Page 1

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5703

fax: 775-689-5976

www.wellsbloomfield.com

SUPPLEMENTAL

SERVICE

INSTRUCTIONS

ELECTRIC

363

for

FRYER

WFAE-55F

WFAE-55FS

With or Without

Optional Filter Wand

IMPORTANT: WELLS MANUFACTURING PROPRIETARY INFORMATION.

DISSEMINATION OF THIS INFORMATION TO ANYONE OTHER THAN

WELLS AUTHORIZED SERVICE AGENTS IS STRICTLY PROHIBITED.

TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR

USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY.

PRINTED IN UNITED STATES OF AMERICA

p/n 507398 Rev. A ECN-13391 S363 071128 cps

Page 2

PRECAUTIONS AND GENERAL INFORMATION

DANGER:

BURN HAZARD

Cooking oil in this appliance

operates at very high

temperatures. Contact with

hot oil can cause severe

injury or death. Wear

appropriate heat-protective

clothing when operating or

servicing this appliance.

WARNING:

SLIP AND FALL

HAZARD

Spilled cooking oil is very

slippery and can cause falls.

Clean up oil spills promptly.

CAUTION:

BURN HAZARD

Exposed surfaces can be hot

to the touch and may cause

burns.

CAUTION:

HEALTH HAZARD

Old cooking oil can be a

breeding ground for bacteria.

Clean and sanitize exterior

surfaces of fryer regularly.

This appliance is intended for use in commercial establishments

only.

This appliance is intended

No other use is

agents.

DO NOT open any panel that requires the use of tools for access. Live

electric circuits may be exposed by opening such panels. Opening

access panels must be performed by an Authorized Service Agent

only.

This appliance is equipped with an oil filtration system designed to filter

hot liquid shortening only. Water, cleaning agents and/or other liquids

will contaminate the oil and may damage the filter pump.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

DO NOT submerge any part of this appliance in water unless

specifically instructed to do so. This appliance is not jet stream

approved. DO NOT direct water jet or steam jet at this appliance,

nor at any control. DO NOT splash or pour water on, in or over any

controls. DO NOT wash area around this appliance with water jet.

Any part which has become wet must be thoroughly dried before use.

Cooking oil will be very hot when in use. Contact will cause severe

injury, and can cause blindness or death. Wear appropriate heatprotective clothing when operating or servicing this appliance.

This appliance must be operated with the supplied legs and casters

properly installed.

The technical content of this manual, including any parts breakdown

illustrations and/or adjustment procedures, is intended for use by

qualified technical personnel only.

Any procedure which requires the use of tools must be performed by a

qualified technician.

recommended or authorized by the manufacturer or its

to prepare food for human consumption.

363 503043 Service Manual for WFAE-55F/FS Fryer

xi

Page 3

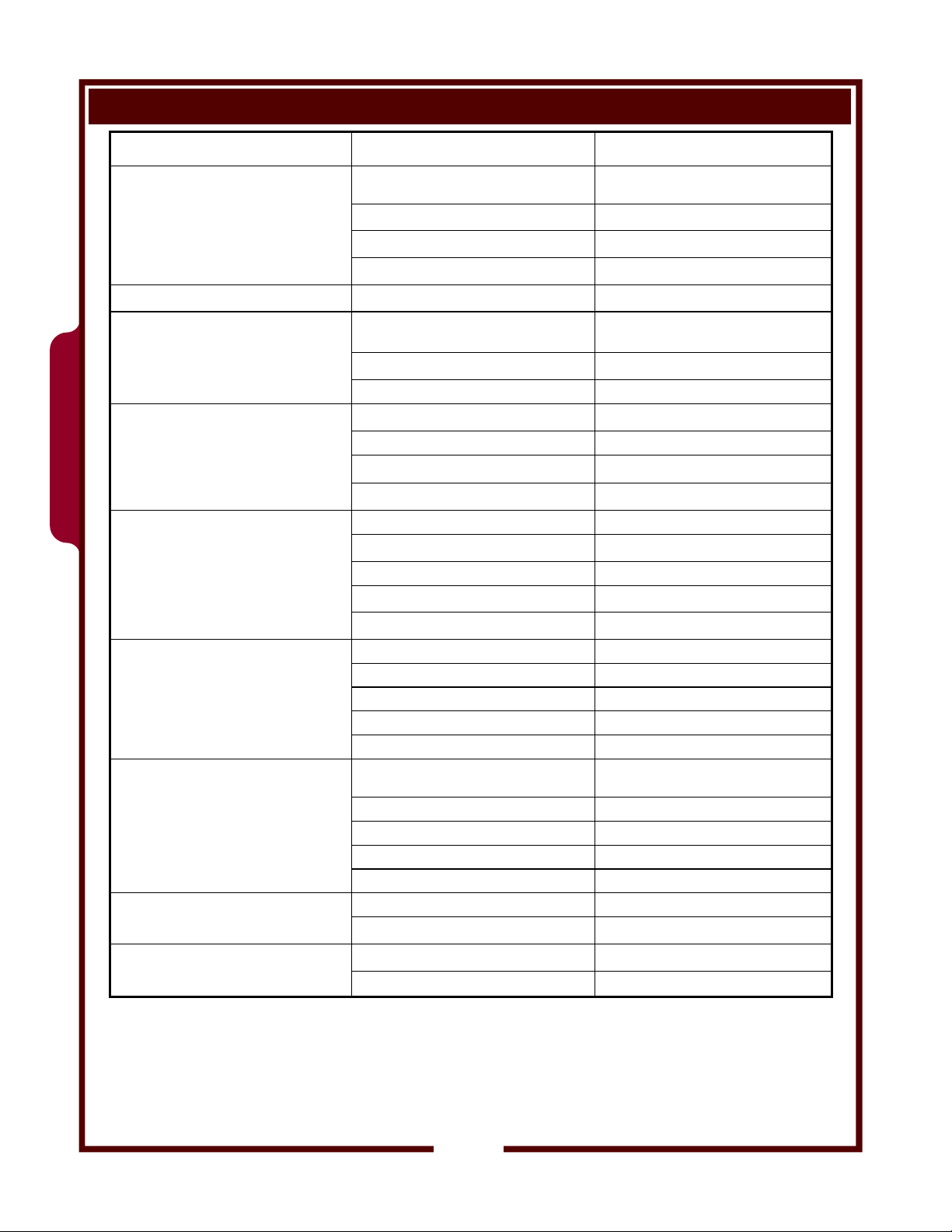

TABLE OF CONTENTS

Precautions & General Information xi

Specifications 1

WFAE-55F Manual Controls

Components and Controls 2

Operation 4

Operation Troubleshooting Guide 5

WFAE-55FS Solid State Controls

Components and Controls 6

Operation 8

Programming - Custom Settings for Customer Needs 9

Operation Troubleshooting Guide & Error Codes 10

Filter Operation 12

Filter System Troubleshooting Guide 13

Servicing Instructions

Lift Actuator & Motor Assembly 14

Filter Pump 16

Electrical Components 18

Heating Element & Thermostat 22

Wiring Diagrams 24

INTRODUCTION

This manual contains information needed to properly service and repair WFPE-30FS Pressure Fryer.

For installation, operation and maintenance instructions, refer to the Operation Manual p/n 300 007.

SPECIFICATIONS

363 503043 Service Manual for WFAE-55F/FS Fryer

DIMENSIONS

CAPACITIES

VOLTAGE

REQUIREMENTS

POWER

CONSUMPTION

AMPERAGE

(Liquid Shortening Only)

Wide Deep High

15.70” 37.38” 48.94” (Basket Up)

Cooking Oil

Lbs. Kg.

55

Chicken (Fresh) 30 13

Chicken (Frozen) 25 11

ELECTRICAL SPECIFICATIONS

DOMESTIC EXPORT (EU)

208 VAC

17,000 watts

47.8 amps (3ø)

43.0 amps (3ø)

