Page 1

WFE-40 ELECTRIC FLOOR FRYER

INSTRUCTIONS

Installation

Operation

Maintenance

WELLS MANUFACTURING COMPANY

P.O. BOX 280 VERDI, NEVADA 89439 (702) 345-0444

FAX 702-345-0569

Item No. 46634

10/92

Page 2

TABLE OF CONTENTS

DESCRIPTION PAGE

Warranty 3

Shipping Claim Procedure 4

Specification Information 4

Warnings! 5-6

Controls and Functions 7-8

Installation Instructions 9-10

Operating Instructions 10-11

Filtering Instructions 11-14

Cleaning Instructions 14-15

Warranty Exclusions 16

2

Page 3

WARRANTY STATEMENT

All commercial cooking equipment manufactured by WELLS has a warranty against defects in materials and

workmanship for one year from the date of original installation, or eighteen months from the date of shipment from our

factory, whichever comes first. This is for the benefit of the original purchaser only. A. The stainless steel fry pots in

gas fryers, model number WFG-40-2, warranty insures fry pots to be free from defects that could cause shortening

leaks for five years from date of purchase. The exception is that after one year the replacement of the fry pot under

warranty will cover at 75% of list price of kettle assembly. Fry kettle includes new shrouds, insulation, flue vent,

burners, thermostats and attaching hardware; travel and labor not included. Fry pots, which fail due to abuse, will not

cover in standard or five year warranty - items include but not limited to firing of burners without shortening or other

cleaning solution in the fry kettle at proper level.

B. with respect to Lite Line Products, warranty is one year parts and labor

on carry-in portable models.

THIS WARRANTY IS THE COMPLETE AND ONLY WARRANTY, EXPRESSED OR IMPLIED IN LAW OR

FACT, INCLUDING BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

ANY PARTICULAR PURPOSE, AND FOR DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES

CONCERNING WELLS' PRODUCTS. This warranty is void if it is determined that upon inspection by an authorized

service agency that the equipment has been modified, misused, misapplied, improperly installed, or damaged in transit

or by fire, flood or act of God. Also, warranty does not apply if the serial nameplate has been removed or service is

performed by unauthorized personnel. The prices charged by Wells for its products are based upon the limitations in

this warranty. Seller's obligation under this warranty limits to the repair of defects without charge by a WELLS' factory

authorized service agency or one of its sub-service agencies and limits to a sixty mile radius to the nearest authorized

service agency or one of its sub-service agencies. This service will be provided on customer's premises for nonportable models. Portable models (a device with a cord and plug) must be taken or shipped to the closest authorized

service agency, transportation charges prepaid for service. Besides restrictions contained in this warranty, specific

limitations show in the Service Policy and Procedure Guide. WELLS' authorized service agencies location are in

principal cities. This warranty is valid in the United States and Canada and void elsewhere. Please consult your

classified telephone directory, your foodservice equipment dealer or write the Factory Service Department, Wells

Manufacturing Company, P.O. Box 280, Verdi, Nevada 89439, phone (702) 345-0444, for information and other

details concerning warranty.

3

Page 4

SHIPPING CLAIM PROCEDURE:

For your protection, please note that equipment in this shipment was carefully inspected and packed by skilled personnel

before leaving the factory. The transportation company assumes full responsibility for safe delivery upon acceptance of this

shipment.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE— Be certain this is noted on freight bill or express receipt and signed by person

delivering.

2. FILE CLAIM FOR DAMAGES IMMEDIATELY— Regardless of extent of damage.

3. CONCEALED LOSS OR DAMAGE— If damage is unnoticed until merchandise is unpacked, notify transportation

company or carrier immediately, and file "concealed damage" claim with them. This should be done within (15) days

of date of delivery is made to you. Be sure to retain container for inspection.

We cannot assume responsibility for damage or loss incurred in transit. We will, however, be glad to furnish you with the

necessary documents to support your claim.

