Page 1

MODEL HA5932

HANDHELD

SPINDLE SANDER

Instruction Manual

NEED HELP? CONTACT US!

Have product questions? Need technical support? Please feel free to contact us:

TECHSUPPORT@WENPRODUCTS.COM800-232-1195 (M-F 8AM-5PM CST)

IMPORTANT: Your new tool has been engineered and manufactured to WEN’s highest standards for dependability,

ease of operation, and operator safety. When properly cared for, this product will supply you years of rugged,

trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. If you use

your tool properly and for its intended purpose, you will enjoy years of safe, reliable service.

For replacement parts and the most up-to-date instruction manuals, visit WENPRODUCTS.COM

Page 2

CONTENTS

WELCOME 3

Introduction ..................................................................................................... 3

Specifications ................................................................................................... 3

SAFETY 4

General Safety Rules ........................................................................................ 4

Specific Rules for Your Spindle Sander ............................................................ 6

Electrical Information ....................................................................................... 8

BEFORE OPERATING 9

Unpacking & Transportation ............................................................................ 9

Know Your Spindle Sander ............................................................................ 10

Assembly & Adjustments ............................................................................... 11

OPERATION & MAINTENANCE 13

Operation ....................................................................................................... 13

Troubleshooting Guide ................................................................................... 14

Maintenance ................................................................................................... 15

Exploded View & Parts List ............................................................................ 16

Warranty Statement ....................................................................................... 18

To purchase accessories for your tool, visit WENPRODUCTS.COM

80-Grit Sandpaper Pack (Model 5932SP80)

120-Grit Sandpaper Pack (Model 5932SP120)

240-Grit Sandpaper Pack (Model 5932SP240)

Combo-Grit Sandpaper Pack (Model 5932SPC)

2

Page 3

INTRODUCTION

Thanks for purchasing the WEN Spindle Sander. We know you are excited to put your tool to work, but first, please

take a moment to read through the manual. Safe operation of this tool requires that you read and understand this

operator’s manual and all the labels affixed to the tool. This manual provides information regarding potential safety

concerns, as well as helpful assembly and operating instructions for your tool.

SAFETY ALERT SYMBOL: Indicates danger, warning, or caution. The safety symbols and the explanations

with them deserve your careful attention and understanding. Always follow the safety precautions to reduce the

risk of fire, electric shock or personal injury. However, please note that these instructions and warnings are not

substitutes for proper accident prevention measures.

NOTE: The following safety information is not meant to cover all possible conditions and situations that may occur.

WEN reserves the right to change this product and specifications at any time without prior notice.

At WEN, we are continuously improving our products. If you find that your tool does not exactly match this manual,

please visit wenproducts.com for the most up-to-date manual or contact our customer service at 1-800-232-1195.

Keep this manual available to all users during the entire life of the tool and review it frequently to maximize

safety for both yourself and others.

SPECIFICATIONS

Model Number HA5932

Motor

Rubber Drum Diameters

Sanding Sleeve Diameters

Sanding Drum Length

Spindle Speed

Spindle Oscillation

Stroke Length

Dust Port Diameter

Spindle Shaft Diameter

Product Weight

Product Dimensions

120V, 60 Hz, 5A, 650W

0.75", 1", 1.5"

0.5", 0.75", 1", 1.5"

3"

1800 - 3200 RPM

50 - 90 SPM

0.25"

1.5"

0.5"

5 lbs.

8.5" x 3.25" x 6.75"

3

Page 4

GENERAL SAFETY RULES

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may

result in electric shock, fire and/or serious injury.

Safety is a combination of common sense, staying alert and knowing how your item works. The term “power tool”

in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE SAFETY INSTRUCTIONS.

WORK AREA SAFETY

1. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

3. Keep children and bystanders away while operating

a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric shock.

2. Avoid body contact with earthed or grounded surfac-

es such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body

is earthed or grounded.

3. Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric shock.

4. Do not abuse the cord. Never use the cord for car-

rying, pulling or unplugging the power tool. Keep cord

away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

5. When operating a power tool outdoors, use an ex-

tension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric

shock.

6. If operating a power tool in a damp location is un-

avoidable, use a ground fault circuit interrupter (GFCI)

protected supply. Use of a GFCI reduces the risk of elec-

tric shock.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a

power tool while you are tired or under the influence

of drugs, alcohol or medication. A moment of inatten-

tion while operating power tools may result in serious

personal injury.

2. Use personal protective equipment. Always wear

eye protection. Protective equipment such as a respiratory mask, non-skid safety shoes and hearing protection

used for appropriate conditions will reduce the risk of

personal injury.

3. Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power source

and/or battery pack, picking up or carrying the tool.

Carrying power tools with your finger on the switch or

energizing power tools that have the switch on invites

accidents.

