Wells Manufacturing WVG-136, WVG-136RW, WVG-136RWT Operation Manual

WELLS BLOOMFI ELD, LLC

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wells-mfg.com

OWNERS MANUAL

502

WVG-1 36 SERIES

ELECTRIC GRIDDLE

with

UNIVERSAL HOOD

MODELS:

WVG-136

WVG-136RW

WVG-136RWT

Includes

INSTALLATION

USE & CARE

EXPLODED VIEW

PARTS LIST

WIRING DIAGRAM

Model WVG-136RW

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

p/n 2M-304986 Rev. E M502 110812

LIMITED WARRANTY STATEMENT

Unless otherwise specified, all commercial cooking

equipment manufactured by WELLS BLOOMFIELD, LLC is

warranted against defects in materials and workmanship for

a period of one year from the date of original installation or

18 months from the date of shipment from our factory,

whichever comes first, and is for the benefit of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW OR IN

FACT, INCLUDING BUT NOT LIMITED TO, WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE, AND/OR FOR DIRECT,

INDIRECT OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH WELLS BLOOMFIELD PRODUCTS.

This warranty is void if it is determined that, upon inspection

by an authorized service agency, the equipment has been

modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God. It also

does not apply if the serial nameplate has been removed, or

if service is performed by unauthorized personnel. The

prices charged by Wells Bloomfield for its products are

based upon the limitations in this warranty. Seller’s

obligation under this warranty is limited to the repair of

defects without charge by a Wells Bloomfield factory

authorized service agency or one of its sub-service

agencies. This service will be provided on customer’s

premises for non-portable models. Portable models (a

device with a cord and plug) must be taken or shipped to

the closest authorized service agency, transportation

charges prepaid, for service. In addition to restrictions

contained in this warranty, specific limitations are shown in

the Service Policy and Procedure Guide. Wells Bloomfield

authorized service agencies are located in principal cities.

This warranty is valid in the United States and Canada and

void elsewhere. Please consult your classified telephone

directory, your foodservice equipment dealer or contact:

10 Sunnen Dr., P.O.Box 430129 St. Louis MO 63143 USA

phone (888) 356-5362 or fax (314) 781-2714

for information and other details concerning warranty.

Wells Bloomfield, LLC

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specified on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted for

ninety (90) days from date of purchase on nonwarranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Bloomfield cannot assume liability for damage or loss

incurred in transit. We will, however, at your request, supply

you with the necessary documents to support your claim.

xi

TABLE OF CONTENTS

WARRANTY ................................................................ xi

SPECIFICATIONS ....................................................... 1

FEATURES & OPERATING CONTROLS ................... 2

PRECAUTIONS & GENERAL INFORMATION ........... 6

AGENCY LISTING INFORMATION ............................ 7

INSTALLATION ........................................................... 8

OPERATION ................................................................ 12

CLEANING INSTRUCTIONS ....................................... 17

MAINTENANCE SCHEDULES .................................... 19

MSDS (Ansulex Low pH) ............................................. 24

TROUBLESHOOTING SUGGESTIONS ..................... 26

ANSUL® SYSTEM COMPONENTS ............................ 27

EXPLODED VIEW & PARTS LIST ............................... 28

WIRING DIAGRAM ....................................................... 33

PARTS & SERVICE ..................................................... 36

CUSTOMER SERVICE DATA ..................................... 36

INTRODUCTION

Thank You for purchasing this Wells Bloomfield appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that

it gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for

the appliance in a manner which will ensure its optimum performance.

This manual applies to the following Wells Bloomfield models:

WVG-136

WVG-136RW

WVG-136RWT

SPECIFICATIONS

MODEL

WVG-136 NO

WVG-136RW

WVG-136RWT

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

ROLL

WARMER

YES

VOLTS

50/60 Hz

208V 17 29 17 35 7,300

240V 20 33 20 40 9,500

208V 20 28 20 38 7,900

240V 24 33 24 43 10,400

3ø AMPS 1ø

L1 L2 L3

AMPS WATTS

(42-3/8" wide including spacers)

Minimum clearances required from unit to nearest combustible surface or object

BACK SIDE BOTTOM TOP

DIMENSIONS

POWER CORD

30-3/8” WIDE

77-1/4” HIGH

35-1/2” DEEP

Power Cord (when provided):

