Wellsaw 1316S User Manual

Fully Automatic Bandsawing

with Conversational Set-Up,

Active Hydraulic Cutting

Force Control, True Swivel

Head for Miter Angles

1316S - Auto

MODEL

Fully Automatic

Bandsaw with Miter Head

Operating Manual

Built better to work stronger and last longer

REV 130610

File Name: S:\Master Parts Manuals\New scanned manuals MLS\1316S-Auto Operating Manual.indd

Shown with Optional

Bundle Clamp System

2829 N. Burdick St. Kalamazoo, MI 49004

Phone: 269-345-1132 Fax: 269-345-0095

ick St. Kalamazoo, MI 49004

www.wellsaw.com

TABLE OF CONTENTS

1316S-Auto Specifi cations ........................................2

1316S-Auto Components ..........................................2

Safety Instructions .....................................................3

Warranty Information .................................................5

Receiving and Installation..........................................5

Machine Overview .....................................................6

Trouble Shooting .......................................................8

Cutting Force Feature...............................................10

Specifi cations

Capacity

@ 0° (90°)

@ 45°

@ 60°

Blade Size 1" x .035" x 12'6" (150")

Blade Speeds Infi nitely Variable 60-420 SFPM

Blade Guides Carbide Guides with Rollers

Blade Tension Double Die Spring with Indicator

Electrical Options 230/3 (See Options for Other Volt-

Coolant System Tank Capacity 8 Gallons

Vise Control Quick Positioning/Air Powered

Feed Rate Control Variable Positive Hydraulic with

Cutting Force

Control

Jobs Storage 99

Band Wheels 15" Diameter Cast Iron

Barfeed Projection 25" Unlimited Indexes

Barfeed Accuracy +/- .002"

Barfeed Remnant 10"

Barfeed Length 5'

Weight Capacity 3,000 Lbs.

Bed Height 35"

Floor Area 90"W x 120"L

Shipping Weight 3,100 Lbs.

Round | Rectangular

13" | 13"H x 16"W

12" | 13"H x 12"W

7-1/2" | 8-1/2"H x 7-1/2"W

ages)

Submersible Pump 115V/.6 Amp/3

GPM

Sawing Force Control

30-120 Lbs.

Auto Quick Start Guide .............................................12

Review of Control Panel Buttons & Operation..........13

The Six Control Screens...........................................15

Manual Operation .....................................................18

Automatic Operation .................................................18

Electrical Maintenance Notes ...................................19

General Operating Information .................................20

Blade Selection Guide ..............................................22

1316S-Auto Components

• Square D® Programmable Machine Controller with

Membrane Keypad and LCD display

• Square D® Vector Type Frequency Motor Controller

• Baldor® 5hp TEFC Blade Drive

• Baldor® 3/4hp Hydraulic Motor

• Textron/Cone Drive® Double Enveloping Gearbox

• Vickers® Hydraulic Valves

• Wellsaw Tiger-Tooth® Bi-Metal Blade

• Active Hydraulic Cutting Force Control

• Encoder Type Barfeed

• Blade Break/Stall Proximity Switch

• Working Light with Transformer

• Unitized Base Design (Saw and Barfeed) with Integral

Fork Pockets

• Out of Stock Shutdown

• Self Centering Shuttle Carriage with Anti-Climbing

Vises

• Discharge Table & Shute

• Spring-Loaded Carbide Guides with Rollers

• 8 Gallon Flood Coolants System with Sample/Start-Up

Coolant

• Full Surround Chip Pan

• Powered Blade Brush

• 110 Volts at Controls

• Overload and Undervoltage Protection

• Precision Ground Beds and Discharge Table

• Auto Shut-Off at End of Cut

• OSHA Blade Guarding

• Low Air Pressure Safety Switch

• NFPA Electrics (with Fused Disconnect)

• Flush Hose

Key Features

Fully Automatic Bandsawing | Conversational

Set-Up

and Multiple Job Programing

Compensation

Cutting Force Control System

Wellsaw® | 2829 N. Burdick Street | Kalamazoo, MI 49004 | Phone: 269-345-1132 | Fax: 269-345-0095 | Web: www.wellsaw.com

| Encoder Type Barfeed | Quick Set- Up

| Automatic Kerf

| Machine Diagnostics | Hydraulic

Available Factory Options

Overhead/Bundle Clamping | Transformer for

460 Volt Operation

Vise Pressure

Non-Powered Conveyors

Lubrication Systems

| Chip Conveyor | Variable

| Laser Line Pointer | 5' and 10'

| Oil Injection Type

| Hour Meter

2

Safety Instructions

1. Always wear protective eye wear when operating machinery.

Eye wear shall be impact resistant, protective safety glasses

with side shields which comply with ANSI Z87.1 specifi cations.

