Page 1

WELLS BLOOMFIELD, LLC

10 Sunnen Dr., St. Louis, MO 63143

telephone: 800-807-9054

fax: 314-781-2714

www.wells-mfg.com

OWNERS MANUAL

WFPE-68KFC

PRESSURE FRYER

434

UNITED STATES

CANADA

INTERNATIONAL

Includes

INSTALLATION

USE & CARE

SERVICE

WFPE-68KFC

Pressure Fryer

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

p/n 2M-305284 Rev. F M434 091230

Page 2

LIMITED WARRANTY STATEMENT

Unless otherwise specified, all commercial cooking

equipment manufactured by WELLS BLOOMFIELD, LLC is

warranted against defects in materials and workmanship for

a period of one year from the date of original installation or

18 months from the date of shipment from our factory,

whichever comes first, and is for the benefit of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW OR IN

FACT, INCLUDING BUT NOT LIMITED TO, WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE, AND/OR FOR DIRECT,

INDIRECT OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH WELLS BLOOMFIELD PRODUCTS.

This warranty is void if it is determined that, upon inspection

by an authorized service agency, the equipment has been

modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God. It also

does not apply if the serial nameplate has been removed, or

if service is performed by unauthorized personnel. The

prices charged by Wells Bloomfield for its products are

based upon the limitations in this warranty. Seller’s

obligation under this warranty is limited to the repair of

defects without charge by a Wells Bloomfield factory

authorized service agency or one of its sub-service

agencies. This service will be provided on customer’s

premises for non-portable models. Portable models (a

device with a cord and plug) must be taken or shipped to

the closest authorized service agency, transportation

charges prepaid, for service. In addition to restrictions

contained in this warranty, specific limitations are shown in

the Service Policy and Procedure Guide. Wells Bloomfield

authorized service agencies are located in principal cities.

This warranty is valid in the United States and Canada and

void elsewhere. Please consult your classified telephone

directory, your foodservice equipment dealer or contact:

Service Department, Wells Bloomfield, LLC

10 Sunnen Dr, St. Louis, MO 63143

phone (800) 807-9054 or fax (314) 781-2714

for information and other details concerning warranty.

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specified on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted for

ninety (90) days from date of purchase on nonwarranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

434 305284 Owners Manual WFPE-68KFC

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Bloomfield cannot assume liability for damage or loss

incurred in transit. We will, however, at your request, supply

you with the necessary documents to support your claim.

xi

Page 3

TABLE OF CONTENTS

GENERAL

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

AGENCY LISTING INFORMATION 3

PRECAUTIONS & GENERAL INFORMATION 4

INSTALLATION

UNPACKING, INSPECTION and SET-UP 6

ELECTRICAL INSTALLATION 7

USE AND CARE

FRYER OPERATION 8

CLEANING INSTRUCTIONS 11

SERVICE & REPAIR

TROUBLESHOOTING SUGGESTIONS 16

EXPLODED VIEWS & PARTS LIST 18

WIRING DIAGRAM 20

SERVICING INSTRUCTIONS 23

PARTS & SERVICE INFORMATION 33

CUSTOMER SERVICE DATA 33

Thank you for purchasing this

Wells Bloomfield appliance.

Proper installation, professional

operation and consistent

maintenance of this appliance

will ensure that it gives you the

very best performance and a

long, economical service life.

This manual contains the

information needed to properly

install the fryer, to use and

care for the fryer, and to

service and repair the fryer in a

manner which will ensure its

optimum performance.

GENERAL

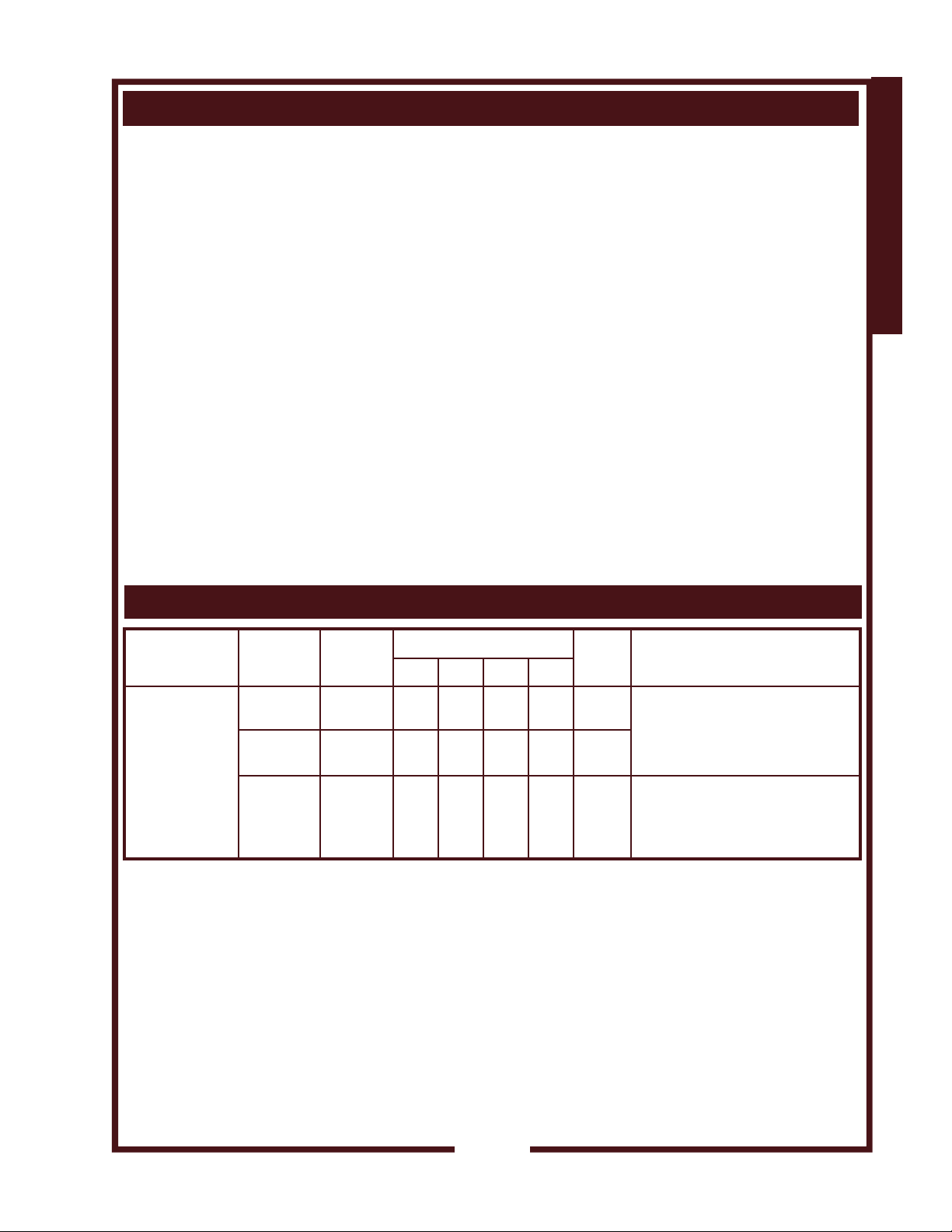

SPECIFICATIONS

MODEL

VOLTS

50/60 Hz

WATTS

208V 3ø 10,500 29 29 29 n/a n/a

WFPE-68KFC

240V

1ø or 3ø

380-415V

3ø

10,500 25 25 25 n/a 44

10,500 14.6 14.6 14.6 0 n/a

IMPORTANT: This appliance must be installed in compliance with all applicable federal, state and

local codes and ordinances.

Height: 38" (top of work surface)

47" (overall)

434 305284 Owners Manual WFPE-68KFC

52-1/2" (top of operating lever swing)

Width: 20"

Depth: 33"

35-1/4" (including operating lever)

