Wells Manufacturing WVAE30F, WVPE30F, WVAE55F, WVAE55FS Service Manual

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5703

fax: 775-689-5976

www.wellsbloomfield.com

SUPPLEMENTAL

SERVICE

INSTRUCTIONS

ELECTRIC

361

for

PRESSURE

FRYER

WFAE-30F

With or Without

Optional Filter Wand

IMPORTANT: WELLS MANUFACTURING PROPRIETARY INFORMATION.

DISSEMINATION OF THIS INFORMATION TO ANYONE OTHER THAN

WELLS AUTHORIZED SERVICE AGENTS IS STRICTLY PROHIBITED.

TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR

USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY.

PRINTED IN UNITED STATES OF AMERICA

p/n 501219 Rev. B ECN-13391 S361 071128 cps

PRECAUTIONS AND GENERAL INFORMATION

DANGER:

BURN HAZARD

Cooking oil in this appliance

operates at very high

temperatures. Contact with

hot oil can cause severe

injury or death. Wear

appropriate heat-protective

clothing when operating or

servicing this appliance.

WARNING:

SLIP AND FALL

HAZARD

Spilled cooking oil is very

slippery and can cause falls.

Clean up oil spills promptly.

CAUTION:

BURN HAZARD

Exposed surfaces can be hot

to the touch and may cause

burns.

CAUTION:

HEALTH HAZARD

Old cooking oil can be a

breeding ground for bacteria.

Clean and sanitize exterior

surfaces of fryer regularly.

This appliance is intended for use in commercial establishments

only.

This appliance is intended

No other use is

agents.

DO NOT open any panel that requires the use of tools for access. Live

electric circuits may be exposed by opening such panels. Opening

access panels must be performed by an Authorized Service Agent

only.

This appliance is equipped with an oil filtration system designed to filter

hot liquid shortening only. Water, cleaning agents and/or other liquids

will contaminate the oil and may damage the filter pump.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

DO NOT submerge any part of this appliance in water unless

specifically instructed to do so. This appliance is not jet stream

approved. DO NOT direct water jet or steam jet at this appliance,

nor at any control. DO NOT splash or pour water on, in or over any

controls. DO NOT wash area around this appliance with water jet.

Any part which has become wet must be thoroughly dried before use.

Cooking oil will be very hot when in use. Contact will cause severe

injury, and can cause blindness or death. Wear appropriate heatprotective clothing when operating or servicing this appliance.

This appliance must be operated with the supplied legs and casters

properly installed.

The technical content of this manual, including any parts breakdown

illustrations and/or adjustment procedures, is intended for use by

qualified technical personnel only.

Any procedure which requires the use of tools must be performed by a

qualified technician.

recommended or authorized by the manufacturer or its

to prepare food for human consumption.

361 501219 Service Manual for WFAE-30F Fryer

xi

TABLE OF CONTENTS

Precautions & General Information xi

Specifications 1

Components and Controls 2

Operation 4

Operation Troubleshooting Guide 5

Filter Operation 6

Filter System Troubleshooting Guide 7

Servicing Instructions

Lift Actuator & Motor Assembly 8

Filter Pump 10

(Optional) Filter Wand 12

Heating Element & Electrical 14

Wiring Diagrams 18

INTRODUCTION

This manual contains information needed to properly service and repair WFPE-30F Pressure Fryer, and

the cooking appliance section of WVPE-30F Ventless Pressure Fryer.

For installation, operation and maintenance instructions, refer to Operation Manual p/n 306785.

For information about the ventilator hood section of the WVPE-30F Ventless Pressure Fryer, refer to

Supplemental Operation Manual p/n 301603, or to Supplemental Service Manual p/n 502944.

