Parts List

4

613

MODEL

Manual Bandsaw

and

Built better to work stronger and last longer

Operating & Maintenance Manual

REV 140502

2829 N. Burdick St. Kalamazoo, MI 49004

Phone: 269-345-1132 Fax: 269-345-0095

rdick St. Kalamazoo, MI 4900

www.wellsaw.com

Index

A

0

W

Model 613 Specifications

General

utomatic Stop

Blade Brushes

Blade Selection Guide

Dash Pot, Hydraulic Feed

Feed Pressure Adjustment

Fixed Vise Jaw

Gear Box Repair

Lubrication

Maintenance

Motor Switch

Notes on Sawing 4

Placing Blade on Saw 6

Receiving & Installation

Safety Rules 3

Servicing Blade Guides

Service Kits

Sliding Vise Jaw

Trouble Shooting

Warranty

Wheel Pitch Adjustment

22

Drawings

Blade Brush Assembly

Blade Guide Assembly

Bed Assembly 12

Coolant System

Electrical Controls

Frame Assembly

Hydraulic System 18

Leg & Chip Pan 14

Motor & Gear Box 18

Right Tensioning Device

16

16

18

20

-

1

14

Parts Lists & Part Numbers

Blade Brush Assembly 17

Blade Guide Assembly

Bed Assembly

Coolant System

Electrical Controls/Diagram

Frame Assembly 11

Hydraulic System

Leg & Chip Pan

Motor & Gear Box

Right Tensioning Device

17

13

19

21

18

15

19

15

Capacity

6

8

6

6

6

7

8

7

8

3

7

9

6

4

Rectangular 6' high x 13' wide

Round 7” diameter

Flat 13' wide

4 5° Angle 6' high x 6.5' wide

Blade Speed 50-90-160-250 FPM

Motor 3/4 HP, 115-230/60/1 or 206-230-460/60/3

Drive V-Belt

Blade Size 3/4” x .035"x8'3"

Swivel Vise To 45°

Vise control Manual Screw

9

7

Band Wheels 11' dia.

Height to top of bed 29'

Coolant System 8 gallon w/115VAC submersible pump

Recommended Workload Weight 600 lbs.

Floor Space 25" x 60'

Shipping weight (approximate) 650 lbs.

Parts Ordering

For your convenience:

When contacting your Wellsaw supplier

or the Company for parts or service,

it is essential that you have both your saw

Serial Number and Purchase Date available.

Jot them down here for handy reference.

Serial Number _____________________

Purchase Date ____________________

Fill out and return your Warranty Card

so that you can be kept informed of

developments concerning your

ellsaw.

Forward

2. Keep Guards in Place

Keep guards in place and in good working order.

The Model 613 Wellsaw has been designed and

manufactured to conform to WeIlsaw's recognized

high standards of quality and performance. Each saw

must pass a series of final inspection tests, including

actual metal cutting operations, before it is shipped.

For this saw to provide satisfactory service, it is

necessary that it be properly installed, operated and

maintained. This manual has been prepared to assist

you in carrying out these functions. We urge you to

study this manual and follow its suggestions.

Receiving and Installation

Uncrating

Carefully remove the protective crating and skid so

the saw and its parts are not marred or otherwise

damaged. In the event of damage in transit, notify the

carrier and file a Proof of Loss Claim immediately.

Shortages

Inspect the complete shipment carefully against the

itemized packing list. Make sure that all items are

present and in good condition. In the event of any

shortage, notify the distributor from whom you purchased the saw and the carrier who made delivery.

Utility Hook-Up

The use of a qualified electrician is always recommended when connecting the saw to the main power

supply. Electrical codes differ from area to area and it

is the customers responsibility to ensure that his saw

complies with applicable codes. Your Wellsaw is prewired at the factory for a specified voltage. Always

check the motor and electrical panel to ensure that

they are both wired to correspond to your electrical

power supply.

3. Remove Adjusting Keys and Wrenches See

that keys and wrenches are removed from the saw

before operating it.

