Page 1

WELLS MANUFACTURING COMPANY

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

Customer Service (775) 345-0444 Ext.502

fax: (775) 345-0569

www.wellsbloomfield.com

INSTALLATION,

OPERATION

AND

MAINTENANCE

MANUAL FOR

ELECTRIC

361

FRYER

MODEL

WFAE-30F

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the FRYER and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS

of the FRYER. Additional manuals are available from your WELLS DEALER .

Part. No 301669 Rev. A

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS FRYER. Contact your WELLS DEALER if you have any questions

concerning installation, operation or maintenance of this equipment.

M361 110800 cps

Page 2

LIMITED WARRANTY STATEMENT

All commercial cooking equipment manufactured by

WELLS MFG. CO. is warranted against defects in

materials and workmanship for a period of one year

from the date of original installation or 18 months

from the date of shipment from our factory, whichever comes first, and is for the benefit of the original purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW

OR IN FACT, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, AND/

OR FOR DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH WELLS

MFG. CO. PRODUCTS. This warranty is void if it is

determined that, upon inspection by an authorized

service agency, the equipment has been modified,

misused, misapplied, improperly installed, or damaged in transit or by fire, flood or act of God. It also

does not apply if the serial nameplate has been removed, or if service is performed by unauthorized

personnel.

The prices charged by Wells Mfg. Co.for its products are based upon the limitations in this warranty.

Seller’s obligation under this warranty is limited to

the repair of defects without charge by a Wells Mfg.

Co. factory authorized service agency or one of its

sub-service agencies. This service will be provided

on customer’s premises for non-portable models.

Portable models (a device with a cord and plug) must

be taken or shipped to the closest authorized service agency, transportation charges prepaid, for service. In addition to restrictions contained in this warranty, specific limitations are shown in the Service

Policy and Procedure Guide. Wells Mfg. Co. authorized service agencies are located in principal cities.

This warranty is valid in the United States and

Canada and void elsewhere. Please consult your

classified telephone directory, your foodservice equipment dealer or write the Factory Service Department,

Wells Manufacturing Company, P.O. Box 280, Verdi,

Nevada 89439, phone (775) 345-0444 or (888) 4922782, for information and other details concerning

warranty.

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, overload protectors, and/or fuse replacements are not covered by this warranty unless

warranted conditions are the cause.

2. All problems due to operation at voltages or phase other than specified on equipment nameplates are not covered by this warranty.

Conversion to correct voltage and/or phase must be the customers responsibility.

3. All problems due to electrical connections not made in accordance with electrical code requirements and wiring diagrams

supplied with the equipment are not covered by this warranty.

4. Replacement of items subject to normal wear, to include such items as knobs, light bulbs; and, normal maintenance functions including

adjustments of thermostats, adjustment of micro switches and replacement of fuses and indicating lights are not covered by warranty.

5. Servicing of filters must be the customer’s responsibility. Replacement of filters and all problems associated with clogged filters are not

covered by this waranty. Inadequate airflow due to a clogged filter and/or grease baffle will disable fryers equipped witha ventilation

hood. Manufacturer assumes no responsibility for loss of business resulting from owner’s failure to have replacement filters available

when existing filters reach the end of their service life.

6. Set-up, adjustment, calibration, repair and servicing of third party equipment and systems, such as fire suppression systems, are not

covered by this warranty, and must be the customer’s responsibility.

7. Full use, care, and maintenance instructions are supplied with each machine. Noted maintenance and preventative maintenance items,

such as servicing and cleaning schedules, are customer responsibility. Those miscellaneous adjustments noted are customer

responsibility. Proper attention to preventatve maintenance and scheduled maintenance procedures will prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an Authorized Service Agency or one of its sub-service agencies.

9. All labor shall be performed during regular working hours. Overtime premium will be charged to the buyer.

10. All genuine Wells replacement parts are warranted for ninety (90) days from date of purchase on non-warranty equipment. This parts

warranty is limited only to replacement of the defective part(s). Any use of non-genuine Wells parts completely voids any warranty.

11. Installation, labor, and job check-outs are not considered warranty and are thus not covered by this warranty.

12. Charges incurred by delays, waiting time or operating restrictions that hinder the service technician’s ability to perform service are not

covered by warranty. This includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in this shipment was carefully inspected and packaged by skilled personnel before

leaving the factory. Upon acceptance of this shipment, the transportation company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any visible loss or damage is noted on the freight bill or express receipt, and that

the note of loss or damage is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY: Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is unnoticed until the merchandise is unpacked, notify the transportation company

or carrier immediately, and file “CONCEALED DAMAGE” claim with them. This should be done within fifteen(15) days from the

date the delivery was made to you. Be sure to retain the container for inspection.

Wells Manufacturing cannot assume liability for damage or loss incurred in transit. We will, however, at your request, supply you with the

necessary documents to support your claim.