361 501219 Service Manual for WFAE-30F Fryer

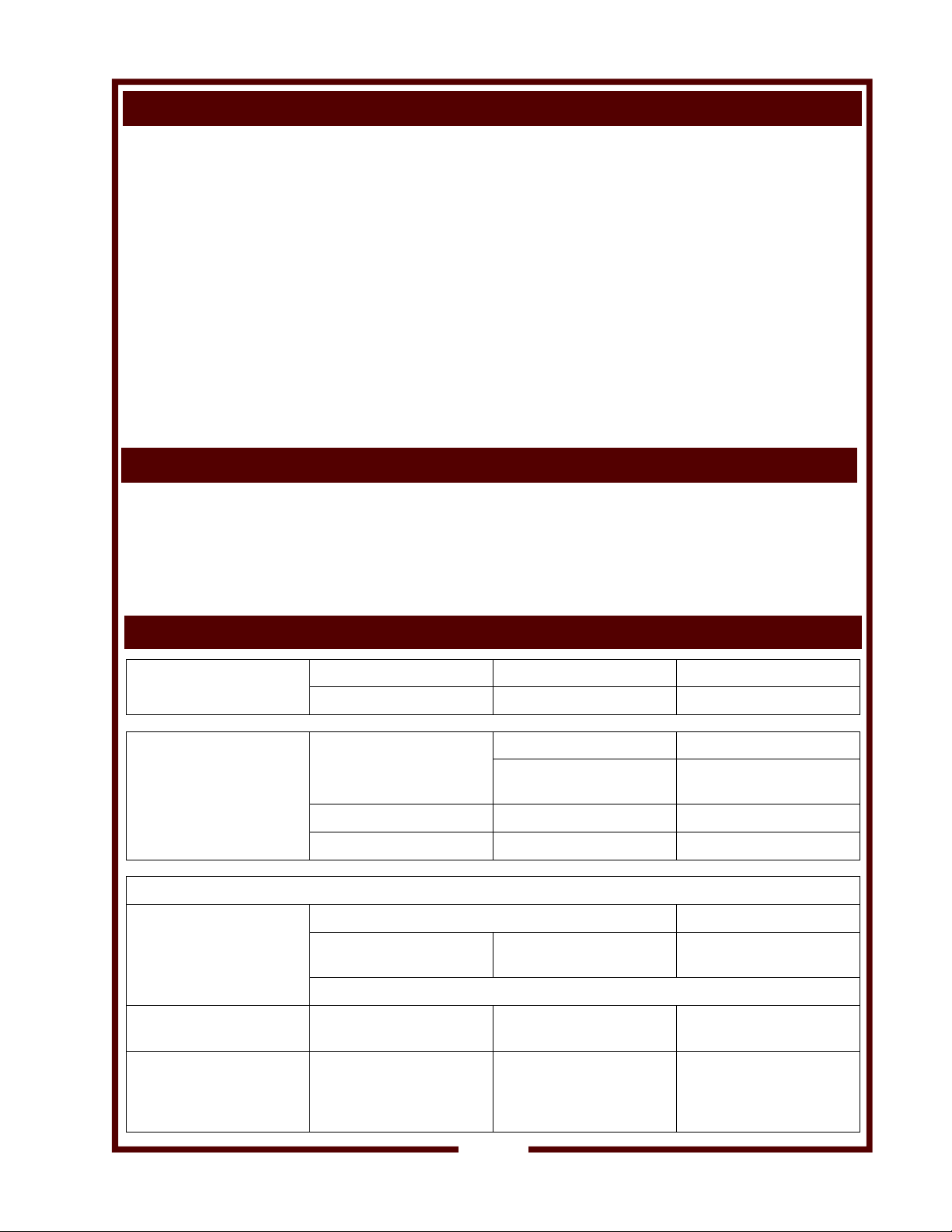

DIMENSIONS

CAPACITIES

VOLTAGE

REQUIREMENTS

POWER

CONSUMPTION

AMPERAGE

SPECIFICATIONS

Wide Deep High

15.70” 33.25” 40.0”

Cooking Oil

(Liquid Shortening Only)

Chicken (Fresh) 14 6

Chicken (Frozen) 12 5

ELECTRICAL SPECIFICATIONS

DOMESTIC EXPORT (EU)

208 VAC

NOTE: Shipped from factory 3Ø, field convertible to 1Ø

9,000 watts

43.3 amps (1 ø)

25.0 amps (3ø)

Lbs. Kg.

30

240VAC

9,000 watts

43.3 amps (1 ø)

25.0 amps (3ø)