4. Keep Working Areas

Clean Clutter invites accidents

5. Avoid Dangerous Environment

Do not use power tools in damp or wet locations.

Keep work areas well illuminated.

6. Keep Children Away

Keep all visitors a safe distance from work areas.

7. Use The Right Tools

Do not force a tool or attachment to do a job or

operate at a speed it was not designed for.

8. Wear Proper Apparel

Avoid all loose clothing or jewelry which may get

caught in moving parts.

9. Use Safety Glasses

Also use a face or dust mask if the cutting operation

being performed requires it.

10. Secure Work

Use proper clamps or the vise to hold work before

cutting.

11. Do Not

Keep your footing and balance at all times. Clean up

all liquids spilled in work area.

12. Maintain Tools in Top Condition

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubrication,

maintenance and changing accessories

Over

Reach

Safety Rules

1. Know Your Saw

Read this manual carefully. Learn your saws' application and limitations as well as the specific potential

hazards peculiar to this machine.

13. Disconnect Power

Before servicing and when changing accessories such

as blades, disconnect the power supply.

14. Use Recommended Accessories

Consult this Manual. The use of improper accessories

may be dangerous and can damage the saw.

3

Notes on Sawing

Trouble Shooting

It is widely recognized that a proficient operator is a

key to optimum bandsawing. He makes certain the

machine is properly maintained and adjusted for dependable operation. He carefully sets up each cutting

job to prevent damage to the machine and obtain the

best performance from the equipment.

Blade dealers can be very helpful in selecting the

grade and proper tooth blade for each sawing job. All

blades should be straight, have sharp teeth with uniform set, and be "broken in" at a reduced feed rate to

obtain good cutting performance and blade life.

Every cutting situation has special characteristics

requiring some experimentation to determine which

blade, speed and feed rate will achieve the most satisfactory result. Cutting charts indicate a good starting

point, but must be modified by direct experience if

optimum performance is desired. (See page 24)

Here are some helpful pointers for adjusting speed and

feed for good cutting performance.

1. Make sure the saw is cutting a good chip from the

workpiece.

2. Watch for blue chips or excessive "smoke"

indicating heat in the cut which could damage the blade

or work-harden the material being cut.

3. Watch for excessive vibration or chatter marks on

the cut-off piece indicating possible damage to saw

teeth by "hammering".

4. Check the cut-off piece for flatness. A dull blade or

excessive feed will produce a "belly" in the cut.

5. Inspect the blade for worn, rounded or shiny cutting

edges. Avoid force cutting which will allow chips to

"weld" to saw teeth and eventually cause the teeth to be

stripped off the blade.

6. When experimenting, start with a slow speed and

feed rate. Gradually increase blade speed and then feed

pressure by small amounts until adverse effects are

noted. You can then set the speed and feed at a

reasonable level for continuous cutting. Remember that

blade speed and feed pressure must be balanced to keep

cutting a good chip.

Premature Dulling of Blade Teeth

1. Feed rate too high or low. Check recommendation.

2. Blade speed too slow or too fast.

3. Faulty material; heavy scale, hard spots, etc.

4. Verify material analysis.

5. If coolant flow is not covering saw teeth, increase

coolant flow rate.

6. If saw is vibrating in cut, reduce blade speed or

increase feed rate.

7. Chipped or broken teeth may be lodged in cut.

8. "Chip welding" caused by improper feed and speed.

9. Incorrect coolant mixture.

10. Incorrect blade selection.

11. Improper break-in of ne w blade. New blades

should be run initially with reduced feed pressure for

approximately 50 to 100 square inches of cutting.

12. Saw blade teeth may be hitting blade guides.

Check for proper blade size and guide adjustment.

Saw Blade Vibration

1. Incorrect blade speed fo r materi al being cut.

2. Blad e tension insu fficient.

3. Back-u p be aring may be worn.

4. Incorrect choice of saw tooth pitch.

5. In correct coolan t mixture.

6. Incorrect feed setting. Increase feed pressure.

7. Workpiece not firmly clamped in vice.

8. Worn or improperly adjusted saw guides. Check and

make necessary adjustments or repairs.

