Page 1

WELLS BLOOMFIELD, LLC

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

OWNERS MANUAL

ELECTRIC

30# PRESSURE

FRYER

MODEL

WFPE30F

with or without

Optional Filter Wand

WVPE30F

(FRYER SECTION ONLY)

with or without

Optional Filter Wand

362

Includes

INSTALLATION

USE & CARE

EXPLODED VIEW

PARTS LIST

WFPE30F

WARNING:

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation and operating

instructions thoroughly before installing, using or servicing this equipment.

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

WIRING DIAGRAM

p/n 2M-301626 Rev. C M362 120227

Page 2

LIMITED WARRANTY STATEMENT

Unless otherwise specified, all commercial cooking

equipment manufactured by WELLS BLOOMFIELD, LLC is

warranted against defects in materials and workmanship for

a period of one year from the date of original installation or

18 months from the date of shipment from our factory,

whichever comes first, and is for the benefit of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW OR IN

FACT, INCLUDING BUT NOT LIMITED TO, WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE, AND/OR FOR DIRECT,

INDIRECT OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH WELLS BLOOMFIELD PRODUCTS.

This warranty is void if it is determined that, upon inspection

by an authorized service agency, the equipment has been

modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God. It also

does not apply if the serial nameplate has been removed, or

if service is performed by unauthorized personnel. The

prices charged by Wells Bloomfield for its products are

based upon the limitations in this warranty. Seller’s

obligation under this warranty is limited to the repair of

defects without charge by a Wells Bloomfield factory

authorized service agency or one of its sub-service

agencies. This service will be provided on customer’s

premises for non-portable models. Portable models (a

device with a cord and plug) must be taken or shipped to

the closest authorized service agency, transportation

charges prepaid, for service. In addition to restrictions

contained in this warranty, specific limitations are shown in

the Service Policy and Procedure Guide. Wells Bloomfield

authorized service agencies are located in principal cities.

This warranty is valid in the United States and Canada and

void elsewhere. Please consult your classified telephone

directory, your foodservice equipment dealer or contact:

10 Sunnen Dr., St. Louis MO 63143 USA

phone (314) 678-6314 or fax (314) 781-2714

for information and other details concerning warranty.

Wells Bloomfield, LLC

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specified on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted for

ninety (90) days from date of purchase on nonwarranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Bloomfield cannot assume liability for damage or loss

incurred in transit. We will, however, at your request, supply

you with the necessary documents to support your claim.

xi

Page 3

TABLE OF CONTENTS

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

AGENCY LISTING INFORMATION 4

PRECAUTIONS & GENERAL INFORMATION 5

INSTALLATION 6

PREPARATION PRIOR TO OPERATION 8

OPERATION 11

MAINTENANCE INSTRUCTIONS

FILTER OPERATION 12

DISCARDING USED OIL 15

CLEANING 16

TROUBLESHOOTING SUGGESTIONS 18

EXPLODED VIEW & PARTS LIST 19

WIRING DIAGRAM 27

PARTS & SERVICE 29

CUSTOMER SERVICE DATA 29

INTRODUCTION

Thank You for purchasing this Wells Bloomfield appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that

it gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for

the appliance in a manner which will ensure its optimum performance.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

DIMENSIONS

CAPACITIES

VOLTAGE

REQUIREMENTS

POWER

CONSUMPTION

AMPERAGE

SPECIFICATIONS

Wide Deep High

15.62” 33.25” 40.0”

Cooking Oil

(Liquid Shortening Only)

Chicken (Fresh) 14 6

Chicken (Frozen) 12 5

ELECTRICAL SPECIFICATIONS

DOMESTIC EXPORT (EU)

208 VAC

NOTE: Shipped from factory 3Ø, field convertible to 1Ø

9,000 watts

43.3 amps (1 ø)

25.0 amps per leg (3ø)

21.7 amps per leg (3ø)

Lbs. Kg.

30

240VAC

9,000 watts

37.5 amps (1 ø)

L1 = 14,3 amps

L2 = 13,0 amps

L3 = 13,0 amps

14

380-415V

3NAC

9.300 watts

N = 2,7 amps

1

Page 4

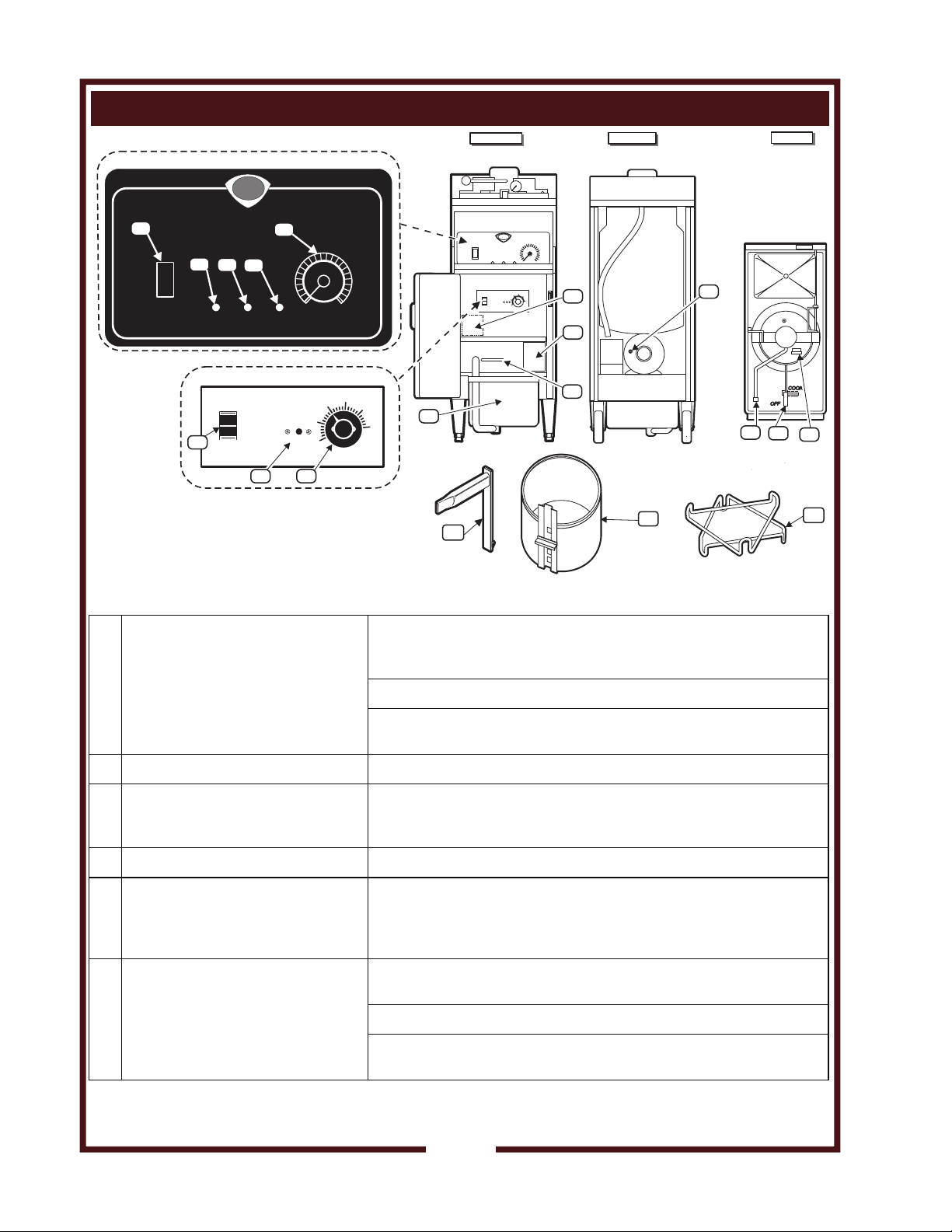

FEATURES & OPERATING CONTROLS

WELLS

1

2

3

4

5

6

7

8

9

10

0

11

12

13

14

15

16

17

18

19

20

21

UPPER CONTROL PANEL

FRONT VIEW

BACK VIEW

TOP VIEW

1

2

FRYER

FILTER

OFF

3

POWER

HEAT

5

4

TIMER

COOK

LOWER CONTROL PANEL

HI-LIMIT

RESET

THERMOSTAT

300

250

275

8

325

350

375

ºF

10

6

FILTER

ON

OFF

CAUTION

FRYERMUST BE OFF

BEFORE USINGFILTER

7

Fig. 1 WFPE-30F Features & Operating Controls

1

POWER SWITCH

(FRYER-OFF-FILTER)

FRYER position energizes the FRYER and POWER LIGHT;

de-energizes FILTER PUMP. HEATING ELEMENTS energized

and regulate to setting on CONTROL THERMOSTAT (8).

