Wells WVU-31CT Installation Manual

WELLS MANUFACTURING

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

OWNERS MANUAL

COUNTERTOP

VENTLESS UNIVERSAL

HOOD SYSTEM

COUNTERTOP ELECTRIC

APPLIANCES

524

for

MODEL

WVU-31CT

Manual Includes

INSTALLATION

USE & CARE

EXPLODED VIEW

PARTS LIST

IL2732

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

WIRING DIAGRAM

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

p/n 2M-Z17951, Rev. B M524 150102

LIMITED WARRANTY STATEMENT

Unless otherwise specied, all commercial cooking

equipment manufactured by Wells Manufacturing is

warranted against defects in materials and workmanship

for a period of one year from the date of original installation

or 18 months from the date of shipment from our factory,

whichever comes rst, and is for the benet of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW

OR IN FACT, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE, AND/OR FOR DIRECT,

INDIRECT OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH WELLS BLOOMFIELD PRODUCTS.

This warranty is void if it is determined that, upon inspection

by an authorized service agency, the equipment has been

modied, misused, misapplied, improperly installed, or

damaged in transit or by re, ood or act of God. It also does

not apply if the serial nameplate has been removed, or if

service is performed by unauthorized personnel. The prices

charged by Wells Manufacturing for its products are based

upon the limitations in this warranty. Seller’s obligation

under this warranty is limited to the repair of defects without

charge by a Wells Manufacturing factory authorized service

agency or one of its sub-service agencies. This service

will be provided on customer’s premises for non-portable

models. Portable models (a device with a cord and plug)

must be taken or shipped to the closest authorized service

agency, transportation charges prepaid, for service. In

addition to restrictions contained in this warranty, specic

limitations are shown in the Service Policy and Procedure

Guide. Wells Manufacturing authorized service agencies

are located in principal cities. This warranty is valid in the

United States and Canada and void elsewhere. Please

consult your classied telephone directory, your foodservice

equipment dealer or contact:

Wells Manufacturing

10 Sunnen Dr., St. Louis MO 63143 USA

phone (314) 678-6314 or fax (314) 781-2714

for information and other details concerning warranty.

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specied on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted

for ninety (90) days from date of purchase on non-

warranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment

in this shipment was carefully inspected and packaged

by skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and le

“CONCEALED DAMAGE” claim with them. This

should be done within fteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Manufacturing cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

xi

TABLE OF CONTENTS

WARRANTY xi

ELECTRICAL SPECIFICATIONS 1

WARNINGS - ENGLISH 2

WARNINGS - FRENCH 3

CLEARANCES 4

FIRE SUPPRESSION SYSTEM 5

FEATURES & OPERATING CONTROLS 6-7

PRECAUTIONS & GENERAL INFORMATION 8

AGENCY LISTING INFORMATION 9

INSTALLATION 9

Unpacking & Inspection 9

Components 9

Under-Hood Appliance Limitations 10

Service Technician Installation Notes 11

Site Preparation 12

Mechanical Installation 13

Electrical Installation 14-15

ANSUL® INSTALLATION & SETUP 14-15

Fire Suppression System Installation 16

Filter Installation 17

OPERATION 18

Control Panel 18

Operation Lights 18

CLEANING INSTRUCTIONS 19-20

REQUIRED MAINTENANCE & MAINTENANCE LOGS 21-25

TROUBLESHOOTING SUGGESTIONS 26

WIRING DIAGRAM 27

EXPLODED VIEW & PARTS LIST 28-33

INTRODUCTION

Thank You for purchasing this Wells Manufacturing appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure

that it gives you the very best performance and a long, economical service life.

This manual contains information and instructions for the ventless ventilation hood, its use and care.

For information regarding cooking appliance(s), please refer to the manufacturer’s operation manual.

ELECTRICAL SPECIFICATIONS

Model Volts Amps Power Supply

WVU-31CT 208/240V 1.9 For supply connection use #12 AWG copper wire only.

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

1

WARNINGS - ENGLISH

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of this

appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR INSTALLING THIS

APPLIANCE. Contact your WELLS DEALER if you have any questions concerning installation, operation

or maintenance of this equipment.

DANGER

FIRE HAZARD

Fire suppression system must be charged and

certied by an authorized Ansul® distributor.

DO NOT attempt to modify or bypass the re

suppression system.

An uncontrolled re can cause serious injury or

death.