Blade Teeth Chipping or Ripping Out

1. Blade pitch too coarse. Use a fine pitch saw blade

on thin work sections.

2. Improper break-in of new blade. Do not start a new

blade in an old cut.

3. Work piece not held firmly enough. Clamp work

securely.

4. Introduce cooling if it is not being used.

5. Faulty material; scale or hard spots.

6. Blade gullets may be loaded. Use higher viscosity

lubricant or coolant.

7. Blade speed and feed may need adjustment.

4

Premature Blade Breakage

1. Poor weld in blade.

2. Feed rate set too high. Reduce it.

3. Excessive blade speed. Adjust it.

4. Blade guides set too tight or misaligned.

5. Blade tension set too high.

6. Blade running against flange on wheels. Adjust

wheel pitch.

Blade Squeal

1. Feed rate too light for blade speed. Increase feed

rate and/or reduce blade speed.

Blade Slips Off Blade Wheels

1. Blade not tensioned correctly.

2. Wheel pitch not set properly.

3. Guides set too tight.

Gullets of Blade Teeth Loading

1. Blade pitch too fine. Review blad e selec tio n.

2. Incorrect blade speed. Consult cutting chart.

3. If not using coolant, apply it.

Chips Welding to B lade T eet h

1. Cutting rate too high.

2. Chip brush may be out of adjustment.

3. Check coolant and application.

Blade Becoming Scored

1. Saw guides may be worn. Check and replace if

necessary.

2. Too much pressure on saw guides. Adjust.

3. Guides may be out of alignment.

Blade Making Belly-Shaped Cut

1. Blade tension too light. Increase it.

2. Saw guides too far from work piece.

3. Blade pitch too fine. Use larger pitch and positive

rake tooth form.

4. Feed force too heavy. Decrease it.

3. Blade guides too far apart. Always set blade

guides as close to work piece as possible.

4. Blade may be dull. Check and replace if necessary.

5. Feed pressure too high. Reduce it.

6. Blade guides loose, worn or out of alignment.

7. Too many teeth-per-inch. Blade not cutting freely.

8.

Chip brush not cleaning teeth properly.

9. Dirty coolant.

10. Check for loose nuts, bolts, etc.

Rough Cut I Poor Finish

1. Excessive feed rate. See recommendations.

2. Blade too coarse. Use finer blade pitch.

3. Inadequate cutting fluid. Change.

Blade Stalls In work.

1. Insufficient blade tension.

2. Excessive feed pressure.

3. Blade tooth spacing too coarse.

4. Motor worn or defective.

5. Guides too tight against blade.

Blade Does Not Track Properly

1. Set wheel pitch so that blade runs to wheel flange

but not against it.

2. Is blade tension proper?

3. Is back of blade riding against back-up bearing? If

not, adjust guides.

Motor Overheating

1. Check for correct voltage supply. Check voltage at

motor. Check magnetic starter heaters.

2. Check for loose electrical connections.

3. Does motor amp reading correspond to rating on

motor specification tag?

4. Is internal motor wiring correct?

5. Is drive belt over-tightened?

Inaccurate Cut-Off

1. Is conveyor or stock stand level with saw bed?

2. Insufficient blade tension.

5

Operating Instructions.

Speed Selection

Cutting Tips

1. For long er bla de life, star t ea c h cut careful ly .

2. For new blade, reduce feed pressure on first two

cuts or about 100 square inches.

3. Keep blade guides as close to the vise jaws as

possible.

4. Make sure all four legs of the saw are in solid

contact with the floor.

Automatic Stop

When the blade has completed a cut through the

material, the saw frame activates a limit switch which

shuts the motor off.

When changing a blade or doing any other maintenance or repair, be sure the automatic stop is engaged or

disconnect the main power supply.

It is necessary to raise the saw frame clear of this limit

switch actuator before the saw can be started.

Dash Pot

Machines are equipped with a dash pot [frame check]

for the purpose of stabilizing downward travel of the

saw frame, thereby protecting the saw blade from

damage. The action of the dash pot is hydraulic and

controlled by fluid being passed through an orifice in

the piston on the downward stroke.

