Page 1

bit.ly/wenvideo

11000 WATT

DUAL FUEL GENERATOR

For replacement parts visit

WENPRODUCTS.COM

EPA CERTIFIED

CARB COMPLIANT

IMPORTANT:

Your new tool has been engineered and manufactured to WEN’s highest standards for dependability, ease

of operation, and operator safety. When properly cared for, this product will supply you years of rugged,

trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. If

you use your tool properly and for its intended purpose, you will enjoy years of safe, reliable service.

NEED HELP? CONTACT US!

Have product questions? Need technical support?

Please feel free to contact us at:

800-232-1195 (M-F 8am-5pm CST)

techsupport@wenproducts.com

NOTICE: Please refer to wenproducts.com for the most up-to-date instruction manual.

WENPRODUCTS.COM

Page 2

TABLE OF CONTENTS

Introduction ....................................................................................2

Safety Information ...........................................................................4

Generator Safety Warnings ..............................................................5

Know Your Generator .......................................................................8

Unpacking & Assembly ..................................................................10

Generator Preparation ...................................................................12

Starting the Generator ...................................................................19

Using the Generator ......................................................................21

Shutting Off the Generator .............................................................24

Maintenance .................................................................................25

Transportation & Storage ...............................................................32

Specifications ...............................................................................33

Exploded View & Parts List ............................................................34

Wiring Diagram .............................................................................38

Troubleshooting Guide ...................................................................39

Warranty Statement ......................................................................40

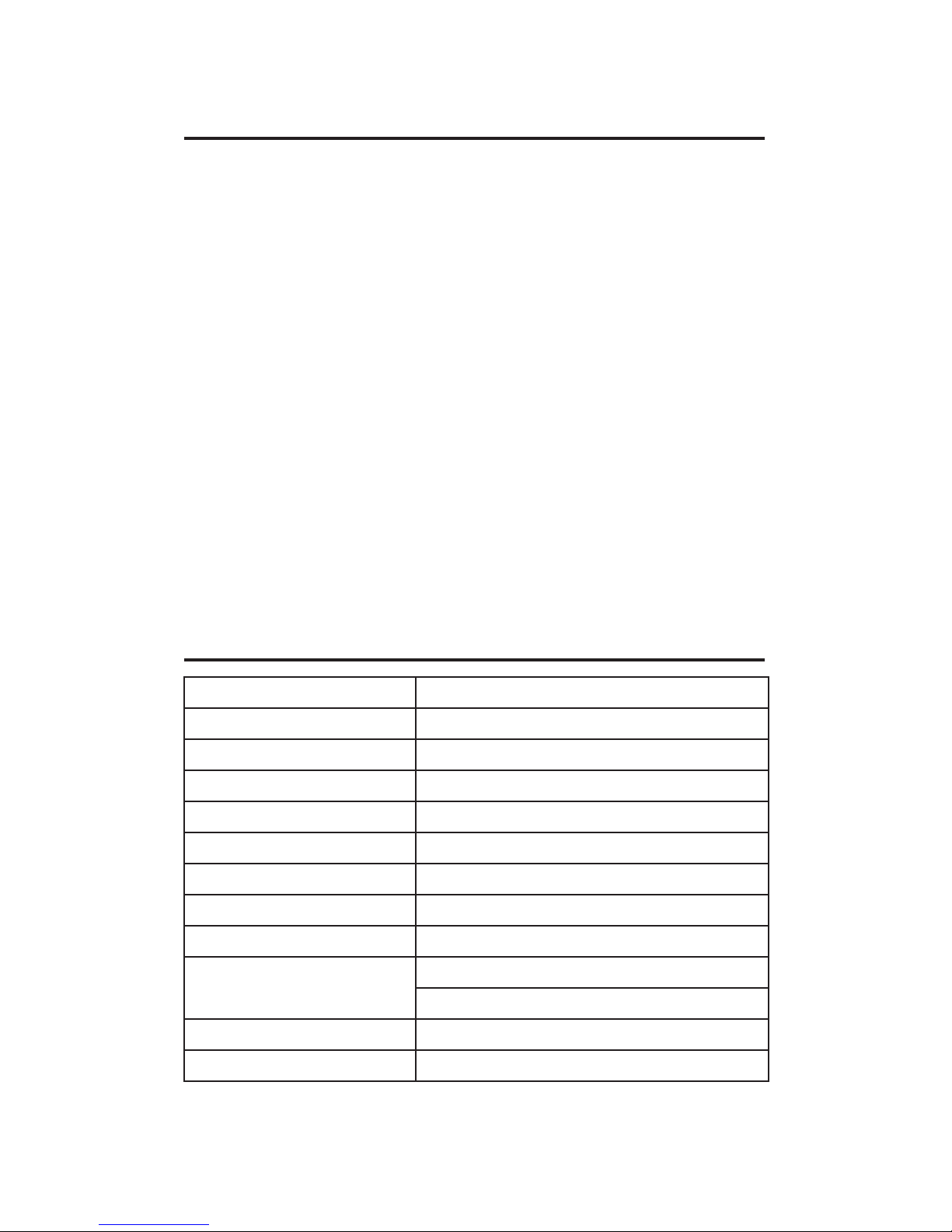

KEY SPECIFICATIONS

Model Number DF1100, DF1100T

Rated Wattage Gasoline: 8300 Watts, LPG: 7500 Watts

Surge Wattage Gasoline: 11000 Watts, LPG: 9500 Watts

Frequency 60Hz

Rated Voltage AC: 120V/240V, DC: 12V

Rated Amperage AC: 70A/35A, DC: 8A

Engine OHV, 4 stroke, single cylinder, 457cc

Fuel Tank Capacity 6.6 US gallons (25 L), 87 octane minimum

Oil Capacity 37.2 fl. oz. (1.1 L)

Gasoline: 8.5 hours

Half-Load Run Time

LPG (with 20 lb tank): 3 hours

Product Dimensions 27.3 x 20.6 x 21.9 in. (L x W x H)

Product Net Weight 213.8 lbs (97 kg)

Your generator is compatible with the WEN 55201 Magnetic Oil Dipstick,

2

available at wenproducts.com

Page 3

INTRODUCTION

THANKS FOR PURCHASING THE WEN GENERATOR!

Refer to the illustration below for the location of the serial number. Record the generator information in the

spaces provided below. If assistance for information or service is required, please contact the Customer

Service Help Line by calling 800-232-1195, M-F 8-5 CST; you will be asked to provide the following generator information when calling.

GENERATOR MODEL NUMBER: WEN DF1100, WEN DF1100T

DATE OF PURCHASE: __________________________________________

PURCHASED FROM: ___________________________________________

SERIAL NUMBER: _____________________________________________

SERVICE RECORD

Record the service dates of your generator in the chart below. Please perform maintenance checks and

operations according to the “MAINTENANCE” section of the manual.

Service Record Date Date Date Date Date Date

Change Oil

Change Spark Plug

Clean Air Cleaner

Clean Spark Arrestor

Clean Fuel Tank

TO MAXIMIZE THE LIFESPAN OF YOUR GENERATOR:

We recommend running your generator at least ONCE A MONTH for 20 to 30 minutes. Start the generator according to the instructions and plug a small load in to make sure the outlet is producing electricity.

SERIAL NUMBER

3

Page 4

SAFETY INFORMATION

WARNING: Before operating the generator, make sure to read all safety warnings and all instruc-

tions. Failure to follow the warnings and instructions may result in electric shock, fire or serious injury.

SAFETY INTRODUCTION

Safety is a combination of common sense, staying alert, and knowing how your tool works. This manual

contains important information regarding the generator’s potential safety concerns, as well as preparation,

operation, and maintenance instructions. Before operating this generator, be sure to read and observe all

warnings and instructions both on the generator labels and in this instruction manual. Failure to follow all

instructions listed below may result in personal injury.

NOTE: The following safety information is not meant to cover all possible conditions and situations that may

occur. WEN reserves the right to change this product and specifications at any time without prior notice.

SAVE THESE INSTRUCTIONS - Please keep this manual available to all users during the entire life of

the tool. Review it frequently to maximize safety for both yourself and others.

SAFETY SYMBOLS

The purpose of following safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve your careful attention and understanding. The safety warnings do not

by themselves eliminate any danger. The instructions or warnings they give are not substitutes for proper

accident prevention measures.

DANGER: indicates a hazard, which, if not avoided, will result in death or serious injury.

WARNING: indicates a hazard, which, if not avoided, could result in death or serious injury.

CAUTION: indicates a hazard, which, if not avoided, might result in minor or moderate injury.

CAUTION: when used without the alert symbol, indicates a situation that could result in damage to

the machine.

NOTICE REGARDING EMISSIONS

Engines that are certified to comply with U.S. EPA emission regulations for SORE (Small Off Road Equipment), are certified to operate on regular unleaded gasoline, and may include the following emission control

systems: (EM) Engine Modifications and (TWC) Three-Way Catalyst (if so equipped).

QUESTIONS? PROBLEMS?

In order to answer questions and solve problems in the most efficient and speedy manner, contact Customer Service at (800) 232-1195, M-F 8-5 CST or email techsupport@wenproducts.com.

4

Page 5

GENERATOR SAFETY WARNINGS

DANGER: CARBON MONOXIDE

Using a generator indoors CAN KILL YOU IN MINUTES. Generator exhaust contains carbon monoxide (CO). This is a poison gas you cannot see or smell. If you can smell the generator exhaust, you are

breathing CO. But even if you cannot smell the exhaust, you could be breathing CO.

NEVER use a generator inside homes, garages, crawl spaces, or other partially enclosed areas. Deadly

levels of carbon monoxide can build up in these areas. Using a fan or opening windows and doors does

NOT supply enough fresh air. ONLY use a generator OUTSIDE and far away from windows, doors, and

vents. These openings can pull in generator exhaust.

Even if you use a generator correctly, CO may leak into the home. ALWAYS use a battery-powered or

battery-backup CO alarm in the home. If you start to feel sick, dizzy, or weak after the generator has

been running, move to fresh air RIGHT AWAY. See a doctor. You may have carbon monoxide poisoning.

