Page 1

MODEL CT1065

6.5-INCH TRACK SAW

Instruction Manual

NEED HELP? CONTACT US!

Have product questions? Need technical support? Please feel free to contact us:

TECHSUPPORT@WENPRODUCTS.COM800-232-1195 (M-F 8AM-5PM CST)

IMPORTANT: Your new tool has been engineered and manufactured to WEN’s highest standards for dependability,

ease of operation, and operator safety. When properly cared for, this product will supply you years of rugged,

trouble-free performance. Pay close attention to the rules for safe operation, warnings, and cautions. If you use

your tool properly and for its intended purpose, you will enjoy years of safe, reliable service.

For replacement parts and the most up-to-date instruction manuals, visit WENPRODUCTS.COM

Page 2

TABLE OF CONTENTS

Specifications ........................................................................................... 2

Introduction ............................................................................................. 3

General Safety Rules ................................................................................ 4

Specific Safety Rules for Your Track Saw ................................................. 6

Electrical Information ............................................................................... 9

Unpacking & Transportation ..................................................................10

Know Your Track Saw ............................................................................ 11

Assembly & Adjustments ....................................................................... 13

Operation ............................................................................................... 19

Troubleshooting Guide ...........................................................................22

Maintenance ........................................................................................... 23

Exploded View & Parts List .................................................................... 25

Warranty Statement ............................................................................... 28

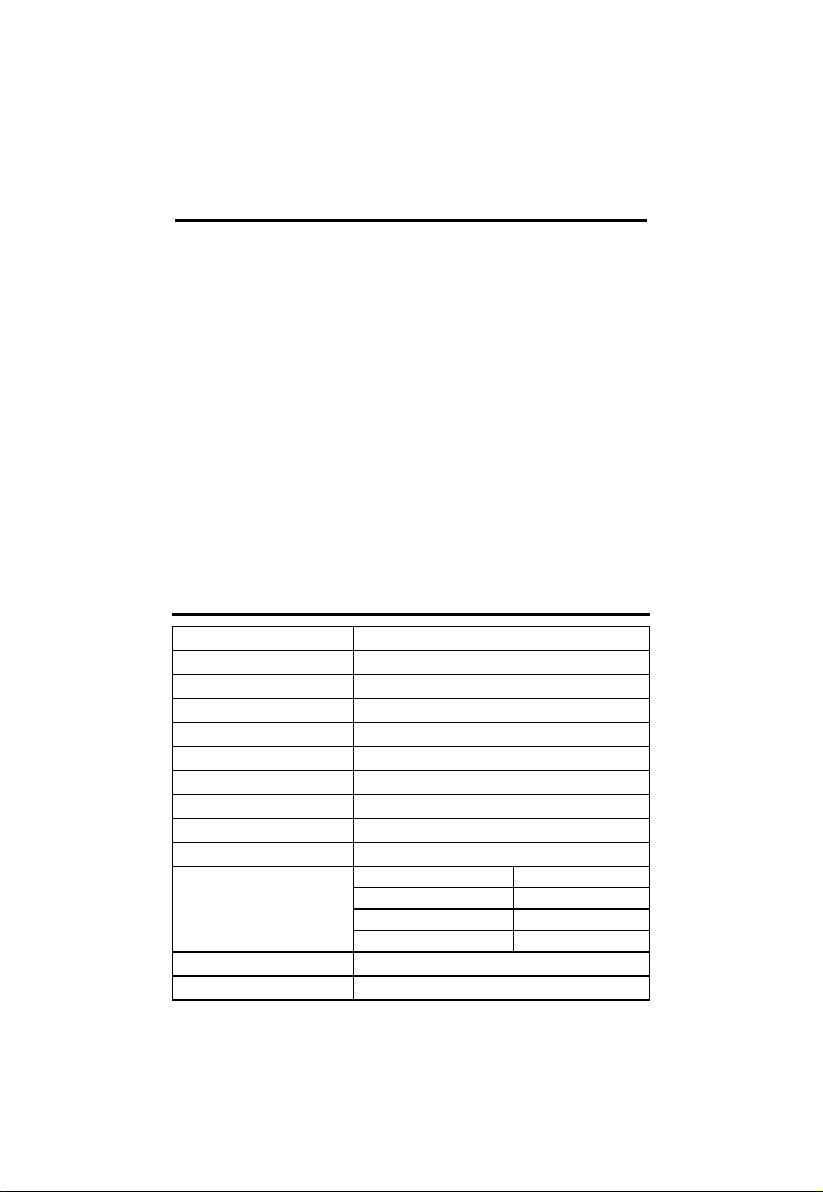

SPECIFICATIONS

Model Number CT1065

Motor 120V, 60Hz, 10A

No-Load Speed 5500 RPM

Blade Part Number CT1065B

Blade Size 6.5" (165mm) TCT

Arbor Size 20mm

Teeth 24T

Blade Thickness 1.6mm

Kerf 2.2mm

Blade Bevel 0° - 45°

90° without track 2.32" (59mm)

Cutting Capacity

Weight 12 lbs

Product Dimensions 12" x 9.5" x 9.5"

45° without track 1.65" (42mm)

90° with track 2.13" (54mm)

45° with track 1.50" (38mm)

Page 3

INTRODUCTION

Thanks for purchasing the WEN Track Saw. We know you are excited to put your tool to work, but first, please

take a moment to read through the manual. Safe operation of this tool requires that you read and understand this

operator’s manual and all the labels affixed to the tool. This manual provides information regarding potential safety

concerns, as well as helpful assembly and operating instructions for your tool.

SAFETY ALERT SYMBOL:

explanations with them deserve your careful attention and understanding. Always follow the safety pre

cautions to reduce the risk of fire, electric shock and personal injury. However, please note that these

instructions and warnings are not substitutes for proper accident prevention measures.

NOTE: The following safety information is not meant to cover all possible conditions and situations that may occur.

WEN reserves the right to change this product and specifications at any time without prior notice.

Keep this manual available to all users during the entire life of the tool and review it frequently to

Indicates danger, warning, or caution. The safety symbols and the

-

maximize safety for both yourself and others.

To purchase accessories for your tool, visit WENPRODUCTS.COM

100-inch Track with Adapters (Model No. CT9502)

4-piece Track Adapter Set (Model No. CT9011)

Pair of Track Clamps (Model No. CT992F)

NOTE:

The rubber strip (Part No. CT9502-001) and foam strips (Part No. CT9502-002) on your track

may wear down with use. This is normal and not covered under the two-year warranty. These parts are

available for purchase on wenproducts.com, just search their part numbers.

32

Page 4

GENERAL SAFETY RULES

Safety is a combination of common sense, staying alert and knowing how your item works.

WARNING:

this tool. Failure to follow all instructions listed below may result in personal injury, electric shock, fire

and/or tool damage.

Read and understand all warnings, cautions and operating instructions before using

WORK AREA SAFETY

1. KEEP WORK AREA CLEAN AND WELL LIT. Cluttered

or dark areas invite accidents.

2. DO NOT OPERATE POWER TOOLS IN EXPLOSIVE

ATMOSPHERES, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

3. KEEP CHILDREN AND BYSTANDERS AWAY WHILE

OPERATING A POWER TOOL. Distractions can cause

you to lose control.

ELECTRICAL SAFETY

1. POWER TOOL PLUGS MUST MATCH THE OUTLET.

Never modify the plug in any way. Do not use any adapt

er plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

2. AVOID BODY CONTACT WITH EARTHED OR GROUND

ED SURFACES such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

3. DO NOT EXPOSE POWER TOOLS TO RAIN OR WET

CONDITIONS. Water entering a power tool will increase

the risk of electric shock.

4. DO NOT ABUSE THE CORD. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric

shock.

5. WHEN OPERATING A POWER TOOL OUTDOORS,

USE AN EXTENSION CORD SUITABLE FOR OUTDOOR

USE. Use of a cord suitable for outdoor use reduces the

risk of electric shock.

SAVE THESE SAFETY INSTRUCTIONS.

