Page 1

WELLS BLOOMFIELD LLC

10 Sunnen Drive, St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

SERVICE

INSTRUCTION

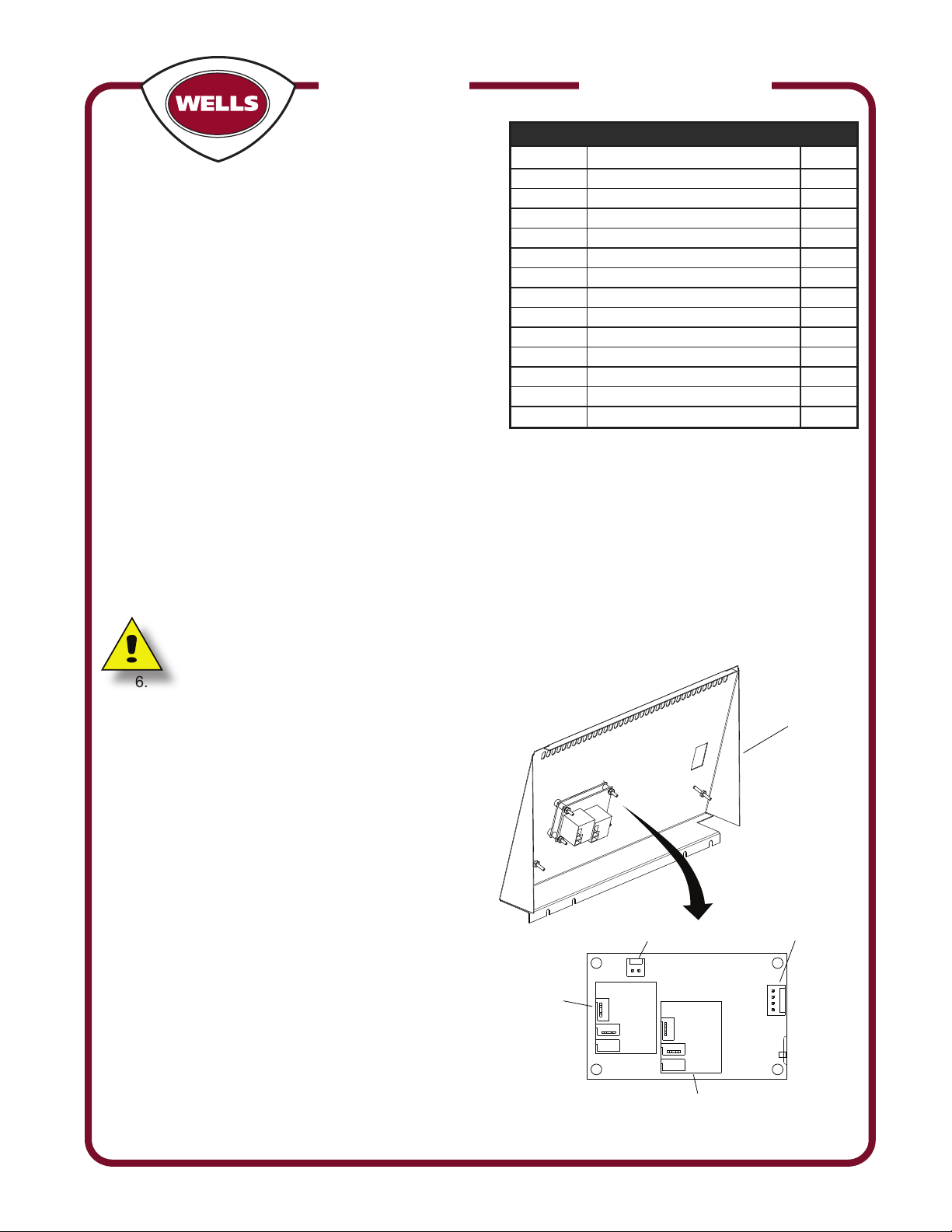

4 PIN CONNECTOR

THERMISTOR

HEATER

RELAY

BASKET

RELAY

2 PIN CONNECTOR

24 VOLT INPUT

N.C.N.O.

COM

N.C.N.O.

COM

Grounding

Stud

(2 Places)

IL2545a

WS-WL0334 Control Retrot Replacement

WFAE55FS & WVAE55FS

CONTROL REPLACEMENT

The kit has been designed to address replacing a

failed controller in a Wells Electric Open Frypot Fryer.

Unfortunately the new controller requires a new control

panel, thermistor, relay and wiring.

Please read these instructions thoughly before beginning these

process. This should be performed by a licensed Wells service

agent.