WARNING: RISK OF EXPLOSION. HIGHLY FLAMMABLE: This generator may emit highly flam-

mable and explosive gasoline vapors, which can cause severe burns or even death, if ignited. A nearby

open flame can lead to explosion even if not directly in contact with gasoline.

• Do not operate near open flame.

• Do not smoke near generator.

• Always operate on a firm, level surface.

• Always turn generator off before refueling. Allow generator to cool for at least 2 minutes before removing fuel cap. Loosen cap slowly to relieve pressure in tank.

• Do not overfill fuel tank. Gasoline may expand during operation. Do not fill to the top of the tank. Allow

for expansion.

• Always check for spilled fuel before operating.

• Empty fuel tank before storing or transporting the generator.

• Before transporting, turn fuel valve to OFF and disconnect spark plug wire.

WARNING: If this generator is used as a supply for a BUILDING’S WIRING SYSTEM, the generator

MUST be installed by a qualified electrician and connected to a transfer switch as a separately derived

system in accordance with all applicable laws and electrical codes and the National Electrical Code,

NFPA 70. The generator shall be connected to a transfer switch that switches all conductors excluding the equipment grounding conductor. The frame of the generator shall be connected to an approved

grounding electrode.

California Proposition 65 WARNING: This product contains chemicals and produces exhaust

known to the State of California to cause cancer, birth defects and other reproductive harm.

5

Page 6

GENERATOR SAFETY WARNINGS

WARNING: Do not let comfort or familiarity with the product replace strict adherence to product

safety rules. Failure to follow the safety instructions may result in serious personal injury.

OPERATING ENVIRONMENT

1. Using a generator indoors can KILL YOU IN MINUTES. Only use a generator outside and far away from windows, doors and vents.

2. Do not operate near open flame or flammable materials. This generator may emit highly flammable and

explosive gasoline vapors, which can cause severe burns or even death if ignited. A nearby open flame can

lead to an explosion even if it isn’t directly in contact with gasoline.

3. Do not smoke near the generator.

4. Do not use the generator in rainy or wet conditions; doing so significantly increases the risk of electrical

shock.

5. Always operate the generator on a dry, firm, level surface.

6. Do not allow children or non-qualified persons to operate the generator.

7. Do not use or store LPG cylinder in a building, garage or enclosed area. Failure to do so will result in death

or serious injury. Liquid Petroleum Gas (LPG) is highly flammable and explosive. Flammable gas under pressure can cause a fire or explosion if ignited. Always keep the LPG cylinder in an upright position. The LPG

cylinder valve should be turned OFF (closed) when generator is not in use; failure to do so could result in death

or serious injury.

GENERATOR PREPARATION

1. Always ground the generator before using it to maximize safety (see “GROUND THE GENERATOR” section

on page 18).

2. Always make sure generator is turned OFF before filling the fuel tank. Do not overfill fuel tank, as gasoline may expand during operation. Do not fill to the very top of the tank. Leave room for gasoline expansion.

Always check for spilled fuel before operating.

3. Do not use receptacles or cords that show signs of damage, such as broken or cracked insulation. If

any part of the generator or electrical device is broken, damaged, or defective, make sure it is repaired or

replaced before operation. Service should only be performed by a qualified technician.

4. Use a ground fault circuit interrupter (GFCI) in highly conductive areas such as metal decking or steel

work. Extension cords with in-line GFCIs are recommended for these operations to maximize safety.

5. NEVER connect the generator to a building’s electrical system without consulting a qualified electrician.

Such connections must comply with local electrical laws and codes. Failure to comply can create a backfeed, which may result in serious injury or death to utility workers.

6

Page 7

GENERATOR SAFETY WARNINGS

GENERATOR OPERATION

1. Only use the generator for its intended purposes. Modifying or using the generator for operations for

which it was not designed may cause hazards and personal injury.

2. Do not touch bare wires or receptacles (outlets).

3. Do not exceed the wattage capacity of the generator by plugging in more electrical devices than the unit

can handle.

4. Allow generator to run for several minutes before connecting electrical devices.

5. Do not exceed the wattage capacity of the generator by plugging in more electrical devices than the unit

can handle (see “OPERATION” section).

6. Do not turn on electrical devices until after they are connected to the generator.

7. Generators vibrate in normal use. During and after the use of the generator, inspect both the generator

as well as extension and power supply cords for damage resulting from vibration.

8. Do not touch HOT PARTS. This generator produces heat when running. Temperatures near exhaust can

exceed 150º F (65º C). Allow generator to cool down after use before touching engine or areas of the generator that become hot during use.

9. Turn off all connected electrical devices before stopping the generator.

10. Always turn generator off before refueling. Allow generator to cool for at least 2 minutes before removing fuel cap. Loosen cap slowly to relieve pressure in tank.

11. Turn the engine switch to “OFF” position when the engine is not running.

12. Empty fuel tank before storing or transporting the generator. Do not store generator or gasoline near

furnaces, water heaters, or any other appliances that produce heat or have automatic ignitions. Store the

generator and fuel away from sparks, open flames, pilot lights, heat and other sources of ignition.

CAUTION: Misuse of this generator can damage it or shorten its lifespan.

TO MAXIMIZE THE LIFESPAN OF YOUR GENERATOR:

We recommend running your generator at least once a month for 20 to 30 minutes. Start the generator

according to the instructions and plug a small load in to make sure the outlet is producing electricity.

If you do not run it often, it will greatly shorten the generator’s lifespan and void the warranty.

7

Page 8

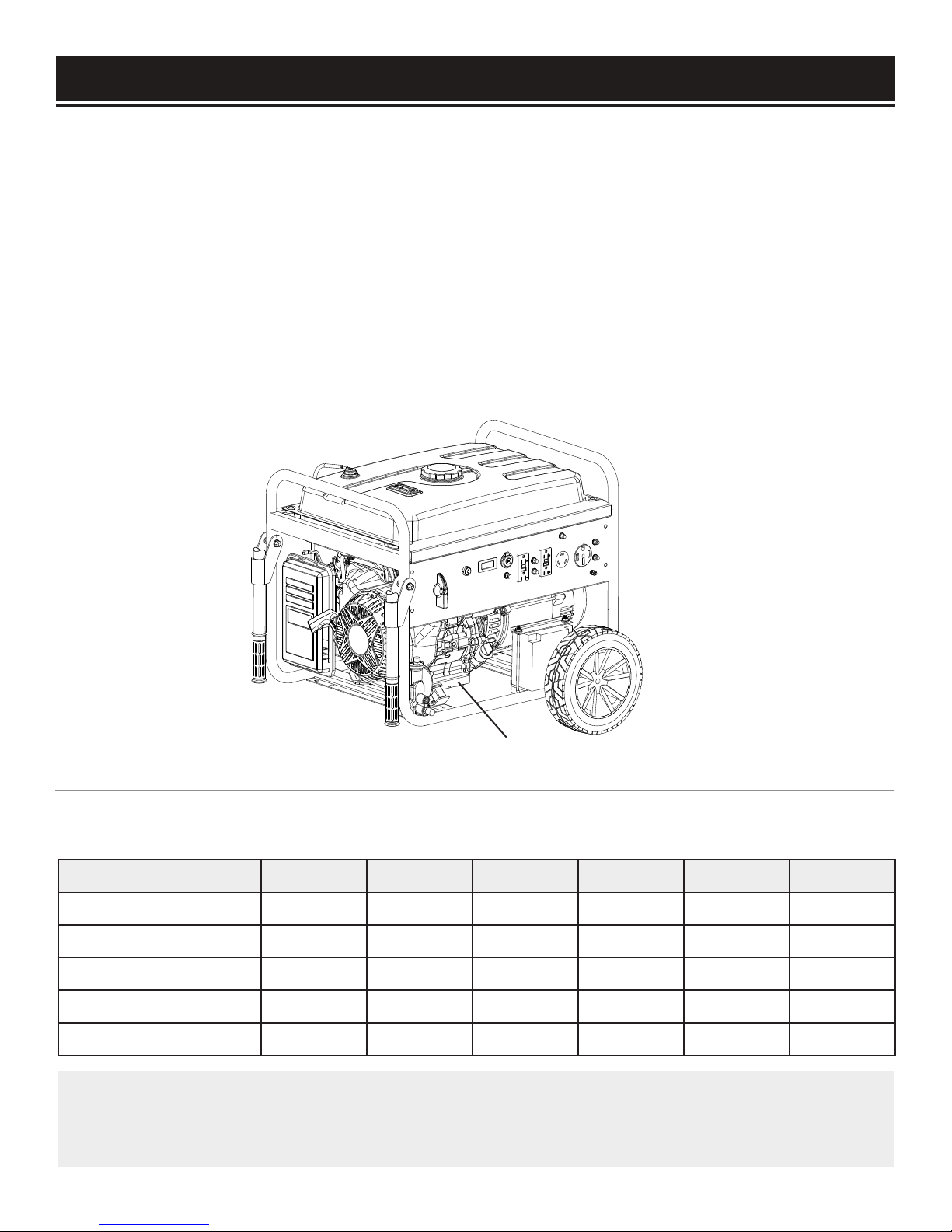

KNOW YOUR GENERATOR

Use the illustration below to become familiar with all the components and controls of this generator. If any

part is damaged or missing, please contact our customer service at (800) 232-1195, M-F 8-5 CST or email

us at techsupport@wenproducts.com.