4. Remove any adjusting key or wrench before turning

the power tool on. A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

5. Do not overreach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or jew-

elry. Keep your hair and clothing away from moving

parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

4

Page 5

GENERAL SAFETY RULES

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and instructions may

result in electric shock, fire and/or serious injury.

Safety is a combination of common sense, staying alert and knowing how your item works. The term “power tool”

in the warnings refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

SAVE THESE SAFETY INSTRUCTIONS.

7. If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

POWER TOOL USE AND CARE

1. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

2. Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

3. Disconnect the plug from the power source and/or

the battery pack from the power tool before making

any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

4. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

5. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained

power tools.

6. Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits, etc.

in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

8. Use clamps to secure your workpiece to a stable

surface. Holding a workpiece by hand or using your

body to support it may lead to loss of control.

9. KEEP GUARDS IN PLACE and in working order.

SERVICE

1. Have your power tool serviced by a qualified repair

person using only identical replacement parts. This will

ensure that the safety of the power tool is maintained.

CALIFORNIA PROPOSITION 65 WARNING

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities may contain

chemicals, including lead, known to the State of California to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling. Some examples of

these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

Your risk from these exposures varies depending on how

often you do this type of work. To reduce your exposure

to these chemicals, work in a well-ventilated area with

approved safety equipment such as dust masks specially designed to filter out microscopic particles.

5

Page 6

SPECIFIC RULES FOR YOUR SPINDLE SANDER

WARNING! Do not operate the power tool until you have read and understood the following instructions and

the warning labels.

SANDER RULES

1. Two-hand operation. This machine requires the use

of two hands to ensure safe operation.

2. Maintain a stable stance. Ensure proper balance

when using the tool. Do not stand on ladders and step

ladders during operation. If the machine is to be used on

a higher and otherwise unreachable surface, a suitable

and stable platform or scaffold tower with hand rails and

kick boards should be used.

3. Preparing the workpiece. Nails, staples, knots, or

other imperfections in workpiece can be dislodged and

thrown into operator or bystanders at a high rate of

speed, or cause damage to sanding sleeves or spindle.

Never sand stock that has embedded foreign objects or

questionable imperfections.

4. Securing the workpiece. Never hold the workpiece in

your hand or across your legs when using the spindle

sander in the handheld mode. Use clamps or vises to

secure workpiece. This protects hands and frees both of

them to operate tool.

5. Checking the power cord. Make sure that the power

cord is prevented from coming into contact with the machine or getting caught up on other objects, preventing

completion of the sanding pass.

8. Spindle Direction. Feeding workpiece / tool incorrectly can cause it to jump or kick back, causing a loss

of control or contact injury. To reduce these risks, feed

workpiece / tool against direction of spindle rotation and

never introduce tapered or pointed stock with point facing direction of spindle rotation.

9. Sanding Dust. Sanding creates large amounts of dust

and flying chips that can lead to eye injury or serious

respiratory illness. Reduce your risk by always wearing

approved eye and respiratory protection and dust collection when using sander.

10. Sanding Sleeve Condition. Worn or damaged sanding sleeves can tear apart, resulting in injury due to loss

of workpiece / tool control. Replace worn or damaged

sanding sleeves promptly.

11. Base Gap. The gap between tool base and oscillating

drum creates a pinch point. Always use largest diameter

of drum possible to minimize this gap.

12. Setting down the sander. Wait for the spindle to

stop before setting the tool down. An exposed, rotating

spindle may engage the surface, leading to possible loss

of control and serious injury. Always lay the sander on

its side to prevent accidents if the machine is inadvertently started.

6. Holding the sander. Keep handles and hands dry,

clean, and free from oil and grease. Rotating sanding

spindles can remove a large amount of flesh in a few

seconds. Always keep hands away from spindle during

operation. Never touch moving spindle on purpose. Use

brush to clean sander of sawdust and chips.

7. Feeding workpiece. Forcefully jamming workpiece /

tool against sanding surface may cause it to kick back at

operator or damage machine. Allow spindle to reach full

speed. Firmly hold workpiece with both hands and ease

it against spindle using light pressure.

6

13. Unplug the sander. Ensure the sander is disconnect-

ed from the main supply before servicing, lubricating,

making adjustments, changing accessories, or replacing

sanding belts. Accidental start-ups may occur if the tool

is plugged in during an accessory change. Before plugging the tool back in, check that the trigger is OFF.

Page 7

SPECIFIC RULES FOR YOUR SPINDLE SANDER

WARNING! Extreme caution required when sanding paint. The dust residue may contain LEAD, which is

poisonous. Exposure to even low levels of lead can cause irreversible brain and nervous system damage, to

which young and unborn children are particularly vulnerable. Any pre-1960s building may have paint containing

lead on wood or metal surfaces that has since been covered with additional layers of paint. Lead-based paints

should only be removed by a professional and should not be removed using a sander. If you suspect that paint

on surfaces contains lead, please seek professional advice.

