Wellsaw 1016 User Manual

Parts List

4

1016

MODEL

Manual Bandsaw

and

Built better to work stronger and last longer

Operating & Maintenance Manual

REV 140320

Rev 4-13

2829 N. Burdick St. Kalamazoo, MI 49004

Phone: 269-345-1132 Fax: 269-345-0095

rdick St. Kalamazoo, MI 4900

www.wellsaw.com

FORWARD

The Model 1016 Wellsaw has been designed and manufactured to conform to Wellsaw's

recognized high standards of quality and performance. Each saw must pass a series of

final inspection tests, including actual metal cutting operations, before it is shipped. For this saw

to provide satisfactory service, it is necessary that it be properly installed, operated and

maintained. This manual has been prepared to assist you in carrying out these functions. We

urge you to study this manual and follow its suggestions.

RECEIVING AND INSTALLATION

Un-crating

Carefully remove the protective crating and skid so the saw and its parts are not marred or

otherwise damaged. In the event of damage in transit, notify the carrier and file a Proof of Loss

Claim immediately.

Shortages

Inspect the complete shipment carefully against the itemized packing list. Make sure that all

items are present and in good condition. In the event of any shortage, notify the distributor from

whom you purchased the saw and the carrier who made final delivery.

Utility Hook-Up

The use of a qualified electrician is always recommended when connecting the saw to the main

power supply. Electrical codes differ from area to area and it is the customer’s responsibility to

ensure that their saw complies with applicable codes. Your Wellsaw is pre-wired at the factory

for a specified voltage. Always check the motor and electrical panel to ensure that they are both

wired to correspond to your electrical power supply.

Parts Ordering

For your convenience:

When contacting your Wellsaw Supplier or the Company for parts or service,

it is essential that you have your Model, Serial Number and Purchase Date

available. Jot them down here for handy reference.

Model: 1016

Serial Number:________________

Purchase Date:________________

1

WARNING

- Misuse of this machine can cause serious injury.

- For safety, machine must be set up, used and serviced

properly.

- Read, understand and follow instructions in the

operator’s and parts manual.

When setting up machine:

- Always avoid using machine in damp or poorly lighted

work areas.

- Always be sure machine is securely anchored to the

floor.

- Always keep machine guards in place.

- Always put start switch in “OFF” position before

plugging in machine.

When using machine:

- Never operate with machine guards missing.

- Always wear safety glasses with side shields (See

ANSI Z87.1)

- Never wear loose clothing or jewelry.

- Never overreach - you may slip and fall into the

machine.

- Never leave machine running while away from it.

- Always shut off the machine when not in use.

When servicing the machine:

- Always unplug machine from electrical power while

servicing.

- Always follow instructions in operators and parts

manual when changing accessory tools or parts.

- Never modify the machine.

Read and follow these simple rules for best results and

full benefits from your machine. Used properly,

Wellsaw’s machinery is among the best in design and

safety. However, any machine used improperly can be

rendered inefficient and unsafe. It is absolutely

mandatory that those who use our products be properly

trained in how to use them correctly. They should read

and understand the Operators and Parts manual as well

as all labels affixed to the machine. Failure in

following all of these warnings can cause serious

injuries.

Machinery general safety warnings

1. Always wear protective eye wear when operating

machinery. Eye wear shall be impact resistant, protective

safety glasses with side shields which comply with ANSI

Z87.1 specifications. Use of eye wear which does not comply

with ANSI Z87.1 specifications could result in severe injury

from breakage of eye protection.

2. Wear proper apparel. No loose clothing or jewelry which

can get caught in moving parts. Rubber soled footwear is

recommended for best footing.

3. Do not overreach. Failure to maintain proper working

position can cause you to fall into the machine or cause your

clothing to get caught - pulling you into the machine.

4. Keep guards in place and in proper working order. Do not

operate the machine with guards removed.

5. Avoid dangerous working environments. Do not use

stationary machine tools in wet or damp locations. Keep work

areas clean and well lit. Special electrics should be used when

working on flammable materials.

6. Avoid accidental starts by being sure the start switch is

“OFF” before plugging in the machine.

7. Never leave the machine running while unattended.

Machine shall be shut off whenever it is not in operation.

8. Disconnect electrical power before servicing.

changing accessories or general maintenance is done on

the machine, electrical power to the machine must be

disconnected before work is done.

Whenever

9. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and the changing of

accessories. No attempt shall be made to modify or have

makeshift repairs done to the machine. This not only voids

the warranty but also renders the machine unsafe.

10. Secure work. Use clamps or a vise to hold work when

practical. It is safer than using your hands and it frees both

hands to operate the machine.

11. Never brush away chips while the machine is in

operation.

12. Keep work area clean. Cluttered areas invite accidents.

13. Remove adjusting keys and wrenches before turning the

machine back on.

14. Use the right tool. Don’t force a tool or attachment to do

a job it was not designed for.

15. Use only recommended accessories and follow

manufacturers instructions pertaining to them.

16. Keep hands in sight and clear of all moving parts and

cutting surfaces.

17. All visitors should be kept at a safe distance from the

work area. Make workshop completely safe by using

padlocks, master switches, or by removing starter keys.

18. Know the tool you are using - its application, limitations,

and potential hazards.

2

19. Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains chemicals

known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

General Electrical Cautions

This saw should be grounded in accordance with the National

Electrical Code and local codes and ordinances. This work

should be done by a qualified electrician. The saw should be

grounded to protect the user from electrical shock.

-Lead from lead based paint

-Crystalline silica from bricks and cement and other masonry

products, and

-Arsenic and chromium from chemically treated lumber

20. Your risk from those exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with

approved safety equipment, such as those dust masks that are

specifically designed to filter out microscopic particles.

