Wells WV48FB Installation Manual

WELLS MANUFACTURING

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

OWNERS MANUAL

VENTLESS

HOOD SYSTEM

ELECTRIC FRYERS &

BROILERS

COOKING

APPLIANCES

525

for

MODEL

WV48FB

Manual Includes

INSTALLATION

USE & CARE

EXPLODED VIEW

PARTS LIST

WIRING DIAGRAM

IL2372

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

p/n 2M-Z17944 Rev.. A M525 150511

LIMITED WARRANTY STATEMENT

Unless otherwise specied, all commercial cooking

equipment manufactured by Wells Manufacturing is

warranted against defects in materials and workmanship

for a period of one year from the date of original installation

or 18 months from the date of shipment from our factory,

whichever comes rst, and is for the benet of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW

OR IN FACT, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE, AND/OR FOR

DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES

IN CONNECTION WITH WELLS MANUFACTURING

PRODUCTS. This warranty is void if it is determined

that, upon inspection by an authorized service agency,

the equipment has been modied, misused, misapplied,

improperly installed, or damaged in transit or by re, ood

or act of God. It also does not apply if the serial nameplate

has been removed, or if service is performed by unauthorized

personnel. The prices charged by Wells Manufacturing for

its products are based upon the limitations in this warranty.

Seller’s obligation under this warranty is limited to the

repair of defects without charge by a Wells Manufacturing

factory authorized service agency or one of its sub-service

agencies. This service will be provided on customer’s

premises for non-portable models. Portable models (a

device with a cord and plug) must be taken or shipped to the

closest authorized service agency, transportation charges

prepaid, for service. In addition to restrictions contained

in this warranty, specic limitations are shown in the

Service Policy and Procedure Guide. Wells Manufacturing

authorized service agencies are located in principal cities.

This warranty is valid in the United States and Canada and

void elsewhere. Please consult your classied telephone

directory, your foodservice equipment dealer or contact:

Wells Manufacturing

10 Sunnen Dr., St. Louis MO 63143 USA

phone (314) 678-6314 or fax (314) 781-2714

for information and other details concerning warranty.

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specied on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted

for ninety (90) days from date of purchase on non-

warranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment

in this shipment was carefully inspected and packaged

by skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and le

“CONCEALED DAMAGE” claim with them. This

should be done within fteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Manufacturing cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

xi

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

TABLE OF CONTENTS

WARRANTY xi

ELECTRICAL SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2-3

PRECAUTIONS & GENERAL INFORMATION 4

AGENCY LISTING INFORMATION 5

INSTALLATION

Unpacking & Inspection 5

Components 5

Under-Hood Appliance Limitations 6

Service Technician Installation Notes 7

Base Assembly 8-9

Electrical Installation 10-11

ANSUL® INSTALLATION & SETUP 12-13

Filter Installation 14

OPERATION

Operation Lights 15

CLEANING INSTRUCTIONS 16-17

WIRING DIAGRAM 19

REQUIRED MAINTENANCE & MAINTENANCE LOGS 20-23

TROUBLESHOOTING SUGGESTIONS 24

EXPLODED VIEW & PARTS LIST 27-36

INTRODUCTION

Thank You for purchasing this Wells Manufacturing appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure

that it gives you the very best performance and a long, economical service life.

This manual contains information and instructions for the ventless ventilation hood, its use and care.

For information regarding cooking appliance(s), please refer to the manufacturer’s operation manual.

ELECTRICAL SPECIFICATIONS

Model Volts Amps Power Supply

WV48FB

WV48FB-50HZ 4.3

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

208/240V

3.5

For supply connection use #12 AWG copper wire only.