240VAC

17,000 watts

380-415V

3NAC

17,000 watts

L1 = 27.0

L2 = 27.0

L3 = 27.0

N = 3.0

25

1

Page 4

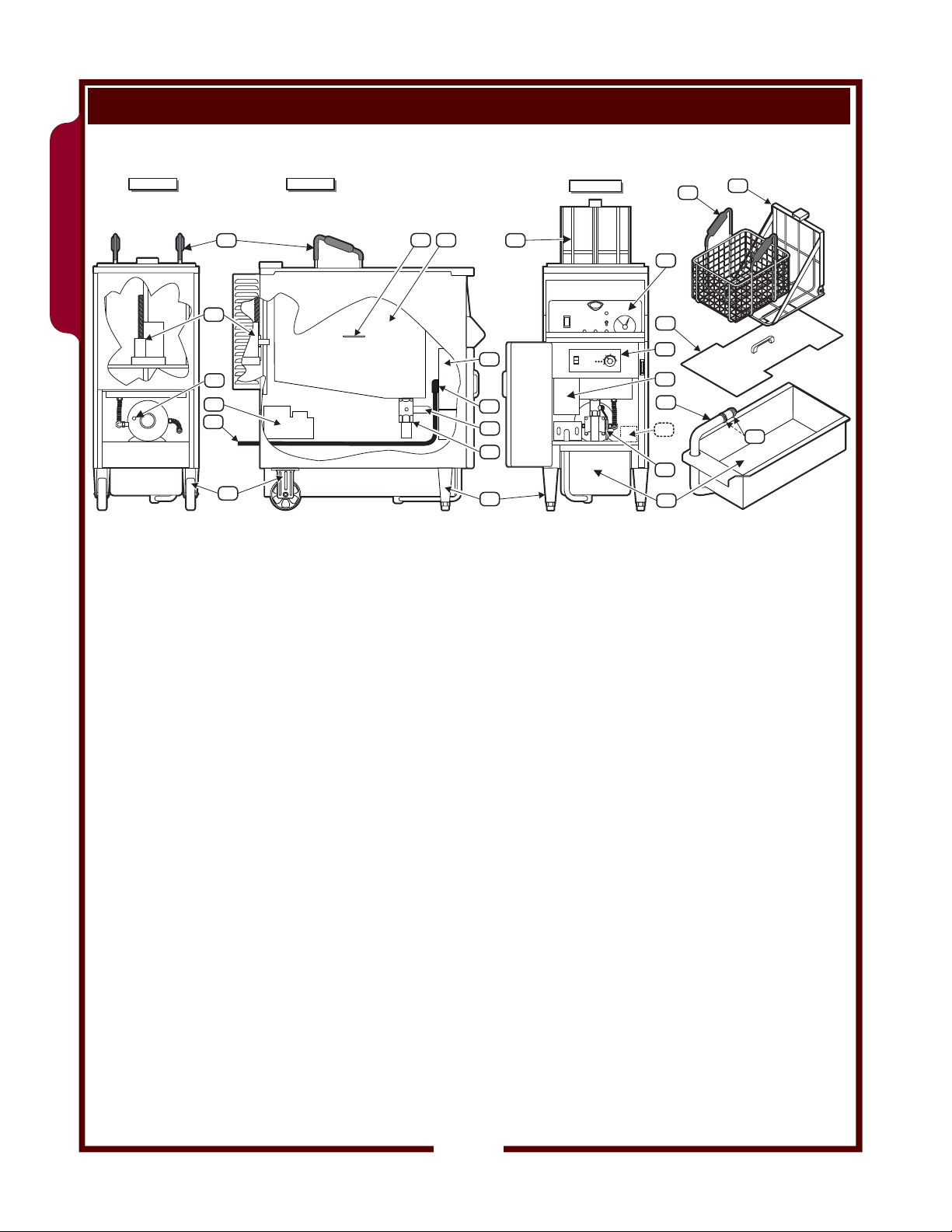

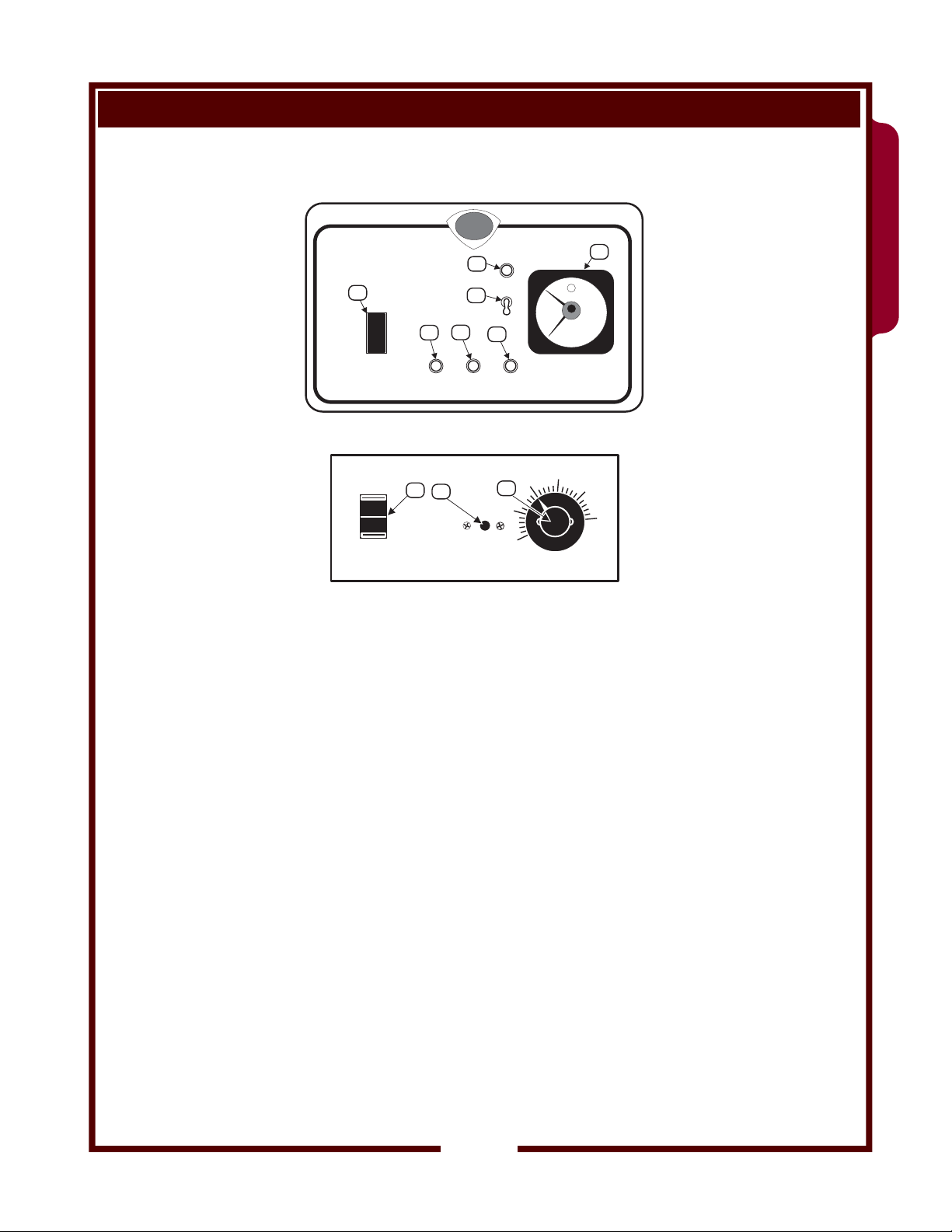

COMPONENTS & MANUAL CONTROLS

WFAE-55F

WFAE-55F

BACK VIEW SIDE VIEW

M

FRONT VIEW

T

E

D

M

N

D

A

COLDOIL LEVEL

J

B

G

H

I

K

Q

F

L

C

O

J

U

P

Q

R

V

ITEM DESCRIPTION NOTES

A LIFT CRADLE MOTOR Operates LIFT ROD / Raises LIFT CRADLE

B PUMP MOTOR RESET Protects against filter pump motor overload

NOTE: must be reset by manually pushing red button

C FRYPOT COVER Protects against hot oil splatter during use, helps prevent oil contamination

D LIFT CRADLE Holds FRY BASKET - lifts/lowers fry basket into/out of frypot

E FRYPOT ASSEMBLY Contains and heats cooking oil

F DRAIN VALVE Allows draining FRYPOT

G FILTER PUMP and MOTOR Pumps oil during filtration cycle

H POWER CORD Electrical power hook-up

I REAR (FIXED) CASTER Allow easy positioning of unit

J LOWER CONTROL BOX

and TERMINAL BOX COVER

Contains power cord connections, power contactor, temperature control

thermostat, hi-limit safety thermostat and heating element connections

K POWER CONNECTION 90º conduit fitting required, angled as shown

L FRONT (FIXED) LEG Adjustable for leveling unit

M FRY BASKEY Holds product to be cooked

N UPPER CONTROL PANEL Contains main controls. See page 3

O LOWER CONTROL PANEL Contains heating controls and pump switch. See page 3

P DRIP PAN Collects liquids that drain from the top of the unit

Q DRAIN VALVE LEVER Operates the drain valve (item F)

R FILTER RESERVOIR Holds filtering media for oil filtration cycle

T OIL LEVEL INDICATOR Measure amount of cooking oil

U FILTER SUCTION TUBE Plugs into suction line receptacle

Allows oil to be drawn through filter media

V SUCTION TUBE O-RING

SPARE O-RINGS

Seals suction tube to receptacle

Up to 3 spares may be stored here

363 503043 Service Manual for WFAE-55F/FS Fryer

2

Page 5

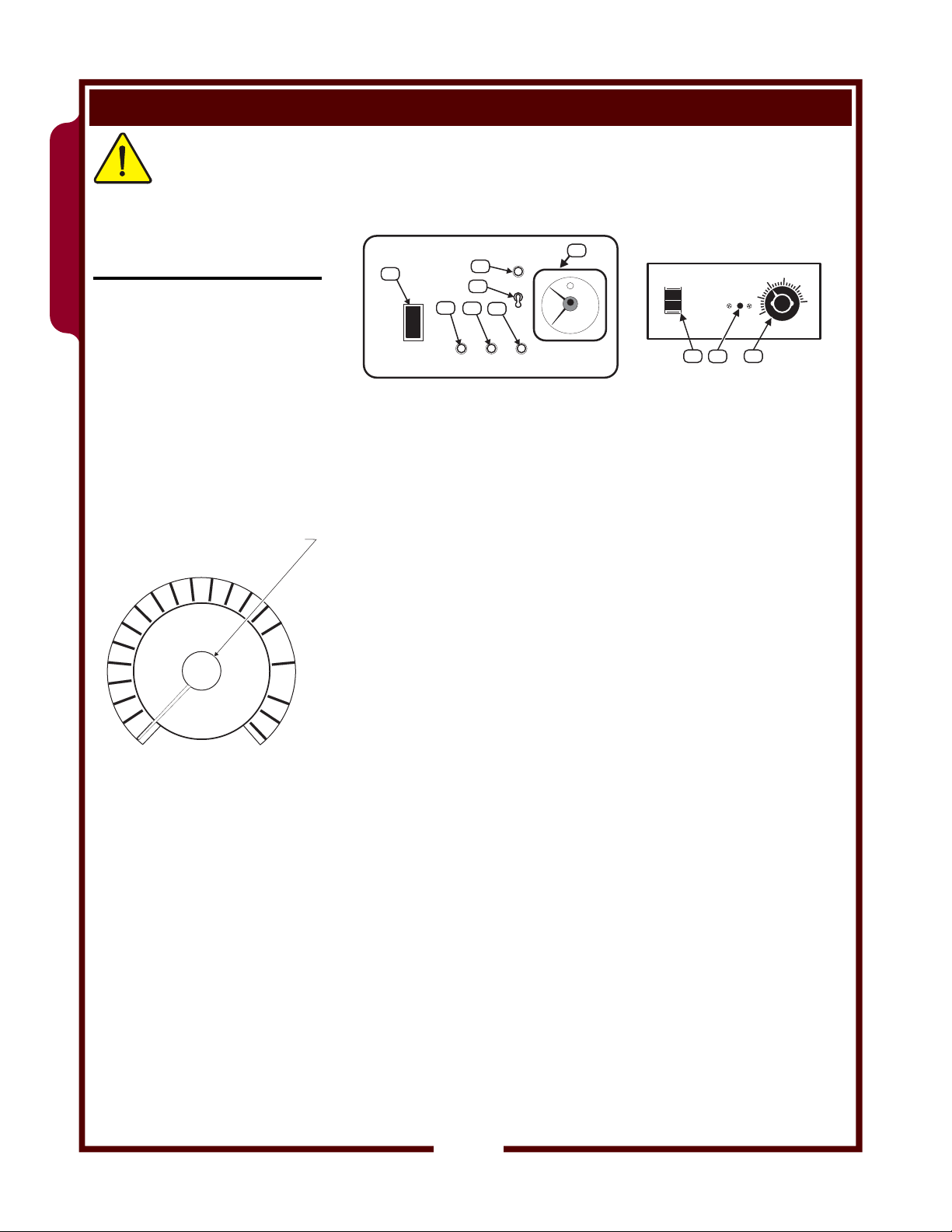

WFAE-55F

COMPONENTS & MANUAL CONTROLS (continued)

UPPER CONTROL PANEL

WELLS

7

1

FRYER

OFF

FILTER

2

POWER

LOWER CONTROL PANEL

FILTER

ON

8

OFF

CAUTION

FRYER MUST BE OFF

BEFORE USING FILTER

6

3

HEAT

9

HI-LIMIT

RESET

B

U

Z

Z

E

R

4

COOK

THERMOSTAT

300

10

250

275

5

WFAE-55F

325

350

375

ºF

ITEM DESCRIPTION NOTES

1 POWER SWITCH FRYER position energizes temperature control thermostat and timer

2 POWER LIGHT Glows when power switch is in FRYER position

3 HEAT LIGHT Glows when heating element is energized

4 COOK LIGHT Glows when cook lever is in COOK position

5 TIMER Indicated set time or counts down time remaining

6 BUZZER SWITCH ON position allows buzzer to sound whenever cradle is down

7 BUZZER LIGHT Glows when BUZZER SWITCH is ON

8 FILTER SWITCH ON position energizes filter pump (power switch must be in FILTER position)

9 HI-LIMIT SAFETY

THERMOSTAT

10 TEMPERATURE CONTROL

THERMOSTAT

363 503043 Service Manual for WFAE-55F/FS Fryer

FILTER position energizes filter switch

OFF position de-energizes temperature control thermostat, timer and filter

switch

Active when cook lever is in COOK position

OFF position silences buzzer

Turns fryer OFF is cooking oil temperature exceeds 425ºF

Turns fryer OFF if heating element is energized without being covered by

cooking oil

RESET by pressing red button after cooking oil has cooled.

Controls cooking oil temperature by energizing/de-energizing heating element

SET by turning pointer to desired cooking temperature marked on panel

Causes heat light to glow when energized

3

Page 6

OPERATION - MANUAL CONTROLS

CAUTION:

WFAE-55F

BURN HAZARD

Hot oil can cause serious burns

on contact. Wear appropriate

protective clothing when using

this fryer.

TURN TO SET TIME

PRESS RED BUTTON TO START TIMER

11

10

9

8

7

6

5

4

3

2

1

0

TIMER

12

13

21

14

20

15

19

16

17

18

PRE-HEATING FRYER

Make sure FRYPOT is filled with 55 LB. of cooking oil.