WARNING! Use a face mask and dust collection. Some wood and wood type products, such as MDF (Me-

dium Density Fiberboard), can produce dust that can be hazardous to your health. We recommend the use of a

dust extraction system and an approved face mask with replaceable filters when using this machine.

REDUCING KICKBACK

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes rapid stalling of the rotating accessory, which in turn causes the uncontrolled

power tool to be forced in the direction opposite of the

accessory’s rotation at the point of binding.

Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions and can be

avoided by taking the proper precautions as given below.

1. Maintain a firm grip on the power tool and position

your body and arm to allow you to resist kickback forces.

Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start-up.

The operator can control kickback forces, if proper precautions are taken.

2. Never place your hand near the rotating accessory.

The accessory may kick back over your hand.

3. Do not position your body in the area where the power

tool will move if kickback occurs. Kickback will propel

the tool in the direction opposite to the wheel’s movement at the point of snagging.

VIBRATION SAFETY

This tool vibrates during use. Repeated or longterm exposure to vibration may cause temporary

or permanent physical injury, particularly to the

hands, arms and shoulders. To reduce the risk of

vibration-related injuries:

1. First, be examined by a doctor and then have

regular medical check-ups to ensure medical

problems are not being caused or worsened from

using this tool. People who are pregnant, have

impaired blood circulation to the hand, past hand

injuries, nervous system disorders, diabetes, or

Raynaud’s disease should NOT use this tool.

2. If you feel any symptoms related to vibration

(such as tingling, numbness, and white or blue

fingers), stop working and seek medical advice as

soon as possible.

3. Do not smoke during use. Nicotine reduces the

blood supply to the hands and fingers, increasing

the risk of vibration-related injury.

4. Wear suitable work gloves to reduce the effects

of vibration.

4. Use special care when working corners, sharp edges,

etc. Avoid bouncing and snagging the accessory. Corners, sharp edges or bouncing have a tendency to snag

the rotating accessory and cause loss of control or kickback

5. Hold the tool firmly enough to keep safe control

of it, but NOT too tightly. The risk associated with

vibration is increased when the gripping force is

high. Let the tool do the work.

6. Take vibration-free breaks during each day of

work.

7

Page 8

ELECTRICAL INFORMATION

DOUBLE-INSULATED TOOLS

The tool’s electrical system is double-insulated where two systems of insulation are provided. This

eliminates the need for the usual three-wire grounded power cord. Double-insulated tools do not need

to be grounded, nor should a means for grounding be added to the product. All exposed metal parts

are isolated from the internal metal motor components with protecting insulation.

IMPORTANT: Servicing a double-insulated product requires extreme care and knowledge of the system, and

should be done only by qualified service personnel using identical replacement parts. Always use original factory

replacement parts when servicing.

1. Polarized Plugs. To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified electrician to install a proper outlet. Do not modify the machine plug

or the extension cord in any way.

2. Ground fault circuit interrupter protection (GFCI) should be provided on the circuit or outlet used for this power

tool to reduce the risk of electric shock.

3. Service and repair. To avoid danger, electrical appliances must only be repaired by a qualified service technician

using original replacement parts.

GUIDELINES AND RECOMMENDATIONS FOR EXTENSION CORDS

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage, resulting in loss of power and overheating. The table below shows

the correct size to be used according to cord length and ampere rating. When in doubt, use a heavier cord. The

smaller the gauge number, the heavier the cord.

REQUIRED GAUGE FOR EXTENSION CORDS

AMPERAGE

25 ft. 50 ft. 100 ft. 150 ft.

5A 16 gauge 16 gauge 14 gauge 12 gauge

1. Examine extension cord before use. Make sure your extension cord is properly wired and in good condition.

Always replace a damaged extension cord or have it repaired by a qualified person before using it.

2. Do not abuse extension cord. Do not pull on cord to disconnect from receptacle; always disconnect by pulling on

plug. Disconnect the extension cord from the receptacle before disconnecting the product from the extension cord.

Protect your extension cords from sharp objects, excessive heat and damp/wet areas.

3. Use a separate electrical circuit for your tool. This circuit must not be less than a 12-gauge wire and should be

protected with a 15A time-delayed fuse. Before connecting the motor to the power line, make sure the switch is in

the OFF position and the electric current is rated the same as the current stamped on the motor nameplate. Running

at a lower voltage will damage the motor.

8

Page 9

UNPACKING & TRANSPORTATION

WARNING! Do not plug in or turn on the tool until it is fully assembled according to the instructions. Failure

to follow the safety instructions may result in serious personal injury.