SPECIFICATION INFORMATION:

Dimensions: 15 5/8 " x 32" x 41"

Shortening Capacity: 30 to 40 Ibs.

Electrical Rating: See Chart

Number of Phase: 3F only

Frequency: 50/60 Hz

KW 208V 240V 480V

LI L2 L3 L1 L2 L3 L1 L2 L3

14

17 47.2 47.2 47.2 40.9 40.9 40.9 20.5 20.5 20.5

38.9 38.9 38.9 33.7 33.7 33.7 16.9 16.9 16.9

NOMINAL CURRENT DRAW

4

Page 5

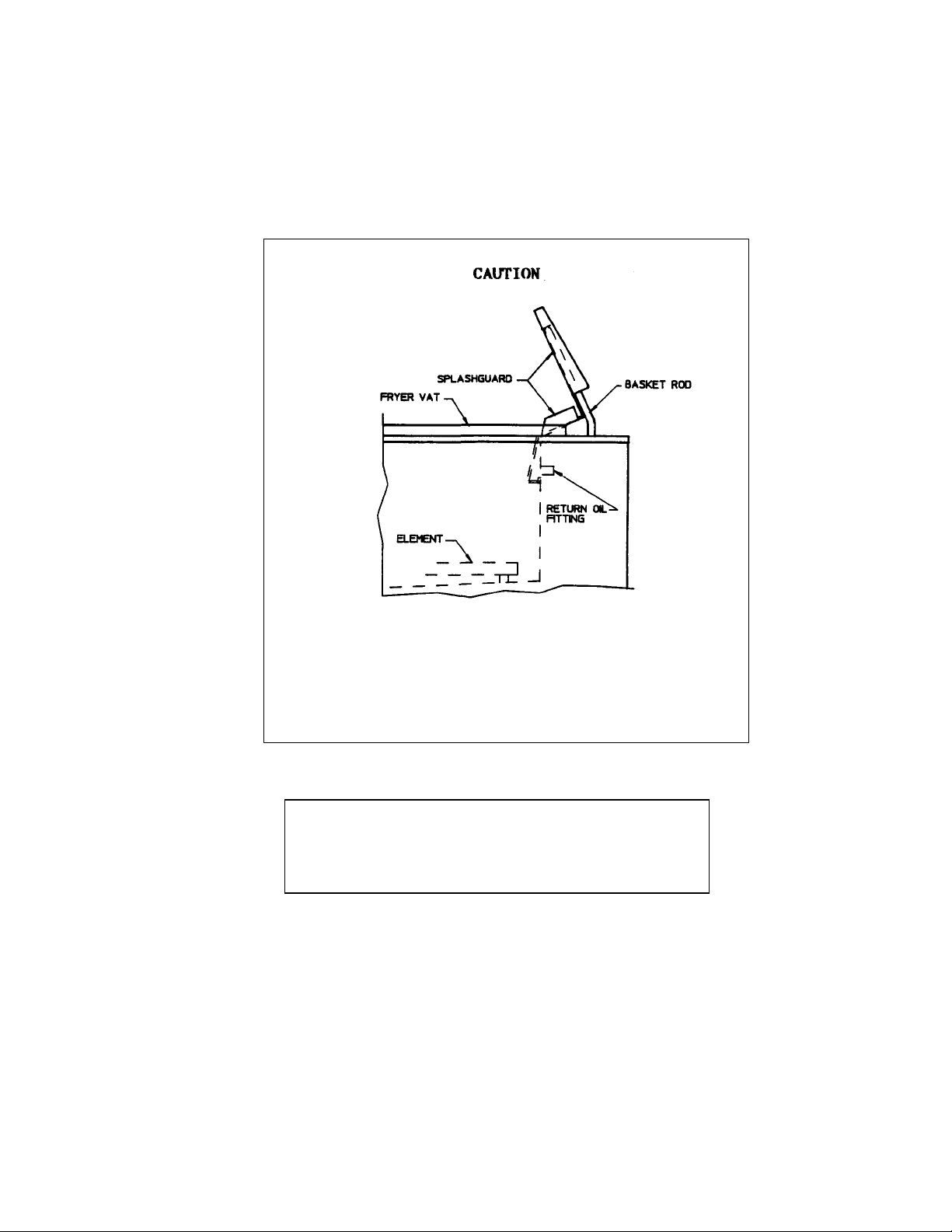

WARNINGS!