1

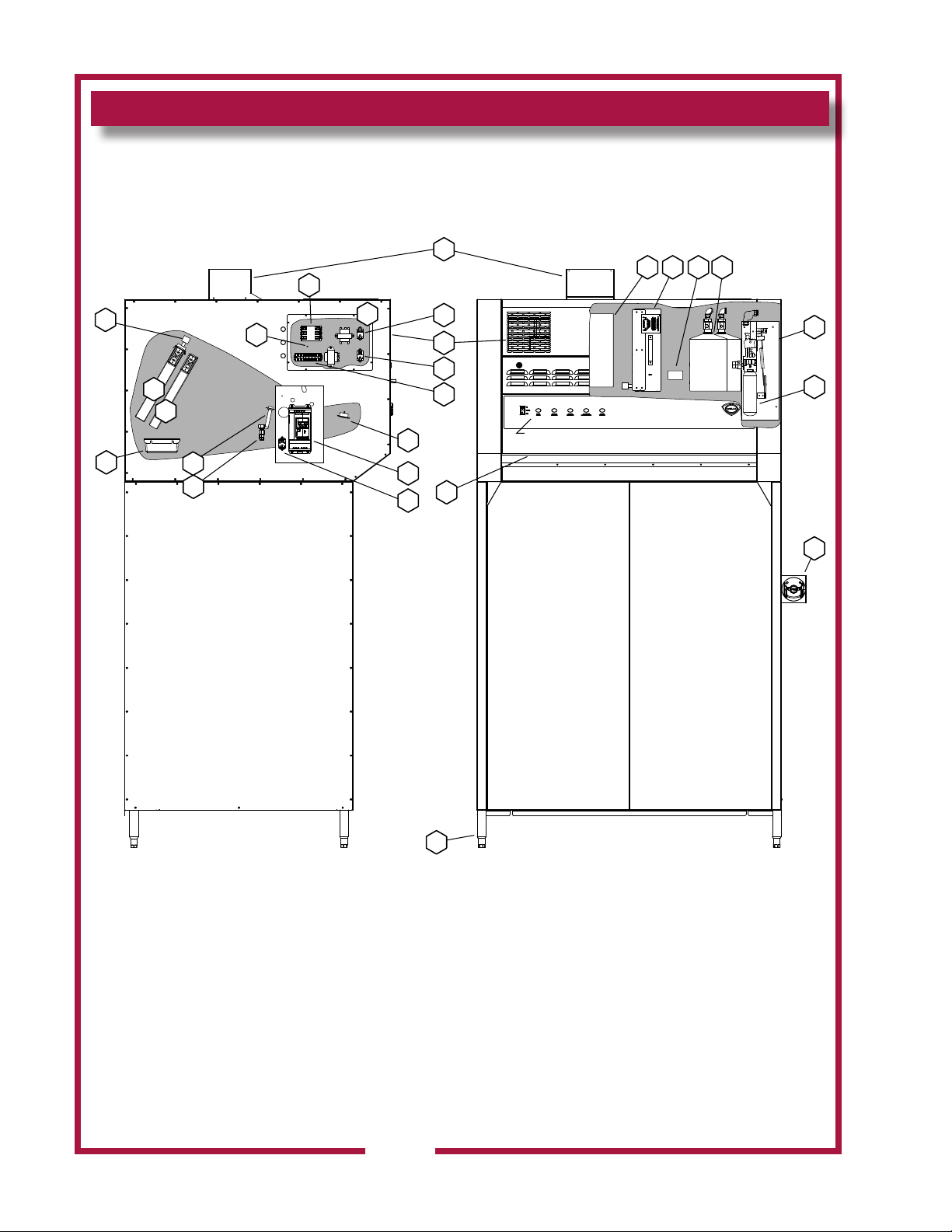

FEATURES & OPERATING CONTROLS

20

1

43 5 6

24

15

17

16

13

12

19

18

14

25

26

21

22

23

7

2

8

VENTILATOR CONTROL PANEL

see page 15

11

9

10

Ventilator Section Operating Features & Controls

2

IL2391a

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

FEATURES & OPERATING CONTROLS continued

FEATURES & OPERATION CONTROLS

ITEM

NO

1 VENTILATOR EXHAUST DUCT, TOP Exit point for ventilator airow - on top of unit. DO NOT BLOCK

2 VENTILATOR EXHAUST DUCT, FRONT Exit point for ventilator airow - on front of unit. DO NOT BLOCK

3 VENTILATOR FAN Provides air movement for ventilation

HI-EFFICIENCY/CHARCOAL FILTER

4

PACK

DESCRIPTION COMMENT

Removes grease and smoke particles. Also assists in cooking odor removal.

5 NAMEPLATE

6 FIRE SUPPRESSION TANK Container for ANSUL® Low-pH Liquid re suppression uid.

7 ACTUATOR ASSY

8 ANSUL® CARTRIDGE Propels suppression liquid through suppression manifold and nozzles.

9 MANUAL PULL STATION

10 ADJUSTABLE LEGS Allows the unit to be leveled.

11 AIR WALL A wall of air that moves the grease and smoke particles into the lter system.

12 DISCHARGE NOZZLES Fire suppression media discharges here, (6 places 48”, 12 places 96”)

13 ELECTRICAL DETECTORS

14 APPLIANCE LIGHT ON when hood power switch is ON. Illuminates cooking area.

15 GREASE DRIP TRAY Collects grease/moisture dripping from bafe lter (16)

16 BAFFLE FILTER Extracts and drains most greases and moisture from the air ow.

17 PRE-FILTER ASSEMBLY

18 ELECTRICAL CONNECTION BOX Houses electrical components

19 GROUND LUG Ground wire of power connection connects here.

Gives manufacturer, make and model description. Also list voltage and amperage

data.