NEMA 15-60P

inches n/a 6 6 19

millimeters n/a 152 152 483

1

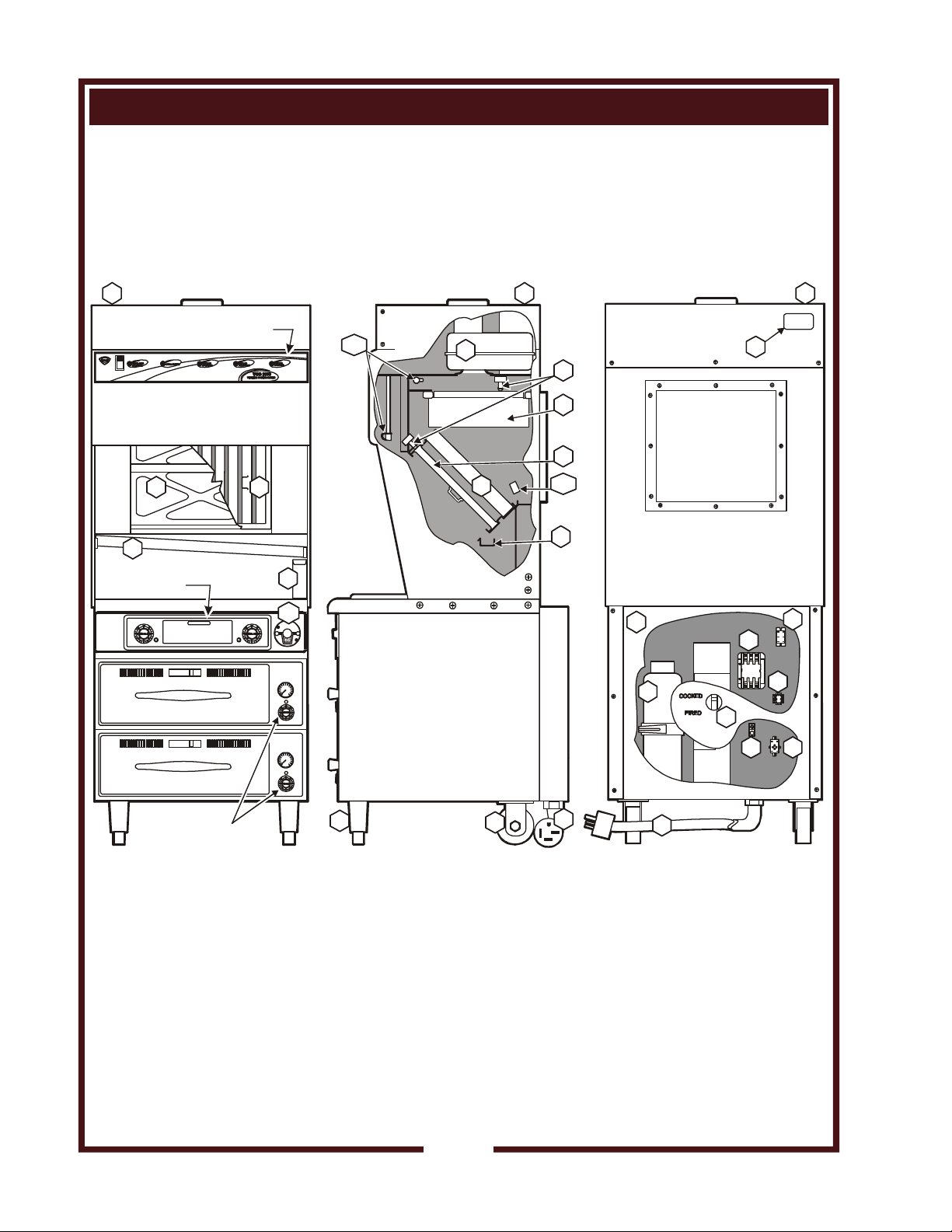

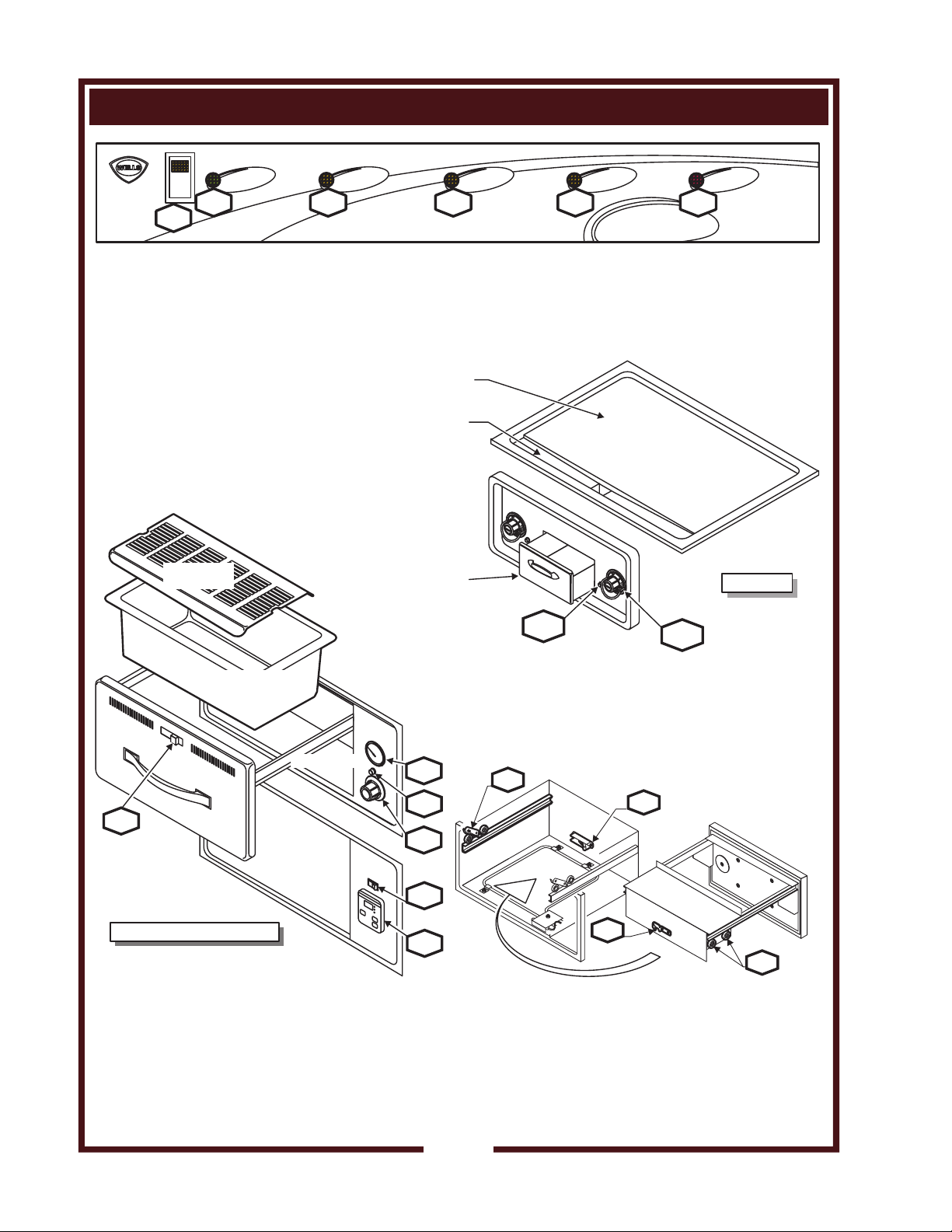

FEATURES & OPERATING CONTROLS

28 28

VENTILATOR CONTROL PANEL

see pages 4 & 5

18

16

a15

56

18

23

GRIDDLE CONTROL PANEL

see pages 4 & 5

IN CASE OF

22

a10

FIRE

ANSUL

PULL

HANDLE

TO ACTI V ATE

FIRE SUPPRESSI O N

SYSTEM

®

53

19

16

a11

23

28

1

12

40

41

a6

a31

44

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

WARMER CONTROLS

see pages 4 & 5

8

Fig. 1 Ventilator Section Operating Features & Controls

2

4243

9

38

38

VENTILATOR SECTION

FEATURES & OPERATING CONTROLS (continued)

ITEM

1.

a6.

8.

9.

a10.

a11.

12.

a15.

16.

18.

19.

22.

23.

28.

a31.

38.

40.

41.

42.

43.

44.

53.

56.

DESCRIPTION

NAMEPLATE

FIRE SUPPRESSION

AGENT TANK (1.5 gal.)

ADJUSTABLE (FRONT) LEG

RIGID (REAR) CASTER

MANUAL PULL STATION

FUSIBLE LINKS

LOWER REAR ACCESS

PANEL

DISCHARGE NOZZLE

GREASE BAFFLE

PRE-FILTER ASSEMBLY

HEPA/CHARCOAL FILTER

PACK

GREASE CUP

GREASE TROUGH

VENTILATOR EXHAUST

DUCT

STATUS INDICATOR

POWER CORD

WARMER RELAY

POWER CONT

BUILDING FIRE ALARM

RELAY

GROUND LUG

INTERLOCK TERMINAL

FILTER INTERLOCK

SWITCHES

VENTILATOR FAN

ACTOR

COMMENT

Lists Manufacturer, Model and Serial Number information.

Also lists electrical specifications.

Container for Ansulex™ Low-pH liquid fire suppression liquid.

Allows the unit to be leveled.

Allows the unit to be easily positioned by lifting the front of the unit