The hinged oil splashguard may be raised for cleaning ONLY.

To avoid serious injury the splashguard must be in the down

(shown above) position before operating the fryer or the filter.

Splashing of HOT OIL may occur if the oil splashguard is not in

the down position.

WARNING!

To avoid injury protective clothing and insulated

gloves must be worn during filtering, cleaning the

fry vat and discarding used oil.

5

Page 6

WARNINGS!

WARNING!

DO NOT ATTEMPT OR RELOCATE THE FRYER WITHOUT THE

ASSISTANCE OF AN AUTHORIZED SERVICE AGENCY. DO NOT

MOVE THE FRYER WITH HOT OIL IN THE VAT. COOL DOWN

OIL TEMPERATURE TO BELOW 135°F. HOT OIL SPILLAGE

WILL CAUSE SEVERE BURNS!

CAUTION

DO NOT LEAVE OIL IN THE FILTER RESERVOIR FOR EXTENDED

PERIODS OR OVERNIGHT. Wells built-in filter system

is designed to handle hot oil only. The filter pump

will not pump cold oil or solid shortening.

The built-in filter system is designed for OIL ONLY.

Water, cleaning agents or other liquids will damage

the filter pump.

6

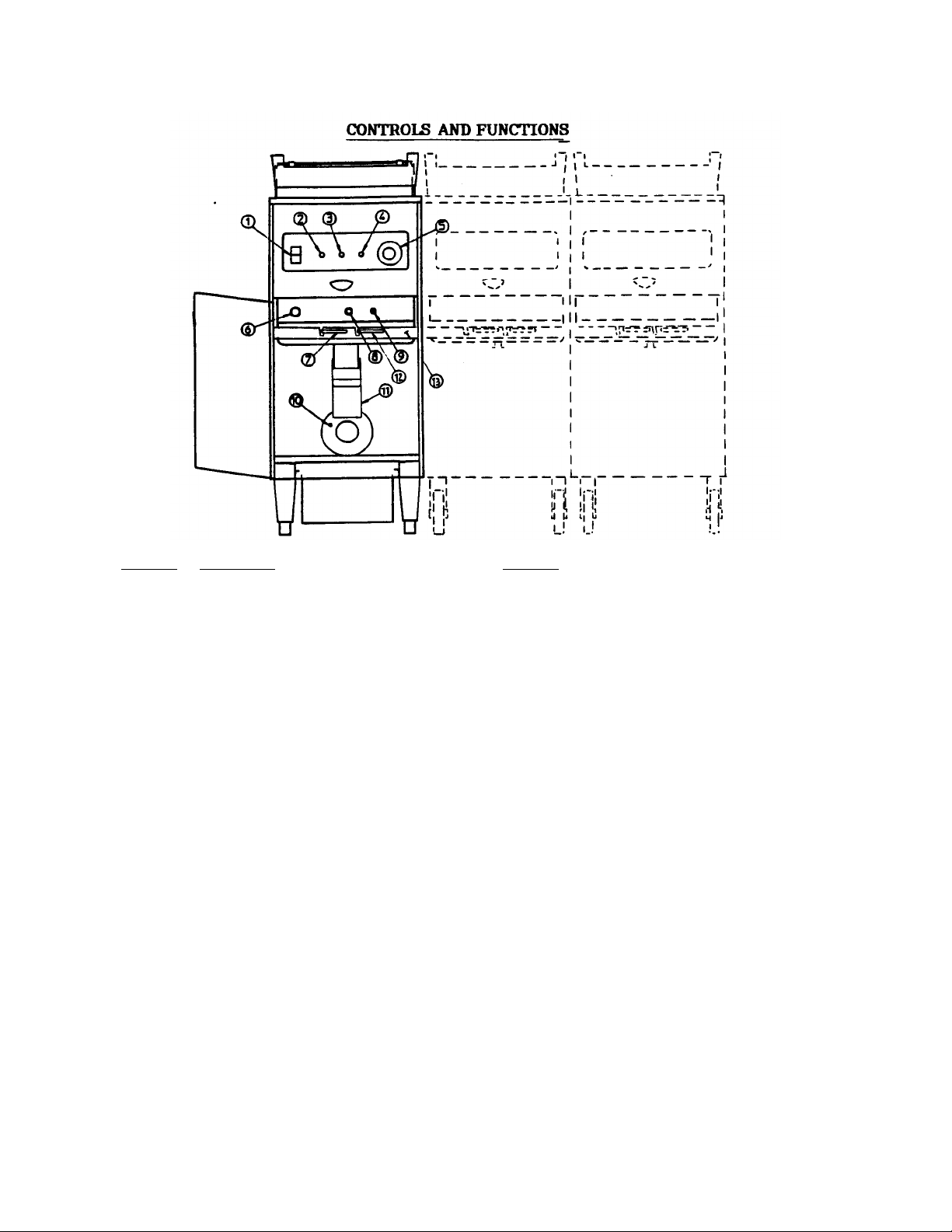

Page 7

Item No. Description Function

1. Three Position Rocker Switch "FRYER" position turns ON the

FRYER-OFF-FILTER fryer and the WHITE power light.

"OFF" position turns OFF the fryer

"FILTER" position turns ON the filter

motor for single fryers, while fryer

"FILTER" position for the banked

fryers makes power available to the

are OFF in this position.

2. Power Light...White When ON indicates power is available

3. Hi-Limit Light—Red When ON this indicates that the

system has allowed the oil to over

have shut off. Wait approximately

five (5) minutes, open the door and

complete information).

and the filter system.

elements are OFF in this position.