6. IF OPERATING A POWER TOOL IN A DAMP LOCA

TION IS UNAVOIDABLE, USE A GROUND FAULT CIRCUIT INTERRUPTER (GFCI) PROTECTED SUPPLY. Use

of a GFCI reduces the risk of electric shock.

PERSONAL SAFETY

1. STAY ALERT, WATCH WHAT YOU ARE DOING AND

USE COMMON SENSE WHEN OPERATING A POWER

TOOL. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may

result in serious personal injury.

2. USE PERSONAL PROTECTIVE EQUIPMENT. ALWAYS

WEAR EYE PROTECTION. Protective equipment such as

a respiratory mask, non-skid safety shoes and hearing

protection used for appropriate conditions will reduce

the risk of personal injury.

3. PREVENT UNINTENTIONAL STARTING. Ensure the

switch is in the off-position before connecting to power

source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch

or energizing power tools that have the switch on invites

accidents.

4. REMOVE ANY ADJUSTING KEY OR WRENCH BE

FORE TURNING THE POWER TOOL ON. A wrench or a

key left attached to a rotating part of the power tool may

result in personal injury.

5. DO NOT OVERREACH. Keep proper footing and bal

ance at all times. This enables better control of the power tool in unexpected situations.

6. DRESS PROPERLY. Do not wear loose clothing or

jewelry. Keep your hair and clothing away from moving

parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

-

-

-

Page 5

GENERAL SAFETY RULES

Safety is a combination of common sense, staying alert and knowing how your item works.

WARNING:

this tool. Failure to follow all instructions listed below may result in personal injury, electric shock, fire

and/or tool damage.

7. IF DEVICES ARE PROVIDED FOR THE CONNECTION

OF DUST EXTRACTION AND COLLECTION FACILITIES,

ENSURE THESE ARE CONNECTED AND PROPERLY

USED. Use of dust collection can reduce dust-related

hazards.

Read and understand all warnings, cautions and operating instructions before using

SAVE THESE SAFETY INSTRUCTIONS.

7. USE THE POWER TOOL, ACCESSORIES AND TOOL

BITS ETC. IN ACCORDANCE WITH THESE INSTRUC

TIONS, taking into account the working conditions and

the work to be performed. Use of the power tool for op

erations different from those intended could result in a

hazardous situation.

POWER TOOL USE AND CARE

1. DO NOT FORCE THE POWER TOOL. Use the correct

power tool for your application. The correct power tool

will do the job better and safer at the rate for which it

was designed.

2. DO NOT USE THE POWER TOOL IF THE SWITCH

DOES NOT TURN IT ON AND OFF. Any power tool that

cannot be controlled with the switch is dangerous and

must be repaired.

3. DISCONNECT THE PLUG FROM THE POWER SOURCE

AND/OR THE BATTERY PACK FROM THE POWER TOOL

BEFORE MAKING ANY ADJUSTMENTS, CHANGING AC

CESSORIES, OR STORING POWER TOOLS. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

4. STORE IDLE POWER TOOLS OUT OF THE REACH

OF CHILDREN AND DO NOT ALLOW PERSONS UNFA

MILIAR WITH THE POWER TOOL OR THESE INSTRUCTIONS TO OPERATE THE POWER TOOL. Power tools

are dangerous in the hands of untrained users.

5. MAINTAIN POWER TOOLS. Check for misalignment

or binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s opera

tion. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained

power tools.

6. KEEP CUTTING TOOLS SHARP AND CLEAN. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

8. USE CLAMPS TO SECURE YOUR WORKPIECE TO A

STABLE SURFACE. Holding a workpiece by hand or us

ing your body to support it may lead to loss of control.

9. KEEP GUARDS IN PLACE and in working order.

SERVICE

1. HAVE YOUR POWER TOOL SERVICED BY A QUALIFIED REPAIR PERSON USING ONLY IDENTICAL REPLACEMENT PARTS. This will ensure that the safety of

the power tool is maintained.

-

CALIFORNIA PROPOSITION 65 WARNING

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities may contain

chemicals, including lead, known to the State of Califor

nia to cause cancer, birth defects, or other reproductive

harm. Wash hands after handling. Some examples of

-

these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks, cement, and other

masonry products.

• Arsenic and chromium from chemically treated

lumber.

-

Your risk from these exposures varies depending on

how often you do this type of work. To reduce your ex

posure to these chemicals, work in a well-ventilated area

with approved safety equipment such as dust masks

specially designed to filter out microscopic particles.

-

-

-

-

-

54

Page 6

SPECIFIC RULES FOR YOUR TRACK SAW

WARNING:

tions and the warning labels.

Do not operate the track saw until you have read and understood the following instruc-

SAW BLADE SAFETY

1. Always wear protective gloves when handling saw

blades.

2. Only use blades with correct size and type for both

your track saw and your workpiece.

• The rated diameter of the saw blade is 6.5" with a

20mm arbor.

• The no-load speed of the track saw is 5500 RPM. The

maximum permissible speed of your saw blade should

always be higher than the no-load rotational speed of

the saw.

3. Never use damaged or deformed saw blades. Only

use sharp blades.

4. Install the saw blade in the correct orientation indi

cated in the instructions (see “Changing the Saw Blade”,

page 18).

5. Keep hands out of path of saw blade. Never use your

hands to remove sawdust, chips or workpiece near the

saw blade or the cutting path of the saw.

6. Never reach around saw blade or reach in back of the

saw blade.

7. Do not use blades made from high-speed steel, abra

sive blades, metal-cutting blades or masonry-cutting

blades. The guards of this saw are not designed to pro

tect against the failure of such blades.

8. The use of accessories or attachments not recom

mended by the manufacturer may result in a risk of personal injury.

PERSONAL SAFETY

1. Operate in a well ventilated area. Keep the floor area

around the track saw level and free of slippery substanc

es or other tripping hazards.

2. Wear ANSI-approved safety goggles to protect your

eyes from sparks and saw dust. Use hearing protection

to protect yourself from hearing loss.

3. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in close

proximity to pacemakers could cause pacemaker inter

ference or pacemaker failure.

4. Wear work gloves when handling saw blades. DO NOT

wear gloves while operating the saw.

5. Sawdust is harmful to your health. Use NIOSH-ap

proved dust masks or other respiratory protection during operation and cleaning.

6. Always turn off and unplug the track saw before mak

ing any adjustments or repair tasks. Never adjust the

track saw or the workpiece while the saw is running.

7. Never use damaged or incorrect blade flanges or bolt.

The blade flanges and bolt were specially designed for

your saw, for optimum performance and safety of op

eration.

8. Do not use to cut metal, logs, tree limbs, or uneven

lumber. Inspect the workpiece and remove all nails and

other embedded objects prior to starting work.

9. Wet lumber, green (unseasoned) lumber, and pres

sure treated lumber all have an increased potential for

kickback and should only be cut with a blade specifically

designed for that lumber type. Wear a NIOSH-approved

respirator and have appropriate ventilation whenever

cutting pressure treated lumber.

PREPARING THE TRACK SAW

-

1. When transporting the track saw, carry it by either the

handle or the base. Never carry the device by its guards

or its accessories. Make sure that the blade is fully cov

ered by the blade cover and not exposed.

2. Securely slide the track saw onto the track before op

erating.

3. Examine the track saw for any damaged or missing

parts. Replace or repair damaged parts before operation. Periodically check that all nuts, bolts and other fasteners are properly tightened.

-

-

-

-

-

-

-

Page 7

SPECIFIC RULES FOR YOUR TRACK SAW

WARNING:

tions and the warning labels.

Do not operate the track saw until you have read and understood the following instruc-

SECURE YOUR WORKPIECE

1. To avoid blade binding or loss of control, always secure the workpiece to a stable platform, ensuring that

body exposure is minimized. Use clamps to secure the

workpiece. Never perform any operation freehand.

2. Ensure that work is correctly supported. Large panels

may sag under their own weight and bind the saw blade.

Supports must be placed under the panel on both sides,

close to the line of cut and near the edge of the panel.

3. For accuracy of cut, and to avoid blade binding, al

ways use a rip fence or straight edge guide.