UNPACKING

With the help of a friend or trustworthy foe, carefully remove the Spindle Sander from the packaging. Make sure to

take out all contents and accessories. Do not discard the packaging until everything is removed. Check the packing

list below to make sure you have all of the parts and accessories. If any part is missing or broken, please contact

our customer service at 1-800-232-1195 (M-F 8-5 CST), or email techsupport@wenproducts.com.

PACKING LIST

Pre-Assembled

Hardware & Tools

Rubber Drums

1" Rubber Drum 0.75" Rubber Drum1.5" Rubber Drum

Sanding Sleeves

Sander

1.5" Sleeve 1" Sleeve 0.75" Sleeve 0.5" Sleeve

Parts & Accessories

Table Mounting Pad Guide Plate

Clip (2)

13mm Washer

Lock Knob

Wing Nut (2)

Knob (2)

6mm Washer

Anchor Bolt (2)

ASSEMBLY/ADJUSTMENT TOOLS

The tools listed below are not included but are required for either assembly or adjustment:

• Straightedge

9

Page 10

KNOW YOUR SPINDLE SANDER

TOOL PURPOSE

Spindle Sanders make sanding easy, and dare I say fun, while also aiding you in taking on arcs, curves, contours,

faces, and more. Refer to the following diagrams to become familiarized with all the parts and controls of your

Spindle Sander. The components will be referred to later in the manual for assembly and operation instructions.

ON / OFF Switch

Variable-Speed Dial

Sanding Drum

Spindle & Lock Knob

Dust Port

10

Page 11

ASSEMBLY & ADJUSTMENTS

WARNING! Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your tool. Failure to

follow the safety instructions may result in serious personal injury.

ATTACHING THE DUST PORT

1. Align the dust port (Fig. 1 - 1) with the keyed opening

(Fig. 2 - 1) at back of tool. Turn the dust port clockwise until

it is locked in place.

2. Secure vacuum or dust collection hose (not included) to

the dust port.

INSTALLING THE SANDING DRUM & SLEEVE

1. Before placing the rubber drum (Fig. 2 - 1) on the spindle

shaft, ensure that the 13mm fender washer (Fig. 2 - 2) is

around the spindle shaft (Fig. 2 - 3).

NOTE: When installing the 0.5” sanding sleeve on the shaft,

a rubber drum is not necessary. The sleeve mounts directly

onto the spindle shaft. Use of the washers and lock knob are

still necessary when using the 0.5” sanding sleeve.

2. Slide the corresponding sanding sleeve (Fig. 2 - 4) over

the rubber drum. Make sure the sanding sleeve is flush with

the end of the rubber drum.

3. Secure the drum on the spindle sander with the 6mm

fender washer (Fig. 2 - 5) and lock knob (Fig. 2 - 6).

Fig. 1

1

2

Fig. 2

2

4

3

6

1

5

NOTE: Tightening the lock knob ensures the sanding sleeve

stays on the drum. If the sanding sleeve is running off the

drum, try tightening the lock knob.

INSTALLING THE EDGE GUIDE

1. Align the holes in the edge guide (Fig. 3 - 1) with the

holes in the base plate (Fig. 3 - 2). Attach the guide using

two (2) plastic knobs (Fig. 3 - 3).

2. Place a straightedge (not included) (Fig. 3 - 4) across the

edge guide faces and sanding drum. Adjust the position of

the edge guide until the straightedge touches the drum.

3. Tighten the left knob (Fig. 3 -3) to hold the edge guide in

place.

4. Set the guide in or out based on the amount of material

you want to remove, then tighten the right knob.

Fig. 3

1 4

3

2

11

Page 12

ASSEMBLY & ADJUSTMENTS

BENCHTOP INSTALLATION

1. Place the mounting pad (Fig. 4 - 1) along the edge of a flat

benchtop so that the sander notches face up.

2. Place the sander (Fig. 4 - 2) upside-down on top of the

mounting pad and fit it into the designated notches.

3. Insert two (2) anchor bolts (Fig. 4 - 3) completely into

the mounting holes on either side of the sander body.

4. Fasten two (2) clips (Fig. 4 - 4) and two (2) wing nuts

(Fig. 4 - 5) to the anchor bolts on either side of the sander

and tighten until the sander is secured to the benchtop.

5. To remove the anchor bolts, loosen the wing nuts and flip

the clips out from under the table. Wiggle the sander until

the anchor bolts are loose enough to remove.

Fig. 4

2

3

4

5

1

12

Page 13

OPERATION

WARNING! Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your tool. Failure to

follow the safety instructions may result in serious personal injury.