filter motor, while fryer elements

either to the Fryer or Filter Motor.

heat, and the fryer heating elements

press reset button (see item 9 for

7

Page 8

4. Heat on Light... Amber When ON it indicates that the Fryer

5. Solid State Temperature This controls the oil temperature

CAUTION: Power switch MUST be used for positive OFF. DO NOT SHUT OFF the

6. Fuse Provides electrical over current

7. Drain Valve Handle Open and closes drain valve.

* 8. Filter Light...Green When ON it indicates that the filter

9. Hi-Limit Thermostat The function of this thermostat is to

* 10. Motor Reset Button The motor is equipped with an

11. Drain Spout Adjustable gutter to lead discharged

**12. Oil Return Valve Handle Open or close oil return valve. If

**13. Interlock Channel Slide side to side when all valves are

Controller from 0° to 375°F.

unit with the solid state temperature controller.

(at back side of motor) overheating protection device. Wait

heating elements are ON. Cycles OFF

when oil reaches preheat

temperature.

protection for the fryer. Use a 10

AMP SC type replacement only.

motor is ON.

shut down the fryer heating elements

in the event of over heated oil.

for the motor to cool down

(approximately 15 minutes). Press the

reset button to restart the motor.

oil to the filter reservoir or

discarding bucket.

main power switch is at the FILTER

position, turning the valve open will

automatically turn filter motor ON,

while turning the valve close will

automatically shut the motor OFF.

closed or rotate clockwise to the up

position and select fryer section to

drain and/or filter, minimizes

overflow to filter reservoir and

fryer vat.

* Available for Fryers with a Filter.