Fill within 1" of the top of the bottom cylinder with

Mobil Velocite Oil #6 or equivalent.

Frame Weight Adjustment

The position of the collar in relation to the spring on

the dash pot acts as the frame weight adjustment.

The proper frame weight is approximately 10 lbs. and

is obtained by positioning the top of the collar 4" down

from the top edge of the upper cylinder. For less frame

weight, loosen the collar and move it down toward the

tension spring. Reverse this action for more frame

weight.

Too much frame weight will cause the blade to make

crooked cuts!

Saws are equipped with step pulleys providing blade

speeds of 50, 90, 160 and 250 feet-per-minute. High

speeds are suggested for cutting thin-wall tubing,

channels, aluminum, brass or any metal that will not

burn blade teeth. Use medium speed for general cutting such as cold rolled, machine steels, heavy channels, etc. Run at low speed for cutting nickel steels or

any metal requiring a slow speed on a lathe. When

cutting brass, use a blade that has not been used on

other metals and apply beeswax to the teeth. See page

22 for suggested Blade Speed combinations.

Belt

Pivoted mounting provides for quick belt change. With

the belt in pulley grooves for the desire speed, swing

motor to put proper tension in the belt. Tighten thumb

screw to hold motor in proper operating position.

Fixed Vise Jaw

The two pins in the fixed vise jaw should be kept in

place the ensure square cuts. For cutting angles, the

pins must be removed to the desired position and

tightened with clamp bolts. The vise pins allow you to

quickly relocate the fixed vise jaw for approximate 90

0

cutting. For final, accurate cutting, the fixed vise jaw

should be squared with the blade. [See Blade Guide

Alignment.]

Sliding Vise Jaw

The sliding vise jaw is fitted with a lift plate and

ratchet dog for quick action. A hand wheel tightens the

vise on the workpiece. Excessive pressure is not needed

to hold the workpiece securely!

Maximum Capacity

To obtain maximum vise capacity, remove vise jaw

pins and move fixed vise toward motor end to the last

two holes in the bed. Make sure the stock in the vise

will not strike the ratchet arm.

Feeding Pressure

Feed pressure is varied by moving the weight on the

top side of the frame. Blade pressure increases as the

weight is moved toward the open end of the saw.

Excessive pressure may cause a run-out of the blade.

[See page 22 for recommendations.]

6

Placing Blade on Saw

1. Raise saw frame.

2. Open Idle and Drive Wheel guards.

3. Loosen Rite Tension take-up screw and remove old

blade. In the event of a broken blade, be sure Rite

Tension is open by turning take-up screw counterclockwise at least six [6] turns.

4. Uncoil new blade. Make certain the blade teeth

point in the direction of blade travel which is toward

the motor. If not, turn blade inside out to have the

proper tooth direction.

5. Place new blade on the guides and the band wheels.

6. Grasp blade on frame side and push it toward guide

bracket beam to hold it in position while turning the

Rite Tension take-up screw.

7. Tighten blade to proper tension. Blade is properly

tensioned when the take-up screw is tightened until the

mechanism bottoms out.

Maintenance Instructions

adjustment. If you then find the saw blade is not

square with the stationary vise jaw, the blade must be

adjusted.