WARNING:

If the re suppression system is

discharged, a buzzer will sound

continuously. The unit will remain

inoperable until the re suppression system

is serviced, recharged and reset by an

authorized Ansul® distributor.

NOTE:

If a REMOTE MANUAL PULL STATION

is installed, moving the ventilator for any

reason may cause the Ansul® system to

discharge.

DANGER - DO NOT BLOCK ACCESS

TO THE FIRE EXTINGUSHING

MANUAL PULL.

DANGER:

SUFFOCATION HAZARD

“Do not attempt to use this ventilator with

gas-red units. This ventilator will not

remove products of combustion. Unvented

exhaust gasses can be deadly.”

WARNING:

SHOCK HAZARD

All servicing requiring access to non-insulated

electrical components must be performed by

a factory authorized technician.

DO NOT open any access panel which

requires the use of tools. Failure to follow this

warning can result in severe electrical shock.

WARNING:

RISK OF INJURY

Installation procedures must be performed by

a qualied technician with full knowledge of all

applicable electrical codes. Failure can result

in personal injury and property damage.

WARNING:

SLIP AND FALL HAZARD

DO NOT operate any grease-producing

cooking appliance unless the grease cup

is properly installed. Oil will drip onto oor

creating a slipping hazard.

WARNING:

DO NOT attempt to wash the HEPA /

CHARCOAL lter pack or pre-lter. Water

absorption will render the lter unusable.

Use of a wet or clogged lter will cause the

ventilator system to shut down. Use only

new, clean Wells® Authorized Service Parts.

Keep spare lter packs on hand to avoid

distrupions. Service Department 1-314-678-

6314.

Exposed surfaces can be hot to the touch and

may cause burns. Allow unit to cool before

cleaning or servicing.

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

2

WARNINGS - FRENCH

IMPORTANT : NE JETEZ PAS CE MANUEL

Ce manuel fait partie intégrante de l’appareil et doit être remis au PROPRIÉTAIRE, au GÉRANT

du restaurant ou au responsable de la FORMATION DES UTILISATEURS. Des manuels

supplémentaires sont disponibles auprès de votre concessionnaire WELLS.

TOUTE PERSONNE INSTALLANT OU UTILISANT CET APPAREIL DOIT LIRE CE MANUEL ET

S’ASSURER DE L’AVOIR COMPRIS.

Veuillez contacter votre CONCESSIONNAIRE WELLS pour toute question concernant

l’installation, l’utilisation ou l’entretien de cet équipement.

DANGER

RISQUE D’INCENDIE

Le système anti-incendie doit être chargé

et certié par un distributeur agréé Ansul®.

N’essayez PAS de modier ou de

contourner le système anti-incendie.

Un feu hors de contrôle risque de

provoquer des blessures graves, voire

mortelles.

AVERTISSEMENT :

Une alarme sonore se déclenche en

continu si le système anti-incendie est

déchargé. L’unité reste inutilisable

jusqu’à ce qu’un distributeur agréé Ansul®

effectue son intervention, le recharge et le

réinitialise.

REMARQUE :

Si un AVERTISSEUR D’INCENDIE À

DISTANCE MANUEL est installé, tout

déplacement du ventilateur, quel qu’en soit

le motif, peut provoquer la décharge du

système Ansul®.

DANGER - NE PAS BLOQUER

L’ACCÈS À LA POIGNÉE DE

L’EXTINCTEUR !

DANGER :

RISQUE DE SUFFOCATION

“Ce ventilateur ne doit pas être utilisé avec

des appareils à gaz. Il n’absorbe pas les

produits de combustion. En l’absence de

sortie d’aération, les gaz de combustion

peuvent être mortels.”

AVERTISSEMENT :

RISQUE DE DÉCHARGE ÉLECTRIQUE

Toute intervention nécessitant d’accéder à des

composants électriques non isolés doit être

effectuée par un technicien agréé usine.

N’ouvrez AUCUN panneau d’accès nécessitant

l’utilisation d’un outil. Le non-respect de cet

avertissement peut exposer à une décharge

électrique sévère.

AVERTISSEMENT :

RISQUE DE BLESSURE

Les procédures d’installation doivent être

effectuées par un technicien qualié ayant pleine

connaissance des réglementations applicables. Le

non-respect de cet avertissement peut provoquer

des blessures et des dommages matériels.