Triggers deployment of suppression uid through manual pull station or electric

detection.

Provides a means of manual activation of the re suppression system. PULL ONLY

IN CASE OF FIRE!

Designed to activate at certain temperature. Activates (i.e. re on the cooktop)

activates re suppression system. Should be checked every 6 months during

ANSUL® Service Inspection

Comprises the PRE-FILTER FRAME and a replaceable PRE-FILTER. Stops large

particles of grease from reaching the FILTER PACK for reduced maintenance costs.

20 EQUIPMENT INTERFACE CONTACTOR Energizes cooking appliances only while ventilator section is sensed as operational.

21 BUILDING FIRE ALARM RELAY Reports re alarm condition to building re management system.

22 DETECTION END OF LINE RELAY Prevents appliance operation if a fault is found in detection circuit.

23

24 FILTER INTERLOCK SWITCHES

25 VARIABLE FREQUENCY DRIVE Converts 50Hz to 60Hz, 1 Phase

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

26 VFD RELAY Engauges VFD

SUPPLY CONNECTION TERMINAL

BLOCK

Provides connection point for electrical circuitry

Proper installation of bafe lter and lter pack closes these switches in ventilator

sensor circuit

50Hz UNITS

3

PRECAUTIONS AND GENERAL INFORMATION

This ventilator hood is part of an engineered system and is intended for

use in commercial establishments only.

This ventilator is intended

DANGER:

SUFFOCATION HAZARD

Do not attempt to use this

ventilator with gas-red units.

This ventilator will not remove

products of combustion.

Unvented exhaust gasses

can be deadly.

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

IMPORTANT:

The ventilator is disabled

when the lters are plugged

to the point of insufcient

airow for proper operation.

Also, power to the cooking

appliances is interrupted if

any lters or service panel

are removed.

It is the responsibility of

the store management to

maintain sufcient spares

of lter packs to avoid

prolonged shutdown due

to a dirty or clogged lter

pack. Filter packs cannot be

cleaned.

Wells Manufacturing

assumes no liability for loss

of business due to a lter

related shutdown. Spare

lters can be purchased

from any authorized Wells

servicer or calling Wells.

in the preparation food for human consumption. No other use is

recommended or authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

This ventilator hood system is designed to reduce odor emissions,

but will not completely eliminate all cooking odors. Air exchange

rates at the installation site must comply with the requirements of the

local jurisdictional authority. To ensure that odors do not accumulate,

recommended minimum air exchange is 200 cfm per linear foot of hood

into and out of the site.

This unit is intended for use with light- and medium duty electric

cooking appliances only. Cooking appliances placed under this

ventilator must comply with the restrictions set forth in the Installation

section of this manual.

Do not connect or energize this appliance until all installation

instructions are read and understood. Property damage or bodily

injury may result if these instructions are not followed. Disconnect this

appliance from electrical power before performing any maintenance or

servicing.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

This appliance is not jet steam approved. Do not direct water jet or

steam jet at this appliance, or at any control panel or wiring.

Do not splash or pour water on, in or over any controls, control panel or

wiring. Do not attempt to wash lter packs. Water will cause their

immediate failure and disable the ventilator.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

Avoid storing ammable or combustible materials in, on or near the

ventilator or associated cooking appliance.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualied technical personnel.

Any procedure which requires the use of tools must be performed by a

qualied technician.

All supplied instructions, diagrams, schematics, parts breakdown

illustrations, notices and labels must remain with the appliance if the

unit is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

for commercial establishments for use

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

4

AGENCY LISTING INFORMATION

SANITATION

This appliance conforms to NSF Standard 2 for sanitation only if

installed in accordance with the supplied Installation Instructions

and operated and maintained in accordance with the instructions in this

manual.

UL CLASSIFIED for use in US and Canada

NSF/ANSI 2

UL710B

Recurculating System

INSTALLATION

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all

protective plastic lm, packing materials and accessories from the

appliance before connecting electrical power or otherwise performing

any installation procedure.

Carefully read all instructions in this manual and any other documents

packed with the appliance before starting any installation.

All documentation should remain with the equipment operator for future

reference.

Read and understand all labels and diagrams attached to the

ventilator.

Carefully account for all components and accessories before

discarding packing materials.

COMPONENTS

4 ft

Pre-Filter 2 ea.

Bafe Filter 2 ea.

Filter pack 1 ea.

Grease cup 1 ea.

Ansul® components - must be installed by an authorized Ansul®

distributor only:

4 ft

2 ea. Fire suppression agent tank

2 ea. Fire suppression agent (Ansulex® Low pH) 1.5 gal.