AMPS 3ø

L1 L2 L3 N

ELECTRICAL

DIMENSIONS

AMPS

1ø

POWER SUPPLY

REQUIREMENTS

3-WIRE (L1, L2, L3) plus GND

Dedicated 50 amp 3ø circuit

8 ga. copper min. 90ºC

3 NAC

(L1, L2, L3, N) plus GND

Dedicated 25 amp 3ø circuit

1.5 mm

2

copper min. 90ºC

1

Page 4

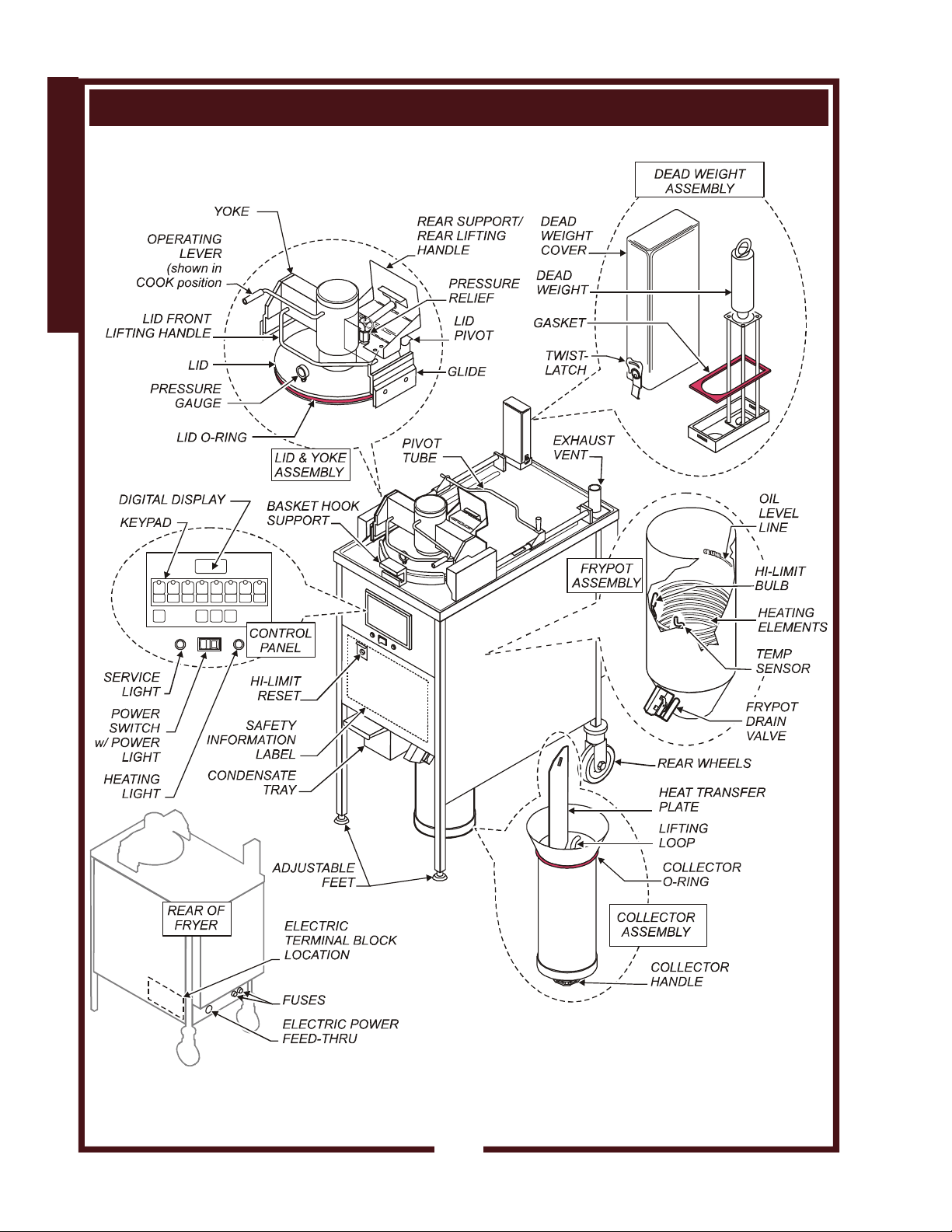

FEATURES & OPERATING CONTROLS

GENERAL

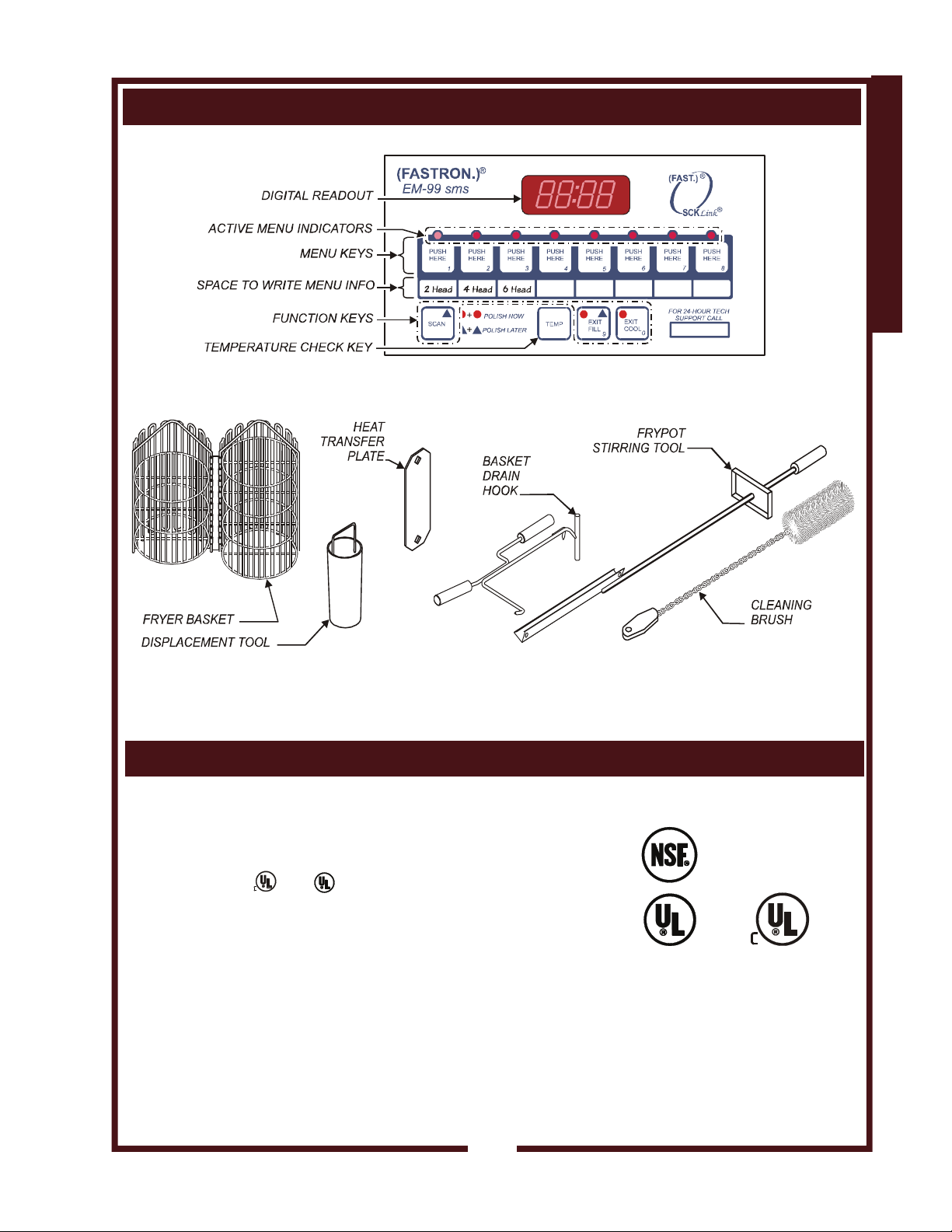

Fig. 1 Features and Operating Controls

434 305284 Owners Manual WFPE-68KFC

2

Page 5

Fig. 2 Electronic Controller

FEATURES & OPERATING CONTROLS (continued)

GENERAL

Fig. 3 Accessories and Tools

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions.

This appliance is

434 305284 Owners Manual WFPE-68KFC

and Listed under E6070.

AGENCY LISTING INFORMATION

STD 4

E6070 E6070

3

Page 6

PRECAUTIONS AND GENERAL INFORMATION

GENERAL

DANGER:

BURN

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

operating or servicing this

fryer.

HAZARD

DANGER:

BURN

Do not attempt to open the

fryer lid until the pressure in

the frypot has fallen to zero.

Opening the lid prematurely

will result in the explosive

release of hot shortening.

Contact with hot shortening

will cause severe injury or

death.

HAZARD

DANGER:

BURN

Do not attempt to open the

fryer drain valve if the frypot

is under pressure.

Opening the drain valve under

pressure will result in the

explosive release of hot

shortening.

Contact with hot shortening

will cause severe injury or

death.

HAZARD

DANGER:

EXPLOSION

Failure to operate this

pressure fryer as described

in this manual can lead to

explosion, severe injury and/

or death.

HAZARD

SAFE OPERATION OF THE PRESSURE FRYER

Contact with hot shortening will cause severe injury to unprotected skin

and eyes. Extensive exposure to hot shortening can cause death.

Protect yourself from contact with hot shortening:

ALWAYS wear protective clothing when operating this pressure

fryer.

ALWAYS wear protective goggles, gloves and apron when

cleaning or servicing this pressure fryer.

Shortening under pressure can be very hazardous unless handled

properly:

DO NOT attempt to operate this fryer without the LID O-RING and

COLLECTOR O-RING properly installed.

Do not operate this fryer if either of the LID O-RING or

COLLECTOR O-RING are damaged. A damaged O-ring will lead

to shortening leaks and/or spraying shortening.

Be sure the LID is seated in the frypot and the OPERATING

LEVER is turned fully COUNTERCLOCKWISE before starting a

cook cycle.

DO NOT attempt to turn the OPERATING LEVER until the

pressure in the frypot has fallen to zero.

DO NOT open the drain valve if the frypot is under pressure.

Opening the lid or drain valve with the fryer under pressure will

result in the explosive release of hot shortening.

Spilled shortening will cause a slip and fall hazard:

Add shortening, replenish the shortening, and service the fryer

carefully to avoid spills.

Clean up shortening spills promptly to avoid creating a slip and fall

hazard.

DO NOT allow water to contaminate the shortening. Water will

boil violently on contact with hot shortening, causing the hot

shortening to splatter.

DO NOT heat water in the fryer

DO NOT use boil-out method to clean the frypot.

DO NOT clean the frypot with water, water spray or steam

spray.

DO NOT use steel wool to clean any part of the fryer.

434 305284 Owners Manual WFPE-68KFC

4

Page 7

PRECAUTIONS AND GENERAL INFORMATION (continued)

WFPE-68KFC Pressure Fryer is intended for use in commercial

establishments only.

This fryer is

other use is

agents.

Operators of this fryer must be thoroughly trained in the appliance use,

precautions, limitations and associated restrictions.

Operating instructions, warnings and labels must be read and

understood by all persons using or installing this appliance.

Cleanliness of this fryer is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

DO NOT operate the fryer with faulty, loose or missing components.

DO NOT operate this fryer if the control panel is torn or damaged.

Contact a Wells Authorized Service Agent for repairs.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT pour water on, into or over any control, control panel or

wiring.

DO NOT store flammable or combustible items (mops, paper, rags or

chemicals) in, on or near the fryer.

This appliance is not jet-stream approved. Do not direct any water or

steam jet at any part of this appliance. Do not use a jet stream to wash

under the appliance.

The fryer is NOT a ladder. Never stand on the fryer to clean hood

filters. Pull the fryer away from the wall and use a step stool or ladder.

DO NOT stand on, sit on or lean on the fryer.

DO NOT allow foreign objects such as closed containers, cigarette

lighters or aerosol cans near the fryer or hot shortening. If dropped in

hot shortening, such objects may explode.

DO NOT allow any foreign object near the fryer that can fall into the

frypot and cause splashing or splattering of hot shortening.

Any procedure which requires the use of tools must be performed by

a qualified technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

434 305284 Owners Manual WFPE-68KFC

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

designed to prepare food for human consumption. No

recommended or authorized by the manufacturer or its

WARNING:

BURN HAZARD

Do not attempt to operate this

fryer without the LID O-RING

and COLLECTOR O-RING

properly installed.

Do not operate this fryer if the

LID O-RING or COLLECTOR

O-RING are damaged.

Hot oil may be released.

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

Do not open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result if

these instructions are not

followed.

IMPORTANT:

The technical content of

this manual, including

any troubleshooting

suggestions, parts breakdown illustrations, wiring

diagrams, schematics,

servicing instructions and/

or adjustment procedures,

is intended for use by

qualified technical

personnel only.