Safety instructions on sawing systems

1. Always wear leather gloves when handling a saw blade.

The operator shall not wear gloves when operating the

machine.

2. All doors shall be closed, all panels replaced, and all other

safety guards in place prior to the machine being started or

operated.

3. Be sure that the blade is not in contact with the workpiece

when the motor is started. The motor shall be started and you

should allow the saw to come to full speed before bringing the

workpiece into the saw blade.

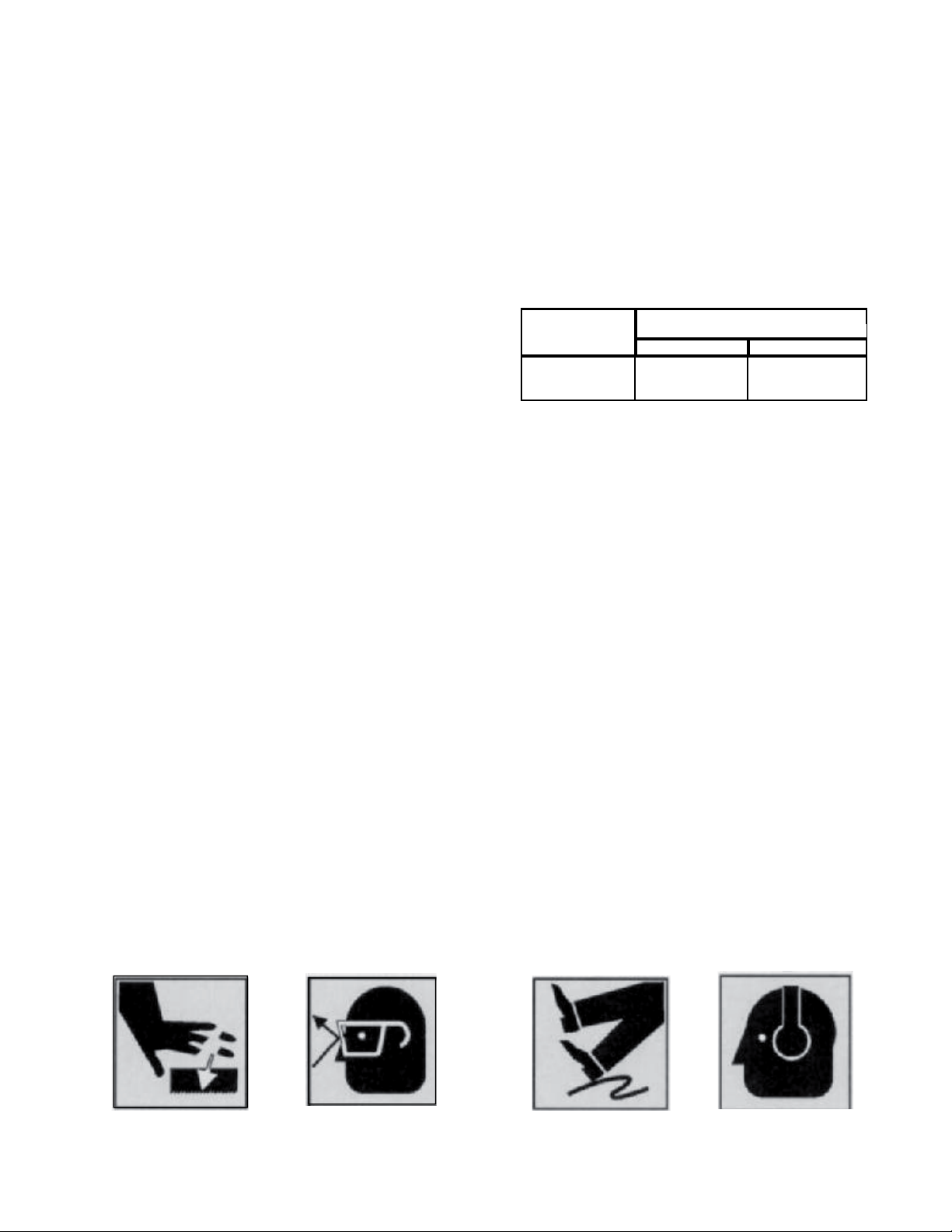

4. Keep hands away from the blade area. See figure A.

5. Remove any cut off piece carefully while keeping your

hands free from the blade area.

6. Saw must be stopped and electrical supply must be cut off

before any blade replacement or adjustment of blade support

mechanism is done, or before any attempt is made to change

the drive belts or before any periodic service or maintenance is

performed on the saw.

7. Remove all loose items and any unnecessary work pieces

from the area before starting machine.

8. Bring adjustable saw guides and guards as close as possible

to the work piece.