1

2

3

10

11

4

5

6

7

8

9

1. Gasoline Fuel Cap

Access to the fuel tank for adding gasoline

2. Fuel Gauge

Indicates amount of fuel inside the fuel tank

E indicates Empty, F indicates Full

3. Pressure Relief Valve

4. Choke Lever

Adjusts the amount of air let into the engine

during startup

5. Fuel Valve

Allows fuel to enter engine from the fuel tank

6. Air Filter

A case with a sponge-like element that filters

the air entering the engine

7. Recoil Starter

Pull cord for manually starting the engine

12

13

14

8. 457cc OHV Engine

9. Transportation Handles

For easy transport of the generator

(installed by user)

10. Fuel Tank

11. Control Panel

Refer to the next page for descriptions

12. Battery

Connect the battery before starting the generator

13. Oil Fill and Dipstick

For filling and checking oil

14. LPG Hose Connector

Connects to LPG hose and LPG cylinder

8

Page 9

KNOW YOUR GENERATOR

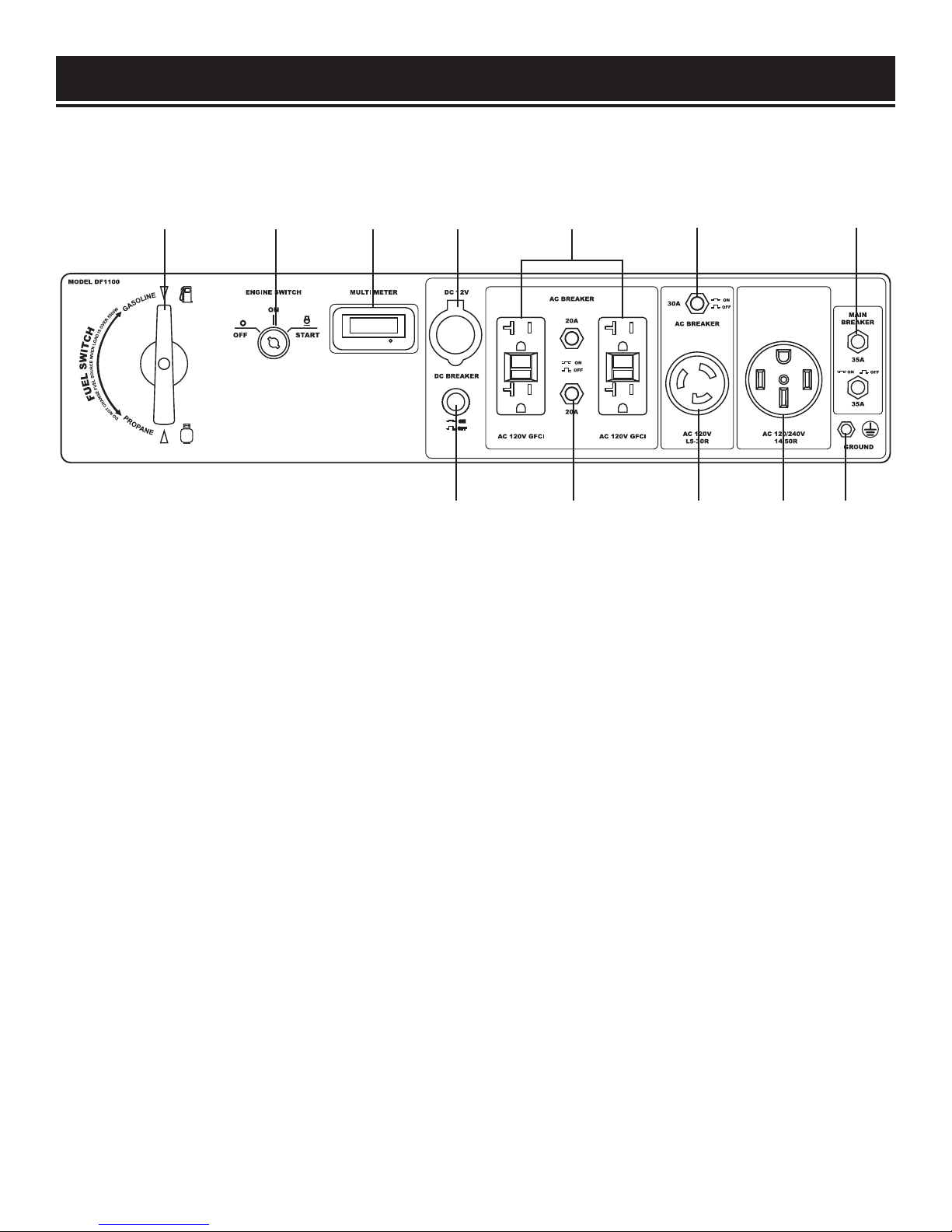

KNOW YOUR CONTROL PANEL

1 2 3 4

1. Fuel Selector Dial

Turn the dial to select between gasoline

or LPG before operation

6

5

7. AC 20A Circuit Breakers (for 5-20R)

Thermal protector that protects the 5-20

receptacles from overload

7

8

9

7

1210

2. Electric Start Switch

Turn the starter key to start, run and stop the

engine

3. Multi-meter

Displays the following information:

- Output voltage

- Output frequency

- Total runtime

- Session runtime

4. DC 12V Receptacle

Cigarette lighter style receptacle, 12V DC, 8A

5. DC Circuit Breaker

Thermal protector that protects the DC circuit

from overload

6. NEMA 5-20R GFCI Duplex Receptacle

Connect electrical devices that run on 120V,

60 Hz, single phase, AC current

8. AC 30A Circuit Breaker (for L5-30R)

Thermal protector that protects the L5-30

receptacle from overload

9. NEMA L5-30R 120V 30A Twistlock Receptacle

Connect electrical devices that run on 120V, 60 Hz,

single phase, AC current

10. NEMA L14-50R 120V/240V 50A Receptacle

Connect electrical devices that run on 120V/240V,

60 Hz, single phase, AC current

11. 35A Main Circuit Breakers

Thermal protectors that protect the generator’s

main circuit from overload

12. Grounding Nut

Connect grounding wire here to properly ground

the generator

9

Page 10

UNPACKING & ASSEMBLY

UNPACKING THE GENERATOR AND ACCESSORIES

Open the packaging and take out all loose parts from the box. With the help of a good friend or trustworthy

foe, carefully lift the generator from the packaging and place it on a sturdy, level surface.

Make sure all the accessories are accounted for and fully assemble the generator before discarding the packaging. If any part is missing or broken, please contact our customer service at (800) 232-1195, M-F 8-5 CST

or email us at techsupport@wenproducts.com.

IMPORTANT: Two red shipping brackets have been added

to the bottom of your generator to protect the generator

during shipping. Please make sure to remove BOTH shipping brackets before operation.

IMPORTANT: The LPG hose is packed underneath the fuel

tank, sitting above the engine. Remove to hose and set it

aside before assembling or operating the generator.

PACKING LIST

No. Accessory Qty.

43 Foot Support Assembly 2

44 Foot Support Isolator 2

32 M6X25 Bolt 2

45 M6 Nut 2

64 M8 Nut 4

48 Wheel Axle 2

42 Wheel 2

16 Flat Washer 2

25 Cotter Pin 2

19 Handle 2

73 Handle Isolator 2

30 Handle Plug 2

67 Handle Bushing 4

31 M8X45 Bolt 2

77 M8 Lock Nut 2

N/A Spark Plug Wrench 1

N/A First Stage Regulator 1

N/A Oil Bottle 1

10

Page 11

UNPACKING & ASSEMBLY

TO INSTALL THE FEET:

1. Insert the M6X25 bolt (32) through the foot support isolator (44) and foot support assembly (43). Tighten

with an M6 nut (45).

2. Install the foot support assembly (43) onto the frame and tighten with M8 nuts (64).

3. Repeat for the other foot.

TO INSTALL THE WHEELS:

1. Slide the wheel axle (48) through the wheel (42), flat washer (16), and wheel bracket on the frame.

2. Insert cotter pin (25) through the hole on the end of the axle to keep the wheel in place.

3. Repeat for the other wheel.

TO INSTALL THE HANDLE ASSEMBLIES:

1. Slide the M8X45 bolt (31) through the handle (19), handle bushing (67), generator frame, and the other

handle bushing (67).

2. Tighten with M8 lock nut (77).

3. Repeat for both handles.

NOTE: Only the generator frame is shown

to maximize clarity for assembly.

11

Page 12

GENERATOR PREPARATION

32

-30 -20 -10 0 10 20 30

-20 0 20 40 60 80 100

40

°F

°C

Synthetic 5W-30

30

10W-30

The following section describes the necessary steps to prepare the generator for use. If you are unsure about

how to perform any of the steps please call (800) 232-1195 M-F 8-5 CST for customer service. Failure to

perform these steps properly can damage the generator or shorten its life.

STEP 1 - ADD/CHECK OIL

The generator is shipped without oil. User must add the proper amount of oil before operating the generator

for the first time. The oil capacity of the engine crankcase is 37.2 fl. oz (1.1 L).

ENGINE OIL RECOMMENDATIONS - Select good quality detergent oil bearing the American Petro-

leum Institute (API) service classifications SJ, SL, or SM (synthetic oils may be used). Select the SAE

viscosity grade of oil that matches the expected operating temperature. For general use (above 40° F),

we recommend 30W engine oil.

• 30W engine oil for temperatures above 40°F.

• 10W-30 engine oil for temperatures between 0°F - 40°F.

To add oil, follow these steps:

1. Place the generator on a level surface. Make sure the engine

is OFF before adding or checking oil.

CAUTION: Keep the generator level! Tilting the generator to

assist in filling will cause oil to flow into the wrong areas of

the engine and cause damage.

2. Unscrew the oil dipstick from the engine.

3. Using an oil funnel or appropriate dispenser, slowly add oil

into the oil fill (Fig. 2), being careful not to overfill the unit. Fill

the crankcase to the upper fill line so you can visually see the oil

coming halfway up the oil fill threads (Fig. 3).

• Synthetic 5W-30 engine oil for

all temperature ranges.

Fig. 1 - Oil Recommendation Chart

Fig. 2

Oil Dipstick

Upper Level

Fill Line

4. Reinstall the oil dipstick and firmly tighten it. Wipe clean any

spilled oil.

12

Lower Level

Fill Line

Fig. 3

Page 13

GENERATOR PREPARATION

For subsequent operation, the oil level should be checked before each use, or after every 8 hours of operation. The generator is equipped with a low-oil sensor and will NOT start without a sufficient amount of oil.

To check oil level (before every subsequent start):

1. Place the generator on a level surface. Make sure the engine is OFF

before adding or checking oil.

2. Remove and wipe the dipstick with a clean rag.

3. Insert the dipstick into the oil fill without screwing it in. Remove the

dipstick to check the oil mark (Fig. 4).

Upper Limit

If the oil mark covers less than one half of the dipstick, slowly add oil

until the oil mark reaches to the top of the dipstick (or when you can

see the oil coming halfway up the oil fill threads).