AVERTISSEMENT :

RISQUE DE CHUTE

N’utilisez PAS d’appareil de cuisson produisant

de la graisse sans que le godet à graisse soit

correctement installé. Vous risqueriez de glisser

car la graisse éclabousserait le sol.

AVERTISSEMENT :

N’essayez PAS de nettoyer le ltre ou le pré-ltre

HEPA ou à CHARBON. L’eau absorbée rendrait

le ltre inutilisable. Un ltre humide ou colmaté

provoque l’arrêt du système de ventilation. Utilisez

uniquement des pièces neuves et propres,

homologuées par Wells®. Conservez des

ltres de rechange pour éviter l’interruption du

fonctionnement.

Service clientèle : +1-314-678-6314.

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

3

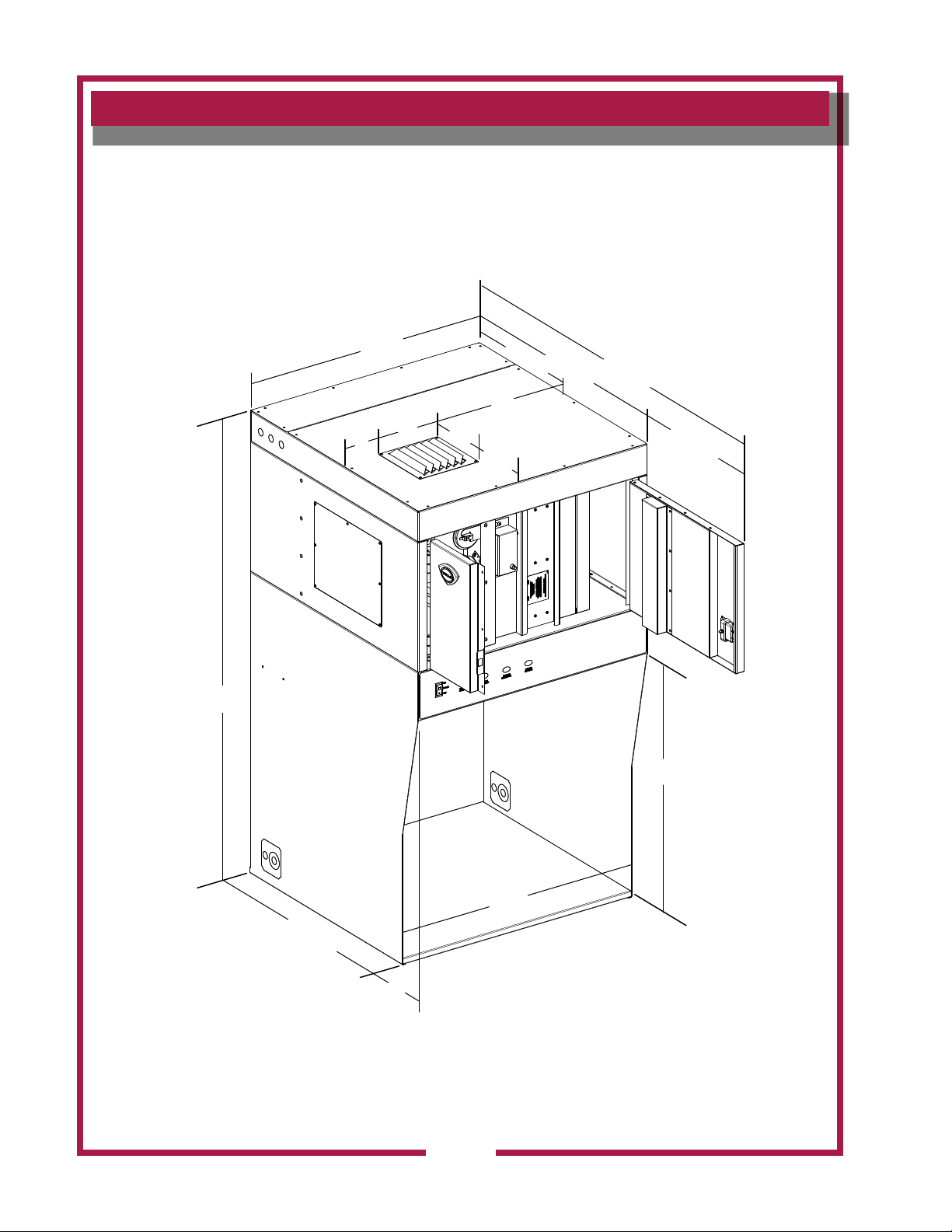

CLEARANCES

56.7”

31.1”

5”

8”

8”

18”

4.8”

19.72”

32.52”

53.30”

20.78”

30.2”

29.5”

31”

3”

IL2734

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

4

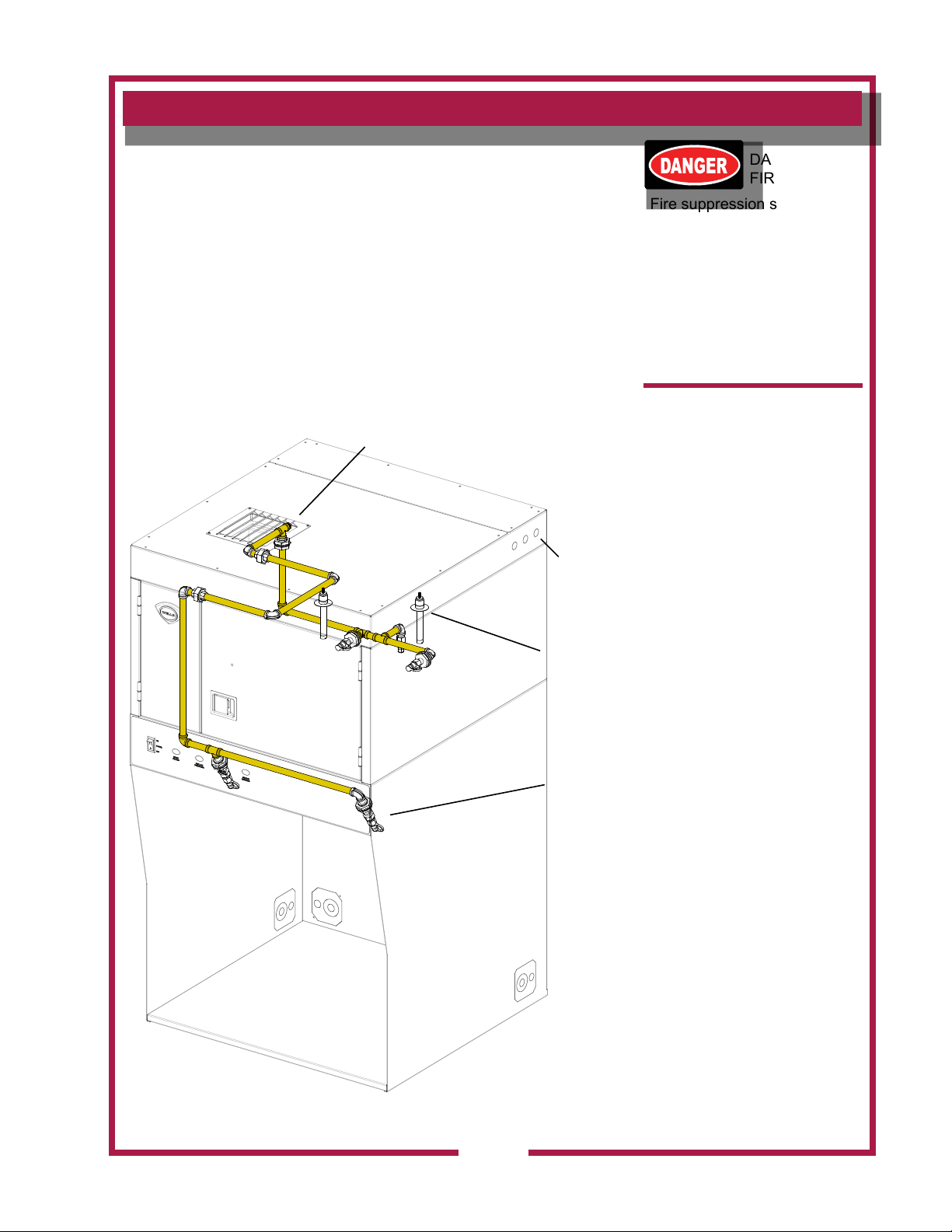

FIRE SUPPRESSION SYSTEM

CUSTOMER

Fire Suppression System Installation

It is required that this unit be protected by a UL listed re suppression

system, provided by the customer. The nal installation, testing and

certication of the system is the responsibility of the customer and MUST

be performed by a qualied Fire Protection Agent in accordance with the

hood system.

This Wells Ventless System includes factory installed piping, plenum,

discharge nozzles, thermal detectors.

