Wells WFPE30F Installation Manual

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

CLEAN THE GAP

WELLS BLOOMFIELD, LLC

telephone: 775-689-5707

fax: 775-689-5976

www.wellsbloomfield.com

360

USER GUIDE

ROUTINE MAINTENANCE

FOR ELECTRIC FRYERS

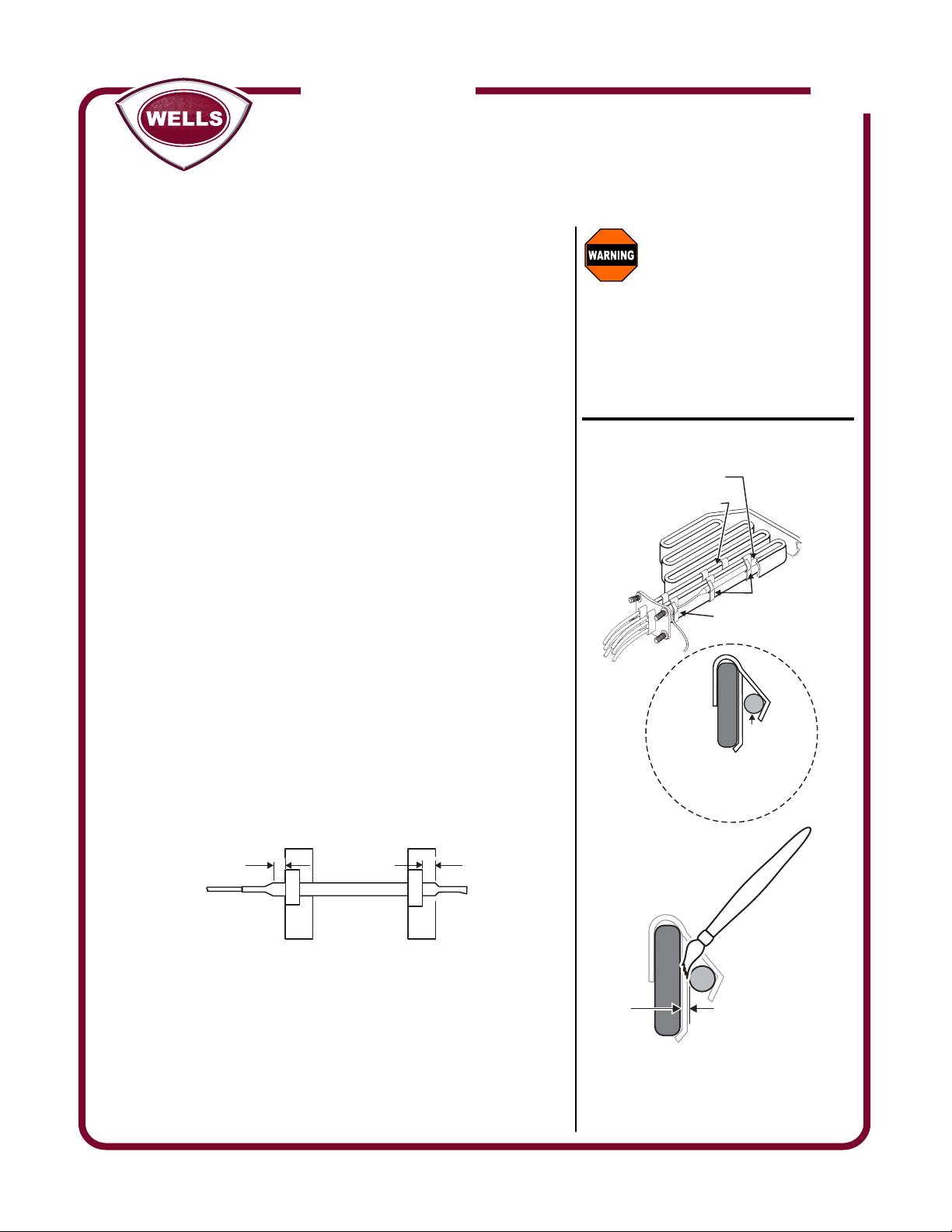

A. KEEP THERMOSTAT SENSING BULBS CLEAN

1. Regular cleaning of the thermostat and hi-limit safety

thermostat sensing bulbs is essential to the proper

operation of fryers. Allowing the build-up of breading

around the thermobulbs will cause fluctuating

temperatures and, eventually, activation of the hi-limit

safety thermostat, shutting down of the fryer.