4. Never hand-hold a workpiece that is too small to be

clamped, as it can be launched away and cause inju

ry. Use proper support and guides to secure the small

workpiece.

DURING CUTTING OPERATIONS

1. Always stand to one side when operating the saw.

Never have any part of the body in line with the path of

the saw. Never hold a workpiece in your hand or across

your legs while cutting.

2. Ensure hands are away from the cutting area and

blade. Keep one hand on the rear handle, and the other

on the front grip. If both hands are holding the tool they

cannot be cut by the blade.

3. Feed work into the blade against the direction of rota

tion of the blade only.

4. If you are interrupted when operating the saw, com

plete the process and switch the saw off before looking

up.

5. Power tools must always be held by the insulated

gripping surfaces when performing an operation, ensur

ing protection if the cutting tool makes contact with its

own cord or hidden wiring. Contact with a ‘live’ wire will

make exposed metal parts of the power tool ‘live’ and

shock the operator if the insulated gripping surfaces are

not used.

6. Do not use the track saw unless all guards are in

place. Do not operate with any guard disabled, dam

aged, or removed. Moving guards must move freely and

close instantly.

7. Turn on the track saw and let it reach full speed, then

slowly slide the saw into the workpiece. This will help

produce safer and cleaner cuts.

8. Always push the saw blade forwards and away from

you. Do not pull the saw towards you, or move the saw

backwards while cutting. Do not apply any sideways or

twisting force to the blade while cutting.

9. Never cut more than one piece at a time. Do not stack

workpieces together. Do not attempt to cut material

thicker than specified on page 2 of this manual. Adjust

the cutting depth to the thickness of the workpiece (less

than a full tooth of the blade should be visible below the

workpiece).

10. If a cut does not extend to the edge of the workpiece,

or if the blade binds in the cut, allow the blade to come

to a complete stop and lift the saw out of the workpiece.

11. Turn off tool and wait for saw blade to stop before

moving workpiece or changing settings. Do not slow or

stop a blade with a piece of wood. Let the blade come

to rest naturally. Do not attempt to free a jammed blade

while the machine is still running and connected to pow

er.

-

12. Always raise the blade to be covered by the blade

guard after use.

-

Specific rules for your track saw continue on the

-

next page.

-

-

76

Page 8

SPECIFIC RULES FOR YOUR TRACK SAW

WARNING:

tions and the warning labels.

Do not operate the track saw until you have read and understood the following instruc-

REDUCING KICKBACK

Kickback is a sudden reaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw to

lift up and out of the workpiece toward the operator, in

creasing the chances of serious personal injury. Do not

rely on the safety devices built into the saw. Track saw

users should take as many precautions as possible to

minimize on-site accidents. Kickback is the result of tool

misuse and/or incorrect operating procedures. These

conditions can be minimized with the following steps:

1. Maintain a firm grip with both hands on the saw and

position your arms to resist kickback forces. Position

your body to either side of the blade but not in line with

the blade. Kickback could cause the saw to jump back

wards, however, if proper precautions are taken, kickback forces can be controlled by the operator. Do not let

go of the track saw.

2. If the blade is binding, or interrupting a cut for any

reason, release the trigger and hold the saw motionless

in the workpiece until the blade comes to a complete

stop. Never attempt to remove the saw from the work

or pull the saw backward while the blade is in motion.

Investigate and take corrective action to eliminate the

cause of blade binding.

3. When restarting a saw within an incomplete cut, center the saw blade in the kerf and check that the saw teeth

are not engaged into the material (a binding saw blade

-

may ‘propel upwards’ or kickback from the workpiece as

the tool is restarted).

4. A large workpiece should be supported close to the

line of the cut, and at the edge of the panel, to prevent

sagging. This will minimize the risk of blade pinching

and kickback.

5. Do not use dull or damaged blades. Unsharpened or

improperly set blades produce narrow kerf causing ex

cessive friction, blade binding, and kickback.

-

6. Blade depth and bevel adjusting locking levers must

be tight and secure before making a cut. If blade ad

justment shifts while cutting, it may cause binding and

kickback.

7. Use extra caution when making a ‘plunge cut’ into

existing walls or other blind areas. The protruding blade

may cut objects causing kickback.

8. Do not use abrasive wheels, doing so will void the

warranty.

-

-

Page 9

ELECTRICAL INFORMATION

DOUBLE-INSULATED TOOLS

The tool’s electrical system is double insulated where two systems of insulation are provided. This

eliminates the need for the usual three-wire grounded power cord. Double insulated tools do not need

to be grounded, nor should a means for grounding be added to the product. All exposed metal parts

are isolated from the internal metal motor components with protecting insulation.

IMPORTANT: Servicing a double-insulated product requires extreme care and knowledge of the system, and should

be done only by qualified service personnel using identical replacement parts. Always use original factory replace

ment parts when servicing.

1. Polarized Plugs. To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the

plug. If it still does not fit, contact a qualified electrician to install a proper outlet. Do not modify the machine plug

or the extension cord in any way.

2. Ground fault circuit interrupter protection (GFCI) should be provided on the circuit or outlet used for this power

tool to reduce the risk of electric shock.

3. Service and repair. To avoid danger, electrical appliances must only be repaired by qualified service technician

using original replacement parts.

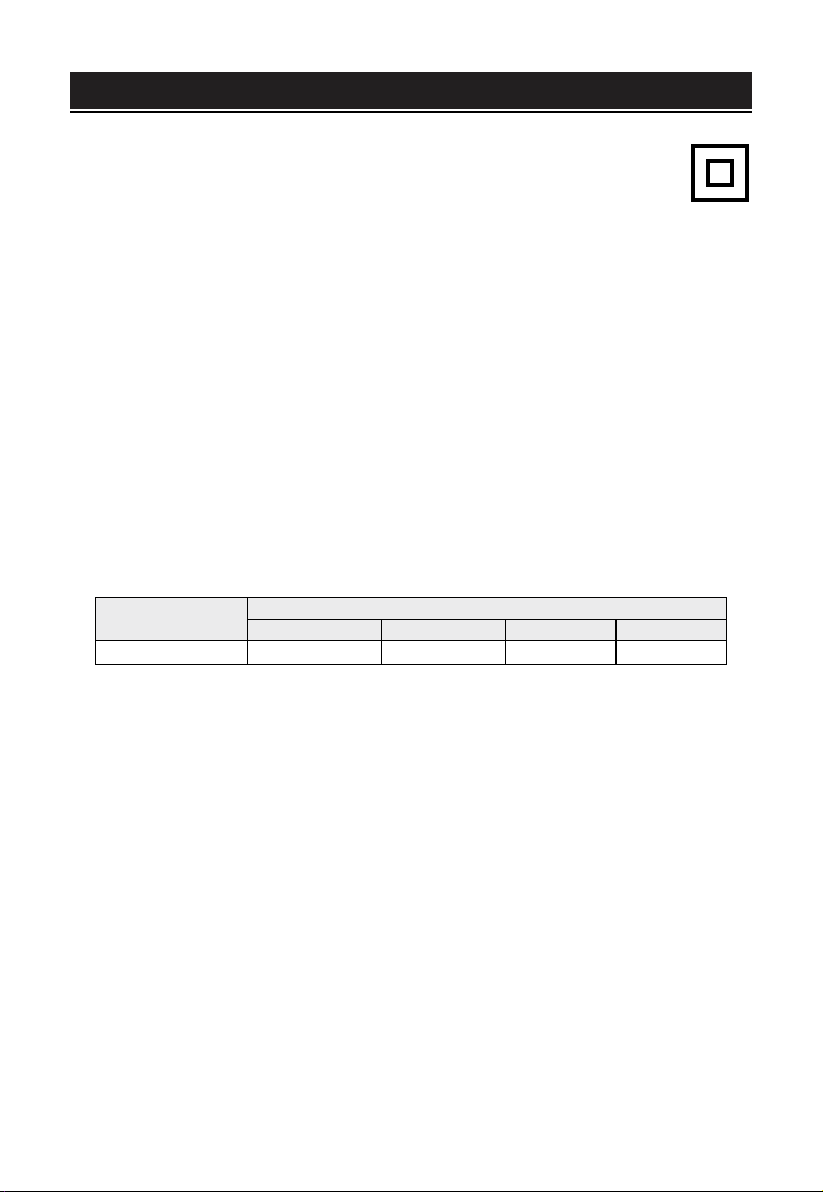

GUIDELINES AND RECOMMENDATIONS FOR EXTENSION CORDS

When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The table below shows

the correct size to be used according to cord length and ampere rating. When in doubt, use a heavier cord. The

smaller the gauge number, the heavier the cord.