slightly.

Provides a means of manual activation of the fire suppression system.

PULL ONLY IN CASE OF FIRE!

Automatically activates fire suppression system in the event of fire on

the griddle.

Allows access to Ansul® fire suppression agent tank (a6) and controls

also access to main power contactor (41).

Fire suppression media discharges here (2 places).

Extracts and drains most grease and moisture from the air flow.

Comprises the PRE-FILTER FRAME and a replaceable

PRE-FILTER. Stops larger particles of grease from reaching the

FILTER PACK for reduced maintenance costs.

Stops most grease and smoke particles. Also assists in some cooking

odor removal.

Collects grease/moisture drained from grease trough (23).

Directs grease/moisture removed by grease baffle to grease cup.

Exit point for ventilator airflow - on top left rear of unit.

DO NOT BLOCK

Displays status of fire suppression system (COCKED - FIRED) If

FIRED, a buzzer will sound continuously.

6’ cord and cap. Plug for NEMA 15-60R (receptacle by user).

Provides power to roll warmer section. Energized at all times except

during fire safety shut-down.

Energizes griddle only while ventilator section is sensed as

operational.

Reports fire alarm condition to building fire management system.

Ground wire of power cord connects here.

Provides connection for shut-down control by building fire

management system.

Proper installation of grease baffle and filter pack close these switches

in ventilator sensor circuit.

Provides air movement for ventilation.