Page 3

TABLE OF CONTENTS

Warranty Inside Cover

Specifications 1

Features and Operating Controls 2

Safety Procedures 4

Installation Instructions 5

Operating instruction 10

Maintenance Instruction

Filter Paper Installation 11

Filtering Oil 12

Discarding Used Oil 14

Cleaning the Fryer 15

Troubleshooting 17

Service Parts List 19

GENERAL SPECIFICATIONS

DIMENSIONS

Wide 15.62”

Deep 33.25”

High 40.0”

CAPACITIES Lb. Kg.

Cooking Oil (Liquid Shortening Only) 30 14

Chicken (fresh) 14 6

Chicken (frozen) 12 5

ELECTRICAL

Voltage Requirement 208 VAC

240 VAC

380-415 VAC Europe)

Note: Shipped from the factory 3 phase, field convertible to single phase

Power Consumption 9,000 Watts

(Europe) 9,300 Watts

Amperage

208V 1∅ 43.3 Amp

240V 1∅ 37.5 Amp

208V 3∅ 25.0 Amp per leg

240V 3∅ 21.7 Amp per leg

380-415V 3∅ L1 14.3 Amp, L2 & L3 13.0 Amp

1

Page 4

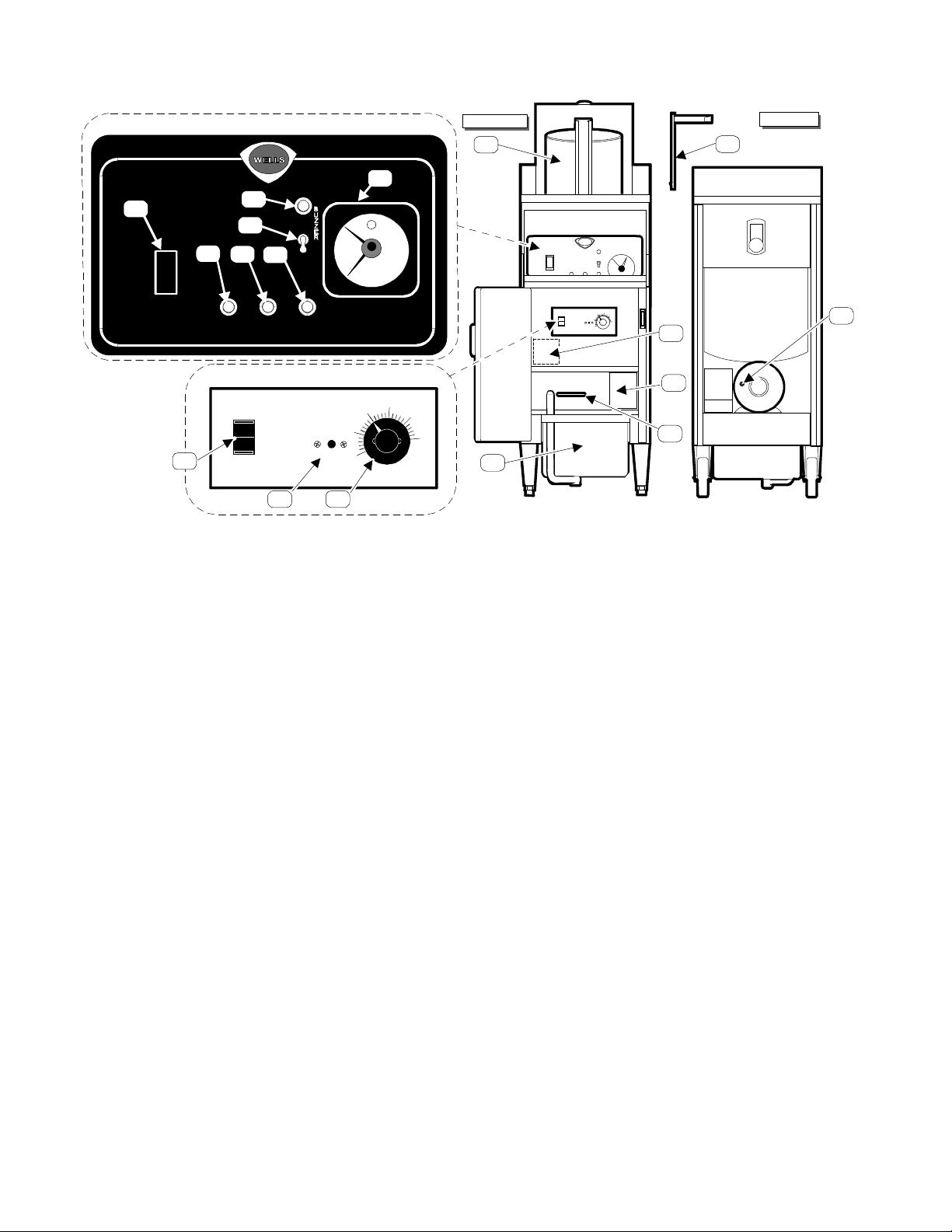

FEATURES and OPERATING CONTROLS

BACK VIEW

14

17

1112LOWER CONTROL PANEL

375

FRONT VIEW

15

13

16

UPPER CONTROL PANEL

5

2

POWER

FILTER

CAUTION

FRYER MUST BE OFF

BEFORE USING FILTER

6

7

3

4

COOKHEAT

THERMOSTAT

325

300

ON

250

HI-LIMIT

RESET

OFF

9

275

10

350

ºF

1

FRYER

OFF

FILTER

8

1. POWER SWITCH FRYER position turns ON the FRYER and POWER LIGHT ; and,

(FRYER-OFF-FILTER) turns OFF the FILTER PUMP.

Heating elements are energized and regulate to the temp. set on

the CONTROL THERMOSTA T (item 10).

OFF position turns OFF the FRYER and de-energizes the lower

panel FILTER PUMP SWITCH (item 8).

FILTER position energizes the lower FILTER PUMP SWITCH

(item 8) and turns OFF the FRYER.

2. POWER LIGHT (amber) When lit: indicates FRYER is energized.

3. HEAT LIGHT (amber) When lit: indicates HEATING ELEMENT is energized.

Light turns OFF when oil has reached temp preset on CONTROL

THERMOSTAT

4. COOK LIGHT (amber) When lit: indicates the TIMER (item 5) is ON and the BASKET

(item 15) is lowered.

5. TIMER Controls the LIFT CRADLE and the BUZZER. TIMER is started

by pressing the red button in the center of the knob. When the

red button is pressed the LIFT CRADLE lowers. The red

pointer on the dial shows time remaining. When TIMER

reaches “0”, BUZZER sounds and LIFT CRADLE raises.

6. BUZZER LIGHT (amber) When lit: indicates BUZZER SWITCH (item 7) is turned ON and

BUZZER CIRCUIT is active.

2

Page 5

7. BUZZER SWITCH Activates the BUZZER CIRCUIT. When turned ON and TIMER