14

380-415V

3NAC

9.000 watts

L1 = 14.3

L2 = 13.0

L3 = 13.0

N = 2.7

1

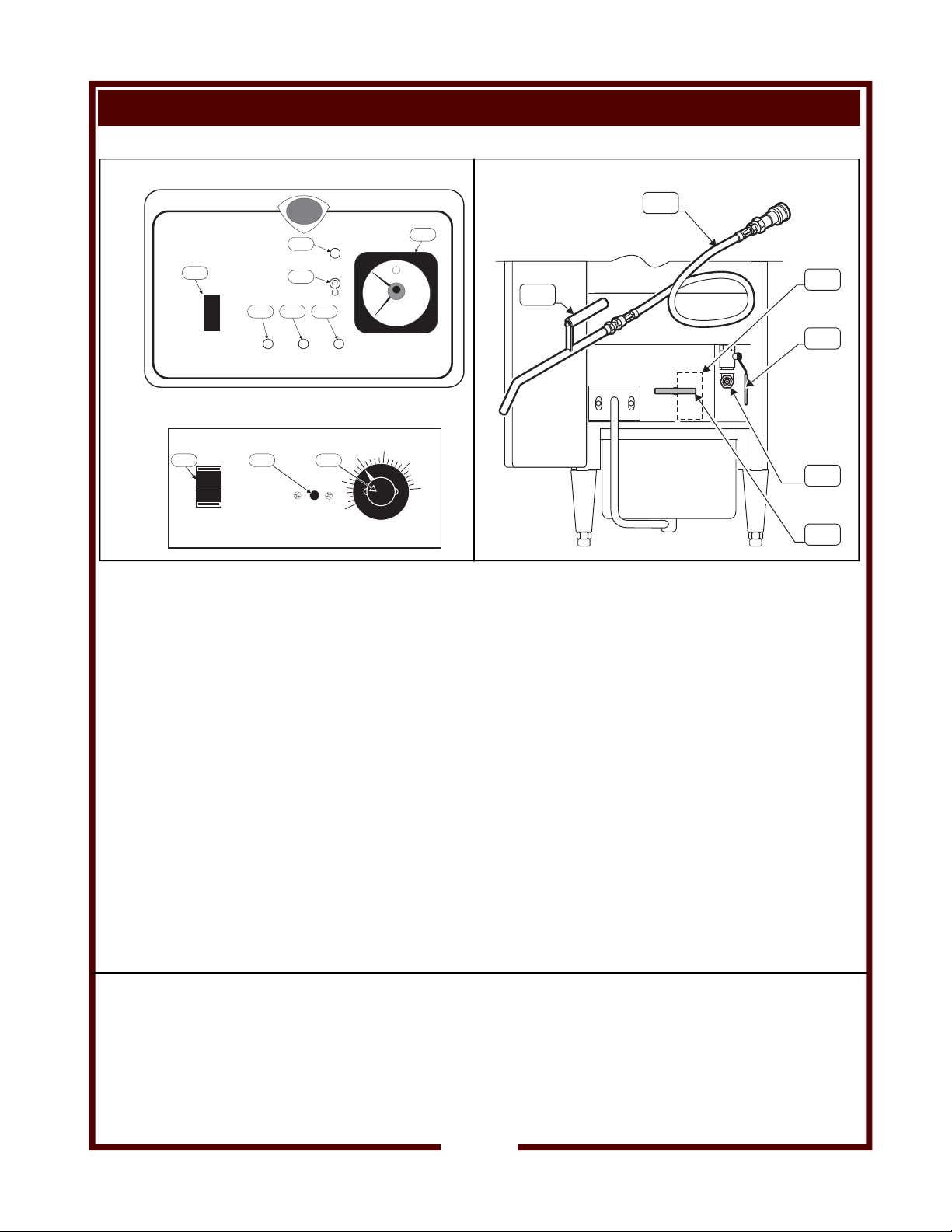

COMPONENTS & CONTROLS

WFAE-30F

BACK VIEW

S

A

FRYPOT

T

FRONT VIEW

M

N

O

J

B

P

Q

K

L

R

U

ITEM DESCRIPTION NOTES

A LIFT CRADLE MOTOR Operates LIFT ROD / Raises LIFT CRADLE

B PUMP MOTOR RESET Protects against filter pump motor overload

C FRYPOT COVER Protects against hot oil splatter

D LIFT CRADLE Holds FRY BASKET - lifts/lowers fry basket into/out of frypot

E FRYPOT ASSEMBLY Contains and heats cooking oil

F DRAIN VALVE Allows draining FRYPOT

G FILTER PUMP and MOTOR Pumps oil during filtration cycle

H POWER CORD Electrical power hook-up

I REAR (FIXED) CASTER Allow easy positioning of unit

J LOWER CONTROL BOX

and TERMINAL BOX COVER

K POWER CONNECTION 90º conduit fitting required, angled as shown

L FRONT (FIXED) LEG Adjustable for leveling unit

M FRY BASKEY Holds product to be cooked

N UPPER CONTROL PANEL Contains main controls. See page 3

O LOWER CONTROL PANEL Contains heating controls and pump switch. See page 3

P DRIP PAN Collects liquids that drain from the top of the unit

Q DRAIN VALVE LEVER Operates the drain valve (item F)

