Page 1

531

OWNERS MANUAL

MODEL

WVSW

VENTLESS

HOOD

For

CONVEYOR

WARMERS

Includes

INSTALLATION

USE & CARE

SERVICE

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

p/n 305812 Rev. (-) M531 012303 cps

Page 2

LIMITED WARRANTY STATEMENT

Unless otherwise specified, all commercial cooking equipment manufactured by WELLS MFG. CO. is warranted

against defects in materials and workmanship for a period of

one year from the date of original installation or 18 months

from the date of shipment from our factory, whichever

comes first, and is for the benefit of the original purchaser

only.

THIS WARRANTY IS THE COMPLETE AND ONLY WARRANTY, EXPRESSED OR IMPLIED IN LAW OR IN FACT,

INCLUDING BUT NOT LIMITED TO, WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND/OR FOR DIRECT, INDIRECT OR

CONSEQUENTIAL DAMAGES IN CONNECTION WITH

WELLS MFG. CO. PRODUCTS. This warranty is void if it

is determined that, upon inspection by an authorized service

agency, the equipment has been modified, misused, misapplied, improperly installed, or damaged in transit or by fire,

flood or act of God. It also does not apply if the serial nameplate has been removed, or if service is performed by unau-

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specified on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

thorized personnel. The prices charged by Wells Mfg. Co.

for its products are based upon the limitations in this warranty. Seller’s obligation under this warranty is limited to the

repair of defects without charge by a Wells Mfg. Co. factory

authorized service agency or one of its sub-service agencies. This service will be provided on customer’s premises

for non-portable models. Portable models (a device with a

cord and plug) must be taken or shipped to the closest authorized service agency, transportation charges prepaid, for

service. In addition to restrictions contained in this warranty,

specific limitations are shown in the Service Policy and Procedure Guide. Wells Mfg. Co. authorized service agencies

are located in principal cities. This warranty is valid in the

United States and Canada and void elsewhere. Please consult your classified telephone directory, your foodservice

equipment dealer or write the Factory Service Department,

Wells Manufacturing Company, P.O. Box 280, Verdi, Nevada 89439, phone (775) 689-5700 or fax (888) 492-2783,

for information and other details concerning warranty.

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted for

ninety (90) days from date of purchase on nonwarranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory. Upon acceptance of this shipment, the transportation company assumes

full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Manufacturing cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

xi

Page 3

TABLE OF CONTENTS

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

AGENCY LISTING INFORMATION 3

PRECAUTIONS & GENERAL INFORMATION 4

INSTALLATION 5

OPERATION 7

CLEANING INSTRUCTIONS 8

TROUBLESHOOTING SUGGESTIONS 9

SERVICE INSTRUCTIONS 10

PARTS & SERVICE 11

CUSTOMER SERVICE DATA 11

INTRODUCTION

Thank You for purchasing this Wells Manufacturing Co. appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that it

gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for the

appliance in a manner which will ensure its optimum performance.