AMPERAGE

10A 16 gauge 16 gauge 14 gauge 12 gauge

1. EXAMINE EXTENSION CORD BEFORE USE. Make sure your extension cord is properly wired and in good condition. Always replace a damaged extension cord or have it repaired by a qualified person before using it.

2. DO NOT ABUSE EXTENSION CORD. Do not pull on cord to disconnect from receptacle; always disconnect by pull

ing on plug. Disconnect the extension cord from the receptacle before disconnecting the product from the extension

cord. Protect your extension cords from sharp objects, excessive heat and damp/wet areas.

3. USE A SEPARATE ELECTRICAL CIRCUIT FOR YOUR TOOL. This circuit must not be less than a 12-gauge wire

and should be protected with a 15A time-delayed fuse. Before connecting the motor to the power line, make sure

the switch is in the OFF position and the electric current is rated the same as the current stamped on the motor

nameplate. Running at a lower voltage will damage the motor.

REQUIRED GAUGE FOR EXTENSION CORDS

25 ft. 50 ft. 100 ft. 150 ft.

-

-

98

Page 10

UNPACKING & TRANSPORTATION

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Failure

to follow the safety instructions may result in serious personal injury.

UNPACKING

Thanks for taking the plunge and buying this saw. With the help of a friend or trustworthy foe, carefully remove the

track saw from the packaging. Make sure to take out all contents and accessories. Do not discard the packaging

until everything is removed. Check the packing list below to make sure you have all of the parts and accessories. If

any part is missing or broken, please contact our customer service at 1-800-232-1195.

PACKING LIST

A. Track Saw (1)

B. Carbon Brushes (2)

C. Dust Port Adapter (1)

D. 5mm Hex Wrench (1)

The tools listed below are not included

but are required for either assembly or

adjustment:

• Flat-head Screwdriver

• Phillips-head Screwdriver

The items listed below are not included, but are commonly bought with the this saw and made specifically for this

track saw (Model Number: CT1065). These items can be purchased at wenproducts.com; to easily find the items on

our website, search their model numbers:

• 100-inch Track with Adapters (Model Number: CT9502)

• 4-piece Track Adapter Set (Model Number: CT9011)

• Pair of Track Clamps (Model Number: CT992F)

A

B

C

D

TRANSPORTING THE TRACK SAW

Before transporting your track saw, make sure that the blade is fully retracted inside the blade guard. Only lift the

saw by the handles.

Page 11

KNOW YOUR TRACK SAW

TOOL PURPOSE

Track Saws allow you to easily make miter cuts and rough cuts on large sheets of material. Refer to the following

diagrams to become familiarized with all the parts and controls of your track saw. The components will be referred

to later in the manual for assembly and operation instructions.

A

B

C

D

E

F

A. Front Grip

B. Depth Scale

C. Bevel Scale

D. Track Compensation

E. Depth Adjustment Knob

G H I J

F. Front Bevel Lock Knob

G. Front Fine Adjustment Knob

H. Track Lock Knob

I. Anti-Kickback Knob

J. Rear Fine Adjustment Knob

K. Base Plate

L. Rear Bevel Lock Knob

M. Rear Handle

N. Power Trigger

O. Plunge Lock Button

O

N

M

L

K

1110

Page 12

KNOW YOUR TRACK SAW

P

Q

R

S

T

P. Spindle Lock

Q. Dust Port

R. Mode Selector

S. Slot for Parallel Guide

T. Saw Blade

U. Track Slot

V. Carbon Brush Cover

V

U

Page 13

ASSEMBLY & ADJUSTMENTS

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your track saw. Failure

to follow the safety instructions may result in serious personal injury.

DUST COLLECTION (FIG. 1)

A dust collection bag (not included) or vacuum system should be used at all times. The inner diameter of

the dust port adapter is 35mm; the outer diameter is

39.5mm.

1. Locate the dust port on the track saw.

2. Insert the dust port adapter into the dust port. Posi

tion the adapter so the dust hose or bag will not interfere

with your work.

3. Securely attach a dust bag or vacuum to the end of

the dust port adapter. If using a vacuum, make sure to

turn it ON before starting your cut.

-

Dust Port

MODE SELECTION (FIG. 2)

The mode selector switch enables fast and easy setting

of major functions by simply rotating the switch to the

desired mode of operation. The functions include:

A. Blade changing (see page 18 for instructions)

B. Free plunge, for general cutting

C. Scribe cut, for a scribe cut 2.5mm (0.1 in) deep

B. FREE PLUNGE MODE (FIG. 3)

The cutting depth can be set between 0" - 2-3/8" (0mm

- 59mm). NOTE: Always maintain an appropriate bladedepth setting. The blade teeth should never protrude

more than 1/8" below the material being cut, as exces

sive blade depth increases the chances of saw kickback

or contact with hidden surfaces beneath the workpiece.

1. Turn the mode selector switch to the free-plunge setting (Fig. 2). Unplug your track saw. Loosen the depth

adjustment knob and slide it up or down so the indi

cation arrow points to the desired depth on the depth

scale.

2. If you are using the saw with the track, turn the track compensation lever clockwise to the lower position to

compensate for the thickness of the track. If you are using the saw without the track, turn the track compensation

lever counterclockwise to the upper position.

-

-

Mode

Selector

Depth

Scale

Depth

Adjustment

Knob

Dust Port

Adapter

A.

B.

C.

Indication

Arrow

Fig. 1

Fig. 2

Blade

Changing

Free

Plunge

Scribe

Cut

Fig. 3

Track

Compensation

Lever

3. Tighten the depth adjustment knob to lock it into place. Test the depth setting on a piece of scrap material to make

sure it is correct before plugging the saw back in.

1312

Page 14

ASSEMBLY & ADJUSTMENTS

C. SCRIBE CUTS

1. Turn the mode selector switch to the scribe cut function; see "Mode Selection" on page 13.

2. Press the plunge lock button (Fig. 4) and plunge the

saw downwards. It will stop at a 2.5mm (0.1 in) depth

of cut.

NOTE: An initial scribe cut (before additional cuts) helps

prevent friction on the blade, particularly when deep

plunge cuts are required. It is also helpful for initial cuts

on veneered or melamine laminates.

ADJUSTING THE BEVEL ANGLE (FIGS. 5 & 6)

The saw can be beveled between 0° - 45°.

1. Unplug your track saw. Loosen both bevel lock knobs

(Fig. 5). Bevel the saw so that the indication arrow is

pointing to the desired angle on the bevel scale.

2. Tighten both bevel lock knobs to lock the bevel angle

into place.

3. Make a test cut in a piece of scrap material. Measure

the angle of the cut to confirm that the bevel angle is

properly set. If necessary, re-adjust the bevel angle be

fore cutting the actual workpiece.

NOTE: the bevel indication arrow should be properly

adjusted at the factory. If you find that it is inaccurate,

adjust it using the steps below.

1. Make a test cut. Measure the bevel angle.

2. Loosen the Phillips-head screw on the bevel indica

tion arrow. Adjust the arrow so that it points to the angle

of the cut. Tighten the screw.

LINE-OF-CUT INDICATORS (FIG. 7)

Two line-of-cut indicators can be found on the base of

the track saw. These notches help you to align your cuts.

-

-

Front Bevel

Lock Knob

Bevel

Scale

Fig. 4

Plunge

Lock

Button

Fig. 5

2

Fig. 6

1. Mark your cut on your workpiece. Locate the line-ofcut indicators on the front and back of the base plate.

Instructions continue on the next page.