R FILTER RESERVOIR Holds filtering media for oil filtration cycle

S BASKET HANDLE Used to move fry basket

T OIL LEVEL INDICATOR Measure amount of cooking oil

U FILTER SUCTION TUBE Plugs into suction line receptacle

V SUCTION TUBE O-RING

SPARE O-RINGS

NOTE: must be reset by manually pushing red button

Contains power cord connections, power contactor, temperature control

thermostat, hi-limit safety thermostat and heating element connections

Allows oil to be drawn through filter media

Seals suction tube to receptacle

Up to 3 spares may be stored here

D

V

R

361 501219 Service Manual for WFAE-30F Fryer

2

WFAE-30F

COMPONENTS & CONTROLS (continued)

UPPER CONTROL PANEL

1

FRYER

OFF

FILTER

2

POWER

WELLS

7

6

3

HEAT

5

B

U

Z

Z

E

R

4

COOK

OPTIONAL FILTER WAND

aa

bb

LOWER CONTROL PANEL

HI-LIMIT

RESET

THERMOSTAT

300

250

275

325

350

375

ºF

FILTER position energizes filter switch

OFF position de-energizes temperature control thermostat, timer and filter

switch

Active when cook lever is in COOK position

OFF position silences buzzer

Turns fryer OFF is cooking oil temperature exceeds 425ºF

Turns fryer OFF if heating element is energized without being covered by

cooking oil

RESET by pressing red button after cooking oil has cooled.

Controls cooking oil temperature by energizing/de-energizing heating element

SET by turning pointer to desired cooking temperature marked on panel

Causes heat light to glow when energized

FILTER

ON

8

OFF

CAUTION

FRYER MUST BE OFF

BEFORE USING FILTER

910

ITEM DESCRIPTION NOTES

1 POWER SWITCH FRYER position energizes temperature control thermostat and timer

2 POWER LIGHT Glows when power switch is in FRYER position

3 HEAT LIGHT Glows when heating element is energized

4 COOK LIGHT Glows when cook lever is in COOK position

5 TIMER Indicated set time or counts down time remaining

6 BUZZER SWITCH ON position allows buzzer to sound whenever cradle is down

7 BUZZER LIGHT Glows when BUZZER SWITCH is ON

8 FILTER SWITCH ON position energizes filter pump (power switch must be in FILTER position)

9 HI-LIMIT SAFETY

THERMOSTAT

10 TEMPERATURE CONTROL

THERMOSTAT

cc

dd

ee

Q

361 501219 Service Manual for WFAE-30F Fryer

aa FILTER WAND ASSY

Optional wand powered by filter pump, used to wash-down frypot sides, or to

transfer oil to disposal container

bb INSULATED HANDLE Handle for maneuvering wand. Insulated from heat of hot oil.

cc ELEMENT INTERLOCK SWITCH Disables heating element anytime drain valve lever is not fully closed

dd 3-WAY VALVE Directs output of filter pump either to frypot, or to wand

ee QUICK DISCONNECT FITTING Male fitting. Female fitting of wand connects here

3

OPERATION

CAUTION:

BURN HAZARD

Hot oil can cause serious burns

on contact. Wear appropriate

protective clothing when using

this fryer.

IMPORTANT:

Always remove basket handle

from basket before lowering lift

cradle.

PRESS RED BUTTON TO START TIMER

6

5

4

3

2

1

TURN TO SET TIME

9

8

7

0

10

11

12

13

14

15

16

17

18

19

20

21

TIMER

PRE-HEATING FRYER

Make sure FRYPOT is filled with 30 LB. of cooking oil.

Open door and set THERMOSTAT (item 10) to desired cooking

temperature. CLOSE THE DOOR.

Set POWER SWITCH (item 1) to FRYER. POWER LIGHT (item 2)

and HEAT LIGHT (item 3) will glow. HEAT LIGHT will cycle on and

off with the HEATING ELEMENTS. When HEAT LIGHT first goes off,

fryer is ready to cook the product.

SET COOK TIMER AND LOAD PRODUCT

Set TIMER (item 5) to desired cooking time.

FROZEN PRODUCT:

Load frozen product into BASKET. Using the BASKET HANDLE

(item 16) set BASKET on LIFT CRADLE.