4. Wipe clean any oil leaks and firmly tighten the dipstick.

Lower Limit

Fig. 4

OIL LEVEL SHUTDOWN

To protect the unit from damage, the generator is equipped with a low-oil-pressure shutoff that will automatically shut down the engine when the oil level is too low. The oil level of the engine should be checked before

each start to ensure that the engine crankcase contains sufficient lubricant.

TIP: Your WEN generator is compatible with the WEN 55201 Magnetic Oil Dipstick (not included), avail-

able for purchase at wenproducts.com. The dipstick’s industrial-strength magnetic tip will collect metal

shavings from your generator’s oil tank to help preserve the engine and extend your generator’s lifespan.

13

Page 14

GENERATOR PREPARATION

STEP 2 - ADD/CHECK FUEL

FUEL OPTION A: GASOLINE

GASOLINE WARNING: Keep generator away from open flame. This generator may emit highly flam-

mable and explosive gasoline vapors, which can cause severe burns or even death if ignited. A nearby

open flame can lead to explosion even if not directly in contact with gasoline.

• Do not operate near open flame.

• Do not smoke near the generator.

• Always operate on a firm, level surface.

• Always turn generator off before refueling. Allow generator to cool for at least 2 minutes before removing fuel cap. Loosen cap slowly to relieve pressure in tank.

• Do not overfill fuel tank. Fuel may expand during operation. Do not fill to the top of the tank. Allow for

expansion.

• Always check for spilled fuel before operating. Clean up any spilled fuel before starting.

• Empty fuel tank before storing or transporting the generator to prevent spilling.

Use ONLY fresh (within 30 days from purchase), lead-free gasoline with a minimum of 87 octane rating.

The generator performs best with ethanol-free gasoline. DO NOT use gasoline with over 10% ethanol.

The capacity of the fuel tank is 6.6 gallons. DO NOT mix oil with gasoline.

To add gasoline, follow these steps:

IMPORTANT:

1. Make sure the generator is shut OFF and on a level surface. Unscrew the fuel cap (Fig. 6) and set it aside. The fuel

cap may be tight and hard to unscrew.

2. Slowly add unleaded gasoline to the fuel tank. Be careful

not to overfill.

NOTE: Do not fill the fuel tank to the very top. If you do so,

gasoline will expand and spill during use, even with the fuel

cap in place.

3. Reinstall fuel cap and wipe clean any spilled gasoline

with a dry cloth.

To check fuel level

(before every subsequent start):

• Never use an oil/gasoline mixture.

• Never use old gasoline.

• Keep gasoline away from sparks, open

flames, pilot lights, heat and other sources

of ignition.

• Avoid getting dirt or water into the fuel

tank.

• Gasoline can age in the tank and make

starting difficult. Never store generator for

more than 2 months with fuel in the tank.

Fuel Cap

Fuel Gauge

Before starting the generator, check the fuel gauge to see if

there is sufficient fuel inside the tank. “E” indicates Empty

and “F” indicates Full. Refill the fuel tank as necessary.

14

Fig. 6

Page 15

GENERATOR PREPARATION

WARNING: If using gasoline, the LPG tank must be shut OFF. If using LPG, the fuel valve on the

generator must be turned to OFF position.

FUEL OPTION B: LIQUID PETROLEUM GAS (LPG)

DANGER: EXPLOSION AND FIRE. LP vapors are extremely flammable and explosive. Do not use or

store LP cylinder in a building, garage or enclosed area. Failure to do so will result in death or serious

injury.

WARNING: EXPLOSION AND FIRE. The cylinder valve should be turned OFF (closed) when generator

is not in use. Failure to do so could result in death or serious injury.

• Always keep the LPG cylinder in an upright position.

• When transporting and storing, keep cylinder secured in an upright position with cylinder valve turned

off. Keep cylinders ventilated and away from heat when in a vehicle.

• Liquid Petroleum Gas (LPG) is highly flammable and explosive. Flammable gas under pressure can

cause a fire or explosion if ignited.

• In any petroleum gas fire, flames should not be extinguished unless the fuel supply valve is turned

OFF. If a fire is extinguished and a supply of fuel is not turned OFF, an explosion hazard could be created.

• RISK OF BURNS. Contact with liquid contents of cylinder will cause freeze burns to the skin. If liquid

contents contacts skin or eyes, seek immediate medical attention.

• When exchanging LPG cylinders, be sure the cylinder valve is of the same type.

NOTE: LPG regulator inlet pressure is approximately 30 PSI at 0 °F, and 218 PSI at 100 °F.

• You can use LPG tanks with Type 1, right hand Acme threads with this generator. Verify that the qualification

date on tank has not expired. Do not use rusted or damaged cylinders.

• All new cylinders must be purged of air and moisture prior to filling. Used cylinders that have not been

plugged or kept closed must also be purged.

• The purging process should be done by the propane gas supplier. (Cylinders from an exchange supplier

should have been purged and properly filled by supplier).

Follow the instruction on the next page for connecting your generator to an LPG cylinder.

15

Page 16

GENERATOR PREPARATION

FUEL OPTION B: LIQUID PETROLEUM GAS (LPG) - CONTINUED

To connect your generator to an LPG cylinder:

1. Take off the safety caps from the cylinder valve, generator

mounted regulator, and regulator connecting hose ends.

2. With the LPG tank closed, attach the LPG regulator connecting

hose into the valve. Turn the plastic coupling from the hose right

(clockwise) to tighten hose assembly onto the LPG tank (Fig. 7).

3. Connect the opposite regulator connecting hose end to the generator’s LPG primary regulator with a 3/4 in. (19mm) wrench (not

supplied) (Fig. 8).

4. Turn the LPG tank valve ON (Fig. 9) and check for leaks by spraying soapy water to check connections. If bubbles appear, become

larger in size, or increase in number, a leak exists. This MUST be

corrected before using generator. Contact your local Independent

Authorized Service Dealer (IASD) for assistance.

Fig. 7

NOTE: You can use Teflon (or other tape) to secure the connection

of the LPG hose to your generator.

CAUTION: Always position the LPG cylinder so the connection

between the valve and regulator won’t cause sharp bends or

kinks in hose.

WARNING: Risk of burns. Contact with liquid contents of

cylinder will cause freeze burns to the skin. If liquid contents

contacts skin or eyes, seek immediate medical attention.

WARNING: When transporting and storing, keep cylinder

secured in an upright position with cylinder valve turned off.

Keep cylinders ventilated and away from heat when in a vehicle.

Fig. 8

Fig. 9

16

Page 17

GENERATOR PREPARATION

STEP 3: CONNECT THE BATTERY

WARNING: BATTERY GIVES OFF EXPLOSIVE HYDROGEN GAS.

• Keep battery away from spark, flame, or cigarette.

• Do not connect or disconnect battery while generator is running.

• Service or use battery only in well ventilated areas.

WARNING: Battery contains sulfuric acid. Battery acid is poisonous. Tilting the generator with the

battery installed can cause battery acid to spill.

• Wear protective clothing and eye wear when servicing battery.

• Keep out of reach of children.

• Do not tilt generator with battery installed.

• If battery acid gets on your skin, wash with water immediately.

• If battery acid gets in your eyes, flush with water for at least 15 minutes and call a doctor immediately.

If battery acid is swallowed, call a doctor immediately. Drink a large amount of water or milk. Then drink

milk of magnesia or vegetable oil.

The generator comes with the battery disconnected for safety. When using gasoline to run the generator,

the battery must be connected whether using electric or recoil start. The battery must also be connected for

electric start when using LPG, but the battery does not need to be connected for recoil start on LPG.

To connect the battery:

1. Remove the red cover from the positive (+) battery terminal.

2. Connect the red cable to the positive (+) battery terminal with the suitable nuts and bolts.

3. Attach the free end of the negative cable to the battery and secure the connection.

4. Make sure connections are secure and slide rubber boot over the positive (+) battery terminal and connection hardware.

5. Connect the black cable to the negative (-) battery terminal with the suitable nuts and bolts.

6. Make sure all connections are secure and slide rubber boot over the negative (-) battery terminal and connection hardware.

IMPORTANT: If you do not plan to use the generator for an extended period of time, it is recommended to

DISCONNECT the negative battery cable from the battery to protect the battery from losing charge. After

disconnecting the cable, cover the free end with an insulator such as electrical tape.

17

Page 18

GENERATOR PREPARATION

STEP 4 - GROUND THE GENERATOR

To reduce the risk of electric shock and to maximize safety, the

generator should be properly grounded.

Ground the generator by tightening the grounding nut on the

front control panel (Fig. 10) against a grounding wire. A generally acceptable grounding wire is a No. 12 AWG (American Wire

Gauge) stranded copper wire.

This grounding wire should be connected at the other end to a

copper, brass, or steel-grounding rod that is driven into the earth.

Wire and grounding rods are not included with the generator.

NOTE: Grounding codes can vary by location. Contact a local electrician to check the area codes.

Grounding Nut

Fig. 10

WARNING: Failure to properly ground the generator increases your risk of electric shock.

HIGH ALTITUDE OPERATION ABOVE 2000 FEET

The fuel system on this generator may be affected by operation at high altitudes. Proper operation can be

ensured by installing an altitude kit at altitudes higher than 2000 feet above sea level. At elevations above

7000 feet, the engine may experience a decrease in performance, even with the proper altitude kit. Operating this generator without said kit may increase the engine’s emissions and decrease both fuel economy

and performance.

This kit should be installed by a qualified mechanic. You can order the kit at wenproducts.com by searching part number DF1100-HA27. Refer to the instructions included with your altitude kit for more information

about installation.

WARNING: To prevent serious injury from fire, follow the kit installation procedures in a well-ven-

tilated area away from ignition sources. If the engine is hot from use, shut the engine off and wait for it

to cool before proceeding. Do not smoke near the generator. Warranty will be void if adjustments are not

made for high altitude use.

CAUTION: Engines with the high-altitude kit installed operated at lower altitudes could cause severe

engine damage and affect emissions compliance. Be sure to UNINSTALL the high altitude kit when operating at altitudes below 2000 feet.

After completing the above preparation, the generator is ready to be started.

18

Page 19

STARTING THE GENERATOR

Before starting the generator, make sure you have read and performed the steps in the “GENERATOR PREPARATION” section of this manual. If you are unsure about how to perform any of the steps in this manual

please call (800) 232-1195 M-F 8-5 CST for customer service.