Open door and set THERMOSTAT (item 10) to desired cooking

temperature. CLOSE THE DOOR.

5

1

FRYER

OFF

FILTER

UPPER CONTROL PANEL

7

6

2

3

POWER

B

U

Z

Z

E

R

4

COOK

HEAT

LOWER CONTROL PANEL

FILTER

ON

OFF

CAUTION

FRYERMUST BE OFF

BEFOREUSING FILTER

HI-LIMIT

RESET

8

9

THERMOSTAT

300

275

250

10

325

350

375

ºF

Set POWER SWITCH (item 1) to FRYER. POWER LIGHT (item 2)

and HEAT LIGHT (item 3) will glow. HEAT LIGHT will cycle on and

off with the HEATING ELEMENTS. When HEAT LIGHT first goes off,

fryer is ready to cook the product.

SET COOK TIMER AND LOAD PRODUCT

Set TIMER (item 5) to desired cooking time.

FROZEN PRODUCT:

Load frozen product into BASKET. Set BASKET on LIFT

CRADLE.

Press RED BUTTON on TIMER to lower BASKET into FRYPOT.

FRESH PRODUCT:

Set BASKET on LIFT CRADLE.

Press RED BUTTON on TIMER to lower BASKET into FRYPOT.

Manually drop each piece of fresh product into hot oil, just above

the oil level to minimize splattering.

ALWAYS USE PROTECTIVE EQUIPMENT, SUCH AS INSULATED

GLOVES, TO PROTECT AGAINST HOT OIL BURNS

COOK CYCLE AND BUZZER

When an audible alarm is desired at end of cook cycle, turn BUZZER

SWITCH (item 7) ON after TIMER has been started. BUZZER LIGHT

(item 6) will glow.

Note: If BUZZER SWITCH is turned ON before BASKET is lowered,

BUZZER will sound until BASKET has fully lowered.

At end of cook cycle, BASKET will raise. BUZZER will sound until

BUZZER SWITCH is turned OFF, or until the next cook cycle is

started.

Use plastic-coated handles on fry basket to remove basket of cooked

product from LIFT CRADLE. Serve or dispense cooked product as

required.

363 503043 Service Manual for WFAE-55F/FS Fryer

4

Page 7

OPERATION (MANUAL CONTROLS) TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

POWER LIGHT not lit

Fryer not operating

POWER LIGHT not lit POWER LIGHT damaged Repair or replace power light

POWER SWITCH not in FRYER position Press POWER SWITCH to FRYER

Disconnected from electric power or Reconnect to electric power

TEMPERATURE CONTROL THERMOSTAT not

HEAT LIGHT not lit

Power light lit - cooking oil cold

HEAT LIGHT not lit HI-LIMIT SAFETY THERMOSTAT tripped Allow oil to cool, press red button to reset hi-limit

HEAT LIGHT not lit

Power light lit - cooking oil hot

COOK LIGHT not lit (CRADLE raised) TIMER not set or not started Turn dial to desired time, press red start button

COOK LIGHT not lit (CRADLE lowered) COOK LIGHT damaged Repair or replace cook light

TIMER does not operate

BUZZER LIGHT not lit

BUZZER does not sound (CRADLE raised)

CRADLE LIFT will not lower

set or set too low

TEMPERATURE CONTROL THERMOSTAT Replace thermostat

Cooking oil at set temperature No action required

HEAT LIGHT damaged Repair or replace heat light

POWER SWITCH not in FRYER position Press POWER SWITCH to FRYER

TIMER not set or not started

TIMER CAM MICROSWITCH damaged or out of

adjustment

TIMER damaged Replace TIMER

BUZZER SWITCH in OFF position Turn SWITCH ON

BUZZER LIGHT damaged Replace LIGHT

BUZZER SWITCH in OFF position Turn SWITCH ON

BUZZER damaged Replace BUZZER

BUZZER SWITCH damaged Replace BUZZER SWITCH

TIMER not set or not started Turn dial to desired time, press red start button

TIMER damaged Replace TIMER

LIFT MOTOR damaged Replace LIFT MOTOR

Set thermostat to desired temperature

Turn dial to desired time, press red button to

start

Adjust or replace microswitch

WFAE-55F

CRADLE LIFT will not raise

FRYPOT COVER does not lower with LIFT

363 503043 Service Manual for WFAE-55F/FS Fryer

CRADLE

LIFT MOTOR MICROSWITCH damaged or out of Adjust or replace microswitch

TIMER has time remaining Allow TIMER to complete cycle to “0”

LIFT CRADLE not properly assembled to LIFT

ROD

TIMER damaged Replace TIMER

LIFT MOTOR damaged Replace LIFT MOTOR

LIFT MOTOR MICROSWITCH damaged or out of

adjustment

ACTUATOR or LIFT CRADLE damaged Repair/replace damaged components

COVER leaned back too far Rest COVER on LIFT CRADLE

HINGE(S) dirty, damaged or misaligned Clean, repair or align HINGES

Install white plastic pivot over end of LIFT ROD

(see page 3)

Adjust or replace microswitch

5

Page 8

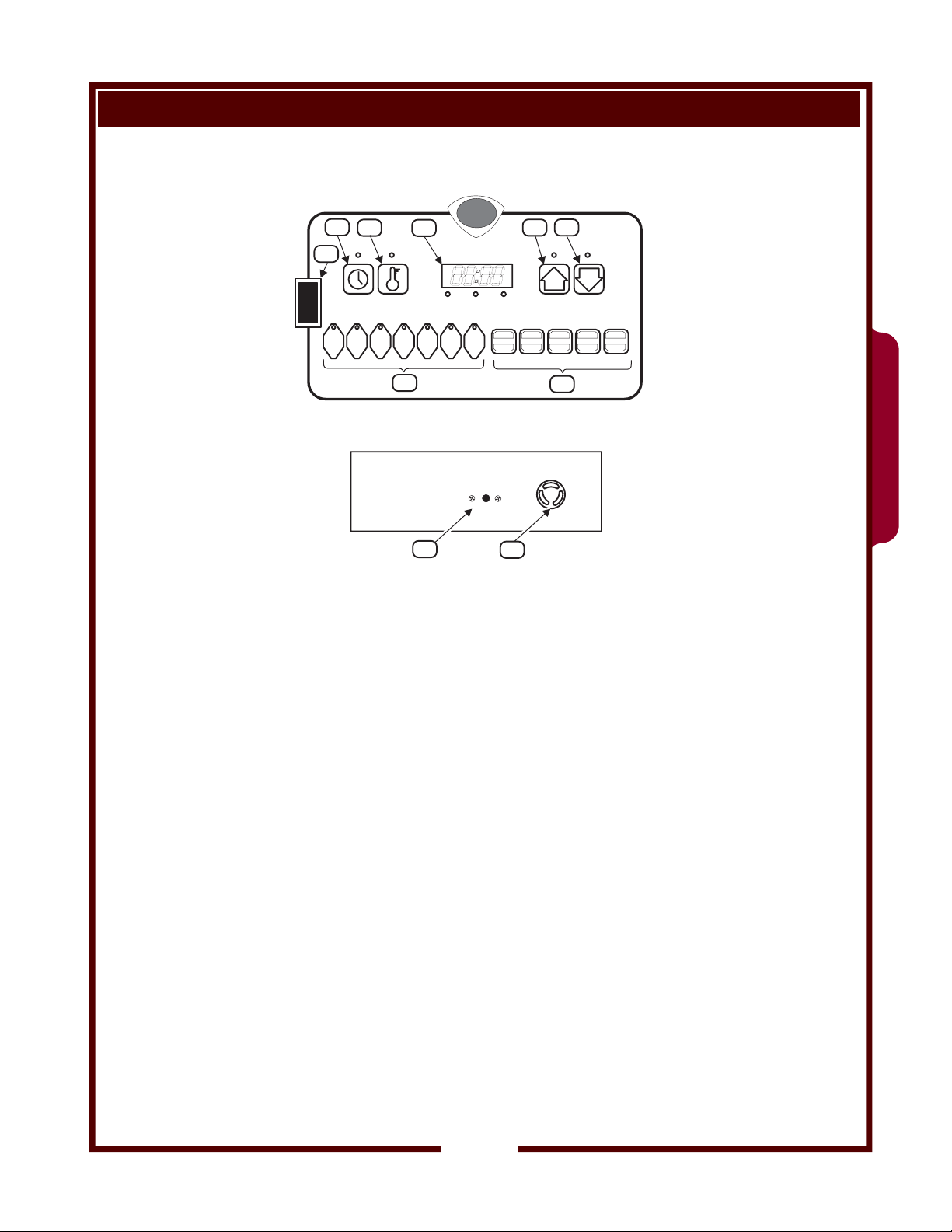

COMPONENTS & SOLID STATE CONTROLS

WFAE-55FS

BACK VIEW SIDE VIEW

T

M

E

FRONT VIEW

D

M

N

D

WFAE-55FS

ITEM DESCRIPTION NOTES

A LIFT CRADLE MOTOR Operates LIFT ROD / Raises LIFT CRADLE

B PUMP MOTOR RESET Protects against filter pump motor overload

C FRYPOT COVER Protects against hot oil splatter during use, helps prevent oil contamination

D LIFT CRADLE Holds FRY BASKET - lifts/lowers fry basket into/out of frypot

E FRYPOT ASSEMBLY Contains and heats cooking oil

F DRAIN VALVE Allows draining FRYPOT

G FILTER PUMP and MOTOR Pumps oil during filtration cycle

H POWER CORD Electrical power hook-up

I REAR (FIXED) CASTER Allow easy positioning of unit

J LOWER CONTROL BOX

K POWER CONNECTION 90º conduit fitting required, angled as shown

L FRONT (FIXED) LEG Adjustable for leveling unit

M FRY BASKEY Holds product to be cooked

N UPPER CONTROL PANEL Contains main controls. See page 3

O LOWER CONTROL PANEL Contains heating controls and pump switch. See page 3

P DRIP PAN Collects liquids that drain from top of fryer (when used in a ventless unit)

Q DRAIN VALVE LEVER Operates the drain valve (item F)

R FILTER RESERVOIR Holds filtering media for oil filtration cycle

T OIL LEVEL INDICATOR Measure amount of cooking oil

S SOLID SHORTENING MELT OPTION Heated components to prevent pump damage when using solid shortening

U FILTER SUCTION TUBE Plugs into suction line receptacle

V SUCTION TUBE O-RING

A

B

G

H

S

I

and TERMINAL BOX COVER

SPARE O-RINGS

COLDOIL LEVEL

C

J

K

Q

F

L

S

O

J

U

P

Q

R

V

NOTE: must be reset by manually pushing red button

Contains power cord connections, power contactor, temperature control

thermostat, hi-limit safety thermostat and heating element connections

(NOTE: must be ordered as a specific option at time of build)

Allows oil to be drawn through filter media

Seals suction tube to receptacle

Up to 3 spares may be stored here

363 503043 Service Manual for WFAE-55F/FS Fryer

6

Page 9

WFAE-55FS

COMPONENTS & SOLID STATE CONTROLS (continued)

UPPER CONTROL PANEL

2

3

WELLS

4

6

5

1

FRYER

FILTER

TIME TEMP

OFF

1234

7

HEAT READY MANUAL

MANUAL

56

PAUSE CLEAN STANDBY BASKET FILTER

7

8

LOWER CONTROL PANEL

HI-LIMIT

RESET

9

10

ITEM DESCRIPTION NOTES

1 POWER SWITCH

(FRYER - OFF - FILTER)

FRYER position energized fryer and de-energizes filter pump

OFF position de-energizes fryer and filter pump

FILTER position allows filter pump operation and de-energizes fryer

2 TIME KEY Used to check and set menu times

3 TEMP KEY Used to check and set menu temperatures

4 READOUT LED display of various functions and data

5 UP ARROW KEY Used to raise fry basket, and to change program settings

6 DOWN ARROW KEY Used to lower fry basket, and to change program settings

7 MENU KEYS Used to start a menu time/temp cycle

Keys 1 - 6 are programmable for time and temperature

Key 7 available for individually set time/temp cook cycles

8 FUNCTION KEYS Used to perform functions of PAUSE, CLEAN, STANDBY, raise/lower BASKET

acknowledge FILTER warning

9 HI-LIMIT THERMOSTAT Turns fryer OFF is cooking oil temperature exceeds 425ºF

Turns fryer OFF if heating element is energized without being covered by

cooking oil

RESET by pressing red button after cooking oil has cooled.