Use of eye wear which does not comply with ANSI Z87.1 specifi cations could result in severe injury from breakage of eye

protection.

2. Keep hands in sight and clear of all moving parts and cutting

surfaces.

3. Wear proper apparel. No loose clothing or jewelry which can

be caught in moving parts. Rubber soled footwear is recommended for best footing.

4. Do not overreach. Failure to maintain proper working position

can cause you to fall into the machine or cause your clothing to

get caught - pulling you into the machine.

5. Keep guards in place and in proper working order. Do not operate the machine with guards removed.

6. Avoid dangerous working environments. Do not use stationary machine tools in wet or damp locations. Keep work areas

clean and well lit. Special electrics should be used when working on fl ammable materials.

7. Avoid accidental starts by being sure the start switch is “OFF”

before plugging in the machine.

8. Never leave the machine running while unattended. Machine

shall be shut off whenever it is not in operation.

9. Disconnect electrical power before servicing. Whenever

changing accessories or general maintenance is done on the

machine, electrical power to the machine must be disconnected before work is done.

10. Maintain all machine tools with care. Follow all maintenance

instructions for lubricating and the changing of accessories.

No attempt shall be made to modify or have makeshift repairs

done to the machine. This not only voids the warranty but also

renders the machine unsafe.

11. Secure work. Use clamps or a vise to hold work when practical. It is safer than using your hands and it frees both hands to

operate the machine.

12. Never brush away chips while the machine is in operation.

13. Keep work area clean. Cluttered areas invite accidents.

14. Remove adjusting keys and wrenches before turning the machine back on.

15. Use the right tool. Don’t force a tool or attachment to do a job

it was not designed for.

16. Use only recommended accessories and follow manufacturer’s

instructions pertaining to them.

17. All visitors should be kept at a safe distance from the work

area. Make workshop completely safe by using padlocks,

master switches, or by removing starter keys.

18. Know the tool you are using - its application, limitations, and

potential hazards.

19. Some dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paints

• Crystalline silica from bricks and cement and other ma-

sonry products, and

• Arsenic and chromium from chemically treated lumber.

20. Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved safety equipment, such as dust masks that are specifi -

cally designed to fi lter out microscopic particles.

General Electrical Cautions

This saw should be grounded in accordance with the National Electrical Code and local codes and ordinances. This work should be

done by a qualifi ed electrician. The saw should be grounded to

protect the user from electrical shock.

Wire Sizes

Caution: for circuits which are far away from the electrical service

box, the wire size must be increased in order to deliver ample voltage to the motor. To minimize power losses and to prevent motor

overheating and burnout, the use of wire sizes for branch circuits or

electrical extension cords according to the following table is recommended:

Conductor

Length

0-50 feet

50-100 feet

Over 100 feet

AWG (American Wire Gauge) Number

240 Volt lines 120 Volt lines

No. 14 No. 14

No. 14 No. 12

No. 12 No. 8

3

Safety Instructions

Misuse of this machine can cause serious injury.

For safety, this machine must be set up, used and properly serviced.

Read, understand and follow instructions in the Parts and Maintenance manual.

DISCONNECT POWER before adjusting or servicing the saw or

changing a blade.

STAY CLEAR of all moving parts. Keep hands and fi ngers away

form the saw blade.

WHEN MOVING SAW, with hinged frame (saw head), secure the

head in its down position.

WHEN CUTTING MAGNESIUM, take special precautions. Use a

sharp saw blade, make only dry cuts, prevent chip accumulation,

and keep fi re-fi ghting equipment nearby.

THIS SAW SHOULD BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM ELECTRICAL SHOCK.

CORD CONNECTED TOOLS. If the saw is equipped with an ap-

proved 3-conductor cord and a 3-prong grounding type plug, it

should only be connected to a properly equipped and grounded

receptacle. The green conductor in the cord is the grounding wire.

Never connect the green wire to a live terminal.

Use only a 3-wire extension cord having a 3-pronged receptacle, a

3-pronged plug and ample amperage rating. Replace or repair a

damaged or worn cord immediately.

PERMANENTLY CONNECTED TOOLS. The saw should be connected to a grounded, metal-enclosed wiring system or an equipment-grounding conductor should be run with the circuit conductors and connected to the saw’s grounding terminal or lead.

To reset the manual starter after a power interruption, return the

switch to OFF and press the RESET button before restarting.

KEEP GUARD IN PLACE and in working order.

REMOVE ADJUSTING KEYS AND WRENCHES. Form a habit.

Check to see that all keys and wrenches are removed from the tool

before turning the tool on.

KEEP WORK AREA CLEAN. Cluttered areas and benched invite

accidents.