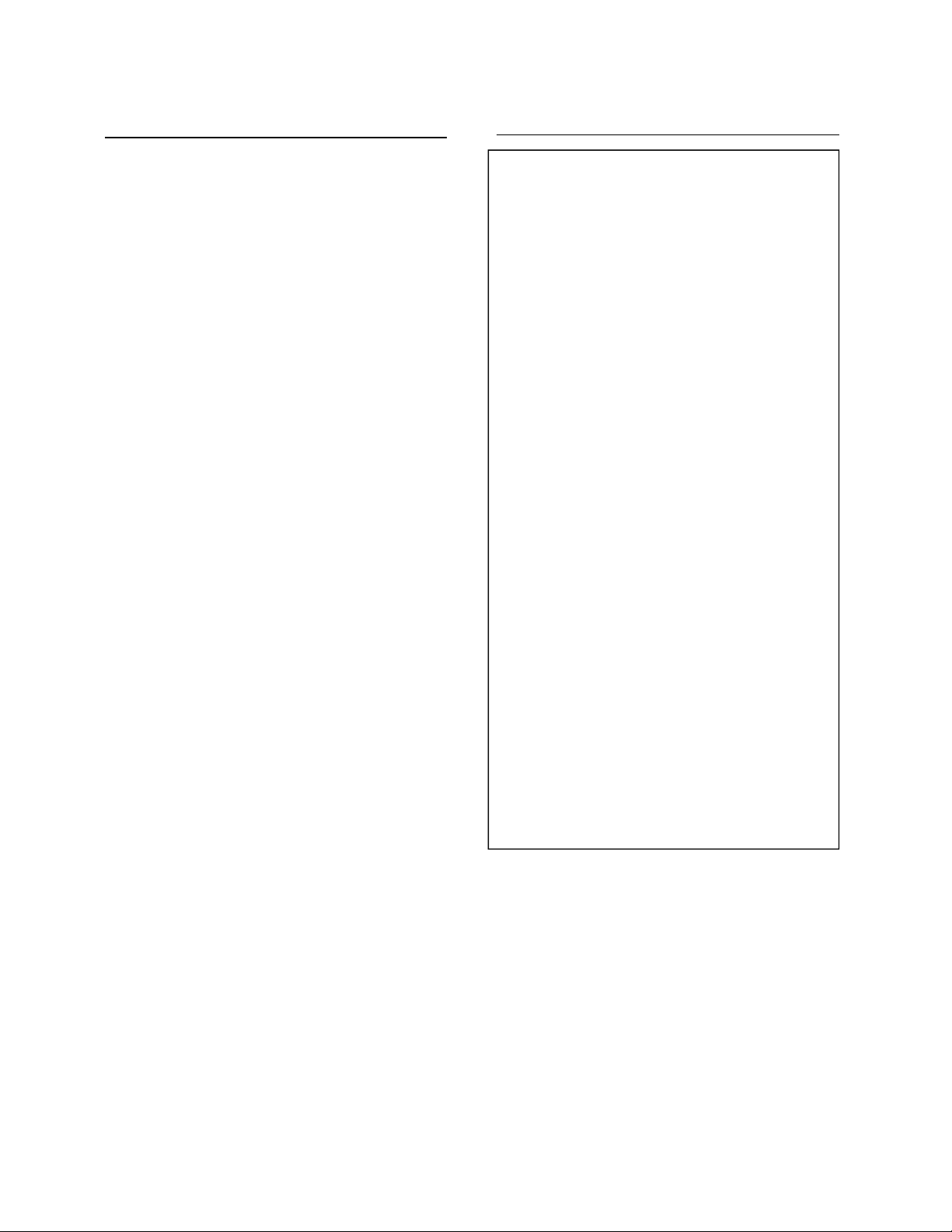

Wire sizes:

Caution: for circuits which are far away from the electrical

service box, the wire size must be increased in order to deliver

ample voltage to the motor. To minimize power losses and to

prevent motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords according to

the following table is recommended:

Conductor Length AWG (American wire gauge) number

240 volt lines 120 volt lines

0-50 feet No. 14 No. 14

50-100 feet No. 14 No. 12

Over 100 feet No. 12 No. 8

9. Always wear protective eye wear when operating, servicing

or adjusting machinery. Eye wear shall be impact resistant,

protective safety glasses with side shields complying with

ANSI Z87.1 specifications. Use of eye wear which does not

comply with ANSI Z87.1 specifications could result in severe

injury from breakage of eye protection. See figure B.

10. Non-slip footwear and safety shoes are recommended. See

figure C.

11. Wear ear protectors (plugs or muffs) during extended

periods of operation. See figure D.

12. The workpiece, or part being sawed, must be securely

clamped before the saw blade enters it.

13. Remove cut off pieces carefully, keeping hands away

from saw blade.

14. Saw must be stopped and electrical supply cut off or

machine unplugged before reaching into cutting area.

15. Avoid contact with coolant, especially guarding your

eyes.

Figure A Figure B

Figure C Figure D

3

Index

General

Automatic Stop 6

Blade Brushes 9

Blade Selection Guide 36-37

Feed Pressure Adjustment 7

Fixed Vise Jaw 7

Gear Box Repair 9

Hydraulic Feed Control 7

Lubrication 10

Maintenance 10

Motor Switch 9

Notes on Sawing 5

Placing Blade on Saw 7

Receiving & Installation 1

Safety Instructions 2-3

Service Kits 10

Servicing Blade Guides 8

Sliding Vise Jaw 7

Specifications 4

Trouble Shooting 5

Variable Speed Drive 7

Warranty 11

Wheel Pitch Adjustment 9

Machine Operation 12

Drawings

Frame Assembly 13

Bed Assembly 15

Blade Guide Assembly (up to S/N 2499) 17

Guide-A-Matic Assembly 17

Carbide Guide Option (up to S/N 2499) 19

Blade Guide Assembly (S/N 2500 on) 21

Coolant System 23

Leg & Chip Pan 23

Rite Tensioning Device® 25

Hydraulic System 27

Motor & Gear Box 29

Variable Speed Drive 31

Electrical Controls 33

Parts Lists & Part Numbers

Frame Assembly 14

Bed Assembly 16

Blade Guide Assembly (up to S/N 2499) 18

Guide-A-Matic Assembly 18

Carbide Guide Option (up to S/N 2499) 20

Blade Guide Assembly (S/N 2500 on) 22

Coolant System 24

Leg & Chip Pan 24

Rite Tensioning Device® 26

Hydraulic System 28

Motor & Gear Box 30

Variable Speed Drive 32

Electrical Controls 34

Specifications

Capacity:

Round 10½”

Flat 16½”

Rectangular 10" x 16"

45 10" x 9"

Blade Speeds 50-100-175-275 SFPM

Motor

2hp 208-230/460/60/3

6.5 - 6.2 - 3.1 amps

2hp 115 - 230/60/1

24 - 12 amps

Drive V-Belt

Blade Size 1" x .035 x 11'6"

Height to top of Bed 29"

Coolant Tank Capacity 8 gallons, 170 GPH

.6 Amp/115 Volt

Floor Space 30" wide x 84" long

Vise Control Manual Screw

Swivel Vise To 45

Blade Tension Manual Rite Tension®

Feed Rate Control Variable, Hydraulic

Band Wheels 15" Diameter Cast Iron

Shipping Weight 900 Lbs.

Options Available:

Variable Speed Blade Drive (70-375 SFPM)

Casters (set of 4, 2 locking)

NFPA or JIC Electrics (w/disconnect)

Totally Enclosed Motor

Work Light

Stock Stand

5' or 10' Non-Powered Conveyor

4

Notes on Sawing

Trouble Shooting

It is widely recognized that a proficient operator is a key to

optimum bandsawing. He makes certain the machine is

properly maintained and adjusted for dependable operation.

He carefully sets up each cutting job to prevent damage to the

machine and obtain the best performance from the equipment.

Experienced blade dealers can be very helpful in selecting the

grade and proper tooth blade for each sawing job. All blades

should be straight, have sharp teeth with uniform set, and be

“broken in” at a reduced feed rate to obtain good cutting

performance and blade life.

Every cutting situation has special characteristics requiring

some experimentation to determine which blade, speed and

feed rate will achieve the most satisfactory result. Cutting

charts indicate a good starting point, but must be modified by

direct experience if optimum performance is desired.

Here are some helpful pointers for adjusting speed and feed

for good cutting performance.

1. Make sure the saw is cutting a good chip from the

workpiece.

.2. Watch for blue chips or excessive “smoke” indicating heat

in the cut which could damage the blade or work harden the

material being cut

3. Watch for excessive vibration or chatter marks on the cutoff piece indicating possible damage to the saw teeth by

“hammering”.

4. Check the cut-off piece for flatness. A dull blade or

excessive feed will produce a “belly” in the cut.

5. Inspect the blade for worn, rounded or shiny cutting edges.

Avoid force cutting which will allow chips to “weld” to saw

teeth and eventually cause the teeth to be stripped off the

blade.

6. When experimenting, start with a slow speed and feed rate.

Gradually increase blade speed and then feed pressure by

small amounts until adverse effects are noted. You can then

set the speed and feed at a reasonable level for continuous

cutting. Remember that blade speed and feed pressure must

be balanced to keep cutting a good chip.

Premature Dulling of Blade Teeth

1. Feed rate too high or low. Check recommendation.

2. Blade speed too slow or too fast.

3. Faulty material; heavy scale, hard spots, etc.

4. Verify material analysis.

5. If coolant flow is not covering saw teeth, increase

coolant flow rate.

6. If saw is vibrating in cut, reduce blade speed or increase

feed rate.

7. Chipped or broken tooth may be lodged in cut.

8. “Chip welding” caused by improper feed and speed.

9. Incorrect coolant mixture.

10. Incorrect blade selection

11. Improper break-in of new blade. New blades should be

run initially with reduced feed pressure for approximately

50 to100 square inches.

12. Saw blade teeth may be hitting blade guides. Check for

proper blade size.

Saw Blade Vibration

1. Incorrect blade speed for material.

2. Blade tension insufficient.

3. Back-up bearing may be worn.

4. Incorrect choice of saw tooth pitch.

5. Incorrect coolant mixture.

6. Incorrect feed setting. Increase feed.

7. Workpiece not firmly clamped in vice.

8. Worn or improperly adjusted saw guides. Check and

make necessary adjustments.

Blade Teeth Chipping or Ripping Out

1. Blade pitch too coarse. Use a fine pitch saw blade on

thin work sections.

2. Improper break-in of new blade. Do not start a new

blade in an old cut.

3. Work piece not held firmly enough. Clamp work

securely.

4. Introduce cooling if it is not being used.

5. Faulty material; scale or hard spots.

6. Blade gullets may be loaded. Use higher viscosity

lubricant or coolant.

7. Blade speed and feed may need adjustment.

5

Premature Blade Breakage

1. Poor weld in the blade.

2. Feed rate set too high. Reduce it.

3. Excessive blade speed. Adjust it.

4. Blade guides set too tight or misaligned.

5. Blade tension set too high.

6. Blade running against flange on wheels. Adjust

wheel pitch.

Blade Squeal

1. Feed rate too light for blade speed. Increase feed

rate and/or reduce blade speed.

Blade Slips Off Band Wheels

9. Dirty coolant.

10. Check for loose fasteners.

Rough Cut / Poor Finish

1. Excessive feed rate. See recommendations.

2. Blade too coarse. Use finer blade pitch.

3. Inadequate cutting fluid. Replace.

Blade Stalls in Work

1. Insufficient blade tension.

2. Excessive feed pressure.

3. Blade tooth spacing too coarse.

4. Motor worn or defective.

5. Guides too tight against blade.

1. Blade not tensioned correctly.

2. Wheel pitch not set properly.

3. Guides set too tight.

Gullets of Blade Teeth Loading

1. Blade pitch too fine. Review blade selection.

2. Incorrect blade speed. Consult cutting chart.

3. If not using coolant, apply it.

Chips Welding to Blade Teeth

1. Cutting rate too high.

2. Chip brush may be out of adjustment.

3. Check coolant and application.

Blade Becoming Scored

1. Saw guides may be worn. Check and replace if

necessary.