1 ea. Fire suppression system charging cartridge

Store these components in a convenient place for later use.

The unit is shipped congured for horizontal discharge of the exhaust.

To convert to vertical discharge:

1. Remove top access cover.

2. Remove internal turning vane.

3. Insert top discharge scoop assy and fasten w/hardware from cover.

4. Remove front discharge vent panel and damper assy.

5. Assemble damper in Top discharge scoop assy.

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

6. Replace front discharge vent panel.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

RISK OF INJURY

Installation procedures must

be performed by a qualied

technician with full knowledge

of all applicable electrical

codes. Failure can result in

personal injury and property

damage.

IMPORTANT:

Fire suppression system must

be charged and certied by an

authorized Ansul® distributor.

Ventilator will not operate and

cooking appliance will not be

energized until the Ansul® re

suppression system has been

charged.

IMPORTANT:

After cooking appliances

are positioned under the

hood, swivel nozzles must

be positioned per Ansul®

recommendations.

5

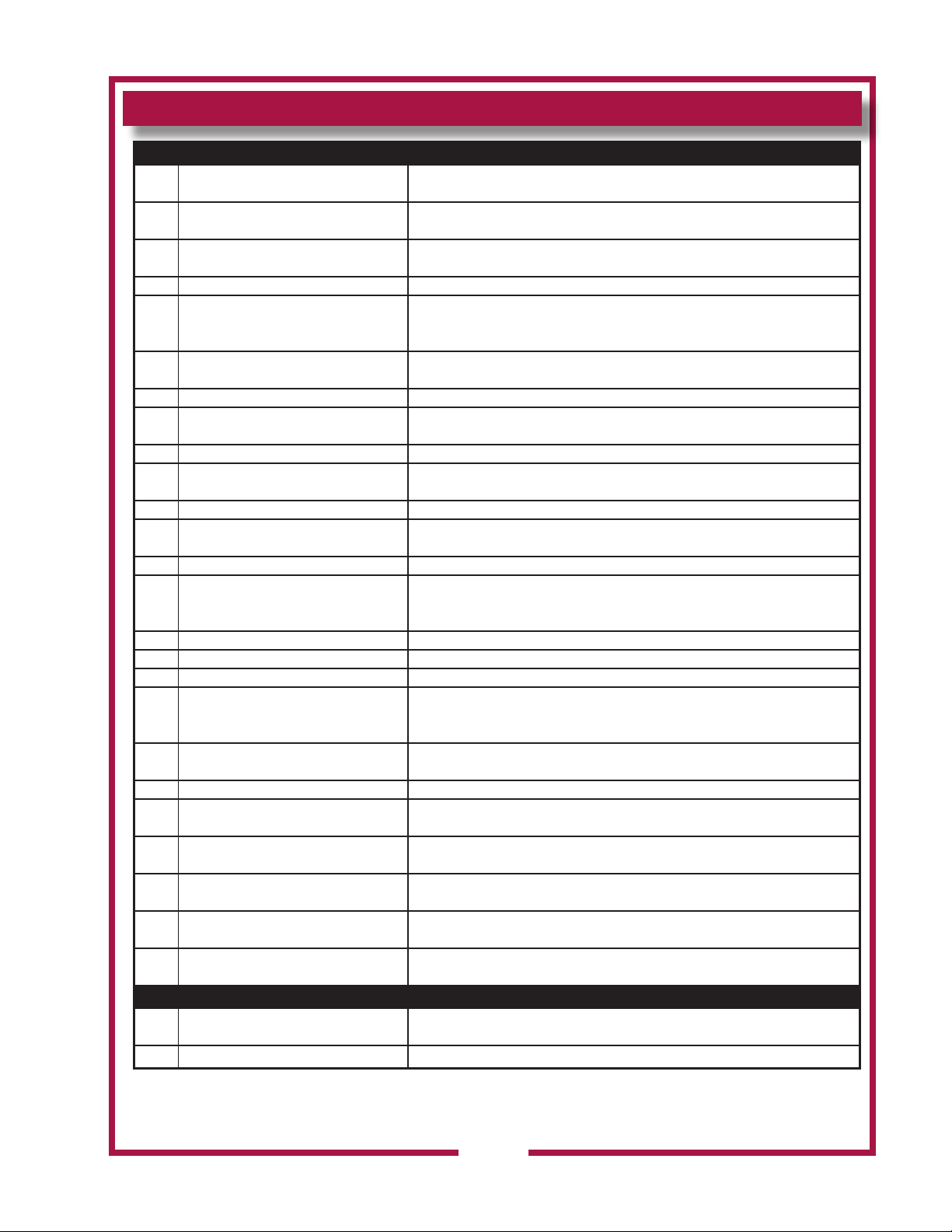

INSTALLATION (continued)