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

3

FEATURES & OPERATING CONTROLS (continued)

VENTILATOR

POWER ON

CHECK FILTERS

REPLACE

PREFILTER

REPLACE

FILTER

PACK

SERVICE

REQUIRED

VCS 2000

VENTLESS COOKING SYSTEM

VENTILATOR

POWER ON

V.02 V.03 V.04 V.05 V.06

V.01

Fig. 2 Ventilator Section Controls & Indicator Lights

GRIDDLE

SURFACE

GREASE

TROUGH

HUMITROL

RACK

GREASE

DRAWER

G.02

REPLACE

FILTER PACK

VCS 2000

GRIDDLE

G.01

DRAWER

INSERT PAN

RW-STYLE

W.03

W.05

W.02

W.04

W.01

RWT-STYLE

W.08

OPTIONAL ROLL WARMER

W.09

Fig. 3 Griddle & Warmer Drawer Operating Features & Controls

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

W.06

W.06

W.07

4

FEATURES & OPERATING CONTROLS (continued)

ITEM

DESCRIPTION

COMMENT

VENTILATOR SECTION CONTROLS

V.01

V.02

V.03

V.04*

V.05*

V.06*

POWER SWITCH

POWER ON INDICATOR

CHECK FILTERS ALARM

INDICATOR

REPLACE PREFILTER

ALARM INDICATOR

REPLACE FILTER PACK

ALARM INDICATOR

SERVICE REQUIRED

ALARM INDICATOR

* See PRECAUTIONS & GENERAL INFORMATION, pages 6 & 7 for special procedures regarding

prefilters and filter packs.

Energizes blower motor. If, after 10 seconds, proper conditions

are met, appliance is energized.

GREEN. Glows when POWER switch is

ON.

AMBER. Glows if one or more filters are out of position. Check

all filters and baffles for proper installation.

AMBER. Glows when PREFILTER is approaching the end of its

service life and must soon be replaced.

AMBER. Glows when FILTER PACK is approaching the end of

its service life and must soon be replaced.

RED. Glows when PREFILTER and/or FILTER PACK has

reached the end of its service life and is too loaded to allow

sufficient air flow. Filter MUST be replaced. Appliance is SHUT

DOWN until expended filters are replaced.

GRIDDLE SECTION CONTROLS

G.01

G.02

GRIDDLE TEMPERATURE

CONTROL

INDICATOR LIGHT

Thermostat control of temperature of one griddle half.

AMBER. Glows when heating element is energized.

OPTIONAL WARMER SECTION CONTROLS

Infinite switch control of temperature of one warmer drawer.

AMBER. Glows when associated temperature control is turned ON.

Reads temperature inside drawer cavity

Must be ordered at time of initial build.

Slide control of shutters to control air circulation within the warmer

drawer.

Holds drawer closed.

Prevents drawer from opening too far. Spring loaded to permit easy

removal of drawer.

Support drawer and allow it to open and close smoothly.

Energizes unit (RWT-style only)

Controls cavity temperature. Readout displays setpoint and actual

temperature information. UP ARROW / DOWN ARROW keys allow

modification of setpoint temperature. (RWT-style units only)

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

W.01

W.02

W.03

W.04

W.05

W.06

W.07

W.08

W.09

WARMER TEMPERATURE

CONTROL

POWER ON INDICATOR

THERMOMETER (optional)

HUMIDITY CONTROL

DRAWER CATCH

DRAWER STOP

DRAWER ROLLERS

POWER SWITCH (RWT)

CONTROLLER (RWT)