OFF position de-energized FRYER and FILTER PUMP.

FILTER position de-energizes FRYER; energizes FILTER PUMP

SWITCH (6).

12

9

16

11

14

13

15

18

19

17

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

POWER LIGHT (amber) Glows to indicate FRYER is energized.

2

3

HEAT LIGHT (amber)

COOK LIGHT (amber) Glows to indicate COOK LEVER in cook position.

4

5 TIMER

FILTER PUMP SWITCH

6

(ON-OFF)

Glows to indicate HEATING ELEMENT energized;

Off when oil temperature reaches setting on CONTROL

THERMOSTAT (8).

Controls LIFT CRADLE AND BUZZER. Start TIMER by pressing

red button at center of knob. Lift CRADLE will lower. Pointer

indicates time remaining. When time reaches “0” BUZZER

sounds and LIFT CRADLE raises.

ON position energizes FILTER PUMP and causes oil in

RESERVOIR (10) to be pumped back into frypot.

OFF position de-energizes FILTER PUMP.

NOTE: POWER SWITCH (1) must be in FILTER position for

FILTER PUMP to operate.

2

Page 5

FEATURES & OPERATING CONTROLS (continued)

hi-limit bulb and the element to enhance oil flow and facilitate reset.

Otherwise, contact your authorized Wells Service Agent for repairs.

7

HI-LIMIT THERMOSTAT

TEMPERATURE CONTROL

8

THERMOSTAT

9 FILTER PUMP MOTOR

RESET BUTTON

(located at rear of motor)

10 OIL FILTER RESERVOIR

11 DRAIN VALVE LEVER

WARNING

WARNING:

FIRE HAZARD / HOT OIL

The HI-LIMIT THERMOSTAT is a FIRE PROTECTION DEVICE.

If tripping persists, clean debris from the space between the

DO NOT ATTEMPT TO BYPASS OR HOLD IN THE BUTTON OF

THE HI-LIMIT THERMOSTAT. A SERIOUS FIRE MAY RESULT.

Provides over-temperature protection by de-energizing HEATING

ELEMENTS should oil temperature exceed factory pre-set limits.

Controls oil temperature. Range: 250ºF (121ºC)

375ºF (191ºC)

FILTER PUMP MOTOR is equipped with an overheating

protection device.

RESET must be performed manually. Allow motor to cool for

approx. 30 min, then firmly press the red button.

Collects oil from FRYPOT for filtering or disposal.

Holds filter screen, filter paper & filter paper holder.

Opens and closes the DRAIN VALVE:

Turn counterclockwise (vertical) to OPEN

Turn clockwise (horizontal) to CLOSE

12 POWER OUTLET BOX

13 COOK LEVER

14 CONTROL HANDLE

15 PRESSURE GAUGE

16 DRIP PAN

17 BASKET HANDLE

18 FRY BASKET

19 BASKET RACK

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

Electrical service connection TERMINAL BLOCK located here.

COOK position allows pressure to build by closing exhaust valve;

also, energizes timer

OFF position relieves frypot pressure by opening exhaust valve

Lifts or lowers LID into/out of frypot

Rotate fully CCW to lock lid under pressure

Shows steam pressure inside frypot

Normal operating pressure is 8—12 psi

Collects liquids that accumulate on top of fryer.

Used to manually raise and lower FRY BASKET into and out of

FRYPOT.

REMOVE FROM BASKET BEFORE SLIDING LID FORWARD!

Holds product to be cooked.

Prevents FRY BASKET from contacting heating elements

3

Page 6

FEATURES & OPERATING CONTROLS (continued)

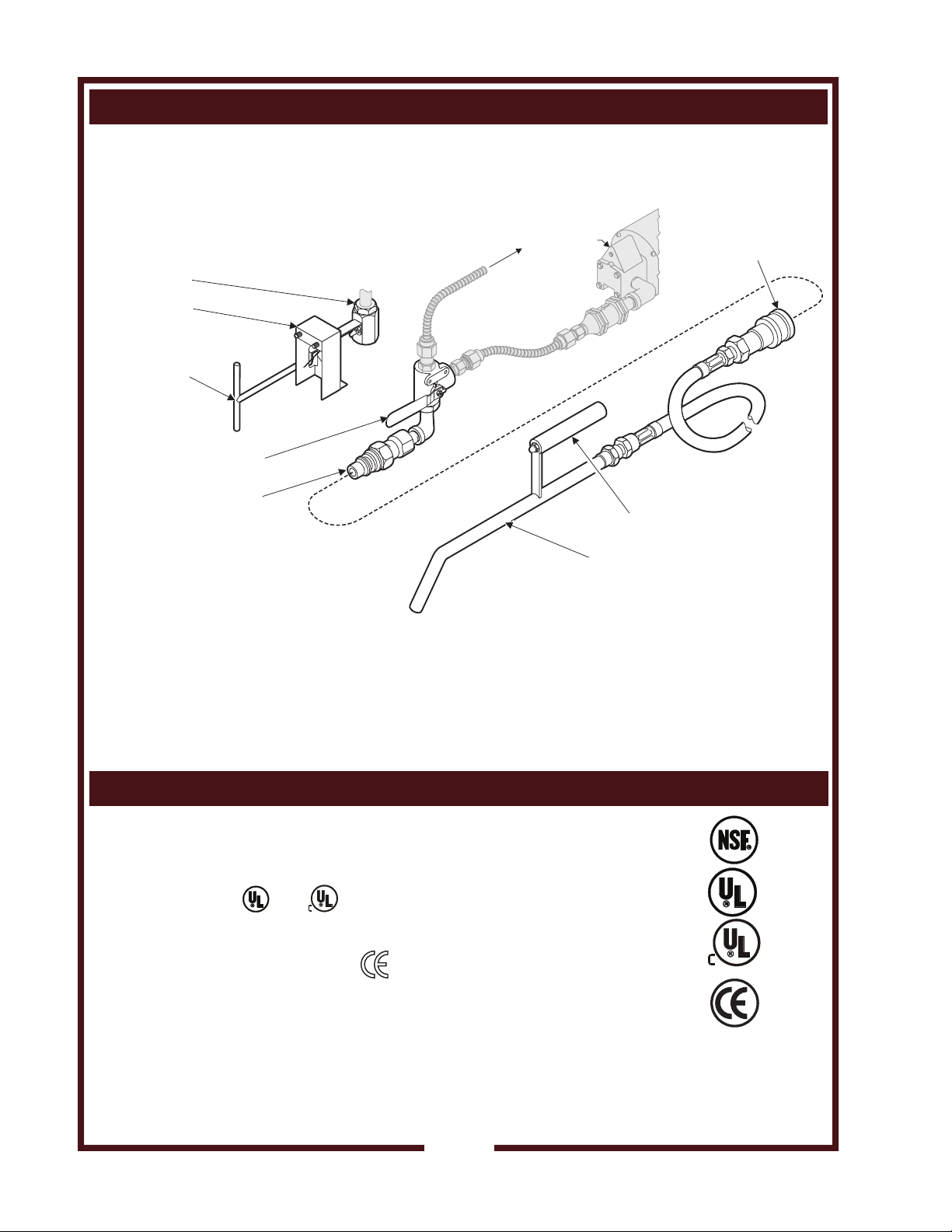

OPTIONAL FILTER WAND

DRAIN VALVE

SAFETY SWITCH

DRAIN HANDLE

3-WAY VALVE HANDLE

QUICK DISCONNECT

MALE FITTING

TO FRYPOT

NOTE: Wand option must be ordered at time of initial build.

FILTER

PUMP

INSULATED HANDLE

WAND ASSEMBLY

QUICK DISCONNECT

FEMALE FITTING

LOCKING RING

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions and

maintained according to the instructions in this manual.

Domestic fryers are and listed under UL File E6070 for 208V

and 240V.

Export (European) fryers comply with standards

for 380-415V 3NAC.