GENERAL

5

Page 8

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

INSTALLATION

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable electrical

codes. Failure can result in

personal injury and property

damage.

RISK OF INJURY

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all protective

plastic film, packing materials and accessories from the appliance

before connecting electrical power or otherwise performing any

installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read all instructions in this manual carefully before starting installation

of this fryer. READ AND UNDERSTAND ALL LABELS AND

DIAGRAMS ATTACHED TO THE FRYER.

Carefully account for all components and accessories before

discarding packing materials.

1 ea Fryer Basket

1 ea Condensate Tray

1 ea Basket Drain Hook/Collector Lifting Tool

1 ea Frypot Stirring Tool

1 ea Collector

1 ea Displacement Tool

1 ea Cleaning Brush

2 ea Lid O-Ring

2 ea Collector O-Ring

1 ea Heat Transfer Plate

Store these components in a convenient place for later use:

SETUP

Verify that this fryer installation is in compliance with the specifications

listed in this manual and with local code requirements. THIS IS THE

RESPONSIBILITY OF THE INSTALLER.

Setup the fryer only on a firm, level, non-combustible surface. Verify

local codes for requirements. Concrete, tile, terrazzo or metal surfaces

are recommended. Metal over combustible material may not meet

code for non-combustible surfaces.

Verify that the unit sits firmly ON BOTH LEGS AND BOTH WHEELS.

With a spirit level, check that the appliance is level front-to-back and

side-to-side. With the adjustable legs, adjust as required to level the

appliance. Both legs must be adjusted to firmly contact the floor in

order to prevent tipping.

Some locations require the fryer to be secured to prevent tipping or

rolling. It is the responsibility of the installer to meet this requirement.

DO NOT store flammable or combustible items (mops, paper, rags or

chemicals) in, on or near the fryer.

434 305284 Owners Manual WFPE-68KFC

6

Page 9

INSTALLATION (continued)

ELECTRICAL INSTALLATION

Refer to the nameplate on the appliance to verify the ELECTRICAL

SERVICE POWER. Voltage and phase must match the nameplate

specifications, and available electrical service amperage must meet or

exceed the specifications listed on page 1. Incoming wiring must

comply with National Electrical Code or International specifications.

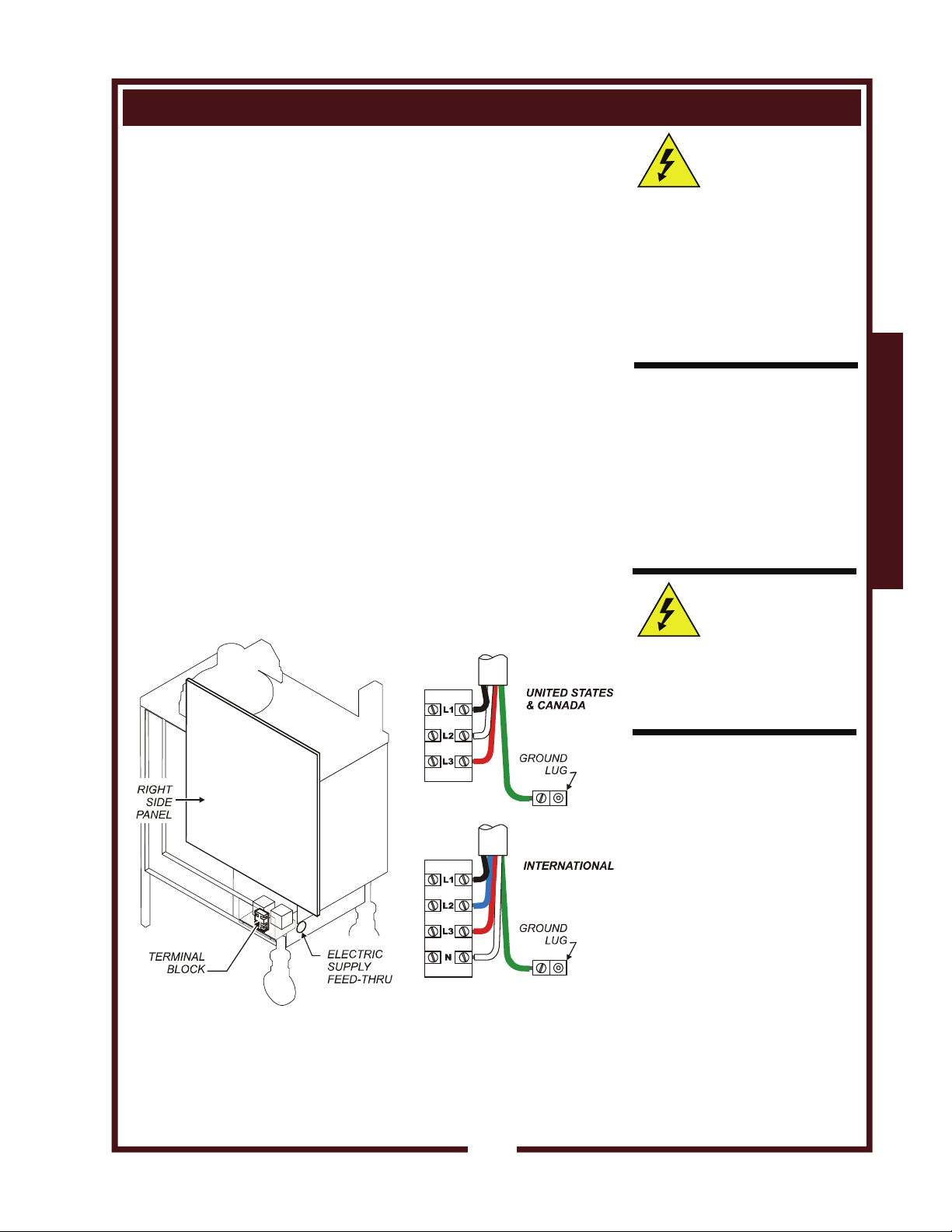

UNITED STATES & CANADA

This appliance requires a dedicated 50 amp, 3-phase circuit. Wiring

must be at least 8 ga. copper suitable for a minimum of 90ºC. Wiring

must be installed with a suitable strain relief (provided by electrical

contactor).

INTERNATIONAL

This appliance requires a dedicated 25 amp, 3-phase circuit (L1, L2,

L3, N plus ground). Wiring must be at least 1.5 mm

a minimum of 90ºC. Wiring must be installed with a suitable strain

relief (provided by electrical contactor).

Remove the RIGHT SIDE PANEL. Route supply wiring from the

FEED-THRU on the lower rear panel, then to the terminal block.

Incoming electrical supply is connected to the L1, L2 and L3 (and N for

international) terminals of the TERMINAL BLOCK.

The chassis-mounted GROUND LUG must be connected to earth

ground.

Verify that all connections are tight.

2

copper suitable for

CAUTION:

SHOCK HAZARD

Removal of any exterior panel

will result in exposed electrical

circuits. Electrical connection

must be performed by a

qualified technician only.

Use care whenever working

around exposed electrical

circuits.

IMPORTANT:

Contact a licensed electrician

to install and connect

electrical power to the

fryer.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

CAUTION:

SHOCK HAZARD

Failure to connect the chassis

ground to a suitable earth

ground will result in a potential

shock hazard.

INSTALLATION

434 305284 Owners Manual WFPE-68KFC

Fig. 4 Terminal Block Location and Wiring

7

Page 10

OPERATION

DANGER:

BURN

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

operating this fryer.

HAZARD

CAUTION

SHOCK HAZARD

If you experience an electrical

shock from the fryer:

IMMEDIATELY disconnect

the fryer at the circuit breaker

and contact an

AUTHORIZED WELLS

SERVICE AGENT for repairs.

USE AND CARE

GENERAL GUIDELINES

ALWAYS be sure the

pressure gauge reads "0"

before turning the operating

lever clockwise.

ALWAYS be sure the

LID O-RING is in good

condition and properly

installed.

*IMPORTANT:

Collector MUST be Wellstype collector with collapsible

handle welded to the bottom.

ALWAYS be sure the

COLLECTOR O-RING is in

good condition and properly

installed.

DAILY START-UP

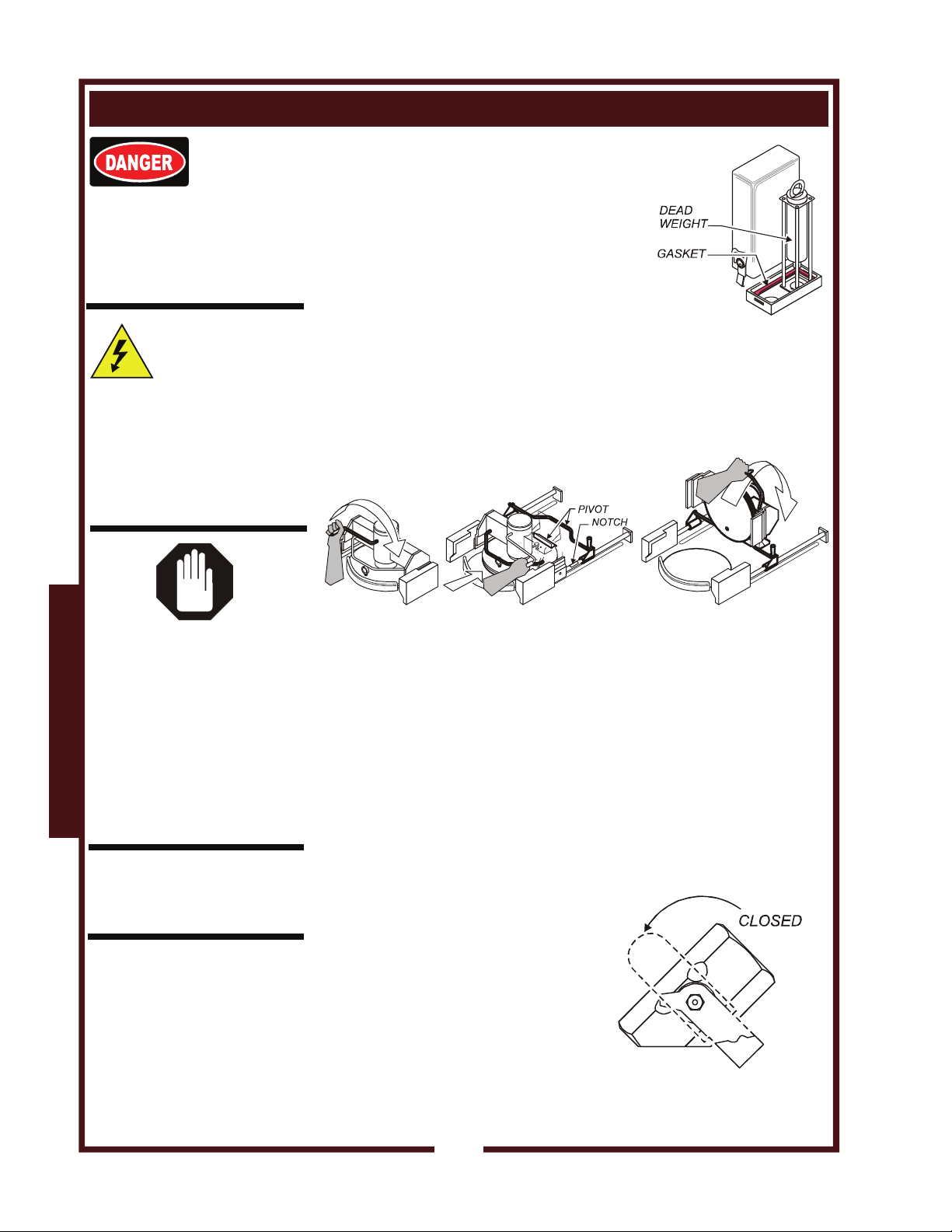

Remove the DEAD WEIGHT COVER.