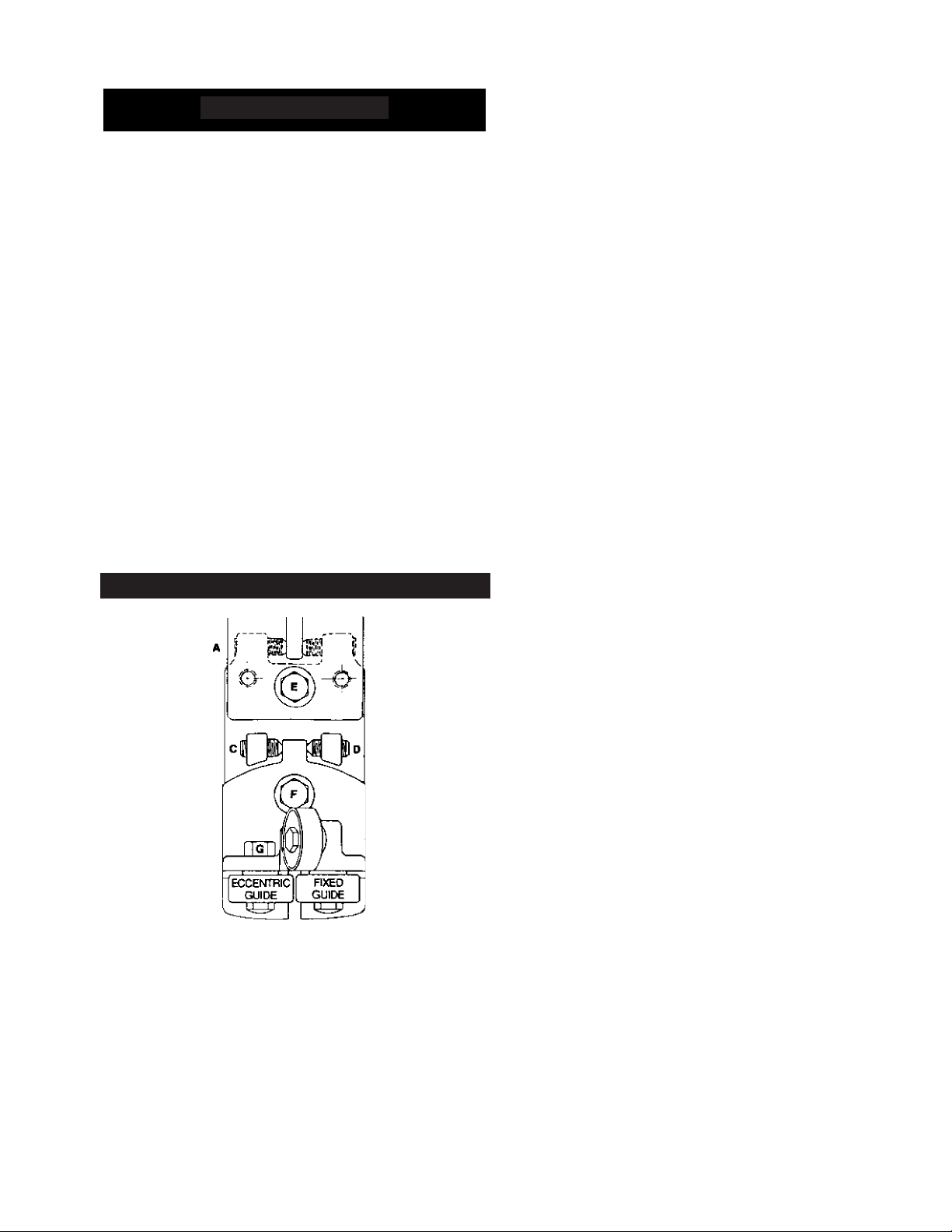

2. This adjustment is. made with the top two Allen

screws on the roller adjusting block of the guide arm.

Looking at the drawing, you will see these adjusting

screws labeled "A" and "B".

3. To make a vertical adjustment of the saw blade, so

that the cut is square from top to bottom, the blade

must be set so that it is perpendicular to the bed. In

making this adjustment, clean the saw bed first.

4. Set the rule of the combination square on the saw

bed with the end of the rule butted against the blade

above the set of the saw teeth. Use a 1-1/2 thousandths

(.0015") shim and slide it along the top and the bottom

edge of the rule where it meets the saw blade. If the

shim slides between the blade and the rule at either the

top or bottom, the roller supports must be adjusted by

using the bottom Allen screws marked "C" and "D" to

obtain the correct 90° angle.