A VOID DANGEROUS ENVIRONMENT. Do not use power tools in

damp or wet locations. Keep your work area well lighted.

KEEP CHILDREN AWAY. All visitors should be kept a safe distance from work area.

MAKE WORKSHOP KID-PROOF with padlocks, master switches,

or by removing starter keys form tools.

DON’T FORCE TOOL. It will do the job better and safer at the rate

for which it is designed

4

USE RIGHT TOOL. Don’t use a tool a or attachment to do a job for

which it was not designed.

WEAR PROPER APPAREL. No loose clothing or jewelry to get

caught in moving parts. Rubber-soled footwear is recommended

for best footing.

USE SAFETY GLASSES. Also use face or dust mask if operation

is dusty.

SECURE WORK. Use clamps or a vise to hold work. Provide

adequate support to prevent injury from falling work pieces.

MACHINE SET UP

• Always avoid using machine in damp or poorly lighted work

areas.

• Always be sure machine is securely anchored to the fl oor

• Always keep machine guards in place.

• Always put start switch in “OFF” position before plugging in

machine.

MACHINE USE

• Never operate with machine guards missing.

• Always wear safety glasses with side shields (See ANSI

Z87.1)

• Never wear loose clothing or jewelry.

• Never overreach - you may slip into the machine.

• Never leave machine running while away from it.

• Always shut off the machine when not in use.

MACHINE SERVICING

• Always unplug machine from electrical poser while servicing.

• Always follow instructions in Parts and Maintenance manual

when changing accessory tools or parts.

• Never modify the machine.

Read and follow these simple rules for best results and full benefi ts from your machine. Used properly, WELLSAW’s machinery

is among the best in design and safety. However, any machine

used improperly can be rendered ineffi cient and unsafe. It is ab-

solutely mandatory that those who use our products be properly

trained in how to use them correctly. They should read and understand the Parts and Maintenance manual as well as all labels

affi xed to the machine. Failure in following all of these warnings

can cause serious injury.

FULL YEAR LIMITED WARRANTY

This WELLSAW is warranted against defects in material or workmanship installed or performed at the factory. Within one year from date

of purchase, we will free of charge and at our option, either repair or replace any part of this WELLSAW which our examination discloses

to be defective because of workmanship or a defect in the material. This warranty does not apply if this WELLSAW has been used in a

manner not consistent with its’ design or which has been subject to accident, alteration, abuse or misuse or which fails due to lack of care

or is the result of inadequate power supply and specifi cally does not apply to normal wear parts. THERE ARE NO WARRANTIES WHICH

EXTEND BEYOND THE DESCRIPTION OF THE FACE HEREOF.

WELLSAW shall not be liable for consequential or incidental damages suffered or incurred with respect to defective materials or workmanship.

We do not authorize any person or representative to make any other warranty or to assume for us any liability in connection with the sale

of our products other than those contained herein. Any agreements outside of or contradictory to the foregoing shall be void and of no

effect.

All transportation costs on products or parts submitted to WELLSAW under this warranty must be paid by the user. No products or parts

are to be returned without fi rst obtaining permission.

RECEIVING AND INSTALLATION

Un-crating

Carefully remove the protective crating and skid so the saw and its parts are not marred or otherwise damaged. In the event of damage

in transit, notify the carrier and fi le a Proof of Loss Claim immediately.

Shortages

Inspect the complete shipment carefully against the itemized packing list. Make sure that all items are present and in good condition. In

the event of any shortage, notify the distributor from whom you purchased the saw and the carrier who made the fi nal delivery.

Utility Hook-Up

The use of a qualifi ed electrician is always recommended when connecting the saw to the main power supply. Electrical codes differ from

area to area and it is the customer’s responsibility to ensure that their saw complies with applicable codes. Your WELLSAW is pre-wired

at the factory for a specifi ed voltage. Always check the motor and electrical panel to ensure that they are both wired to correspond to

your electrical power supply.

PARTS ORDERING

When contacting your WELLSAW Supplier of the Company for parts or service, it is essential that you have

your MODEL NUMBER, SERIAL NUMBER and PURCHASE DATE available. Jot them down here for handy

reference.