4

STD 4

E6070

E6070

Page 7

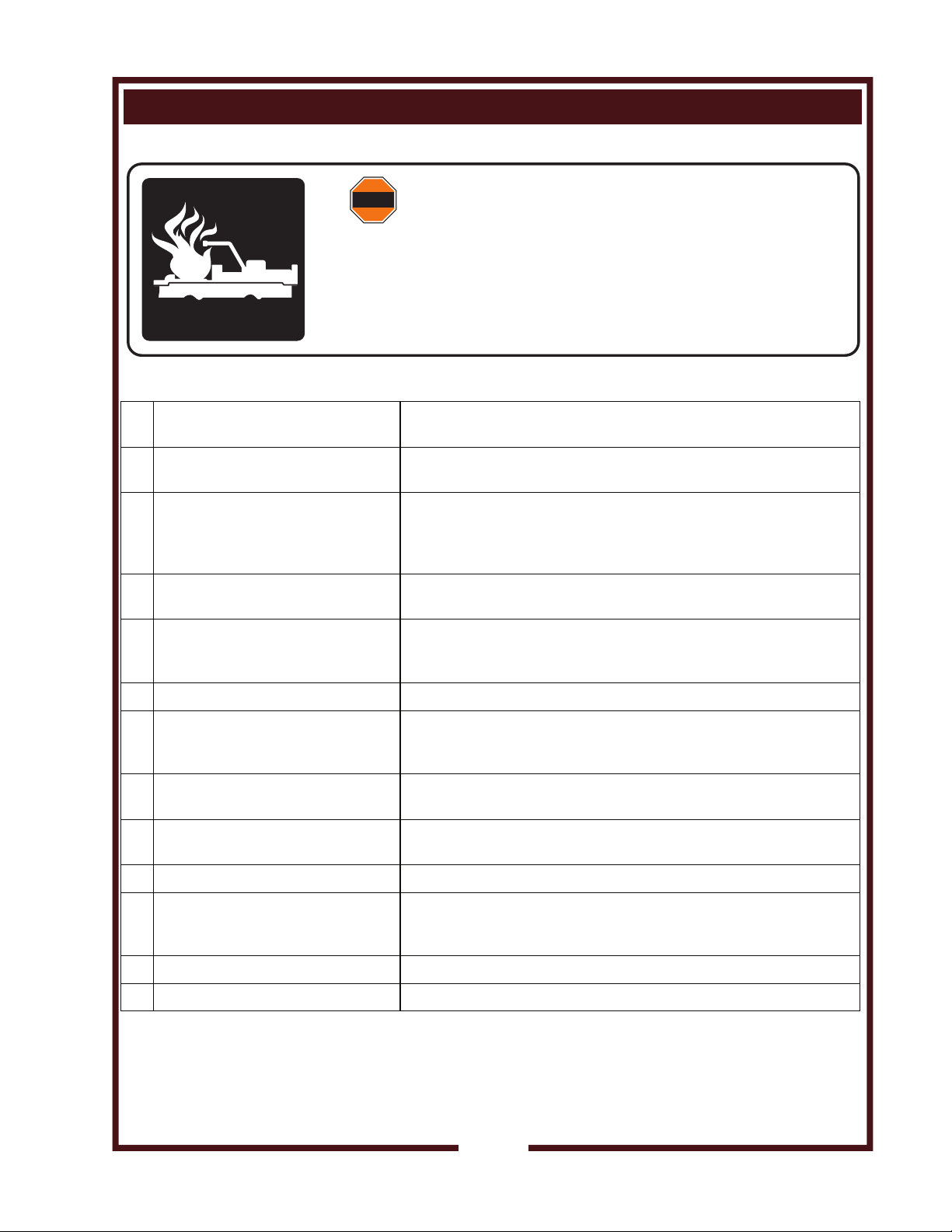

PRECAUTIONS AND GENERAL INFORMATION

This appliance is intended for use in commercial establishments

only.

This appliance is intended

No other use is

agents.

DO NOT open any panel that requires the use of tools for access. Live

electric circuits may be exposed by opening such panels. Opening

access panels must be performed by an Authorized Service Agent

only.

This appliance is equipped with an oil filtration system designed to filter

hot liquid shortening only. Water, cleaning agents and/or other liquids

will contaminate the oil and may damage the filter pump.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

DO NOT submerge any part of this appliance in water unless

specifically instructed to do so. This appliance is not jet stream

approved. DO NOT direct water jet or steam jet at this appliance,

nor at any control. DO NOT splash or pour water on, in or over any

controls. DO NOT wash area around this appliance with water jet.

Any part which has become wet must be thoroughly dried before use.

Cooking oil will be very hot when in use. Contact will cause severe

injury, and can cause blindness or death. Wear appropriate heatprotective clothing when operating or servicing this appliance.

This appliance operates under pressure. Be sure CONTROL HANDLE

is turned fully counterclockwise before initiating a cook cycle. Do not

attempt to open FRYPOT LID until all pressure has bled off and

pressure gauge reads “0”.

This appliance must be operated with the supplied legs and casters

properly installed

The technical content of this manual, including any parts breakdown

illustrations and/or adjustment procedures, is intended for use by

qualified technical personnel only.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

recommended or authorized by the manufacturer or its

to prepare food for human consumption.

DANGER:

BURN HAZARD

Cooking oil in this appliance

operates at very high

temperatures. Contact with

hot oil can cause severe

injury or death. Wear

appropriate heat-protective

clothing when operating or

servicing this appliance.

Never attempt to open the

frypot if the pressure gauge

reads anything other than

“zero” (0) psi.

WARNING:

BURN HAZARD

DO NOT allow water or ice to

contact hot oil. DO NOT

attempt to cool the oil with

water or ice. The water will

boil violently, causing hot oil

to foam and splatter.

Contact with splattering or

foaming hot oil will cause

severe burns.

WARNING:

SLIP AND FALL

HAZARD

Spilled cooking oil is very

slippery and can cause falls.

Clean up oil spills promptly.

CAUTION:

BURN HAZARD

Exposed surfaces can be hot

to the touch and may cause

burns.

CAUTION:

HEALTH HAZARD

Old cooking oil can be a

breeding ground for bacteria.

Clean and sanitize exterior

surfaces of fryer regularly.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

4

Page 8

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

FIRE HAZARD

Do not store gasoline or

any other flammable or

combustible material near this

appliance.

The area where the fryer is

installed must be kept clear of

combustibles and flammables.

This includes mops, rags,

grease, wrapping paper and

electric cords.

Installation and startup must

be performed by a Wells

Manufacturing Authorized

Service Agency.

IMPORTANT:

Certain jurisdictions require

fryers to be restrained with a

TETHER or other approved

restraint device. It is the

responsibility of the installer

to check with the AUTHORITY

HAVING JURISDICTION in

order to ascertain the applicability

of this requirement

THIS SPECIFIC INSTALLATION.

Installer must complete the

WARRANTY REGISTRATION

and FRYER CHECKOUT

form, and record the details of

the particular installation on

the CUSTOMER SERVICE

DATA form in this manual.

to

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all

protective plastic film, packing materials and accessories from the

appliance before connecting performing any installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before

discarding packing materials. Store all accessories in a convenient

place for later use.

COMPONENTS

1 ea. FILTER RESERVOIR

1 ea. FILTER SCREEN

1 ea. FILTER PAPER HOLDER

4 ea. OIL FILTER SUCTION TUBE O-RINGS (small, bla c k)

1 ea. O-RING FOR LID (large, red)

1 ea. FRY BASKET

1 ea. BASKET LIFTING HANDLE

1 ea. BASKET RACK

ACCESSORIES

1 ea. LITERATURE PACKAGE

1 pk. FILTER PAPER

1 pk. FILTER POWDER

2 ea. HIGH TEMPERATURE BRUSHES

1 ea. CLEANOUT DOWEL (wood rod)

SETUP

It is the responsibility of the installer to verify that this fryer installation is

in compliance with local code authorities and with the specifications

listed in this manual.

Certain local or state codes require fryers to be restrained with a tether

or other approved restraint device. It is the responsibility of the installer

to check with the authority having jurisdiction, in order to ascertain the

applicability of this requirement to this specific fryer installation.

Setup the fryer only on a firm, level, non-combustible surface. Verify

local codes for requirements. Concrete, tile, terrazzo or metal surfaces

are recommended. Metal or tile over combustible material may not

meet code for non-combustible surfaces.

Verify that the unit sits firmly ON BOTH CASTERS AND BOTH LEGS.

With the adjustable legs, adjust as required to level the appliance.

Both legs and both casters must be adjusted to firmly contact the floor

in order to prevent tipping.

Refer to the Installation Instruction Sheet for required clearances.