** Available for two or more Banked Fryers with Filters.

8

Page 9

INSTALLATION INSTRUCTIONS:

1. Start Up

2.

A. When moving the fryer with filter and/or casters, remove filter

B. An authorized service agent should install the fryer and perform the

C. The power supply must be rated the same as the unit being installed.

reservoir to allow free swiveling caster action.

initial start up procedures.

Leveling

A. Check that the unit sits firmly on all four legs and is level.

B. For fryers with casters, lock all front casters by pressing the brake

lever ON treadle (see figure below.)

3. Cleaning

A. Prior to leaving the factory the fryer is tested for proper

operation. Oil is placed in the fryer vat and the thermostat is calibrated. After testing is complete the

oil is removed, but residue remains. Therefore, it is necessary to clean the fryer vat before filling with

fresh oil. Refer to cleaning instructions.

4. Filter Component Assembly

SIDE VIEW FRONT VIEW

FIGURE D-1

9

Page 10

Explanation of Terms

Locator Clip:

Filter Screen:

Filter Paper:

Paper Holder:

Provides alignment between filter screen and the drain

fitting.

Allows spacing for filtered shortening/oil to move and run

through pumping system.

Filters crumbs and food particles from shortening/oil.

Serves as a counter weight to hold filter paper in place,

preventing food particles and crumbs from going through the

system unfiltered.

FIGURE D-2

To prevent damage during shipment, the O-Ring is pulled away from the groove on the tube at the factory. Before

operating this unit, return the position of the O-Ring to the groove on the tube. Remove the extra 20 pieces of filter paper

from the reservoir and store for future use.

OPERATING INSTRUCTIONS:

Pre-Heating the Fryer:

1. Turn the Power Switch to Fryer position. The WHITE Power light indicator will come ON.

2. Set the temperature controller to desired setting. The AMBER element light will come ON.

3. Wait for one hour, or until the element light cycles OFF three (3) times. The fryer is ready

for cooking.

Cooking with the Fryer:

1. Prepare Food

a. Drain and/or wipe dry raw and wet foods before frying.

b. Keep the size of the food uniform for consistent product taste and production.

10

Page 11

2. Basket Loading

b.

After the basket is covered by oil, carefully drop batter

-

covered

used.

b.

Hang baskets to drain on rear basket supports.

c. Remove food.

a. Load baskets in accordance with recipes and food types being

prepared.

b. when cooking a light product that floats, fill baskets only 1/2 full.

3. Special Processing

a. Potatoes and Onion Rings: Shake basket several times in a manner

that prevents grease from splattering.

foods individually into the basket, or the fry vat if a basket is not

c. Foods such as corn-on-the-cob must be submerged during frying to

ensure uniform processing. Cover bottom of basket with corn, then

stack a second (empty) basket on the corn to keep the product

4. Helpful Hints

a. Remove baskets immediately after frying.

d. Season food as necessary, but NOT OVER the fryer. Salt and other

types of seasonings hasten oil breakdown.

e. Cover kettle during idle periods. This could cut power consumption

as much as 15 %. An optional fry vat cover is available from Wells.

submerged.

FILTERING INSTRUCTIONS FOR FRYERS WITH BUILT-IN FILTER:

WARNING: PROTECTIVE CLOTHING AND GLOVES MUST BE WORN DURING FILTERING

PROCESS.

Always follow these step by STEP procedures to ensure proper filtering operation and great tasting fried

foods.

1. Before draining the oil for filtering, check the

filter reservoir and make sure that screen,

filter paper, and filter retainer are properly

installed. (See figure D-1 on page 10 of

Instruction Manual).

2. Push the filter reservoir in to fully engage the

filter return pipe.

3. Slide oil drain chute back and lower into filter

reservoir (see figure 1).

4. Open door of fryer section to be filtered.

5. Turn power switch on control panel to filter

position (see figure 2).

FIG. 1 FILTERING

11

Page 12

FIG 3 DISCARDING OIL POSITION

6. Slide interlock channel to

position that allows opening of

drain and refill valves.