OPERATING THE SANDER

1. Connect the tool to power supply.

2. Hold the sander base in contact with a stable, secure

workpiece (Fig. 5) and flip the ON / OFF switch (Fig. 6 - 1)

to the ON position.

3. Use the speed control dial (Fig. 6 - 2) to adjust the speed

between 1800 RPM and 3200 RPM.

4. When sanding is complete, flip the ON / OFF switch to the

OFF position.

USING THE EDGE GUIDE

1. Begin sanding operation at one end of the workpiece with

the face of the edge guide against the workpiece. The tool

will remove an even amount of material (Fig. 5).

2. Gradually feed sander along the entire edge of the workpiece (Fig. 5).

Fig. 5

Fig. 6

1

2

13

Page 14

TROUBLESHOOTING GUIDE

WARNING! Stop using the tool immediately if any of the following problems occur. Repairs and replacements

should only be performed by an authorized technician. For any questions, please contact our customer service

at (800) 232-1195, M-F 8-5 CST or email us at techsupport@wenproducts.com.

PROBLEM CAUSE SOLUTION

Sanding grains

easily rub off.

Deep sanding

grooves or scars in

workpiece.

Sanding surface

clogs quickly

Burns on

workpiece

Sander does not

turn on

Motor will not

start—fuses or

circuit breakers

tripping/blowing

Motor overheats

1. Sanding belt / sleeve has been stored in the wrong

environment.

2. Sanding belt / sleeve has been damaged or folded. 2. Call customer service (1-800-232-1195) for assistance.

1. Sanding belt / sleeve grit is too coarse. 1. Use a finer-grit sanding accessory.

2. Workpiece sanded across the grain. 2. Sand with the grain of the wood.

3. Too much sanding force on workpiece. 3. Reduce pressure on workpiece while sanding.

4. Workpiece held still against sanding surface for too

long.

1. Too much pressure against belt/spindle.

2. Sanding softwood.

1. Use a sanding grit that is too fine. 1. Use a coarser-grit sanding accessory.

2. Using too much pressure. 2. Reduce sanding pressure on workpiece.

3. Work held still for too long.

4. Sanding belt / sleeve loaded with debris. 4. Clean or replace the sleeve or belt.

1. Not plugged in to an electrical outlet. 1. Connect the unit to an outlet.

2. Defective power switch. 2. Call customer service (1-800-232-1195) for assistance.

3. Onboard circuit breaker tripped. 3. Press circuit breaker to reset.

4. Carbon brushes worn down 4. Call customer service (1-800-232-1195) for assistance.

5. Motor or wiring problem. 5. Call customer service (1-800-232-1195) for assistance.

1. Short circuit in line, cord or plug. 1. Inspect cord / plug for damaged insulation / shorted wires.

2. Short circuit or faulty circuit breaker. 2. Call customer service (1-800-232-1195) for assistance.

3. Incorrect fuses or circuit breakers in power line.

4. Carbon brushes worn down. 4. Call customer service (1-800-232-1195) for assistance.

1. Motor overloaded.

2. Extension cord too long with an insufficient gauge.

1. Sanding belt / sleeve out of balance/loose. 1. Ensure sleeve / belt is properly installed.

1. Store sanding accessories away from extremely hot/dry

temperatures.

4. Keep workpiece moving while sanding on the sanding

accessory.

1. Clean sanding belt / sleeve and then reduce pressure on

workpiece while sanding.

2. Use different stock / sanding accessories or clean / remove

sanding sleeves frequently.

3. Keep workpiece moving while sanding on the sanding

accessory.

3. Install correct fuses or circuit breakers or switch tool to an

appropriately sized circuit.

1. Reduce sanding pressure on workpiece and take more

frequent breaks.

2. Refer to section “Guidelines and Recommendations for

Extension Cords” on page 8.

Sander vibrates

excessively or has

noisy operation.

Sander turns on but

spindle does not

spin / oscillate.

14

2. Motor or component loose.

3. Pulley loose. 3. Re-align / replace shaft, pulley set screw and key.

4. Machine incorrectly mounted to bench. 4. Adjust anchor bolts. Tighten mounting hardware.

5. Faulty motor bearings. 5. Call customer service (1-800-232-1195) for assistance.

1. Broken / worn belt. 1. Call customer service (1-800-232-1195) for assistance.

2. Inspect / replace damaged bolts / nuts and retighten with

thread-locking fluid.

Page 15

MAINTENANCE

WARNING! To avoid accidents, turn OFF and unplug the tool from the electrical outlet before cleaning,

adjusting, or performing any maintenance work. .

WARNING! Any attempt to repair or replace electrical parts on this tool may be hazardous. Servicing of the

tool must be performed by a qualified technician. When servicing, use only identical WEN replacement parts.

Use of other parts may be hazardous or induce product failure.