2. The thermobulb is located adjacent to the heating

element, and is held in position by two clips. Actual oil

temperature is sensed by the thermostat only when the

gap between element and bulb is maintained, allowing

oil to circulate around the thermobulb. A build-up of

breading in the gap stops oil from circulating. Result:

inaccurate temperature readings.

3. Maintain oil circulation by brushing breading and other

cooking waste from the gap between element and

bulb. The best time to perform this operation is when

the oil being filtered.

Clean this gap every time you filter the oil.

4. Check the safety clamps. Each thermobulb must be held

by two clamps, spaced 1/4” - 3/8” from the ends of the

bulb.

a. Verify that the safety clamps are in the proper place.

b. Verify that the clamps are pushed down fully on the

element.

c. Never use more than two clamps on any one bulb.

3/8”

3/8”

PLACE CLAMPS 3/8” FROM THE

ENDS (WIDE PORTION) OF BULB

AS SHOWN ABOVE

Check the safety clamps every time you filter the oil.

WARNING

BURN HAZARD

The following procedures involve

exposure to hot oil.

Wear appropriate protective face

shield, apron and gloves.

Hot oil will cause serious burns on

contact.

TEMPERATURE

CONTROL BULB

RIGHT SIDE

(HI-LIMIT BULB

LEFT SIDE)

TWO CLAMPS

HOLD BULB

ONE CLAMP HOLDS

CAPILLARY

ELEMENT

BULB

SAFETY CLAMP

HOLDS BULB

CLEAR OF

ELEMENT

p/n 303700 Rev. A ECN-13360 I 360 071023 cps

Page 1 of 2

WARNING

BURN HAZARD

The following procedures may

involve exposure to hot oil.

Wear appropriate protective face

shield, apron and gloves.

Hot oil will cause serious burns on

contact.

IMPORTANT:

Filtering, boil-out and oil polishing

procedures are described in the

Operation Manual for your fryer.

Be sure to follow all recommended

safety procedures.

IMPORTANT:

A build-up of cooking debris will

degrade the taste of the food

product and decrease the life of

the oil.

B. FILTER COOKING OIL

1. Regular oil filtering maintains the quality of the food

product and significantly increases the life of the oil.

2. All breading and crumbs must be brushed from the frypot

and elements each time the oil is filtered. Failure to

remove cooking wastes will prevent the thermostats from

sensing the correct temperature, resulting in fluctuating

oil temperature and possible safety shutdown.

3. Using an oil polishing media, such as Wells Flavor Saver, is recommended each time the oil is filtered. This

will remove acids and other contaminants filtering alone

will not remove. Your fryer will produce better tasting

product and the life of your cooking oil will be noticeably

extended.

C. BOIL-OUT FOR CONSISTENT PERFORMANCE

1. The frypot must be thoroughly cleaned by performing a

boil-out procedure at least weekly, and more often

depending upon the amount of use and type of product.

Failure to boil-out the frypot will result in inaccurate

temperatures and premature tripping of the hi-limit

safety.

2. The best time to perform a frypot boil-out is during a

change of cooking oil.

D. RUN YOUR FRYER AT THE PROPER VOLTAGE

1. Any piece of electric equipment must be powered by the

voltage for which it was designed. This is particularly true

for electric fryers.

2. Using a 208 volt fryer at 240 volts will cause heating

elements to run exceptionally hot. This will result in

inaccurate temperatures, frequent tripping of the hi-limit

safety, and premature failure of the heating element.

3. Using a 240 volt fryer at 208 volts will result in a serious

loss of performance.

Page 2 of 2

Loading...

Loading...