ANSUL HOOK-UP

ELECTRIC & ANSUL

KNOCK-OUTS

(3 SIDES)

THERMAL

DETECTORS

(2 PLACES)

NOZZELS

(5 TOTAL)

DANGER

FIRE HAZARD

Fire suppression system

must be charged and certied

by an authorized Ansul®

distributor.

DO NOT attempt to modify or

bypass the re suppression

system.

An uncontrolled re can

cause serious injury or death.

NOTE:

If the re suppression system

is discharged, a buzzer will

sound continuously. The unit

will remain inoperable until

the re suppression system is

serviced, recharged and reset

by an authorized Ansul®

distributor.

Charging of the Ansul®

Fire Suppression system

must be in accordance with

Ansul® Design, Installation,

Recharge and Maintenance

Manual, #418087.

NOTE:

If a REMOTE MANUAL PULL

STATION is installed, moving

the ventilator for any reason

may cause the Ansul®

system to discharge.

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

IMPORTANT:

Should the re suppression

system discharge: all nozzles

must be replaced, and all

lines thoroughly cleaned,

prior to recharging the

system.

Residual re suppression

media may compromise the

ow and dispersion of re

IL2740

suppression media in any

subsequent activation.

5

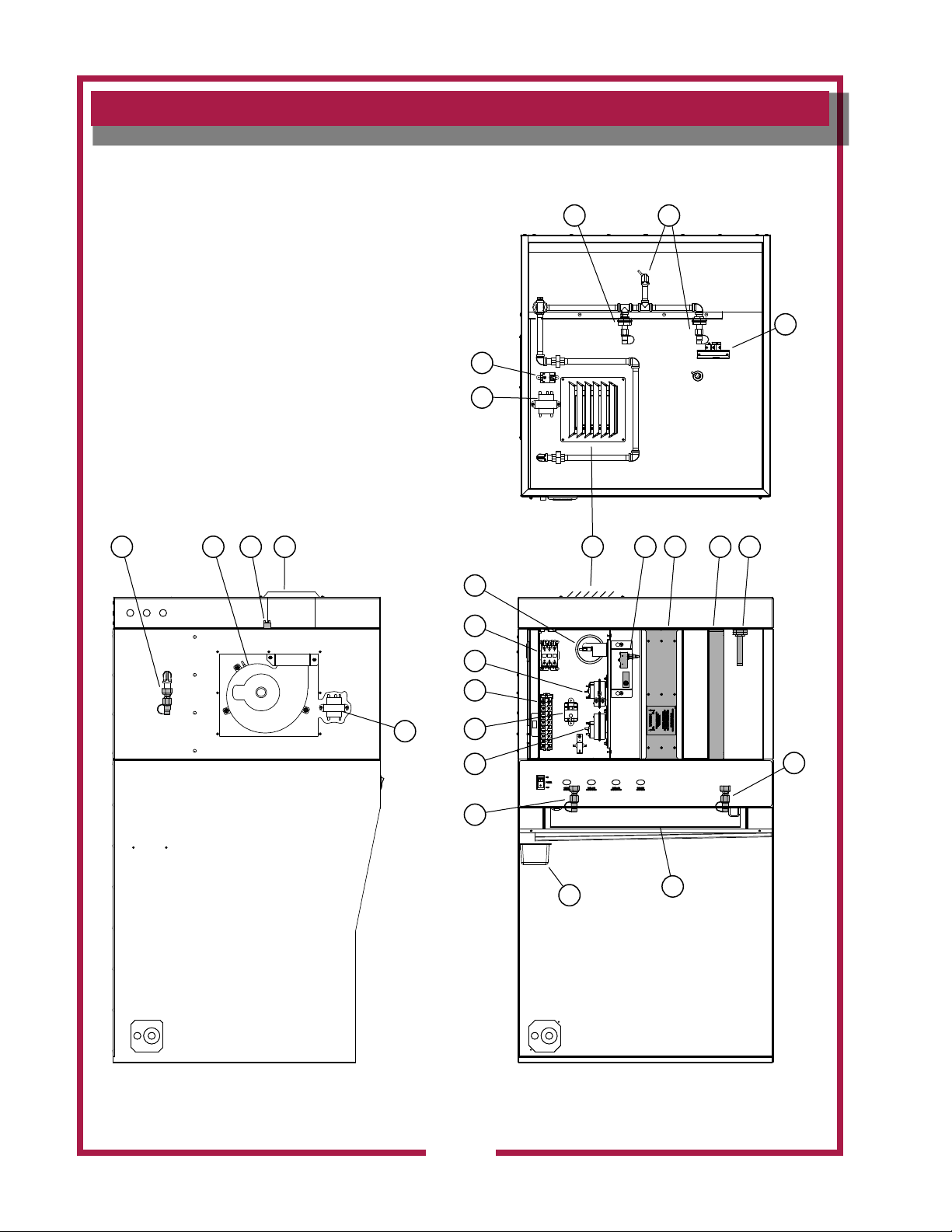

FEATURES & OPERATING CONTROLS

11

5

3

17

4

3

21

84

765

9

10

11

12

18

19

13

1

1

14

15

Countertop Ventilator Section Operating Features & Controls

6

IL2735

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

FEATURES & OPERATING CONTROLS continued

FEATURES & OPERATION CONTROLS

ITEM NO DESCRIPTION COMMENT

1 DISCHARGE NOZZLES Fire suppression media discharges here, (5 places)

2 VENTILATOR FAN Provides air movement for ventilation

3 DETECTION END OF LINE RELAY Prevents appliance operation if a fault is found in detection circuit.

4 VENTILATOR EXHAUST DUCT, FRONT Exit point for ventilator airow - on front of unit. DO NOT BLOCK

5 FILTER INTERLOCK SWITCHES

6 HI-EFFICIENCY/CHARCOAL FILTER PACK

7 PRE-FILTER

8 ELECTRICAL DETECTORS

9 PRE-FILTER SWITCH

10 EQUIPMENT INTERFACE CONTACTOR

11 HEPA FILTER SWITCH

12 SUPPLY CONNECTION TERMINAL BLOCK Provides connection point for electrical circuitry

13 UNIT SHUT-DOWN SWITCH

14 GREASE DRIP TRAY Collects grease/moisture dripping from bafe lter (16)

15 BAFFLE FILTER Extracts and drains most greases and moisture from the air ow.

16 APPLIANCE LIGHT (Not Shown) ON when hood power switch is ON. Illuminates cooking area.

17 120V TRANSFORMER Provides power to appliance lights

18 120V TRANSFORMER Provides power to contactor relay