Indication

Arrow

Screw

Page 15

ASSEMBLY & ADJUSTMENTS

NOTE: The track, track adapters, clamps, and 3mm hex wrench are not included. These items can be purchased

separately at wenproducts.com.

2. Follow step "2.1" if you are using the track, follow step

"2.2" if you are not using the track.

2.1) When using the saw with the track, always align

position A (the "0" mark on the base plate) with your

marked cutting line.

2.2) When using the saw without the track, align posi

tion A (the "0" mark on the base plate) with your

marked cutting line for straight cuts. Align posi

tion B (the "45" mark on the base plate) with your

marked cutting line for 45° bevel cuts.

NOTE: Since blade thicknesses vary, it is necessary to

make test cuts along a guide line on a piece of scrap ma

terial to determine the proper alignment of the guideline

within the notch. This will help to obtain an accurate cut

with blades of various thicknesses.

SETTING UP THE TRACK

NOTE: You will need to remove the protective sleeves

from the ends of each track before using the track. To

help your saw glide smoothly along the track, do not

allow dust, shavings, or other debris to build up on the

track.

1. Each track adapter assembly is made up of 6 pieces:

a spacer, a sleeve, and four hex screws. Assemble the

track adapter by fitting the spacer into the sleeve, op

posite the hex screws. See Fig. 8.

2. Slide the track adapter assembly into the groove on

the front face of the track. Half of the adapter should be

in the groove and half should hang off the track. The

hex screws should be accessible. Tighten the two hex

screws that are within the track with a 3mm hex wrench

(Fig. 9).

Fig. 7

-

-

-

Track

-

A

Sleeve

1514

B

Hex Screws

Spacer

Track Adapter Assembly

Fig. 8

Fig. 9

3. Repeat step 2 with the second adapter and the groove

on the underside of the track. Be sure to tighten the two

hex screws that are within the track.

Instructions continue on the next page.

4. Guide the two free halves of the track adapters onto another

1514

Page 16

ASSEMBLY & ADJUSTMENTS

piece of track (Fig. 10) and tighten the hex screws on the

face side and the underside (Fig. 11).

5. Align the track along the workpiece, the right-hand

(flat) side of the track is where the actual cut will occur.

Clamp down the track to the work surface so the track

is secure.

6. Place the saw onto the track. Make sure the blade will

contact the workpiece as intended.

7. Use the fine-adjustment cams to line up the track's

edge and the saw’s cutting path with one another. Refer

to page 17.

CUTTING THE RUBBER STRIP

The rubber strip running along the edge of the track

comes in its uncut original state. This rubber strip has

two main applications. Firstly, it acts as a straightedge,

allowing users to visualize the exact location of the cut.

Secondly, it helps prevent dust from flying up during

sawing operations. Because of the precision required for

these two applications, users must cut this rubber strip

themselves before using the track saw on any workpiec

es. This ensures every track perfectly complements a

particular track saw.

1. Turn the mode selector switch to the free-plunge set

ting, see "Mode Selection" on page 13. Set the depth

stop to 1/2", limiting the blade’s maximum cutting depth.

2. Clamp the track into place so that you can cut the full

length of the track in one go.

3. Position the saw onto the end of the track with the

back two-thirds of the saw hanging off. The goal should

be to maximize the amount of the saw’s base that is on

the track while still being able to plunge the full 1/2"

downwards without yet contacting the rubber strip with

the blade (Fig. 12).

4. Start the saw and then plunge downwards, making

sure to not yet contact the rubber strip. Once the saw has reached full speed and is plunged the full 1/2", progress

forward along the track so that the blade makes contact with the rubber strip.

-

-

Track Base

1/2"

Blade

Fig. 10

Fig. 11

Fig. 12

1/3 of

Track

with Strip

5. Cut the rubber strip along the full length of the track. Once you have made it all the way down the track, the strip

should be precision-cut to meet the specifications of your particular track saw.

Page 17

ASSEMBLY & ADJUSTMENTS

USING THE TRACK LOCK

The track lock is an added measure to prevent the track

saw from separating from the track during operation.

1. Pull upwards on the track lock knob and rotate it

counterclockwise (so the arrow on the knob points to

the 0 on the base), then set the track saw onto the track.

2. Once the saw is sitting properly on the track, pull up

wards on the track lock knob and rotate it clockwise (so

the arrow on the knob points to the 1 on the base). This

hooks a small plate on the base of the saw under the lip

of the track, preventing the saw from separating from

the track.

USING THE FINE-ADJUSTMENT CAMS

(FIG. 14)

There are two fine-adjustment cams on the base

of the saw to help eliminate play between the track

guide rail and the track slot on the base of the saw.

1. Loosen the fine-adjustment cam knobs, then

move the lever on the cam all the way to the left or

the right. Tighten the knobs.

2. Set the track saw on the track, ensuring that the

track rail enters the slot in the saw base.

3. Loosen the knobs and move the lever on each cam

to take any play out of the track saw’s movement.

The saw base should be snug against the track rail.

Tighten the knobs to lock the cams in place.

-

Track Lock

Knob

Fig. 13

Fig. 14

Fine-Adjustment

Knobs

Fine-Adjustment

Levers

Fig. 15

4. Move the saw forward along the track, ensuring

its movement is smooth. Repeat step 3, if necessary,

if adjustments are needed.

NOTE: some tracks’ rails may be wide enough that

the saw cannot be placed on the track without re

moving the cams. If this is the case, unscrew the

knobs and remove the cams.

-

Anti-Kickback

Knob

ANTI-KICKBACK CAM (FIG. 15)

For your safety, an anti-kickback cam is included on the base of the saw. The cam is designed to prevent

backwards movement of the saw along the track, and therefore kickback that can result from this movement.

If you are not making a cut and need to easily slide the saw backwards along the track, turn the cam knob

so the arrow points to the 0 (disengaged) position on the base, hold it in this position, then slide the saw

backwards. NOTE: the cam is spring-loaded and should return to the 1 (engaged) position automatically.

1716

Page 18

ASSEMBLY & ADJUSTMENTS

DANGER! Never try to use a blade larger than the stated capacity of the saw. Do not use a blade thicker than

1.9mm. It will prevent the blade screw from properly securing the blade on the arbor. Install the suitable blade

for your cutting operation. See page 2 and page 6 for specifications and saw blade safety.

CAUTION: Always wear gloves while handling blades

to prevent cuts and injuries.

CHANGING THE SAW BLADE

1. Unplug your track saw. Turn the mode selector switch

to the blade changing setting (p. 13, Fig. 2).

2. Press and hold the plunge lock button (Fig. 16) and

plunge the saw downwards until the arbor screw is vis

ible in the blade guard window. Release the plunge lock

button; the saw should now be locked in place and un

able to be plunged or raised.

3. Press and hold the spindle lock (Fig. 16), then use

the included 5mm hex wrench to loosen the arbor screw

(turn it counterclockwise).

4. Remove the screw and outer flange (Fig. 17). Slide

the blade off the arbor and downwards until it is clear of

the blade guard.

5. Install the new blade on the arbor. Ensure that the

blade rotation direction is correct. Install the outer flange

and arbor screw. Press and hold the spindle lock button,

then use the hex wrench to tighten the arbor screw.

6. Press and hold the plunge lock button to release the

saw, then raise it.

-

-

Plunge Lock

Button

Spindle

Lock

Fig. 16

Fig. 17

Screw

Outer

Flange

Blade

Rotation

Direction

Page 19

OPERATION

WARNING: Do not plug in or turn on the tool until it is fully assembled according to the instructions. Read

through and become familiarized with the following procedures of handling and adjusting your track saw. Failure

to follow the safety instructions may result in serious personal injury.

WARNING: Always let the blade reach full speed before guiding the saw into the workpiece. The blade coming into contact with the workpiece before reaching full speed, could cause your saw to KICKBACK towards you

resulting in serious personal injury.

WARNING: If, while operating the saw, the cord hangs up on the workpiece or some other object during

a cut, release the switch trigger immediately. Unplug the saw and reposition the cord to prevent it from hanging

up again.

STARTING/STOPPING THE SAW (FIG. 18)

1. Plug in the tool.

2. To start the saw, press and hold the plunge lock but

ton, then pull the power trigger. Once the saw reaches

maximum speed, plunge the saw downwards.

3. To stop the saw, release the power trigger. Allow the

blade to come to a complete stop.

NOTE: Do not remove your saw from the workpiece

while the blade is still moving.

OPERATING THE SAW (FIG. 19)

1. Hold the tool firmly with both hands, using both the

front grip and the rear handle. Avoid placing your hand

on the workpiece while making a cut.

2. Place the workpiece with the “good” side down.

3. Set-up and support the workpiece so the cut is always

on your right side. The larger (left) side of the saw’s base

should be on the part that does not fall off when a cut

is made.

4. Securely clamp the workpiece so it will not move dur

ing the cut. If you are cutting with the track, use two

clamps to clamp the track to the workpiece. If you are

cutting without the track, place a clamp as close to the

base of the saw as possible to support the workpiece.

Make sure the clamp is as close to the cut as possible

without getting in the way of the saw’s line of motion.

Instructions continue on the next page.

Plunge

-

Clamp without

Track

-

Clamp with

Track

Lock

Button

Fig. 18

Power

Trigger

Fig. 19

Clamp

Close to

Base

1918

Page 20

OPERATION

5. Draw a guideline along the desired path of the cut

before starting your saw or the cut. Set up the track to

meet the needs of your particular guide line (see “Set

ting Up the Track” on page 15).

6. Keep the cord away from the cutting area. Position the

cord to prevent it from hanging up on the workpiece and

stop you from standing or tripping on the cord during

operation. Start the saw and make your cut.

CAUTION: To make sawing easier and safer, be sure to

move the tool forward gently in a straight line. Never

force or twist the saw during operation. Forcing or twist

ing the tool will result in overheating the motor and will

increase the chances of dangerous kickback, possibly

causing severe personal injury. Do not pull the saw to

wards you, or move the saw backwards, while cutting.

CROSS-CUTTING AND RIP CUTTING

Cutting directly across the grain of a piece of wood is

called crosscutting. Cutting wood lengthwise, or with the

grain, is referred to as rip cutting (or simply “ripping”).

Both types of cuts are performed in the same manner

with the exception of the methods used to support and

secure the workpiece for cutting. After you have secured

the workpiece in position, positioned the cord so it won’t

be cut or hung up, performed the saw set-up adjust

ments, made the necessary measurements, drawn a

straight guide line, and put on your personal protection,

you can begin the cutting operation.

1. Hold the tool firmly with both hands, using both the

front grip and the rear handle. Avoid placing your hand

on the workpiece while making a cut.

2. Set the front portion of the saw’s base on the work

piece to be cut without the blade making any contact.

Align the line-of-cut indicator notch on the right side of

the base with your guideline. Turn the saw on and wait

until it reaches full speed.

3. Ease the tool forward over the workpiece surface,

keeping it flat and advancing smoothly while following

your guideline until sawing is completed.

4. Once the cut is complete, release the power trigger.

Wait for the blade to completely stop. Raise the saw.

Now you can safely remove the saw from the workpiece

and set it out of the way.

5. To achieve clean cuts, keep your sawing line straight

while smoothly advancing forward. Do not force the saw

-

forward too quickly in order to try and hurry up the pro

cess. Let the tool work at its own pace.

6. If the cut fails to properly follow your intended cut

line, do not attempt to turn or force the tool back to the

cut line. Doing so may bind the blade and lead to dan

gerous kickback and possible serious injury. Do not pull

the saw towards you, or move the saw backwards, while

cutting. Instead, release the switch trigger, wait for the

blade to stop, and then remove the tool. Realign saw on

-

a new cut guide line and start the cut again.

7. Position yourself in a way that allows you to avoid the

-

wooden chips and dust being ejected from the saw.

BEVEL CUTTING

For instructions on how to bevel the saw blade, see “Adjusting the Bevel Angle” on page 14.

Bevel cuts are made using the same technique as cross

cuts and ripping described in the previous section. The

difference is that the blade is set at a tilted angle be

tween 0° - 45°. A bevel cut made at an angle to the edge

of a board is called a compound miter.

There are tools better suited for bevel and compound

cuts than the track saw. Although the inner line-of-cut

indicator notch aids the operator in following the cut’s

guideline, the tilted motor housing sometimes obstructs

the operator’s ability to see the blade, making accurate

cuts difficult. Before taking on a project with numerous

compound or bevel cuts, it is suggested that inexperi

enced saw users spend time making practice cuts in

-

scrap material to become familiar with and overcome

difficulties associated with compound/bevel cutting.

NOTE: Keep in mind that bevel cutting may cause mis

alignment or alter the rubber strip along the edge of your

track.

WARNING: Always let the blade reach full speed

before guiding the saw into the workpiece. The blade

coming into contact with the workpiece before reach

ing full speed, could cause your saw to KICKBACK

towards you resulting in serious personal injury.

-

-

-

-

-

-

-

Page 21

OPERATION

PLUNGE CUTS

A plunge cut is a cut that must be made inside the area

of the workpiece, rather than starting from an outside

edge and working inward.

1. Adjust the bevel setting to zero; see "Adjusting the

Bevel Angle" on page 14.

2. Turn the mode selector switch to the free-plunge set

ting, see "Mode Selection" on page 13.

3. Set the blade to the correct blade depth setting and

position it where you would like your cut to occur. You

will find two notches along the blade cover. The notches

indicate the maximum points that the saw’s blade will

reach (Fig. 20).

4. Press the plunge lock button (Fig. 21) to allow the

saw to plunge downwards, while not allowing the blade

to actually contact the workpiece.

5. Power the saw on by pulling the trigger switch (Fig.

21). Allow it to reach full speed.

6. Once the blade has reached its maximum speed,

lower the blade down into the workpiece until the set

cutting depth has been reached. Once the saw cannot be

lowered anymore, move the saw along the desired cut

line in an even and steady motion.

FLUSH CUTTING (FIG. 22)

Your track saw can perform cuts close to walls or

other obstructions (for example, when removing

hardwood flooring). NOTE: the minimum distance

between the cut line and wall is 16mm (5/8").

1. Turn the mode selector switch to the scribe-cut or

free-plunge setting,

see "Mode Selection" on page 13

.

-

Minimum

Distance

from Wall

16mm

Plunge

Lock

Button

Fig. 20

Fig. 21

Power

Trigger

Fig. 22

2. Adjust the bevel angle to 0 degrees, see “Adjust

ing the Bevel Angle” on page 14.

3. If using the free-plunge setting, set the desired plunge depth and ensure that the track compensation

mechanism is properly adjusted, see “B. Free Plunge Mode" on page 13. If using the scribe-cut setting, the

cutting depth is pre-set at 2.5mm (0.1").

4. Plunge the saw downwards and complete the cut, see "Operating the Saw" on page 19. After completing

the cut, release the power trigger (Fig. 21) and allow the blade to come to a complete stop before removing

the saw from the workpiece.

-

2120

Page 22

TROUBLESHOOTING GUIDE

WARNING: Stop using the tool immediately if any of the following problems occur. Repairs and replace-

ments should only be performed by an authorized technician. For any questions, please contact our customer

service at (800) 232-1195, M-F 8-5 CST or email us at techsupport@wenproducts.com.

PROBLEM CAUSE SOLUTION

Motor does

not start

Saw overheats

Excessive slop

(play) between

track and saw

Saw difficult to

pull backwards

along track

Ineffective

cutting

performance

Plunge button not pressed, or not

pressed all the way

Power cord damaged or not properly

plugged in

Defective power switch

Insufficient power from outlet

Wrong extension cord gauge Select proper extension cord. Refer to page 9.

Worn carbon brushes

Defective motor or other internal

problem

Tool forced to work too fast

Wrong extension cord gauge Select proper extension cord. Refer to page 9.

Blocked motor housing vents

Fine-adjustment cams improperly

adjusted

Anti-kickback cam engaged (safety

feature)

Blade is dull Sharpen or replace blade.