Part Number Description Quantity

2C-1810 WASHER 3/16 BURR STL NP 4

2C-2553 NUT 6-32 HEX STL NP 4

2E-307334 RELAY 240VAC 1

2E-49550 SWITCH ROCKER POWER WFAE 1

2J-Z16332 THERMISTOR 91K W/ LEADS 1

2J-Z16356 CONTROL CTT 1

2K-Z1530 SPACER 4

2K-Z16357 COMPRESSION FITTING 1

2M-Z16212 FACEPLATE CONTROLLER 55FC 1

2M-Z16330 INSTRUCTION SHEET 1

2M-Z16331 LABEL DIAGRAM 55FS SERIES 1

E7-Z16328 CONTROL PANEL 1

E7-Z16329 WIRE KIT CTT RETROFIT 1

Installation Instruction

1. Unit must be disconnected from power supply before service

2. Drain oil from fry kettle.

3. Remove front panel with control board.

4. Remove ground wires from front panel.

5. Remove power switch from old control panel and disconnect the associated wires from the

switch. (8A, 9A, 16, 24, 25, 26, 27, 28) Note: wires 24 & 28 non-ventless units only.

a. For ventless fryers the wires that need to be disconnected from the switch are 8A, 9A, 16, 40, 25,

26, 27 & 42.

Note: Audible alarm needs to be disconnected but should remain in place.

6. Remove and discard wires attached to multi

pin connectors from old control.

(10, 11, 12, 13, 22, 21, 19, 20)

7. Attach ground wires to new control panel.

8. Reinstall main power switch and associated

wiring (8A, 9A, 16, 24, 25, 26, 27, 28) into

replacement control panel.

a. If ventless model; the following wires need to

be re-attached 8A, 9A, 16, 40, 25, 26, 27 & 42.

9. Remove Basket lift solid state relays from

control housing rear panel & replace with new

relay 2E-307334.

10. Remove and discard old wires (23, 30, 31, 32

& 33) from the control housing rear panel.

11. Remove ring terminals from wires 17 & 18 and

replace with ¼” inch push on terminals.

12. Attach wire 17 to the N.O. terminal of the lift

relay on the new control board.

(see wiring diagram).

13. Attach wire 18 to the N.C. terminal of the lift

relay on the new control board.

(see wiring diagram).