19 BUILDING ALARM RELAY Provides electrical connections for building alarm system

Proper installation of bafe lter and lter pack closes these switches

in ventilator sensor circuit

Removes grease and smoke particles. Also assists in cooking odor

removal.

Replaceable PRE-FILTER, stops large particles of grease from

reaching the FILTER PACK for reduced maintenance costs.

Designed to activate at a certain temperature. Activates (i.e. re on

the cooktop) activates re suppression system. Should be checked

every 6 months during ANSUL® Service Inspection

Monititors the Pre-Filter and indicates when it needs replacing, if

ignored it will lead to unit shut down.

Energizes cooking appliances only while ventilator section is sensed

as operational.

Montitors the HEPA lter and indicates when it needs replacing, if

ignored it will lead to unit shut down.

Shuts down the unit and appliances when the lack of air ow reaches

a certain level, triggers a service unit indicator.

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

7

PRECAUTIONS AND GENERAL INFORMATION

This ventilator hood is part of an engineered system and is intended for

use in commercial establishments only.

This ventilator is intended

DANGER:

SUFFOCATION HAZARD

Do not attempt to use this

ventilator with gas-red units.

This ventilator will not remove

products of combustion.

Unvented exhaust gasses

can be deadly.

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

IMPORTANT:

The ventilator is disabled

when the lters are plugged

to the point of insufcient

airow for proper operation.

Also, power to the cooking

appliances is interrupted if

any lters or service panel

are removed.

It is the responsibility of

the store management to

maintain sufcient spares

of lter packs to avoid

prolonged shutdown due

to a dirty or clogged lter

pack. Filter packs cannot be

cleaned.

Wells Manufacturing

assumes no liability for loss

of business due to a lter

related shutdown. Spare

lters can be purchased

from any authorized Wells

servicer or calling Wells.

in the preparation food for human consumption. No other use is

recommended or authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

This ventilator hood system is designed to reduce odor emissions,

but will not completely eliminate all cooking odors. Air exchange

rates at the installation site must comply with the requirements of the

local jurisdictional authority. To ensure that odors do not accumulate,

recommended minimum air exchange is 200 cfm per linear foot of hood

into and out of the site.