DANGER: CARBON MONOXIDE

Using a generator indoors CAN KILL YOU IN MINUTES. Generator exhaust contains carbon monoxide (CO). This is a poison gas you cannot see or smell. If you can smell the generator exhaust, you are

breathing CO. But even if you cannot smell the exhaust, you could be breathing CO.

NEVER use a generator inside homes, garages, crawl spaces, or other partially enclosed areas. Deadly

levels of carbon monoxide can build up in these areas. Using a fan or opening windows and doors does

NOT supply enough fresh air. ONLY use a generator OUTSIDE and far away from windows, doors, and

vents. These openings can pull in generator exhaust.

Even if you use a generator correctly, CO may leak into the home. ALWAYS use a battery-powered or

battery-backup CO alarm in the home. If you start to feel sick, dizzy, or weak after the generator has

been running, move to fresh air RIGHT AWAY. See a doctor. You may have carbon monoxide poisoning.

WARNING: The exhaust from this product contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

WARNING: DO NOT operate generator near open flame or flammable materials This generator

may emit highly flammable and explosive gasoline vapors, which can cause severe burns or even death

if ignited. A nearby open flame can lead to explosion even if it isn’t directly in contact with gasoline. Do

not smoke near the generator.

WARNING: This generator produces powerful voltage, which can result in electrocution.

WARNING: Do not use in rainy or wet conditions. Do not touch bare wires or receptacles (outlets).

Do not allow children or non-qualified persons to operate.

WARNING: Generator should ONLY be connected to electrical devices, either directly or with an

extension cord. NEVER CONNECT TO A BUILDING ELECTRICAL SYSTEM without a qualified electrician

and connected to a transfer switch as a separately derived system. Such connections must comply with

local electrical laws and codes. Failure to comply can create a back-feed, which may result in serious

injury or death to utility workers.

To maximize safety, ALWAYS ground the generator before using it (see the “GROUND THE GENERATOR” section on page 18).

Use a ground fault circuit interrupter (GFCI) in highly conductive areas such as metal decking or steel work.

GFCIs are available in-line with some extension cords.

CAUTION: Disconnect all electrical loads from the generator before attempting to start.

19

Page 20

STARTING THE GENERATOR

BEFORE STARTING THE GENERATOR

1. Verify that the generator is outside on a dry, level surface. Allow at least two feet of clearance on all sides

of the generator.

2. To maximize safety, check that the generator is properly grounded (see “GROUND THE GENERATOR”).

3. Check there is sufficient level of oil in the crankcase. Add oil if necessary (see “ADD/CHECK OIL”).

4. Verify the fuel selection dial is turned to the desired fuel. Turn the dial up to 12 o’clock position for gasoline

and down to 6 o’clock position for LPG. Check that there is adequate supply of the selected fuel.

5. Make sure all electrical devices are unplugged from the generator during ignition. Otherwise it will be difficult for the engine to start.

WARNING: The LPG cylinder valve must be shut OFF when using

gasoline. The generator’s fuel valve must be shut OFF when using LPG.

STARTING THE GENERATOR

1. To use gasoline, turn the fuel valve to the ON position.

To use LPG, make sure all of the LPG connectors and hoses are well connected and sealed. Close the fuel valve, then open the LPG tank valve.

2. Move the choke lever to the CLOSE/START position.

a. To start the engine with electric starter:

3. Insert the key and turn the engine switch to the

START position for 2-3 seconds. NOTE: If the engine

does not start, release the switch and try again.

Keeping the switch in the START position too long

can damage the starter.

4. When engine starts, release the switch to the ON.

5. Slowly move choke lever to the OPEN/RUN position. If engine fires, but does not continue to run,

move choke lever to CLOSE/START position and repeat starting instructions.

b. To start the engine with recoil starter:

3. Turn the engine switch to the ON position.

4. Pull on the recoil starter handle slowly until a

slight resistance is felt, then pull quickly to start the

engine. Return cord gently into the recoil starter.

Never allow the cord to snap back.

If engine fails to start, repeat this step.

5. Once the engine has started, slowly return the

choke lever all the way to the OPEN/RUN position.

6. Allow the engine to run for several minutes before attempting to connect any electrical devices. This allows

the generator to stabilize its speed and temperature. Follow the instructions in the next section for properly

connecting your electrical devices.

NOTE: In case you have had repeated failed attempts to start the engine, please consult the troubleshooting

guide before attempting to start the generator. If problems persist please call (800) 232-1195, M-F 8-5 CST.

20

Page 21

USING THE GENERATOR

CALCULATING THE WATTAGE OF YOUR DEVICE(S)

Connect electrical devices running on AC current according to their wattage requirements. Calculate the total

running wattage and starting wattage of the device(s) you wish to connect, and MAKE SURE that they are

within the capacity of your generator and the capacity of each individual outlet.

Generator Running (Rated) Watts Generator Starting (Surge) Watts

Gasoline: 8300W Gasoline: 11000W

LPG: 7500W LPG: 9500W

Generator

Wattage

Capacity

What this means:

The generator can produce a maximum of

8300W/7500W on a continuous basis to

supply ongoing power to your electronic

devices.

NOTE: Also check the rated amperage for

each outlet and make sure not to overload

the individual outlets.

Find the wattage information of each device you plan to connect. The information

should be listed on the device or in its instruction manual, or you may refer to Fig. 11.

The wattage can be calculated using this equation:

Watts = Volts x Amperes

To calculate the total running watts of

your devices:

What this means:

Some devices such as box fans require

short bursts of extra power in addition to

the rated wattage listed by the device to

start their motors.

The generator can produce a maximum

wattage of 11000W/9500W for a short

period of time (seconds) to cover the extra

starting power required by your electronic

devices.

To calculate the total starting watts of

your devices:

+ Add up the running wattages of all the

device(s) you plan to connect

Electronic

Device Wattage

Calculation

= The total running wattage

This wattage should NOT exceed the running wattage of 8300W/7500W.

It is recommended to maintain a load at

or below 7470W/6750W (90% of the rated

output) to ensure steady voltage output

and to prolong the generator’s lifespan.

If any of either of the total calculated running watts or starting watts is higher than the

capacity of your generator, adjust the load until both wattage requirements are met.

Otherwise you will overload the generator, and cause damage to the engine and your

electrical device(s).

+ Add up the total running wattage of all

the device(s) you plan to connect

+ Add the single highest ADDITIONAL

starting wattage out of the device(s) you

plan to connect

= The total surge (starting) wattage

This wattage should NOT exceed the

starting wattage of 11000W/9500W.

21

Page 22

USING THE GENERATOR

CALCULATING THE WATTAGE OF YOUR DEVICE(S) - CONTINUED

The chart below serves as a reference

for the estimated wattage requirements of common electrical devices.

However, do not solely rely on this chart - all electronics and appliances are built differently. Always check

the wattage listed on the electrical device before consulting this chart.

Tool or Appliance Rated (Running) Watts Surge (Starting) Watts

Electric water heater (40 Gal) 4000 0

Hot plate 2500 0

Saw - radial arm 2000 2000

Electric stove (each element) 1500-2800 0

Saw - circular 1500 1500

Air compressor (1 HP) 1500 3000

Window air conditioner 1200 1800

Saw - miter 1200 1200

Microwave 1000 0

Well water pump 1000 1000

Sump pump 800 1200

Refrigerator freezer 800 1200

Furnace blower 800 1300

Computer 800 0

Electric drill 600 900

Television 500 0

Deep freezer 500 500

Garage door opener 480 0

Stereo 400 0

Box fan 300 600

Clock radio 300 0

Security system 180 0

DVD player / VCR 100 0

Common light bulb 75 0

Fig. 11 -

Estimated wattage requirements of common electrical devices

22

Fig. 12 -

Control Panel

Page 23

USING THE GENERATOR

CONNECTING ELECTRICAL DEVICES

CAUTION: Become familiar with the functions and capacity of each component on the control panel

(page 9) before connecting electrical devices. Do not overload generator or individual panel receptacles.

DO NOT connect 50Hz or 3-phase loads to the generator.

Follow the steps below to properly connect your device(s) to the generator:

1. Before connecting electrical devices, allow the generator to run for a few minutes to stabilize the speed

and voltage output.

2. Select the device with the highest wattage, and make sure it is turned off. Plug the device into the matching

generator outlet and then turn the device on. Allow the engine to stabilize.

3. Repeat step 2 to plug in each additional device. DO NOT attempt to plug in or start multiple devices at the

same time.

IN CASE OF OVERLOAD

If your generator becomes overloaded from too much drawn wattage, the push-to-reset circuit breaker(s) on

your control panel will activate and cut off the output. When an overload occurs, reduce the load by turning

off and unplugging your electronic device(s), then press the activated circuit breaker to reset your generator.

If the circuit breaker does not reset, wait several minutes and try again. If no power is produced after resetting, restart your generator.

SOME NOTES ABOUT POWER CORDS

Long or thin extension cords can drain the power provided to your electrical devices. Refer to the following

chart in determining the necessary gauge extension cord for each of your devices. Round up to the higher

amperage in the chart to maximize safety.

Device Requirements Max. Cord Length (ft) by Wire Gauge

Amps Watts (120V) Watts (240V) #8 wire #10 wire #12 wire #14 wire #16 wire

2.5 300 600 NR NR NR 375 250

5 600 1200 NR NR 300 200 125

7.5 900 1800 NR 350 200 125 100

10 1200 2400 NR 250 150 100 50

15 1800 3600 NR 150 100 65 NR

20 2400 4800 175 125 75 50 NR

25 3000 6000 150 100 60 NR NR

30 3600 7200 125 65 NR NR NR

40 4800 9600 90 NR NR NR NR

NR - Not Recommended

Fig. 13 - Power Cord Requirement Guide

23

Page 24

USING THE GENERATOR

CHANGING FUELS

1. Before changing the fuel source, make sure the generator is turned OFF or running UNDER half-load. DO

NOT change fuel when generator is over half-load.

2. If switching from LPG to gasoline, turn OFF the LPG tank valve and disconnect LPG fuel tank from generator. Then turn ON the fuel valve.