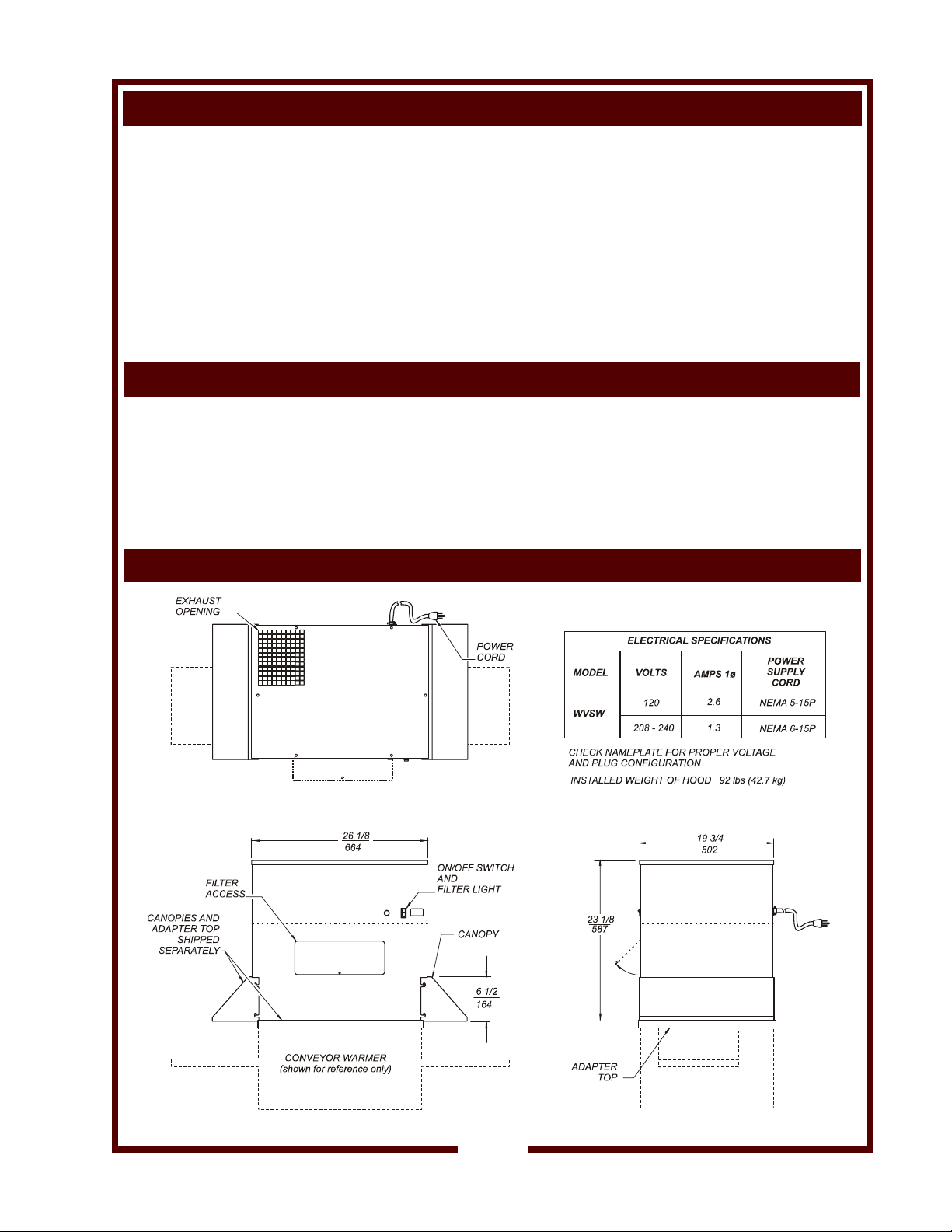

SPECIFICATIONS

1

Page 4

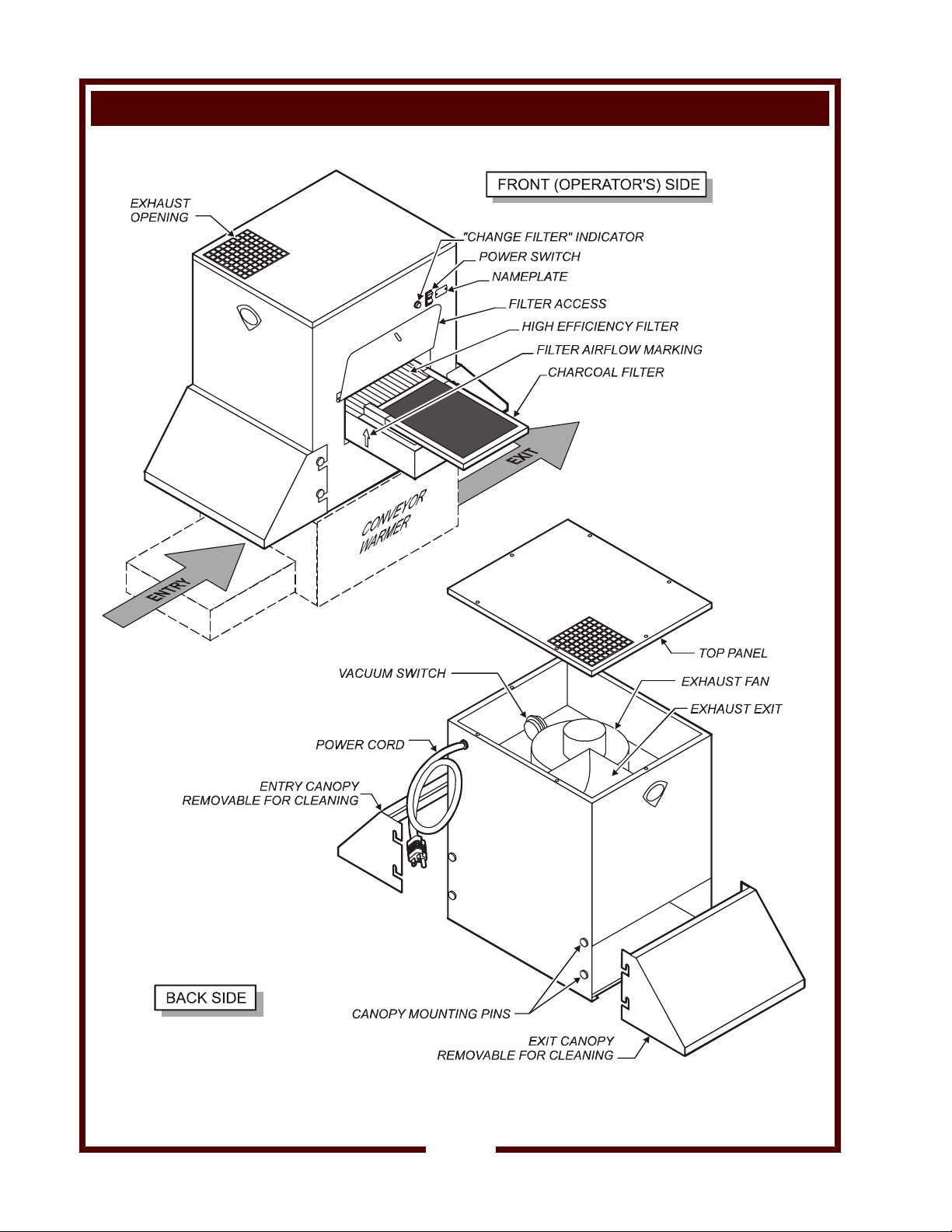

FEATURES & OPERATING CONTROLS

WVSW VENTLESS HOOD

Fig. 1 Features & Operating Controls

2

Page 5

FEATURES & OPERATING CONTROLS (continued)

ITEM DESCRIPTION

CANOPY Removable canopies aid in vapor capture at entry and exit of the conveyor

warmer. Canopies hang from mounting pins at each end of the hood.

ELECTRICAL The hood plugs into a NEMA 5-15R (120V) or 6-15R (208/240V) receptacle

with a 6' power cord. An illuminated power switch on the front panel is used

to start/stop the hood fan.

EXHAUST The hood uses an exhaust fan to provide air movement. The fan exhausts

through a screened opening in the top of the hood.

IMPORTANT: DO NOT block exhaust opening.

FILTERS The hood uses two filters. A high efficiency filter is used to capture

particulate emissions.

A charcoal filter is used to help control odors.

Filters are accessed by opening a hinged panel on the front (operator's)

side of the hood.

Filter operation is monitored by a vacuum switch. When the filter(s)

become loaded to the point of being unable to remove particulates, a front

panel "change filters" indicator will glow.

NAMEPLATE Provides Manufacturer, Model and Serial Number information.

Also, provides electrical ratings.

TOP PANEL

CAUTION!

Electric Shock Hazard

Exposed Electric Circuits

Top panel must be opened ONLY by qualified personnel.

Allows access to interior components.

DO NOT stack anything on top of the hood.

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 4 for sanitation only if installed

and maintained according to the instructions in this manual.

This appliance is

This appliance is

IMPORTANT: For use with conveyor warmer of 9,000 watts maximum.

NOTE: This ductless hood has not been evaluated to the requirements of

NFPA 96.

Local jurisdictions may require additional evaluations for installation

of this product.

U Listed for 120V and 208 - 240V.

V Listed for 120V and 208 - 240V.

STD 4

3

Page 6

PRECAUTIONS AND GENERAL INFORMATION

WARNING:

Electric

Shock hazard

All servicing requiring

access to non-insulated

electrical components

must be performed by a

factory authorized

technician.

DO NOT open or remove

the top panel. Failure to

follow this warning can

result in severe electrical

shock.

CAUTION:

Risk of

Damage

DO NOT connect or

energize this appliance

until all installation

instructions are read and

followed. Damage to the

appliance will result if

these instructions are not

followed.