This unit is intended for use with light- and medium duty electric

cooking appliances only. Cooking appliances placed under this

ventilator must comply with the restrictions set forth in the Installation

section of this manual.

Do not connect or energize this appliance until all installation

instructions are read and understood. Property damage or bodily

injury may result if these instructions are not followed. Disconnect this

appliance from electrical power before performing any maintenance or

servicing.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

This appliance is not jet steam approved. Do not direct water jet or

steam jet at this appliance, or at any control panel or wiring.

Do not splash or pour water on, in or over any controls, control panel or

wiring. Do not attempt to wash lter packs. Water will cause their

immediate failure and disable the ventilator.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

Avoid storing ammable or combustible materials in, on or near the

ventilator or associated cooking appliance.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualied technical personnel.

Any procedure which requires the use of tools must be performed by a

qualied technician.

All supplied instructions, diagrams, schematics, parts breakdown

illustrations, notices and labels must remain with the appliance if the

unit is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

for commercial establishments for use

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

8

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 2 for sanitation only if

installed in accordance with the supplied Installation Instructions

and operated and maintained in accordance with the instructions in this

manual.

This appliance is ETL listed.

STD 2

UL710B

Recurculating System

INSTALLATION

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all

protective plastic lm, packing materials and accessories from the

appliance before connecting electrical power or otherwise performing

any installation procedure.

Carefully read all instructions in this manual and any other docments

packed with the appliance before starting any installation.

All documentation should remain with the equipment operator for future

reference.

Read and understand all labels and diagrams attached to the

ventilator.

Carefully account for all components and accessories before

discarding packing materials.

COMPONENTS

Pre-Filter 1 ea.

Bafe Filter 1 ea.

Filter pack 1 ea.

Grease cup 1 ea.

Ansul® components - must be supplied by customer and installed

by an authorized Ansul® distributor only:

The unit is shipped with an angled discharge grill.

To change the direction of the discharge airow:

1. Remove the discharge grill by removing the four (4) mounting

screws on the grill.

2. Rotate the discharge grill to the desired discharge position.

3. Re-Secure the grill using the four (4) mounting screws.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

Risk of injury

Installation procedures must

be performed by a qualied

technician with full knowledge

of all applicable electrical

codes. Failure can result in

personal injury and property

damage.

IMPORTANT:

Fire suppression system must

be charged and certied by an

authorized Ansul® distributor.

Ventilator will not operate and

cooking appliance will not be

energized until the Ansul® re

suppression system has been

charged.

IMPORTANT:

After cooking appliances

are positioned under the

hood, swivel nozzles must

be positioned per Ansul®

recommendations.

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

9

INSTALLATION (continued)