If switching from gasoline to LPG, turn OFF the fuel valve. Then follow the LPG connecting procedure in section “FUEL OPTION B: Liquid petroleum gas (LPG)”.

3. Check the fuel level of the selected fuel and make sure there is adequate amount.

4. Turn the fuel selection dial to the desired fuel - Turn the dial up to 12 o’clock position for gasoline and down

to 6 o’clock position for LPG.

SHUTTING OFF THE GENERATOR

TO STOP THE GENERATOR

1. Turn off all electrical devices. Unplug the devices from the generator. Never start or stop the generator with

electrical devices plugged in or turned on.

2. Let engine run at no-load for several minutes to stabilize internal temperatures of engine and generator.

3. Turn the engine switch to the OFF position.

4. If using gasoline, turn the fuel valve to the OFF (horizontal) position. If using LPG, turn the LPG tank valve

to the OFF position.

IMPORTANT: Always ensure that the fuel valve and the engine switch are in the OFF position when the generator is not in use.

5. Turn the fuel selection dial to Gasoline position (12 o’clock).

6. Drain the carburetor (See “Draining the Carburetor“ on Page 26).

WARNING: Allow the generator to cool down before touching areas that become hot during use.

CAUTION: Allowing gasoline to sit in the fuel tank for long periods of time can make it difficult to start

the generator in the future. Never store the generator for extended periods of time (over 2 months) with

fuel in the fuel tank. Refer to “STORING THE GENERATOR”.

24

Page 25

MAINTENANCE

RECOMMENDED MAINTENANCE SCHEDULE

Proper routine maintenance of the generator will help prolong the life of the machine. Please perform maintenance checks and operations according to the Maintenance Schedule in Fig. 14. If there are any questions

about the maintenance procedures listed in this manual, please call (800) 232-1195 M-F 8-5 CST or email

techsupport@wenproducts.com.

WARNING: Never perform maintenance operations while the generator is running. Before maintaining or servicing the generator, turn OFF the generator, disconnect all devices and allow the generator

to cool down.

Recommended

Maintenance Schedule

Engine Oil

Air Filter

Spark Plug

Fuel

Carburetor

Spark

Arrestor

Battery

Check level x

Replace x* x

Check x*

Clean x*

Check/clean/

regap

Change x x

Check level x

Drain x x

Drain x x

Check/Clean x

Disconnect x

Each 8

hours or

daily

Every 25

hours

Every 3

months

or 50

hours

Every 6

months or

100 hours

x

Before

Storage

As

necessary

Fig. 14 - Recommended Maintenance Schedule

* Clean/change more often under dusty conditions or operating under heavy load.

IMPORTANT GENERATOR MAINTENANCE TIPS:

• Drain your carburetor after each use and before storage to prevent it from clogging.

• Do not store the generator with fuel inside the tank for more than 2 months - the fuel will go bad.

• Run the generator for 20 to 30 minutes every month to maximize its lifespan.

NOTE: Failure to properly maintain the generator will void the warranty.

25

Page 26

MAINTENANCE

CLEANING THE GENERATOR

Keep the generator clean to prevent improper operation or machine damage from dirt and debris. Inspect all

ventilation openings on the generator. These openings must be kept clean and unobstructed.

If the generator becomes dirty, use a damp cloth to wipe exterior surfaces. Use a soft bristle brush to loosen

dirt and oil and use a vacuum to pick up loose dirt. Use low pressure air (not to exceed 25 PSI) to blow

away dirt.

WARNING: Never clean the generator when it is running! Never clean with a bucket of water or a

hose. Water can get inside the working parts of the generator and cause corrosion or a short circuit.

DRAINING THE CARBURETOR

We recommend draining the carburetor after every use and before storing the generator. Draining the

carburetor can help prevent build-up and blockages caused by stagnant fuel inside of the carburetor.

1. Prepare an approved gasoline-storage container under

the carburetor to collect the drained fuel.

2. The carburetor (Fig. 18 - 1) can be accessed from the

backside of the generator between the engine and the air

filter. To drain the carburetor, open up the carburetor drain

screw with a Phillips-head screwdriver (not included) and

drain out any gasoline that has built up inside.

3. Once the fuel has drained, close the drain screw.

NOTE: Make sure to drain your carburetor before storing

the generator for long periods of time.

Fuel Drain

Screw

Fig. 15 - Draining the Carburetor

26

Page 27

MAINTENANCE

CHECKING/ADDING OIL

Check the oil level before each use and every 8 hours of operation (refer to Fig. 14).

The oil capacity of the generator engine is 37.2 fl. ounces. Add oil when the oil level is low. For proper

type and weight of oil refer to “ADD OIL” portion of the “GENERATOR PREPARATION” section. This is a critical step for proper engine starting. The generator is equipped with an automatic shutoff to protect it from

running on low oil.

To check the oil level and add oil:

1. Make sure the generator is on a level surface. Do not tilt the generator, as oil will flow into engine areas

and cause damage. Keep generator level!

2. Clean around the oil fill. Remove the dipstick and wipe the it with a

clean rag.

3. Insert the dipstick into the oil fill opening without screwing in. Remove the dipstick to check the oil mark (Fig. 16). Add oil if the oil mark

covers less than one half of the dipstick.

4. Using a funnel or appropriate dispenser, slowly add more oil. Repeat

step 3 until the oil mark reaches the top of the dipstick (you can see oil

coming up the threads of the oil fill). Do not over fill.

5. Reinstall dipstick and wipe clean any spilled oil with a rag. Reinstall

the oil access cover.

Upper Limit

Lower Limit

Fig. 16

DRAINING/CHANGING OIL

Change the oil according to the Recommended Maintenance

Schedule in Fig. 14.

Change the oil MORE OFTEN if operating under heavy load or high

ambient temperatures. It is also necessary to drain the oil from the

crankcase if it has become contaminated with water or dirt. Changing

the oil when the engine is warm allows for complete drainage.

Oil Drain Bolt

To drain the oil from the generator:

1. Place generator on elevated platform. Prepare an approved gasoline-storage container underneath the

oil drain bolt next to the oil dipstick to catch the oil as it drains.

Fig. 17

2. Unscrew the oil drain bolt (Fig. 17) and allow oil to drain from the engine completely.

3. Reinstall the oil drain bolt and tighten it securely. Wipe clean any oil spillage.

NOTE: Never dispose of used engine oil in the trash or down a drain. Please call a local recycling center

or auto garage to arrange proper oil disposal.

27

Page 28

MAINTENANCE

AIR FILTER MAINTENANCE

Check every 50 hours of operation (refer to Fig. 14 - Recommended Maintenance Schedule).

Routine maintenance of the air filter helps maintain proper airflow to the carburetor. Occasionally check that

the air filter is free of excessive dirt. Clean air filter more frequently in dirty or dusty conditions

To inspect and clean the air filter:

1. Remove the air filter cover (Fig. 18) by undoing the clasps at the

top and bottom of the air filter cover.

2. Remove the sponge-like air filter element from the casing.

Wipe excessive oil and any dirt from inside of the air filter casing.

3. Check and clean the foam air filter element. Good elements can

be washed in soapy water. Dry the element in clean cloth (do not

twist it). A small amount of oil left in the element is normal and

necessary for the engine to work properly.

If the air filter element has been damaged, replace it with a new

one. Replacement air filters can be ordered from wenproducts.com by searching part no. DF1100-175.1.

Air Cleaner Cover

Fig. 18

4. Reinstall the air filter element and air filter cover.

WARNING: Running the engine with a dirty, damaged or missing air filter element can result in

danger to the operator and cause the engine to wear out prematurely.

SPARK ARRESTOR MAINTENANCE

Inspect and clean the spark arrestor every 100 hours of operation.

The spark arrester is located outside the muffler, which gets very hot during operation. Allow the engine to

cool completely before servicing the spark arrester. To inspect and clean the spark arrester:

1. Remove the screws holding the cover plate which retains the

end of the spark arrester to the muffler (Fig. 19).

2. Remove the spark arrester screen.

3. Carefully clean and remove the carbon deposits from the spark

arrestor screen with a wire brush. Replace the spark arrestor if it

is damaged.

4. Reinstall the spark arrestor in the muffler and secure it in place

with the screws.

28

Fig. 19

Page 29

MAINTENANCE

SPARK PLUG MAINTENANCE

Refer to Recommended Maintenance Schedule in Fig. 14 for maintaining the spark plug.

The spark plug is important for proper engine operation. Check the spark plug regularly to maintain proper

engine operation. A good spark plug should be intact, free of deposits, and properly gapped.

To inspect or replace the spark plug:

1. Pull on the spark plug boot to remove it (Fig. 20). Be careful

not to tear insulation or wire.

2. Remove the spark plug rubber boot and unscrew the spark plug

from the engine using the spark plug wrench provided (Fig. 21).

TIP: There is limited space for the wrench to turn. Use both rows

of holes in the spark plug wrench to gain leverage to loosen the

plug.

3. Visually inspect the spark plug. If it is cracked or chipped, or if

the electrodes are worn or burned, discard it and replace with a

new spark plug.

We recommend replacing with an NGK BP7ES/Torch F7TC spark

plug (part no. DF475-145), available for purchase at

wenproducts.com.

4. If re-using the spark plug, use a wire brush to clean any dirt

from around the spark plug base, then re-gap the spark plug.

5. Measure the plug gap with a spark plug gap gauge. The gap

should be 0.7 to 0.8 mm (0.028-0.031 in.) (Fig. 22). Carefully adjust the gap if necessary.

Cylinder

Assembly

Spark Plug

Boot

Fig. 20

Plug Wrench

Spark Plug Boot

Fig. 21

6. Screw the spark plug back into the spark plug hole using the

spark plug wrench. Do not over-tighten spark plug. Recommended

tightening of spark plug is ½ to ¾ of a turn (15 ft-lb torque/20.33

Nm) after spark plug gasket contacts spark plug hole.

7. Reinstall the spark plug boot over the spark plug.

0.7 - 0.8 mm

Fig. 22

29

Page 30

MAINTENANCE

BATTERY MAINTENANCE/STORAGE

The battery (part no. DF1100-041) shipped with the generator has been fully charged. The battery will receive charge when the engine is running. Remember to run the generator once a month for 20-30 minutes

to charge the battery. A charged battery will allow you to start the generator using the electric start switch

during your next time of need.

If the battery is out of charge, you can still manually start the generator using the recoil start with LPG as your

fuel source.

IMPORTANT: If the generator is not used for a long period, it is recommended to disconnect the positive

battery cable from the battery to protect the battery from losing charge. After disconnecting the cable, cover

the free end with an insulator such as electrical tape. You may can also connect the battery to an automatic

trickle charger to keep the battery charged.

To reinstall/replace the battery:

1. Disconnect the negative (-) battery terminal first (black wire).

2. Disconnect the positive (+) battery terminal second (red wire).

3. To install a new battery, install the hold down bracket, insert the threaded rod and tighten with M6 nuts.

4. Connect the positive (+) battery terminal (red wire) first. Slide rubber boot over the connection hardware.

5. Connect the negative (-) battery terminal (black wire) second. Slide rubber boot over connection hardware.

NOTE: Always recycle used batteries in accordance with local laws and regulations. Contact your local solid

waste collection site or recycling facility to obtain information on local recycling processes.

30

Page 31

MAINTENANCE

DRAINING THE FUEL TANK

Drain and clean the fuel tank each year, or before storing the generator for longer than two months.

To drain the fuel tank:

1. Prepare an approved gasoline-storage container to collect the drained fuel. Place it near the fuel valve.

2. Turn the fuel valve to the OFF position.

3. Locate the fuel line between the fuel valve and back of control panel. Disconnect the fuel line from the fuel

valve. NOTE: A small amount of fuel may leak from the fuel line during removal.

4. Place a funnel below the fuel valve opening, and direct the other end of the funnel over the prepared

container. Turn the fuel valve to ON to start draining the fuel from the fuel valve opening.

5. Once the fuel is drained, shut OFF the fuel valve.

6. Start and run the engine until the fuel runs out.

7. Drain the carburetor according to the instructions on page 26.

8. Store the emptied gasoline in a suitable place. DO NOT store flammable materials near the gasoline.

Do not store fuel for more than 3 months.

CAUTION: Store the emptied gasoline in a suitable place. Never store fuel for more than 2 months.

31

Page 32

TRANSPORTATION & STORAGE

TRANSPORTING THE GENERATOR

To prevent fuel spillage when transporting, be sure to perform the following to your generator:

1. Tighten the fuel cap and make sure the fuel valve is turned to OFF.

2. Make sure the engine switch is in the OFF position.

3. Drain the fuel tank if possible (see “DRAINING THE FUEL TANK”).

4. Keep the generator upright. Never place the generator on its side or upside down - doing so could

damage the internal components of the generator and make it difficult to start.

WARNING: Avoid direct sunlight inside a vehicle. If the generator is left in an enclosed vehicle for

many hours, the high temperature could cause the fuel to vaporize and result in a possible explosion.

STORING THE GENERATOR

Shut off the generator and allow the unit to cool to room temperature before storing it. NEVER place any

type of storage cover on the generator while it is still hot. Do not obstruct any ventilation openings.

Follow the procedures below for properly storing your generator. We highly recommend running your generator once a month for 20 to 30 minutes. Plug in a small load in to ensure there is proper power output.

For Short Periods (30 to 60 Days):

For Extended Periods

(Over 60 Days):

• Drain the carburetor (see page 26).

• Disconnect the negative terminal from the battery.

• Add fuel stabilizer:

Follow the suggested portions and instructions of your

preferred stabilizer. Run the engine for 15 to 20 minutes, allowing the fuel stabilizer to mix with the gasoline

and circulate through the carburetor, and then top off

with fuel. Filling the fuel tank full reduces the amount of

air in the tank and helps fight deterioration of fuel.

WARNING: Store the generator upright in a cool and dry location, away from sources of heat, open

flames, sparks or pilot lights.

• Disconnect the negative terminal from the

battery (see page 30) .

• Drain the fuel tank and carburetor (see

“

DRAINING THE FUEL TANK”

generator with fuel in the tank for more than

two months.

• Change the engine oil (see “CHANGING

OIL”).

). NEVER store

PRODUCT DISPOSAL

Do not dispose of used generator or parts with your household waste. This product contains electrical or

electronic components that should be recycled. Please take this product to your local recycling facility for

responsible disposal to minimize its environmental impact.

Do not dispose of used oil or fuel in the trash or down a drain. Please contact your local recycling center or

auto garage to arrange proper oil/fuel disposal.

32

Page 33

SPECIFICATIONS

GENERATOR

Gasoline: 8300 Watts

Rated Wattage

LPG: 7500 Watts

Gasoline: 11000 Watts

Surge Wattage

LPG: 9500 Watts

Phase Single

Frequency 60Hz

Rated Voltage AC: 120V/240V, DC: 12V

Rated Amperage AC: 70A/35A, DC: 8A

Product Dimensions 27.3 x 20.6 x 21.9 in. (L x W x H)

Product Net Weight 213.8 lbs

ENGINE

Engine Type 4-stroke, OHV, single cylinder with forced air cooling system

Engine Displacement 457cc

Engine Horsepower 12.6 HP at 3600 RPM

Fuel Type Gasoline and LPG

Gas Tank Capacity 6.6 US Gallons (25 L), 87 octane minimum

Oil Capacity 37.2 fl. oz. (1.1 L)

Gasoline: 8.5 hours

Half-Load Run Time

LPG (with 20 lb tank): 3 hours

Spark Plug Type Torch F7TC/NGK BP7ES

Spark Plug Gap 0.7 - 0.8 mm (0.028 - 0.031 in)

Spark Plug Torque 1/2 - 3/4 turn after gasket contacts base or 15 ft-lbs

IMPORTANT: Repairs and replacements should only be performed by an authorized technician. Parts and

accessories that wear down over the course of normal use are NOT covered by the two-year warranty.

33

Page 34

GENERATOR

EXPLODED VIEW

EXPLODED VIEW & PARTS LIST

1.4

80

1.3

81

34

82

Page 35

EXPLODED VIEW & PARTS LIST

No. Part No. Description Qty.

1 DF1100-001 Rotor & Stator Assembly 1

1.1 DF475-001.1 Carbon Brush Assembly 1

1.2 DF475-001.2 Grounding Post Assembly 1

1.3 DF1100-001.3 Rotor 1

1.4 DF1100-001.4 Stator 1

2 DF1100-002 Motor Stand 1

3 DF1100-003 Bolt M5X230 2

4 DF1100-004 Nut M5 2

5 DF1100-005 Flat Washer Ø5 2

6 DF1100-006 Spring Washer Ø5 3

7 DF1100-007 Frame 1

8 DF1100-008 Rack Cable 1

9 DF1100-009 Isolator B 4

10 DF475-010 Fuel Filter 1

11 DF1100-011 Fuel Tank Assembly 1

12 DF475-012 Fuel Cock 1

13 DF1100-013 Regulator Assembly 1

14 DF475-014 LPG Hose Assembly 1

15 DF1100-015 Crankcase Guard Cover 1

16 DF1100-016 Flat Washer 2

17 DF1100-017 Bolt M10X1.25X283 1

18 DF475-016 Gasket, Rotor Bolt Ø10.5XØ30X4 1

19 DF1100-019 Handle Assembly 2

20 DF1100-020 Bolt M6X195 4

21 DF1100-021 Bolt M6X12 9

22 DF1100-022 Nut M10 4

23 DF1100-023 Air Cleaner Bracket 1

24 DF1100-024 Exhaust Pipe Gasket 1

25 DF1100-025 Cotter Pin 2

26 DF1100-026 Muffler Assembly 1

27 DF1100-027 Spring Washer 2

28 DF1100-028 Bolt M8X30 2

29 DF1100-029 Panel Assembly 1

29.1 DF475-029.1 Ignition Switch 1

N/A P55340

29.2 DF475-029.4

29.3 DF1100-029.3 AC Thermal Protector 20A/CSA 2

29.4 DF1100-029.4 Multifunction Meter 1

29.5 DF475-029.2 DC Receptacle 12V 1

29.6 DF1100-029.6 Thermal Protector 35A/CSA 2

29.7 DF1100-029.7 NEMA L14-30R 120V/240V 30A 1

29.8 DF1100-029.8 NEMA L14-50R 120V/240V 50A 1

29.9 DF1100-029.9 DC Thermal Protector 8A/CSA 1

29.10

DF1100-029.10 AC Thermal Protector 35A/CSA 2

29.11

DF1100-029.11 Rectifier/Charger 1

30 DF1100-030 Handle Plug 2

31 DF1100-031 Bolt M8X45 2

32 DF1100-032 Bolt M6X25 2

33 DF1100-033 Automatic Voltage Regulator (AVR) 1

Starter Key (Set of 2)

NEMA 5-20R 120V 20A GFCI Duplex

No. Part No. Description Qty.