Maintain required clearances between the appliance and adjacent

combustible surfaces.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

6

Page 9

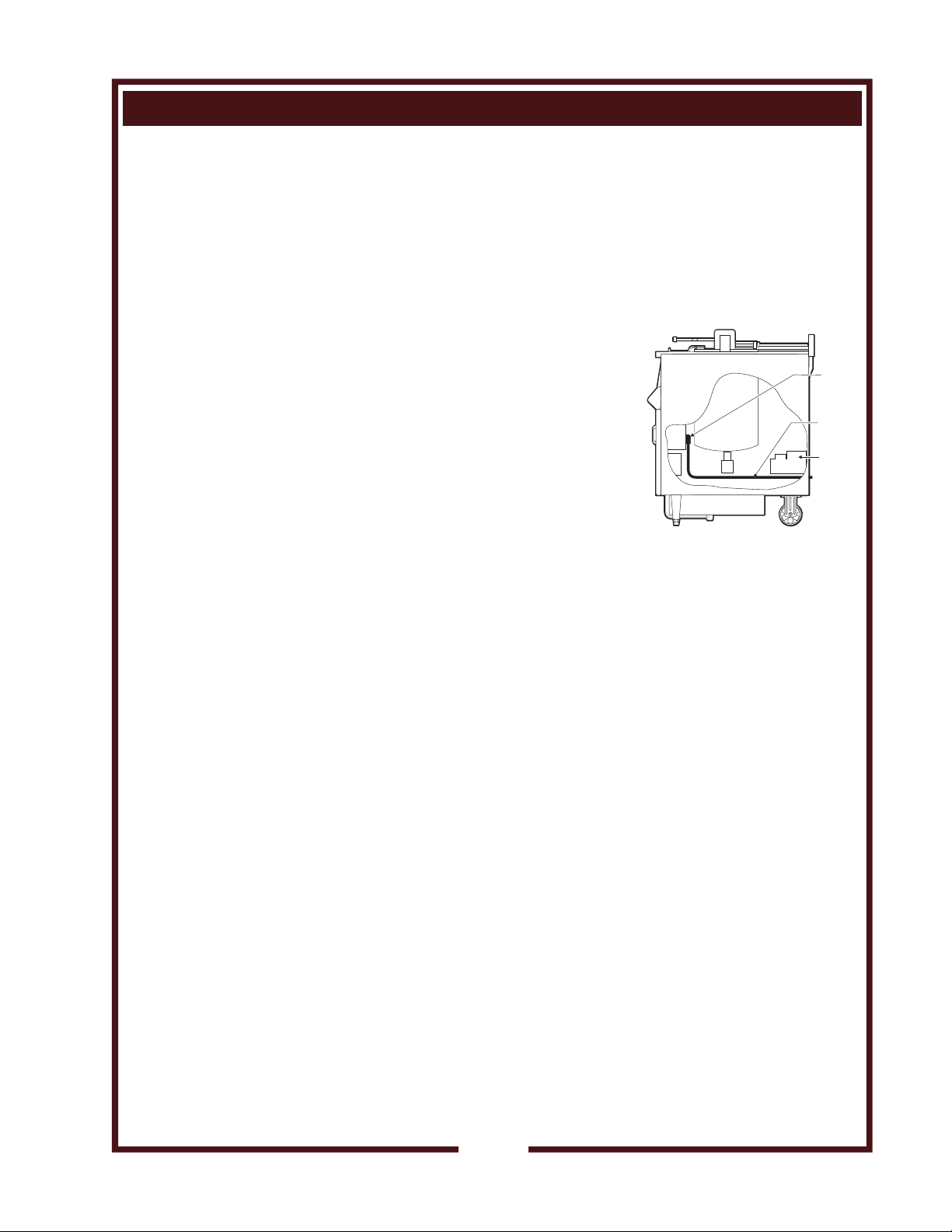

INSTALLATION (continued)

SUPPLY

SERVICE

(FIELD)

WIRING

FILTER

PUMP &

MOTOR

FRYPOT

90º

CONDUIT

FITTING

ELECTRICAL INSTALLATION

Refer to the nameplate on the front of the fryer and to the specifications

listed on page 1 of this manual. Verify that electric service voltage,

phase and amperage capacity meet or exceed these specifications.

Field wiring must be no less than 12 ga. Solid copper wire, rated for at

lease 75ºC.

Fryers are shipped from the factory wired for 3Ø. Verify that field wiring

conforms to the Three-Phase Wiring Diagram included with the fryer.

NOTE: Fryers are FIELD-CONVERTIBLE TO 1Ø. For single-phase

operation refer to the 3-phase to 1-phase Instructions included with the

fryer. Verify that both internal wiring and field wiring conforms to the

Single-Phase Wiring Diagram included with the fryer.

IMPORTANT:

Field wiring must be routed and secured away from the FRYPOT,

TUBING and FILTER PUMP MOTOR. Field wiring must be configured

to allow access to the rear of fryer for cleaning and access to the filter

pump motor RESET BUTTON.

IMPORTANT:

Electric installation of this

appliance must be performed

by a licensed electrician.

Installation must conform to

the requirements of local

codes and ordinances, as

well as to the requirements of

the National Electrical Code.

Fig. 2 Field Wiring

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

7

Page 10

PREPARATION PRIOR TO OPERATION

CAREFULLY FOLLOW CLEANSER INSTRUCTIONS AND WARNINGS.

Prior to leaving the factory,

each fryer is tested for proper

operation. Oil residue must be

cleaned from the frypot before

filling it with fresh oil.

IMPORTANT:

Use a LOW-FOAMING

COMMERCIAL fryer cleanser

only.

IMPORTANT:

Stretch the o-ring only enough

to install it in the o-ring groove.

IMPORTANT:

Verify that the o-ring is fully

seated in the o-ring groove for

its entire circumference.

WARNING

WARNING:

BURN HAZARD

TURN THERMOSTAT TO LOWEST TEMPERATURE SETTING

(FULLY COUNTERCLOCKWISE)

USE ONLY LOW-FOAMING COMMERCIAL FRYER CLEANSER.

DO NOT LEAVE FRYER UNATTENDED

WHILE BOILING OUT FRYPOT.

WHEN WATER BEGINS FOAMING,

BE PREPARED TO TURN POWER SWITCH OFF.

Boiling water and splatter can result in moderate to serious injury.

PRE-CLEANING PROCEDURE

Slide the LID AND YOLK back. Press POWER SWITCH OFF.

Close DRAIN VALVE (lever horizontal). Fill FRYPOT with 4 gallons of

cold water.

Press POWER SWITCH to FRYER.

When water comes to a full boil, press POWER SWITCH OFF.

When boiling ceases, slowly add and stir in the LOW FOAMING

COMMERCIAL FRYER CLEANSER. Using the HIGH

TEMPERATURE BRUSH supplied with the fryer, stir until the

cleanser is completely dissolved.

Press POWER SWITCH to FRYER. When the water begins to boil,

press POWER SWITCH OFF. When the boiling subsides, again

press POWER SWITCH to FRYER. Repeat this procedure

continuously for five (5) minutes.

Press POWER SWITCH OFF. Allow the solution to cool to 120ºF or

less.

Place a suitable METAL container under the DRAIN VALVE. Open

DRAIN VALVE (lever vertical) to drain the cleaning solution.

NOTE: Drain no more than 4” at a time into the container to prevent

splashing and spilling.

ordinances.

Rinse frypot with clean water. Dry with a soft clean cloth.

PREPARE FRYPOT LID

Tilt LID AND YOKE to the right.

Coat the large red O-RING, and the O-RING GROOVE in the LID with

clean cooking oil.

Carefully work the O-RING into the O-RING GROOVE.

Dispose of used solution as required by local

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

8

Page 11

PREPARATION PRIOR TO OPERATION (continued)

PREPARE FILTER RESERVOIR

Install SUCTION TUBE O-RINGS, FILTER PAPER and FILTER

PAPER HOLDER into RESERVOIR.

Install assembled FILTER RESERVOIR in place a bottom of FRYER.

FILTER

PAPER

HOLDER

FILTER

PAPER

FILTER

SCREEN

(clip inserts into

drain opening)

“O” RING

FILTER

RESERVOIR

RESERVOIR

ASSEMBLY

CROSS-SECTION VIEW

STORAGE FOR 3

SPARE “O” RINGS

“O” RING IN

“O” RING GROOVE

WARNING

WARNING:

DO NOT OPERATE UNLESS DRIP PAN IS INSTALLED.

Oil will drip on the floor and slips/falls will result.

Death or serious injury may result from slipping and falling in spilled oil.

Install DRIP PAN (item 17) into mounting bracket behind fryer door.

WARNING

WARNING:

CLOSE DRAIN VALVE BEFORE FILLING WITH OIL.

Unless drain valve is closed, oil poured into kettle will drain into

reservoir or onto the floor. Oil spill may occur.

Death or serious injury may result from slipping and falling in spilled oil.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

Close DRAIN VALVE (item 11) by turning lever to horizontal position.