Verify that the DEAD WEIGHT is in place

and that the vent holes are clean and free

from obstructions. Be sure the gasket is in

position, then latch the cover in place.

Be sure the EXHAUST VENT is free from

obstructions.

Open the FRYPOT LID. Turn the operating lever fully clockwise.

Slide pivot tube forward until it drops into the indents in the rods.

Slide the lid and yoke assembly to the rear until the lid pivot is in

the pivot tube.

Using the LID HANDLE, lift the front of the lid and yoke until it

rests on the REAR SUPPORT in the raised position.

Lubricate a freshly cleaned LID O-RING with a thin coating of

vegetable oil, then install the o-ring in the groove in the lid. Set the

lid and yoke assembly back onto the glides.

Lift the pivot tube slightly and slide it to the rear of the fryer.

Be sure the frypot is clean, and all breading and crumbs have been

brushed from between the heating elements.

Lubricate a freshly cleaned COLLECTOR O-RING with a thin

coating of vegetable oil, then install the o-ring in the groove in the

COLLECTOR*. Fully insert the COLLECTOR ASSEMBLY into the

opening in the bottom of the FRYPOT. DO NOT install the HEAT

TRANSFER PLATE at this time.

Check the DRAIN VALVE.

Make sure the valve is fully

closed.

Be sure the CONDENSATE TRAY

is empty and properly installed.

434 305284 Owners Manual WFPE-68KFC

8

Page 11

OPERATION (continued)

ADD SHORTENING

Pack 68 lbs (31 kg) of solid shortening into the

frypot. If using liquid shortening, fill frypot to

LOWER OIL LEVEL line. Be sure the heating

elements are completely covered with shortening.

Connect the fryer to electric power by turning on

the circuit breaker. Press the POWER SWITCH

ON. The POWER LIGHT will glow.

Press EXIT COOL, then press 2, 4 or 6-head

MENU KEY (first product to be cooked) The

digital readout will display "LO" while the fryer is

in the shortening melt cycle.

With the FRYPOT STIRRING TOOL, stir the

shortening. Push the stirring tool through the

shortening to the bottom of the collector as the

shortening heats, until all shortening is melted.

Be sure the heating elements are covered with

shortening at all times. Stir until all shortening

is melted.

All shortening in the collector must be completely

melted. Stir into the collector until all shortening is

visibly melted, and at least 5 minutes thereafter.

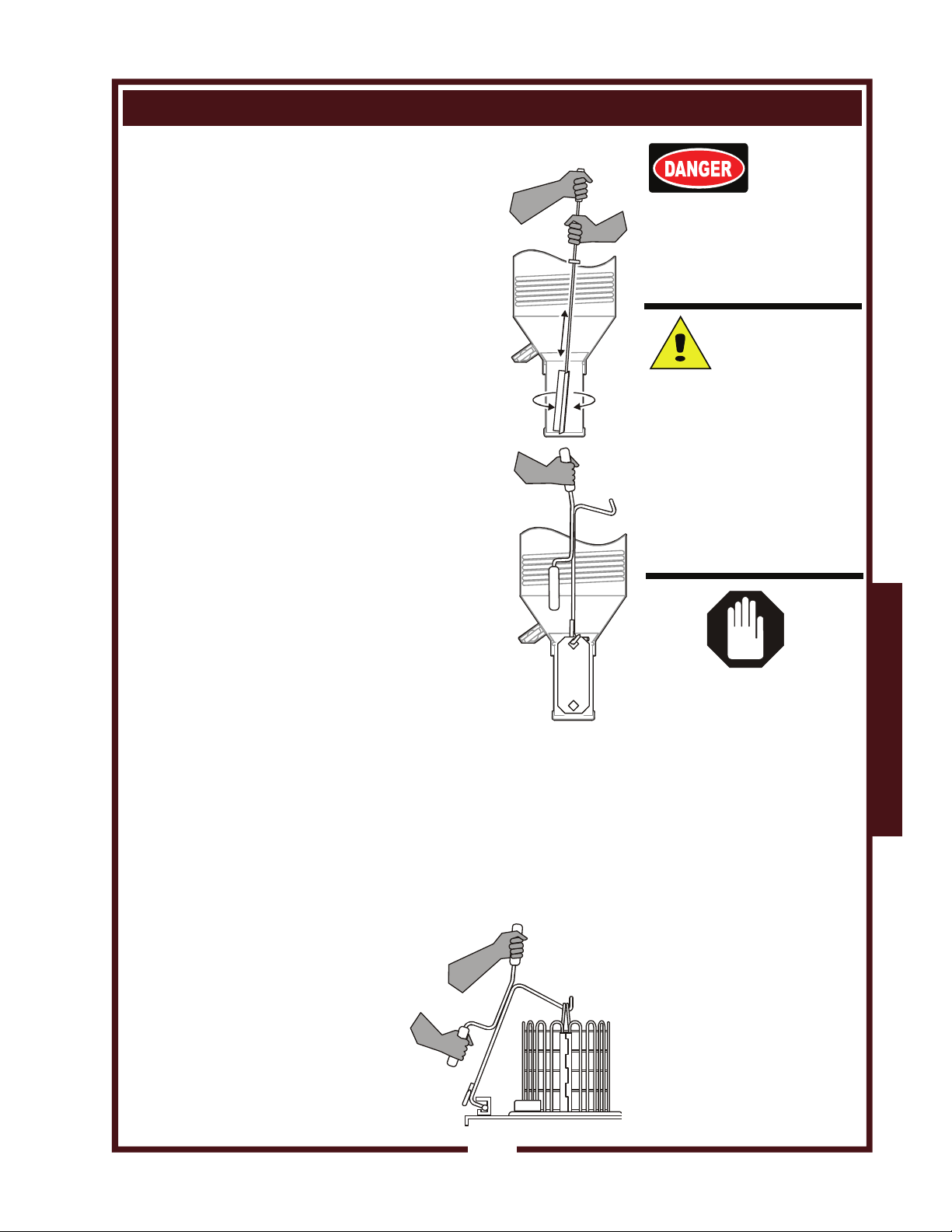

Using the hook of the BASKET/COLLECTOR

REMOVAL TOOL, lower the HEAT TRANSFER

PLATE into the bottom of the collector.

When the digital readout displays droP, and the

HEAT LIGHT begins to cycle, check the shortening level.

The level must be up to the UPPER OIL LEVEL line scribed into

the frypot above the elements.

Add shortening if necessary.

If overfilled, dip out excess shortening using a saucepan. Use

the excess shortening later as add-back.

Stir the shortening in the frypot thoroughly at least once before

cooking. Do not stir the collector once the heat transfer plate is in

place.

LOAD FRYER BASKET

434 305284 Owners Manual WFPE-68KFC

Using established procedures,

load the FRYER BASKET.

Suspend the fryer basket over the

frypot using the BASKET DRAIN

HOOK.

DANGER:

BURN

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

operating this fryer.

HAZARD

CAUTION:

FIRE HAZARD,

EQUIPMENT

DAMAGE

The heating elements must

be covered with shortening

before the fryer is energized,

and at all times during the

shortening

operation.

damage and possible fire will

result if the elements are

dry-fired.

GENERAL GUIDELINES

ALWAYS be sure the drain

valve is closed before filling

the frypot.

ALWAYS check the fryer

leveling before operating.

Shortening should be at the

same distance from the rim

all the way around the frypot.

ALWAYS use the basket

drain hook to raise / lower the

fryer basket into / out of the

frypot.

ALWAYS use two hands to

manipulate the drain hook.

melt cycle and fryer

Serious equipment

USE AND CARE

9

Page 12

OPERATION (continued)

DANGER:

BURN

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

operating this fryer.

HAZARD

CAUTION:

FIRE HAZARD

EQUIPMENT

The heating elements must

be covered with shortening

before the fryer is energized,

and at all times during the

shortening

operation.

damage and possible fire will

result if the elements are dryfired.

To cancel a cook cycle, press

and hold the active menu key

for 3 seconds.

USE AND CARE

ALWAYS be sure the lid

o-ring is in place before

closing the frypot cover.

ALWAYS be sure the

operating lever is turned fully

counterclockwise before

starting a cook cycle.

ALWAYS be sure the

pressure gauge reads "0"

before turning the operating

lever clockwise.

ALWAYS use the basket

drain hook to raise / lower the

fryer basket into / out of the

frypot.

ALWAYS use two hands to

manipulate the drain hook.

DAMAGE

melt cycle and fryer

Serious equipment

GENERAL GUIDELINES

FRYER OPERATION

Press the EXIT COOL key. When the digital readout displays

droP, lower the fryer basket into the frypot. Lower slowly to avoid

foaming. Remove and properly store the drain hook.

Slide the lid and yoke forward. When it is over the frypot, turn the

operating lever fully counterclockwise. This lowers the lid into the

frypot.

