Wells Manufacturing WOF-80 Service Manual

439

OPERATION MANUAL

WOF-80 Oil Filtration Unit

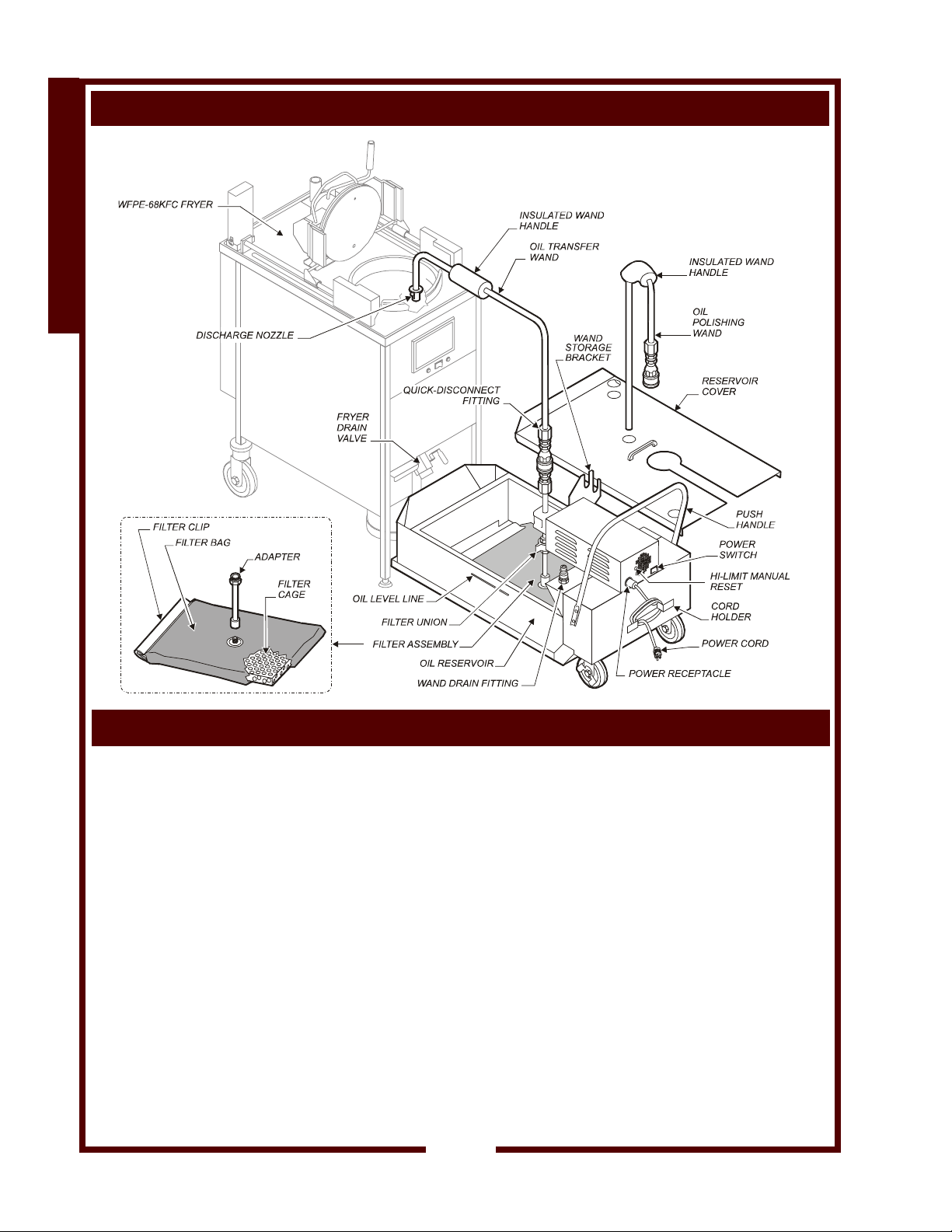

(wands shown stowed)

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

MODEL

WOF-80

Cooking Oil

Filtration System

for use with

WFPE-68KFC

Pressure Fryer

Includes

INSTALLATION

USE & CARE

IMPORTANT: DO NOT DISCARD THIS MANUAL

p/n 305728 Rev. A M439 060403 cps

LIMITED WARRANTY STATEMENT

GLOBAL W ARRANTY STATEMENT for:

YUM! Restaurants International and YUM Brands Inc.