2. Too much pressure on saw guides. Adjust.

3. Guides may be out of alignment.

Blade Making Belly-Shaped Cut

1. Blade tension too light. Increase it.

2. Saw guides too far from work piece.

3. Blade pitch too fine. Use larger pitch and positive

rake tooth form.

4. Feed force too heavy. Decrease it.

Blade Does Not Track Properly

1. Set wheel pitch so that blade runs to wheel flange but

not against it.

2. Is blade tension correct?

3. Is back of blade riding against backup bearing? If not,

adjust it.

Motor Overheating

1. Check for correct voltage supply. Check voltage at

motor. Check magnetic starter heaters.

2. Check for loose electrical connections.

3. Does motor amp reading correspond to rating on

motor specifications tag?

4. Is internal motor wiring correct?

5. Is drive belt over tightened?

Operating Instructions

Cutting Tips

1. For longer blade life, start each cut carefully.

2. For new blades, reduce feed pressure on first two cuts

or about 100 square inches.

3. Keep blade guides as close to the vise jaws as possible.

4. Make sure all four legs of the saw are in solid contact

with the floor.

Inaccurate Cut-Off

1. Is conveyor or stock stand level with saw bed?

2. Insufficient blade tension.

3. Blade guides too far apart. Always set blade

guides as close to the piece as possible.

4. Blade may be dull. Check and replace if necessary.

5. Feed pressure too high. Reduce it.

6. Blade guides loose, worn or out of alignment.

7. Too many teeth-per-inch. Blade not cutting freely.

8. Chip brush not cleaning teeth properly.

Automatic Stop

When the blade has completed a cut through the material,

the saw frame drops onto a limit switch actuator which shuts

the motor off.

When changing a blade or doing any other maintenance or

repair,be sure the automatic stop is engaged and disconnect

the main power supply.

It is necessary to raise the saw frame to clear the limit switch

actuator before the saw can be started.

6

Dash Pot

Machines are equipped with a dash pot (frame check) for the

purpose of stabilizing downward travel of the saw frame,

thereby protecting the saw blade from damage. The action

of the dash pot is hydraulic and controlled by fluid being

passed through an orifice in the piston on the downward

stroke.

Fill withing 1" of the top of the bottom cylinder with Mobil

Velocite Oil #6 or equivalent.

Frame Weight Adjustment

Before adjusting the frame spring at motor end, remove the

hydraulic dash pot and move the sliding weight to the rear

position (motor end). The frame spring should be adjusted

for approximately 16 pounds of weight at the frame handle.

Too much frame weight will cause the blade to make

crooked cuts!

Feeding Pressure

For saws before S/N 3319 feed pressure is varied by moving

the weight on the top side of the frame. Blade pressure

increases as the weight is moved toward the open end of the

saw. For saws starting at S/N 3319 feed pressure is varied

by turning the needle valve mounted on the side of the

dashpot cylinder. Excessive pressure may cause a run-out

of the blade (see Feed & Speed chart for recommendations).

Hydraulic Feed Control

speed or counter-clockwise to decrease speed. Do not adjust

the speed unless the pulley system is in operation (spinning).

The handwheel drag is set at the factory during assembly.

This drag prevents handwheel “creep” during operation but

still permits easy adjustment. Due to normal wear and

environment, the drag setting may change. To readjust,

tighten set screw in thrust nut.

Belt

Pivoted mounting provides for quick belt change. With the

belt in pulley grooves for the desired speed, swing motor to

put proper tension in the belt. Tighten thumb screw to hold

motor in proper operating position.

Fixed Vise Jaw

The two pins in the fixed vise jaw should be kept in place in

order to ensure square cuts. For cutting angles, the pins must

be removed and the turned to the desired position and

tightened with clamp bolts. These pins enable operators to

quickly relocate the fixed vise jaw for approximate 90

cutting. For final, accurate cutting, the fixed vise jaw should

be squared with the blade. (See Guide Alignment)

Sliding Vise Jaw

The sliding vise jaw is fitted with a lift plate and ratchet dog

for quick action. A hand wheel tightens the vise on the

workpiece. Excessive pressure is not required to hold

workpiece securely.

The feed rate is hydraulically controlled with a needle

valve located on the side of the cylinder. Caution: Do not

attempt to loosen or remove hoses until the saw frame is

supported in its “Down” position.

Speed Selection

Saws are equipped with step pulleys providing blade speeds

of 50, 100, 175 and 275 feet-per-minute. High speeds are

suggested for cutting thin wall tubing, channels, aluminum,

brass or any metal that will not burn the blade teeth. Use

medium speed for general cutting such as cold rolled,

machine steels, heavy channels, etc. Run at low speed for

cutting nickel steels or any metal requiring a slow speed on

a lathe. When cutting brass, use a blade that has not been

used on other metals and apply beeswax to the teeth.

Variable Speed Drive

Model 1016 may be equipped with variable speed pulleys

providing infinite speed selection between 70 and 375 feetper-minute. See Cutting Speed Chart for settings.

To vary blade speed, rotate handwheel clockwise to increase

Maximum Capacity

To obtain maximum vise capacity, remove vise jaw pins and

move fixed vise toward motor end to the last two holes in the

bed. Make sure the stock in the vise will not strike the ratchet

arm.