CAUTION:

Hot Surface

Exposed surfaces can be hot

to the touch and may cause

burns.

This appliance is intended for use in commercial establishments

only.

This appliance is intended

designed for use with specified warming equipment. No other use is

recommended or authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT submerge this appliance in water. This appliance is not jet

stream approved. Do not direct water jet or steam jet at this appliance,

or at any control panel or wiring. Do not splash or pour water on, in or

over any controls, control panel or wiring. Do not wash floor around

this appliance with water or steam jet.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualified technical personnel.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

as a smoke and odor control device,

4

Page 7

INSTALLATION

UNPACKING & INSPECTION

Carefully read all instructions in this manual before starting any

installation.

Carefully remove the hood from the carton.

IMPORTANT: Appliance weighs 92 lbs (42.7 kg). Use appropriate

care when removing from carton and installing on conveyor warmer.

Remove all protective plastic film, packing materials and accessories

from the hood before connecting electrical power or otherwise

performing any installation procedure.

Read and understand all labels and diagrams attached to the hood.

Carefully account for all components and accessories before

discarding packing materials. Store all accessories in a convenient

place for later use.

COMPONENTS:

HIGH EFFICIENCY FILTER

CHARCOAL FILTER

COMPONENTS SHIPPED SEPARATELY

CANOPY (2 ea)

ADAPTER TOP

SETUP

The conveyor-style warmer requires an adapter top (shipped

separately) for mounting the hood. Place adapter top on warmer

before setting hood in place. Carefully place hood on top of warmer.

Orient hood so that power switch is on the same side as the power

switch of the warmer. Center hood over the body of the warmer as

shown in Fig. 2 below:

Fig. 2 Hood installation on warmer

Check high efficiency filter and charcoal filter for proper installation.

Charcoal filter slides into clips on the high efficiency filter. Airflow

marks must point "up".

Attach entry and exit canopies to pins on sides of hood. Canopies are

interchangeable and may be mounted at either end.

Maintain required clearances of at least 6" between the appliance and

adjacent combustible surfaces.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the hood for hidden

damage and tested it for

proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING!

Risk of

Personal Injury

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable electrical

codes. Failure can result in

personal injury and property

damage.

CAUTION!

Risk of

Personal Injury

and Property

Damage

Unplug conveyor warmer and

allow to cool before beginning

installation.

IMPORTANT:

Maintain required clearances

of at least 6" between the

appliance and adjacent

combustible surfaces.

Avoid storing flammable or

combustible materials in, on

or near the appliance.

5

Page 8

INSTALLATION (continued)

WARNING!

Electric

Shock hazard

All servicing requiring

access to non-insulated

electrical components

must be performed by a

factory authorized

technician.

DO NOT open any access

panel which requires the

use of tools. Failure to

follow this warning can

result in severe electrical

shock.

CAUTION!

Electrical Shock

The ground prong of the

power cord is part of a

system designed to protect

you against electric shock in

the event of internal damage.

DO NOT cut the ground

prong (large round prong) or

twist a blade to make the plug

fit an existing receptacle.

IMPORTANT:

Contact a licensed electrician

to install and connect

electrical power to the

appliance.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

Hazard

ELECTRICAL INSTALLATION

Refer to the nameplate. Verify the electrical power source. Voltage

and phase must match the nameplate specifications. Plugging the

hood into the wrong voltage can severely damage the unit .

Your hood is equipped with a grounded electrical cord. This cord

must be plugged into a properly grounded NEMA 5-15R (120V) or

NEMA 6-15R (208/240V) single phase receptacle.

Fig. 3 Electrical Plug and Receptacle Configuration

6

Page 9

OPERATING CONTROLS

Controls include a lighted POWER SWITCH and an amber REPLACE

FILTER indicator light.

Press POWER SWITCH to ON anytime conveyor warmer is operating.

When power is first turned on, the REPLACE FILTER light will glow.

As the fan comes up to speed and air flow is established, the REPLACE

FILTER light will go out.

If the REPLACE FILTER light does not go out, the filters must be

replaced. However, the fan will continue to operate when the

REPLACE FILTER light is lit.

FILTER REMOVAL AND INSTALLATION

Disconnect power from hood and conveyor warmer before servicing

filters.

Remove screw from filter access panel on front (operator's) side of

hood. Slide filter pack (high efficiency filter and charcoal filter) from

filter chamber.