UNDER-HOOD APPLIANCE LIMITATIONS:

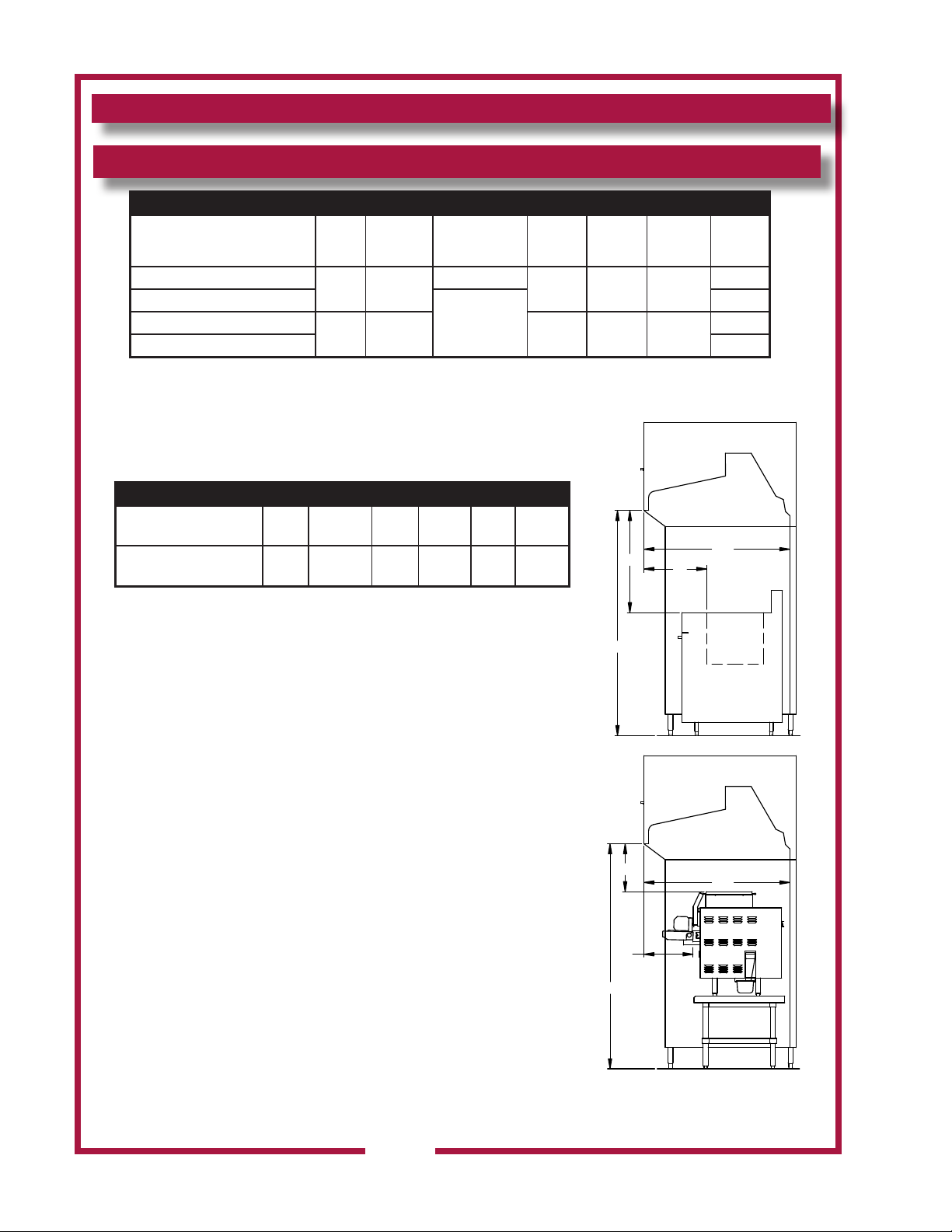

COOKING APPLIANCE LIMITATIONS

Acceptable Appliances by

Appliance Type

Single Vat Fryer

Multi Vat Fryer

Oven/Convection Oven

Steamer / Combi Oven 0

kW / Ft

Max

16.9

N/A

Max

Cooking

Temp

400°F

(204°C)

550°F

(287°C)

(1) Maximum single width 18”

(2) Front of hood to front edge of heated cooking surface.

(3) Bottom front edge of hood to height of heated cooking surface.

(4) Clearance from hood side panel to heated cooking surface.