Press the desired menu (2, 4 or 6 head) key. The active menu

indicator will glow. And the timer will count down the cook time.

While there is pressure in the frypot, the operating lever is locked in

the down position.

Pressure will build during the cook cycle. At the end of the cook

cycle, pressure in the frypot is released, the audible signal sounds,

and the digital display reads donE.

When the pressure gauge drops to zero, raise the lid by turning the

operating lever counterclockwise (which releases the lid lock), then

fully clockwise to raise the lid.

Slide the lid and yoke assembly toward the rear until it clears the

frypot. Using the basket drain hook, lift the fryer basket out of the

frypot and hook on the front edge of the fryer frame. Suspend the

fryer basket over the frypot to drain.

Once drained, remove basket with drain hook. Product is ready for

any additional processing prior to serving.

434 305284 Owners Manual WFPE-68KFC

10

Page 13

CLEANING INSTRUCTIONS

PROCEDURE: Cleaning During Operation

PRECAUTIONS: Wear protective goggles, gloves, and apron

FREQUENCY: As required, approximately every 3 - 6 loads

TOOLS: Frypot Stirring Tool

Hi-Temperature Brush

Breading will build up at the oil line. This breading must be removed

from the cooking zone to prevent leaving burned specks on product.

Also, the elements must be kept free of breading crumbs and other

cooking debris to ensure optimum operation.

1. Remove the fryer basket from the fryer. Using the blade of the

FRYPOT STIRRING TOOL, scrape the built-up breading from the

oil line.

2. Using a hi-temperature brush, brush all breading and other cooking

debris from the face of the heating elements, and from between the

elements, element retainers and the frypot.

IMPORTANT: Be careful when cleaning around the temperature

probe and hi-limit thermobulb. Damage to either component will

put the fryer out of service.

3. Using a hi-temperature brush, push all breading and crumb s into

the collector.

4. Check the shortening level. Add shortening as required to bring the

level between the MIN OIL and MAX OIL lines.

5. Using the FRYPOT STIRRING TOOL, stir the frypot until all

shortening is melted. DO NOT stir into the collector.

6. Raise LID AND YOKE assembly (see page 8). Clean bottom of lid

then carefully return lid & yoke to horizontal position.

7. Check CONDENSATE TRAY. Empty if necessary and reinstall.

434 305284 Owners Manual WFPE-68KFC

8. Properly store tools.

Procedure is complete

DANGER:

BURN

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

cleaning this fryer during

operation.

Clean Breading from Oil Line

Clean Heating Elements

HAZARD

USE AND CARE

11

Page 14

CLEANING INSTRUCTIONS (continued)

DANGER:

BURN

HAZARD

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

changing shortening.

FRYER MUST NOT BE

PRESSURIZED WHEN

PERFORMING THIS

PROCEDURE

CAUTION:

BURN HAZARD

Open the valve slowly to

avoid splashing hot

shortening.

CAUTION:

BURN HAZARD

The drained shortening and

the container are hot and can

cause burns.

USE AND CARE

CAUTION:

SLIPPING

Avoid spilling shortening on

the floor. Clean up all spills

immediately to prevent

creating a slip and fall

hazard.

IMPORTANT:

The displacement tool is to

be used to force shortening

up to the drain opening.

DO NOT use the

displacement tool to bail or

transport shortening.

HAZARD

PROCEDURE: Drain or Replace Shortening

PRECAUTIONS: Disconnect fryer from electric power

Wear protective goggles, gloves, and apron

FREQUENCY: As required, shortening to be filtered or replaced

TOOLS: Basket / Collector Tool, Displacement Tool

Container for Shortening

1. Disconnect fryer from electric power.

Frypot lid must be in the open position.

Remove fryer basket from fryer.

2. Position an appropriate container or

approved shortening filtration system

under the drain valve. Open the drain

valve and drain frypot shortening into

the container.

3. Using the BASKET / COLLECTOR TOOL, remove the HEAT

TRANSFER PLATE from the COLLECTOR.

4. Using the DISPLACEMENT TOOL, force as much shortening as

possible to drain into the container.

Follow established procedures for handling used shortening.

Empty the collector (see page 13), or clean the fryer (see page 13).

Procedure is complete

434 305284 Owners Manual WFPE-68KFC

12

Page 15

CLEANING INSTRUCTIONS (continued)

PROCEDURE: Daily Cleaning

PRECAUTIONS: Disconnect fryer from electric power

Drain shortening. Allow fryer to cool

Wear protective goggles, gloves, and apron

FREQUENCY: Daily

TOOLS: Basket / Collector Tool, Frypot Stirring Tool,

Clean Cloth or Sponge, Nylon Brush

1. Disconnect fryer from electric power. Remove fryer basket from

fryer. Drain shortening (see page 12).

2. Using the BASKET / COLLECTOR TOOL, lift the

COLLECTOR from the frypot. Empty collector

contents per established procedures. Hold the

collector by the HANDLE on the bottom when

emptying.

3. Place a stockpot under frypot to catch all

breading and oil drips. Using a nylon brush, clean

all breading and crumbs from frypot.

4. Clean components by wiping with a clean cloth:

DO NOT use caustic cleaners.

DO NOT use steel wool.

DO NOT use soap.

DO NOT spray with water or steam.

Raise LID AND YOKE assembly (see page 8).

Carefully remove LID O-RING, then turn OPERATING LEVER

fully counterclockwise. Clean lid and yoke. Install a freshly

cleaned o-ring before operating fryer. Turn operating lever fully

clockwise.

Clean cabinet and counter top. Do not pour water on, into or over

the control panel.

Set yoke and lid assembly back into the horizontal position.

Disassemble DEAD WEIGHT ASSEMBLY (see page 8). Clean all

internal components, then reassemble.

Remove COLLECTOR O-RING from COLLECTOR. Clean

collector. Install a freshly cleaned o-ring. Set collector back into

frypot.

Empty and clean CONDENSATE TRAY. Reinstall in fryer.

434 305284 Owners Manual WFPE-68KFC

Clean HEAT TRANSFER PLATE. Set aside.

Clean fryer baskets, brushes, collector lifting tool, frypot stirring tool

and displacement tool.

Clean lid and collector o-rings. Store o-rings in a shallow pan of

water in a refrigerator until ready for the next use cycle.

5. Close lid. Properly store tools.

Procedure is complete

DANGER:

BURN

HAZARD

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

cleaning this fryer during

operation.

CAUTION:

SLIPPING

HAZARD

Avoid spilling shortening on

the floor. Clean up all spills

immediately to prevent

creating a slip and fall

hazard.

CAUTION:

HOT OIL

SPLATTER

HAZARD

DO NOT clean the frypot with

commercial boil-out products.

DO NOT clean with water or

steam spray. Water will boil

violently causing splatter

when the shortening reaches

temperature.

IMPORTANT:

Clean components with a

clean towel or sponge Scrub

with a soft bristle brush only if

necessary to remove food

particles.

NOTE: The following may

safely be cleaned in a

dishwasher:

Collector, heat transfer plate,

fryer basket, condensate tray,

tools.

IMPORTANT:

Be sure all components are

completely dry. Water will

boil violently on contact with

hot oil, causing hot oil to

splatter.

USE AND CARE

13

Page 16

CLEANING INSTRUCTIONS (continued)

DANGER:

BURN

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

cleaning this fryer during

operation.

HAZARD

CAUTION:

HOT OIL

SPLATTERING

HAZARD

DO NOT use water to clean

lid. Water can contaminate

the shortening, causing

violent splattering of hot oil.

IMPORTANT:

Yoke and lid assembly

weighs approximately 70 lbs.

Use appropriate lifting

procedures.

IMPORTANT:

USE AND CARE

Clean components with a

clean towel or sponge Scrub

with a soft bristle brush only if

necessary to remove food

particles.

PROCEDURE: Clean Lid and Yoke Assembly

PRECAUTIONS: Wear protective gloves and apron

Lid Assembly is heavy! Use caution lifting.

FREQUENCY: Weekly or As Needed

TOOLS: Clean Towels or Sponge, Soft Bristle Brush

1. Open the FRYPOT LID. Turn the operating lever fully clockwise.

Slide pivot tube forward until it drops into the indents in the rods.

Slide the lid and yoke assembly to the rear until the lid pivots in the

pivot tube.

Using the LID HANDLE, lift the front of the lid and yoke until it

rests on the REAR SUPPORT.

2. Remove lid o-ring from groove. Wipe o-ring clean, then store in

water in the refrigerator.

3. Wipe bottom of lid until clean. Be sure o-ring groove is clean and

free from shortening build-up.

4. Lower lid to horizontal position. Slide pivot tube fully to the rear.

5. Turn operating lever fully counterclockwise to raise yoke assembly.

Wipe all components until clean. Be sure area at base of piston is

free from shortening build-up.

6. Turn operating lever fully clockwise. Raise lid to vertical position as

in step 1.

7. Lubricate fresh lid o-ring with clean vegetable oil and install in lid

o-ring groove. Lower lid to horizontal position. Slide pivot tube fully

to the rear.

Procedure is complete

434 305284 Owners Manual WFPE-68KFC

14

Page 17

CLEANING INSTRUCTIONS (continued)

PROCEDURE: Clean Pivot Tube and Slide Rods

PRECAUTIONS: Wear protective gloves and apron

FREQUENCY: Monthly or As Needed

TOOLS: Clean Towels or sponge, Bottle Brush

Flat Blade Screwdriver

1. Lower lid into the frypot. Unlatch and remove dead weight cover.

2. Loosen screws in right and left rod mounting blocks. Work slide

rods to the rear until they are clear of the front mounting blocks.

3. Free pivot tube from slide rods. Pivot tube may be cleaned in the

dishwasher. Use a bottle brush to clean the inside of the pivot tube

guides.

4.

Work slide rods out of the rod mounting blocks. Slide rods may be

cleaned in the dishwasher. Scrub with a soft bristle brush only if

necessary to remove food particles from indents.

5. Reinsert slide rods into mounting blocks. Install pivot tube on slide

rods.

6. Reinstall slide rods in front mounting blocks. Tighten screws in rod

mounting blocks. Test pivot rod for proper operation.

Procedure is complete

DANGER:

BURN

Contact with hot shortening

will cause severe injury or

death. Wear protective

gloves and clothing when

cleaning this fryer during

operation.