Adjust the side roller guides with the eccentric axle

until both rollers contact blade. When this adjustment

has been made, the roller should be adjusted so that

the PATH OF THE BLADE IS STRAIGHT and the

blade is not forced to curve around the rollers. The top

roller guide should be in contact with the top of the

blade at all times. When running idle, this contact

pressure should be very light

Blade Guide Alignment

To properly align the saw blade for a straight and

accurate cut, do the following.

1. Check the stationary vise jaw. Make sure it is

square. To do this, place a combination square against

the vise jaw slot in the saw bed. Slide the square

toward the stationary vise jaw. Make the necessary

Wheel Pitch Adjustment

If the saw blade runs too low or off the wheels, or runs

too high and rubs the wheel flange, a wheel pitch

adjustment must be made. Loosen the blade before

making the following adjustments.

Idler Wheel

Blade running too low or off the wheel. Adjust the Idler

Wheel Block. Loosen one-half [112] turn the two cap

screws in the block closest to the take-up screw end.

Tighten by one-half turn [112] the two cap screws in the

opposite end of the block. Repeat if more adjustment is

necessary.

Blade running too high and running against the Idler

Wheel Flange. The blade can become distorted, its top

edge rolled over and the wheel flange will wear excessively. To correct this, loosen by one-half [112] turn the

two cap screws opposite the take-up screw on the wheel

block. Tighten the two cap screws closest to the

7

take-Up screw end. Repeat if necessary.

Drive Wheel:

Blade running too low or off the drive wheel.

Loosen the two cap screws closest to the motor

end of the wheel plate by one-half [1/2] turn.

Tighten the two hollow-head screws at the same

end by one-half [1/2] turn. Repeat if more

adjustment is necessary.

Preventive Maintenance

Caution:

emergency STOP button before performing any

maintenance. DO NOT service the Dash Pot unless

the frame is in the Down position or resting on a

mechanical stop, such as a block of wood.

Daily

Disconnect the electrical supply and press

Make certain that all screws are tight after

adjustments have been made.

Gear Box Repair

1. Remove gear box from saw.

2. Remove four machine screws holding gear box

together.

3. Separate gear box by carefully prying castings

apart at a location near pulley shaft. Caution: Do not

use excessive force!

4. Once the gear box is open, the internal parts may

be inspected for wear.

5. Liquid plastic gasket is used to seal the gear case.

Use Loctite No. 51580 or equivalent.

Blade Brushes

Brushes should be cleaned frequently in kerosene

and reversed to take advantage of both rows of

bristles. For efficient cutting, replace worn blade

brushes. In replacing brushes, be sure bristles are

bent in the direction the blade travels.

1. Keep the saw clean and free of chips.

2. Maintain the coolant level and keep the coolant

tank and filter clean of chip accumulation or sludge.

Monthly

1. Check, adjust and replace blade brush as needed.

2. Lubricate drive gears.

3. Inspect guides and bearings.

4. Inspect drive belt.

5. Clean coolant tank and filter as needed.

Annually

1. Check hydraulic oil level.

2. Replace guide rollers.

3. Inspect gear box. Lubricate as needed.

Lubrication

Correct and adequate lubrication is a very important

factor in determining the life and service of your

Wellsaw. It is essential that all dust, dirt, chips, etc. be

thoroughly removed before lubricating the saw. The

following lubrication recommendations cover usual

saw applications. Heavy use and hostile environments

may indicate more frequent lubrication for best saw

performance.

Switch

A "Stop-Start" switch across the line controls the

motor. A heater coil breaks the circuit if an overload

occurs. Allow time for the coil to cool before restarting

the saw. An automatic shut-off operates when the saw

frame contacts a limit switch. Low voltage protection is

provided by the magnetic starter. A separate switch

controls the automatic coolant system.

Vise Screw, Ring Gear, Drive Pinion

1. Inspect monthly.

2. Use anti-seize on vise screw.

3. Use Extreme Pressure Open Gear Lube sparingly

on Ring Gear and Drive Pinion.

Gear Case

1. Inspect after 3 years (6,000 hours).

2. Use Mobilgrease XHP 220 or equivalent.

3. Viscosity: Heavy grease, drop point 550 EF.

4. Military Specification: None.

Loading...

Loading...