10 SONALERT Audible alert to signal end of cook cycle and other programmed functions

WFAE-55FS

363 503043 Service Manual for WFAE-55F/FS Fryer

7

Page 10

OPERATION - SOLID STATE CONTROLS

Hot oil can cause serious burns

on contact. Wear appropriate

protective clothing when using

this fryer.

Controller operation for solid

shortening melt optioned fryers

is essentially identical to the

WFAE-55FS

operation of the standard solid

state controller. Important

differenced are noted in the

text.

CAUTION:

BURN HAZARD

1

2

3

5

4

12

MANUAL

7

BASKET

MANUAL

6

7

MANUAL

PROGRAMMING KEY FUNCTIONS

2

3

4

6

5

1

FRYER

OFF

FILTER

TIME TEMP

1234

7

As each control panel key is pressed, a “beep” will sound. Illuminated

indicator light for each key will light whenever that key is pressed, and

any time the function associated with that key is active.

FRYER - OFF - FILTER switch (item 1) allows the fryer to be placed

in a normal cook mode (FRYER), an oil-filtering mode (FILTER) or

turned OFF.

TIME key (item 2) controls time functions.

TEMP key (item 3) controls temperature functions. Data can be read

on the solid state READOUT (item 4).

HEAT indicator is lit whenever the burners are energized; READY

indicator is lit when cooking oil is at programmed temperature.

MANUAL indicator is lit whenever MENU key 7 is selected.

Arrow keys (item 5 & 6) control the basket lift (after pressing BASKET

key), and are used to scroll through program settings.

MENU keys (item 7) allow a choice of six (or seven) pre-programmed

time / temp settings.

Suggestion: MENU keys 1 and 2 incorporate a feature that will

inform the operator when to “drop” wings and drumsticks during cook

cycle. “Drop” feature will allow you to cook breasts and thighs longer

than wings and drumsticks by sounding a beep, and displaying “

on readout (item 4). Your fryer installer can program this feature

into your controller upon request.

Any selected MENU key can be cancelled by pressing and holding

for 3 seconds.

MENU key 7 is unprogrammed so that special or one-of-a-kind

product may be programmed any time:

With fryer is ON, press and hold TIME key and MENU 7 key

at the same time.

Press the UP or DOWN arrow key until the desired time is

displayed.

If this MANUAL feature is not desired, MENU key 7 may be

programmed in the identical fashion to MENU keys 1 thru 6.

HEAT READY MANUAL

56

MANUAL

7

PAUSE

8a

CLEAN STANDBY

8b

8c

BASKET

8d

FILTER

8e

DrOP

363 503043 Service Manual for WFAE-55F/FS Fryer

”

8

Page 11

PROGRAMMING - SOLID STATE CONTROLS

SERVICE MODE PROGRAMMING

CUSTOMIZING PROGRAMMING FOR END USER SPECIAL NEEDS

PRESS DISPLAY DESCRIPTION and DEFAULT RANGE

POWER SWITCH ON 00:00 Energize fryer none

Aut alternates with 0

Pb 1 alternates with 0

StP

Loop

nnS

CLE

alternates with 275º(F)

alternates with 135º(C)

CLE

bStP

Oil alternates with 5

Per alternates with 19

AUdF

AUdd

AUdn alternates with 10

00:00 Return to operating mode none

Enter Service Mode Programming

AUTO-TUNE

PROPORTIONAL BAND

Factory set at 0

alternates with

or 2 or 3

1

COOKING PROGRAM STEPS

Factory set at 1

alternates with OFF SHORTED SENSOR PROTECTION

Factory set at OFF

SOLID SHORTENING MELT CYCLE

alternates with OFF

Factory set at OFF for units without melt option

Factory set at ON for units with melt option

or

alternates with

CleanTemp

COOL DOWN TEMPERATURE

Factory set to 275ºF or 135ºC

CLEANING SET POINT TEMPERATURE

Factory set to 200ºF or 93ºC

Set on installation for site altitude

OIL FILTER MENU CYCLES COUNTER

Factory set to 5

DROP CYCLE ALARM

Factory set 19 % of elapsed time (menu 1, 2)

alternates with –2

alternates with –1

FILTER CYCLE ALARM Configuration

Factory set to 2 sec. ON / 2 sec. OFF

DROP ALARM Configuration

Factory set to 1 sec. ON / 1 sec. OFF

END OF MENU Configuration

Factory set to 1 tone, 10 sec. long

DO NOT CHANGE

0

0

DO NOT CHANGE

1, 2 or 3

ON or OFF

Leave OFF

ON or OFF

Leave OFF for all units not

equipped with melt option

195ºF to 350ºF

93ºC to 191ºC

185ºF to 208ºF

85ºC to 99ºC

see BOIL CHART below

0 = OFF

1 to 20 = # of loads for alert

0 = OFF

1 (%) to 90 (%)

-10 to -1 = seconds ON/OFF

1 to 59 = seconds on

0 = OFF, 60 = continuous

-10 to -1 = seconds ON/OFF

1 to 59 = seconds on

0 = OFF, 60 = continuous

-10 to -1 = seconds ON/OFF

1 to 59 = seconds on

0 = OFF, 60 = continuous

WFAE-55FS

Once in the Service Mode (Aut

210

205

363 503043 Service Manual for WFAE-55F/FS Fryer

200

195

TEMP. (ºF)

190

0

500

1,000

ELEVATION (feet above sea level)

NOTE: If no key is pressed within 30 seconds, controller will revert to operating mode.

displayed), TIME key must be pressed 12 times to complete programming cycle and save changes.

Alternately, wait 30 seconds for controller to revert to operating mode without saving changes.

BOILING POINT OF WATER and CLEANING TEMPERATURE SETTING - - - BASED ON ALTITUDE

100

97

94

91

TEMP. (ºC)

88

1,500

2,000

2,500

3,000

3,500

4,000

4,500

5,000

5,500

6,000

6,500

0

300

150

450

600

750

900

1.050

1.200

1.350

ELEVATION (meters above sea level)

BOILING POINT OF WATER

9

MAXIMUM TEMPERATURE SETTING

1.500

1.650

1.800

1.950

Page 12

TROUBLESHOOTING GUIDE (SOLID STATE CONTROLS)

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

READOUT not lit

(Fryer not operating)

(Fryer operating norm.) CONTROLLER damaged Replace CONTROLLER

HEAT LIGHT not lit

(READOUT lit /cooking oil cold)

WFAE-55FS

COOKING OIL COLD

(HEAT light lit)

CRADLE LIFT won’t lower Improper key strokes Press ”BASKET” then “DOWN ARROW”

POWER SWITCH not

in FRYER position

Circuit breaker OFF or tripped Reset circuit breaker

Service wiring problem Correct service wiring

Controller connection faulty Check/replace connector

Programmed temperature too low Raise programmed temperature

HI-LIMIT THERMOSTAT tripped Allow oil to cool, reset HI-LIMIT

CONTROLLER damaged Replace CONTROLLER

HEATING ELEMENT damaged Replace HEATING ELEMENT

Wiring problem / loose connection Correct wiring problem

TEMP PROBE damaged Replace PROBE

CONTROLLER damaged Replace CONTROLLER

LIFT MOTOR damaged Replace LIFT MOTOR

DOWN RELAY damaged Replace RELAY

Wiring problem / loose connection Correct wiring problem

CONTROLLER damaged Replace CONTROLLER

Press POWER SWITCH

to FRYER position

select another MENU KEY

CRADLE LIFT won’traise READOUT not “00:00” or “PAUSE” Press “PAUSE” + “UP ARROW”

LIFT MOTOR damaged Replace LIFT MOTOR

UP RELAY damaged Replace RELAY

Wiring problem / loose connection Correct wiring problem

CONTROLLER damaged Replace CONTROLLER

BUZZER does not sound, or is not

loud enough

MENU KEY does not operate MENU KEY not programmed Program MENU KEY. See pg. 8

FUNCTION KEY does not operate

Buzzer programmed OFF See page 9

BUZZER SHUTTER closed Open SHUTTER

BUZZER damaged Replace BUZZER

Wiring problem / loose connection Correct wiring problem

CONTROLLER damaged Replace CONTROLLER

CONTROLLER damaged Replace CONTROLLER

Improper KEY entry See pg. 8 for proper usage

CONTROLLER damaged Replace CONTROLLER

363 503043 Service Manual for WFAE-55F/FS Fryer

10

Page 13

ERROR CODES (SOLID STATE CONTROLS)

ERROR CODE / PROBLEM POSSIBLE CAUSE SUGGESTED REMEDY

Er01

Read Only Memory checksum error

Er02

Random Access Memory checksum error

Er03

Ambient temperature sensor error

Er04

Configuration error

Er05

EEprom error

Er06*

Zone 1 Analog/Digital underflow error

Er07*

Zone 1 Analog/Digital overflow error

Er08*

Zone 2 Analog/Digital underflow error

Internal ROM corrupted Press power switch to OFF, then ON

Internal RAM corrupted Press power switch to OFF, then ON

Ambient temperature is below 32ºF/0ºC Verify ambient temperature agrees with

temp readout

Factory calibration parameters altered Restore factory calibration (call factory

for calibration instructions)

Microprocessor functions halted Press power switch to OFF, then ON

Replace controller

Stored data corrupted or incomplete Press power switch to OFF, then ON

Reprogram controller

Sensor leads reversed Verify sensor connection polarity

Incorrect sensor type Contact factory for instructions for

verifying InP1 parameter.

Verify InP1 matches sensor

Measured temp outside sensor range Verify temp within sensor range

Open sensor Verify sensor connections

Replace sensor

Sensor leads reversed Verify sensor connection polarity

Incorrect sensor type Contact factory for instructions for

verifying InP1 parameter.

Verify InP1 matches sensor

Measured temp outside sensor range Verify temp within sensor range

WFAE-55FS

Er09*

Zone 2 Analog/Digital overflow error

Er10

Stack overflow error

Er11*

Zone 1 open sensor error

Er12*

Zone 1 shorted sensor

Er13*

Zone 2 open sensor error

Er14*

Zone 2 shorted sensor

Er15*

Zone 1 loop error

Er16*

Zone 2 loop error

363 503043 Service Manual for WFAE-55F/FS Fryer

* These errors will automatically clear when the condition causing the alarm has been resolved.

In all instances of error message, check connections of probes to controller for tightness and polarity.