5

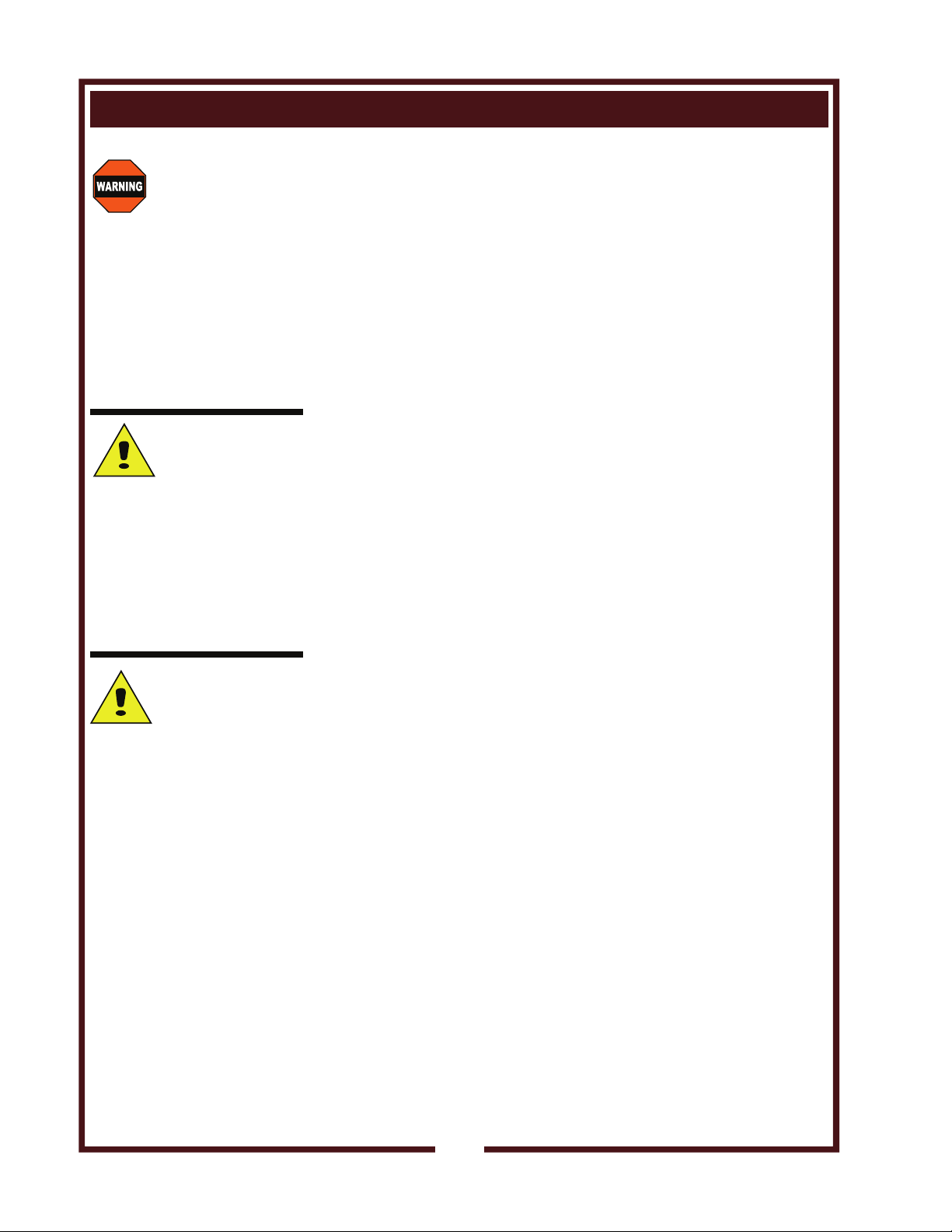

PRECAUTIONS AND GENERAL INFORMATION

WARNING:

ELECTRIC

All servicing requiring access

to non-insulated electrical

components must be

performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

SHOCK HAZARD

CAUTION:

RISK OF

DO NOT connect or

energize this appliance

until all installation

instructions are read and

followed. Damage to the

appliance will result if these

instructions are not

followed.

DAMAGE

CAUTION:

HOT SURFACE

Cooking surface is very hot

during operation. Contact with

the griddle can cause serious

burns.

NOTE: Fire suppression system and all associated components must

only be serviced by an authorized Ansul® Distributor. All setup,

charging, repair and/or adjustment of the fire suppression system must

be performed by an Authorized Ansul® Distributor ONLY.

IMPORTANT: If a remote pull station is installed, both rear casters (9)

must be replaced with legs to deter moving the unit. MOVING AN

APPLIANCE WITH A REMOTE PULL STATION WILL DISCHARGE

THE FIRE SUPPRESSION SYSTEM.

This Ventless Cooking System™ is designed to help reduce odor

emissions, but will not completely eliminate cooking odors. Air

exchange at the installation site must comply with the requirements of

the local jurisdictional authority. To ensure that odors do not build-up,

recommended minimum air exchange is 300 - 400 cfm of outside air

into and out of the area where the unit is used.

This appliance is intended for use in commercial establishments

only.

This appliance is intended

No other use is

agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

Do not splash or pour water on, in or over any exposed element,

control, control panel or wiring.

DO NOT submerge pre-filter or filter pack in water.

Use only genuine Wells replacement parts and filters, call (314) 6786314 or your authorized Wells service agent. Parts supplied by others

will void your warranty and may not provide safe operation.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualified technical personnel.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

recommended or authorized by the manufacturer or its

to prepare food for human consumption.

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

6

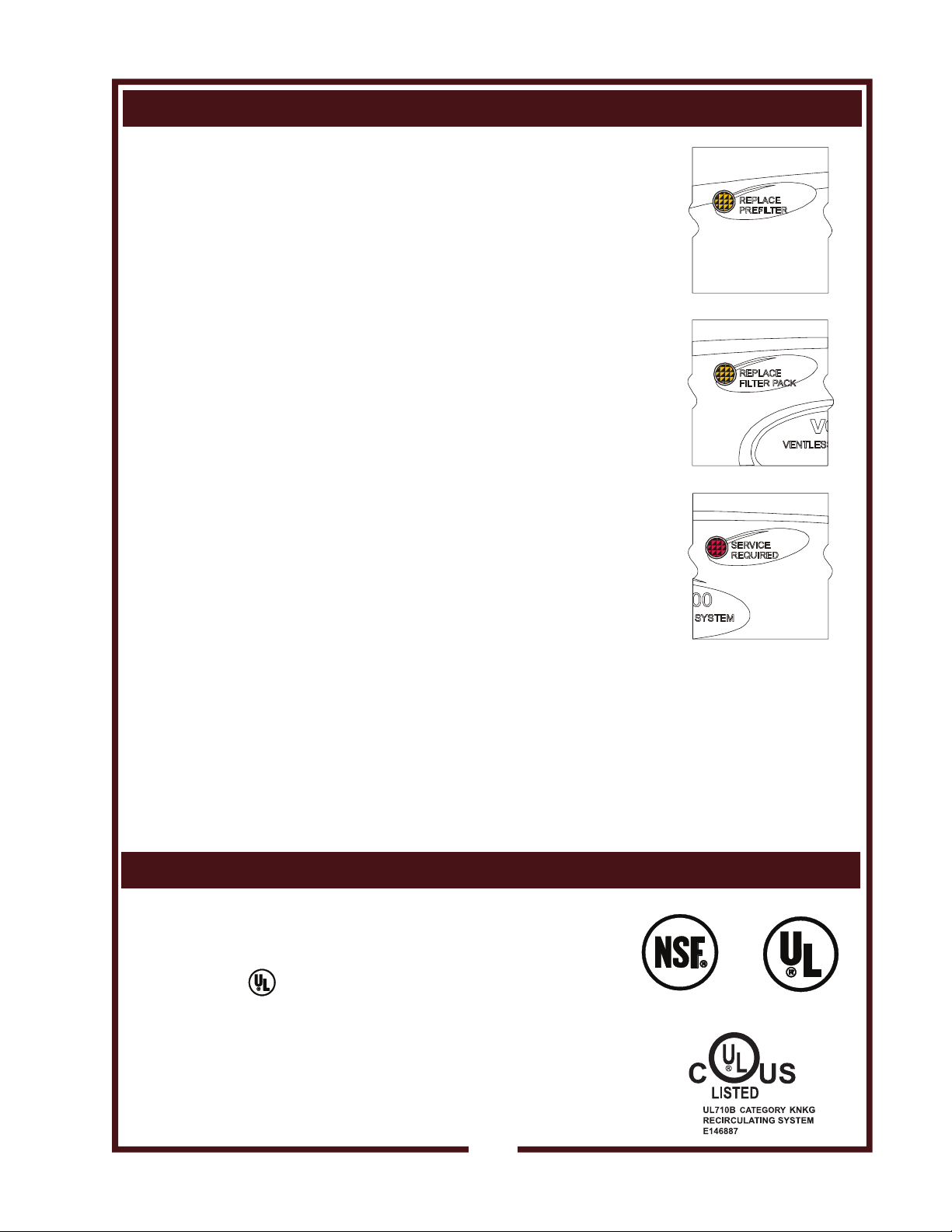

PRECAUTIONS AND GENERAL INFORMATION (continued)

OPERATIONAL NOTES:

REPLACE PREFILTER and REPLACE FILTER PACK indicator lights

provide a timely warning that a system shut-down is imminent.

The actual time between the indicator light coming on and the loss of

cooking appliance power will depend upon the cooking conditions.

Anytime a dirty PRE-FILTER is replaced, the system airflow will

increase. If the condition of the FILTER PACK is marginal, the

REPLACE FILTER PACK light could then come on. If this happens,

a fresh FILTER PACK must be installed within a reasonably short time.

Loss of airflow through the old filter pack will soon cause a system

shut-down when the airflow falls below minimum vapor capture levels.

KEEP SPARE FILTER PACKS ON HAND.

IMPORTANT: If you decide to “get the most” out of the old filter pack,

and continue to use it until a system shut-down happens, it is advisable

to have a fresh filter pack readily at hand, and have someone available

who is capable of replacing it. Otherwise, you may experience an

extended down time, with consequent associated loss of business.

The manufacturer assumes no liability for loss of business due to

a system shutdown caused by a dirty pre-filter and/or filter pack

(i.e. red SERVICE REQUIRED light is on), when the user fails to

have the proper replacement pre-filter and/or filter pack on hand.

The Ventless Cooking System™ hood is designed as part of a WELLS

cooking appliance only. No other use of this product is authorized by

the manufacturer or its agents. Wells Mfg. assumes no liability for the

use of this equipment with products by any other manufacturer’s, or for

use of this equipment with any Wells Manufacturing product other than

in factory certified applications.

Fig. 4 Ventilator

Warning

Indicators

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions

And operated and maintained in accordance with the instructions in this

manual.

This appliance is Listed under UL File E146882.

This appliance is evaluated to BOCA, ICBO and SBCCI Building Code

Requirements by National Evaluation Service, Inc. (NES) under Report

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

No. NER-620.

7

AGENCY LISTING INFORMATION

STD 4

E146882

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

RISK OF

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable electrical

codes. Failure can result in

personal injury and property

damage.

INJURY

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all

protective plastic film, packing materials and accessories from the

Appliance before connecting electrical power or otherwise performing

any installation procedure.

Carefully read all instructions in this manual packed with the appliance

before starting any installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before

discarding packing materials. Store these components in or near the

appliance for later use. To prevent loss, these items should be

installed as soon as possible

1 ea. FIRE SUPPRESSION AGENT (ANSULEX® Low pH, 1.5 GAL.)

See Material Safety Data Sheet, page 24.

1 ea. FIRE SUPPRESSION MEDIA TANK

1 ea. FIRE SUPPRESSION TANK CHARGING CARTRIDGE

1 ea. GREASE BAFFLE

1 ea. FILTER PACK ASSEMBLY

1 ea. PRE-FILTER HOLDER with PRE-FILTER

1 ea. GREASE CUP

1 ea. GREASE TROUGH (VENTILATOR SECTION)

1 ea. GREASE DRAWER (GRIDDLE SECTION)

1 ea. SCRAPER

2 ea. 6” SIDE SPACERS

1 ea. LITERATURE PACKAGE

Additionally:

2 ea. DRAWER INSERTS (if ordered with warmer drawers)

2 ea. HUMITROL RACKS (if ordered with warmer drawers)

SETUP

Setup the appliance only on a firm level surface. Non-combustible

material is recommended.

Refer to the Installation Instruction Sheet for required clearances.

Maintain required clearances between the appliance and adjacent

combustible surfaces. Verify 6” left and right side clearances to

combustible construction. This appliance requires a minimum of 8 ft

(96”) (floor to overhead) to allow for adequate exhaust.

Verify that the VENTILATOR HOOD ASSEMBLY is properly and

securely assembled to the cooking appliance before beginning the

installation procedure.

If a remote manual pull station is to be installed, replace the rear

casters with legs.

Level the unit after it is in its final position. Using a spirit level, verify

that the unit is level front-to-back and side-to-side.

Avoid storing flammable or combustible materials near the appliance.

.

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

8

INSTALLATION (continued)

SERVICE TECHNICIAN INSTALLATION NOTES

An Ansul® technician must charge and arm the fire suppression system

before the ventilator blower will operate. See page 10.

Installation and start up must be performed by an Authorized

Installation Company.

Installer must complete the WARRANTY REGISTRATION form, and

record appliance installation particulars on the CUSTOMER SERVICE

DATA form in this manual.

Certain codes require cooking equipment to be restrained with a

RESTRAINT DEVICE. It is the RESPONSIBILITY OF THE

INSTALLER to check with the AUTHORITY HAVING JURISDICTION,

in order to ascertain the applicability of this requirement to THIS

SPECIFIC EQUIPMENT INSTALLATION. Any restraint device must

allow access to the back and sides of the unit to provide for servicing

and maintenance, and must not interfere with the operation of the FIRE

SUPPRESSION SYSTEM.

ELECTRICAL INSTALLATION

Refer to the nameplate on the cooking appliance to verify the

ELECTRICAL SERVICE POWER. Voltage and phase must match the

nameplate specifications, and available electrical service amperage

must meet or exceed the specifications listed on page 1. Incoming

wiring must comply with National Electrical Code specifications.

All universal hood appliances ship from the factory wired 3ø and include

a 3ø cordset.

For 1ø operation:

a. Remove rear lower panel (item 12)

b. Refer to the wiring schematic diagram located on the inside of

the panel.

c. Service wiring and conduit, or appropriate cordset must be

provided by the electrical installer.

d. Wiring change must be performed by a licensed electrician.

e. Be sure to reinstall the panel when wiring change is completed.

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

IMPORTANT!

Verify that this VENTILATOR

and food cooking equipment

installation is in compliance

with the specifications listed

in this manual, with local

code requirements, and in

accordance with N.F.P.A 96

(THE STANDARD FOR

VENTILATION CONTROL

AND FIRE PROTECTION

OF COMMERCIAL

COOKING OPERATIONS -

current edition).

THIS IS THE

RESPONSIBILITY

OF THE INSTALLER

DANGER

SHOCK HAZARD

ELECTRIC CONNECTIONS

MUST BE MADE BY A

LICENSED ELECTRICIAN

Electrical shock will cause

death or serious injury.

NOTE: This appliance

requires a dedicated 60 Amp

electrical branch circuit

protection.

IMPORTANT:

Contact a licensed electrician

to install and connect

electrical power to the

appliance.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

9

INSTALLATION (continued)

DANGER

FIRE

HAZARD

THE FIRE SUPPRESSION

SYSTEM MUST BE

CHARGED AND CERTIFIED

BY AN AUTHORIZED

ANSUL® DISTRIBUTOR.

NEVER ATTEMPT TO

MODIFY OR BYPASS THE

FIRE SUPPRESSION

SYSTEM.

AN UNCONTROLLED FIRE

CAN CAUSE SERIOUS

INJURY, DEATH AND/OR

PROPERTY LOSS.

IMPORTANT: The FIRE

SUPPRESSION SYSTEM

must be SET-UP and

CHARGED by an authorized

Ansul® distributor before the

ventilator blower will operate.

NOTE: If the fire suppression

system is discharged, a

buzzer will sound

continuously and the cooking

appliance will remain

inoperable until the fire

suppression system is

serviced. Recharging and

resetting must be

performed by an authorized

Ansul® distributor ONLY.

Charging of the Ansul Fire

Suppression system must be

in accordance with Ansul®

Design, Installation, Recharge

and Maintenance Manual.

(Ansul® #418087-05)

FIRE SUPPRESSION SYSTEM INSTALLATION

1. Any REMOTE MANUAL PULL STATION must be installed by an

authorized ANSUL® distributor in accordance with the

AUTHORITY HAVING JURISDICTION.