NOTE: If interlock channel will

7. Open drain valve handle by

8. Open return valve handle and

9. To refill the fry pot at the

10. When the fry pot is full, close

11. Turn the power switch to the

not slide, open door of

other fryer section(s)

and check drain and fill

valve handles. They must

be closed in order to

slide the interlock

channel.

This step can be disregarded

for single fryers. Applicable

for banked fryers only.

rotating counter clockwise to

the down (vertical) position to

drain oil into filter reservoir

(see figure 2).

start filter pump by rotating

counter clockwise to the down

(vertical) position. Green

light will turn on the indicate

filter pump is operating (see

figure 2).

NOTE: The return valve must be

open and the power

switch must be in the

filter position or the

filter pump will not

operate.

end of the filtering cycle,

close the drain valve handle by

rotating clockwise to the up

(horizontal) position.

the return valve and turn off

the filter pump by rotating

the return valve handle

clockwise to the up

(horizontal) position.

OFF position to shut down the

fryer, or the fry position to

continue cooking (see CAUTION

note on page 6 of Instruction

Manual).

12

Page 13

Discarding Used Oil:

1. DO NOT use filter reservoir to

2. Place bucket against the front

3. Lift up oil drain chute and

4. Slide interlock channel to

5. Open drain valve handle by

FIG 4

6.

When bucket is 2/3 full (or fry pot is empty, whichever occurs first), turn

discard used oil, use a metal

bucket with a proper handle.

Fill the bucket 2/3 full

maximum. DO NOT OVER FILL THE

BUCKET.

of the filter reservoir (see

figure 3).

slide forward to rest over

bucket (see figure 3).

position that allows opening of

drain and refill valves (see

figure 4).

rotating counter clockwise to

the down (vertical) position to

drain oil into filter reservoir

(see figure 4).

OFF drain valve by rotating clockwise to up (horizontal) position.

NOTE: A small amount of oil may still drain from the manifold after valve is

closed. DO NOT REMOVE BUCKET UNTIL IT STOPS.

7.

Slide oil drain chute back and lower into the filter reservoir.

NOTE: If there is excessive crumbs, assist flush down by using WELLS

supplied high temperature brush. Brush the sides and bottom of the

vat, while leaving the drain open.

Cleaning the Splash Guard:

1. Turn the ROCKER SWITCH to the OFF positions.

2. Empty all oil from the vat.

3. Swing splash guard to up position and wipe clean.

4. Lower and push splash guard back into place.

CAUTION: Observe the pattern of the showered oil. If it has noticeably changed, check the shower

holes of the splash guard for obstruction. Follow steps a to c of these instructions before

attempting to clean or unclog the holes.

Pump Filtered Oil to the Fryer Vat:

1. Turn power switch to FILTER position and turn oil return valve to the open position for banked fryers.

2. CLOSE the drain valve.

NOTE: 40 Ibs., of oil at 350°F can be filtered in just one minute.

Temperature of the oil and the varying amounts of crumbs and food particles in the shortening will

effect the speed of the filtering process.

13

Page 14

Filtering Tips:

1. Wells filter system is designed to handle hot oil up to 375°F.

2. You can filter your oil immediately after cooking without waiting for oil to cool down.

3. DO NOT run water or chemicals other than cooking oil through the filter system. Running liquids other that

oil damage the pump and void your warranty.

4. Perform filtration as frequently as possible. Crumbs and food particles will hasten oil break down.

5. Replace filter paper as frequently as necessary. In some cases one filter

paper may be reused repeatedly for filtering. See local health code

requirements.

CAUTION: Timely filtering and replacement of the filter paper is

determined by the amount of crumbs and food particles that are mixed with the oil during

the cooking process. As a general guide line, when frying breaded or buttered products,

filter the oil and replace the filter paper after every 40 LBS of cooked product. This will aid

in avoiding clogging of the drain and filter.