NOTE: The following may

safely be cleaned in the

dishwasher:

Pivot Tube

Slide Rods

IMPORTANT:

Be sure all components are

completely dry before

reinstalling. Water will boil

violently on contact with hot

oil, causing hot oil to splatter.

SUGGESTION:

When reinstalling, engage

pivot tube guides in slide rod

indents prior to tightening

screws in order to ensure

proper alignment.

HAZARD

USE AND CARE

434 305284 Owners Manual WFPE-68KFC

15

Page 18

These troubleshooting suggestions are intended for use by qualified technical personnel only.

TROUBLESHOOTING SUGGESTIONS

Problem Possible Cause Suggested Remedy

No power to fryer Fryer unplugged or circuit breaker off or

tripped

Power switch off or damaged Press power switch to ON

Blown fuse Correct cause of fuse failure

No power -

"service" light lit

Hi-limit safety trips often Thermobulb contaminated with crumbs Clean hi-limit thermobulb

Fryer does not heat

"power" light lit

"heat" light lit

"service" light not lit

Hi-limit safety tripped Allow to cool, reset safety

Temp sensor contaminated with crumbs Clean temperature sensor probe

Temp sensor or wiring damaged Check wiring for damage, repair as req'd.

Hi-limit safety or thermobulb damaged Replace hi-limit safety

24v relay R1 damaged (welded

contacts)

Controller damaged If relay R1 remains energized at all oil temps,

Wiring damage (elements, contactors) Check wiring for damage, repair as req'd.

Damaged E-Safe relay Replace E-Safe relay

Damaged back-up contactor Replace back-up contactor

Connect fryer to power

Reset circuit breaker

Replace power switch

Replace fuse

Replace temperature sensor probe

Replace relay R1

replace controller

Fryer does not heat

"power" light lit

"heat" light not lit

"service" light not lit

Fryer will not build

pressure

SERVICE

Temp sensor or wiring damaged Check wiring for damage, repair as req'd.

Replace temperature sensor probe

Relay R3 or wiring damage Check wiring for damage, repair as req'd.

Replace relay R3

24v relay R1 or wiring damaged Replace relay R1

24v transformer damaged Replace transformer

Controller damaged If no 24v to R1 when calling for heat , replace

controller

Insufficient moisture in product Cook only authorized product

Lid o-ring damaged or missing Replace lid o-ring

Dead weight damaged or dirty Clean dead weight, replace if req'd.

Pressure relief body damaged or dirty Clean pressure relief body, replace if req'd.

Relief pin bent or dirty Clean relief pin, replace as req'd.

Pressure relief valve damaged Replace pressure relief valve

Pressure gauge damaged Replace pressure gauge

Solenoid damaged Replace solenoid

Connecting link or cotter pin damaged Replace connecting link and cotter pins

Pressure hose damaged Replace pressure hose

24V relay R2 or wiring damaged Check wiring for damage, repair as req'd.

Replace relay R1

434 305284 Owners Manual WFPE-68KFC

Controller damaged If no 24v to R2 during pressure phase of cook

cycle, replace controller

16

Page 19

TROUBLESHOOTING SUGGESTIONS (continued)

Problem Possible Cause Suggested Remedy

Fryer slow to heat /

recover

Controller works only

intermittently

Cannot lower lid Pivot tube engaged Be sure pivot tube is disengaged from pivot

Cannot raise lid Pressure not bled off Lid cannot be raised until all pressure has

Heating elements dirty Clean elements and frypot

One or more damaged elements Replace defective heating elements

Insufficient ventilation Be sure area u nder fryer remains clear

Cooling fan damaged or dirty Clean or replace cooling fan

24v transformer damaged Replace transformer

Damaged controller If internal temperature and 24v supply OK,

replace controller. Be sure cooling fan is

operating

bracket at back of lid

Lid not centered over frypot Position lid & yoke properly

Lid o-ring not properly installed Properly install o-ring

Piston and/or yoke damaged or dirty Disassemble, thoroughly clean yoke & lid

Repair or replace as required

been relieved from frypot

Improper procedure for opening After all pressure has been relieved, turn

operating lever fully counterclockwise to

release cam pawl, then fully clockwise to raise

lid.

Lid has cocked in frypot Tap front and back of lid while attempting to

move operating lever both directions

Lid hard to raise or lower Lid o-ring not properly installed Properly install o-ring

Piston and/or yoke damaged or dirty Disassemble, thoroughly clean yoke & lid

Repair or replace as required

Excess water and grease

vented from exhaust

Steam vents from

pressure relief cover

Frypot leaks at collector Collector o-ring missing or damaged Replace o-ring

Fryer basket will not lower

434 305284 Owners Manual WFPE-68KFC

fully into frypot

Muffler full of condensate and

shortening

Latches not properly engaged Engage extended fingers of latches fully in

Gasket missing or damaged Replace gasket

Pressure relief cover damaged Replace pressure reli ef cover

Collector o-ring improperly installed Properly install o-ring

Collector damaged Replace collector

Excessive built up of crumbs in frypot Clean frypot, empty collector

Bracket for hi-limit thermobulb damaged Repair or replace thermobulb bracket.

One or more element clamps damaged Repair or replace element clamps

Remove and clean muffler. Be sure drain line

is clear.

slots, then turn twist latch handle 180º

clockwise

Examine thermobulb for damage.

Examine elements for damage

These troubleshooting suggestions are intended for use by qualified technical person nel only.

SERVICE

No reading or incorrect

reading on pressure

gauge

Gauge orifice dirty Remove gauge and clean

Damaged pressure gauge Replace gauge

17

Page 20

EXPLODED VIEW & PARTS LIST

These parts breakdown drawings are intended for use by qualified technical personnel only.

SERVICE

434 305284 Owners Manual WFPE-68KFC

18

Page 21

WFPE-68KFC EXPLODED VIEW & PARTS LIST (continued)

ITEM PART NO DESCRIPTION ITEM PART NO DESCRIPTION

1 2J-305297 PROBE, TEMPERATURE 47 2C-305361 PIN, RETAINING

2 WS-506379 CLAMP, HI-LIMIT THERMOBULB 48 2V-305388 PIVOT ARM

WS-506130 THERMO, HI-LIMIT SAFETY, (s/n before KFC10170) 49 E7-305236 CONNECTING ROD

4

2T-306470

2N-306149UL ELEMENT, 240V 3500W 51 2E-305798 RELAY, 24V

5

2N-306150UL ELEMENT, 208V 3500W 52 2J-31157 LIGHT, INDICATING RED

6 2D-306167 CLAMP, HEATING ELEMENT 53 2E-305295 SWITCH, 240V DPST LIGHTED

8 2V-306036 VALVE, FRYPOT DRAIN 54 2J-30516 LIGHT, INDICATING AMBER

9

DD-305451 DEAD WEIGHT 11 PSI 56 2E-43880 RELAY, 240V

E7-305433 DEAD WEIGHT 12 PSI 57 2E-Z5741 TRANSFORMER, 208/240—24VAC, 40VA

10 2I-305218 GASKET, DEAD WEIGHT COVER 58 2U-303655 FAN, 240V

11 <305400> ASSEMBLY, DEAD WEIGHT CAGE 59 2A-306161 FOOT ADJUSTABLE

12 E7-505972 SUPPORT BLOCK, BASKET HOOK 60 2P-305419 CASTER NON-SWIVEL

13 E7-305289 COVER, DEAD WEIGHT 61 2E-306967B RELAY, 240V E-SAFE

14 2R-306158 GLIDE, LID

15 DD-305373 PISTON, LID 2E-37780 CONTACTOR 240V

16 2V-305449 GAUGE, PRESSURE 0-15 PSI

17 2L-305406 LID 2E-40310 TERMINAL BLOCK 4P

18 2I-305308 O-RING, LID 64 2D-305413 ASSEMBLY, COLLECTOR

19 2D-306152 CAP, YOKE 65 2I-305309 O-RING, COLLECTOR

20 <305389> CAM PLATE 66 E7-305337 HEAT TRANSFER PLATE

21 <305398> ASSEMBLY, YOKE 67 E7-306079 TRAY, CONDENSATE

22 2R-305192 HANDLE, OPERATING LEVER 71 <306081> ASSEMBLY, ADAPTER, 1/2 MPT x HOSE

23 E7-305366 TUBE, PRESSURE RELIEF VENT 72 2J-306080 FLEX HOSE

24 2V-305306 VALVE, PRESSURE RELIEF 73 2K-306083 ADAPTER, 1/2 FPT x HOSE FLARE

25 2K-305365 ADAPTER, PRESSURE RELIEF VALVE 74 2K-306082 NIPPLE 1/2MPT CLOSE

26 <305203> ASSEMBLY, LID SUPPORT 75 DD-506078 SWITCH GUARD

27 2V-305383 MOUNTING BLOCK, LEFT 80 ASSEMBLY, FRAME

28 2V-305384 MOUNTING BLOCK, RIGHT 81 E7-305231 PANEL, SIDE

29 2A-305382 SLIDE ROD 82 E7-305270 PANEL, FRONT UPPER, CONTROL

30 E7-505439 PIVOT TUBE 83 E7-305212 PANEL, FRONT LOWER

31 E7-505381 MOUNTING BLOCK, ROD 84 E7-305229 PANEL, REAR

32 E7-305254 ASSEMBLY, EXHAUST VENT 85 2I-306183 O-RING, DEAD WEIGHT PIN

33 E7-505307 CLAMP, EXHAUST TUBE 86 E7-305227 SHELF, ELECTRICAL

34 2J-306134 TUBE, EXHAUST MUFFLER INLET 87 2E-34768 FUSE, SC-10 10A 300V (pk 4)

35 2J-306135 TUBE, EXHAUST MUFFLER OUTLET 88 2E-34769 FUSE HOLDER, HPG-EE 10A 240V

36 E7-305174 LID, EXHAUST MUFFLER 90 2D-305378 ASSEMBLY, FRYPOT

37 2I-305425 GASKET, EXHAUST MUFFLER

38 <305178> MUFFLER, EXHAUST WS-23079 BASKET, CHICKEN COOKING 4-HEAD

39 E7-305164 BRACKET, PIVOT T2 2V-305326 TOOL, DISPLACEMENT

434 305284 Owners Manual WFPE-68KFC

40 2C-305362 PIVOT PIN T3 E7-306138

41 505361 CLIP, RETAINING T5 DD-22886 TOOL, STIRRING

42 2E-305387 PIN, PRESSURE RELIEF T6 2P-305355 BRUSH

43 505167 BUSHING

44 E7-305235 COVER, MOUNTING BRACKET

45 2E-305426 SOLENOID, PRESSURE RELIEF

46 E7-305234 BRACKET, SOLENOID MOUNTING

THERMO, HI-LIMIT SAFETY,

(s/n KFC10170 and later)

DEAD WEIGHT 9 PSI 55 2J-305280 CONTROLLER F.A.S. T. EM99

50 2K-48689 STRAIN RELIEF, WATER-TIGHT

2E-37779 CONTACTOR 208V

62

WS-50131 TERMINAL BLOCK 3P

63

DD-22891 BASKET, CHICKEN COOKING 6-HEAD

T1

BASKET DRAIN HOOK/COLL. REMOVAL

TOOL

5E-22943 INCL. ITEMS T2 thru T6

KIT

PART NUMBERS IN <BRACKETS> ARE FOR REFERENCE ONLY

These parts breakdown drawings are intended for use by qualified technical personnel only.