Blade is dirty

The blade is not secure

Blade is installed improperly Ensure blade is installed in correct orientation.

Incorrect blade used for workpiece

Worn carbon brushes

Troubleshooting guide continues on the next page.

Ensure plunge button is fully pressed before beginning plunge.

Check the power cord, extension cord, power plug, and the

power outlet. Do not use the tool if any cord is damaged.

Stop using the tool and call 1-800-232-1195 for customer

service.

Make sure the outlet is functional and is the right capacity for

the tool.

Inspect and replace carbon brushes as needed (see page 24).

Replacement carbon brushes (part no. CT1065-031) can be

ordered from wenproducts.com.

Stop using the tool and call 1-800-232-1195 for customer

service.

Do not force the tool. Let it work at its own pace. Ensure blade

selection is appropriate for cut type and workpiece.

Wear safety glasses & dust mask. Blow dust out of motor

housing vents.

Adjust the fine-adjustment cams. Refer to page 17.

Refer to page 17 for information about the anti-kickback cam.

Remove the blade and clean the surface and cutting edge with

steel wool and turpentine.

Make sure the blade flanges are flush against the blade and

arbor bolt is tightened completely.

Ensure the blade is compatible with the material type and

thickness being cut.

Inspect and replace carbon brushes as needed (see page 24).

Replacement carbon brushes (part no.

ordered from wenproducts.com.

CT1065-031) can be

Page 23

TROUBLESHOOTING GUIDE

WARNING: Stop using the tool immediately if any of the following problems occur. Repairs and replace-

ments should only be performed by an authorized technician. For any questions, please contact our customer

service at (800) 232-1195, M-F 8-5 CST or email us at techsupport@wenproducts.com.

PROBLEM CAUSE SOLUTION

Blade is installed improperly Ensure blade is installed in correct orientation.

Blade is damaged Replace blade.

Excessive noise

or vibration

Blade will not

turn

Saw will not

plunge

Blade is not secure

Cutting too fast

Worn bearings

Spindle lock engaged

Worn bearings

Defective gears

Plunge button not pressed, or not

pressed all the way

Incorrect plunge mode selected Select correct plunge mode (see page 13).

Broken plunge linkage

Make sure the blade flanges are flush against the blade and

arbor bolt is tightened completely.

Do not force the tool. Let it work at its own pace. Ensure blade

selection is appropriate for cut type and workpiece.

Stop using the tool and call 1-800-232-1195 for customer

service.

Disengage the spindle lock; move blade back and forth to

ensure it is disengaged.

Stop using the tool and call 1-800-232-1195 for customer

service.

Stop using the tool and call 1-800-232-1195 for customer

service.

Ensure plunge button is fully pressed before beginning plunge.

Stop using the tool and call 1-800-232-1195 for customer

service.

MAINTENANCE

ROUTINE INSPECTION

Before each use, inspect the general condition of the

tool. If any of these following conditions exist, do not

use until parts are replaced or the saw is properly re

paired.

Check for:

• Loose hardware,

• Misalignment or binding of moving parts,

• Damaged cord/electrical wiring,

• Cracked or broken parts, and

• Any other condition that may affect its safe operation

Maintenance information continues on the next page.

WARNING: To avoid accidents, turn OFF and

unplug the tool from the electrical outlet before

cleaning, adjusting, or performing any maintenance

-

work.

WARNING: Any attempt to repair or replace

electrical parts on this tool may be hazardous. Ser

vicing of the tool must be performed by a qualified

technician. When servicing, use only identical WEN

replacement parts. Use of other parts may be haz

ardous or induce product failure.

-

-

2322

Page 24

MAINTENANCE

NOTE: Electric tools used on fiberglass material, wallboard, spackling compounds, or plaster are subject to

accelerated wear and possible premature failure because

the fiberglass chips and grindings are highly abrasive to

bearings, brushes, commutators, etc. Consequently, we

do not recommend using this tool for extended work on

these types of materials. However, if you do work with

any of these materials, it is extremely important to clean

the tool using compressed air after operation.

CLEANING & STORAGE

1. Keep the ventilation openings free from dust and debris to prevent the motor from overheating.

2. Wipe the tool surfaces clean with a clean cloth. Make

sure water does not get into the tool.

CAUTION: Most plastics are susceptible to damage

from various types of commercial solvents. Do not

use any solvents or cleaning products that could

damage the plastic parts. Some of these include but

are not limited to: gasoline, carbon tetrachloride,

chlorinated cleaning solvents, and household deter

gents that contain ammonia.

3. Store the tool in a clean and dry place away from the

reach of children. Store in temperatures between 41° to

86°F.

4. Cover the track saw in order to protect it from dust

and moisture. It is preferable to store it in its original

packaging with the instruction manual and all accesso

ries.

-

LUBRICATION

The bearings of your track saw are permanently sealed

and require no extra lubrication. The gearbox is also suf

ficiently lubricated from the factory and requires no additional lubrication.

PRODUCT DISPOSAL

Used power tools should not be disposed of together

with household waste. This product contains electronic

components that should be recycled. Please take this

product to your local recycling facility for responsible

disposal and to minimize its environmental impact.

Please recycle the packaging where facilities exist.

CarbonBrush

Cover

Carbon

Brush

Length

CARBON BRUSH REPLACEMENT

The wear on the carbon brushes depends on how frequently and how heavily the tool is used. To maintain

maximum efficiency of the motor, we recommend in

specting the two carbon brushes every 60 hours of operation or when the tool stops working. Your track saw

comes with a carbon brush replacement set.

NOTE: Replacement carbon brushes (Part No. CT1065-

031) can be ordered at wenproducts.com. Only genu

ine WEN replacement brushes designed specifically for

your tool should be used. Carbon brushes are not cov

ered under the two-year warranty.

1. Unplug the saw. To access the carbon brushes, re

move the carbon brush cover (Fig. 23) with a flat-head

screwdriver (not included).

-

2. Carefully remove the old carbon brushes using pliers.

Keep track of which orientation the old carbon brushes

were in to prevent needless wear if they will be rein

stalled.

-

3. Measure the length of the brushes (Fig. 23). Install the

new set of carbon brushes if either carbon brush length

is worn down to 3/16" or less. Reinstall the old carbon

brushes (in their original orientation) if your brushes are

not worn down to 3/16" or less. Both carbon brushes

should be replaced at the same time.

4. Replace the carbon brush cover.

NOTE: New carbon brushes tend to spark for a few min

utes during the first use as they wear down.

Fig. 23

-

-

-

-

-

-

Page 25

EXPLODED VIEW & PARTS LIST

55

54

54

55

54 93

92

91

90

89

88

86

55

3

3

9998979596

107

101

100

55

54

55

17

109

53

52

51

87

49

85

84

83

82

81

80

79

77

78

76

56

60

75

74

73

72

70

103

69

64

104

6667102

105

106

18

22

19

20

50

49

48

47

46

44

45

43

42

41

40 39

30

57

58

59

29

6

61

62

108

63

60 68

64

24

23

25

26

29

16

30

31

28

31

24

38

32

24

37

1

2

3

7

6

15

14

8

9

10

3

33

12

36

3

11

3

2524

Page 26

EXPLODED VIEW & PARTS LIST

No. Part. No. Description Qty.

1 CT1065-001 Right Handle 1

2 CT1065-002 Power Cord Clamp 1

3 CT1065-003

6 CT1065-006 Trigger Spring 2

7 CT1065-007 Power Switch 1

8 CT1065-008 Plunge Release Button 1

9 CT1065-009

10 CT1065-010 Left Handle 1

11 CT1065-011 Power Cord 1

12 CT1065-012

14 CT1065-014

15 CT1065-015 Trigger 1

16 CT1065-016 Plastic Board 1

17 CT1065-017 Bearing, 6001zz-2RS 1

18 CT1065-018 Rotor 1

19 CT1065-019 Bearing, 698zz 1

20 CT1065-020 Rotor Bearing Bushing 1

22 CT1065-022 Screw, M5x30 1

23 CT1065-023 Motor Dust Shield 1

24 CT1065-024 Flat Washer 5mm 5

25 CT1065-025

26 CT1065-026 Stator 1

28 CT1065-028 Motor Housing 1

29 CT1065-029 Carbon Brush Cap 2

30 CT1065-030 Brush Holder 2

31 CT1065-031 Carbon Brush 2

32 CT1065-032

Self-tapping Screw

ST4x16

Plunge Release Button

Spring

Power Cord Strain

Relief

Plunge Release

Linkage Album

Self-tapping Screw,

ST5x65

Self-tapping Screw,

ST4x11

17

No. Part. No. Description Qty.