Unclogging the Drain:

1. In the event of heavy accumulation of crumbs clogging the drain, use the WELLS supplied cleaning rod to

dislodge food particles. WARNING: DO NOT refill the fryer vat by manually pouring the hot oil through

filter reservoir. This may cause serious injury.

Unclogging the Filter:

1. Use only the WELLS HIGH TEMPERATURE BRUSH supplied with your fryer. Remove crumb cradle.

Brush the top of the filter paper while the filter motor is operating. Continue to brush until minimal oil is left

in the reservoir.

2. Discard the soiled filter paper according to your local health codes.

3. Re-assemble reservoir and replace filter paper.

4. Filter system is now ready for another filtering cycle.

CLEANING INSTRUCTIONS:

Boil Out:

1. Drain the oil into the filter reservoir.

2. After emptying the fryer vat, close the drain valve.

CAUTION: To avoid filtering difficulty, DO NOT postpone or extend

cleaning operation for long periods. The pump WILL NOT filter cold oil.

3. Turn drain pipe to discarding position (see illustration on page 7).

4. Fill vat with water to the 40 Ibs. level.

5. Add approximately 2 ounces of detergent per gallon of water or use commercial fryer cleaner, following the

manufacturer's instructions.

14

Page 15

6. Turn the temperature controller setting to CLEAN (175°F to 225°F). The

7. Keep basket rack and baskets in the vat.

liquid may boil at this setting.

CAUTION: Turn the knob CLOCKWISE to reach a boiling temperature.

Turn the knob COUNTER CLOCKWISE to avoid vat boil over.

Scrubbing:

1. When water begins to boil, scrub the fry vat and baskets to remove burnt-

2. Continue boiling process for a least five (5) minutes or the recommended

3. Turn fryer OFF and drain into metal bucket.

Rinsing:

1. Fill the fryer vat with clean water.

2. Turn the Power Switch to the ON position.

3. Boil for at least five (5) minutes.

A. Drain and discard.

5. Rinse thoroughly with warm clean tap water to remove any cleaner residue.

6. Wipe down and dry using a clean non-abrasive cloth.

Refilling the Fryer:

1. Close drain valve.

2. Return filtered fryer oil to the vat.

Daily Cleaning of Fryer Exterior:

on-material.

time specified by the manufacturer of the cleaner.

CAUTION: Use a metal bucket with a handle to discard water and other

cleaning solutions. DO NOT use filter reservoir to discard the

water or cleaning solution.

Residue left in the vat will hasten breakdown of oil.

It is very important to wash all exterior surfaces at least once a day. Use a

clean non-abrasive cloth, warm water and a mild soap or detergent. Follow with a

clear rinse, then dry.

This simple treatment eliminates the danger of grease accumulation which forms

hard-to-remove stains and may create a potential hazard.

15

Page 16

WELLS MANUFACTURING COMPANY SERVICE POLICY

AND PROCEDURE GUIDE ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting the safety thermostats, circuit breakers, overload protectors, or fuse replacements unless warranted

conditions are the cause.

2. All problems due to operation at voltages other than specified on equipment nameplates -

conversion to correct voltage must be the customer's responsibility.

3. All problems due to electrical connections not made in accordance with electrical code requirements and

wiring diagrams supplied with the equipment.

4. Calibration of heat controls after the first sixty (60) days on original

components. Replacement of items subject to normal wear to include such items as knobs, light bulbs, baskets,

grids, mechanical timers and thermocouples. Normal maintenance functions including lubrication, adjustments

of airflow, thermostats, door mechanisms, microswitches, burners and pilot burners and replacement of fuses

and indicating lights are not covered by warranty.

5. All fry pots welded in the field.

6. Deterioration of aluminum vessels due to insertion of food product or use of abrasive cleaners is not covered

by warranty.

