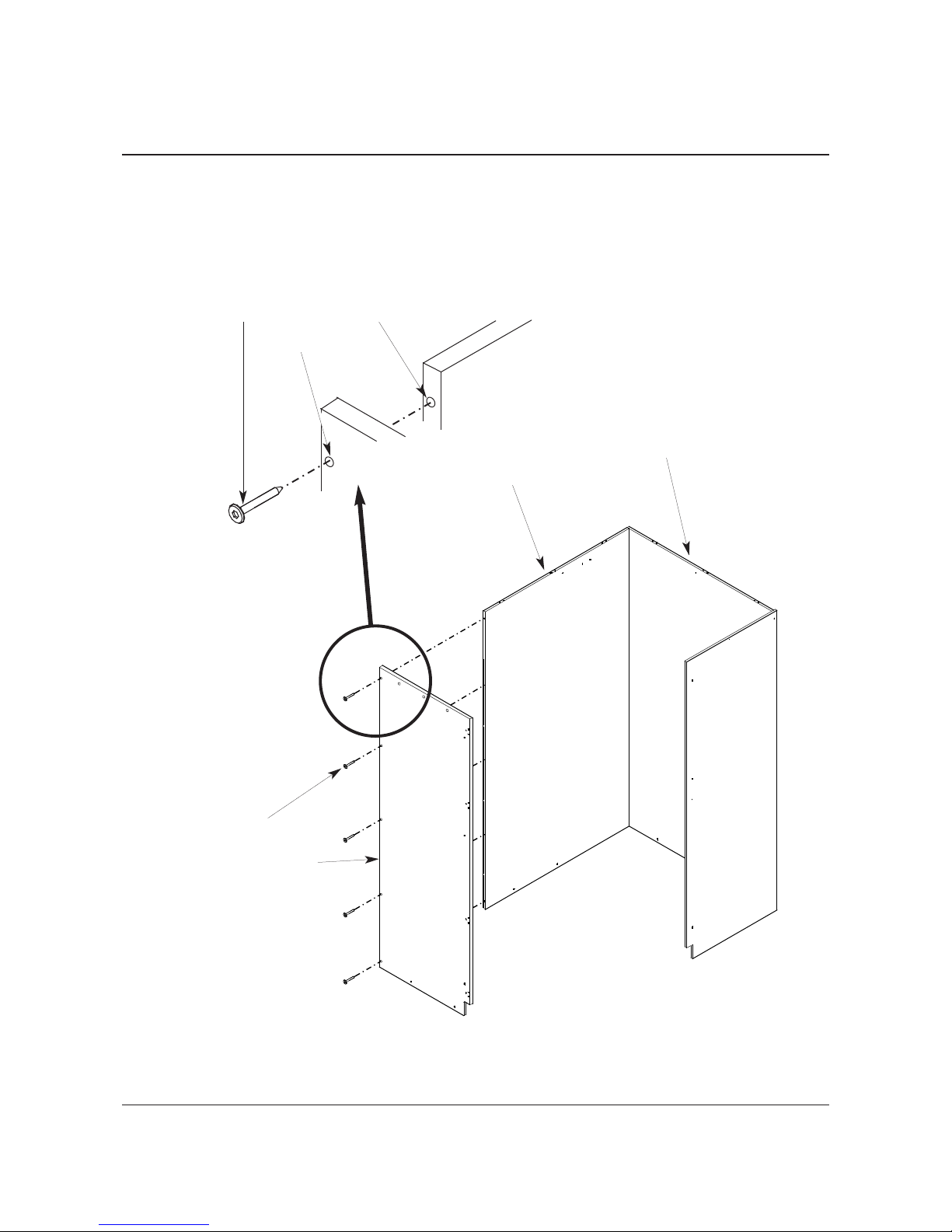

27. With two people working together, place the Right Hand Back Panel (17) and the Left Hand Back

Panel (18) vertical as shown below.

28. Using the Hex Insert Bit (13), connect the two Back Panels together with five Hex Lag Screws (7).

Pilot holes locate the position of the Hex Lag Screws.

Right Hand Back Panel (17)

Left Hand Back Panel (18)

Hex Lag Screw (7)

Pilot Holes

Right Hand Back Panel (17)

Left Hand Back Panel (18)

Hex Lag Screw (7)

Pilot Hole

Clearance Hole

Clearance Hole

CORNER CABINET ASSEMBLY CONTINUED

NOTE: Depending on Corner Cabinet configuration, hole positioning in the individual panels may vary.

Page 14

14

29. With two people working together, attach the Right Hand Side Panel (15) to the two assembled Back

Panels, keeping the panels vertical as shown below.

30. Using the Hex Insert Bit (13), connect the Right Hand Side Panel (15) to the Right Hand Back Panel

(17) with five Hex Lag Screws (7). Pilot holes locate the position of the Hex Lag Screws.

NOTE: Do not tighten the Lag Screws. Allow the head of each Lag Screw to extend 1/2” from the surface

of the Side Panel.

Right Hand Back Panel (17)

Right Hand Side Panel (15)

Hex Lag Screw (7)

Pilot Hole

Right Hand Back Panel (17)

Right Hand Side Panel (15)

Hex Lag Screw (7)

Clearance Hole

CORNER CABINET ASSEMBLY CONTINUED

Page 15

15

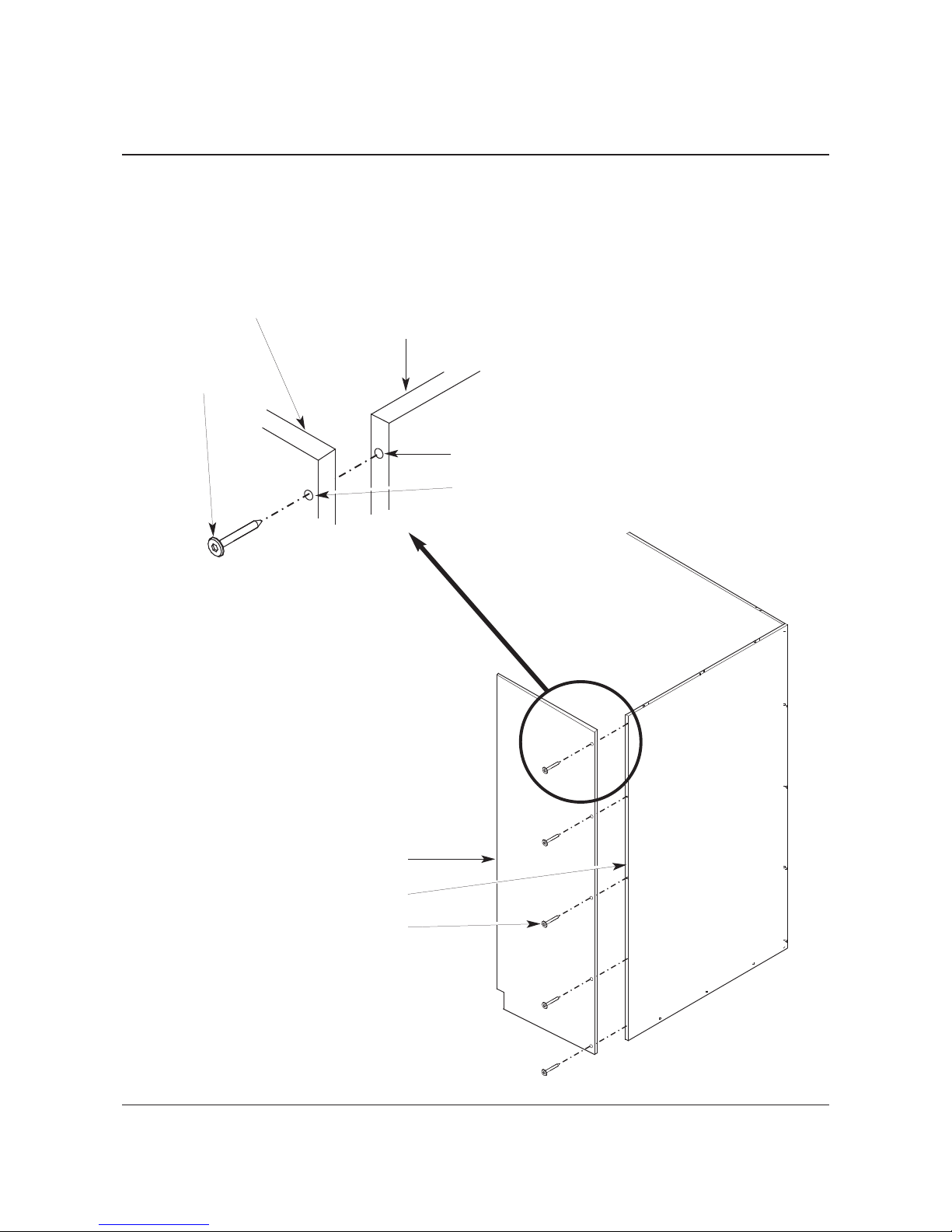

31. With two people working together, attach the Left Hand Side Panel (16) to the two assembled Back

Panels keeping them vertical as shown below.

32. Using the Hex Insert Bit (13), attach the Left Hand Side Panel (16) to the Left Hand Back Panel (18)

with five Hex Lag Screws (10). Pilot holes locate the position of the Hex Lag Screws.

NOTE: Do not tighten the Lag Screws. Allow the head of each Lag Screw to extend 1/2” from the

surface of the Side Panel.

Hex Lag Screw (7)

Left Hand Side Panel (16)

Hex Lag Screw (7) Pilot Hole

Left Hand Back Panel (18)

Clearance Hole

Right Hand Back Panel (17)

CORNER CABINET ASSEMBLY CONTINUED

Page 16

16

33. Make sure that the Hex Lag Screws (7) holding the two Side Panels to the two Back Panels are

loosened.

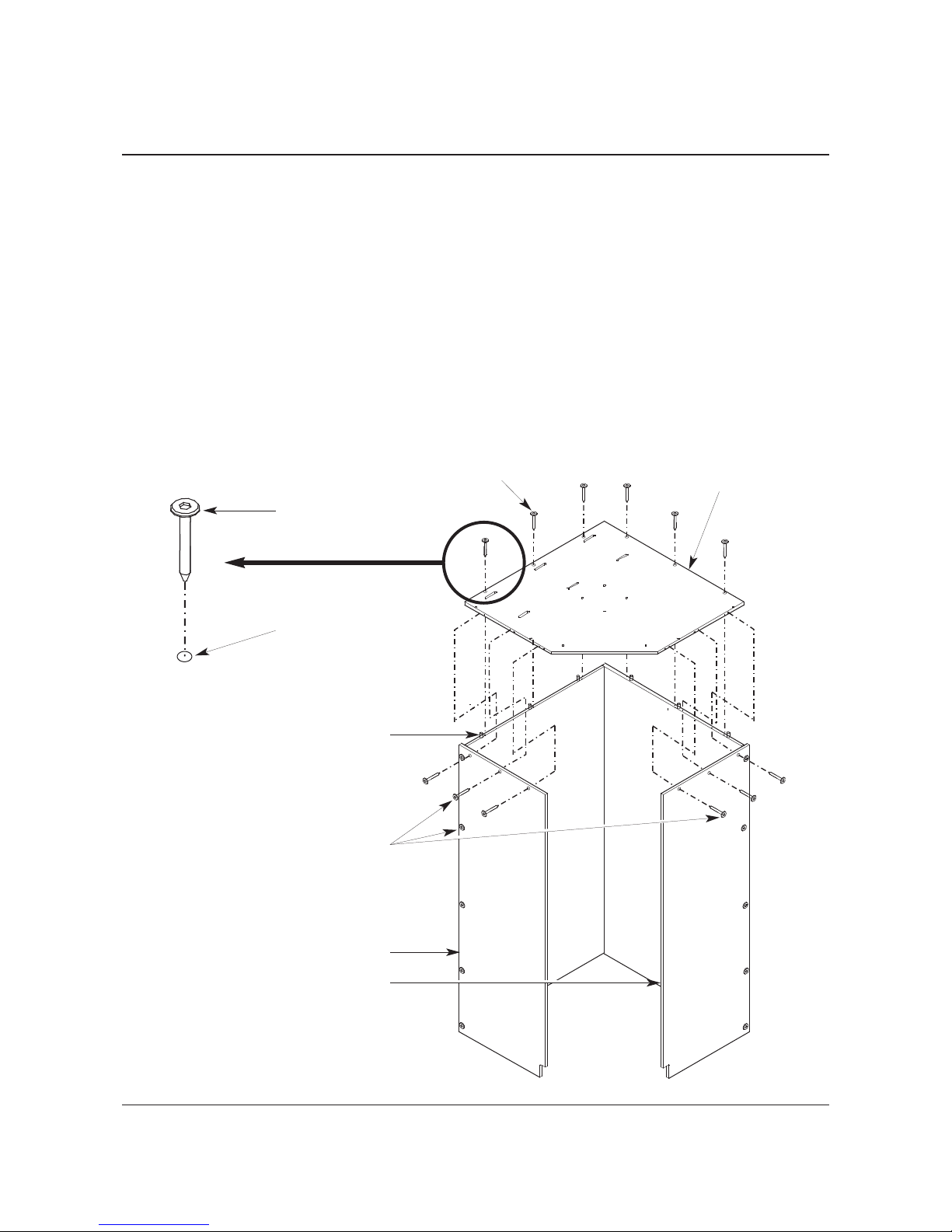

34. Carefully place the Top Panel (19) onto the Back Panels aligning the Wood Dowels (4) in the two

Back Panels to the dowel pilot holes on the inside surface of the Top Panel.

35. Make sure that the Wood Dowels (4) in the two Side Panels align to the dowel pilot holes in the Top

Panel and, using the Hex Insert Bit (13), tighten the 10 Hex Lag Screws (7) that fasten the Side

Panels to the Back Panels.

36. Using the Hex Insert Bit (13), fasten:

a. Six Hex Lag Screws (7) through the clearance holes in the Top Panel (19) into the two Back

Panels.

b. Three Hex Lag Screws (7) through the clearance holes in the Left Hand Side Panel (16) into the

pilot holes in the Top Panel.

c. Three Hex Lag Screws (7) through the clearance holes in the Right Hand Side Panel (17) into

the pilot holes in the Top Panel.

Top Panel (19)

Hex Lag Screw, 2" long (7)

Left Hand Side Panel (16)

Right Hand Side Panel (17)

Wood Dowel (4)

Hex Lag Screw, 2" long (7)

Hex Lag Screw, 2" long (7)

3

/8" Clearance Hole

CORNER CABINET ASSEMBLY CONTINUED

Page 17

17

37. Attach a Trim Strip (12) to the Left Hand Side Panel (16) and the Right Hand Side Panel (15) using

a Pan Head Screw, 11/4” long (11) for each Trim Strip as shown in the illustration below.

Pan Head Screw,

painted, 1

1

/4" long (11)

Trim Strip (12)

Trim Strip (12)

Right Hand Side Panel (15)

Left Hand Side Panel (16)

CORNER CABINET ASSEMBLY CONTINUED

Page 18

18

38. Install the Upper Frame (21) inside the upper part of the Corner Cabinet by doing the following.

a. Hold the Upper Frame in position as shown below.

b. Using the Hex Insert Bit (13), fasten the Upper Frame to the Top Panel (19) with six Hex Socket

Machine Screws (10).

c. Using the Hex Insert Bit (13), fasten the Upper Frame to the Left Hand Side Panel(16) with two

Hex Socket Machine Screws (10).

d. Using the Hex Insert Bit (13), fasten the Upper Frame to the Right Hand Side Panel(17) with two

Hex Socket Machine Screws (10).

Top Panel (19)

Left Hand Side

Panel (16)

Right Hand Side

Panel (17)

Upper Frame (21)

Hex Socket Machine Screw,

1.77" (45 mm) long (10)

Hex Socket Machine Screw,

1.77" (45 mm) long (10)

The Top Panel, Right Hand Side

Panel, and Left Hand Side Panels are

shown disassembled for clarity only.

CORNER CABINET ASSEMBLY CONTINUED

Page 19

19

39. Fasten five Leveler Glides (5) to the Bottom Frame (20) using a 7/8" open end wrench as shown

below. Screw the Leveler Glide into the Bottom Frame until the head of the Leveler Glide is against

the Bottom Frame Weld Nut. Do not tighten.

NOTE: The Weld Nut is on the bottom surface of the Bottom Frame (20) as shown in the illustration

below.

40. Using the mallet, drive a Tube Plug (2) into each open end of the Bottom Frame (20).

Bottom Frame (20)

Leveler Glide, 3/8-16 x 21/2" (5)

Leveler Glide, 3/8-16 x 21/2" (5)

Bottom Frame (20)

Leveler Glide,

3

/8-16 x 21/2" (5)

Leveler Glide,

3

/8-16 x 21/2" (5)

Bottom Frame (20)

Weld Nut

Tube Plug (2)

Tube Plug (2)

The Weld Nut must be

on the bottom of the

Bottom Frame when the

Leveler Glide is

attached.

CORNER CABINET ASSEMBLY CONTINUED

Page 20

20

41. Install the Bottom Frame (20) inside the lower part of the Corner Cabinet by doing the following.

a. Hold the Bottom Frame (20) in position as shown below.

b. Using the Hex Insert Bit (13), fasten the Bottom Frame to the Right Hand Back Panel (17) and

Left Hand Back Panel (18) with six Hex Socket Machine Screws (10) as shown below.

c. Using the Hex Insert Bit (13), fasten the Bottom Frame to the Left Hand Side Panel(16) with two

Hex Socket Machine Screws (10).

d. Using the Hex Insert Bit (13), fasten the Bottom Frame to the Right Hand Side Panel(15) with

two Hex Socket Machine Screws (10).

Left Hand Side

Panel (16)

Right Hand Side

Panel (15)

Hex Socket Machine Screw,

1.77" (45 mm) long (10)

The Right Hand Side Panel and Left

Hand Side Panels are shown

disassembled for clarity only.

Hex Socket Machine Screw,

1.77" (45 mm) long (10)

Bottom Frame (20)Left Hand Back Panel (18)

Right Hand Back Panel (17)

CORNER CABINET ASSEMBLY CONTINUED

Page 21

21

1. Check the level of the entire floor where the Corner Cabinet will be installed. Determine the highest

point of the floor in that area. Extend all Leveler Glides until the bottom of the cabinet is higher than

the highest point in the floor (so that the bottom of cabinet is not touching the floor).

2. Adjust the Leveler Glides at points 2 and 3 (adjustments to 5 may be necessary) until the edges X

and Y of the cabinet are plumb and parallel.

3. Measure A and B with a measuring tape and adjust the Leveler Glides 1 and 2 until A is equal to B

(±1/32”). Adjustments to 3 and 4 may be necessary.

4. Adjust Leveler Glides at points 1 and 2 (adjustments to 5 may be necessary) until the edges Z and

W of the cabinet are plumb (front-to-back).

5. Re-measure A and B with a measuring tape and make sure that A is still equal to B (±1/32”).

Readjust if necessary (steps 2 to 4).

A B

1

2

3

4

5

X

Z

Y

W

!

CAUTION

DO NOT try to level

the cabinet to

match soffits.

!

CAUTION

DO NOT try to

plumb the cabinet

to match adjacent

walls.

!

CAUTION

For proper door

alignment, follow

these instructions

carefully.

NOTE: Filler Strips (22) are used when attaching the Corner Cabinet to other Wenger storage

cabinets. Refer to the Storage Cabinet Installation Instruction Manual for information about

fastening cabinets together.

LEVEL THE CABINET

Page 22

22

1. Place the Corner Cabinet in its final position against a wall or surface that will serve as an anchor

for the cabinet.

2. Using the Cabinet Connector Bracket (19) as a template, mark the position for the four holes to

mount the bracket.

3. Drill pilot holes for the four (1) Pan Head Screws, 5/8” long, with a 1/8” drill bit.

4. Attach the Cabinet Connector Bracket (19) to the Corner Cabinet Top Panel using four (1) Pan Head

Screws, 5/8” long.

5. Connect the Bracket to the wall with the appropriate fasteners.

NOTE: Numerical notations that follow part names in this document refer to part list item numbers

on pages 22 and 23.

!

CAUTION

The Corner Cabinet can be

unsafe unless it is fastened

to a wall as described in

this procedure.

Use a method to fasten the

bracket to the wall that is

appropriate for the wall

surface.

Pan Head Screw, 5/8" long (1)

Cabinet Connector Bracket (19)

ASSEMBLE CABINET CONNECTOR BRACKET

Page 23

23

Item Description Part Number Item Description Part Number

1 Pan Head Screw X000045 10 Handle, Full Wood Door 250A502._

2 Hex Nut with Lock washer X001762 11 Latch Assembly, Full Wood Door 250A501._

3 Truss Head Screw X001767 12 Hinge, Wood Door 250A505._

4 Pan Head Screw, painted 250A511._ 13 Door Catch, Full Length 145R475

5 Flat Head Screw, painted 250A509._ 14 Door Stop, Corner Cabinet 250A535._

6

Screw Insert, 8-32 x 7/16"

250A506._ 15

Hex Insert Bit, 5/32"

X001962

7 Flat Head Screw, painted 250A507._ 16 Door, Full 27" Wood 250A332._

8 Hex Cap Insert Nut 250A510._ Door, Full 27" Grille 250A302._

9 Door Stop, Cabinet 145L098 19 Cabinet Connector Bracket 145A288

DOOR ASSEMBLY PARTS LIST

DOOR ASSEMBLY REQUIRED TOOLS

• Variable Speed Drill

• 6-foot Ladder

• Mallet

• Philips Screwdriver

• Hex Insert Bit

Pan Head Screw

5

/8”

1

Screw Insert, 8-32 x 7/16”

(oyster)

6

DOOR ASSEMBLY FASTENERS PARTS LIST

The following tools must be supplied by the installer to install the doors:

Hex Cap Insert Nut

8

5

3

/4”

Flat Head Screw (painted)

Pan Head Screw

5

/8”

7

Pan Head Screw

3

/4”

4

Lock Washer

Hex Nut

2

Truss Head Screw

3

/4”

3

Page 24

24

Before starting the Door assembly, do the following.

1. Read and understand this assembly instruction.

2. Remove all items from the shipping carton and arrange the parts as shown in the diagram below.

Make sure that all parts are present. Item numbers refer to the Part List on page 22 and the table

below.

3. Inventory the hardware package and make sure that everything required is present. Discard any

items not used during the assembly.

IMPORTANT: The following “Door Assembly” procedures are for a left side hinge. For a right side

hinge, the images would be mirrored.

NOTE: Make sure that the

cabinet is level before

assembling the door.

Item Description

9 Door Stop Cabinet

10 Handle, Wood Full Door

11 Latch Assembly, Full Wood Door

12 Hinge Wood Door

Item Description

13 Door Catch Full Length

14 Door Stop, Corner Cabinet

16 Door, Full

19 Cabinet Bracket

DOOR ASSEMBLY

Page 25

25

WOOD DOOR ASSEMBLY

1. Assemble the Screw Inserts (6) to the Wood Door (16) as follows.

a. Place the Wood Door (16) on the floor with the outside surface facing upward.

b. Using a mallet, drive eight Screw Inserts (6) into the eight clearance holes in the Door as shown

below.

NOTE: Reference Holes (do not go through) are between the hinge clearance holes on the inside

surface. Refer to the illustration at the bottom of this page.

Wood Door (16)

Screw Insert, 8-32 x 7/16" (6)

Outside Surface

Clearance Hole

Wood Door (16)

Clearance Hole

Bottom Edge

Reference Hole

Inside Surface

Pilot Hole

DOOR ASSEMBLY CONTINUED

Page 26

26

WOOD DOOR ASSEMBLY CO

NTINUED

2. Assemble the Wood Door Hinges (12) to the Wood Door as follows.

a. Lay the Wood Door flat with the inside surface facing upward (heads of the Screw Inserts,

installed in step 1, are on the outside surface and must face downward).

b. Align the four Wood Door Hinges (12) to the clearance holes in the Wood Door and, using a

phillips head screwdriver fasten the HInges to the Screw Inserts in the Door using eight Flat

Head Screws (5) (matches hinge color).

c. Fasten one Flat Head Screw (7) (Matches hinge color) to each Hinge using a phillips head

screwdriver.

Wood Door (16)

Inside Surface

Flat Head Screw,

3

/4" long (5)

Flat Head Screw,

5

/8" long (7)

Wood Door

Hinge (12)

Flat Head Screw,

5

/8" long (7)

Wood Door

Hinge (12)

DOOR ASSEMBLY CONTINUED

Page 27

27

3. Assemble the Wood Door Latch Assembly (11) and Wood Door Handle (10) to the Wood Door (16)

as follows.

a. Insert the two Wood Door Latch Assembly Threaded Post (11) into the two clearance holes on

the outside surface of the Door as shown below.

b. Insert two Hex Cap Insert Nuts (8) into the two clearance holes and tighten the Nuts to the

Threaded Posts using a Hex Insert Bit (15).

c. Insert the two Wood Door Handle Threaded Post (10) into the two clearance holes as shown

below.

d. Insert two Hex Cap Insert Nuts (8) into the two clearance holes and tighten the Nuts to the

Wood Door Handle Threaded Posts using a Hex Insert Bit (15).

NOTE: All door hardware should match hinge color.

Hex Cap Insert Nut (8)

Wood Door (16)

Wood Door

Handle (10)

Wood Door Latch

Assembly (11)

Clearance Hole

Inside Surface of

Wood Door

Wood Door Handle

Threaded Post

Latch Assembly

Threaded Post

DOOR ASSEMBLY CONTINUED

WOOD DOOR ASSEMBLY CO

NTINUED

Page 28

28

4. Install the Door Catch (13) to the inside (lower) surface of the Top Panel by inserting two Pan

Head Screws (1) through the clearance holes in the Catch and into the two Pilot Holes in the inside

surface of the Top Panel. Use a phillips head screw driver to tighten the Screws. See the illustration

below.

Door Catch (13)

Pan Head Screw, 5/8" long (1)

Top Panel

DOOR ASSEMBLY CONTINUED

WOOD DOOR ASSEMBLY CO

NTINUED

Page 29

29

5. Assemble the Door Stop to the Right Hand Side Panel as follows.

a. Assemble the Cabinet Door Stop (9) to the Corner Cabinet Door Stop (14) with two Lock

Washer Hex Nuts (2) and two Truss Head Screws (3) (Corner Cabinet Door Stop color matches

Hinge color).

NOTE: Make sure that the wide lip of the Cabinet Door Stop (9) is oriented as shown below

(wide lip facing the Corner Cabinet Door Stop and the narrow lip facing away from the Corner

Cabinet Door Stop).

b. Attach the Door Stop Assembly to the inside surface of the Right Hand Side Panel with two

Painted Pan Head Screws (4) using a phillips head screwdriver.

Right Hand Side

Panel

Hex Nut with Lock

Washer (2)

Corner Cabinet

Door Stop (14)

Cabinet Door

Stop (9)

Truss Head Screw,

3

/4" long (3)

Pan Head Screw,

3

/4" long (4)

Clearance Holes (Screw

Inserts on outside surface

Wide Lip

Narrow Lip

a

b

DOOR ASSEMBLY CONTINUED

WOOD DOOR ASSEMBLY CO

NTINUED

Page 30

30

6. Attach the Wood Door (16) to the Corner Cabinet as follows.

a. Align the Wood Door to the Corner Cabinet so that the mounting holes in each Wood Door

Hinge (12) align to the clearance holes in the Left Hand Side Panel with screw inserts.

b. Using a phillips head screwdriver, attach the upper hinge of the door to the Left Hand Side

Panel by using three Painted Flat Head Screws (5) as shown below.

A screw may be inserted into the rear-most hole of the cabinet and the door may be hung from it

by placing the slotted hole in the hinge onto the screw and moving the hinge forward until the other

two screw inserts are exposed. Tighten the three screws in each hinge.

c. Attach the lower hinges in the same manner.

NOTE: All door hardware should match hinge color.

Wood Door (16)

Top Panel

Right Hand Side Panel

Clearance Hole

Flat Head Screw, Painted,

3

/4" long (5)

Wood Door Hinge (12)

DOOR ASSEMBLY CONTINUED

WOOD DOOR ASSEMBLY CO

NTINUED

Page 31

31

1. Assemble the Grille Door Stop as follows.

a. Attach the Cabinet Door Stop (9) to the Corner Cabinet Door Stop (14) with two Lock Washer

Hex Nuts (2) and two Truss Head Screws (3) (Corner Cabinet Door Stop color matches Hinge

color).

NOTE: Make sure that the narrow lip of the Cabinet Door Stop (9) is oriented as shown below (narrow

lip facing the Corner Cabinet Door Stop and the wide lip facing away from the Corner Cabinet

Door Stop).

b. Attach the Door Stop Assembly to the inside surface of the Right Hand Side Panel with two

Painted Pan Head Screws (4) using a phillips head screwdriver.

Right Hand Side

Panel

Hex Nut with Lock

washer (2)

Corner Cabinet

Door Stop (14)

Cabinet Door

Stop (9)

Truss Head Screw,

3/4" long (3)

Pan Head Screw,

3/4" long (4)

Right Hand Side

Panel

Clearance Holes (Screw

Inserts on outside surface)

Narrow Lip

Wide Lip

a

b

DOOR ASSEMBLY CONTINUED

GRILLE DOOR ASSEMBLY

Page 32

32

2. Attach the Grille Door (16) to the Corner Cabinet as follows.

a. Align the Grille Door (16) to the Corner Cabinet so that the mounting holes in each Grille Door

Hinge aligns to the clearance holes in the Left Hand Side Panel with screw inserts.

b. Using a phillips screwdriver, attach the upper Hinge of the door to the Left Hand Side Panel by

using three Painted Flat Head Screws (5) as shown below.

A screw may be inserted into the rear-most hole of the cabinet and the door may be hung from it

by placing the slotted hole in the hinge onto the screw and moving the hinge forward until the other

two screw inserts are exposed. Tighten the three screws in each hinge.

c. Attach the lower hinges in the same manner.

Grille Door (16)

Top Panel

Right Hand Side Panel

Clearance Hole

Flat Head Screw, Painted,

3/4” long (5)

Grille Door Hinge

DOOR ASSEMBLY CONTINUED

GRILLE DOOR ASSEMBLY CONTINUED

Page 33

33

Shelf/Hanger Bar Option Assembly Instructions

Corner Cabinet with a Fixed Shelf Corner Cabinet with Hanger Bars

CONTENTS

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Shelf/Hanger Bar Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Shelf/Hanger Bar Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Shelf/Hanger Bar Fasteners Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Shelf/Hanger Bar Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Brass Clothes Hook Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Fixed Shelf Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Band Uniform Hanger Bar Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Choral Robe Hanger Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Page 34

34

Item Description Part Number Item Description Part Number

1

Truss Head Screw, 3/4"

X001767 5 Brass Clothes Hook, Pair X002585

2

Hex Insert Bit, 5/32"

X001962 6 Shelf, 30" x 48", oyster 145R439

3

Pan Head Screw, 13/4"

X001969 7 Shelf Support, 48", oyster 145R899

4

Hex Socket Button Head Screw, 5/8"

145L441 8 Hanger Bar, 48", oyster 145A328

9 Velcro Strip 145R492

IMPORTANT USER INFORMATION

INSTALLATION

• The Wenger Corner Cabinet Shelf/Hanger Bar installation must comply with local building

regulations and codes.

• Personnel installing the Wenger Corner Cabinet Shelf/Hanger Bar must comply with the Warnings

and Cautions in the Safety Section.

INTENDED USE

• The Wenger Corner Cabinet Shelf/Hanger Bar is intended for indoor use in normal ambient

temperature and humidity conditions — it must not be exposed to prolonged outside weather

conditions.

• The Wenger Corner Cabinet Shelf/Hanger Bar is intended to be permanently installed only as

described in this manual.

SHELF/HANGER BAR REQUIRED TOOLS

• Variable Speed Drill

• Philips Screwdriver

SHELF/HANGER BAR PARTS LIST

SHELF/HANGER BAR FASTENERS PARTS LIST

The following tools must be supplied by the installer to install the Wenger Corner Cabinet Shelf/Hanger

bar:

Pan Head Screw

13/4”

3

Hex Socket Button Head Screw

5

/8”

4

Truss Head Screw

3

/4”

1

Page 35

Before starting the Shelf/Hanger Bar assembly, do the following.

1. Read and understand this assembly instruction.

2. Remove all items from the shipping carton and make sure that all parts are present. Item numbers

refer to the Part List above and the table below.

3. Inventory the hardware package and make sure that all required hardware is present. Discard any

items not used during the assembly.

Item Description

5 Brass Clothes Hook/Screws

6 Shelf

7 Shelf Support

8 Hanger Bar

35

1. Install four Brass Clothes Hooks (5) as follows.

a. Fasten each Brass Clothes Hook (5) to the inside surface of the Left Hand Side Panel with two

Brass Clothes Hook Screws.

b. Pilot holes, 1/8" diameter, on the inside surface of the Left Hand Side Panel locate the Clothes

Hooks.

SHELF/HANGER BAR ASSEMBLY

BRASS CLOTHES HOOK ASSEMBLY

Left Hand Back PanelLeft Hand Side Panel

Brass Clothes Hook (5)

Brass Clothes Hook (5)

Brass Clothes Hook

Screws (5)

1

/8" Pilot Holes

1

/8" Pilot Holes

NOTE: Numerical notations

that follow part names

in this document refer

to part list item

numbers on this page.

Page 36

36

SHELF/HANGER ASSEMBLY CONTINUED

To install a Shelf, do as follows.

1. Align one of the Shelf Supports (7) to the 3/8" diameter clearance holes on the inside surface

of the Left Hand Back Panel next to the Right Hand Side Panel as shown below.

Orient the Tabs to face away from the Back Panel.

2. Using the Hex Insert Bit, fasten the Support Bar with four Hex Socket Button Head Screws (4).

The screws fasten to a screw insert.

3. Repeat steps 1 and 2 for the remaining Shelf Support (7). Make sure that the Shelf Support

Tabs are oriented as shown below.

Left Hand Back Panel

3

/8" Clearance Hole

Right Hand Back Panel

Shelf Support Tab facing away

from the Right Hand Back

Panel

Shelf Support Tab facing

toward the Right Hand

Back Panel

3

/8" Clearance Hole

Shelf Support Tab

Hex Socket Button Head

Screw, 5/8" (4)

Shelf Support (7)

Shelf Support (7)

Shelf Support (7)

Hex Socket Button Head

Screw, 5/8" (4)

FIXED SHELF ASSEMBLY

Page 37

37

SHELF/HANGER ASSEMBLY CONTINUED

Shelf (6)

4. To install an upper Shelf (6), do as follows.

a. Place the Shelf (6) on the Shelf Supports (7).

b. Align the three clearance holes in the front Shelf Support (7) with the three pilot holes on the

front bottom side of the Shelf (6).

c. Attach the Shelf (6) to the front Shelf Support (7) with three Pan Head Screws (3) as shown

below.

NOTE: Tighten the screws snugly, but do not over tighten (use care with power screwdrivers).

d. Align the clearance holes in the rear Self Support with the pilot holes on the rear bottom side of

the Shelf and attach with two Pan Head Screws (3).

Clearance Hole

Pan Head

Screw, 1

3

/4" (3)

Front Shelf Support (7)

Pilot holes on

bottom of Shelf

Rear Shelf Support (7)

5. To install a bottom Shelf (6), do as follows.

a. Apply five Velcro Strips (9) to the front and rear Shelf Supports (7) as shown below.

b. Remove the paper backing from the five Velcro Strips (9).

c. Place the Shelf (6) onto the Velcro Strips (9) and Shelf Supports (7) and against the cabinet

back panel. The Shelf can be removed if the cabinet needs additional leveling.

Shelf Support (7)

Shelf (6)

Velcro Strip (9)

Pan Head Screw, 13/4" (3)

Velcro Strip (9)

Front Edge

FIXED SHELF ASSEMBLY CONTINUED

Page 38

38

SHELF/HANGER ASSEMBLY CONTINUED

To install the Hanger Bars (8) for Uniform Storage, do as follows.

1. Align the clearance holes in the end of a Hanger Bars (8) to the upper pair of 1/4" diameter clearance

holes in the Left Hand Back Panel and the Right Hand Side Panel.

2. Using a phillips head screwdriver, fasten the Hanger Bar to the Left Hand Back Panel and the Right

Hand Side Panel with four Truss Head Screws (1). The screws fasten to a screw insert.

3. Repeat steps 1 and 2 for the second Hanger Bar (8) using the lowest set of 1/4" diameter clearance

holes (these are about 38" below the upper set of holes) as shown below.

1

/4" Clearance Holes

Truss Head Screw, 3/4" (1)

Hanger Bar (8)

Right Hand Side Panel

Left Hand Back Panel

Hanger Bar (8)

1

/4" Clearance Holes

BAND UNIFORM HANGER BAR ASSEMBLY

Page 39

39

SHELF/HANGER ASSEMBLY CONTINUED

Truss Head Screw, 3/4" (1)

Hanger Bar (8)

1

/4" Clearance Holes

Right Hand Side Panel

Left Hand Back Panel

Hanger Bar (8)

1

/4" Clearance Holes

To install the Hanger Bar (8) for Choral Robes, do as follows.

1. Align the clearance holes in the end of a Hanger Bar (8) to the mid-pair of 1/4" diameter clearance

holes (13" below the upper set of holes) in the Left Hand Back Panel and the Right Hand Side

Panel.

2. Using a phillips head screwdriver, fasten the Hanger Bar to the Left Hand Back Panel and the Right

Hand Side Panel with four Truss Head Screws (1). The screws fasten to a screw insert.

3. Discard the second Hanger Bar (8).

CHORAL ROBE HANGER ASSEMBLY

Page 40

40

This page is intentionally blank.

Page 41

41

Revolving Shelf Option Assembly Instructions

Corner Cabinet Revolving Shelf Option

shown with six Half Shelf Assemblies

Corner Cabinet Flag Storage Option shown

with four Flag/Robe Assemblies and two

Half Shelf Assemblies

CONTENTS

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Revolving Shelf Required Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Revolving Shelf Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Revolving Shelf Fasteners Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Revolving Shelf Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Assemble Deflector Panel to the Corner Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Assemble Base Frame and Center Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Assemble a Half Shelf to the Center Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Assemble a Flag/Choral Robe Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Page 42

42

Item Description Part Number Item Description Part Number

1

Capscrew, 1/4-20 x 3/4" long

X000047 8 Deflector Panel 250A284._

2

Flat Washer, 3/8" ID

X000410 9 Top Plate Assembly 145R838

3

Capscrew, 3/8-16 x 13/4" long

X001552 10 Base Frame Assembly 145R839

4

Capscrew, 3/8-16 x 31/4" long

X001560 11 Center Column Assembly 145R840

5

Locknut, 3/8-16

X001848 12 Half Shelf Assembly 145R860

6

Thrust Washer, 11/64ID

X002666 13 Flag/Choral Robe Bar Assembly 145R861

7

Truss Head Screw, 5/8" long, oyster

146B509 14 Leveler Glide X002820

IMPORTANT USER INFORMATION

INSTALLATION

• The Wenger Corner Cabinet Revolving Shelf installation must comply with local building regulations

and codes.

• Personnel installing the Wenger Corner Cabinet Revolving Shelf must comply with the Warnings and

Cautions in the Safety Section.

INTENDED USE

• The Wenger Corner Cabinet Revolving Shelf is intended for indoor use in normal ambient temperature

and humidity conditions — it must not be exposed to prolonged outside weather conditions.

• The Wenger Corner Cabinet Revolving Shelf is intended to be permanently installed only as described

in this manual.

REVOLVING SHELF REQUIRED TOOLS

• Philips Screwdriver

• Adjustable Wrench

•

9

/16” Socket and Ratchet

(7/16” and 1/2” sockets are optional)

•

7

/16”, 1/2” and 9/16” Open End Wrenches

REVOLVING SHELF PARTS LIST

Locknut

5

Leveler Glide

31/4”

4

Capscrew 1/4-20 x 3/4"

3

/4”

1

Capscrew 3/8-20 x 13/4"

3

Flat Washer 3/8” ID

2

Thrust Washer 11/64” ID

6

REVOLVING SHELF FASTENERS PARTS LIST

The following tools must be supplied by the installer to install the Wenger Corner Cabinet Revolving Shelf:

3”

14

Truss Head Screw

5

/8”

7

13/4”

Capscrew 3/8-20 x 31/4"

Page 43

43

Before starting assembly of the Corner Cabinet Revolving Options, do the following.

1. Read and understand this assembly instruction.

2. Remove all items from the shipping carton and arrange the parts as shown in the diagram below.

Make sure that all parts are present. Item numbers refer to the Part List on page 42 and the table

below.

3. Inventory the hardware package and make sure that all required hardware is present. Discard any

items not used during the assembly.

Item Description

8 Deflector Panel

9 Top Plate Assembly

10 Base Frame Assembly

11 Center Column Assembly

12 Half Shelf Assembly

13 Flag/Choral Robe Assembly

REVOLVING SHELF ASSEMBLY

Page 44

44

To assemble the Deflector Panel (8) to the Corner Cabinet, do as follows.

1. Place the Deflector Panel (8) against the Right Hand Back Panel and the Left Hand Back Panel.

2. Align the 14 Clearance Holes in the Deflector Panel (8) to the seven Pilot Holes in the Right Hand

Back Panel and the seven Pilot Holes in the Left Hand Back Panel.

3. Insert a Truss Head Screw (7) into the upper left Clearance Hole and, using a phillips head

screwdriver, screw it into the upper Pilot Hole in the Left Hand Back Panel.

4. Repeat step 3, fastening a Truss Head Screw (7) to the upper right Pilot Hole on the Right Hand

Back Panel.

5. Continue attaching the Deflector Panel with the other 12 Truss Head Screws.

NOTE: Numerical notations that follow part names in this document refer to part list item numbers

on pages 42 and 43.

Truss Head Screw, 5/8" long (7)

Right Hand Back Panel

Upper Left Clearance Hole

Deflector Panel (8)

Pilot Hole

Right Hand Back Panel

Left Hand Back Panel

Deflector Panel (8)

Truss Head Screw, 5/8" long (7)

REVOLVING SHELF ASSEMBLY CONTINUED

ASSEMBLE DEFLECTOR PANEL TO THE CORNER PANEL

Page 45

45

1. Assemble the Leveler Glides (14) to the Base Frame Assembly (10) as follows.

a. Screw four Leveler Glides (14) into the lower surface of the four 3/8-16 threaded holes in the

Base Frame Assembly (10).

b. Use a 1/2" wrench, if necessary, and screw the Leveler Glides into the Base Frame until the head

of each Leveler Glide is nearly against the lower surface as shown below.

Threaded Hole, 3/8-16

Leveler Glide, 3" long (14)

Threaded Hole, 3/8-16

Leveler Glide,

3" long (14)

Bass Frame Assembly (10)

Turn the Leveler Glide (14) into the

threaded hole until it is nearly flush

with the lower surface of the Base

Frame Assembly (10)

Lower Surface

Upper Surface

Head

REVOLVING SHELF ASSEMBLY CONTINUED

ASSEMBLE BASE FRAME AND CENTER COLUMN

Page 46

46

2. Assemble the Base Frame Assembly (10), Center Column (11), and Top Plate Assembly (9)

as follows.

a. Place the Base Frame Assembly (10) flat on the floor.

b. Place the Thrust Washer (6) onto the Base Frame Assembly Post (10).

c. Place the Center Column Assembly (11) onto the Base Frame Assembly Post and Thrust

Washer (6).

NOTE: One person should hold the Center Column Assembly (11) in an upright position until

completing step 3 on the next page.

d. Insert the the Top Plate Assembly Post (9) into the Clearance

Hole at the top of the Center Column Assembly.

Top Plate Assembly (9)

Bass Frame Assembly (10)

Thrust Washer (6)

Center Column Assembly (11)

Bass Frame Assembly Post

Top Plate Assembly Post (facing downward)

Center Column Assembly Clearance Hole

REVOLVING SHELF ASSEMBLY CONTINUED

ASSEMBLE BASE FRAME AND CENTER COLUMN CO

NTINUED

Page 47

47

3. Fasten the Center Column Assembly components to the Corner Cabinet as follows.

a. With two people working together, slide the Base Frame, Center Column and Top Plate

(assembled together) through the doorway into the Corner Cabinet. It may be necessary to

rotate the Base Frame Assembly as it is pushed through the doorway.

NOTE: The Center Column Assembly can be placed inside the Corner Cabinet without

removing any panels (such as the Top Panel or side panels).

b. Rotate the Base Frame Assembly (10) so that the two short legs face the back panels (see

illustration below) and the wings rest on top of the Base Frame.

c. Align the four Clearance Holes in the Base Frame Assembly Wings (10) to the four

3

/8" diameter

clearance holes in the Bottom Frame.

d. Insert four Capscrews (3) into the clearance holes on the Base Frame Assembly (10) and, using

a 9/16" wrench or socket and ratchet, screw the Capscrews (3) into the Bottom Frame.

e. Turn the Top Plate Assembly (9) so that the four Clearance Holes in the corners align with the

four holes on the inside surface of the Top Panel (these holes have Screw Inserts on the outside

surface).

f. Insert four Capscrews (1) into the four Top Plate Assembly (9) Clearance Holes and, using a 7/16"

wrench or socket and ratchet, screw the Capscrews (1) into the four Top Panel Screw Inserts.

Top Panel

(shown cut away)

Screw Insert

Center Column Assembly (11)

Top Plate Assembly (9)

Capscrew, 3/8-16 x 13/4" (3)

Clearance Hole

Capscrew,

1

/4-20 x 3/4" long (1)

Top Panel

Bottom Frame

Bottom Frame

Clearance Hole

Base Frame Assembly (10)

3

/8" Clearance Hole

Base Frame

Assembly (10)

Shorter Legs

Base Frame Assembly (10) Wing

REVOLVING SHELF ASSEMBLY CONTINUED

ASSEMBLE BASE FRAME AND CENTER COLUMN CO

NTINUED

Page 48

48

To install the Half Shelf Assembly to the Center Column Assembly, do as follows.

1. Place the Half Shelf Assembly (12) against the Center Column Assembly (11), aligning the

Clearance Holes in the Half Shelf with the Clearance Holes in the Center Column.

2. Insert a Capscrew (4) through a Flat Washer (2) and then through the upper Clearance Hole in the

Half Shelf, until the capscrew threaded end extends from the Center Column.

3. If a second Half Shelf Assembly (12) is to be assembled, align the upper clearance hole to the

threaded end of the Capscrew (4) and push the Shelf against the Center Column.

4. Place a Flat Washer (2) onto the threaded end of the Capscrew (4).

5. Screw a Locknut (5) onto the Capscrew (4).

6. Repeat steps 2, 4, and 5 at the lower clearance hole.

7. Using two 9/16" wrenches or sockets and ratchets, tighten the Capscrews and Locknuts.

8. Install additional Half Shelf Assemblies by repeating steps 1 to 7.

Half Shelf Assembly (12)

Capscrew, 3/8-16 x 31/4" long (4)

Locknut, 3/8-16 (5)

Flat Washer (2)

!

CAUTION

Make sure all

weight on shelves

is evenly

distributed.

!

CAUTION

Do not place more

than 50 pounds on

a Half Shelf

Assembly.

Clearance Holes

Center Column Assembly (11)

Locknut, 3/8-16 (5)

REVOLVING SHELF ASSEMBLY CONTINUED

ASSEMBLE A HALF SHELF TO THE CENTER COLUMN

Page 49

49

1. Assemble two Flag/Choral Robe Assemblies (13) to the Center Column (11) as follows. Refer to

page 51 for the placement of the Flag/ Choral Robe Assemblies.

NOTE: If you are assembling a Flag Storage Option, install the Flag/Choral Robe Assemblies (13)

five feet above the Revolving Shelf (12). Refer to the illustration for step 3.

a. Hold a Flag/Choral Robe Assembly (13) against the Center Column Assembly (11) aligning the

Upper Clearance Hole to the clearance hole in the Center Column Assembly.

b. Insert a Capscrew (4) through a Flat Washer (5) and then through the upper Clearance Hole in

the Flag/Choral Robe Assembly, until the threaded end extends from the the Center Column

Assembly.

c. Align the Upper Clearance Hole in a second Flag/Choral Robe Assembly (13) to the threaded

end of the Capscrew (4) and push the Shelf against the Center Column.

d. Place a Flat Washer (2) onto the Capscrew (4).

e. Screw a Locknut (5) onto the Capscrew (4).

f. Repeat steps b to e using the third clearance hole from the top (shown in the illustration below).

g. Using two 9/16" wrenches, tighten the Capscrews and Locknuts.

Capscrew, 3/8-16 x 31/4" long (4)

Flat Washer (2)

Upper Clearance Hole

Third Clearance Hole from the Top

Flat Washer (2)

Flag/Choral Robe Assembly (13)

Center Column

Assembly (11)

Locknut, 3/8-16 (5)

REVOLVING SHELF ASSEMBLY CONTINUED

ASSEMBLE A FLAG/CHORAL ROBE PACK

Page 50

50

2. To assemble the second pair of Flag/Choral Robe Assemblies (13), do as follows.

a. Place a Flag/Choral Robe Assembly (13) against the Center Column Assembly (11) between the

two assembled Flag/Choral Robe Assemblies with the upper edge even with the other

assemblies(refer to the illustration below).

b. Insert a Capscrew (4) through a Flat Washer (5) and then through the second from the top

Clearance Hole in the Flag/Choral Robe Assembly, pushing the Capscrew (4) until the threaded

end extends from the Center Column Assembly.

c. Align the second from the top Clearance Hole in the fourth Flag/Choral Robe Assembly (13) to

the Capscrew (4) and push the Flag/Choral Robe Assembly (13) against the Center Column.

d. Place a Flat Washer (2) onto the Capscrew (4).

e. Screw a Locknut (5) onto the Capscrew (4).

f. Repeat steps b to e using the lowest clearance hole (shown in the illustration below).

g. Using two 9/16" wrenches or sockets and ratchets, tighten the Capscrews and Locknuts.

Flag/Choral Robe Assembly (13)

Capscrew, 3/8-16 x 31/4" long (4)

Lowest Clearance Hole

Second Clearance Hole from the Top

Flat Washer (2)

Center Column

Assembly (11)

Make sure these edges are

at the same level

Complete Flag/Choral Robe

Assembly Option

Locknut, 3/8-16 (5)

REVOLVING SHELF ASSEMBLY CONTINUED

ASSEMBLE FLAG/CHORAL ROBE PACK (C

ONTINUED

)

Page 51

51

Flag Storage Option — Place the

Flag/Choral Robe Assemblies five feet

higher than the upper surface of the Half

Shelf Assemblies

5-feet

Flag/Choral Robe

Assembly (13)

Center Column

Assembly (11)

Half Shelf

Assemblies (12)

3. If you are assembling a Flag Storage Option, locate the Flag/Choral Robe Assembly (13) five feet

above the Half Shelf Assemblies (12) and place a Pad on the upper surface of each Half Shelf

Assembly (12) as shown below.

Pad

4. If you are assembling a Revolving Garment Option with two Flag/Choral Robe Packs, locate the

Flag/Choral Robe Assemblies (13) about at the top and at the mid point on the Center Column

Assembly and the Half Shelf Assemblies (12) at the bottom as shown below. Place a Pad on the

upper surface of each Half Shelf Assembly (12)

Pad

Flag/Choral Robe

Assembly (13)

approximately at the top

Center Column Assembly (11)

Half Shelf

Assemblies (12)

Revolving Garment Option — Place the

Flag/Choral Robe Assemblies at the

mid-point and at the top of the Center

Column and the Half Shelf Assemblies at

the bottom as shown above.

Flag/Choral Robe

Assembly (13)

approximately at the

mid-point

Half Shelf

Assemblies (12)

REVOLVING SHELF ASSEMBLY CONTINUED

ASSEMBLE FLAG/CHORAL ROBE PACK (C

ONTINUED

)

Page 52

52

This page is intentionally blank.

Loading...

Loading...