SERVICE

19

Page 22

WIRING DIAGRAM

This wiring diagram is intended for use by qualified technical personnel only.

SERVICE

434 305284 Owners Manual WFPE-68KFC

20

Page 23

WIRING DIAGRAM (continued)

434 305284 Owners Manual WFPE-68KFC

SERVICE

21

Page 24

WIRING DIAGRAM (continued)

This wiring diagram is intended for use by qualified technical personnel only.

SERVICE

434 305284 Owners Manual WFPE-68KFC

22

Page 25

CABINET COMPONENTS

A. Removable Components

The following major components may be removed without the use

of service tools:

Lid and Yoke Assembly

Condensate Tray

Collector and Heat Transfer Plate (use the Collector Lifting Tool)

Dead Weight Cover and Dead Weight

Remove the Muffler by loosening the four hose clamps that secure

the exhaust tubing. Work the tubing off of the vent tubes, then lift

the muffler out of the cabinet.

B. Access Panels

Remove the following panels by removing two screws at the

bottom, then sliding the panel out of the channel in the frame:

Lower Front Panel

Right Side and Left Side Panels

Upper Rear Panel

434 305284 Owners Manual WFPE-68KFC

After removing the Lower Front Panel, remove two screws at the

bottom of the Upper Front Panel and slide it out of the frame.

Disconnect the controller connectors in the front electrical

compartment.

The Electrical Shelf is held by two screws at the bottom, and slides

out to the limit of the wiring.

SERVICING INSTRUCTIONS

WARNING

SHOCK HAZARD

Disconnect from electrical

power before removing any

panel or cover.

CAUTION

BURN

HAZARD

Allow fryer to cool. Be sure

all pressure is relieved before

proceeding.

TOOLS REQUIRED:

#2 Phillips Screwdriver

Container to hold

fasteners

IMPORTANT:

Yoke and lid assembly

weighs approximately 70 lbs.

Use appropriate lifting

procedures.

These servicing instructions are intended for use by qualified technical personnel only.

SERVICE

23

Page 26

SERVICING INSTRUCTIONS (continued)

These servicing instructions are intended for use by qualified technical personnel only.

WARNING

SHOCK HAZARD

Disconnect from electrical

power before removing any

panel or cover.

CAUTION

BURN

HAZARD

Allow fryer to cool. Be sure all

pressure is relieved before

proceeding.

TOOLS REQUIRED:

#2 Phillips Screwdriver

Flat blade screwdriver

Container to hold fasteners

CHASSIS ELECTRICAL COMPONENTS

A. Access

Remove RIGHT SIDE PANEL

Remove LOWER FRONT PANEL then UPPER FRONT PANEL.

Note wiring connections to control panel, switches and indicators.

Disconnect wiring and set upper front panel aside.

B. Components

Note location of wiring connections, then disconnect wires from

component. Detach component from chassis.

Reassemble in reverse order

434 305284 Owners Manual WFPE-68KFC

SERVICE

24

Page 27

SERVICING INSTRUCTIONS (continued)

CONTROL PANEL COMPONENTS

A. Access

Remove LOWER FRONT PANEL. Remove screws holding

UPPER FRONT PANEL to cabinet.

B. Controller

Disconnect two connectors from electrical compartment. Note

orientation of connectors.

Remove two screws holding controller to panel.

C. Indicator Lights

Disconnect wiring from light.

Collapse mounting tabs on light body. Withdraw light through front

of panel.

D. Power Switch

Note position of wires on switch. Disconnect wires.

Collapse mounting tabs on switch body. Withdraw switch with

switch guard through front of panel.

434 305284 Owners Manual WFPE-68KFC

Reassemble in reverse order. Be careful that no wires are pinched

when reinstalling upper front panel.

WARNING

SHOCK HAZARD

Disconnect from electrical

power before removing any

panel or cover.

TOOLS REQUIRED:

#2 Phillips Screwdriver

Needle Nose Pliers

Container to hold

fasteners

These servicing instructions are intended for use by qualified technical personnel only.

SERVICE

25

Page 28

SERVICING INSTRUCTIONS (continued)

These servicing instructions are intended for use by qualified technical personnel only.

YOKE AND LID ASSEMBLY

CAUTION

BURN

HAZARD

Allow fryer to cool. Be sure all

pressure is relieved before

proceeding.

TOOLS REQUIRED:

#2 & #3 Phillips Screwdrivers

Flat Blade Screwdriver

Screw Starter

7/16" Box End Wrench or

Hex Socket

1/2" & 1" Open End

Wrenches

Container to hold

Fasteners

IMPORTANT:

Yoke and lid assembly

weighs approximately 70 lbs.

Use appropriate lifting

procedures.

ASSEMBLY & TORQUE

SPECS:

SERVICE

Piston Assy to Lid

Loctite™246

Lockwasher (35486)

75 in.-lbs

Cam Plate to Piston Assy

Loctite™246

Lockwasher (35486)

75 in.-lbs

A. Access

Turn operating lever fully clockwise. Slide yoke and lid assembly to

the rear until it clears the blocks. Assembly may be lifted off, or

work may be performed in place.

IMPORTANT: Yoke and lid assembly weighs approximately 70 lbs.

Use appropriate lifting procedures.

B. Yoke Assembly

Remove two screws from CAP.

Remove three inside screws/lock washers holding CAM PLATE.

Lift YOKE ASSEMBLY off of LID AND PISTON ASSEMBLY.

Glides: Remove two screws holding glides to yoke.

No other field operations can be performed on the yoke assembly.

C. Lid and Piston Assembly

O-RING may be worked out of the groove in the lid. Lubricate

o-ring with clean vegetable oil before reinstalling.

Remove four screws/lock washers holding piston to lid.

Reassemble in reverse order

Remove four screws holding LID REAR SUPPORT/PIVOT to lid.

Unscrew PRESSURE RELIEF TUBE from PRESSURE RELIEF

VALVE. Unscrew PRESSURE RELIEF and PRESSURE GAUGE

from lid. Unscrew ADAPTER from PRESSURE RELIEF VALVE.

To reinstall, lightly coat male threads with hi-temperature silicone

sealant.

Reassemble in reverse order.

Lubricate cam with food-grade grease before installing cam plate

and cap.

When reassembling lid & piston to yoke, support lid and piston on

a suitable 1" high object to ease installation of cam plate.

Be sure lid is assembled to yoke with the pressure gauge on the

operating lever side.

434 305284 Owners Manual WFPE-68KFC

26

Page 29

SERVICING INSTRUCTIONS (continued)

MOUNTING BLOCKS AND ASSOCIATED COMPONENTS

A. Access

Turn operating lever fully clockwise and slide lid and yoke assembly

to rear until it clears the blocks. Lift lid and yoke off of fryer.

IMPORTANT: Yoke and lid assembly weighs approximately 70 lbs.

Use appropriate lifting procedures.

Remove LEFT SIDE PANEL, RIGHT SIDE PANEL and UPPER

REAR PANEL.

B. Pivot Tube and Guide Rods

Loosen screws in top of ROD MOUNTING BLOCKS. Slide GUIDE

RODS to the rear. Slide PIVOT ROD forward until it clears the

GUIDE RODS.

To reinstall, be sure guide rods are properly oriented with the flat

ends toward the rear and the locating notch “up”. Pivot tube must

be positioned on the guide rods with the ears “up” and the handle

on the right side. After installation, test pivot rod for smooth

operation, to be sure it locates securely into the notches, and that it

is easily moved from the notches.

C. Mounting Blocks

Remove five bolts from each mounting block. Note that mounting

blocks may be attached with sealant to cabinet top.

To reinstall, be sure mounting blocks are oriented with the smooth

side toward the outside, and the notched upper flange toward the

rear. Apply a thin bead of food-grade silicone sealant to the bottom

of the mounting block before installing.

434 305284 Owners Manual WFPE-68KFC

D. Basket Hook Support Block

Remove two bolts from support block. Note that support block may

be attached with sealant to cabinet top.

To reinstall, be sure support block is oriented with the smooth

side toward the frypot. Apply a thin bead of food-grade silicone

sealant to the bottom of the block before installing.

CAUTION

BURN

HAZARD

Allow fryer to cool. Be sure all

pressure is relieved before

proceeding.

TOOLS REQUIRED:

3/8" & 3/4" Sockets w/ 4"

extension

Container to hold

fasteners

Food-Grade Silicone Sealant

IMPORTANT:

Yoke and lid assembly

weighs approximately 70 lbs.

Use appropriate lifting

procedures.

ASSEMBLY & TORQUE

SPECS:

Mounting Blocks

Loctite™246

80 ft.-lbs

Basket Hook Block

Loctite™246

Lockwasher (37500)

20 ft.-lbs

These servicing instructions are intended for use by qualified technical personnel only.

SERVICE

27

Page 30

SERVICING INSTRUCTIONS (continued)

These servicing instructions are intended for use by qualified technical personnel only.

WARNING

SHOCK HAZARD

Disconnect from electrical

power before removing any

panel or cover.

CAUTION

BURN

HAZARD

Drain oil and allow fryer to

cool before proceeding

TOOLS REQUIRED:

#2 Phillips Screwdriver

Assorted open wrenches

from 3/8" to 15/16"

Molex™ connector tool

Container to hold fasteners

IMPORTANT:

Tighten fittings only enough

to prevent leaks.