NOTE: If a REMOTE MANUAL PULL STATION is installed, moving

the unit for servicing will cause the Ansul® system to discharge. In

this case, the unit must only be installed with four fixed legs

(i.e. remove rear casters and replace with legs). Additional legs may

be ordered through an Authorized Wells Service Agency. See page 25.

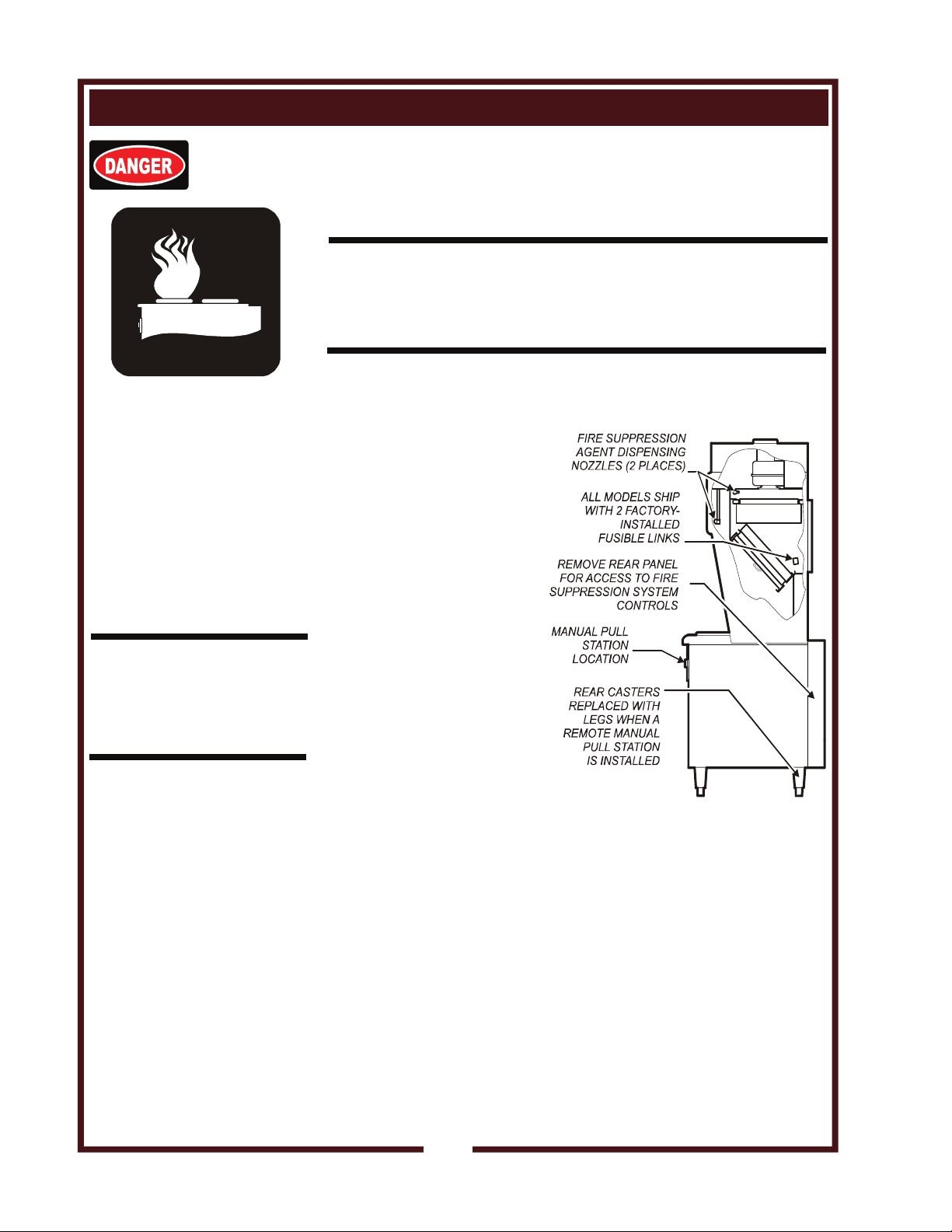

2. The FIRE SUPPRESSION SYSTEM is comprised of a

pressurized cartridge &

container of liquid fire

suppressant, with

associated plumbing and

controls. It utilizes factory

installed FUSIBLE LINKS

for automatic actuation,

and a factory installed

MANUAL PULL STATION

for manual actuation.

Two NOZZLES are used

to disperse the liquid fire

suppression media.

3. When the fire suppression

system activates, the fire

suppression media is

discharged, both the

cooking appliance and the

ventilator are de-energized,

and a buzzer will sound

continuously.

The fire suppression media

will form an emulsion

designed to both smother

and cool the fire.

Call your Authorized Ansul® Distributor immediately for

service.

NOTE: See page 22 for the Material Safety Data Sheet for the fire

suppression agent.

4. The MANUAL PULL STATION and any similar REMOTE MANUAL

PULL STATION will activate the fire suppression system when the

ring on the pull station is pulled horizontally.

Fig. 5 Fire Suppression System

M502 p/n 2M-304986 Owners Manual WVG-136 Ventless Griddle

10

Loading...

Loading...