Placing the Blade on Saw

1. Raise saw head part way.

2. Open idle and drive wheel guards.

3. Loosen Rite Tension® by turning “T” handle CounterClockwise (CCW) at least six (6) times. Gently pushing in on

the handle while turning will ensure that the device will reset

properly.

5. Open each carbide guide (if equipped). Reach behind each

blade guide assembly and turn the black knurled knob

Counter Clockwise (CCW) until it stops. This pulls the

carbide block away from the blade.

6. Remove the blade. Always wear gloves when handling

bandsaw blades.

7. Install the blade on the bandwheels making sure the teeth

are pointing in the direction of travel (toward the motor). If

not turn the blade inside out. Fit the blade into the guides and

close the carbides by turning the black knob clockwise until

7

it stops. It does not need to be tight. Be sure that the band

is not riding up on the bandwheel flange.

8. Begin tightening the Rite Tension® device by turning

“T” handle Clockwise (CW). Pull out on handle while

tightening. Spot check the blade to be sure that it does not

ride up on the bandwheel flanges. Continue to tighten. The

correct tension will be achieved when the “T” handle comes

to a hard stop.

9. Close all guards. Test run the saw. A new blade may

stretch a small amount after run-in. Repeat the loosen and

tighten procedure to eliminate this.

Maintenance Instructions

Servicing the Blade Guides

Up to S/N 2499

Blade Guide Alignment

Up to S/N 2499

To properly align the saw blade for a straight andaccurate cut,

do the following:

1. Check the stationary vise jaw. Make sure it is square. To

do this, place a combination square against the vise jaw slot

in the saw bed. Slide the square toward the stationary vise

jaw. Make the necessary adjustment. If you then find the saw

blade is not square with the stationary vise jaw, the blade

must be adjusted.

2. This adjustment is made with the top two socket headed

screws on the roller adjusting block of the guide arm.

Looking at the drawing (figure 2) you will see these adjusting

screws labeled “A” and “B”.

3. To make a vertical adjustment of the saw blade, so that the

cut is square from top to bottom, the blade must be set so that

it is perpendicular to the bed. In making this adjustment,

clean the saw bed first.

4. Set the rule of the combination square on the saw bed with

the end of the rule butted against the blade above the set of

the saw teeth. Use a 1½ thousandths (.0015") shim and slide

it along the top and the bottom edge of the rule where it meets

the saw blade. If the shim slides between the blade and the

rule at, either the top or bottom, the roller supports must be

adjusted by using the bottom socket head screws marked “C”

and “D” to obtain the correct 90 angle.