SLIP/FALL HAZARD

SLIP/FALL HAZARD

9

Page 12

PREPARATION PRIOR TO OPERATION (continued)

COOK

HEAT

POWER

FRYER

OFF

FILTER

WELLS

300

325

350

THERMOSTAT

FILTER

ON

OFF

CAUTION

FRYER

MUSTBEOFF

BEFORE

USINGFILTER

250

275

375

ºF

HI-LIMIT

RESET

NOTE:

Fill frypot with 30 lbs of

LIQUID SHORTENING

ONLY.

MAX (COLD)

30 LB. 13KG OILLEVEL

MIN (HOT)

OIL LEVEL INDICATOR

DO NOT USE

• SOLID SHORTENING

• LARD

Solid shortening will solidify in

the filter reservoir and filter

pump rendering the filtration

system inoperable.

Damage caused the use of

anything other than liquid

shortening is NOT COVERED

BY WARRANTY.

Fill the FRYPOT to the COLD (MAX) line on OIL LEVEL INDICATOR

with room temperature commercial-quality LIQUID SHORTENING.

This requires 30lbs. of oil.

Check operation of FRYER and all CONTROLS.

CONTROL HANDLE

(SHOWN CLOSED

AND LOCKED)

COOK

OFF

13

COOK

LEVER

14

OFF

CAUTION

FRYERMUSTBEOFF

BEFOREUSINGFILTER

CONTROL HANDLE

(SHOWN OPEN)

DRIP

250

PAN

DRAIN

VALVE

LEVER

RESERVOIR

14

16

FILTER

DRAIN VALVE

11

The weight of product that can safely be cooked in this pressure fryer

will vary with oil level, product moisture content and oil temperature.

FAILURETO DETERMINE THE SAFE WEIGHT OF PRODUCT

Death or serious injury may result from slipping and falling in spilled oil.

IMPORTANT:

For operational safety it is

important to determine the

maximum load weight for the

specific operation:

• Start with small loads

• Gradually increase load

size

• Determine the largest load

that still allows the operator

time to close and lock the

lid handle (item 14) without

oil foaming out of the frypot.

• Post the maximum load in a

conspicuous spot near the

fryer.

WARNING

WARNING: OIL SPLATTER HAZARD

WILL RESULT IN HOT OIL RELEASE FROM THE FRYER

HOT OIL WILL CAUSE SEVERE BURNS ON CONTACT

LATCH LID - TURN

LOWER BASKET

REMOVE HANDLE

SLIDE LID

FORWARD

CONTROL LEVER

TO COOK POSITION

Load product, and determine maximum load.

10

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

Page 13

OPERATION

1

2

3

4

5

6

7

8

9

10

0

11

12

13

14

15

16

17

18

19

20

TIMER

21

TURN TO SET TIME

PRESS RED BUTTON TO STARTTIMER

PRE-HEATING FRYER

Make sure FRYPOT is filled with 30 LB. of cooking oil.

Open door and set THERMOSTAT (item 10) to desired cooking

temperature. CLOSE THE DOOR.

Set POWER SWITCH (item 1) to FRYER. POWER LIGHT (item 2)

and HEAT LIGHT (item 3) will glow. HEAT LIGHT will cycle on and

off with the HEATING ELEMENTS. When HEAT LIGHT first goes off,

fryer is ready to cook the product.

SET COOK TIMER AND LOAD PRODUCT

Set TIMER (item 5) to desired cooking time.

FROZEN PRODUCT:

Load frozen product into BASKET. Using the BASKET HANDLE

(item 17) set BASKET on BASKET RACK.

IMPORTANT: REMOVE HANDLE.

FRESH PRODUCT:

Using BASKET HANDLE, set BASKET on BASKET RACK.

IMPORTANT: REMOVE THE HANDLE.

Manually drop each piece of fresh product into hot oil, just above

the oil level to minimize splattering.

ALWAYS USE PROTECTIVE EQUIPMENT, SUCH AS INSULATED

GLOVES, TO PROTECT AGAINST HOT OIL BURNS.

Slide FRYPOT LID forward until feet of yoke assembly are engaged

in slots in frypot blocks.

Rotate CONTROL HANDLE fully counter-clockwise to lower lid into

frypot and to engage lock pawl.

Rotate COOK LEVER to COOK position.

Set desired time on TIMER. Press RED BUTTON on TIMER to begin

cook cycle.

COOK CYCLE

Pressure will build in frypot as moisture in the product is converted to

steam. Pressure may be monitored on PRESSURE GAUGE.

At end of cook cycle rotate COOK LEVER to OFF position to relieve

steam pressure. Wait until all pressure has bled from frypot and

PRESSURE GAUGE reads “0”.

Turn CONTROL HANDLE fully counterclockwise to disengage locking

pawl, then fully clockwise to raise lid from frypot. Slide frypot lid fully

to the rear.

Use BASKET HANDLE to remove basket of cooked product from

frypot. Serve or dispense cooked product as required.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

11

CAUTION:

BURN HAZARD

Hot oil can cause serious burns

on contact. Wear appropriate

protective clothing when using

this fryer.

IMPORTANT:

Always remove basket handle

from basket before sliding frypot

lid forward.

Page 14

MAINTENANCE - FILTER OPERATION

DO NOT REMOVE FILTER RESERVOIR WHEN IT CONTAINS HOT OIL

Death or serious injury may result from contact with, or slipping and falling in, spilled oil.

IMPORTANT:

Replace filter paper after each

day’s filtration, or as needed to

return oil promptly to kettle.

IMPORTANT:

Crumbs and other debris left in

the filter reservoir can prevent

filter paper from sealing to

bottom of reservoir completely.

This will cause incomplete

filtration.

WARNING

WARNING:

BURN HAZARD

HOT OIL SPILL OR SPLATTER

HOT OIL WILL CAUSE SEVERE BURNS ON CONTACT

PROTECTIVE CLOTHING AND GLOVES MUST BE WORN

DURING THE FILTERING PROCESS

WARNING

WARNING:

BURN HAZARD

DO NOT REMOVE FILTER RESERVOIR IF IT IS HOT

WEAR PROTECTIVE GLOVES OR

ALLOW RESERVOIR TO COOL BEFORE REMOVING

Oil will rapidly heat the reservoir. Serious burns can result

from touching the filter reservoir with bare hands.

FILTER PAPER INSTALLATION

1. Open FRYER DOOR and remove FILTER RESERVOIR.

2. Remove FILTER PAPER HOLDER, used FILTER PAPER and

FILTER SCREEN. Discard used filter paper and make sure filter

reservoir, filter screen and filter paper holder are clean and dry.

3. Install FILTER SCREEN in reservoir with spring clip on screen

pressed firmly into drain hole, and aligned parallel to sides of

reservoir. See diagram, page 9.

4. Place a NEW SHEET of filter paper on reservoir, with edges of

the paper evenly overhanging reservoir flanges.

5. Center FILTER PAPER HOLDER over filter paper, then press

firmly into reservoir. Make sure filter paper holder rests firmly on

reservoir bottom, with paper protruding evenly up all sides.

6. Inspect O-RING on FILTER SUCTION TUBE for damage.

Replace o-ring if it is scuffed, cut or cracked. Spare o-rings are

stored midway on the top portion of the suction tube.

7. Install filter reservoir assembly into fryer. Make sure o-ring

closest to end of suction tube is firmly seated in SUCTION LINE

RECEPTACLE.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

12

Page 15

MAINTENANCE - FILTER OPERATION (continued)

FILTERING OIL

NOTE:

Oil should be at least 300ºF (149ºC) DO NOT attempt to filter cold oil.

DO NOT attempt to pump oil when less than 300ºF. Cold oil will not

pass through the filter paper. Filtering cold oil will result in the

premature failure of the filter pump. Damage as a result of pumping

cold oil IS NOT COVERED BY WARRANTY.

NOTE:

DO NOT store oil in the reservoir for any extended period, including

overnight.

IMPORTANT:

The filtration system in your Wells Fryer is designed to filter hot liquid

shortening ONLY. Water, cleaning agents or other liquids will

damage the filter pump and may contaminate the food product

1. Press POWER SWITCH (item 1) to FILTER. Pump controls will

be energized and heating elements are de-energized.

2. Remove and examine filter reservoir:

• Verify that a serviceable sheet of filter paper is properly

installed.

• Verify that an o-ring is in place and in good condition.

Reinstall reservoir, making sure the SUCTION TUBE is firmly

seated in the SUCTION RECEPTACLE.

3. Press FILTER PUMP SWITCH (item 8) to ON to start filter pump.

4. Slowly rotate DRAIN VALVE LEVER (item 11) to the vertical

position. Oil will drain from the frypot and into the reservoir. The

filter pump will draw oil through the filter paper and return it to the

frypot.