ROUTINE INSPECTION

Before each use, inspect the general condition of the

tool. If any of these following conditions exist, do not

use until parts are replaced or the saw is properly repaired.

Check for:

• Loose hardware,

• Misalignment or binding of moving parts,

• Damaged cord/electrical wiring,

• Cracked or broken parts, and

• Any other condition that may affect its safe operation.

NOTE: Electric tools used on fiberglass material, wallboard, spackling compounds, or plaster are subject to

accelerated wear and possible premature failure because

the fiberglass chips and grindings are highly abrasive to

bearings, brushes, commutators, etc. Consequently, we

do not recommend using this tool for extended work on

these types of materials. However, if you do work with

any of these materials, it is extremely important to clean

the tool using compressed air after operation.

CAUTION! Most plastics are susceptible to damage from

various types of commercial solvents. Do not use any

solvents or cleaning products that could damage the

plastic parts. Some of these include but are not limited

to: gasoline, carbon tetrachloride, chlorinated cleaning

solvents, and household detergents that contain ammonia.

3. Store the tool in a clean and dry place away from the

reach of children. Store in temperatures between 41° to

86°F.

4. Cover the Spindle Sander in order to protect it from

dust and moisture. It is preferable to store it in its original packaging with the instruction manual and all accessories.

PRODUCT DISPOSAL

Used power tools should not be disposed of together

with household waste. This product contains electronic

components that should be recycled. Please take this

product to your local recycling facility for responsible

disposal and to minimize its environmental impact.

CLEANING & STORAGE

1. Keep the ventilation openings free from dust and debris to prevent the motor from overheating.

2. Wipe the tool surfaces clean with a clean cloth. Make

sure water does not get into the tool.

Cleaning & storage continues in the next column.

Please recycle the packaging and electronic

components where facilities exist.

15

Page 16

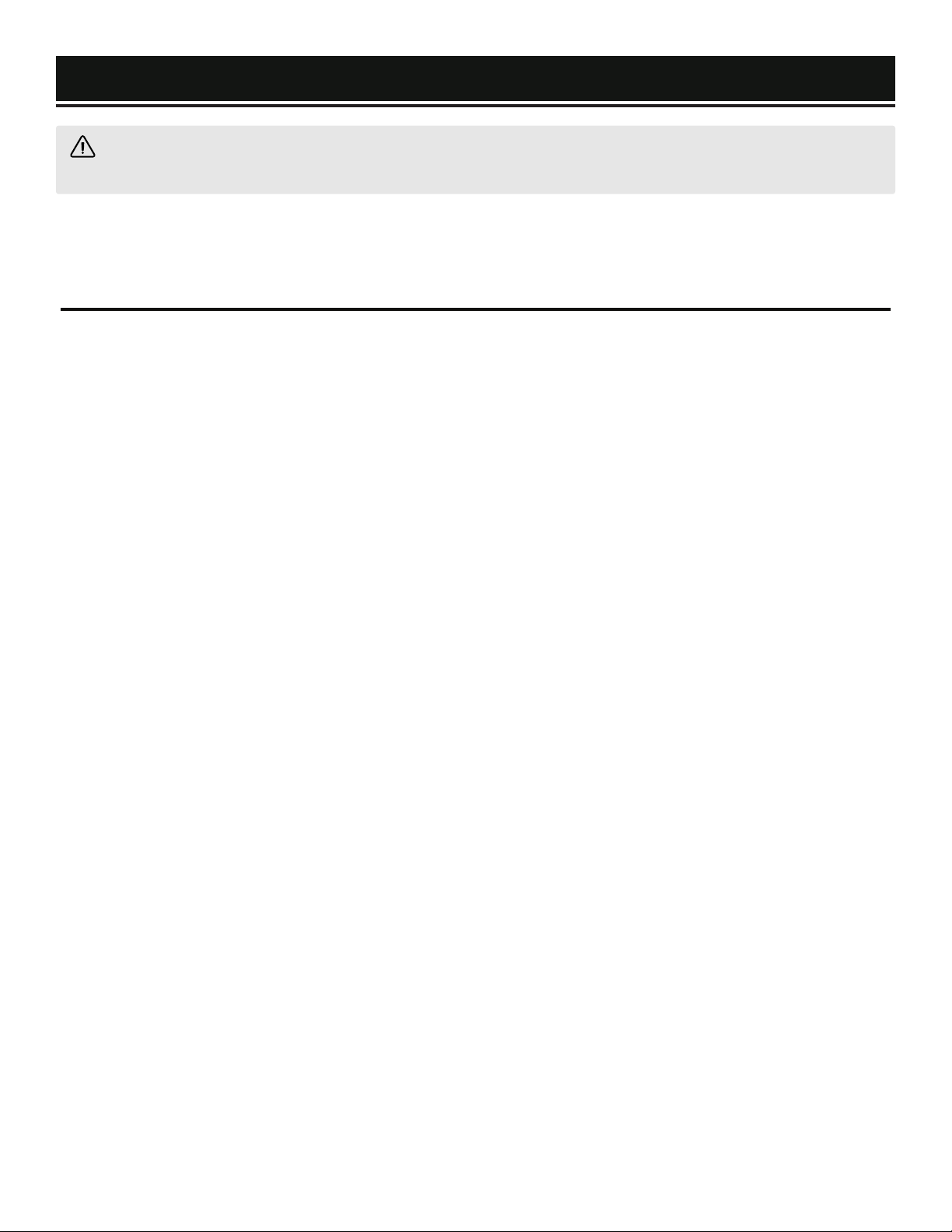

EXPLODED VIEW & PARTS LIST

19

1

20

67

66

65107

62 63 64

3

4

102

8

9

10

11

5

13 14 15

16

12

17

2

18

43

101

42

44

495150

102

41

3839

106

37

103

32

3640

35

31

104

30

25

34

24

23

29

33

22

21

28

105

27

26

58 59 60 61

16

45

46

47

48

52

53

45

54

55

56

57

Page 17

EXPLODED VIEW & PARTS LIST

NO PART NO DESCRIPTION QTY

1 HA5932-001 Nameplate Label 1

2 HA5932-002 Housing, Left 1

3 HA5932-003 Dust Port, 1-1/2" 1

4 HA5932-004 Power Cord 1

5 HA5932-005 Cable Guard 1

8 HA5932-008 Cable Clamp 1

9 HA5932-009 Self-tapping Screw, M4x16 2

10 HA5932-010 Wire Connector 1

11 HA5932-011 Stator 1

12 HA5932-012 Rotor Bushing 1

13 HA5932-013 Carbon Brush 1

14 HA5932-014 Brush Holder 1

15 HA5932-015 Brush Housing 1

16 HA5932-016 Ball Bearing, 626ZZ 1

17 HA5932-017 Rotor 1

18 HA5932-018 Ball Bearing, 608ZZ 1

19 HA5932-019 Drive Pulley 1

20 HA5932-020 V-groove Drive Belt, EPJ206 1

21 HA5932-021 Retaining Ring, 5mm 2

22 HA5932-022 Flat Washer, 5mm 2

23 HA5932-023 Idler Shaft 1

24 HA5932-024 Needle Bearing, HK0509 1

25 HA5932-025 Idler Pulley 1

26 HA5932-026 Hex Nut, M8-1.25 1

27 HA5932-027 Large Poly-V Pulley 1

28 HA5932-028 Ball Bearing 608Zz 1

29 HA5932-029 Intermediate Shaft 1

30 HA5932-030 Small Timing-Belt Pulley 2

31 HA5932-031 Stop Collar 1

32 HA5932-016 Ball Bearing, 626ZZ 1

33 HA5932-033 Self-tapping Screw, M4x12 6

34 HA5932-034 Base Plate Cover 1

35 HA5932-035 Base Plate 1

36 HA5932-036 PCB 1

37 HA5932-037 Cap 3

38 HA5932-038 Rubber Pad 5

39 HA5932-039 Self-tapping Screw, M2x10 1

40 HA5932-040 Power Switch 1

41 HA5932-041 Timing Belt, XL100 2

42 HA5932-042 Housing, Right 1

43 HA5932-009 Self-tapping Screw, M4x16 13

NO PART NO DESCRIPTION QTY

44 HA5932-044 Secondary Label 1

45 HA5932-045 Ball Bearing, 6004ZZ 2

46 HA5932-046 Transmission Pulley 1

47 HA5932-047 Differential Pulley 1

48 HA5932-048 Output Shaft 1

49 HA5932-049 Flat Washer, 4mm 1

50 HA5932-050 Needle Bearing 1

51 HA5932-051 Clevis Pin, 4x24mm 1

52 HA5932-052 Differential Wheel Cover 1

53 HA5932-009 Self-tapping Screw, M4x16 3

54 HA5932-054 Guide Plate 1

55 HA5932-055 Knob, M5x18 2

56 HA5932-056 Fender Washer, 1/2" 1

57 HA5932-057 Fender Washer, 6mm 1

58 HA5932-058 Knob, M6x12 1

59 HA5932-059

60 HA5932-060

61 HA5932-061

62 HA5932-062 Sanding Sleeve, 1-1/2" x 3" 1

63 HA5932-063 Sanding Sleeve, 1" x 3" 1

64 HA5932-064 Sanding Sleeve, 3/4" x 3" 1

64 HA5932-065 Sanding Sleeve, 1/2" x 3" 1

66 HA5932-066 Mounting Pad 1

67 HA5932-067 Mounting Clamp Assembly 2

101

102

103

104

105

106

107

108

HA5932-

101ASM

HA5932-

102ASM

HA5932-

103ASM

HA5932-

104ASM

HA5932-

105ASM

HA5932-

106ASM

HA5932-

107ASM

HA5932-

108ASM

Rubber Sanding Drum,

1-1/2" x 3"