SPECIFIC APPLIANCE LIMITATIONS

Specic Appliance

see notes (5) (6)

Input

Max

Max Temp

Setting

Dim D

Min (7)

NIECO Conveyor Broiler 7 Kw 500 15 14.5 18 0

Max Single

Heated Surface

Length

18

48

Dim E

Min (8)

Dim E

Max (8)

Dim

“A” (2)

Minimum

Dim

“B” (3)

Minimum

14 37 42

6 8 N/A

Dim F

Min (9)

B

Dim

“B” (3)

Maximum

Dim

“C” (4)

Minimum

0

0

0

BY APPLIANCE TYPE

48"

A

(5) Model JF91E with electrically interlocked exhaust catalyst.

(6) Meat paties must be frozen.

(7) Front edge of hood to front edge of heated chamber.

(8) Bottom edge of hoot to exhaust catayst.

(9) Clearance from hood side panel to broiler side.

All under hood appliances must be controlled by the equipment shutoff

interface. See owners manual pages 10-11 and wire diagram in supply

connection box. Only electrically heated appliances are acceptable for

installation. Appliance operation requires the re suppression system

be setup, charged and certied by an Authorized Ansul® Distributor.

The airow monitoring system will prevent appliance operation if

insufcient airow is detected or all lters are not in place.

The service panel must be in place for blower operation.

This hood and all under hood appliances must be installed in

accordance with the standard for ventilation control and re protection

of commercial cooking operations NFPA 96. The national electrical

code NFPA70 and all local codes where applicable.

Wells Manufacturing Model WV48FB

Lower Airow Limit: 1500 CFM

Broiler Maximum Measured Grease Emissions: 0.0063 LBS/HR/FT

Other Accepted Appliances: 0.0024 LBS/HR/FT

ANSI-UL710B Recirculating System UL Category YZCT FILE NO. MH4808

* The 10” - 12” leg option

increases the overall vertical

height.

74

NIECO MODEL JF91E

E

48"

D

74”

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

IL2744

6

INSTALLATION (continued)

SERVICE TECHNICIAN INSTALLATION NOTES

This ventilator hood is to be used with light-duty and medium-duty

electrically powered cooking appliances only.

• DO NOT attempt to use this ventilator hood with gas-red units.

• DO NOT use this ventilator hood with electrical appliances whose

dimensions or wattage characteristics exceed those dened in the

Under Hood Cooking Appliance Limitations, page 6.

Installation and start up must be performed by an Authorized

Installation Company.

Ansul® Installer must complete the WARRANTY INITIATION form

(2M-303912) included with the unit for the warranty to begin, and record

installation particulars on the CUSTOMER SERVICE DATA form

located at the end of this manual.

IT IS THE RESPONSIBILITY OF THE INSTALLER TO verify that this

VENTILATOR installation is in compliance with the specications listed

in this manual, with local code requirements, and in accordance with

NFPA 96 the STANDARD FOR VENTILATION CONTROL AND FIRE

PROTECTION OF COMMERCIAL COOKING OPERATIONS.

NOTE: Certain codes require FRYERS to be restrained with a

TETHER or other RESTRAINT DEVICE. If this ventilator is to be used

with a fryer, it is the RESPONSIBILITY OF THE INSTALLER to check

with the AUTHORITY HAVING JURISDICTION, in order to ascertain

the applicability of this requirement to this specic installation .

SETUP

Setup the appliance only on a rm, level, non-combustible surface.

Verify local codes for requirements. Concrete, tile, terrazzo or metal

surfaces are recommended. Metal over combustible material may not

meet code for non-combustible surfaces.

Verify vertical clearances. Ceiling height shall be no less than 103”

inches when utilizing horizontal discharge option. Ceiling height shall

be no less than 120” inches when utilizing vertical discharge option.

Verify that the unit sits rmly on ALL LEGS. With a spirit level, check

that the appliance is level front-to-back and side-to-side. With the

adjustable legs, adjust as required to level the appliance. In order to

prevent tipping or deection, legs must be adjusted such that all legs

are in rm contact with the oor.

WARNING:

Equipment must be installed in accordance with the equipment

parameters table located on the service door. Fire suppression

sensors used on this unit provide superior re detection but are

sensitive to rapid temperature rise. To prevent unintentional

deployment of the re extinguishing system,

DO NOT move equipment from installed position when in use.

DO NOT power off hood when under hood equipment is HOT.

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

DANGER:

SUFFOCATION HAZARD

Do not attempt to use this

ventilator with gas-red units.

This ventilator will not remove

products of combustion.

Unvented exhaust gasses

can be deadly.

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Property

damage or bodily injury could

result if these instructions are

not followed.

IMPORTANT:

If a remote pull station is to

be used, ventilator cannot be

moved without rst disabling

the remote pull station.

Contact your Ansul® agent

for details.