IMPORTANT:

DO NOT leave the fryer unattended during the filtering process.

Continuously monitor oil level in the reservoir to avoid overflowing

the reservoir and spilling oil on the floor. Be prepared to turn the

drain valve lever clockwise to stop or regulate the flow of oil to the

reservoir.

5. Carefully and slowly add the contents of one package of FILTER

POWDER to the oil in the frypot. Sprinkle the filter powder onto

the surface of the oil at the point where it is being drawn down the

drain and into the filter reservoir.

(CONTINUED ON PAGE 14)

CAUTION

BURN HAZARD

Protective clothing and gloves

must be worn during the filtering

process

CAUTION

BURN HAZARD

Filter reservoir may be hot.

Wear insulated gloves, or

allow reservoir to cool,

before touching it.

IMPORTANT:

Filtering cooking oil helps to

ensure the quality of the food

product. Careful observation of

the finished food product will

help you determine the optimal

filtering frequency.

(Example: Filter the oil after

each six loads of fresh breaded

chicken)

FILTER POWDER absorbs

acids and many other

contaminants in the cooking oil,

allowing the oil to be used

longer before it must be

replaced. Wells Flavor Saver

Oil Filter Powder is available

from your Wells Equipment

Dealer or Authorized Service

Agent in a case of 45 packages

(p/n 22410).

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

13

Page 16

MAINTENANCE - FILTER OPERATION (continued)

WHEN CLEANING FRYPOT WITH HI-TEMP BRUSH AND WHEN

NOTE:

Use the provided WOOD

DOWEL to clear clogs in the

frypot drain. Push dowel down

through drain hole in the center

of frypot..

IMPORTANT:

Verify that all oil has been

returned to frypot at end of

filtering cycle.

IMPORTANT:

Crumbs and other debris left in

the filter reservoir can prevent

filter paper from sealing to

bottom of reservoir completely.

This will cause incomplete

filtration.

IMPORTANT:

Avoid contaminating the oil or

food product by verifying that all

components of filter reservoir

assembly are completely dry

before reassembling.

WARNING

WARNING: BURN HAZARD

WEAR PROTECTIVE CLOTHING AND INSULATED GLOVES

CLEARING DRAIN WITH WOOD CLEANOUT DOWEL.

Frypot and oil will be hot. Hot oil may splatter.

Contact with hot oil can cause serious injury

(CONTINUED FROM PAGE 13)

6. Brush down sides and bottom of frypot using provided

hi-temperature brush. Loosen crumbs and other debris to flush

them into filter reservoir.

7. Rotate DRAIN VALVE LEVER (item 11) to the horizontal position

when filtering is complete,

8. Observe the oil returning to frypot. When bubbles appear, wait

approximately 15 seconds, then press FILTER PUMP SWITCH

to OFF.

9. Press POWER SWITCH to either:

a. FRYER position to resume cooking; or,

b. OFF position to service filter or shut-down fryer.

FILTER SERVICE - REPLACE FILTER PAPER

IMPORTANT:

Service filter and replace filter paper after each day’s filtration, or as

needed to promptly return oil to frypot.

1. Allow FILTER RESERVOIR to cool. Remove reservoir from fryer

and disassemble.

2. Dispose of used filter paper as required by local ordinances.

3. Clean FILTER RESERVOIR, FILTER SCREEN and FILTER

PAPER HOLDER in the dishwasher, or use warm water with a

mild detergent. Be sure all components are thoroughly dry, then

reassemble reservoir using a fresh sheet of filter paper.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

14

Page 17

MAINTENANCE - DISCARDING USED OIL

WARNING

WARNING:

BURN HAZARD

OIL MUST COOL TO BELOW 120ºF (49ºC)

BEFORE DRAINING OIL FROM FRYER FOR DISPOSAL

Normal operating temperature of the fryer is 375ºF (191ºC)

Contact with hot oil can cause serious injury

WARNING

WARNING:

SLIP AND FALL HAZARD

DO NOT USE FILTER RESERVOIR TO DISCARD OIL

USE A METALCONTAINER TO COLLECT OIL FOR DISPOSAL

DO NOT FILL DISPOSAL CONTAINER MORE THAN ½ FULL

Do not leave fryer unattended when draining oil

Oil spills may occur

Death or serious injury may result from contact with, or slipping and falling in, spilled oil.

WARNING

WARNING:

BURN HAZARD

DO NOT REMOVE FILTER RESERVOIR IF IT IS HOT

WEAR PROTECTIVE GLOVES OR

ALLOW RESERVOIR TO COOL BEFORE REMOVING

Oil will rapidly heat the reservoir. Serious burns can result

from touching the filter reservoir with bare hands.

1. Press POWER SWITCH to OFF. Allow oil to cool to 120ºF (49ºC)

or less before attempting to drain oil from fryer.

2. With a suitable METAL container under DRAIN VALVE, slowly

rotate DRAIN VALVE LEVER to the vertical position. Fill the

container no more than 4” (100mm) deep.

3. Move the DRAIN VALVE LEVER to the horizontal position.

4. Carefully remove container from under fryer. Dump used oil into

your WASTE OIL CONTAINER. Repeat steps 2 & 3 until frypot is

empty.

5. Be sure DRAIN VALVE LEVER is in the CLOSED (horizontal)

position when finished.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

IMPORTANT NOTE:

These instructions for

discarding used oil may be

disregarded if you are using

WELLS MOBILE OIL CADDY

WOC-1 (p/n 22470).

The WAOC-1 is a manual oil

pump/removal system that

allows you to pump used oil

directly into the caddy, and then

to pump the used oil into your

oil disposal container simply by

reversing pump direction.

REMEMBER:

Always follow the directions

provided with the caddy.

WAOC-1 is designed to handle

COLD oil. Always, and without

fail, allow the oil to cool to

120ºF or less prior to pumping.

HOT OIL WILL BURN YOU!

15

Page 18

MAINTENANCE - OPTIONAL FILTER WAND OPERATION

DANGER:

Contact with hot oil will cause

severe burns.

Always wear protective clothing

and heat resistant gloves when

using the oil wand.

IMPORTANT:

Be sure the wand is properly

installed, and that the discharge

nozzle of the oil wand is directed

either:

into the frypot, or

into the disposal container, before

pressing the

switch to the FILTER position.

BURN HAZARD

FRYER-OFF-FILTER

CAUTION:

BURN HAZARD

Contact with hot oil may cause

burns. DO NOT fill fryer beyond

MAX OIL line on frypot.

For disposal of oil use only a

container specifically designed

for the disposal of hot oil.

DO NOT fill hot oil disposal

container beyond MAX OIL line.

NOTE:

If the discharge from the nozzle is

not a steady stream, the filter is

clogged with breading and/or filter

powder:

a. Close the frypot drain valve

by turning the drain valve

handle to the horizontal

position. When all oil is

returned to the frypot,

press the FRYER-OFF FILTER to OFF.

b. Allow the filter reservoir to

cool. Refer to the Operation

Manual for instructions on

cleaning the filter and filter

reservoir.

TO WAND

OPTIONAL OIL WAND

WASH OUT FRYPOT or DISCARD OIL

1. If discarding oil, be sure a suitable hot oil disposal container

is available. Otherwise, prepare filter reservoir pan for

filtering (see page 12).

2. Turn DRAIN VALVE HANDLE vertical to open the drain and fill

3. Connect wand (female) fitting to the fryer (male) fitting:

a. Slide locking ring of wand female fitting fully toward the

hose.

b. Seat wand fitting fully onto fryer fitting.

c. Allow locking ring to return to its original position.

d. Check to verify that wand fitting is held securely by pulling

on the hose. It must NOT “pop” off of fitting.

4. Turn 3-WAY VALVE HANDLE to horizontal position to direct

5. Direct discharge nozzle of wand into the frypot, or into a

suitable hot oil disposal container. DO NOT fill beyond

the MAX OIL line.

6. Press FRYER-OFF-FILTER switch to FILTER position.

7. Wand may be used to wash down sides of the frypot during

filtering, or to pump oil into a container for disposal.

DRAIN "OPEN"

(HANDLE VERTICAL)

3-WAY VALVE TO "WAND"

(HANDLE HORIZONTAL)

WAND PROPERLY

CONNECTED

filter reservoir.

the pump output to wand.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

16

Page 19

MAINTENANCE - OPTIONAL FILTER WAND OPERATION (continued)

FRYER

OFF

FILTER

HEATER SAFETY SWITCH

(" " WHEN DRAIN

SAFE

HANDLE FULLY CLOSED)

DRAIN "

CLOSED"

(HANDLE HORIZONTAL)

3-WAY VALVE

TO “ ”

FRYPOT

(HANDLE

VERTICAL)

OPTIONAL OIL WAND

RETURN FRYER TO NORMAL OPERATION

1. After washing down frypot, turn DRAIN VALVE HANDLE

horizontal to close the frypot drain.