Open sensor Verify sensor connections

Microprocessor error Press power switch to OFF, then ON

Open sensor Verify sensor connections

Incorrect sensor type

Measurement outside of sensor range

Open sensor Verify sensor connections

Incorrect sensor type

Measurement outside of sensor range

Shorted sensor Check connections / replace sensor

Incorrect Pb1/Pb2 value See programming instructions, page 9

Damaged heating element / wiring Replace element / repair wiring

Damaged heating relay / wiring Replace relay / repair wiring

Replace sensor

Replace sensor

Verify correct sensor

Verify sensor connections

Replace sensor

Replace sensor

Verify correct sensor

Verify sensor connections

Replace sensor

11

Page 14

FILTER LEAF ASSEMBLY

MAINTENANCE INSTRUCTIONS - FILTER OPERATION

WARNING

WARNING: BURN HAZARD

HOT OIL SPILL OR SPLATTER

DO NOT REMOVE FILTER RESERVOIR WHEN IT CONTAINS HOT OIL

HOT OIL WILL CAUSE SEVERE BURNS ON CONTACT

PROTECTIVE CLOTHING AND GLOVES MUST BE WORN

DURING THE FILTERING PROCESS

Death or serious injury may result from contact with, or slipping and falling in, spilled oil.

WARNING

WARNING:

BURN HAZARD

DO NOT REMOVE FILTER RESERVOIR IF IT IS HOT.

WEAR INSULATED GLOVES OR ALLOW IT TO COOL.

Hot oil quickly heats reservoir. Touching hot reservoir

with bare hands can causing serious injury

Clean FILTER LEAF after each day’s filtration, or as needed to return

oil promptly to the kettle.

Open FRYER DOOR and slide the FILTER RESERVOIR forward to

remove it. Remove FILTER LEAF from reservoir.

Disassemble FILTER LEAF by separating the two side rails at the

joint with the straight pin. Clean all components in a sink with warm

water and mild detergent, or in a dishwasher.

Assemble SCREEN with the SEPARATOR installed between the

two screens. Verify that O-RING is in place on the suction tube on

BOTTOM SCREEN.

Slide screens into SIDE RAIL “B” (L-shaped pin). Hook SIDE RAIL

“A” over the pin on SIDERAIL “B” and work the screens into SIDE

RAIL “A” until straight pin on “A” is held by the “bump” on “B”.

STRAIGHT

PIN

FILTER RAIL “A”

UPPER

FILTER SCREEN

SEPARATOR

FILTER SCREEN

“L”-SHAPED

PIN

FILTER RAIL “B”

LOWER

TOP VIEW

Install FILTER LEAF in RESERVOIR with suction tube firmly into

filter drain hole.

Install filter reservoir into the fryer. Make sure the “O” ring closest

to end of SUCTION TUBE is firmly seated in SUCTION LINE

RECEPTACLE.

SIDE VIEW

IMPORTANT: Make sure all oil

is pumped into FRYPOT before

removing reservoir.

NOTE:

When properly assembled,

handle will point away from

suction tube on BOTTOM

SCREEN.

NOTE:

Inspect the “O” RING on

FILTER SUCTION TUBE for

damage. Replace “O” ring if it

is cut, cracked or scuffed using

one of the spare o- rings in the

suction tube groove.

IMPORTANT:

Avoid contaminating the oil or

food product by verifying that all

components of filter reservoir

assembly are completely dry

before reassembling.

363 503043 Service Manual for WFAE-55F/FS Fryer

12

Page 15

FILTER SYSTEM

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

FILTER PUMP does not run

FILTER SYSTEM TROUBLESHOOTING

POWER SWITCH not in FILTER Press power switch to filter

FILTER PUMP MOTOR OVERLOAD

tripped

FILTER SWITCH damaged Replace filter switch

POWER SWITCH damaged Replace power switch

SUCTION TUBE not seated in suction

receptacle

SUCTION TUBE O-RING missing or

damaged

Allow motor to cool. Press red button on

back of pump motor

Properly install filter reservoir

Replace suction tube o-ring

FILTER PUMP runs but will not pump

cooking oil

Bubbles in circulating oil at all times during

filtration cycle

PUMP MOTOR tripped

Will not reset

Damaged SUCTION TUBE

Damaged SUCTION RECEPTACLE

Pump CHECK VALVE plugged Clean check valve

Pump CHECK VALVE reversed

(improperly installed during repair)

FILTER LEAF clogged

Solid shortening melt option - Oil solidified

in reservoir, filter or tubing

SUCTION TUBE not seated in suction receptacle

SUCTION TUBE O-RING missing or

damaged

Insufficient oil entering

Pump jammed with debris

PUMP HEAD damaged Replace pump head

PUMP MOTOR damaged Replace pump motor

Solid shortening melt option - Oil solidified

in reservoir, filter or tubing

FILTER RESERVOIR

Replace filter reservoir assembly

Replace suction receptacle

Note TOP marked on valve

Install check valve correctly

Clear face of filter leaf or replace filter leaf

IMPORTANT: Allow oil to cool before

moving reservoir

Be sure reservoir pan is pushed fully to the

rear so that heater contacts are engaged

Repair / replace heat tape, contact

assembly or transformer as required

Properly install filter reservoir

Replace suction tube o-ring

Incrementally open DRAIN VALVE

Clear crumbs/debris from DRAIN VALVE

Clear debris from pump

Be sure reservoir pan is pushed fully to the

rear so that heater contacts are engaged

Repair / replace heat tape, contact

assembly or transformer as required

Oil not being filtered

363 503043 Service Manual for WFAE-55F/FS Fryer

FILTER leaf missing, damaged or not

properly installed

13

Properly install filter leaf. Be sure filter leaf

o-ring is properly installed

Page 16

SERVICING INSTRUCTIONS

FRY BASKET & CRADLE LIFT SYSTEM COMPONENTS

BASKET, HALF-SIZE

(TWIN) 505097

BASKET, FULL SIZE

(FIXED HANDLES)

22913

BASKET, FULL SIZE

(FOLDING HANDLE)

CRADLE 69961

23135

SCREW, 1/4-20 x3/4

HEX SS 61048

BEARING, ROLLER

.75 OD x .25 ID

500031

PIVOT, CRADLE

500037

BUSHING, LIFT

ROD 69972

LIFT ROD

500542

MOTOR, LIFT

230V 1/10HP

500513

YOKE, LIFT

ROD 69812

363 503043 Service Manual for WFAE-55F/FS Fryer

14

Page 17

TOP PANEL

FRAME

LIFT ROD

BUSHING

LIFT ROD

BUSHING

YOKE

LIFT ROD

LIFT

MOTOR

CLAMP

LIFT ROD

GUARD

FRAME

BACK PLATE

MOTOR

MOUNT

PLATE

FRAME

BOTTOM

PLATE

10-1/4“

to

10-3/8“

A

C

D

E

B

B

SCREW

MOTOR

MOUNT

BACK

PLATE

BRASS

NUT

TOP

PANEL

YOKE

363 503043 Service Manual for WFAE-55F/FS Fryer

SERVICING INSTRUCTIONS (continued)

FRY BASKET & CRADLE LIFT SYSTEM ASSEMBLY

A. LIFT ROD GUARD

Assemble LIFT ROD GUARD into FRAME. GUARD slides

through holes in the MOTOR MOUNT PLATE and bottom of

FRAME BACK PLATE, and rests on BOTTOM PLATE of frame.

It is held in place by HOSE CLAMPS above and below MOTOR

MOUNT PLATE.

B. LIFT ROD BUSHING

1. Top bushing assembles through TOP PANEL and FRAME.

WAVE WASHER and JAM NUT go BELOW top part of frame.

2. Bottom bushing assembles through the top hole in FRAME

BACK PANEL.

C. LIFT MOTOR

1. Apply voltage to BLACK and WHITE wires of the motor until

screw stops turning. This is the full-down position.

Turn BRASS NUT until the distance from the top of the

nut to the top of the screw is 10-1/4” to 10-3/8”.

2. Assemble the LIFT MOTOR to the MOTOR MOUNT PLATE

with four bolts and threadlock.

D. CRADLE PIVOT

Assemble CRADLE PIVOT to LIFT ROD. SET SCREW on

PIVOT COLLAR must be centered on flat on LIFT ROD.

E. LIFT ROD YOKE

1. Slide fingers of YOKE over flats of BRASS NUT. Set screws

must be on the side away from the motor.

2. Slide PIVOT / LIFT ROD through top BUSHING, YOKE,

bottom BUSHING and LIFT ROD GUARD. CRADLE PIVOT

must be parallel to rear portion of TOP PANEL, with the

downturned lip of the PIVOT toward the front of the fryer.

3. Center the YOKE on the flats of the BRASS NUT, then

tighten YOKE SET SCREWS on flat of LIFT ROD.

4. Apply voltage to the motor leads and carefully observe the

end points of the up-and-down motion. Yoke must clear

bushings: adjust by loosening yoke set screws and

“bumping” the lift motor as required by applying voltage

momentarily to the appropriate motor leads. Tighten set

screws and re-test for proper up-and-down operation.

F. LUBRICATION

Lubricate screw threads with a generous amount of “moly”

(molybdenum disulfide) grease. Wipe any excess from motor, lift

rod and yoke.

15

Page 18

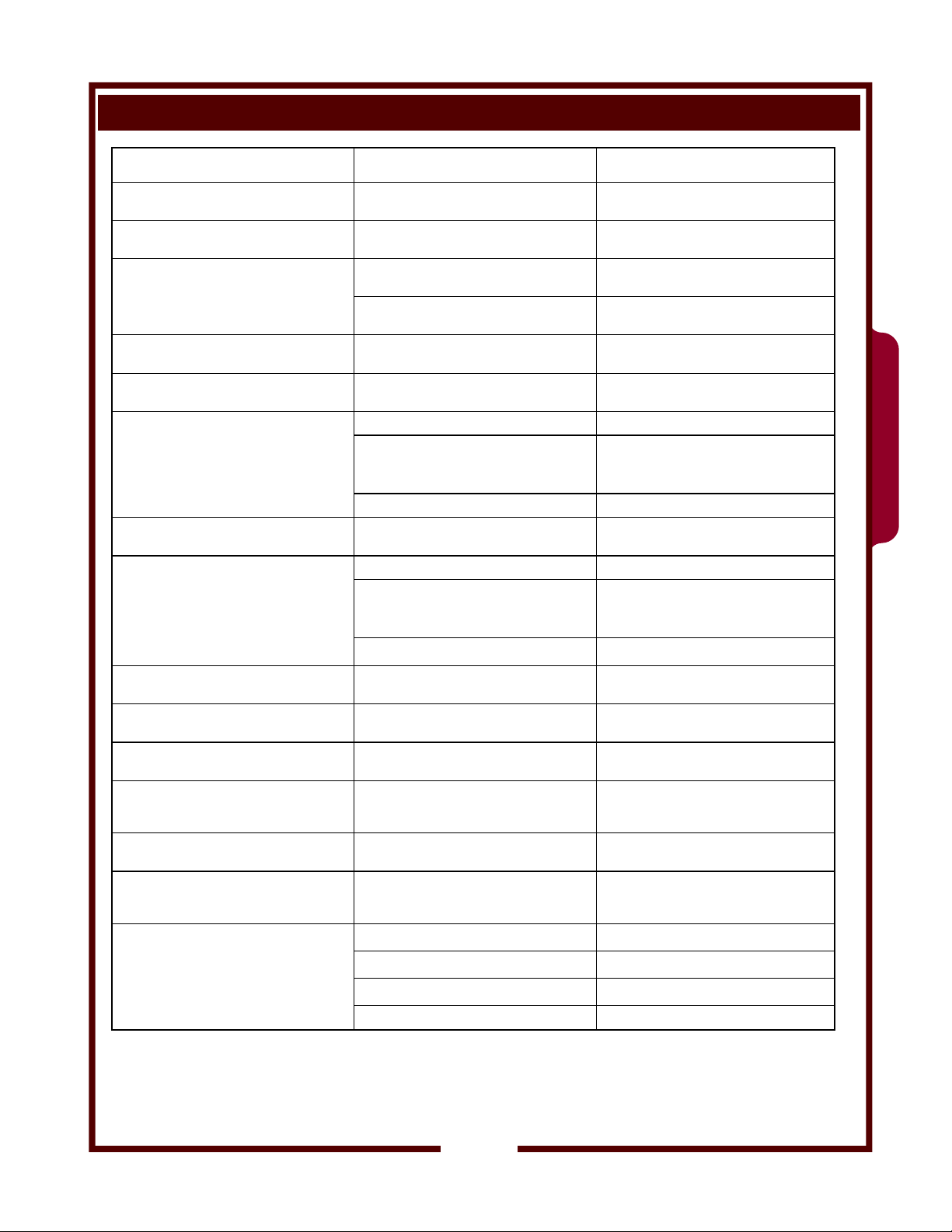

SERVICING INSTRUCTIONS (continued)

FILTER SYSTEM COMPONENTS

WASHER, FIBER

FITTING, CONDUIT

3/8 x 90º 8706-109

MOTOR, FILTER

125/230V 1ø 50/60Hz

HOSE, SUCTION LINE

3/4” x 16.5” SS 502287

1-1/4 NPT 69816

SUCTION LINE

FITTING 66720

50177

501205

VALVE, BALL

PUMP, FILTER

501231

CHECK VALVE

3/8 NPT 66692

FRYPOT

HOSE, PRESSURE

.6” x 13.5” SS 502283

FRYPOT

363 503043 Service Manual for WFAE-55F/FS Fryer

16

Page 19

FILTER SYSTEM - PUMP & PIPING ASSEMBLY

SERVICING INSTRUCTIONS (continued)

ADAPTER

3/8“ FPT x 3/4“ M FLARE

TORQUE TO

25 ft.-lb.