GENERAL

This WOF-80 Cooking Oil Filtration System manufactured by

Wells Manufacturing Company exclusively for KFC is

warranted against defects in materials and workmanship for

a period of two years from the date of original installation.

THE FOREGOING OBLIGATION IS EXPRESSLY GIVEN

IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHICH ARE HEREBY EXCLUDED.

WELLS MANUFACTURING COMPANY, A DIVISION OF

CARRIER COMMERCIAL REFRIGERATION INC., SHALL

NOT BE LIABLE FOR INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES FROM ANY

CAUSE WHATSOEVER.

This warranty is void if it is determined that upon inspection

by an authorized service agency that the equipment has

been modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God. It also

does not apply if the serial nameplate has been removed or

service is performed by unauthorized personnel. The prices

charged by Wells for its products are based upon the

limitations in this warranty. Seller’s obligation under this

warranty is limited to the repair of defects without charge by

Wells’ factory authorized service agency or one of its

sub-agencies. In addition to restrictions contained in this

warranty, specific limitations are shown in the Service Policy

and Procedure Guide. Please consult your classified telephone

directory, your foodservice equipment dealer or for information

other details concerning warranty write to:

Service Parts Department

Wells Manufacturing Company

Verdi, NV 89439

Phone (775) 689-5700 Fax: (775) 345-0569

P.O. Box 280

and

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting the safety overload protector unless

warranted conditions are the cause.

2. All problems due to operation at voltages other than

specified on equipment nameplates – conversion to

correct voltage and phase are the customer’s

responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements and

wiring diagrams supplied with the equipment.

4. Replacement of items subject to normal wear to

include such items as: knobs and couplings. Normal

maintenance functions including cleaning are not

covered by warranty.

5. Full use, care and maintenance instructions are

supplied with each machine. Those miscellaneous

adjustments noted are customer responsibility. Proper

attention will prolong the life of the machine.

6. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-agencies.

7. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

8. All genuine Wells replacement parts are warranted

for ninety (90) days from the date of purchase on

non-warranty equipment. This parts warranty is limited

only to replacement of the defective part. Any use of

non-genuine Wells parts completely voids any

warranty.

9. Installation, labor and job checkouts are not

considered warranty.

10. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technicians’ ability to

perform service are not covered by warranty.

This includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged

by skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Manufacturing cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

xi

TABLE OF CONTENTS

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY LISTING INFORMATION 4

INSTALLATION 4

OPERATION 5

CLEANING INSTRUCTIONS 7

TROUBLESHOOTING SUGGESTIONS 8

WIRING DIAGRAMS 9

EXPLODED VIEW and PARTS LIST 10

PARTS & SERVICE 11

CUSTOMER SERVICE DATA 11

INTRODUCTION

GENERAL

Thank You for purchasing this Wells Manufacturing Co. appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that it

gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for the

appliance in a manner which will ensure its optimum performance.

SPECIFICATIONS

MODEL VOLTS WATTS AMPS POWER SUPPLY CORD

WOF-80 115V 50/60 Hz 460 4.0 NEMA 5-15P

WOF-80EU 220 - 240V

50/60 Hz

MODELS WOF-80 and WOF-80EU DIMENSIONS:

HEIGHT: 28" (710 mm) with wands stowed

46-11/16" (1185 mm) with discharge wand in place

WIDTH: 20" (508 mm) overall

DEPTH: 36-1/2" (926 mm) with wands stowed

43-3/4" (1110 mm) with discharge wand in place

OIL RESERVOIR CAPACITY: 76 pounds (34.5 Kg)

725 - 790 3.3 CORD PROVIDED

WITHOUT PLUG

1

FEATURES & OPERATING CONTROLS

GENERAL

PRECAUTIONS AND GENERAL INFORMATION

IMPORTANT:

The technical content of this

manual, including any

troubleshooting suggestions,

parts breakdown illustrations,

wiring diagrams, schematics,

servicing instructions and/or

adjustment procedures, is

intended for use by qualified

technical personnel only.