has reached “0”, BUZZER will sound until BUZZER SWITCH is

turned OFF or TIMER is activated.

8. FILTER PUMP SWITCH ON causes the oil to be filtered / pumped back into the FRYPOT.

(ON - OFF) The POWER SWITCH (item 1) must be in the FILTER position for

the FILTER PUMP SWITCH to operate.

CAUTION: FIRE HAZARD / HOT OIL

THE HI-LIMIT THERMOSTAT IS A FIRE PROTECTION DEVICE.

If tripping persists, clean the space between the

hi-limit bulb and the element in order to enhance oil flow and facilitate reset.

Otherwise, contact your authorized Wells service agency for repairs.

DO NOT ATTEMPT TO BYPASS OR HOLD IN THE BUTTON OF THE

HI-LIMIT THERMOSTAT. A FIRE MAY RESULT.

9. HI-LIMIT THERMOSTAT Provides over-temperature protection by de-energizing the

HEATING ELEMENTS if the oil temperature exceeds the factoryset limit. RESET must be performed manually. Allow the oil to

cool below 300ºF (93ºC), then firmly press the red button on the

LOWER CONTROL PANEL until it resets (snaps).

10. TEMP. CONTROL Controls the oil temperature from 250ºF (121ºC) turned fully

THERMOSTAT counter-clockwise, to 375ºF (191ºC) fully clockwise.

11. DRAIN VALVE LEVER Opens and closes the DRAIN VALVE.

To OPEN, turn the handle counterclockwise (to vertical).

To CLOSE, turn the handle clockwise (to horizontal).

12. POWER OUTLET BOX Contains the electrical service connection terminal block.

13. OIL FILTER RESERVOIR Holds the filter screen, filter paper and filter paper holder.

14. FILTER PUMP MOTOR The FILTER PUMP MOTOR is equipped with an over-

RESET BUTTON heating protection device.

(located at the rear RESET must be performed manually. Allow the motor to

of the motor) cool for approx. 15 min., then press the red button.

15. BASKET Sits on the LIFT CRADLE and holds product to be cooked.

Raised and lowered by the LIFT CRADLE.

16. BASKET HANDLE Used to handle the BASKET when it is hot. REMOVE

FROM BASKET BEFORE ACTIVATING TIMER.

17. DRIP PAN Collects any liquids which accumulate on top of the fryer.

3

Page 6

SAFETY PROCEDURES

Knowledge of proper procedures is essential to the safe operation of electrically energized

equipment. In accordance with generally accepted product safety labeling guidelines for

potential hazards, the following signal words and symbols are used throughout this manual.

DANGER - Danger is used to indicate the presence of a hazard which will

DANGER

WARNING - