Page 1

MODEL MM1214

12" DUAL-BEVEL SLIDING

COMPOUND MITER SAW

For replacement parts visit

WENPRODUCTS.COM

IMPORTANT:

Your new tool has been engineered and manufactured to WEN’s highest standards for dependability, ease

of operation, and operator safety. When properly cared for, this product will supply you years of rugged,

trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions.

If you use your tool properly and for its intended purpose, you will enjoy years of safe, reliable service.

NEED HELP? CONTACT US!

Have product questions? Need technical support?

Please feel free to contact us at:

800-232-1195 (M-F 8am-5pm CST)

techsupport@wenproducts.com

WENPRODUCTS.COM

NOTICE: Please refer to wenproducts.com for the most up-to-date instruction manual.

Page 2

TABLE OF CONTENTS

Specifications ........................................................................................... 2

Introduction ............................................................................................. 3

General Safety Rules ................................................................................ 4

Specific Safety Rules for Your Miter Saw ................................................. 6

Electrical Information ............................................................................... 8

Unpacking & Transportation .................................................................... 9

Know Your Miter Saw ............................................................................ 10

Assembly & Adjustments ....................................................................... 12

Operation ............................................................................................... 19

Maintenance ........................................................................................... 21

Troubleshooting Guide ........................................................................... 22

Exploded View & Parts List .................................................................... 23

Warranty Statement ............................................................................... 27

SPECIFICATIONS

Model Number MM1214

Motor 120V, 60Hz, 15A

Laser Type 650 nm, <1 mW

Laser Class II

No-Load Speed 3800 RPM

Blade Part Number MM1214B

Blade Size 12" (305mm) TCT

Arbor Size 1" (25.4mm)

Kerf 2.8mm

Teeth 60T

Miter Table Angles 0° - 45° Left & Right

Bevel Cut Angles 0° - 45° Left & Right

Positive Miter Stops

Cutting Capacity

0°, 15°, 22.5°, 30°, and 45° Left & Right

0° Miter, 90° Bevel 3-1/2" x 13-3/8"

45° Miter, 90° Bevel 3-1/2" x 9-1/2"

0° Miter, 45° Bevel 2-1/8" x 13-3/8"

45° Miter, 45° Bevel 2-1/8" x 9-1/2"

Weight 61 lbs

Product Dimensions 27" x 35" x 20"

Replacement blades (Part MM1214B), carbon brushes (Part MM1214-114),

and additional blades can be purchased from wenproducts.com.

Page 3

INTRODUCTION

Thanks for purchasing the WEN Miter Saw. We know you are excited to put your tool to work, but first, please

take a moment to read through the manual. Safe operation of this tool requires that you read and understand this

operator’s manual and all the labels affixed to the tool. This manual provides information regarding potential safety

concerns, as well as helpful assembly and operating instructions for your tool.

SAFETY ALERT SYMBOL: Indicates danger, warning, or caution. The safety symbols and the

explanations with them deserve your careful attention and understanding. Always follow the safety precautions to reduce the risk of fire, electric shock and personal injury. However, please note that these

instructions and warnings are not substitutes for proper accident prevention measures.

NOTE: The following safety information is not meant to cover all possible conditions and situations that may occur.

WEN reserves the right to change this product and specifications at any time without prior notice.

Keep this manual available to all users during the entire life of the tool and review it frequently to

maximize safety for both yourself and others.

32

Page 4

GENERAL SAFETY RULES

Safety is a combination of common sense, staying alert and knowing how your item works.

SAVE THESE SAFETY INSTRUCTIONS.

WARNING: Read and understand all warnings, cautions and operating instructions before using

this tool. Failure to follow all instructions listed below may result in personal injury, electric shock, fire

and/or tool damage.

WORK AREA SAFETY

1. KEEP WORK AREA CLEAN AND WELL LIT. Cluttered

or dark areas invite accidents.

2. DO NOT OPERATE POWER TOOLS IN EXPLOSIVE

ATMOSPHERES, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

3. DO NOT EXPOSE POWER TOOLS TO RAIN OR WET

CONDITIONS. Water entering a power tool will increase

the risk of electric shock.

4. KEEP CHILDREN AND BYSTANDERS AWAY WHILE

OPERATING A POWER TOOL. Distractions can cause

you to lose control.

ELECTRICAL SAFETY

1. POWER TOOL PLUGS MUST MATCH THE OUTLET.

Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

2. AVOID BODY CONTACT WITH EARTHED OR GROUNDED SURFACES such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

3. DO NOT ABUSE THE CORD. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

PERSONAL SAFETY

1. STAY ALERT, WATCH WHAT YOU ARE DOING AND

USE COMMON SENSE WHEN OPERATING A POWER

TOOL. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may

result in serious personal injury.

2. USE PERSONAL PROTECTIVE EQUIPMENT. ALWAYS

WEAR EYE PROTECTION. Protective equipment such as

a respiratory mask, non-skid safety shoes and hearing

protection used for appropriate conditions will reduce

the risk of personal injury.

3. DRESS PROPERLY. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from moving

parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

4. PREVENT UNINTENTIONAL STARTING. Ensure the

switch is in the off-position before connecting to power

source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch

or energizing power tools that have the switch on invites

accidents.

5. REMOVE ANY ADJUSTING KEY OR WRENCH BEFORE TURNING THE POWER TOOL ON. A wrench or a

key left attached to a rotating part of the power tool may

result in personal injury.

6. DO NOT OVERREACH. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

4. IF OPERATING A POWER TOOL IN A DAMP LOCATION IS UNAVOIDABLE, USE A GROUND FAULT CIRCUIT INTERRUPTER (GFCI) PROTECTED SUPPLY. Use

of a GFCI reduces the risk of electric shock.

7. IF DEVICES ARE PROVIDED FOR THE CONNECTION

OF DUST EXTRACTION AND COLLECTION FACILITIES,

ENSURE THESE ARE CONNECTED AND PROPERLY

USED. Use of dust collection can reduce dust-related

hazards.

Page 5

GENERAL SAFETY RULES

POWER TOOL USE AND CARE

1. DO NOT FORCE THE POWER TOOL. Use the correct

power tool for your application. The correct power tool

will do the job better and safer at the rate for which it

was designed.

2. DO NOT USE THE POWER TOOL IF THE SWITCH

DOES NOT TURN IT ON AND OFF. Any power tool that

cannot be controlled with the switch is dangerous and

must be repaired.

3. DISCONNECT THE PLUG FROM THE POWER SOURCE

AND/OR THE BATTERY PACK FROM THE POWER TOOL

BEFORE MAKING ANY ADJUSTMENTS, CHANGING ACCESSORIES, OR STORING POWER TOOLS. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

4. STORE IDLE POWER TOOLS OUT OF THE REACH

OF CHILDREN AND DO NOT ALLOW PERSONS UNFAMILIAR WITH THE POWER TOOL OR THESE INSTRUCTIONS TO OPERATE THE POWER TOOL. Power tools

are dangerous in the hands of untrained users.

CALIFORNIA PROPOSITION 65 WARNING

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities may contain

chemicals, including lead, known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling. Some examples of

these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies depending on

how often you do this type of work. To reduce your exposure to these chemicals, work in a well-ventilated area

with approved safety equipment such as dust masks

specially designed to filter out microscopic particles.

SERVICE

Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

5. MAINTAIN POWER TOOLS. Check for misalignment

or binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained

power tools.

6. USE THE POWER TOOL, ACCESSORIES AND TOOL

BITS ETC. IN ACCORDANCE WITH THESE INSTRUCTIONS, taking into account the working conditions and

the work to be performed. Use of the power tool for operations different from those intended could result in a

hazardous situation.

7. USE CLAMPS TO SECURE YOUR WORKPIECE TO A

STABLE SURFACE. Holding a workpiece by hand or using your body to support it may lead to loss of control.

8. KEEP GUARDS IN PLACE and in working order.

54

Page 6

SPECIFIC RULES FOR YOUR MITER SAW

WARNING: Do not operate the miter saw until you have read and understood the following instruc-

tions and the warning labels.

SAW BLADE SAFETY

1. Always wear protective gloves when handling saw

blades.

2. Only use blades with correct size and type for both

your miter saw and your workpiece.

• The rated diameter of the saw blade is 12" with a 1"

arbor.

• The no-load speed of the miter saw is 3800 RPM.

The maximum permissible speed of your saw blade

should always be higher than the no-load rotational

speed of the saw.

3. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in close

proximity to pacemakers could cause pacemaker interference or pacemaker failure.

4. Wear work gloves when handling saw blades. DO NOT

wear gloves while operating the saw.

5. Sawdust is harmful to your health. Use NIOSH-approved dust masks or other respiratory protection during operation and cleaning.

3. Never use damaged or deformed saw blades. Only

use sharp blades.

4. Install the saw blade in the correct orientation indicated in the instructions (see “Changing the Saw Blade”,

p. 17).

5. Keep hands out of path of saw blade. Never use your

hands to remove sawdust, chips or workpiece near the

saw blade or the cutting path of the saw.

6. Never reach around saw blade or reach in back of the

saw blade.

7. Do not use blades made from high-speed steel, abrasive blades, metal-cutting blades or masonry-cutting

blades. The guards of this saw are not designed to protect against the failure of such blades.

8. The use of accessories or attachments not recommended by the manufacturer may result in a risk of personal injury.

6. Always turn off and unplug the miter saw before making any adjustments or repair tasks. Never adjust the

miter saw or the workpiece while the saw the running.

7. The lock down pin is to be used only to lock the head

in place for carrying and storage. It is not to be used for

any cutting operation.

8. Never use damaged or incorrect blade flanges or bolt.

The blade flanges and bolt were specially designed for

your saw, for optimum performance and safety of operation.

9. Do not use to cut metal, logs, tree limbs, or uneven

lumber.

10. Wet lumber, green (unseasoned) lumber, and pressure treated lumber all have an increased potential for

kickback and should only be cut with a blade specifically

designed for that lumber type. Wear a NIOSH-approved

respirator and have appropriate ventilation whenever

cutting pressure treated lumber.

PERSONAL SAFETY

1. Operate in a well ventilated area. Keep the floor area

around the miter saw level and free of slippery substances or other tripping hazards.

2. Wear ANSI-approved safety goggles to protect your

eyes from sparks and saw dust. Use hearing protection

to protect yourself from hearing loss.

PREPARING THE MITER SAW

1. When transporting the miter saw, carry it by either the

carrying handle or the base. Never carry the device by its

guards or its accessories. Make sure that the lower part

of the saw blade is covered by the blade guard during

transportation.

2. Securely bolt the miter saw onto a miter saw stand or

a workbench before operating.

Page 7

SPECIFIC RULES FOR YOUR MITER SAW

WARNING: Do not operate the miter saw until you have read and understood the following instruc-

tions and the warning labels.

3. Examine the miter saw for any damaged or missing

parts. Replace or repair damaged parts before operation. Periodically check that all nuts, bolts and other fasteners are properly tightened.

SECURE YOUR WORKPIECE

1. Always position the workpiece on the miter table and

firmly against the fence. Use the included hold-down

clamp to secure the workpiece. Never perform any operation freehand.

2. Use a clamp or other securing methods to support the

workpiece whenever possible.

3. When cutting round workpieces, use clamps on both

sides of the table to prevent the workpiece from turning.

Position the convex (curved) side against the fence.

4. Always support long workpieces properly using

stands or roller tables.

5. Never hand-hold a workpiece that is too small to be

clamped, as it can be launched away and cause injury. Use proper support and guides to secure the small

workpiece.

5. Turn on the miter saw and let it reach full speed, then

slowly lower the saw into the workpiece. This will help

produce safer and cleaner cuts.

6. During slide cutting, always push the saw blade away

from you. Do not pull the saw towards you.

7. Never cut more than one piece at a time. Do not stack

workpieces together.

8. Turn off tool and wait for saw blade to stop before

moving workpiece or changing settings. Do not slow or

stop a blade with a piece of wood. Let the blade come

to rest naturally. Do not attempt to free a jammed blade

while the machine is still running.

9. To reduce risk of injury, return carriage to the full rear

position after each crosscut operation.

LASER SAFETY

ATTENTION: LASER RADIATION. Class 2 laser.

DO NOT STARE INTO THE BEAM

1. Do not look directly into the laser beam with unprotected eyes. Never look into the path of the beam.

DURING CUTTING OPERATIONS

1. Make sure the path of the saw blade is clear of obstruction. Before turning on the miter saw, do a dry run

and make sure that the saw blade does not touch anything other than the workpiece during its entire line of

travel.

2. Always stand to one side when operating the saw.

Never have any part of the body in line with the path of

the saw.

3. Feed work into a blade against the direction of rotation of the blade only.

4. Do not use the miter saw unless all guards are in

place. Do not operate with any guard disabled, damaged, or removed. Moving guards must move freely and

close instantly.

2. Never point the laser beam towards reflecting surfaces. Never point the laser towards people or animals.

Even a laser beam with a low output can cause damage

to the eyes.

3. Never open the laser module as unexpected exposure

to the beam can occur. The laser cannot be replaced with

a different type of laser.

4. Repairs of the laser may only be carried out by the

laser manufacturer or an authorized representative.

76

Page 8

ELECTRICAL INFORMATION

GROUNDING INSTRUCTIONS

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN, grounding provides the path of least resistance for an electric current and reduces the risk of electric shock. This tool is equipped with an electric cord that has an equipment

grounding conductor and a grounding plug. The plug MUST be plugged into a matching outlet that is properly

installed and grounded in accordance with ALL local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the outlet, have the proper outlet installed by a licensed

electrician.

IMPROPER CONNECTION of the equipment grounding conductor can result in electric shock. The conductor with

the green insulation (with or without yellow stripes) is the equipment grounding conductor. If repair or replacement

of the electric cord or plug is necessary, DO NOT connect the equipment grounding conductor to a live terminal.

CHECK with a licensed electrician or service personnel if you do not completely understand the grounding instructions or whether the tool is properly grounded.

USE ONLY THREE-WIRE EXTENSION CORDS that have three-pronged plugs and outlets

that accept the tool’s plug (Fig. 1). Repair or replace a damaged or worn cord immediately.

CAUTION:

are not sure, have a licensed electrician check the outlet.

In all cases, make certain the outlet in question is properly grounded. If you

Fig. 1

GUIDELINES AND RECOMMENDATIONS FOR EXTENSION CORDS

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The table below shows the

correct size to be used according to cord length and ampere rating. When in doubt, use a heavier cord. The smaller

the gauge number, the heavier the cord.

AMPERAGE

25 ft. 50 ft. 100 ft. 150 ft.

15A 14 gauge 12 gauge Not Recommended

1. EXAMINE EXTENSION CORD BEFORE USE. Make sure your extension cord is properly wired and in good condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it.

2. DO NOT ABUSE EXTENSION CORD. Do not pull on cord to disconnect from receptacle; always disconnect by pulling on plug. Disconnect the extension cord from the receptacle before disconnecting the product from the extension

cord. Protect your extension cords from sharp objects, excessive heat and damp/wet areas.

REQUIRED GAUGE FOR EXTENSION CORDS

3. USE A SEPARATE ELECTRICAL CIRCUIT FOR YOUR TOOL. This circuit must not be less than a 12-gauge wire

and should be protected with a 15A time-delayed fuse. Before connecting the motor to the power line, make sure

the switch is in the OFF position and the electric current is rated the same as the current stamped on the motor

nameplate. Running at a lower voltage will damage the motor.

Page 9

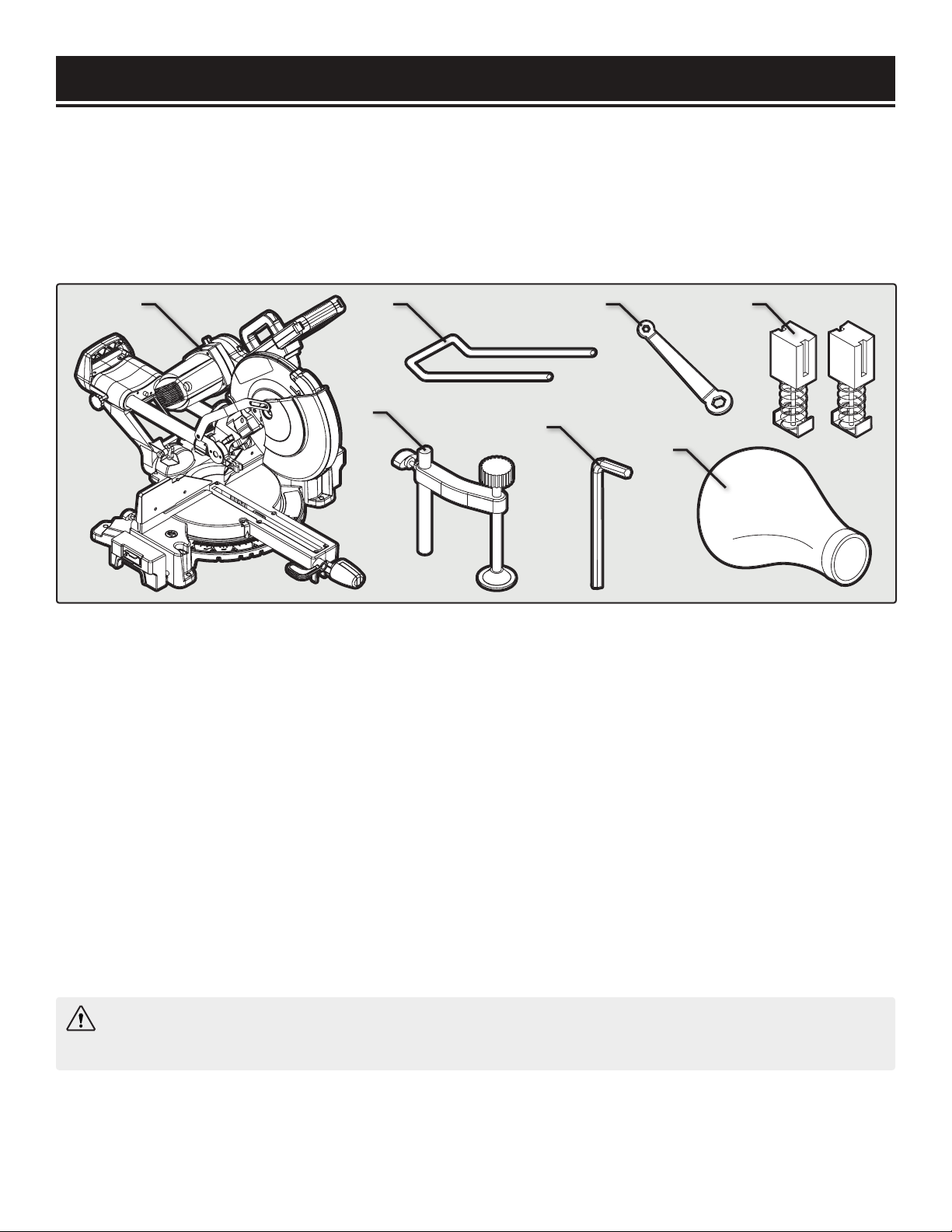

UNPACKING & TRANSPORTATION

UNPACKING

With the help of a friend or trustworthy foe, carefully remove the miter saw from the packaging. Make sure to take

out all contents and accessories. Do not discard the packaging until everything is removed. Check the packing list

below to make sure you have all of the parts and accessories. If any part is missing or broken, please contact our

customer service at 1-800-232-1195.

PACKING LIST

A

A. Miter Saw (1)

B. Support Stand (1)

C. 10mm/13mm Box-End Wrench (1)

D. Carbon Brush Replacement (2)

E. Clamp Assembly (1)

F. 6mm Hex Wrench (1)

G. Dust Collection Bag (1)

B

E

F

G

DC

The tools listed below are not included but are required for either assembly or adjustment.

• Mounting Hardware

• Combination Square

• Phillips-head Screwdriver

TRANSPORTING THE MITER SAW

Before transporting your miter saw, make sure saw arm is locked down, the miter table is locked in position and

the slide lock knob is tightened. Only lift the saw by the carrying handle located on top of the belt housing or at the

back of the rails. Do not lift the saw using the guards or the operating handle.

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Failure

to follow the safety instructions may result in serious personal injury.

98

Page 10

KNOW YOUR MITER SAW

TOOL PURPOSE

Miter Saws allow you to easily make cuts at a variety of angles. Refer to the following diagrams to become familiarized with all the parts and controls of your miter saw. The components will be referred to later in the manual for

assembly and operation instructions.

E

D

F

G

H

C

B

A

P O N M

A. Table Extension

B. Fence

C. Clamp Assembly

D. LED Work Light

E. Slide Lock Knob

F. Trigger Locks

G. Laser

H. Lower Blade Guard

I. Blade

J. Miter Table

K. Kerf Board

L. Miter Lock Knob

M. Miter Stop Lever

N. Bevel Lock Lever

O. Miter Angle Indicator

P. Miter Scale

I

J

K

L

Page 11

KNOW YOUR MITER SAW

T

S

R

Q

U

V

W

X

Q. Spindle Lock

R. Operating Handle

S. Carrying Handle

T. Power Trigger

U. Laser ON/OFF

V. Work Light ON/OFF

W. Rear Carrying Handle

X. Support Stand

Y

Z

Y. Bevel Scale

Z. Stop Plate

1110

Page 12

ASSEMBLY & ADJUSTMENTS

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your miter saw. Failure

to follow the safety instructions may result in serious personal injury.

GUARD OPERATION

NOTE: Keep hands clear of the blade when the operat-

ing handle is lowered. Do not interfere with the proper

movement of the blade guard.

When the handle is lowered, the blade guard raises automatically. When the handle is raised, the blade guard

returns to its safety position, covering the blade.

RAISING/LOWERING THE SAW ARM

The saw arm needs to be raised up before operation and

locked down for transporting and storing.

To raise saw arm from the lower position:

1. Holding the operating handle (Fig. 2 - 3), lightly press

down on the saw arm and pull out the release knob (Fig.

2 - 2). Slowly raise the saw arm to the upper position.

2. Set the release knob pin into the deep groove (Fig.

3 - 1) to lock the cutting head. Set the release knob pin

into the shallow groove (Fig. 3 - 2) to unlock the cutting

head.

To lower saw arm from the upper position:

1. Holding the operating handle (Fig. 2 - 3), push the

blade guard lever and pull out the release knob (Fig. 2

- 2).

3

2

1

2

Fig. 2

4

5

Fig. 3

2. Slowly lower the saw arm to the lower position and

lock the release knob into the deep groove (Fig. 3 - 1).

ADJUSTING THE BEVEL ANGLE

The saw arm can bevel from 0° to 45° to the left or right.

1. Unlock the bevel lock lever (Fig. 2 - 1) by rotating it

upwards (clockwise).

2. Tilt the saw arm until the bevel angle indicator points

to the desired angle on the bevel scale (Fig. 2 - 5).

3. Tighten the bevel lock lever (Fig. 2 - 1) by rotating it

down (counterclockwise). Be sure to tighten firmly without over-tightening.

1

SETTING UP ARM SLIDE

The saw arm can be adjusted to different lengths using

the slide bar, and can slide back and forth when crosscutting.

For sliding cuts: Loosen the slide lock knob (Fig. 2 - 4)

and slide the saw arm to desired position.

For non-sliding cuts and transportation: Tighten the

slide lock knob (Fig. 2 - 4) for non-sliding operations

and before transporting the miter saw.

Page 13

ASSEMBLY & ADJUSTMENTS

1 2

Fig. 4 Fig. 5

Clamp

Assembly

5

3

4

1

2

ADJUSTING THE MITER ANGLE

The miter table can be adjusted from 0° to 45° to both

left and right to create miter cuts.

1. Loosen the miter lock knob (Fig. 4 - 5) by turning it

one or two turns counterclockwise.

2. Pull up on the miter stop lever (Fig. 4 - 4) to unlock

the table. While holding the miter stop lever up, adjust

the table to the desired angle. The miter scale indicator (Fig. 4 - 3) will point towards the selected angle. To

make micro adjustments to a specific angle, rotate the

table while pulling up on the miter stop lever. The miter

table has positive stops at 0°, 15°, 22.5°, 30°, and 45°

in both directions for quick adjustments.

3. After selecting your miter angle, release the miter

stop lever and tighten the miter lock knob (Fig. 4 - 5) by

turning it clockwise to lock the table in place.

WARNING: Be sure the miter table is locked in place before making a cut. Failure to do so can cause the table

to move during the cut, which could result in serious

personal injury.

USING THE TABLE EXTENSIONS

The table extensions (Fig. 4 - 1) come pre-installed on

either side of your miter saw and serve as extra support

for your workpiece. Loosen the table extension knobs

(Fig. 4 - 2) to adjust their positioning. The stop plate on

each table extension can be raised to quickly and easily

make repeated cuts.

INSTALLING THE CLAMP ASSEMBLY

The clamp comes pre-assembled and can be mounted

on the left or right side of the saw depending on the cutting task at hand.

1. Locate the hole for the clamp on the left or right side

of the miter saw behind the fence (Fig. 5 - arrows). Insert the clamp assembly (Fig. 5) into the slot.

2. Secure the clamp into place by tightening the clamp

lock screw (Fig. 5 - 1).

NOTE: Check that the clamp won’t interfere with the

blade travel before operating the saw.

3. Rotate the clamp knob (Fig. 5 - 2) to move it up or

down as needed to securing the workpiece. Check that

the workpiece is secure and does not wobble before cutting.

1312

Page 14

ASSEMBLY & ADJUSTMENTS

18"

17-7/8"

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your miter saw. Failure

to follow the safety instructions may result in serious personal injury.

INSTALLING THE SUPPORT STAND

The support stand offers additional stability for your

miter saw. Follow the instructions below to install the

support stand.

1. Locate the two holes for the support stand on the back

of the miter saw (Fig. 6 - arrows). Loosen the Phillipshead screw on the bottom of the left hole (Fig. 6 - 2),

then insert the support stand (Fig. 6 - 1) into the holes.

2. Secure the stand into place by tightening the stand

lock screw (Fig. 6 - 1). See p. 11 - X for installation orientation.

BENCH MOUNTING

1. The miter saw base has four holes on the base for

bench mounting (Fig. 7 - arrows). Mount and fix the

saw to a level, horizontal bench, worktable, or miter

saw stand (compatible with WEN Models MSA330 and

MSA750) using four bolts and nuts (not included).

Fig. 6

1

2

Back View

Fig. 7

2. If desired, you can mount the saw to a piece of 1/2"

or thicker plywood which can then be clamped to your

work bench or moved to other job sites and reclamped.

CAUTION: Make sure that the mounting surface is not

warped. Uneven surfaces can cause binding and inaccurate sawing.

INSTALLING THE DUST COLLECTION BAG

The dust collection bag should be used at all times. Follow the instructions below to install the bag.

1. Locate the dust port on the back of the miter saw (Fig.

8 - arrow).

2. Squeeze the metal clip on the dust collection bag to

open the mouth of the bag. Slip the mouth of the dust

collection bag over the dust port and release the clip to

secure the bag to the outlet.

3. Open the zipper on the bottom of the bag to empty.

For efficient operation, empty the dust bag when half full

to allow for better air flow through the bag.

Fig. 8

Page 15

ASSEMBLY & ADJUSTMENTS

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your miter saw. Failure

to follow the safety instructions may result in serious personal injury.

1

2

SQUARING THE FENCE WITH THE BLADE

To make accurate cuts, the fence must be perpendicular

to the saw blade.

1. Lower the saw arm down to the lower position and

lock the release knob. See section titled, "Raising/Lowering the Saw Arm" on page 12.

2. Slide the saw arm to the back and tighten the slide

lock knob. See section titled, "Setting Up Arm Slide" on

page 12.

Fig. 10 Fig. 9

SQUARING THE TABLE WITH THE BLADE

To make accurate cuts, the table must be perpendicular

to the saw blade.

1. Lower the saw arm down to the lower position and

lock the release knob. See section titled, "Raising/Lowering the Saw Arm" on page 12.

2. Slide the saw arm to the back and tighten the slide

lock knob. See section titled, "Setting Up Arm Slide" on

page 12.

3. Set the miter table indicator (Fig. 9 - 2) to 0° and

tighten the miter lock knob. Place a combination square

(not included) against the fence and alongside the saw

blade (should be in contact with the surface of the blade,

not the teeth).

4. Slightly loosen the four fence adjusting bolts on the

back of the fence (Fig. 10 - arrows) with the included hex

wrench. Adjust the fence position until it is 90° with the

blade. Tighten the four bolts to secure the fence.

5. Make a test cut. Repeat step 4 until your test cut is

accurate.

SETTING THE MITER SCALE INDICATOR

1. Loosen the screw (Fig. 9 - 1) holding the miter scale

indicator.

2. Adjust the direction of the indicator (Fig. 9 - 2) so that

it accurately points to 0° on the miter scale. Tighten the

screw.

3. Set the miter table indicator (Fig. 9 - 2) to 0° and

tighten the miter lock knob. Set the bevel angle indicator

to 0° (Fig. 11 - 6, p. 16) and tighten the bevel lock lever.

4. Place a combination square (not included) against the

table and alongside the saw blade (should be in contact

with the surface of the blade, not the teeth). Wearing

work gloves, rotate the blade by hand and check the

blade-to-table alignment at several points. The edge of

the combination square and the saw blade should be

parallel. If the saw blade tilts away from the combination square, continue on with the steps on the following

page.

WARNING: To prevent serious injury, after making any adjustments to the cutting angle, make sure

the both sides of the fence are clear of the blade's

cutting path. With the power OFF, move the blade

through its full range of motion to check this.

Instructions continue on the next page.

1514

Page 16

ASSEMBLY & ADJUSTMENTS

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your miter saw. Failure

to follow the safety instructions may result in serious personal injury.

5. Flip the bevel stop block (Fig. 11 - 4) up. Loosen the

zero stop lock nut (Fig. 11 - 2) and adjust the zero stop

screw (Fig. 11 - 1) until the table is 90° with the blade.

Tighten the zero stop lock nut to secure the blade.

6. Make a test cut. Repeat step 5 until your test cut is

accurate.

NOTE: To adjust one of the 45° bevel stop screws (Fig.

11 - 3 & 7), loosen the bevel adjustment nut (Fig. 11 -

8), flip down the bevel stop block, and turn the bevel

adjustment screw (Fig. 11 - 7) using a hex wrench. Turn

clockwise to increase the bevel and counterclockwise to

decrease the bevel. Tighten the nut after adjustment.

SETTING THE BEVEL SCALE INDICATOR

1. Before setting the bevel scale indicator, the table must

be perpendicular to the saw blade. See section titled,

"Squaring the Table with the Blade" on page 15.

2. Loosen the screw (Fig. 11 - 5) holding the bevel scale

indicator.

1

4

2

3

1

Fig. 11

5

6

7

8

Fig. 12

2

3. Adjust the direction of the indicator so that it accurately points to 0° on the bevel scale. Tighten the screw.

ADJUSTING THE CUTTING DEPTH

The saw cutting depth can be adjusted if you would like

to perform a kerfing or rabbet cut that does not cut all

the way through the workpiece.

WARNING: Only adjust the front bolt (Fig. 12

- 1). The rear bolt is used to prevent the blade from

cutting the table during normal cutting. DO NOT adjust the rear depth bolt.

1. Unplug the tool from its power source and raise the

saw head assembly.

2. Locate the depth stop settings on the left side of the

saw (Fig. 12). Rotate the depth stop plate (Fig. 12 - 3) to

the left to use the depth stop bolt setting.

3

3. Pull down on the saw head to check the current setting. To change the setting, continue to step 4.

4. Loosen the depth stop nut (Fig. 12 - 2) on the depth

stop bolt (Fig. 12 - 1). To decrease depth, turn the depth

stop bolt clockwise. To increase depth, turn the depth

stop bolt counterclockwise. Tighten the nut after adjustment.

NOTE: If needed, push the depth stop plate (Fig. 12 - 3)

to the position shown in Fig. 12 to temporarily disable it.

Make sure the depth stop is properly aligned to allow the

bolt to pass through it.

5. Check the cutting depth setting by completing a test

cut on a piece of scrap wood. Repeat steps 4 - 5 until the

desired depth is achieved.

Page 17

ASSEMBLY & ADJUSTMENTS

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your miter saw. Failure

to follow the safety instructions may result in serious personal injury. Wear gloves while changing the blade.

CHANGING THE SAW BLADE

DANGER! Never try to use a blade larger than the stated capacity of the

saw. Do not use a blade thicker than 1.9mm. It will prevent the blade

screw from properly securing the blade on the spindle. Install the suitable

blade for your cutting operation.

1. Unplug the tool from its power source. Place a piece of paper on the

miter table to catch the screws.

2. Lift the saw arm to the upper position and lock it in place. Raise the

lower blade guard (Fig. 13 - 2) out of the way and hold it up. Loosen the

lower blade guard screw (Fig. 14 - 1) with a Phillips-head screwdriver

(not included) until it disengages the guard plate (Fig. 14 - 2). Swing the

guard plate up and out of the way. NOTE: the safety guard does not need

to be taken off from the saw.

3. Firmly press down the saw spindle lock (p. 11 - Q) on the back of the

saw's head and hold it in. Use the 13mm box-end wrench to turn the arbor bolt (Fig. 15) clockwise and remove it (the bolt is left-hand threaded),

remove outer flange (Fig. 16 - 4), and arbor insert (Fig. 16 - 2). Make sure

the inner flange (Fig. 16 - 5) stays in place on the spindle (Fig. 16 - 6).

Fig. 13

1

2

Fig. 14

1

2

4. Slowly remove the blade by pulling it out and down. Clean the arbor

bolt (Fig. 15 - 3), outer flange (Fig. 15 - 4), and arbor insert (Fig. 15 - 2).

5. Place the arbor insert (Fig. 16 - 2) onto the spindle (Fig. 16 - 6). Place

the new blade over the arbor insert.

IMPORTANT: Make sure the blade's rotation arrow points in the same

direction as the rotation arrow on the upper blade guard (Fig. 16 - 7).

6. Reinstall the outer flange and arbor bolt. Hold down the spindle lock

and tighten the arbor bolt with the 13mm box-end wrench, turning it

counterclockwise. Release the spindle lock.

7. Return the guard plate (Fig. 14 - 2) back into place, and secure it with

the guard plate screw (Fig. 14 - 1).

IMPORTANT: Carefully rotate the saw blade and make sure that it does

not wobble. Lower the saw arm and check if the blade spins freely in the

table insert in both perpendicular and 45° angles. Make sure the lower

blade guard operates properly before using the saw.

Fig. 15

Outer

Flange

Arbor

Bolt

1

2

5

4

3

Fig. 16

6

7

1716

Page 18

ASSEMBLY & ADJUSTMENTS

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your miter saw. Failure

to follow the safety instructions may result in serious personal injury.

ADJUSTING THE DRIVE BELT

1. Unplug the tool from its power source. Loosen the 3 screws securing

the drive belt housing cover (Fig. 17) to the drive belt housing. Remove

the drive belt housing cover.

2. Using a 5mm hex wrench (not included), loosen, but do not remove,

the 6 hex screws (Fig. 18) that secure the motor to the belt drive housing.

3. Using a 4mm hex wrench (not included), turn counterclockwise

to loosen the set screw (Fig. 19 - 1) at the top of the of the belt drive

housing. This will release the tension on the drive belt and allow for

adjustments or replacements of the belt.

4. Re-seat the belt on the pulley, making sure the belt is properly

seated in the grooves of both pulleys. Re-tighten the belt by turning

the set screw (Fig. 19 - 1) clockwise. Re-tighten the 6 hex screws

(Fig. 18).

5. Test belt tension by squeezing both sides of the belt. If properly

adjusted, the belt should “give” between 1/16" - 1/8" (1.5mm - 3mm).

Make sure that the belt grooves are properly seated in the pulleys.

Screw

Drive

Belt Housing

Cover

Fig. 17

Screw

Screw

Fig. 18

Fig. 19

6. Carefully reinstall the drive belt housing cover by tightening the 3

screws (F

NOTE: Excessive tightness on the pulley belt will cause increased

noise and motor overload. Premature failure will occur if the belt is

too loose.

ADJUSTING THE FENCES

1. Loosen the fence adjustment knob (Fig. 20 - 2).

2. Adjust the fence as desired. The top portion of the fence (Fig. 20 - 1)

can slide to the left and right, while the bottom portion of the fence (Fig.

20 - 3) stays stationary.

3. Tighten the fence adjustment knob to lock the fence into place.

WARNING: To prevent serious injury, after making any adjustments to the cutting angle, make sure the

both sides of the fence are clear of the blade's cutting path. With the power OFF, move the blade through its full

range of motion to check this.

ig. 17

).

1

Fig. 20

1

2

3

Page 19

OPERATION

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your miter saw. Failure

to follow the safety instructions may result in serious personal injury.

1. RAISE THE SAW ARM

Before operation, raise the saw arm from the lower position. See section

titled, "Raising/Lowering the Saw Arm" on page 12.

2. SET UP THE CUT ANGLE & DEPTH

The miter saw can be set up to create cuts at different angles by adjusting the angle of the miter table and the saw bevel angle. There are four

types of cuts you can create: a cross cut, a miter cut, a bevel cut, and a

compound cut. See Fig. 21 to understand each type of cut. If you do not

want to cut all the way through your workpiece, adjust the cutting depth.

See note below.

To adjust the bevel angle: see section titled, "Adjusting the Bevel Angle"

on page 12. To adjust the miter angle: see section titled, "Adjusting the

Miter Angle" on page 13. To adjust the cutting depth: see section titled,

"Adjusting the Cutting Depth" on page 16.

2. SET UP SLIDING FUNCTION (FIG. 22)

For materials with a width under 4 inches (100 mm): the sliding func-

tion isn’t necessary. See section titled, "Setting Up Arm Slide" on page 12

to disable the sliding function.

Fig. 21

CROSS CUT

Miter table 0°, Saw arm 0°

BEVEL CUT

Miter table 0°, Saw arm 0° - 45°

For materials with a width over 4 inches (100 mm): the saw arm will

need to slide to cut through the workpiece. See section titled, "Setting Up

Arm Slide" on page 12 to enable the sliding function.

4. SET UP WORKPIECE

Place the workpiece flat on the table with one edge securely against the

fence.

Warped Boards: If the board is warped, place the convex side against the

fence (Fig. 23). CAUTION: The board could break and jam the blade if the

concave side is placed against the fence

Long Boards: When cutting long workpieces, support the opposite end of

the material with the support table, a roller stand or a work surface that

is level with the saw table.

Fig. 22 Fig. 23

w

MITER CUT

Miter table 0° - 45°, Saw arm 0°

COMPOUND CUT

Miter table 0° - 45°,

Saw arm 0° - 45°

1918

Page 20

OPERATION

WARNING: Before operating the miter saw, make sure to equip yourself with a dust mask, ear protection,

and safety glasses for protection from possible injuries. Tie back long hair and do not wear loose clothing or

jewelry. DO NOT look into the laser beam, this can cause serious eye damage or blindness. Do not wear gloves

while operating the saw.

5. SECURE WORKPIECE

Secure the workpiece with the clamping device on the fixed table whenever possible to prevent the material from moving during the cutting operations. See section, "Installing the Clamp Assembly" on page 13.

6. CHECK BEFORE OPERATION

• Check that the miter table does not rotate and the saw arm does not

bevel.

• Check that the workpiece is fully supported, against the fence and securely clamped down.

• Check that you have the proper blade for the material you are cutting.

• Without turning on the saw, perform a dry run of the cutting operation

to check that nothing is obstructing the path of the saw.

7. PERFORM THE CUT

1. Plug in the miter saw. Turn on the work light (Fig. 24 - 2) so you can

easily see what you are working on. Turn on the laser (Fig. 24 - 1) to see

where your cut will land on the material. CAUTION: DO NOT look into the

laser beam.

2. Grip the operating handle firmly, press one of the blade trigger lock

buttons (Fig. 24 - 4) with your thumb, and squeeze the power trigger (Fig.

24 - 3) to turn the saw ON. NOTE: The trigger locks are a safety feature

that prevent the power trigger from being pressed down to reduce the

risk of accidentally starting the machine.

2. Allow the blade to reach full speed. Make sure the workpiece is held

securely against the table and fence at all times. If the material binds the

blade, release the power trigger.

• For non-sliding cuts: Slowly lower the blade into and through the

workpiece.

• For sliding cuts: Pull the saw arm all towards the front of the machine.

Slowly lower the blade into the workpiece while steadily pushing it

away from you until the workpiece is cut (Fig. 25). CAUTION: Never

slide the saw arm towards yourself while cutting. Always push away.

WARNING: Be sure to tighten

the miter lock and bevel lock before

making a cut. Failure to do so could

result in the table moving during the

cut and may cause serious personal

injuries.

Fig. 24

21

3

4

4

1. Pull

Forwards

Fig. 25

2. Lower

Blade

3. Push Back

To Cut

3. Release the power trigger and wait until the blade fully stops before

raising it from the workpiece.

4. Unplug the miter saw before leaving your work station. Clean your

work station and store tools out of reach of children.

Page 21

MAINTENANCE

WARNING: To avoid accidents, turn OFF and unplug the tool from the electrical outlet before cleaning,

adjusting, or performing any maintenance work.

WARNING: Any attempt to repair or replace electrical parts on this tool may be hazardous. Servicing

of the tool must be performed by a qualified technician. When servicing, use only identical WEN replacement

parts. Use of other parts may be hazardous or induce product failure.

ROUTINE INSPECTION

Before each use, inspect the general condition of the tool. If any of these

following conditions exist, do not use until parts are replaced or the

sharpener is properly repaired.

Check for:

• Loose hardware,

• Misalignment or binding of moving parts,

• Damaged cord/electrical wiring,

• Cracked or broken parts, and

• Any other condition that may affect its safe operation

CLEANING & STORAGE

1. Keep the ventilation openings free from dust and debris to prevent

the motor from overheating.

2. Wipe the tool surfaces clean with a clean cloth. Make sure water does

not get into the tool.

3. Store the tool in a clean and dry place away from the reach of chil-

dren. Store in temperatures between 41° to 86°F.

CAUTION: Most plastics are susceptible to damage from various types

of commercial solvents. Do not use

any solvents or cleaning products

that could damage the plastic parts.

Some of these include but are not

limited to: gasoline, carbon tetrachloride, chlorinated cleaning solvents, and household detergents

that contain ammonia.

Fig. 26

4. Cover the miter saw in order to protect it from dust and moisture. It is preferable to store it in its original pack-

aging with the instruction manual.

CARBON BRUSH REPLACEMENT

Replacement carbon brushes (Part No.

replacement brushes designed specifically for your tool should be used.

1. To access the carbon brushes, remove the carbon brush cap (Fig. 26) with a flat-head screwdriver (not included).

2. Carefully remove the old carbon brushes using pliers.

3. Install the new carbon brushes. Both carbon brushes should be replaced at the same time. Replace the carbon

brush cap. NOTE: New carbon brushes tend to spark for a few minutes during the first use as they wear down.

MM1214-114

) can be ordered at wenproducts.com. Only genuine WEN

PRODUCT DISPOSAL

Used power tools should not be disposed of together with household waste. This product contains electronic

components that should be recycled. Please take this product to your local recycling facility for responsible disposal and to minimize its environmental impact.

2120

Page 22

TROUBLESHOOTING GUIDE

WARNING: Stop using the tool immediately if any of the following problems occur. Repairs and replace-

ments should only be performed by an authorized technician. For any questions, please contact our customer

service at (800) 232-1195, M-F 8-5 CST or email us at techsupport@wenproducts.com.

PROBLEM CAUSE SOLUTION

Blade is dull Sharpen or replace blade.

Ineffective

cutting perfor-

mance

Excessive noise

or vibration

Blade will not

turn

Blade is dirty

The blade is not secure

Belt is worn See page 18 to replace the belt.

Incorrect blade used for workpiece

Blade mounted backwards. Mount blade in correct orientation.

Not mounted properly

Damaged saw blade Replace blade.

The blade is not secure

Belt is worn See page 18 to replace the belt.

Excessive sawdust or chips between blade

and frame

Spindle lock is depressed

Belt is broken See page 18 to replace the belt.

Remove the blade and clean the surface and cutting edge

with steel wool and turpentine.

Make sure the blade flanges are flush against the blade and

arbor bolt is tightened completely.

Ensure the blade is compatible with the material type and

thickness being cut.

Make sure the saw is mounted securely to a flat and level

work surface.

Make sure the blade flanges are flush against the blade and

arbor bolt is tightened completely.

Clean the space between the blade and frame with compressed air and ensure no chips are stuck within.

Move the blade back and forth to unlock the spindle lock

button.

Motor does not

start

Saw overheats

Power cord damaged or not properly

plugged in

Defective power switch

Insufficient power from power outlet.

Carbon brushes are worn

Defective motor or other internal problem

Tool forced to work too fast

The extension cord is too long

or too thin

Blocked motor housing vents

Check the power cord, extension cord, power plug and

the power outlet. Do not use the tool if any cord is damaged.

Stop using the tool and contact customer service at (800)

232-1195, M-F 8-5 CST for assistance.

Make sure the outlet is functional and is the right capacity

for the tool.

Inspect and replace carbon brushes as needed (see page

21) Replacement brushes (Model MM1214-114) can be

ordered from wenproducts.com.

Stop using the tool and contact customer service at (800)

232-1195, M-F 8-5 CST for assistance.

Do not force the tool and make sure the workpiece is compatible with the blade in use.

See page 8 for selecting the proper size of extension cord

for your tool.

Blow dust out of the motor housing vents while wearing

safety goggles and dust mask.

Page 23

EXPLODED VIEW & PARTS LIST

201 202 203 204 205

211

210

209

198

197

196

194

195

193

200

199

206

207

208

2322

Page 24

EXPLODED VIEW & PARTS LIST

No. Part. No. Description Qty.

1 MM1214-001 Base 1

2 MM1214-002 Foot 4

3 MM1214-003

4 MM1214-004 Ø2 x 4 Rivet 2

5 MM1214-005 Miter Scale 1

6 MM1214-006 M8 x 55 Hex Bolt 1

7 MM1214-007 M5 x 6 Cross Head Screw 2

8 MM1214-008

9 MM1214-009 Table Extension Rod 4

10 MM1214-010 M5 Lock Nut 3

11 MM1214-011

12 MM1214-012 M5 x 8 Cross Head Screw 4

13 MM1214-013

14 MM1214-014

15 MM1214-015

16 MM1214-016 Anti-Tip Support 1

17 MM1214-017 Swivel Plate 2

18 MM1214-018 Fence 1

19 MM1214-019 M6 x 32 Knob 2

20 MM1214-020 M8 Flat Washer 4

21 MM1214-021 M8 x 25 Hex Screw 2

22 MM1214-022 M8 Spring Washer 4

23 MM1214-023 M8 x 35 Hex Screw 2

24 MM1214-024 Left Fence Extension 1

25 MM1214-025 Right Fence Extension 1

26 MM1214-026 M12 Washer 1

27 MM1214-027

28 MM1214-028 Lock Nut 1

29 MM1214-029 Locking Rod 1

30 MM1214-030 Bevel Lock Lever 1

31 MM1214-031 M5 Flat Washer 9

32 MM1214-032 M5 x 10 Hex Screw 1

33 MM1214-033 Miter Detent Lever 1

34 MM1214-034 Compression Spring 1

M4 x 12 Self-Tapping

Screw

M6 x 25 Table Extension

Knob

Table Extension Block

(Left)

Left Table Extension Stop

Plate

M5 x 20 Cross Head

Screw

M6 x 10 Cross Head

Screw

M5 x 10 Cross Head

Screw

4

2

1

1

9

4

1

No. Part. No. Description Qty.

35 MM1214-035

36 MM1214-036

37 MM1214-037 Miter Lock Knob 1

38 MM1214-038 Miter Lock Knob Washer 1

39 MM1214-039

40 MM1214-040 Small Press Board 1

41 MM1214-041 M4 x 8 Cross Head Screw 8

42 MM1214-042 Kerf Board 1

43 MM1214-043 Table 1

44 MM1214-044 Miter Angle Indicator 1

45 MM1214-045

46 MM1214-046 M8 Flat Washer 1

47 MM1214-047 M8 Lock Nut 2

48 MM1214-048 Bevel Scale 1

49 MM1214-049 M8 x 20 Hex Screw 2

50 MM1214-050 Bevel Hinge 1

51 MM1214-051 Lock-Down Pin 1

52 MM1214-052 Lock-Down Spring 1

53 MM1214-053 Lock-Down Pin Head 1

54 MM1214-054

55 MM1214-055 Depth Stop 1

56 MM1214-056 M8 Wavy Washer 2

57 MM1214-057 M8 Pan Head Bolt 1

58 MM1214-058 Bearing Cover 2

59 MM1214-059

60 MM1214-060 Bevel Angle Indicator 1

61 MM1214-061 Table Support 1

62 MM1214-062 Stop Pin 2

63 MM1214-063 M10 Hex Nut 1

64 MM1214-064 M6 Flat Washer 8

65 MM1214-065 Bevel Stop Block 1

66 MM1214-066

67 MM1214-067

Table Extension Block

(Right)

Right Table Extension

Stop Plate

M5 x 35 Socket Head

Screw

M5 x 10 Cross Head

Screw

Ø3 x 16 Spring Cylindrical

Pin

M4 x 10 Cross Head

Screw

M6 x 16 Non-Standard

Screw

M6 x 14 Cross Head

Screw

1

1

1

17

1

1

1

3

Page 25

EXPLODED VIEW & PARTS LIST

No. Part. No. Description Qty.

68 MM1214-068 M6 Spring Washer 8

69 MM1214-069 M6 x 10 Cross Bolt 1

70 MM1214-070 Connecting Bar Support 1

71 MM1214-071 M6 Lock Nut 2

72 MM1214-072 Hinge Pin 1

73 MM1214-073 Spring Sleeve 2

74 MM1214-074 Torsion Spring 1

75 MM1214-075 M10 x 80 Stud 1

76 MM1214-076 Locking Rod 1

77 MM1214-077 M8 x 25 Zero Stop Screw 1

78 MM1214-078 M8 Zero Stop Lock Nut 1

79 MM1214-079 M6 x 25 Slide Lock Knob 1

80 MM1214-080 Spring 1

81 MM1214-081 M10 x M28 x 3 Flat Washer 1

82 MM1214-082 M10 Lock Nut 1

83 MM1214-083

84 MM1214-084 Slide Rail 2

85 MM1214-085 Ø5 x 44 Roll Pin 2

86 MM1214-086 Slide Rail Cover 1

87 MM1214-087 Cable Clamp 2

88 MM1214-088

89 MM1214-089 Outer Flange 1

90 MM1214-090 Arbor Insert 1

91 MM1214B TCT 12 in. Blade 1

92 MM1214-092 Inner Flange 1

93 MM1214-093

94 MM1214-094 M5 Spring Washer 9

95 MM1214-095 Gearbox Cover 1

96 MM1214-096 Gasket 1

97 MM1214-097 6003 Bearing 1

98 MM1214-098 Bearing Retainer 1

99 MM1214-099 M4 Spring Washer 2

100 MM1214-100

101 MM1214-101 Spindle 1

102 MM1214-102 Flat Key 4 x 4 x 8 1

103 MM1214-103 Large Gear 1

104 MM1214-104 Ø15 Retaining Ring 1

Ø45 x Ø30 x 35 Linear

Bearing

M8 x 18 Arbor Screw

(Left)

M5 x 40 Cross Pan Head

Screw

M4 x 12 Cross Head

Screw

4

1

2

2

No. Part. No. Description Qty.

105 MM1214-105 Roller Bearing HK1010 1

106 MM1214-106 Guard Label 1

107 MM1214-107 M6 x 10 Set Screw 2

108 MM1214-108 Upper Blade Guard 1

109 MM1214-109

110 MM1214-110 6001 Bearing 1

111 MM1214-111 Flat Key 4 x 4 x 20 1

112 MM1214-112 Gear Shaft 1

113 MM1214-113 Brush Holder Cap 2

114 MM1214-114 Carbon Brush 2

115 MM1214-115 Brush Holder 2

116 MM1214-116

117 MM1214-117 Motor Housing 1

118 MM1214-118 Motor Housing Label 1

119 MM1214-119 Stator 1

120 MM1214-120

121 MM1214-121 Seal 1

122 MM1214-122 6000 Bearing 1

123 MM1214-123 Rotor 1

124 MM1214-124 6002 Bearing 1

125 MM1214-125 Middle Cover 1

126 MM1214-126 M8 x 25 Set Screw 1

127 MM1214-127 Small Pulley 1

130 MM1214-130

131 MM1214-131 Connecting Bar Screw 1

132 MM1214-132 Connecting Bar 1

133 MM1214-133 Lower Blade Guard Panel 1

134 MM1214-134

135 MM1214-135

136 MM1214-136 Rubber Stopper 1

137 MM1214-137 M6 x 7 Flat Head Bolt 1

138 MM1214-138 Guard Plate 1

139 MM1214-139 Lower Blade Guard 1

140 MM1214-140 M6 x 14 Hex Screw 1

141 MM1214-141 Dust Collection Bag 1

Upper Blade Guard

Bushing

M5 x 35 Cross Head

Screw

ST4.8 x 65 Self-Tapping

Screw

Lower Blade Guard

Washer

Lower Blade Guard Coil

Spring

Lower Blade Guard

Washer

1

4

2

1

1

1

2524

Page 26

EXPLODED VIEW & PARTS LIST

No. Part. No. Description Qty.

142 MM1214-142 Dust Outlet 1

143 MM1214-143 M6 x 25 Hex Screw 2

144 MM1214-144 M6 Hex Nut 2

145 MM1214-145 M6 x 35 Hex Screw 1

146 MM1214-146 Depth Adjustment Nut 1

147 MM1214-147 M6 Flat Washer 1

148 MM1214-148 Belt (10PJ560) 1

149 MM1214-149 Belt Cover 1

150 MM1214-150 M6 x 20 Hex Screw 3

151 MM1214-151 M6 x 16 Hex Screw 3

152 MM1214-152 Cover 1

153 MM1214-153 M6 x 16 Cap Screw (Left) 1

154 MM1214-154 M6 Spring Washer 1

155 MM1214-155 M6 Thick Flat Washer 1

156 MM1214-156 Large Pulley 1

157 MM1214-157 Ø28 Retaining Ring 1

158 MM1214-158 Spindle Lock Bracket 1

159 MM1214-159 Spindle Lock 1

160 MM1214-160

161 MM1214-161 ST6 x 18 Screw 2

162 MM1214-162 Handle 1

163 MM1214-163

164 MM1214-164 Upper Handle 1

165 MM1214-165 Pin 2

166 MM1214-166 Trigger Lock Connector 1

167 MM1214-167 Right Trigger Lock 1

168 MM1214-168 Left Trigger Lock 1

169 MM1214-169 Switch Torsion Spring 1

170 MM1214-170 Trigger 1

171 MM1214-171 Switch 1

172 MM1214-172

173 MM1214-173

174 MM1214-174 Lower Handle 1

175 MM1214-175 M5 Toothed Washer 1

176 MM1214-176 Terminal 1

177 MM1214-177 Cable Clamp 1

178 MM1214-178 Grommet 1

Spindle Lock Taper

Spring

M5 x 50 Cross Pan Head

Bolt

ST3.9 x 14 Self-Tapping

Screw

ST3.9 x 10 Self-Tapping

Screw

1

2

7

2

No. Part. No. Description Qty.

179 MM1214-179 Power Cord 1

180 MM1214-180 M10 Flat Washer 1

181 MM1214-181 M8 Hex Nut 2

182 MM1214-182 M5 Cross Head Screw 5

183 MM1214-183 607 Bearing 1

184 MM1214-184 Cover 1

185 MM1214-185 LED Light 1

186 MM1214-186 Reflecting Board 1

187 MM1214-187 Transparent Panel 1

188 MM1214-188 LED Light Cover 1

189 MM1214-189 LED Wire Cover 1

190 MM1214-190 Laser Wire Cover 1

191 MM1214-191 Double Switch 1

192 MM1214-192 Transformer PCB 1

Clamp Assembly MM1214-197ASM

193 MM1214-193 M5 x 12 Cross Screw 1

194 MM1214-194 M5 Spring Washer 1

195 MM1214-195 M6 Flat Washer 1

196 MM1214-196 Clamp Pressure Plate 1

197 MM1214-197 Clamp 1

198 MM1214-198 Small Connecting Bar 1

199 MM1214-199 M6 x 20 Knob 1

200 MM1214-200 Clamp Locating Bar 1

Laser Module MM1214-206ASM

201 MM1214-201 M4 Wavy Washer 2

202 MM1214-202 Laser Seat 1

203 MM1214-203 M3 Flat Washer 2

204 MM1214-204 M3 x 8 Cross Screw 2

205 MM1214-205 M4 x 6 Screw 1

206 MM1214-206 Laser 1

207 MM1214-207 Laser Cover 1

208 MM1214-208 M4 x 14 Screw 1

209 MM1214-209 M4 Nut 1

210 MM1214-210 M4 x 8 Cross Screw 8

211 MM1214-211 Dust Cover 1

Page 27

WARRANTY STATEMENT

WEN Products is committed to building tools that are dependable for years. Our warranties are consistent

with this commitment and our dedication to quality.

LIMITED WARRANTY OF WEN PRODUCTS FOR HOME USE

GREAT LAKES TECHNOLOGIES, LLC (“Seller”) warrants to the original purchaser only, that all WEN consumer power tools will be free from defects in material or workmanship during personal use for a period of

two (2) years from date of purchase or 500 hours of use; whichever comes first. Ninety days for all WEN

products if the tool is used for professional or commercial use. Purchaser has 30 days from the date of

purchase to report missing or damaged parts.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited Warranty and, to the

extent permitted by law, any warranty or condition implied by law, shall be the replacement of parts, without charge, which are defective in material or workmanship and which have not been subjected to misuse,

alteration, careless handling, misrepair, abuse, neglect, normal wear and tear, improper maintenance, or

other conditions adversely affecting the Product or the component of the Product, whether by accident or

intentionally, by persons other than Seller. To make a claim under this Limited Warranty, you must make

sure to keep a copy of your proof of purchase that clearly defines the Date of Purchase (month and year) and

the Place of Purchase. Place of Purchase must be a direct vendor of Great Lakes Technologies, LLC. Purchasing through third party vendors, including but not limited to garage sales, pawn shops, resale shops,

or any other secondhand merchant, voids the warranty included with this product. Contact techsupport@

wenproducts.com or 1-800-232-1195 with the following information to make arrangements: your shipping

address, phone number, serial number, required part numbers, and proof of purchase. Damaged or defective

parts and products may need to be sent to WEN before the replacements can be shipped out.

Upon the confirmation of a WEN representative, your product may qualify for repairs and service work.

When returning a product for warranty service, the shipping charges must be prepaid by the purchaser.

The product must be shipped in its original container (or an equivalent), properly packed to withstand the

hazards of shipment. The product must be fully insured with a copy of the proof of purchase enclosed. There

must also be a description of the problem in order to help our repairs department diagnose and fix the issue.

Repairs will be made and the product will be returned and shipped back to the purchaser at no charge for

addresses within the contiguous United States.

THIS LIMITED WARRANTY DOES NOT APPLY TO ITEMS THAT WEAR OUT FROM REGULAR USAGE OVER

TIME, INCLUDING BELTS, BRUSHES, BLADES, BATTERIES, ETC. ANY IMPLIED WARRANTIES SHALL BE

LIMITED IN DURATION TO TWO (2) YEARS FROM DATE OF PURCHASE. SOME STATES IN THE U.S. AND

SOME CANADIAN PROVINCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE OF THIS

PRODUCT. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER

RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA AND

FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO ITEMS SOLD WITHIN THE UNITED STATES OF AMERICA,

CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR WARRANTY COVERAGE WITHIN OTHER

COUNTRIES, CONTACT THE WEN CUSTOMER SUPPORT LINE. FOR WARRANTY PARTS OR PRODUCTS REPAIRED UNDER WARRANTY SHIPPING TO ADDRESSES OUTSIDE OF THE CONTIGUOUS UNITED STATES,

ADDITIONAL SHIPPING CHARGES MAY APPLY.

2726

Page 28

THANKS FOR

REMEMBERING

Loading...

Loading...