Over tightening is not

necessary.

ASSEMBLY & TORQUE

SPECS:

Temperature Probe

25 ft.-lbs

Compression Nut

35 ft.-lbs

Hi-Limit Thermostat

25 ft.-lbs

Compression Nut

35 ft.-lbs

Element

Element Clamp

23 in.-lbs

Bulkhead Fitting

SERVICE

30 ft.-lbs

Terminal Nut, Inner

8 in.-lbs

Terminal Nut, Outer

30 in.-lbs

Terminal Locknut

30 in.-lbs

FRYPOT ELECTRICAL COMPONENTS

A. Access

Remove LOWER FRONT PANEL then UPPER FRONT PANEL.

Note wiring connections to control panel, switches and indicators.

Disconnect wiring and set upper front panel aside.

Carefully remove insulation from around frypot electrical terminals.

B. Temperature Probe

Disconnect temperature probe connector. Work pins out of

connector with Molex™ tool.

Remove nut and o-ring (interior of frypot). Withdraw probe and

fitting from frypot.

Remove compression nut and ferrule, then remove probe from

fitting.

Reassemble in reverse order.

Be sure frypot surfaces are clean before reassembly.

Use a fresh fiber washer and o-ring.

Be sure connector pins are fully

seated in connector.

F. REPLACE HI-LIMIT THERMOSTAT

Disconnect wiring from old hi-limit

thermostat.

Remove old hi-limit probe from frypot.

Remove and discard old hi-limit

thermostat and bulkhead fitting.

Mount new hi-limit thermostat bracket

to cabinet. Be sure green ground

wire is attached to one of the bracket

screws.

434 305284 Owners Manual WFPE-68KFC

28

Page 31

SERVICING INSTRUCTIONS (continued)

FRYPOT ELECTRICAL COMPONENTS (continued)

Clean frypot at bulkhead fitting.

THERMOBULB

Apply hi-temp sealant around hole

for bulkhead fitting.

ELEMENT

Slide probe through compression

nut, ferrule and fitting, then insert

probe into frypot.

Slide green fiber washer, belleville

washer (with bell toward frypot) and

nut over probe. Assemble all

components of bulkhead fitting

finger-tight.

Push probe back through bulkhead

CLAMP

APPLY

HI-TEMP

SEALANT

COMPRESSION NUT

FITTING

FERRULE

TEMP PROBE

FIBER WASHER

fitting until bend in probe contacts

fitting nut.

FRYPOT

Gently contour free end of probe to

match curvature of element.

Assemble clamp approximately

3 inches from free end of probe. Be

sure clamp captures two loops of the element, then tighten screw.

Tighten bulkhead fitting to frypot. Torque to 25 ft-lb.

Tighten compression nut. Torque to 35 ft-lb.

Be sure glass sleeving completely covers exposed portion of probe

on outside of frypot.

Reconnect wiring.

D. Heating Elements

Disassemble hi-limit thermobulb clamp. Carefully position

thermobulb out of the way.

Remove screws from bottom of element clamps, then remove

clamps.

Disconnect wiring from heating elements. Disassemble bulkhead

fittings and withdraw elements from frypot in the following order:

Top heating element

Middle heating element

Bottom heating element

Reassemble in reverse order

Be sure frypot surfaces are clean before reassembly.

Use fresh o-rings.

Be sure ceramic spacer is properly installed before connecting

wiring.

434 305284 Owners Manual WFPE-68KFC

Be sure all three elements are firmly held by the element

clamps.

Be sure hi-limit thermobulb is firmly held by the bulb clamp.

NUT

BELLEVILLE

WASHER

(NOTE: BELL

TOWARD

FRYPOT)

WARNING

SHOCK HAZARD

Disconnect from

electrical power before removing any panel or cover.

CAUTION

BURN

HAZARD

Drain oil and allow fryer to

cool before proceeding

TOOLS REQUIRED:

#2 Phillips Screwdriver

Assorted open wrenches

from 3/8" to 15/16"

Container to hold fasteners

IMPORTANT:

Tighten fittings only enough

to prevent leaks.

Over tightening is not

necessary.

Wells recommends that if any

element must be replaced, all

three elements be replaced at

the same time.

These servicing instructions are intended for use by qualified technical personnel only.

SERVICE

29

Page 32

SERVICING INSTRUCTIONS (continued)

These servicing instructions are intended for use by qualified technical personnel only.

These servicing instructions are intended for use by qualified technical personnel only.

WARNING

DEAD WEIGHT ASSEMBLY

SHOCK HAZARD

Disconnect from electrical

power before removing any

panel or cover.

CAUTION

BURN

HAZARD

Allow fryer to cool. Be sure all

pressure is relieved before

proceeding.

TOOLS REQUIRED:

7/16" Nut Driver

1" Open End Wrench

Container to hold

fasteners

Food-Grade Silicone Sealant

A. Access

Remove RIGHT SIDE PANEL, LEFT SIDE PANEL and UPPER

REAR PANEL.

B. Pressure Relief Components

Unlatch DEAD WEIGHT COVER and lift off.

DEAD WEIGHT lifts straight out of the CAGE.

The GASKET may be lifted out of the BODY ASSEMBLY

C. Body Assembly

Remove PIVOT ARM and RELIEF PIN (see page 31).

Disconnect PRESSURE HOSE ASSEMBLY from BODY.

Be careful that the hose does nor twist or kink.

Remove four nuts holding body assembly to cabinet. Remove

body. Note that body may be attached with sealant to cabinet top.

Reassemble in reverse order.

When reinstalling relief pin, do not over tighten retaining plate

screws. Relief pin must be free to drop of its own weight.

Be sure to seal body to cabinet top with a thin bead of food-grade

silicone sealant.

SERVICE

434 305284 Owners Manual WFPE-68KFC

30

Page 33

SERVICING INSTRUCTIONS (continued)

SOLENOID AND RELATED COMPONENTS

WARNING

SHOCK HAZARD

Disconnect from electrical

power before removing any

panel or cover.

TOOLS REQUIRED:

#2 Phillips Screwdriver

Needle Nose Pliers

Container to hold

fasteners

A. Access

Remove RIGHT SIDE PANEL and UPPER REAR PANEL.

B. Pivot Arm

Remove cotter pin from lower portion of CONNECTING ROD.

While supporting the assembly, remove four nuts holding PIVOT

ARM and BRACKET to cabinet. Lower carefully. Be sure to

withdraw RELIEF PIN from pressure relief body and store safely.

Remove RETAINING PIN. Withdraw PIVOT. Be sure to capture

PIVOT BUSHING.

C. Solenoid

Remove three screws holding MOUNTING BRACKET COVER to

mounting bracket. Remove cover.

Disconnect wiring from SOLENOID.

Remove cotter pin from upper portion of CONNECTING ROD.

Remove four nuts holding solenoid to mounting bracket. Remove

434 305284 Owners Manual WFPE-68KFC

solenoid from bracket.

Disassemble STRAIN RELIEF from mounting bracket only if

replacing wiring.

Reassemble in reverse order. Replace cotter pins if worn or damaged.

These servicing instructions are intended for use by qualified technical personnel only.

These servicing instructions are intended for use by qualified technical personnel only.

SERVICE

31

Page 34

SERVICING INSTRUCTIONS (continued)

These servicing instructions are intended for use by qualified technical personnel only.

WARNING

SHOCK HAZARD

Disconnect from electrical

power before removing any

panel or cover.

CAUTION

BURN

HAZARD

Allow fryer to cool. Be sure

all pressure is relieved before

proceeding.

TOOLS REQUIRED:

Flat Blade Screwdriver

7/16" Nut Driver

Container to hold

fasteners

Food-Grade Silicone Sealant

MUFFLER COMPONENTS

A. Access

Remove UPPER REAR

PANEL.

B. Exhaust Hoses

Loosen CLAMPS. Work

hose up upper vent fitting

until hose clears vent filling

on muffler. Move end of

hose to the side, then work

hose off of upper fitting.

C. Muffler Assembly

Remove both exhaust hoses

per above, Lift muffler until

drain pipe clears cabinet,

then remove muffler from

cabinet toward rear.

Remove 10 nuts holding lid

to muffler. Remove lid

assembly.

GASKET lifts off.

D. Exhaust Vent

Remove four nuts holding VENT to cabinet. Remove vent. Note

that vent may be attached with sealant to cabinet top.

Reassemble in reverse order. Be sure to seal vent to cabinet top with

a thin bead of food-grade silicone sealant.

SERVICE

434 305284 Owners Manual WFPE-68KFC

32

Page 35

PARTS & SERVICE

ACCESSORIES & OPTIONAL COMPONENTS

DESCRIPTION PART NO.

BASKET, 6-HEAD 22891

BASKET, 4-HEAD 23079

BASKET DRAIN HOOK/

COLLECTOR REMOVAL TOOL 22885

STIRRING TOOL 22886

DISPLACEMENT TOOL 22887

HEAT TRANSFER PLATE 22888

CLEANING BRUSH 22892

TRAY, CONDENSATE 23080

SELECTED SERVICE PARTS

DESCRIPTION PART NO.

O-RING, LID 506201

O-RING, COLLECTOR 506202

DEADWEIGHT, 9 PSI 505435

DEADWEIGHT, 11 PSI 505451

DEADWEIGHT, 12 PSI 505433

IMPORTANT: Use only

factory authorized service

parts and replacement

filters.

For factory authorized

service, or to order factory

authorized replacement parts,

contact your Wells authorized

service agency, or call:

Wells Bloomfield, LLC

2 Erik Circle

P. O. Box 280

Verdi, NV 89439

Service Parts Dept.

phone: (775) 689-5707

fax: (775) 689-5976

Service Parts Department can

supply you with the name and

telephone number of the

WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

CUSTOMER SERVICE DATA

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

434 305284 Owners Manual WFPE-68KFC

EQUIPMENT MODEL NO. _______________

EQUIPMENT SERIAL NO. _______________

VOLTAGE: (check one) 208 3Ø 240 1Ø 240 3Ø 380-415 3Ø

please have this information available if calling for service

33

These servicing instructions are intended for use by qualified technical personnel only.

SERVICE

Page 36

WELLS BLOOMFIELD, LLC

10 Sunnen Dr., St. Louis, MO 63143

telephone: 800-807-9054

fax: 314-781-2714

www.wells-mfg.com

Loading...

Loading...