2M-Z16330, Rev. A 130305 SV363

Page 2

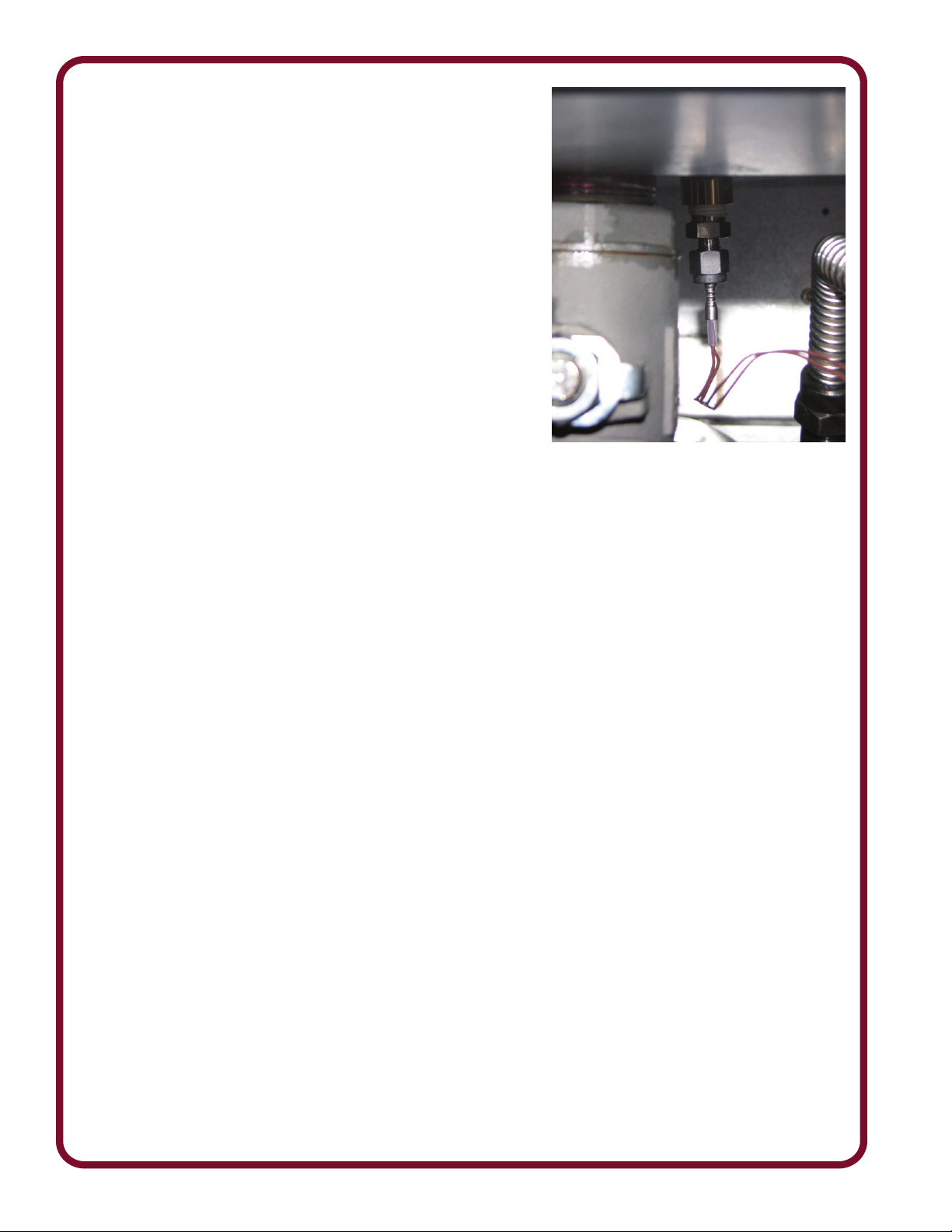

14. Usingteontapeonthethreadedconnections,

replace temperature probe assembly with new probe &

compression assemblies located in the bottom of the kettle.

(As shown here)

15. Connect temperature probe to the control board terminal

marked “J4”.

16. Remove surge suppressors (if present) from hybrid

contactor, high limit contactor, and control circuit

transformer.

17. Attach new wire assembly 12/13 to secondary on

transformer and power input connector “J3” on new board.

18. Attach new wire assembly 11A to hybrid relay terminal and

COM terminal on the new relay mounted to the wall of the

fryer. (see wiring diagram).

19. Attach wire 19 to the safety contactor and to the N.O.

terminal on the relay, mounted to the control housing rear

panel.

20. Attach new wire assembly 11 to COM terminal heater relay

mounted to center of the new board (see wiring diagram).

21. Attach the other end of new wire 11 to the 3/16 input terminal on the relay mounted on the wall of the

fryer.

22. Attach new wire 14A to the remaining input terminal on the new relay mounted on the wall of the

fryer (see wiring diagram) and to the safety contactor.

23. Attach the tandem end of the new wire assembly 30/23 to the COM terminal on the lift relay on the

control board (see wiring diagram).

24. Attach wire 23 to the high limit thermostat with wire 24 (Non-Ventless Units Only).

25. For ventless models 23 & 43 attach together at the high limit thermostat.

26. Attach wire 30 to the terminal of the transformer that corresponds to the nameplate voltage on the

fryer (208 or 240).

27. Attach the new control panel to the fryer body.

28. Connectpowertothefryerandllthekettlewithoil.

29. Checkforleaksattheprobetting.

2M-Z16330, Service Instructions 55FS Series Control Retrot

Page 3

TIME

PROG

HEAT

BASKET

DOWN

TEMP

PROG

4

3

21

FRYER IS BELOW COOKING TEMPERATURE

FRYER HAS REACHED COOKING TEMPERATURE

COOK CYCLE HAS BEEN COMPLETED

FRYER HAS EXCEEDED COOKING TEMPERATURE

DISPLAY DESCRIPTIONS

New Board Operating Instructions

Program Time:

1. Press and hold the “TIME” program key 3

seconds. Display will read “Prog”

2. Select a key 1 – 4 to program.

3. Adjust time up or down using keys 1 & 4.

4. Press program key to accept (control is now

ready for pre-alarm time set (optional)

5. Adjust pre-alarm “UP” or “DOWN” using keys 1

and 4, or

6. Press “PROG” key to accept (Default Value “0”)

7. Select Another key to program and repeat steps

2 – 6.

8. Press “TIME PROG” key to exit program mode.

Program Temperature:

1. Press and hold the “TEMP PROG” key 3

seconds. Display will read “Prog”.

2. Select either key 1 or 4 to program.

3. Choose “C” (Celsius) or “F” (Fahrenheit) using

keys 1 or 4.