SERIAL NUMBER:

PURCHASE DATE:

MODEL:

5

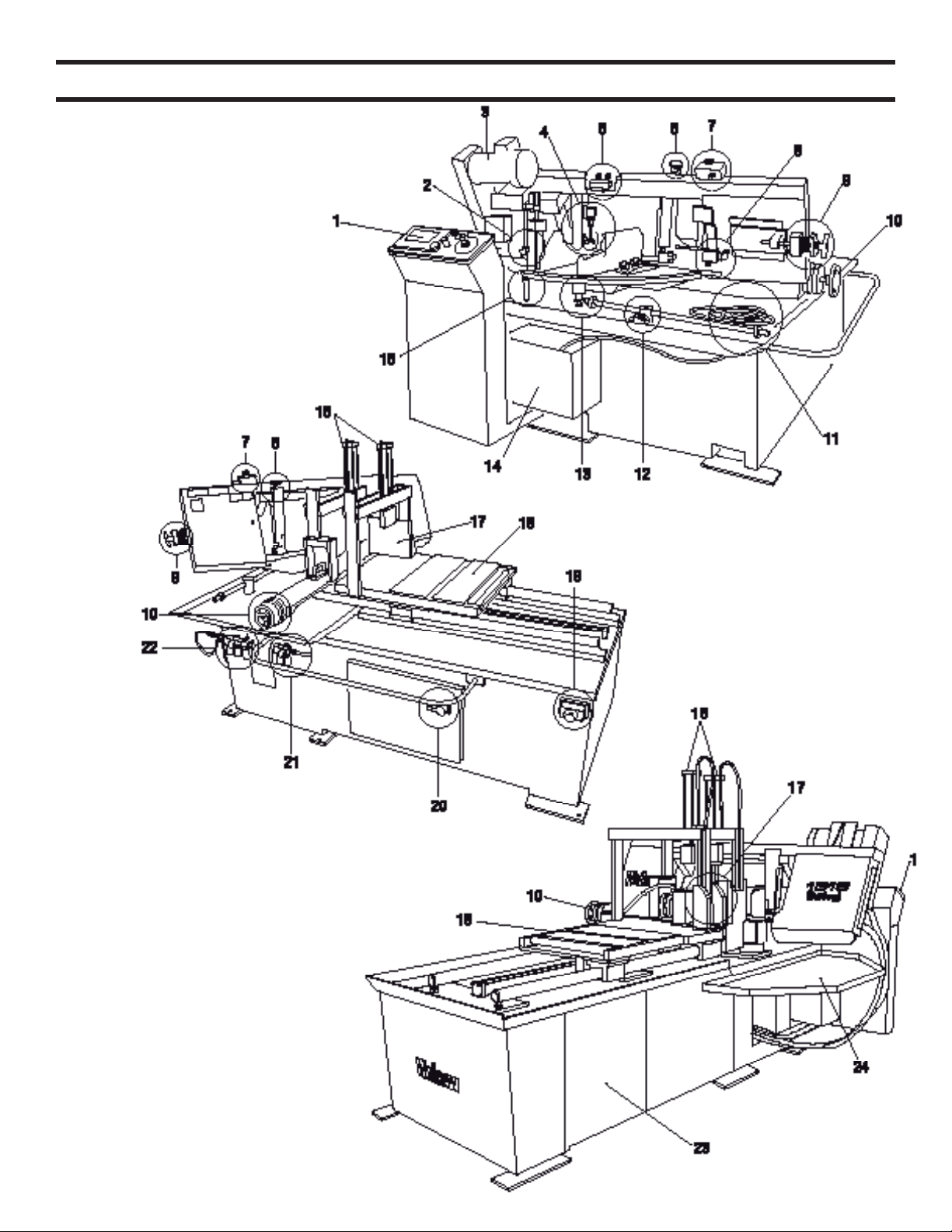

MODEL 1316S-AUTOMATIC OVERVIEW

1 Control Panel

2 Frame Height Adjustment

3 Blade Motor

4 Metering Valve

5 Coolant Manifold

6 Blade Guide

7 Emergency Stop

8 End of Cut Switch

9 Blade Tensioner

10 Air Vise Cylinder

11 Coolant Hose

12 Table Lock

13 Table Swivel

14 Coolant Tank & Pump

15 Pointer

16 Holddown Clamps

17 Stationary Vise

18 Shuttle Table

19 Emergency Stop

20 Electrical Disconnect

21 Regulator

22 Filter Regulator Lubricator

23 Hydraulics (inside)

24 Chip Pan

6

MODEL 1316S-AUTOMATIC OVERVIEW

MANAGED FROM THE CONTROL PANEL

• Length of Cut

• Number of Cuts

• Blade Motor Start, Stop and Band Speed

• Saw Head Raise, Lower, or Stop

• Clamp and Unclamp both Vise Jaws

• Move Shuttle Carriage Forward or Return

• Automatic or Manual Sawing Mode

• Feed Rate Control

MANAGED BY THE OPERATOR

With stock placed on the infeed conveyor and against

the blade, adjustments can be readily made to:

• Position of both Vise Jaws

• Height of Saw Head when raised

• Position of Moveable Blade Guide

• Swivel of Saw Head (if making miter cut)

• Sawing Force Control and Feed Rate Control

• Rate of Coolant Flow to each Blade Guide

• Blade Tension (when changing blade)

7

Loading...

Loading...