7. Full use, care, and maintenance instructions are supplied with each machine. Those miscellaneous

adjustments noted are customer responsibility. Proper attention will prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an Authorized Service Agency or one of its sub-

service agencies.

9. All labor shall be performed during regular working hours. Overtime premium will be charged to the

buyer.

10. All genuine Wells replacement parts are warranted for ninety (90) days from date of purchase on non-

warranty equipment. This parts warranty is limited only to replacements of the defective part. Any use of non genuine Wells parts completely voids any warranty.

11. Installation, labor, and job check-outs are not considered warranty.

16

Page 17

ADDENDUM

WFE-40 BANKED ELECTRIC FLOOR FRYER

INSTALIATION:

1. The WFE-40 banked fryer is equipped with locking swivel casters instead of legs.

2. When installing be sure to lock all front casters on the fryer (see figure below) by pressing the brake

lever "ON" treadle.

3. When moving the banked fryer, the filter reservoir must be removed to allow free swiveling caster

action. See WARNINGS on page 6, and INSTALLATION INSTRUCTIONS on page 10 of the

Instruction Manual.

17

Page 18

FOR YOUR SAFETY

WARNING!

Protective clothing and insulated

gloves must be worn during filtering

and oil discarding procedures.

FILTERING:

1. Before draining the oil for filtering, check the

filter reservoir and make sure that screen, filter

paper, and filter retainer are properly installed.

(See figure D-1 on page 10 of Instruction

Manual).

2. Push the filter reservoir in to fully engage the

filter return pipe.

3. Slide oil drain chute back and lower into filter

reservoir (see figure 1).

4. Open door of fryer section to be filtered.

5. Turn power switch on control panel to filter

position (see figure 2).

6. Slide interlock channel to

position that allows opening of

drain and refill valves

(see figure 2).

NOTE: If interlock channel will not slide, open

door of other fryer section(s) and

check drain and fill valve handles.

They must be closed in order to slide

the interlock channel.

7. Open drain valve handle by rotating counter

clockwise to the down (vertical) position to

drain oil into filter reservoir (see figure 2).

18

Page 19

8. Open return valve handle and start filter pump

by rotating counter clockwise to the down

(vertical) position. Green light will turn on the

indicate filter pump is operating (see figure 2).

NOTE: The return valve must be open and the

power switch must be in the filter position or

the filter pump will not. operate.

9. To refill the fry pot at the end of the filtering

cycle, close the drain valve handle by rotating

clockwise to the up (horizontal) position.

10. When the fry pot is full, close the return valve

and turn off the filter pump by rotating the

return valve handle clockwise to the up

(horizontal) position.

11. Turn the power switch to the OFF position to

shut down the fryler, or the fry position to

continue cooking (see CAUTION note on page

6 of Instruction Manual).

DISCARDING USED OIL:

1. DO NOT use filter reservoir to discard used

oil, use a metal bucket with a proper handle.

Fill the bucket 2/3 full maximum. DO NOT

OVER FILL THE BUCKET.

2. Place bucket against the front of the filter

reservoir (see figure 3).

3. Lift up oil drain chute and slide forward to

rest over bucket (see figure 3).

4. Slide interlock channel to position that allows

opening of drain and refill valves (see figure

4).

5. Open drain valve handle by rotating counter

clockwise to the down (vertical) position to

drain oil into filter reservoir (see figure 4).

19

Page 20

6. When bucket is 2/3 full (or fry pot is empty, whichever occurs first), turn OFF drain valve by rotating

clockwise to up (horizontal) position. NOTE: A small amount of oil may still drain from the manifold

after valve is closed. DO NOT REMOVE BUCKET UNTIL IT STOPS.

7. Slide oil drain chute back and lower into the filter reservoir.

MOTOR RESET BUTTON;

The filter motor reset button is located at the rear of the fryer (see figure 5).

CAUTION!

Always close drain valve immediately

after draining oil.

20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Loading...

Loading...