SS FLEX HOSE ASSY

.6“ OD x 13.5” LG

TORQUE TO

25 ft.-lb.

ADAPTER

3/8“ FPT x 3/4“ M FLARE

CHECK VALVE

note: ARROW POINTS

TOWARD FRYPOT

NIPPLE

3/8“ x CLOSE

FITTING, 3/8“ NPT

90º STREET ELBOW

FRYPOT

F

J

C

C

J

F

F

F

J

C

REDUCER

1/2“ x 3/8” NPT

F

APPLY PIPE SEALANT ( ™ PST) TO

MALE PIPE THREADS.

ANY TYPE OF PIPE COMPOUND OR TAPE

AT FLARE FITTINGS.

ASSEMBLE FLARE FITTINGS FINGER TIGHT

WITHOUT ANY TYPE OF PIPE COMPOUND.

THEN, TORQUE FLARE FITTING:

DISCHARGE TUBE TO 25 ft-lb

SUCTION TUBE TO 33 ft-lb.

ALWAYS USE A BACKUP WRENCH ON THE

MALE FLARE FITTING.

DO NOT ALLOW CORRUGATED PIPE TO

TWIST DURING ASSEMBLY.

DO NOT BEND CORRUGATED TUBE

WITHIN 1“ OF ANY FITTING

F

Loctite

DO NOT APPLY

.

PUMP /

MOTOR

F

SUCTION

FITTING

J

C

J

C

ADAPTER

1/2“MPT x 15/16” M FLARE

F

ADAPTER

1/2“ FPT x

15/16“ M FLARE

TORQUE TO

33 ft.-lb.

SS FLEX

HOSE ASSY

.75“ x 16.5” LG

TORQUE TO

33 ft.-lb.

363 503043 Service Manual for WFAE-55F/FS Fryer

IMPORTANT:

• Motor is a dual voltage rated unit, and must be field wired to match the electrical service

supply voltage.

• Motor is shipped from the factory wired for 230V and may be wired for either 230V or 125V. •

Verify supply voltage. If necessary, rewire motor, at terminal block in the end of the motor,

per the table shown below.

IMPORTANT: Failure to correctly wire the motor will result in failure to start, motor tripping or

permanent damage to the pump motor.

125V

(requires field conversion)

2

1

1 (LINE)

YELLOW / BLACK

2

3

5

4

6

3

4

5

6 (LINE)

BLUE

BLUE

(unused)

BLACK

BROWN

ORANGE

WHITE

YELLOW

(factory configuration)

1 (LINE)

2

3

4

5

6 (LINE)

230V

YELLOW/BLACK

BLUE

BLUE

BROWN

BLACK

WHITE

ORANGE

YELLOW

17

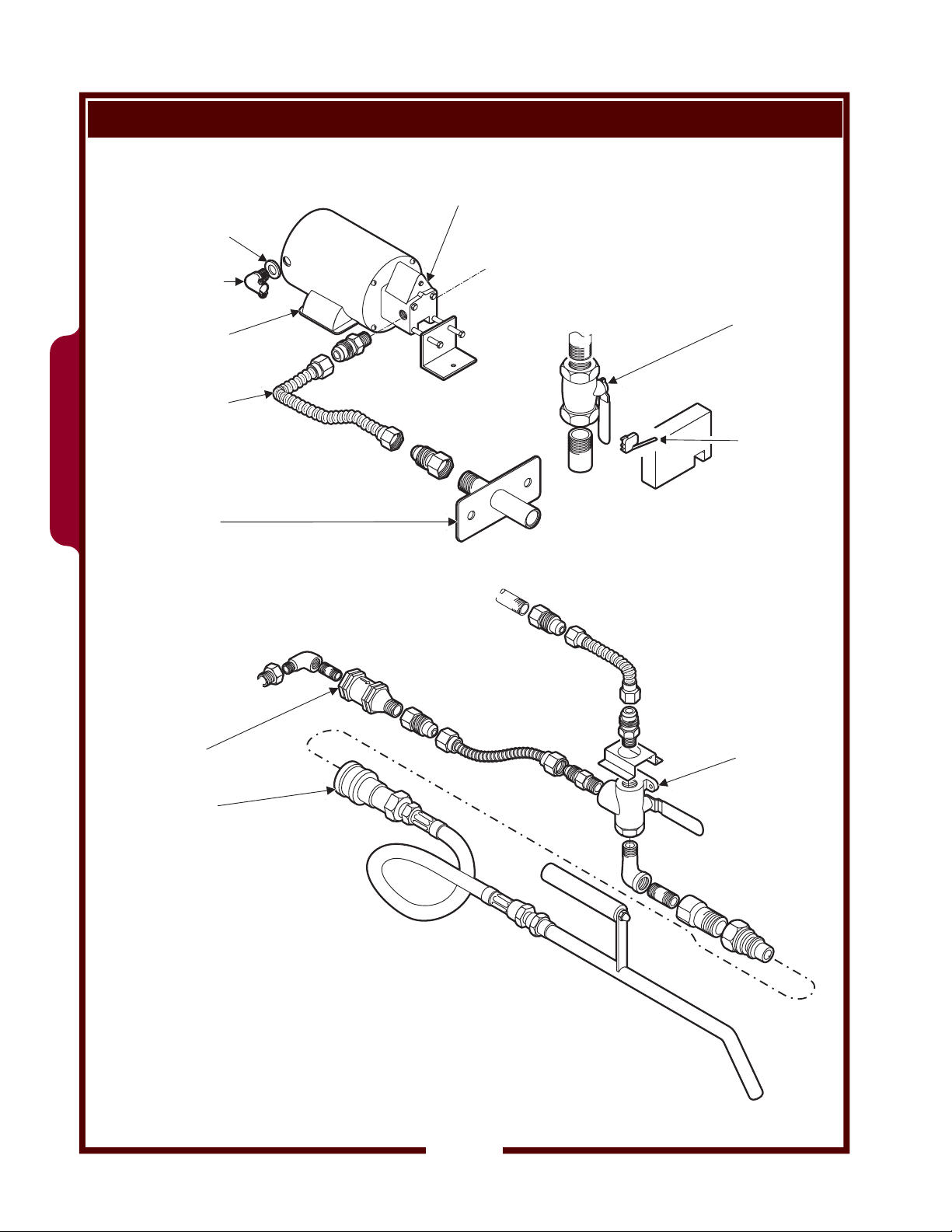

Page 20

SERVICING INSTRUCTIONS (continued)

OPTIONAL FILTER WAND - ASSEMBLY

WASHER, FIBER

50177

FITTING, CONDUIT

3/8 x 90º 8706-109

MOTOR, FILTER

125/230V 1ø 50/60Hz

501205

WFAE-55FS

HOSE, SUCTION LINE

3/4” x 16.5” SS 502287

SUCTION LINE

FITTING 66720

PUMP, FILTER

501231

VALVE, BALL

1-1/4 NPT 69816

FRYPOT

MICROSWITCH

DRAIN SAFETY

64887

FROM PUMP

CHECK VALVE

3/8 NPT 66692

OIL WAND & HOSE

ASSY 23188

FRYPOT

VALVE 3-WAY

SS 504309

361 501219 Service Manual for WFAE-30F Fryer

18

Page 21

OPTIONAL FILTER WAND - DRAIN SAFETY SWITCH

DRAIN VALVE

MICROSWITCH

VALVE HANDLE

(CLOSED POSITION)

SERVICING INSTRUCTIONS (continued)

VALVE HANDLE ACTIVATES

DRAIN SAFETY SWITCH WHEN

IN THE “CLOSED” POSITION

WFAE-55FS

The MICRO SWITCH is in the control circuit for the heating element

contactor. The switch must be closed before the heating elements

can be energized.

When rotated to the CLOSED position, the valve handle will contact

the micro switch actuator, closing the switch.

Assemble the switch so that it is made when the valve handle is in

the fully closed position.

The drain safety switch is an

interlock to prevent energizing

the heating elements unless

the drain valve handle is in the

closed position.

361 501219 Service Manual for WFAE-30F Fryer

19

Page 22

SERVICING INSTRUCTIONS (continued)

WFAE-55F (MANUAL CONTROLS) HEATING ELEMENTS & ELECTRI CA L C OMPONENTS

WFAE-55F

RELAY, MERCURY

(OBSOLETE)

USE 504892

RELAY, E-SAFE

504892

CONTACTOR

3P 208V 40A

57779

SWITCH, TOGGLE

W/SEAL 64904

FACEPLATE, CONTROL

PANEL (DECAL) 502391

LIGHT, SIGNAL

AMBER 50516

SWITCH, ROCKER

POWER 69550

PLATE, SWITCH

ON-OFF 53192

CONNECTION BOX

HH

BUZZER 220V

64834

CONTROL PANEL

STRAIN RELIEF

1” NPT 500102

TERM BLOCK

50131

BEHIND CONTROL PANEL

TIMER 40MIN

240V 60Hz

68469

THERMO

FUSEHOLDER

10A 240V 54769

HI-LIMIT

66663

ELEMENT 8.5KW

500009 208V

500013 240V

KIT, ELEMENT

GASKET 66863

CLAMP, THERMOBULB

62504 (pk 4)

363 503043 Service Manual for WFAE-55F/FS Fryer

NUT, 8-32 x7/8” Alu

61974 (pk 10)

TERM BLOCK

FLAME SENSOR

53068

JUMPER, FLAME

SENSOR 54005

FUSE SC-10

10A (bx 4)

54871

20

KNOB, CONTROL

65653

KIT, CAPILLARY

FEED-THRU 66656

THERMO

TEMP CONTROL

66688

Page 23

SERVICING INSTRUCTIONS (continued)

WFAE-55FS (SOLID STATE CONTROLS) HEATING ELEMENTS & ELECTRICAL COMPONENTS

COOK CONTROLLER

FACEPLATE

(DECAL) 502417

SWITCH, ROCKER

POWER 69550

TRANSFORMER

208/240V : 24V

501454

502968

RELAY, MERCURY

(OBSOLETE)

USE 504892

RELAY, E-SAFE

504892

SPARK

QUENCHER

500688

CONTACTOR

3P 208V 40A

57780

RELAY, SOLID

STATE 501200

BEHIND CONTROL PANEL

ELEMENT 8.5KW

506258 208V 1ø

500009 208V 3ø

506259 240V 1ø

500013 240V 3ø

WFAE-55FS

363 503043 Service Manual for WFAE-55F/FS Fryer

CONTROL PANEL

CONNECTION BOX

HH

NUT, 8-32 x7/8” Alu

61974 (pk 10)

JUMPER, FLAME

SENSOR 54005

STRAIN RELIEF

1” NPT 500102

TERM BLOCK

50131

TERM BLOCK

FLAME SENSOR

53068

CLAMP, THERMOBULB

KIT, CAPILLARY

FEED-THRU 66656

THERMO

HI-LIMIT

66663

62504 (pk 4)

UNIT W/FILTER WAND

MICROSWITCH

DRAIN SAFETY

64887

KIT, ELEMENT

GASKET 66863

SONALERT

500974

FRAME BACKPLATE (EUROPEAN)

PROBE,

THERMOSTAT

501465

SPARK

QUENCHER

500688

TERMINAL BLOCK

4P 75A (EURO)

60310

21

Page 24

SERVICING INSTRUCTIONS (continued)

HEATING ELEMENT INSTALLATION INSTRUCTIONS

CAUTION

EXPOSED ELECTRIC

CIRCUITS

Disconnect electric power before

servicing heating element or

thermostats.