7

INSTALLATION (continued)

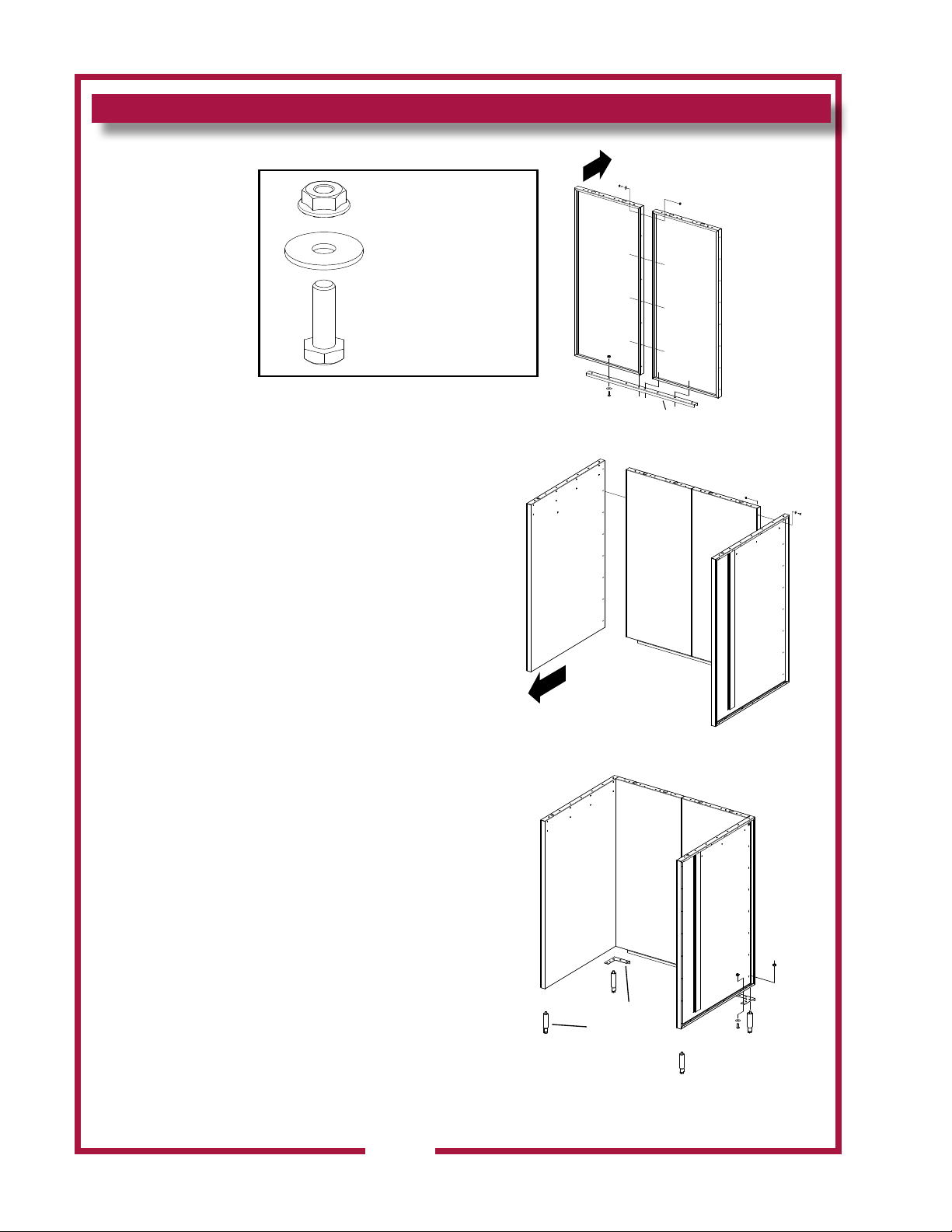

Hardware Provided

Front

Nut; 2C-6517

Washer; 2C-A27469

Bolt; 2C-Z5555

IL2977

BASE ASSEMBLY

Prior to assembling the base, locate it as close to the

nial position as possible. Then follow these steps.

1. Align the two rear panels (Fig 1) and secure with a

bolt, washer and nut (8 places).

2. Place the Base Bottom Stiffener (N1-Z15330) to the

bottom of the two rear panels and secure with bolt,

washer and nut (8 places).

3. Align the left and right side of the base to the rear

panel (Fig 2) and secure with bolt, washer and nut

(8 places each side).

4. Align the rear corner brackets in place (Fig 3) and

secure with bolt, washer and nut

(4 places each bracket).

5. Install the 6” adjustable legs and secure in place with

the bolt provided.