34 DF475-034 Bolt M5X16 3

35 DF475-035 Bolt M5X12 5

36 DF475-036 Fuel Tank Washer 4

37 DF475-037 Bolt M6X25 4

38 DF1100-038 Generator End Cover 1

39 DF475-039 Positive Lead 1

40 DF1100-040 Negative Lead 1

41 DF1100-041 Battery 1

42 DF1100-042 Wheel 2

43 DF1100-043 Foot Support Assembly 2

44 DF1100-044 Vibration Isolation Pad 2

45 DF475-045 Nut M6 3

46 DF475-046 Bolt M8X16 4

47 DF475-047 Clip Ø12 2

48 DF1100-048 Wheel Axel 2

49 DF475-005 Bolt M8X16 4

50 DF1100-050 Muffler Bracket 1

51 DF1100-051 Tie Wrap 1

52 DF475-063 Fuel Line Clip Ø10 1

53 DF1100-053 Low Pressure Pipe 1

54 DF1100-054 Toothed Washer Ø5 1

55 DF1100-055 Fuel Line (Fuel Cock) 1

56 DF475-055 Fuel Line 1

57 DF1100-057 Connecting Pipe (Gas Tank) 1

58 DF1100-058 Manual Choke Assembly 1

59 DF475-003 Fuel Selector Switch (Panel) 1

60 DF475-060 Clip, Fuel Line Ø7.5 1

61 DF475-061 Clip, Fuel Line Ø9.5 5

62 DF1100-062 Dustproof Sheet (Right) 1

63 DF475-004 Hex Pan Head Screw M6X12 1

64 DF475-064 Nut M6 4

65 DF475-073 Fuel Tank Cap Assembly 1

66 DF475-022 Nut M5 3

67 DF1100-067 Handle Bush 4

2

2

68 DF1100-068 Dustproof Sheet (Left) 1

69 DF1100-069 One-Way Valve Gasket Washer 1

70 DF475-070 Fuel Selector Switch 1

71 DF1100-071 Crossing Screw M5X12 3

72 DF475-072 Paper Washer 4

73 DF1100-073 Handle Rubber 2

74 DF1100-074 Grounding Wire 1

75 DF1100-075 Carbon Tank Assembly 1

76 DF475-074 LPG Regulator Cover 1

77 DF1100-077 Lock Nut M8 2

79 DF1100-079 Connecting Pipe 1

80 DF1100-080 Fuel Gauge 1

81 DF1100-081 Fuel Tank Filter 1

82 DF1100-082 Engine Complete 1

35

Page 36

ENGINE EXPLODED VIEW

EXPLODED VIEW & PARTS LIST

36

74.1

75.1

Page 37

EXPLODED VIEW & PARTS LIST

No. Part No. Description Qty.

1 DF1100-101 Crankcase 1

2 DF1100-102 Ball Bearing (Small) 2

3 DF1100-103 Oil Seal 2

4 DF1100-104 Governor Arm Shaft Seal 1

5 DF1100-105 Governor Arm Shaft 1

6 DF1100-106 Governor Arm Shaft Washer 1

7 DF1100-107 Lock Pin 1

8 DF1100-108 Drain Plug Bolt 2

9 DF1100-109 Drain Plug Washer 2

10 DF1100-110 Oil Level Switch Assembly 1

11 DF1100-111 Bolt M6X16 2

12 DF1100-112 Casecover Dowel Pin 2

13 DF1100-113 Piston 1

14 DF1100-114 Piston Scraper Ring Set 1

15 DF1100-115 Connecting Rod Assembly 1

16 DF1100-116 Piston Pin 1

17 DF1100-117 Piston Clip 2

18 DF1100-118 Crank Casecover Assembly 1

19 DF1100-119 Ball Bearing (Big) 1

20 DF1100-120 Governor Assembly 1

21 DF1100-121 Cylinder Head 1

22 DF1100-122 In Valve 1

23 DF1100-123 Valve Exhaust 1

24 DF1100-124 Intake Valve Returner 2

25 DF1100-125 Valve Oil Seal 2

26 DF1100-126 Valve Spring 2

27 DF475-132 Fuel Line (Carburetor) 1

28 DF1100-128 Ex Valve Spring Seat 2

29 DF1100-129 Push Rod Guide Plate 1

30 DF1100-130 Rocker Assembly 2

31 DF1100-131 Rotator 2

32 DF1100-132 Stud Bolt (Carburetor) 2

33 DF1100-133 Stud Bolt (Exhaust) 2

34 DF1100-134 Exhaust Gasket 1

35 DF1100-135 Dipstick 1

36 DF1100-136 Spring Washer 2

37 DF1100-137 Nut M8 2

38 DF1100-138 Carburetor Assembly 1

39 DF1100-139 Governor Arm 1

40 DF1100-140 Governor Arm Bolt 1

41 DF1100-141 Nut M6 3

42 DF1100-142 Crankshaft Assembly 1

No. Part No. Description Qty.

43 DF1100-143 Valve Lifter 2

44 DF1100-144 Casecover Gasket 1

45 DF1100-145 Balancing Shaft 1

46 DF1100-146 Camshaft Assembly 1

47 DF1100-147 Bolt M8X35 2

48 DF1100-148 Bolt M8X40 7

49 DF1100-149 Dowel Pin 2

50 DF1100-150 Cylinder Head Gasket 1

51 DF1100-151 Bolt M10X80 4

52 DF475-145 Spark Plug 1

53 DF1100-153 Push Rod 2

54 DF1100-154 Shroud 1

55 DF1100-155 Bolt M6X12 9

56 DF1100-156 Cylinder Head Cover Assembly 1

57 DF1100-157 Head Cover Gasket 1

58 DF1100-158 Lock Bolt 1

59 DF1100-159 Upper Shroud Assembly 1

60 DF1100-160 Flywheel Assembly 1

61 DF1100-161 Recoil Starter Fan 1

62 DF1100-162 Starter Pulley 1

63 DF1100-163 Nut Flywheel 1

64 DF1100-164 Rubber Starter Assembly 1

65 DF1100-165 Ignition Coil Assembly 1

66 DF1100-166 Bolt M6X25 2

67 DF1100-167 Intake Gasket 1

68 DF1100-168 Carburetor Insulator 1

69 DF1100-169 Carburetor Gasket 1

70 DF1100-170 Adjuster Rocker Arm 2

71 DF1100-171 Exhaust Pipe 1

72 DF1100-172 Governor Rod 1

73 DF1100-173 Throttle Return Spring 1

74 DF1100-174 Recoil Starter Assembly 1

74.1 DF1100-174.1 Recoil Starter 1

75 DF1100-175 Air Cleaner Assembly 1

75.1 DF1100-175.1 Air Filter Element 1

76 DF1100-176 Breather Tube 1

77 DF1100-177 Governor Spring 1

78 DF1100-178 Locking Flaps 4

79 DF1100-179 Clip 2

80 DF1100-180 Fuel Rubber 1

81 DF1100-181 Air Cleaner Gasket 1

82 DF1100-182 Fuel Line Clip 1

83 DF1100-183 Starting Motor Assembly 1

37

Page 38

WIRING DIAGRAM

35A

35A

38

Page 39

TROUBLESHOOTING GUIDE

WARNING: Stop using the generator immediately if any of the following problems occur or risk se-

rious personal injury. If you have any questions, please contact our customer service at (800) 232-1195,

M-F 8-5 CST or email us at techsupport@wenproducts.com.

PROBLEM POSSIBLE CAUSE SOLUTION

Engine switch is set to OFF. Set engine switch to ON.

Fuel valve is turned to OFF. Turn fuel valve to ON.

Oil is low. Add or replace oil.

Engine will not

start.

Engine runs but

there is no

electrical output.

Generator runs but

does not support

all electrical devices connected.

Engine is out of fuel. Add fuel.

Engine is filled with

contaminated or old fuel.

Spark plug is dirty or broken. Clean or replace the spark plug.

Carburetor is air locked.

Circuit breaker has been

tripped due to overload.

Bad connecting cords/wires.

Bad electrical device connected to the generator.

Voltage regulator is bad

Carbon brushes worn or need

adjustment

Generator is overloaded.

Short circuit in one of the

devices.

Air filter is dirty. Clean or replace the air filter element.

Drain fuel in the tank. Fill with fresh fuel.

Shut off the fuel valve. Remove the bolt from the bottom of

the carburetor. Take off the carburetor bowl to allow it to

reset. Replace carburetor bowl and reinstall the bolt.

Turn off and unplug electrical device(s). Wait 5 minutes, then

press the circuit breaker to reset. Check the total wattage of

the devices and reduce the load if it exceeds the capacity of

the generator. Then plug the loads back in one by one.

Check the power cords and extension cords. Do not use if

any cord is damaged. Replace damaged cords immediately.

Try connecting a different device.

Check voltage regulator (p. 35, DF1100-033) with a multimeter, replace if necessary.

Check carbon brushes (p. 35, DF475-001.1), adjust so that

both brushes extrude the same length, or replace if worn.

Turn off and unplug all electrical devices. Wait 5 minutes,

then press the circuit breaker to reset. Reduce load as necessary, then plug devices back in one by one.

Try disconnecting any faulty or short-circuited electrical

loads.

1. The fuel isn’t running

Engine is

“Hunting” during

Operation

(Engine RPM is

fluctuating).

through the fuel valve.

2. The air filter is clogged.

3. The muffler or spark arrester is blocked

4. There is gunk in the carburetor preventing a consistent

fuel/air mixture.

Turn off the generator and wait for it to cool down.

Perform the following steps:

1. Check if the fuel is properly and consistently going

through the fuel valve

2. Check for any blockage in the air filter. Check and clean

the air filter as necessary.

3. Check if the spark arrester is blocked. Clean with metal

brush as necessary.

4. Use “gunk remover” spray on the carburetor jets.

39

Page 40

WARRANTY STATEMENT

REMEMBER TO SAVE THE RECEIPT. PROOF OF PURCHASE IS REQUIRED FOR ALL WARRANTY WORK.

WEN® Generators are under warranty to be free from defects in materials and workmanship for a period

of two (2) years from date of original purchase. Generators used for Commercial or Rental use have a

warranty period of 90 days from date of original purchase. Keep purchase receipt and mail in the product

registration card for proof of purchase.

WEN® will repair or replace, at its discretion, any part that is proven to be defective in materials or workmanship under normal use during the two (2) years warranty period. Warranty repairs or replacements will

be made without charge for parts or labor. Parts replaced during warranty repairs will be considered as

part of the original product and will have the same warranty period as the original product.

To exercise the warranty, DO NOT RETURN TO RETAILER. Instead, call the toll free Customer Service number

at (800) 232-1195 and you will be instructed on where to take the generator for warranty service. Take the

generator and proof of purchase (the receipt) to the repair facility recommended by the Customer Service

Representative. To make a claim under this Limited Warranty, you must make sure to keep a copy of your

proof of purchase that clearly defines the Date of Purchase (month and year) and the Place of Purchase.

Place of purchase must be a direct vendor of Great Lakes Technologies, LLC. Third party vendors such as

garage sales, pawn shops, resale shops, or any other secondhand merchant void the warranty included

with this product. Contact techsupport@wenproducts.com or 1-800-232-1195 to make arrangements for

repairs and transportation.

When returning a product for warranty service, the shipping charges must be prepaid by the purchaser.

The product must be shipped in its original container (or an equivalent), properly packed to withstand the

hazards of shipment. The product must be fully insured with a copy of the warranty card and/or the proof