ELEMENT (ref)

GORTEX

GASKET

FRYPOT (ref)

BACKING PLATE

BELLEVILLE WASHER

(note orientation)

NUT

FRYPOT ELEMENT

NUT TIGHTENING SEQUENCE

Refer to drawings at left for assembly of Gortex gasket and Belleville

washer, and for nut tightening sequence.

1. Install 1/4” Gortex gasket (p/n 66864) over element studs.

DO NOT USE RTV!

Insert element through frypot, element and gasket on the inside

of frypot, and studs through the appropriate holes.

2. Install 1/4” Belleville washers with the high center away from

frypot, as shown (4 places).

3. Install four nuts finger tight.

4. Using a torque wrench, tighten all four nuts 1/2 turn at a time.

Work in a cross pattern to tighten each nut in sequence, until a

uniform reading of 70 inch-lbs is achieved on all four nuts.

5. To counter the slow compressibility characteristics of the Gortex

gasket:

a. Wait 2 minutes, then re-torque all four nuts to 70 inch-lbs.

b. Wait an additional two minutes, then re-torque all four nuts

to a uniform 70 inch-lbs.

12

3

GASKET BEHIND

VIEW FROM FRONT OF UNIT

4

363 503043 Service Manual for WFAE-55F/FS Fryer

22

Page 25

SERVICING INSTRUCTIONS (continued)

THERMOSTAT INSTALLATION INSTRUCTIONS

GREEN GASKET

NOTE: FRAGILE

FEED-THRU

BUSHING

17mm

OUTSIDE OF FRYPOT

BELLEVILLE WASHER

INSIDE OF FRYPOT

(p/n 69962)

LOCK NUT

17mm

CAPILLARY

WASHER

BLACK OIL SEAL

PAR T O F

1. Insert feed-thru bushing through green gasket, and insert both

through frypot wall. Slide Belleville washer over protruding

threads of bushing, with the high center of washer

frypot. Thread locknut onto bushing and tighten. Torque lock nut

to 30 inch pounds.

SAFETY CLAMP

ELEMENT

HOLDS BULB

CLEAR OF

ELEMENT

HI-LIMIT BULB: LEFT SIDE

TEMPERATURE CONTROL BULB: RIGHT SIDE (WFAE-55F ONLY)

3/8“

max.

BULB

TWO CLAMPS

HOLD BULB

ONE CLAMP HOLDS

CAPILLARY

PLACE CLAMPS WITHIN 3/8“

OF THE ENDS (WIDE PORTION)

OF BULB

2. Slip bulb of capillary tube through bushing. Mount bulb to center

portion of element with safety clamps. Positioning clamps within

3/8” of ends of the widest part of bulb. Route capillary tube

alongside of the element, but out of the way of cleaning brushes,

etc. Secure capillary tube near frypot end of element with a

safety clamp.

3. Seat washers and oil seal into bushing. Insert compression nut

into bushing, then torque to 30 - 40 inch-lbs.

COMPRESSION

NUT, 10mm

THERMOSTAT

CAPILLARY

away

from the

3/8“

max.

CAUTION

EXPOSED ELECTRIC

CIRCUITS

Disconnect electric power before

servicing heating element or

thermostats.

IMPORTANT:

17mm. hex head feed thru bushing

pictured at the left of drawing

MUST NOT

during assembly procedure.

Always support bushing with a box

wrench while tightening both lock

nut and compression nut to avoid

damage to green gasket!

NOTE:

capillary tube.

be allowed to rotate

Use care not to twist or kink

363 503043 Service Manual for WFAE-55F/FS Fryer

23

Page 26

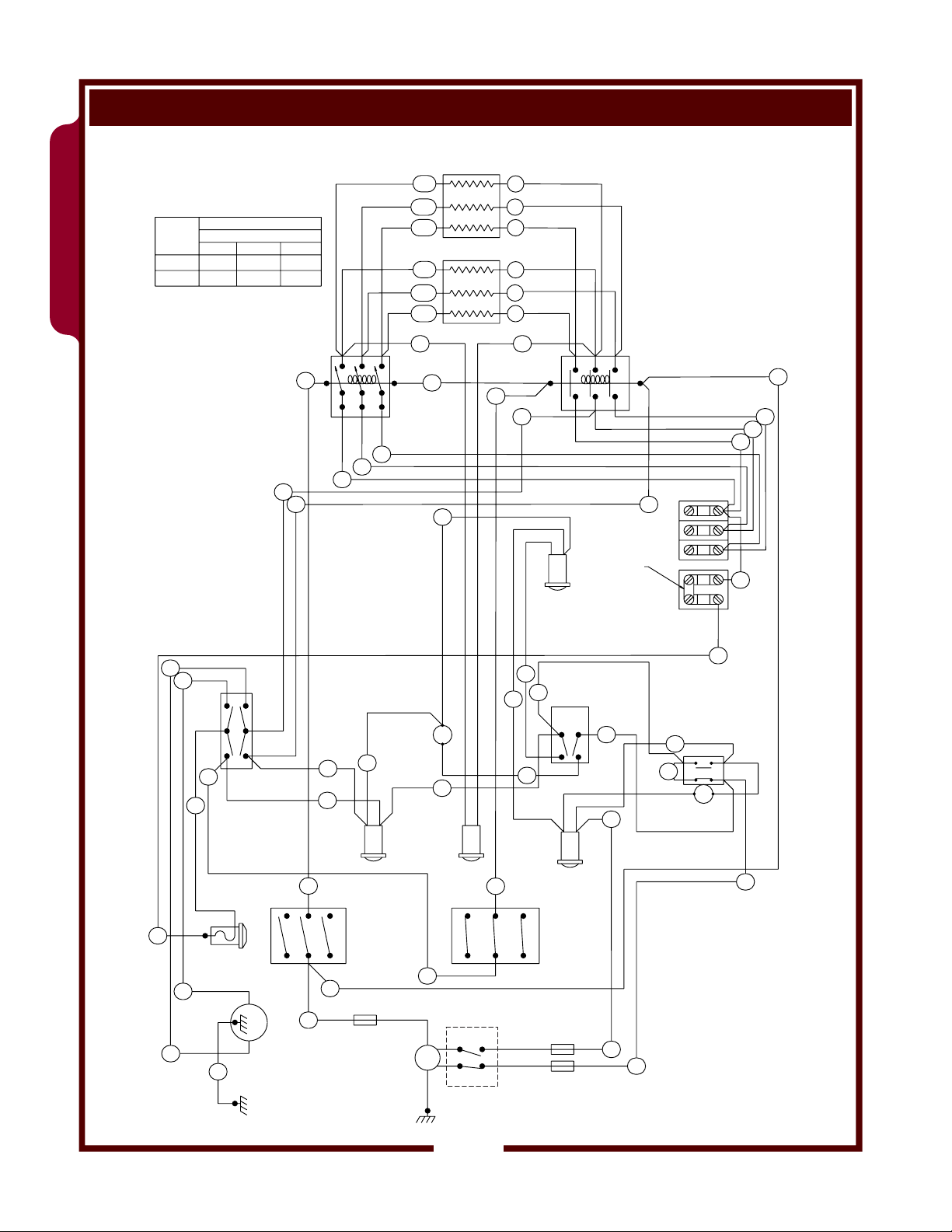

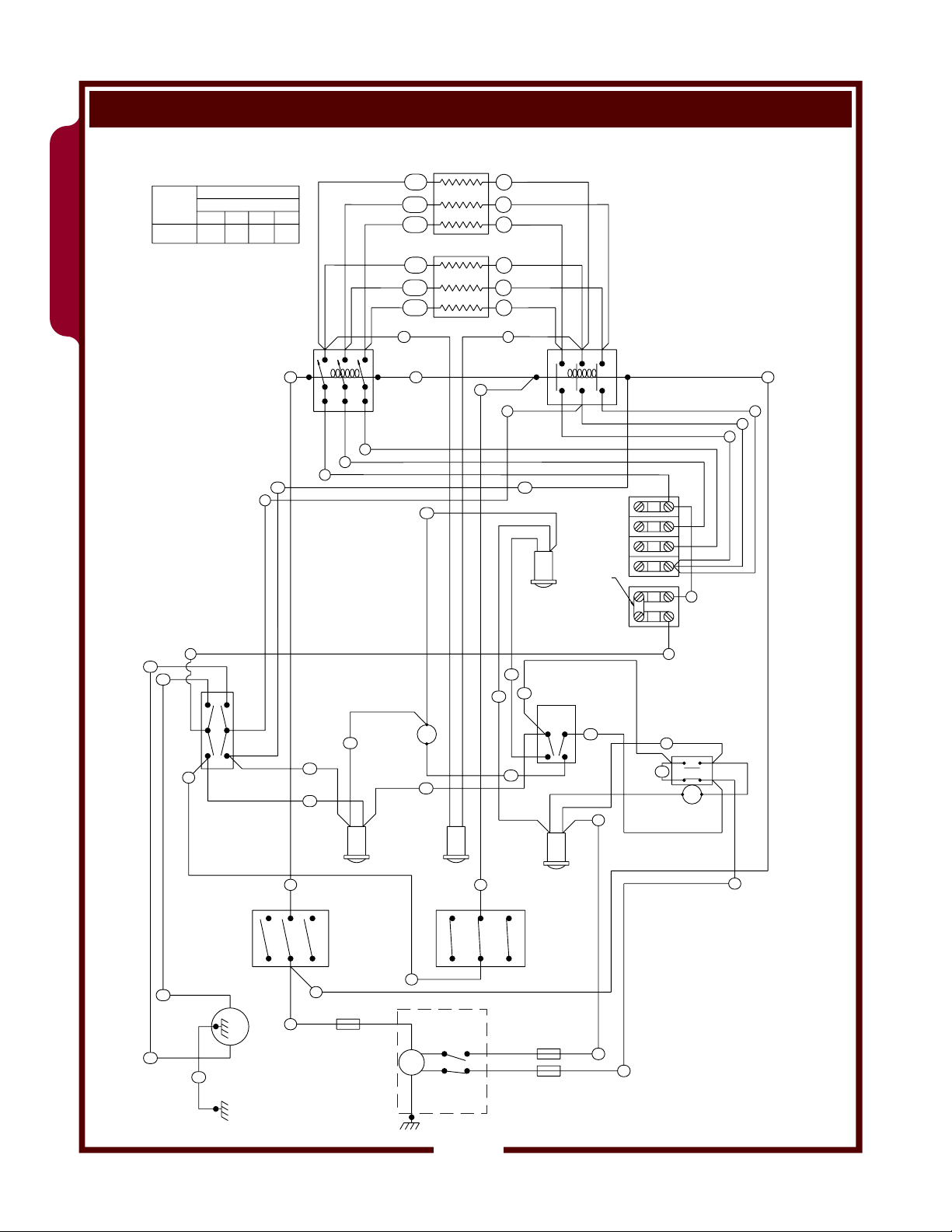

WIRING DIAGRAM

WFAE-55F

VOLT

50/60 HZ

208

240

REV. B P/N 49938

WIRING DIAGRAM FOR WFAE-55F FRYER - MANUAL CONTROLS

3Ø, 208 OR 240V, 17KW

FRYER RATING

L1

47.8

41.5

AMPS 3ø

L2

47.8

41.5

L3

47.2

40.9

1L1

1L2

1L3

8500W HEATING

ELEMENT(2)