4. Press “TEMP PROG” key to accept.

5. Set temperature using keys 1 and 4, DO NOT EXCEED 375°F (190°C).

6. Press “TEMP PROG” to accept.

7. Press “TEMP PROG” key again to exit program mode.

Display Descriptions

Lo Fryer is below cooking temperature

rEdY Fryer has reached cooking temperature

2M-Z16330, Service Instructions 55FS Series Control Retrot

done cook cycle has been completed

Hi Fryer has exceeded cooking temperature

Page 4

55FS SERIESLABEL, DIAGRAM 55FS CTT RETROFIT

2M-Z16331a

NOTE: -WIRE NUMBERS 16, 17 AND 18 ARE ROUTED THRU

A 3/8 INCH FLEXIBLE CONDUIT.

-WIRE NUMBERS 26, 27, AND 36 ARE ROUTED THRU

A 3/8 INCH FLEXIBLE CONDUIT.

17

RED

17

8500W ELEMENT

8500W ELEMENT

24V

208V

240V

13

12

16

16

25

24

WHITE

18

EXTERNAL INTERLOCK

TERMINAL BLOCK

(REMOVE JUMPER

WHEN EXTERNAL

CONTROL IS USED)

CONTROLLER

TRANSFORMER

GREEN

34

27

26

27

26

FILTER

PUMP

MAIN

TERMINAL

BLOCK

HYBRID RELAY

1L1

1L2

1L3

1L1

1L2

1L3

SAFETY

CONTACTOR

1

2

3

1

2

3

1

2

3

6

5

4

15

C

POWER

SWITCH

9

14

BASKET LIFT

ACTUATOR

LIMIT SWITCHES

INSIDE MTR HSG

BLACK

7

8

28

30

10

11A

(DN)

(UP)

(COM)

FUSE

15A MAX

FUSE

15A MAX

L3

L2

L1

JUMPER

24

HI LIMIT

THERMOSTAT

23

14

8A

28

9A

THERMISTOR

J4

24V AC

COM

NO

NC

COM

NO

NC

LIFT

TEMP

18

GREEN

COM

NO

11

14A

19

BLD'G ALARM RELAY

(2&4) BEHIND REAR

BOTTOM COVER ON

RIGHT HAND SIDE OF

BOTTOM PANEL.

NO

COM

NC

3

4

2

5

1

58

58

220V 60HZ

BUZZER

40

57

BAFFLE FILTER

MAGNET OPERATED

SWITCH

HEPA FILTER

MAGNET OPERATED

SWITCH

WIRE

NUT(2)

41

42

BROWN

56

BLACK

RED

1/4 INS

FEMALE

1/4 INS

MALE

40

54

41

52

44

44

45

M

1/4 INS

FEMALE(2)

VENTILATOR

POWER

LIGHT

(GREEN)

53

CHECK

FILTER

LIGHT

(AMBER)

REPLACE

FILTER

LIGHT

(AMBER)

SERVICE

REQUIRED

LIGHT

(RED)

NC

C

2

1

3

NO

C

1/4 INS

MALE

1/4 INS

FEMALE

AIR FLOW

VACUUM

SWITCH

(LARGE)

BLOWER

MOTOR

REPLACE

FILTER

VACUUM

SWITCH

(SMALL)

INTERVAL TIMER

50

44

45

46

47

48

49

56

55

44

41

51 51

HOOD

HOOD

UPPER CONTROL BOX

UPPER CONTROL BOX

1/4 INS

MALE(2)

42

43

59

59

M-S

43

FOR VENTLESS MODELS ONLY

ALTERNATE WIRING FOR SINGLE PHASE OPERATION

NOT UL LISTED

ON SINGLE PHASE

ALTERNATE WIRING FOR 380-415V

5670W ELEMENT

5670W ELEMENT

1L1

1L3

1L1

1L3

1

3

1

3

1

3

5

4

L3

L2

L1

1Ø, 208V OR 240V, 11.3KW

8

7

4

5

6

3

2

1

TERMINAL

BLOCK

JUMPER

L1

L2

L3

N

WIRES 40,41,42, AND 43 ONLY NECESSARY ON VENTLESS MODELS WVAE

WIRES 24 AND 28 ARE ONLY USED ON NON VENTLESS MODELS WFAE

414242

240

47

4848

L3

L2L1

AMPS

FRYER RATING

VOLTS

208

50-60 HZ

WFAE55FS

3Ø, 208V,17KW

WVAE55FS

3Ø, 208V,17KW

-----47-----

*1Ø, 240

-----

56

-----

*1Ø, 208

WFAE55FS

3Ø, 380-415V, 17KW

* NOT UL LISTED

ON SINGLE PHASE

1Ø, 208V OR 240V, 11.3KW

3Ø, 380

N

-----

-----

-----

-----

24 24 24

5

2M-Z16330, Service Instructions 55FS Series Control Retrot

Loading...

Loading...