Slide new filter pack into filter chamber. Be sure airflow markings on

both filters point "up".

Close access panel and reinstall screw.

IMPORTANT:

Filters are disposable. Never attempt to wash either filter.

Filters will absorb water if washed, causing food contamination and

possible equipment damage.

Fig. 5 Filter Installation

OPERATION

Fig. 4 Operating Controls

CAUTION!

Personal Injury

Hazard

Disconnect power from hood

and conveyor warmer before

servicing filters.

IMPORTANT:

DO NOT store anything on

top of the hood.

DO NOT block the exhaust

opening.

IMPORTANT:

Both the high efficiency and

charcoal filters must be in

place at all times during

operation.

7

Page 10

CLEANING INSTRUCTIONS

CAUTION!

Personal Injury

Hazard

Disconnect power from hood

and conveyor warmer before

cleaning.

IMPORTANT: DO NOT spill

or pour water into controls,

control panel or wiring.

DO NOT spill or pour water

into exhaust opening.

DO NOT submerge hood in

water or wash with water or

steam spray. Damage to

internal components will

occur.

Damage to internal

components from water

damage is not covered by

warranty.

PREPARATION Unplug hood and conveyor warmer

Allow to cool completely before cleaning

FREQUENCY Daily

TOOLS Mild Detergent

Soft Cloth or Sponge

1. Disconnect power from hood and conveyor warmer before cleaning.

2. Remove entry and exit canopies. Canopies may be washed in a

sink or dishwasher. Rinse and dry canopies thoroughly.

3. Wipe interior and exterior surfaces of hood with a soft cloth or

sponge dampened with water and a mild detergent.

IMPORTANT:

Never attempt to wash either filter.

Filters will absorb water if washed, causing food contamination and

possible equipment damage.

4. Rinse all washed areas by wiping with a clean soft cloth dampened

with clean water. Dry with a soft cloth.

5. Reinstall entry and exit canopies.

Procedure is complete

8

Page 11

TROUBLESHOOTING SUGGESTIONS

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

No operation, no lights Cord unplugged

Circuit breaker off or tripped Reset circuit breaker

Damaged power cord or plug Replace power cord

Damaged power switch Replace power switch

REPLACE FILTER light remains

lit (never shuts off)

If filters are clean

and fan is operating

Exhaust opening blocked

Filter opening blocked Clear filter opening

Vacuum hose kinked Unkink vacuum hose

Filters dirty Replace filters

New filter still in plastic wrapper Remove plastic wrapper

Plug cord into appropriate power

receptacle.

Clear or clean exhaust duct and

opening

Vacuum line plugged Clean or replace vacuum line

Damaged vacuum switch Replace vacuum switch

If fan is not operating Fan jammed Unjam fan

Damaged motor start capacitor Replace start capacitor

Damaged fan motor Replace fan motor

9

Page 12

SERVICE INSRTUCTIONS

IMPORTANT:

DO NOT store anything on

top of the hood.

DO NOT block the exhaust

opening.

Filter operation is monitored

by a vacuum switch and a

system of vacuum hoses.

The switch energizes the

REPLACE FILTER light if

airflow through the filters is

insufficient for efficient

operation. The light is a

warning only, and does not

control the operation of the

hood.

VACUUM DIAGRAM

10

Page 13

PARTS & SERVICE

DESCRIPTION PART NO.

HIGH EFFICIENCY FILTER 16 x 20x 4 22862

CHARCOAL (CARBON) FILTER 14 x 20 x 7/8 22403

IMPORTANT: Use only

factory authorized service

parts and replacement

.

filters

For factory authorized

service, or to order factory

authorized replacement

parts, contact your Wells

authorized service agency,

or call:

Wells Manufacturing Co

2 Erik Circle

P. O. Box 280

Verdi, NV 89439

phone: (775) 689-5700

fax: (888) 492-2783

(Service Parts Dept.)

Service Parts Department

can supply you with the

name and telephone

number of the WELLS

AUTHORIZED SERVICE

AGENCY nearest you.

.

CUSTOMER SERVICE DATA

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. _______________

EQUIPMENT SERIAL NO. _______________

VOLTAGE: (check one) 120 208 240

please have this information available if calling for service

11

Page 14

Loading...

Loading...