IMPORTANT: Drain handle must be fully closed in order to

activate HEATER SAFETY SWITCH. Drain handle must be

horizontal before for fryer heating element can be energized.

2. At conclusion of use, press FRYER-OFF-FILTER switch to

OFF position, disconnect wand from fryer fitting and return

handle of the 3-WAY VALVE to the vertical position.

3. Drain any remaining oil in wand by pointing discharge nozzle

of wand down into frypot or disposal container.

4. Be sure 3-WAY VALVE HANDLE is vertical.

Press FRYER-OFF-FILTER switch to FILTER position.

When all oil has been returned to frypot, press FRYER-OFF FILTER switch to FRYER position to resume operation, or to

OFF position to shut down.

FILTER

DANGER:

Contact with hot oil will cause

severe burns.

Always wear protective clothing

and heat resistant gloves when

operating the fryer.

BURN HAZARD

CAUTION:

BURN HAZARD

Overflow of hot oil may

cause burns. DO NOT fill fryer

beyond MAX OIL line on frypot.

IMPORTANT:

When refilling the frypot, be

sure the 3-way valve handle is

vertical, and the drain valve

handle is horizontal before

pressing FRYER-OFF-FILTER

switch to the FILTER position.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

17

Page 20

MAINTENANCE - CLEANING INSTRUCTIONS

DANGER: BURN HAZARD

Contact with hot oil will cause severe burns. Allow the fryer to cool before cleaning.

Always wear protective clothing and heat resistant gloves when cleaning the fryer.

CAUTION:

ELECTRIC SHOCK

HAZARD

Disconnect fryer from electric

power before cleaning.

CAUTION:

BURN HAZARD

Allow fryer to cool completely

before cleaning.

IMPORTANT: DO NOT spill

or pour water into controls,

control panel or wiring.

IMPORTANT: DO NOT use

steel wool or abrasive

cleansers for cleaning the

fryer cabinet or frypot.

122 306626 OpManual for HDG-Series Griddles

PREPARATION Press POWER SWITCH to OFF

Allow fryer to cool completely before cleaning

Disconnect fryer from electric power before

cleaning

FREQUENCY Daily, or as needed

TOOLS Mild Detergent, Non-abrasive cleanser

Soft Cloth or Sponge, Plastic Scouring Pad

Clean Vegetable Oil

DAILY CLEANING

1. Press POWER SWITCH to OFF.

2. Remove FRY BASKET and FILTER RESERVOIR ASSEMBLY.

IMPORTANT: Clean reservoir only when empty.

3. Allow the oil to cool to a safe temperature (120ºF or less).

4. Fry baskets may be washed in a dishwasher, or with warm water

and mild detergent. Rinse thoroughly and dry completely.

5. Clean FILTER RESERVOIR, FILTER SCREEN and FILTER

PAPER HOLDER in the dishwasher, or use warm water with a

mild detergent. Be sure all components are thoroughly dry, then

reassemble reservoir using a fresh sheet of filter paper.

IMPORTANT: Be sure inside of RESERVOIR SUCTION TUBE is

completely dry.

6. Keep all exterior surfaces free from splashed grease by wiping with

a clean cloth dampened with warm water and mild detergent.

• Slide LID AND YOKE fully forward. Clean accessible top

surfaces of cabinet. Slide LID AND YOKE fully to the rear.

Again, clean accessible top areas of cabinet, including

surfaces of LID AND YOKE.

• Clean side, front and accessible interior areas of cabinet.

• A non-abrasive detergent and plastic scouring pad may be

used for stubborn deposits.

• Dry with a soft clean cloth.

IMPORTANT: DO NOT use steel wool or abrasive cleansers

as these will damage the surface finish.

122 306626 OpManual for HDG-Series Griddles

IMPORTANT: DO NOT spill or pour water into controls, control

panel or wiring. Damage to internal components will occur.

7. Examine LID O-RING. Replace if cracked or scuffed. Wipe lightly

with clean vegetable oil.

Procedure is complete.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

18

Page 21

MAINTENANCE - CLEANING INSTRUCTIONS (continued)

WARNING

WARNING:

BURN HAZARD

TURN THERMOSTAT TO LOWEST TEMPERATURE SETTING

(FULLY COUNTERCLOCKWISE)

USE ONLY LOW-FOAMING COMMERCIAL FRYER CLEANSER.

CAREFULLY FOLLOW CLEANSER INSTRUCTIONS AND WARNINGS.

DO NOT LEAVE FRYER UNATTENDED

WHILE BOILING OUT FRYPOT.

WHEN WATER BEGINS FOAMING,

BE PREPARED TO TURN POWER SWITCH OFF.

Boiling water and splatter can result in moderate to serious injury.

PREPARATION Drain oil from fryer before cleaning

FREQUENCY Monthly, or as needed

TOOLS Low-foaming commercial fryer cleanser

Metal disposal container

FRYPOT CLEANING - HOT BOILOUT PROCEDURE

Slide the LID AND YOLK back. Press POWER SWITCH OFF.

Close DRAIN VALVE (lever horizontal). Fill FRYPOT with 4 gallons of

cold water.

Press POWER SWITCH to FRYER.

When water comes to a full boil, press POWER SWITCH OFF. When

boiling ceases, slowly add and stir in the LOW FOAMING COMMER-

CIAL FRYER CLEANSER. Using the HIGH TEMPERATURE BRUSH supplied with the fryer, stir until the cleanser is completely dissolved.

Press POWER SWITCH to FRYER. When the water begins to boil,

press POWER SWITCH OFF. When the boiling subsides, again press

POWER SWITCH to FRYER. Repeat this procedure continuously for five (5) minutes.

Press POWER SWITCH OFF. Allow the solution to set for thirty (30)

minutes.

Allow solution to cool to 120ºF (49ºC) or less before draining.

Place a suitable METAL container under the DRAIN VALVE. Open

DRAIN VALVE (lever vertical) to drain the cleaning solution.

NOTE: Drain no more than 4” at a time into the container to prevent

splashing and spilling.

ordinances.

Rinse frypot with clean water. Dry with a soft clean cloth.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

Dispose of used solution as required by local

IMPORTANT:

Use a LOW-FOAMING

COMMERCIAL fryer cleanser

only.

IMPORTANT:

DO NOT press FILTER PUMP

SWITCH to ON with anything

other than shortening in the

filter reservoir. Water and/or

cleaning chemicals can:

• cause severe oil splatter

• damage the filter pump

• contaminate cooking oil

and food product.

19

Page 22

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

Fryer will not heat

Fryer heats but will not build pressure

Filter pump will not run

Filter reservoir overflows

during filter cycle

Filter pump won’t pump, or pumps air

when filtering

Unit disconnected from electric power Reconnect to power

Temp control thermostat (item 6) not set Set thermostat to desired temperature

Hi-Limit thermostat (item 7) tripped Allow unit to cool, reset hi-limit

Internal damage Contact your Authorized Wells Service

Pressure builds as water content of

product turns to steam.

Cook lever (item 13) or control handle

(item 14) not properly set

O-ring on lid damaged Replace damaged o-ring

Internal damage or mis-adjustment Contact your Authorized Wells Service

Switches not set for filtering Press power switch (item 1) to FILTER

Pump overload (item 9) tripped Reset overload. Press red button until it

Internal damage (pump overload trips

frequently)

Drain valve (item 11) not properly set Oil level in reservoir must be monitored at

Filter paper surface clogged with crumbs

or other cooking debris

Suction tube not seated, allowing air to

enter system

Suction tube o-ring damaged Replace o-ring

Internal damage Contact your Authorized Wells Service

Check/reset circuit breaker

See page 3

Agency for repairs

Be sure product has sufficient water

content to build pressure.

Turn cook lever and control handle fully

counter-clockwise to initiate cook cycle.

Be sure lid lowers smoothly into frypot.

Agency for repairs

Press pump filter switch (item 6) to ON

“clicks” and stays locked in

Contact your Authorized Wells Service

Agency for repairs

all times while filtering. Adjust flow by

opening or closing drain valve

Turn drain valve OFF. When bubbles

begin appearing in frypot turn filter pump

switch OFF. Carefully slide reservoir out

6” and clear surface of filter paper with

hi-temp brush or wooden dowel. Reinstall

reservoir and resume filtering.