IMPORTANT: REMOVE HANDLE.

Press RED BUTTON on TIMER to lower BASKET into FRYPOT.

FRESH PRODUCT:

Using BASKET HANDLE, set BASKET on LIFT CRADLE.

IMPORTANT: REMOVE THE HANDLE.

Press the red button on TIMER to lower BASKET into FRYPOT.

Manually drop each piece of fresh product into hot oil, just above

the oil level to minimize splattering.

ALWAYS USE PROTECTIVE EQUIPMENT, SUCH AS INSULATED

GLOVES, TO PROTECT AGAINST HOT OIL BURNS

COOK CYCLE AND BUZZER

When an audible alarm is desired at end of cook cycle, turn BUZZER

SWITCH (item 7) ON after TIMER has been started. BUZZER LIGHT

(item 6) will glow.

Note: If BUZZER SWITCH is turned ON before BASKET is lowered,

BUZZER will sound until BASKET has fully lowered.

At end of cook cycle, BASKET will raise and BUZZER will sound until

BUZZER SWITCH is turned OFF, or until the next cook cycle is

started.

Use BASKET HANDLE (item 16) to remove basket of cooked product

from LIFT CRADLE. Serve or dispense cooked product as required.

361 501219 Service Manual for WFAE-30F Fryer

4

OPERATION TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

POWER LIGHT not lit

Fryer not operating

POWER LIGHT not lit

Fryer operating normally

HEAT LIGHT not lit

Power light lit - cooking oil cold

HEAT LIGHT not lit

Power light NOT lit - cooking oil cold HEAT

LIGHT not lit

Power light lit - cooking oil hot

COOK LIGHT not lit (CRADLE raised) TIMER not set or not started Turn dial to desired time, press red start button

COOK LIGHT not lit (CRADLE lowered) COOK LIGHT damaged Repair or replace cook light

TIMER does not operate

BUZZER LIGHT not lit

BUZZER does not sound (CRADLE raised)

POWER SWITCH not in FRYER position Press POWER SWITCH to FRYER

Disconnected from electric power or

Circuit breaker off or tripped

POWER LIGHT damaged Repair or replace power light

TEMPERATURE CONTROL THERMOSTAT not

set or set too low

TEMPERATURE CONTROL THERMOSTAT

damaged

DRAIN VALVE not fully closed (optional filter

wand only)

HI-LIMIT SAFETY THERMOSTAT tripped Allow oil to cool, press red button to reset hi-limit

Cooking oil at set temperature

HEAT LIGHT damaged Repair or replace heat light

POWER SWITCH not in FRYER position Press POWER SWITCH to FRYER

TIMER not set or not started Turn dial to desired time, press red button to start

TIMER CAM MICROSWITCH damaged or out of

adjustment

TIMER damaged Replace TIMER

BUZZER SWITCH in OFF position Turn SWITCH ON

BUZZER LIGHT damaged Replace LIGHT

BUZZER SWITCH in OFF position Turn SWITCH ON

BUZZER damaged Replace BUZZER

BUZZER SWITCH damaged Replace BUZZER SWITCH

Reconnect to electric power

Reset circuit breaker

Set thermostat to desired temperature

Replace thermostat

Be sure drain handle lever is horizontal

No action required

Set thermostat if oil not hot enough

Adjust or replace microswitch

CRADLE LIFT will not lower

CRADLE LIFT will not raise

361 501219 Service Manual for WFAE-30F Fryer

FRYPOT COVER does not lower with LIFT

CRADLE

TIMER not set or not started Turn dial to desired time, press red start button

TIMER damaged Replace TIMER

LIFT MOTOR damaged Replace LIFT MOTOR

LIFT MOTOR MICROSWITCH damaged or out of

adjustment

TIMER has time remaining Allow TIMER to complete cycle to “0”

LIFT CRADLE not properly assembled to LIFT

ROD

TIMER damaged Replace TIMER

LIFT MOTOR damaged Replace LIFT MOTOR

LIFT MOTOR MICROSWITCH damaged or out of

adjustment

ACTUATOR or LIFT CRADLE damaged Repair/replace damaged components

COVER leaned back too far Rest COVER on LIFT CRADLE

HINGE(S) dirty, damaged or misaligned Clean, repair or align HINGES

Adjust or replace microswitch

Install white plastic pivot over end of LIFT ROD

(see page 3)

Adjust or replace microswitch

5

Loading...

Loading...