Front

Bottom Stiffener

IL2387

Figure 1

IL2388

Figure 2

Corner Bracket

6” Adj. Legs

IL2389

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

Figure 3

8

INSTALLATION (continued)

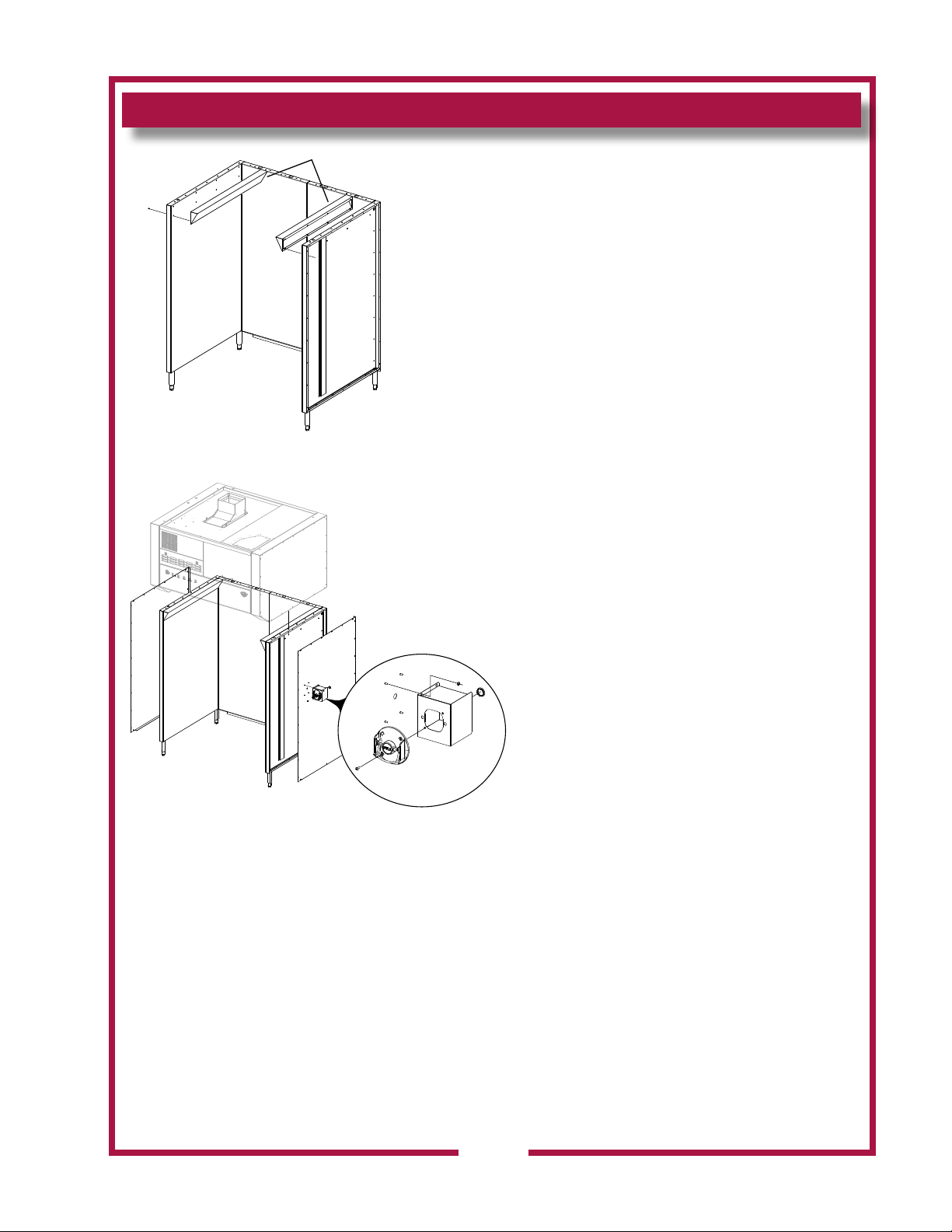

Base Deflectors

Figure 4

6. Align the two base deectors (Fig 4) in place and

secure with screws (8 per deector)

7. Move the base into position, and using a level,

adjust the legs until level.

8. Remove the side panels of the hood assembly so

when lowered onto the base assembly it will be

easier to secure in place.

9. Using the upper supporting brackets on the hood,

lower the hood on top of the base (Fig 5) so the

mounting holes line up. Secure with bolt, washer

and nut (7 places each side).

10. Contact your electrical & Ansul® contractors

to provide service to the system. Refer to

the ELECTRICAL INSTALLATION & FIRE

SUPPRESSION SYSTEM INSTALLATION

sections in this manual.

11. Once complete the side panels can be installed

using hardware provided.

M525 p/n 2M-Z17944 OpM WV48FB- Fryer & Broiler Ventless Hood

Figure 5

IL2743

9

Loading...

Loading...