1L1

1L2

1L3

1

2

3

1

2

3

10

15

3

2

9

28

27

26

12

POWER

SWITCH

C

21

1

29

25

POWER ON

LIGHT

30

MERCURY

RELAY

BUZZER

13

33

24

HEAT ON

LIGHT

11

14

9

BUZZER

LIGHT

35

BUZZER

23

SWITCH

32

34

COOK

LIGHT

CONTACTOR

28

TERMINAL

BLOCK

JUMPER

EXTERNAL

INTERLOCK

TERMINAL BLOCK

(REMOVE JUMPER

WHEN USING

EXTERNAL CONTROL)

20

17

31

22

TIMER

19

6

5

4

L1

L2

L3

7

8

363 503043 Service Manual for WFAE-55F/FS Fryer

8

27

FUSE 10A-SC

w/FUSE HOLDER

26

GREEN

36

FILTER

PUMP

18

LIMIT

SWITCHES

14

HI LIMIT

THERMOSTAT

BLACK

RED

17

18

15

TEMPERATURE

CONTROL

THERMOSTAT

19

16

BASKET LIFT

ACTUATOR

21

WHITE

GREEN

24

Page 27

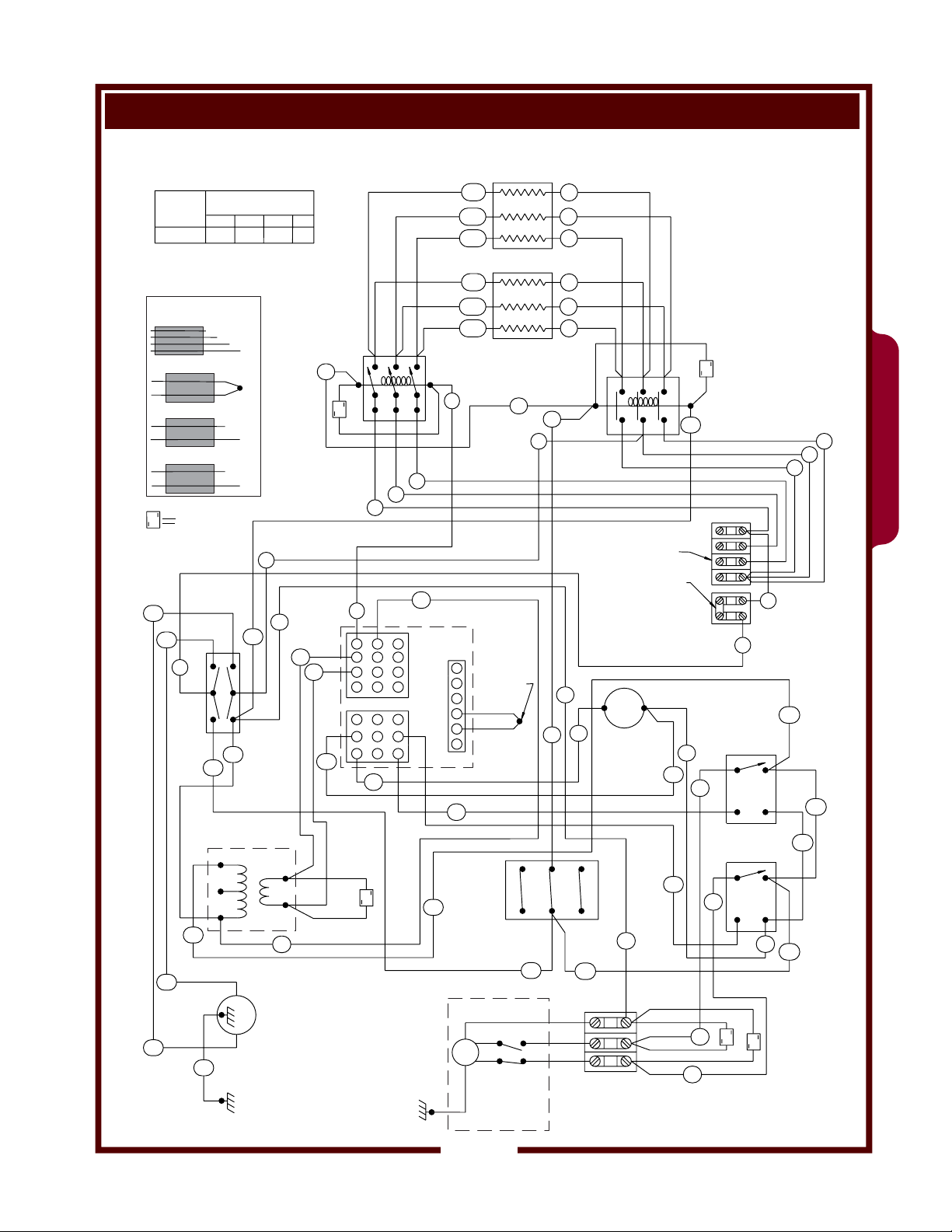

WIRING DIAGRAM (continued)

WIRING DIAGRAM FOR WFAE-55FS FRYERS w/ SOLID STATE CONTROL

3Ø, 208 OR 240V, 17KW

VOLTS 3ø

50/60 HZ

REV. B P/N 301724

NOT UL LISTED

*

FOR SINGLE

PHASE

S

27

208

240

26

8

26

L1

SPARK

QUENCHER

(SNUBBER)

CONTROLLER

TRANSFORMER

30

FRYER RATING

AMPS

L2

4848

4242

28

C

POWER

SWITCH

25

24

240V

208V

1L1

3

10

-

UP

MERCURY

RELAY

11

6

5

4

3

-

2

+

1

19

30

1L2

1L3

8500W HEATING

ELEMENT(2)

1L1

1L2

1L3

THERMOCOUPLE

RED

WHITE

DOWN

THERMOSTAT

HI LIMIT

L3

47

41

15

S

2

1

9

11

16

12

13

+

22

COM

24V

10

CONTROLLER

123

654

8

9

7

101112

963

852

147

21

S

CONTACTOR

15

9

24

1

2

3

1

2

3

SAFETY

14

16

14

S

28

6

5

4

WFAE-55FS

SOLID STATE

RELAY

1

TOP

-

4

SOLID STATE

RELAY

1

BOTTOM

18

-

4

L1

L2

L3

7

8

30

2

AC

+

DC

AC

DC

31

33

3

32

2

+

3

23

*

TERMINAL

BLOCK

JUMPER

EXTERNAL INTERLOCK

TERMINAL BLOCK

(REMOVE JUMPER

WHEN USING

EXTERNAL CONTROL )

-

+

21

AUDIBLE

ALARM

16

23

31

22

17

20

UP

363 503043 Service Manual for WFAE-55F/FS Fryer

FILTER

PUMP

27

GREEN

34

BASKET LIFT

ACTUATOR

GREEN

LIMIT

SWITCHES

INSIDE

MOTOR

HOUSING

(COM)

(DN)

(UP)

WHITE

BLACK

RED

17

S

S

18

25

Page 28

WIRING DIAGRAM (continued)

WFAE-55F

VOLTS 3ø

50 HZ

380-415

P/N 300447 REV A

FRYER RATING

MAX AMPS

L1

27.0

26.5

L3L2

26.5

N

0.5

WIRING DIAGRAM FOR WFAE-55FEU

3Ø, 380-415V, 17KW 50 HZ

1L1

1L2

1L3

8500W HEATING

ELEMENT(2)

1L1

1L2

1L3

1

2

3

1

2

3

14

11

9

2828

BUZZER LIGHT

EXTERNAL INTERLOCK

TERMINAL BLOCK

(REMOVE JUMPER

WHEN USING

EXTERNAL CONTROL)

35

BUZZER

23

32

34

SWITCH

TERMINAL

BLOCK

JUMPER

20

17

CONTACTOR

L1

L2

L3

N

19

6

5

4

7

8

31

22

TIMER

363 503043 Service Manual for WFAE-55F/FS Fryer

10

MERCURY

RELAY

BUZZER

13

33

24

HEAT ON

LIGHT

15

3

2

1

9

8

27

26

POWER

SWITCH

C

21

POWER ON

30

29

25

LIGHT

COOK

RED

LIGHT

HI LIMIT

THERMOSTAT

17

18

LIMIT

SWITCHES

14

BLACK

15

TEMPERATURE

CONTROL

THERMOSTAT

26

FILTER

27

GREEN

36

PUMP

19

16

BASKET

LIFT

ACTUATOR

21

WHITE

GREEN

18

26

Page 29

WIRING DIAGRAM (continued)

WIRING DIAGRAM FOR WFAE-55FSEU

380-415V, 50HZ, 17KW

363 503043 Service Manual for WFAE-55F/FS Fryer

VOLTS 3ø

50 HZ

FRYER RATING

L1

380-415

REV. B P/N 303039

*

NOT UL LISTED

FOR SINGLE

PHASE

USE FERRITE CLAMPS

(P/N 302979 - 4 PLCS):

10

11

12

THERMOCOUPLE

19

20

SPARK

S

QUENCHER

(SNUBBER)

27

26

8

C

25

24

CONTROLLER

TRANSFORMER

240V

208

30

26

27

GREEN

34

MAX AMPS

L2

2424

13

21

22

9

28

POWER

SWITCH

FILTER

PUMP

L3

24

16

24V

10

1L1

N

5

1L2

1L3

8500W HEATING

ELEMENT(2)

1L1

1L2

1L3

MERCURY

15

S

RELAY

11

15

1

2

3

1

2

3

SAFETY

CONTACTOR

14

9

S

28

6

5

4

3

2

1

31

18

17

18

17

L1

L2

L3

N

8

SOLID STATE

RELAY

1

AC

TOP

-

DC

4

SOLID STATE

RELAY

1

AC

BOTTOM

-

DC

4

31

S

S

7

30

2

+

33

3

32

2

+

3

23

*

TERMINAL

BLOCK

JUMPER

11

12

321

987

13

12 11

+

741

22

COM

21

10

CONTROLLER

456

10

-

369

+

-

258

UP

EXTERNAL INTERLOCK

TERMINAL BLOCK

(REMOVE JUMPER

WHEN USING EXTERNAL

6

THERMOCOUPLE

5

4

RED

3

2

WHITE

1

14

CONTROL)

16

-

+

21

AUDIBLE

ALARM

22

DOWN

19

20

S

30

BASKET LIFT

ACTUATOR

THERMOSTAT

GREEN

HI LIMIT

LIMIT

SWITCHES

INSIDE

MOTOR

HOUSING

24

(COM)

(DN)

(UP)

23

WHITE

BLACK

RED

UP

16

WFAE-55FS

27

Loading...

Loading...