33 CT1065-033 Screw, M5x45 4

36 CT1065-036 Motor Housing Cover 1

37 CT1065-037 Spindle Lock Sleeve 1

38 CT1065-038 Gearbox 1

39 CT1065-039 Depth Selector 1

40 CT1065-040 Depth Selector Switch 1

41 CT1065-041

1

42 CT1065-042 Depth Selector Cover 1

43 CT1065-043 Screw, M5x8 2

44 CT1065-044 Bearing Housing 1

1

45 CT1065-045 Bearing, 6002zz 1

46 CT1065-046 Bearing Housing Cover 1

1

47 CT1065-047 Spring Washer 5mm 2

48 CT1065-048 Screw, M5x16 2

49 CT1065-049 Screw, M4x8 3

50 CT1065-050 Depth Scale Plate 1

51 CT1065-051 Screw, M5x8 1

52 CT1065-052 Connecting Shaft 1

53 CT1065-053 Dust Port 1

54 CT1065-054 Flat Washer 4mm 6

55 CT1065-055 Screw, M4x16 6

56 CT1065-056 Locating Pin 1

2

57 CT1065-057

58 CT1065-058 Steel Ball Ø3mm 1

59 CT1065-059 Roller Pin 1

60 CT1065-060 Bevel Locking Knob 2

61 CT1065-061 Spindle Lock Spring 1

62 CT1065-062

2

Depth Selector Switch

Spring

Depth Selector

Locating Pin Spring

Bevel Guide Plate,

Front

1

1

1

Page 27

EXPLODED VIEW & PARTS LIST

No. Part. No. Description Qty.

63 CT1065-063 Spindle Lock 1

64 CT1065-064

66 CT1065-066

67 CT1065-067 Reset Spring Spacer 1

68 CT1065-068 Rail Adjustment Cam 2

69 CT1065-069

70 CT1065-070 Plunge Return Spring 1

72 CT1065-072

73 CT1065-073 Locating Rod Spacer 1

74 CT1065-074 Base 1

75 CT1065-075 Bevel Guide Plate, Rear 1

76 CT1065-076 Bearing, 607zz 1

77 CT1065-077 Gear Assembly 1

78 CT1065-078 Depth Locking Knob 1

79 CT1065-079

80 CT1065-080 Knob 1

81 CT1065-081 Depth Indicator Frame 1

82 CT1065-082

83 CT1065-083 Locating Spring 1

84 CT1065-084

85 CT1065-085

86 CT1065-086 Bevel Pointer 1

87 CT1065-087 Depth Locking Nut 1

88 CT1065-088 Inner Blade Cover 1

89 CT1065-089 Inner Flange 1

90 CT1065B Blade 1

Rail Adjustment Cam

Knob

Rail Locking Plate

Knob

Rail Anti-Kickback Cam

Knob

Plunge Return Spring

Rod

Self-tapping Screw,

ST2.5x10

Depth Indicator Rail

Adjustment Button

Depth Indicator Frame

Base

Self-tapping Screw,

ST3x6

No. Part. No. Description Qty.

91 CT1065-091 Outer Flange 1

92 CT1065-092 Arbor Screw 1

2

93 CT1065-093 Outer Blade Cover 1

1

95 CT1065-095 Screw, M6x8 2

96 CT1065-096

97 CT1065-097

1

98 CT1065-098 Rail Anti-Kickback Cam 1

99 CT1065-099 Cam Reset Spring 1

1

100 CT1065-100

101 CT1065-101 Rail Locking Plate 1

102 CT1065-102

103 CT1065-103 Roller Pin 1

104 CT1065-104

105 CT1065-105 Roller Pin 1

1

106 CT1065-106

107 CT1065-107 Roller Pin 1

108 CT1065-108 Flat Washer 6mm 2

1

109 CT1065-109 Dust Port Adapter 1

1

2

Self-tapping Screw,

ST4x34

Self-tapping Screw,

ST4x25

Self-tapping Screw,

ST4x10

Self-tapping Screw,

ST4x18

Rail Locking Plate

Spring

Rail Locking Plate

Body

1

1

1

1

1

1

2726

Page 28

WARRANTY STATEMENT

WEN Products is committed to building tools that are dependable for years. Our warranties are consistent

with this commitment and our dedication to quality.

LIMITED WARRANTY OF WEN PRODUCTS FOR HOME USE

GREAT LAKES TECHNOLOGIES, LLC (“Seller”) warrants to the original purchaser only, that all WEN consumer power tools will be free from defects in material or workmanship during personal use for a period of

two (2) years from date of purchase or 500 hours of use; whichever comes first. Ninety days for all WEN

products if the tool is used for professional or commercial use. Purchaser has 30 days from the date of

purchase to report missing or damaged parts.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited Warranty and, to the

extent permitted by law, any warranty or condition implied by law, shall be the replacement of parts, without charge, which are defective in material or workmanship and which have not been subjected to misuse,

alteration, careless handling, misrepair, abuse, neglect, normal wear and tear, improper maintenance, or

other conditions adversely affecting the Product or the component of the Product, whether by accident or

intentionally, by persons other than Seller. To make a claim under this Limited Warranty, you must make

sure to keep a copy of your proof of purchase that clearly defines the Date of Purchase (month and year)

and the Place of Purchase. Place of Purchase must be a direct vendor of Great Lakes Technologies, LLC.

Purchasing through third party vendors, including but not limited to garage sales, pawn shops, resale

shops, or any other secondhand merchant, voids the warranty included with this product. Contact techsupport@wenproducts.com or 1-800-232-1195 with the following information to make arrangements: your

shipping address, phone number, serial number, required part numbers, and proof of purchase. Damaged

or defective parts and products may need to be sent to WEN before the replacements can be shipped out.

Upon the confirmation of a WEN representative, your product may qualify for repairs and service work.

When returning a product for warranty service, the shipping charges must be prepaid by the purchaser.

The product must be shipped in its original container (or an equivalent), properly packed to withstand the

hazards of shipment. The product must be fully insured with a copy of the proof of purchase enclosed.

There must also be a description of the problem in order to help our repairs department diagnose and fix

the issue. Repairs will be made and the product will be returned and shipped back to the purchaser at no

charge for addresses within the contiguous United States.

THIS LIMITED WARRANTY DOES NOT APPLY TO ITEMS THAT WEAR OUT FROM REGULAR USAGE OVER

TIME, INCLUDING BELTS, BRUSHES, BLADES, BATTERIES, ETC. ANY IMPLIED WARRANTIES SHALL BE

LIMITED IN DURATION TO TWO (2) YEARS FROM DATE OF PURCHASE. SOME STATES IN THE U.S. AND

SOME CANADIAN PROVINCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS) ARISING FROM THE SALE OR USE

OF THIS PRODUCT. SOME STATES IN THE U.S. AND SOME CANADIAN PROVINCES DO NOT ALLOW THE

EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER

RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE TO PROVINCE IN CANADA AND

FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO ITEMS SOLD WITHIN THE UNITED STATES OF AMERICA,

CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR WARRANTY COVERAGE WITHIN OTHER

COUNTRIES, CONTACT THE WEN CUSTOMER SUPPORT LINE. FOR WARRANTY PARTS OR PRODUCTS

REPAIRED UNDER WARRANTY SHIPPING TO ADDRESSES OUTSIDE OF THE CONTIGUOUS UNITED

STATES, ADDITIONAL SHIPPING CHARGES MAY APPLY.

Loading...

Loading...