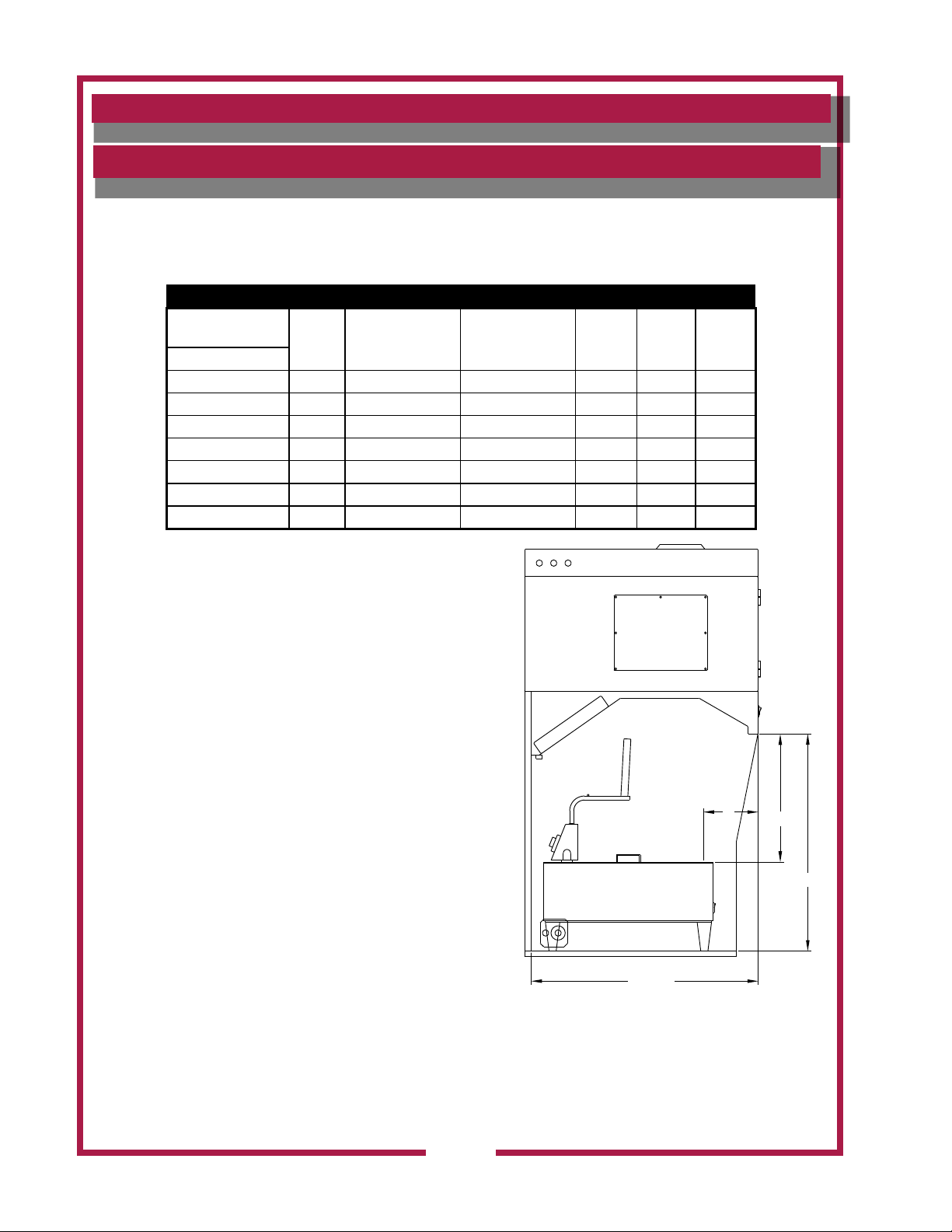

UNDER-HOOD APPLIANCE LIMITATIONS:

Appliance must be installed per manufactures instructions.

1.

2. Electrical appliances only. Not Intended for gas red units.

3. All appliances under the hood must be connected to the hood appliance interlock circuit.

4. All appliances must meet the requirements outlined in the cooking appliance limitations chart below.

EQUIPMENT PARAMETER WVU-31CT

Coverage Parameters

Appliance Type

Fryer 16.9 400°F (204°C) 24 5 12 20

Griddle 5.5 450°F (232°C) 24 5 12 20

Hotplate 5.5 N/A N/A 5 15 25

Counter Top Oven N/A 550°F (287°C) 27 4 5 N/A

Sandwich Grills 5.5 450°F (232°C) 24 5 10 25

Convection Oven N/A 550°F (287°C) 27 5 5 N/A

Micro Combi Oven N/A 550°F (287°C) 27 4 5 N/A

(A) FRONT OF HOOD TO FRONT EDGE OF HEATED

COOKING SURFACE.

(B) BOTTOM FRONT EDGE OF HOOD TO HEIGHT OF

HEATED COOKING SURACE.

Maximum

kW / Ft

Maximum Cooking

Temperature

Maximum Single

Appliance Heated

Cooking Surface

The hood and all under hood appliances must be installed

in accordance with the standard for ventilation control and

re protection of commercial cooking operations NFPA

96, the national electric code NFPA 70 and all local codes

where applicable.

All under hood appliances must be controlled by the

equipment shutoff interface. Only electrically heated

appliances are acceptable for installation. Appliance

operation requires the re suppression system be setup,

charged and certied by an authorized ansul ® distributor.

The airow monitoring system will prevent appliance

operation if insufcient airow is detected or all lters are

not in place. The service panel must be in place for blower

operation.

Dim A,

Minimum

(A)

Dim B,

Minimum

(B)

Dim B,

Maximum

(B)

A

B

30.24

WELLS MANUFACTURING

MODEL NO: WVU-31CT

LOWER AIR FLOW LIMIT: 375CFM

MAXIMUM MEASURED GREASE EMISSIONS: .000693 LB/HR/FT

ANSI-UL710B RECIRCULATING SYSTEM

10

31.63

SIDE VIEW

M524 p/n 2M-Z17951 OpM WVU- Countertop Universal Hood

Loading...

Loading...