IMPORTANT: Cleanliness of

this oil filtration system is

essential to good sanitation.

Read and follow all included

cleaning instructions and

schedules to ensure the

safety of the food product.

Wells WOF-80 cooking oil filtration system is intended for use in

commercial establishments only.

This device is

WFPE-68KFC Pressure Fryer to filter hot cooking oil. No other use is

recommended or authorized by the manufacturer or its agents.

Operators of this oil filtration system must be thoroughly trained in the

appliance use, precautions, limitations and associated restrictions.

Operating instructions, warnings and labels must be read and

understood by all persons using or installing this appliance.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

designed for use in conjunction with the Wells Model

2

PRECAUTIONS AND GENERAL INFORMATION (continued)

Contact with hot shortening will cause severe injury to unprotected skin

and eyes. Extensive exposure to hot shortening can cause death.

Protect yourself from contact with hot shortening:

ALWAYS wear protective clothing and eye protection when

operating, cleaning or servicing this oil filtration device.

Shortening under pressure can be very hazardous unless handled

properly:

DO NOT attempt to turn the FRYER OPERATING LEVER until the

pressure in the frypot has fallen to zero.

DO NOT open the FRYER DRAIN VALVE if the frypot is under

pressure.

Opening the lid or drain valve with the fryer under pressure will

result in the explosive release of hot shortening.

Spilled shortening will cause a slip and fall hazard:

Be sure the oil filter is properly in place under the fryer drain valve

and that the wand in properly in place in the fryer frypot before

opening the drain valve or connecting the unit to electric power.

Clean up shortening spills promptly to avoid creating a slip and fall

hazard.

DO NOT allow water to contaminate the shortening. Water will

boil violently on contact with hot shortening, causing the hot

shortening to splatter.

DO NOT clean the filter with water, water spray or steam

spray.

DO NOT use steel wool to clean any part of the filter

DO NOT pour water on, into or over the motor, motor enclosure, power

switch or wiring.

This appliance is not jet-stream approved. Do not direct any water or

steam jet at any part of this appliance. Do not use a jet stream to wash

under the appliance.

The filter unit is NOT a ladder. Never stand on the filter unit.

DO NOT stand on, sit on or lean on the filter unit.

DO NOT allow foreign objects such as closed containers, cigarette

lighters or aerosol cans near the filter unit or hot shortening. If dropped

in hot shortening, such objects may explode.

DO NOT allow any foreign object near the fryer or filtration unit that can

fall into the frypot or filter and cause splashing or splattering of hot

shortening.

Keep the RESERVOIR COVER in place at all times except when the

filter unit is being cleaned.

DO NOT push or pull the filter unit by the wand, filter adapter or pump

discharge pipe. Always use the PUSH HANDLE to maneuver the filter

unit into place.

DANGER:

BURN

Contact with hot shortening

will cause severe injury or

death. Wear eye protection,

protective gloves and clothing

and when operating or

servicing this fryer.

HAZARD

DANGER:

BURN

HAZARD

Do not attempt to open the

fryer lid or fryer drain valve

until the pressure in the frypot

has fallen to zero.

Opening the lid or valve

prematurely will result in the

explosive release of hot

shortening.

Contact with hot shortening

will cause severe injury or

death.

WARNING:

ELECTRIC

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

Do not open any access panel

which requires the use of

tools. Failure to follow this

warning can result in severe

electrical shock.

CAUTION:

Hot Surface

Exposed surfaces can be hot

to the touch and may cause

burns.

GENERAL

3

Loading...

Loading...