When inserting filter reservoir be sure

suction tube is fully seated in suction line

receptacle.

Agency for repairs

NOTE: There are no user serviceable

components in the fryer. In all cases of

damage or malfunction, contact your

Authorized Wells Service Agency for

repairs.

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

20

Page 23

WFPE-30F CABINET COMPONENTS

GUARD

E7-300527

FACEPLATE

2M-302391

EXPLODED VIEW & PARTS LIST

BUSHING, SLIDE

ROD 2K-46753

ASSEMBLY, DOOR

E7-WL0033

(includes 2R-38668

HANDLE)

HANDLE, DOOR

(only) 2R-38668

CONDENSATE

TRAY E7-46711

MAGNET, DOOR

2R-46502

FITTING,

SUCTION LINE

E7-46720

NOT SHOWN

PANEL, RIGHT SIDE, E7-46722

PANEL, LEFT SIDE, E7-46723

CLAMP, TOP FRYER

2E-70666 (2 places)

TUBE, SILICONE

.375 IDx 24-1/4”

E7-70906

CASTER, RIGID 5”

2P-47011 (2 places)

LEG, ADJUSTABLE

6” to 7-1/4”

2A-46480 (2 places)

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

Model: WFPE30F Cabinet Components

IL2162, Rev. -, 1/11/11

21

Page 24

EXPLODED VIEW & PARTS LIST

WFPE-30F YOKE & LID COMPONENTS

KIT , YOKE ASSY

REPLACEMENT

DD-501041

BEARING, YOKE

2P-46906

HOLE PLUG

1/2” Ni

2P-34282

CAP, YOKE

E7-47017

SCREW, 1/4-20 x1/2

SOC CAP

2C-47058

PLATE, PISTON TOP

(CAM FOLLOWER)

2V-46776

YOKE & HANDLE

ASSEMBLY E7-46783

PISTON ASSEMBL Y

E7-46779

VALVE, PRESSURE

RELIEF 2V-46655

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

GAUGE, PRESSURE

0-31 PSI 2V-305449

COVER ASSEMBL Y

(LID) 2L-46707

O-RING (LID)

2I-46652

Model: WFPE30F Yoke & Lid Components

IL2164, Rev. -, 1/11/11

22

Page 25

WFPE-30F PRESSURE SYSTEM EXHAUST COMPONENTS

EXPLODED VIEW & PARTS LIST

CONTROL ROD/

COOK LEVER

ASSEMBLY E7-300276

SLEEVE, EXHAUST

LINE E7-49728

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

Model: WFPE30F Exhaust Components

O-RING, EXHAUST

VALVE 2I-49596

EXHAUST VALVE

WS-66782

INSULATOR

MICROSWITCH

E7-47085

MICROSWITCH

2E-44887

SPOUT, CONDENSATE

E7-47018

IL2163, Rev. -, 1/11/11

23

Page 26

EXPLODED VIEW & PARTS LIST

WFPE-30F ELECTRICAL COMPONENTS

SWITCH

FRY/OFF/FILTER

2E-49550

LIGHT,

SIGNAL AMBER

2J-30516 (3 places)

TIMER KIT, WS-66735

TIMER ASSEMBLY, E7-307475

COOK LEVER

INSULATOR

MICROSWITCH

E7-47085

MICROSWITCH

2E-44887

UPPER CONTROL PANEL

CONTACTOR

3P 40A 208/240V 2E-Z14960

TERMINAL BLOCK

3P (DOMESTIC), 2E-30412

4P (EUROPEAN), WS-57465

CONTROL BOX

SWITCH, FILTER

DD-47052

LOWER CONTROL PANEL

THERMOSTAT,

HI-LIMIT SAFETY

WS-66663

ELEMENT, HEATING 208V 9000W WS-66664

ELEMENT, HEATING 240V 9000W WS-66691

SAFETY CLAMP

ELEMENT, 2C-49689

(6 places)

THERMOSTAT,

TEMPERATURE CONTROL

KNOB, TEMP. CONTROL

2R-45653

WS-66688

GASKET, ELEMENT

WS-66863

FRYPOT

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

Model: WFPE30F Electrical Components

IL2166, Rev. B, 2/27/12

24

Page 27

WFPE-30F PUMP AND WAND COMPONENTS

MOTOR, FILTER

1ø 125/230v 50/60 Hz

WASHER, FIBER

FITTING,

FLEX CONDUIT

2K-33996X

2I-Z12311

WS-501205

PUMP, FILTER

WS-501231

CHECKVALVE

3/8 NPT FEMALE x

3/8 NPT MALE

2V-46692

FRYPOT

OUTLET

EXPLODED VIEW & PARTS LIST

FLEX LINE, DISCHARGE

.6” OD x 9.5” LONG

2J-302289

FRYPOT

INLET

DRAIN VALVE

W/HANDLE

E7-303769

FLEX LINE, SUCTION

.75” OD x 16.5” LONG

2J-302287

STANDARD FRYER

FRYER W/ OPTIONAL OIL WAND & DRAIN SAFETY SWITCH

FRYPOT

OUTLET

MICROSWITCH

120V 15A

2E-44887

VALVE, 3-WAY

DD-304309

part of DD-304734

FRYPOT

INLET

SUCTION LINE

CHECKVALVE

3/8 NPT FEMALE x

3/8 NPT MALE

2V-46692

MAKE FROM

FLEX LINE, DISCHARGE

.6” OD x 32” LONG

(ref. 2J-303094 - discard end fittings)

FITTING,

E7-46720

PUMP/MOTOR

FLEX LINE, DISCHARGE

.6” OD x 9.5” LONG

2J-302289

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

Model: WFPE30F Pump Components

25

OIL WAND

& HOSE ASSY

DD-304734

IL2165, Rev. -, 1/11/11

Page 28

EXPLODED VIEW & PARTS LIST

WFPE-30F ACCESSORIES & REMOVEABLE COMPONENTS

PADDLE, STIRRING

CHICKEN 2B-302203

BRUSH, CLEANING FRYER

(HI-TEMP) 2P-302204

BASKET HANDLE

E7-300249

BASKET RACK

OPTIONAL LEAF FILTER

FRY BASKET 10.75” DIA

(STD) E7-300254

FRY BASKET 9.5” DIA

w/HANDLE WS-500253

2B-46757

2I-301847

BRUSH, CLEANING

ELEMENT 2P-46479

DOWEL, CLEANOUT

FRYER 2C-49752

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

FILTER PAPER

HOLDER E7-304829

FILTER PAPER

WS-21711 (pk 100)

FILTER SCREEN

E7-46446

O-RING FOR

FILTER LEAF (not shown)

WS-501900

Model: WFPE30F Basket Components

O-RING

2I-46474

FILTER RESERVOIR

E7-305626

FLAVOR-SAVER

FILTER POWDER

(not shown)

2M-301698 (9 packs)

IL2167, Rev. A, 1/27/12

26

Page 29

WIRING DIAGRAM

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

27

Page 30

NOTES

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

28

Page 31

PARTS & SERVICE

DESCRIPTION PART NO.

BRUSH, CLEANING HEATING ELEMENT 2P-46479

FILTER PAPER, 30-SERIES FRYER (pk100) WS-21711

FLAVOR-SAVER OIL FILTER POWDER (pk45) WS-22410

PADDLE, STIRRING CHICKEN 2B-302203

BRUSH, CLEANING FRYPOT 2P-302204

*FILTER WAND ASSY DD-304734

*NOTE: The filter wand assembly involves a different plumbing

arrangement than standard fryer. This option must be ordered at time

of initial build and cannot be economically retrofitted to existing fryers.

IMPORTANT: Use only

factory authorized service

parts and replacement

filters.

For factory authorized

service, or to order factory

authorized replacement parts,

contact your Wells authorized

service agency, or call:

Wells Bloomfield, LLC

10 Sunnen Dr., P.O.Box 430129

St. Louis MO 63143 USA

Service Dept.

phone: (314) 678-6314

fax: (314) 781-2714

Service Parts Department can

supply you with the name and

telephone number of the

WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

CUSTOMER SERVICE DATA

RESTAURANT ____________________________ LOCATION _____________

INSTALLATION DATE ______________________ TECHNICIAN ___________

SERVICE COMPANY ______________________________________________

ADDRESS __________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. _______________

EQUIPMENT SERIAL NO. _______________

FUEL (check one) 208VAC 240VAC 380-415 3NAC

362 2M-301626 Owners Manual WFPE-30F Free-Standing Electric Pressure Fryer

please have this information available if calling for service

29

Page 32

WELLS BLOOMFIELD, LLC

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

Loading...

Loading...