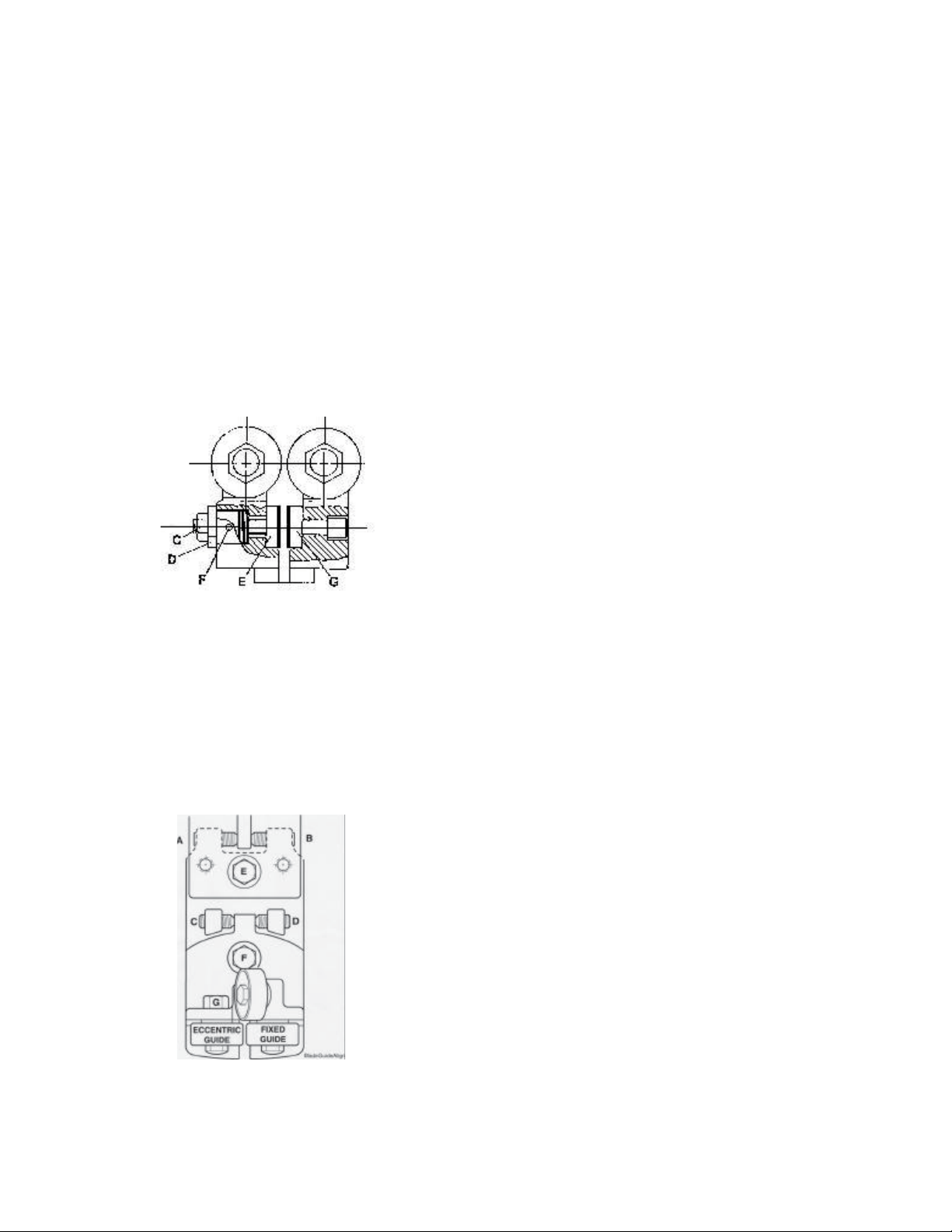

Figure 1

1. To adjust blade guide setting, loosen screw “F”.

2. Turn nut and stem assembly “C” clockwise to verify full

engagement of threads into guide “E”. If threads are not

fully engaged, item “C” will not turn. Caution: Do not use

excessive force when adjusting!

3. While holding nut and stem assembly “C” with a ½”

wrench, turn adjusting nut “D” with a ¾” wrench until

spacing guides “E” and “G” are set to .038. Set screw “F”

has a nylon tip to hold adjusting nut in place. Carbide guide

“G” is stationary and requires no adjustment.

Figure 2

Adjust the side roller guides with the Guide-A-Matic until

both rollers contact blade. When this adjustment has been

made properly, the PATH OF THE BLADE IS STRAIGHT

and the blade is not forced to curve around the rollers. The

top ball bearing should be in contact with the top of the blade

at all times. When running the saw at idle, this contact

pressure

should be light.

Blade Guide Adjustment

Starting S/N 2500

To properly align the saw blade for a straight and accurate cut,

do the following:

1. Square the stationary vise jaw. Make sure it is square to

the front of the vise slot. Check by placing a combination

square against the front of the vise slot in the saw bed. Slide

the square toward the stationary vise. Make any necessary

adjustment to the vise jaw to bring it into square. Set the

combination square so that one leg is along the face of the

stationary vise and check to see that the blade is square to the

vise jaw. If it is not square, follow the instructions for

horizontal adjustment.

2. Vertical Adjustment. The back of the saw blade should

just touch the carbide back up guide (item 15 in the parts

drawing) when the saw is running but not cutting. To adjust,

loosen the two cap screws [A] and move the block up or down

as required. (Before making this adjustment, be sure the back

of the blade is properly contacting the flange on both the drive

and idle wheels).

8

3. Horizontal Adjustment. Loosen the two cap screws [B]

securing the horizontal adjusting block (items 11 & 12 of the

parts drawing). Turn the top adjusting bolt (item 13 of the

parts drawing) to move the blade either in, toward the saw

bed, or out, away from the saw bed.

Normally, the blade comes off the Drive Wheel with a

minimum amount of adjustment needed in the Horizontal

Adjusting Block. The Idle End adjusting block is more

likely to require adjustment.

4. Blade Tilt. To ensure the blade is perpendicular to the

bed of the saw, loosen the two cap screw [C] holding the

Guide Support (28 & 29 of the parts drawing) and turn the

bottom adjusting bolt (13 of the parts drawing).

Set the combination square on the saw bed with the end of

the rule butted against the blade above the set of the teeth.

Use a 1-1/2 thousandths (.0015") shim and slide it along the

top and bottom edge of the rule where it meets the saw

blade. If the shim slides between the blade and the rule at

either the top or bottom, the blade guides must be adjusted.

5. Safety. Ensure that all bolts are properly tightened and

that all guards are in place before using the saw.

Wheel Pitch Adjustment

If the saw blade runs too low, runs off the wheels, or runs

too high and rubs the wheel flange, a wheel adjustment must

be made.

Loosen the blade before making the following adjustments.

Idler Wheel:

Blade running too low or off the wheelwheel block. Loosen the two cap screws in the block,

opposite the take up screw end, one-half (½) turn. Tighten

the opposite two cap screws one-half (½) turn. Repeat if

necessary.

adjust the idler

blade. To open the roller guide while inserting a new blade,

pull down on the knurled brass housing and rotate it. After

inserting the new blade, re engage the Guide-A-Matic by

pulling the knurled brass housing down and rotating it again

so that the mechanism closes and locks into posistion. (See

drawing and instructions on pages 17).

Gear Box Repair

1. Remove gear box from saw.

2. Remove four machine screws holding gear box

together.

3. Separate gear box by carefully prying castings apart at a

location near pulley shaft. Caution: Do not use excessive

force.

4. Once the gear box is open, the internal parts may be

inspected for wear.

5. Liquid plastic gasket is used to seal the gear case, Loctite

No. 51580 or equivalent.

6. Grease, Texaco Marfax ‘0' or equivalent is

recommended. The grease must have excellent clinging

characteristics. (See Lubrication).

Blade Brushes

Brushes should be cleaned frequently in kerosene and

reversed to take advantage of both rows of bristles.

For efficient cutting and blade life, keep blade brushes

adjusted so they are contacting blade teeth and replace them

when wore.

Motor Switch

Blade running too high and against the idler wheel flangeThe blade can become distorted, its top edge rolled over and

wheel flange will wear excessively.

To correct this, loosen the two cap screws closest to the take

up screw one-half (½) turn. Tighten the opposite cap screws

one-half (½) turn. Repeat if necessary.

Drive Wheel:

Blade running too low or off the drive wheeltwo cap screws opposite the outside end of the wheel plate

one-half (½) turn. Tighten the two set screws on the same

end one-half (½) turn. Repeat if necessary.