Rubber Sanding Drum,

1" x 3"

Rubber Sanding Drum,

3/4" x 3"

Stator Assembly 1

Carbon Brush Assembly 2

Rotor Assembly 1

Idler Pulley Assembly 1

Intermediate Shaft Assembly 1

Output Shaft Assembly 1

Sanding Sleeve Set 1

Mounting Assembly 1

1

1

1

17

Page 18

WEN Products is committed to building tools that are dependable for years. Our warranties are consistent with this

commitment and our dedication to qualit

GRE

consumer

power tools will be free from defects in material or workmanship during personal use for a period of two (2) years

from

used

damaged parts.

SELLER’S

mitted

are

defective

misrepai

improper maintenance, or other conditions adversely affecting the

Product

make

clearly

defines the Date of Pur

dor

sales,

product.

Contact techsupport@wenproducts.com or 1-800-232-1195 with the following information to make arrangements:

your

or

defective parts and products may need to be sent to WEN before the replacements can be shipped out.

Upon

turning

must

be

product

the

problem

will be returned and shipped back to the pur

THIS

INCLUDING

DURA

PROVINCES

TA

IN

BUT

SOME ST

TION

OF

TO YOU.

THIS

WHICH

TO COUNT

THIS

DA

COUNTRIES,

CONT

W

SHIPPING

CHARGES MAY APPLY.

WARRANTY STATEMENT

y.

AT LAKES TECHNOLOGIES, LLC (“Seller”) warrants to the original purchaser only, that all WEN

18

date of purchase or 500 hours of use; whichever comes first. Ninety days for all WEN products if the tool is

for professional or commercial use. Purchaser has 30 days from the date of purchase to report missing or

SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited Warranty and, to the extent per-

by law, any warranty or condition implied by law, shall be the replacement of parts, without charge, which

in material or workmanship and which have not been subjected to misuse, alteration, careless handling,

r, abuse, neglect, normal wear and tear,

or the component of the Product, whether by accident or intentionally, by persons other than Seller. To

a claim under this Limited Warranty, you must make sure to keep a copy of your proof of purchase that

of Great Lakes Technologies, LLC. Purchasing through third party vendors, including but not limited to garage

pawn shops, resale shops, or any other secondhand merchant, voids the warranty included with this

shipping address, phone number, serial number, required part numbers, and proof of purchase. Damaged

the confirmation of a WEN representative, your product may qualify for repairs and service work. When re-

a product for warranty service, the shipping charges must be prepaid by the purchaser. The product

shipped in its original container (or an equivalent), properly packed to withstand the hazards of shipment. The

must be fully insured with a copy of the proof of purchase enclosed. There must also be a description of

in order to help our repairs department diagnose and fix the issue. Repairs will be made and the product

LIMITED WARRANTY DOES NOT APPLY TO ITEMS THAT WEAR OUT FROM REGULAR USAGE OVER TIME,

BELTS, BRUSHES, BLADES, BATTERIES, ETC. ANY IMPLIED WARRANTIES SHALL BE LIMITED IN

TION TO TWO (2) YEARS FROM DATE OF PURCHASE. SOME STATES IN THE U.S. AND SOME CANADIAN

DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMI-

TION MAY NOT APPLY TO YOU.

NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING

NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE OF THIS PRODUCT.

ATES IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITA

INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

VARY FROM STATE TO STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA AND FROM COUNTRY

RY.

LIMITED WARRANTY APPLIES ONLY TO ITEMS SOLD WITHIN THE UNITED STATES OF AMERICA, CANA-

AND THE COMMONWEALTH OF PUERTO RICO. FOR WARRANTY COVERAGE WITHIN OTHER

ACT THE WEN CUSTOMER SUPPORT LINE. FOR WARRANTY PARTS OR PRODUCTS REPAIRED UNDER

ARRANTY SHIPPING TO ADDRESSES OUTSIDE OF THE CONTIGUOUS UNITED STATES, ADDITIONAL

LIMITED WARRANTY OF WEN PRODUCTS FOR HOME USE

chase (month and year) and the Place of Purchase. Place of Purchase must be a direct ven-

chaser at no charge for addresses within the contiguous United States.

Page 19

NOTES

19

Page 20

THANKS FOR

REMEMBERING

Loading...

Loading...