Blade running too high, and against the drive wheel flangeLoosen the cap screws closest to the outside end of the wheel

plate and loosen the two set screws at the same time by the

same amount. Repeat if necessary.

Make certain all screws are tight after adjustments have

been made.

Loosen the

Guide-A-Matic©

The Guide-A-Matic is a patented self-adjusting mechanism

that insures proper roller guide tension against the side of the

The “Start-Stop” motor starter is provided with heater coils

to de-energize the circuit if an overload occurs. Allow the

coil to cool before trying to restart the motor.

Low/No Voltage Control also de-energizes the circuit and

prevents automatic restarts after power is restored. Allow

the coil to cool.

To stop the saw at any time,

press the stop button or

press down on the limit switch actuator

Stock Stop Feature

The saw is equipped with an adjustable stock stop for use

when making repeated cuts of the same length. The stop

length is adjusted with the same type of lock used on the

saw head angle lock. The stop can be adjusted width-wise

using the “T” handle on the lower portion of the support.

The stop mechanism can also be swung completely out of

the way. To do this, loosen the “T” handle two turns, lift

up on the stop and let it down behind the saw.

9

Preventive Maintenance

4. Military Specification: None.

Caution: Disconnect the electrical supply and press

emergency STOP button before performing any

maintenance. DO NOT service the Frame Hydraulic

Cylinder or Down Feed Valve unless the frame is in the

DOWN position or resting on a mechanical stop, such as a

block of wood.

Daily

1. Keep the saw clean and free of chips.

2. Maintain the coolant level and keep the coolant tank and

filter clean of chip accumulation or sludge.

Monthly

1. Check, adjust and replace blade brush as needed.

2. Lubricate drive gears

3. Inspect carbide guides and bearings.

4. Inspect drive belt.

5. Clean coolant tank and filter as needed.

Annually

1. Check hydraulic oil level.

2. Replace guide rollers and carbide inserts.

3. Inspect gear box. Lubricate as needed.

Lubrication

Correct and adequate lubrication is a very important factor

in determining the life and service of your Wellsaw. It is

essential that all dust, dirt, chips, etc. be

removed before lubricating the saw. The following

lubrication recommendations cover usual saw applications.

Heavy use and hostile environments may indicate more

frequent lubrication for best saw performance.

Vise Screw, Ring Gear, Drive Pinion

1. Inspect Monthly.

2. Use anti-seize on Vise Screw

3. Use an Extreme Pressure open gear lube sparingly on

Ring Gear and Drive Pinion

Gear Case

thoroughly

Motor

1. Inspect annually. Re-lubricate every 2 years (4,000 hours)

1 to 2 full strokes.

2. Use Shell Dolium R or equivalent.

3. Viscosity: Heavy Grease, drop point 219EC.

4. Military Specification: None.

Recommended Service Kits

For Insurance

Against Downtime

Up to S/N 2499

1 year

M-426 Blade Brush 2 req’d.

2 year

100406-002 Top Bearing 2 req’d.

100416-003 Side Bearing 4 req’d.

100053-025 Roll Pin, Guide A Matic 4 req’d

100066-005 V-Belt 1 req’d.

M-426 Blade Brush 2 req’d.

M-166 Dash Pot Cup Leather 1 req’d.

After S/N 2499

1 year

M-426 Blade Brush 2 req’d

2 year

100416-001 Side Bearing 4 req’d.

100066-005 V-Belt 1 req’d.

M-426 Blade Brush 2 req’d.

100133-004 Blade Brush (after s/n 3329) 1 req’d.

1. Inspect after 3 years (6,000 hours).

2. Use Mobilgrease XHP 220 or equivalent.

Hydraulic Cylinder

1. Inspect annually. Fill to top of plug. Drain and replace

every 5 years (10,000 hours).

2. Fill with Mobil Velocite Oil #6 or equivalent.

3. Viscosity at 100EF: SUS 57-61.

Note: Check Carbide Guides

10

Model 1016 History

The most widely used of the Wellsaws has been the Model 8. Originally introduced in 1933, it has

continued, with constant improvements in design and materials, to be built today in the form of the

Model 1016.

The original Model 8 used a 3/4" blade, a 3/4 HP motor and had a 9" x 16" cutting capacity.

Successive improvements in this popular design were known by various model numbers. The Model

850 featured a 1" blade. Model 1000 offered a larger 10" x 16" cutting capacity with a 1 HP motor

and Guide-A-Matic, a patented mechanism for controlling blade roller guides automatically.

Today’s Model 1016 includes a coolant system, a precision ground bed, the Rite-Tensioning

Device® to insure more positive blade tension control, and low voltage controls for operator safety.

One Year Limited Warranty

This Wellsaw is warranted against defects in material and workmanship installed or performed at

our factory. Within one year from the date of purchase, we will, free of charge, at our option,

either repair or replace any part of the Wellsaw which our examination discloses to be defective

because of workmanship or a defect in material, and to make any necessary service adjustments

as required. This warranty does not apply if the Wellsaw has been subject to accident, alteration,

abuse, misuse or which fails due to lack of care or as the result of inadequate power supply and

specifically does not apply to normal wear of moving parts such as bearings, gears, pinion or

blade. There is no warranties beyond the description on the face hereof. Wellsaw shall not be

liable for consequential or incidental damage suffered or incurred with respect to defective

material or workmanship.

All transportation costs or parts submitted to Wellsaw under this warranty must be paid by the

saw’s owner. No products or parts are to be returned to our factory without first obtaining

written permission.

NOTE: Be sure to fill out and return the Warranty Card provided with this Wellsaw

11

Loading...

Loading...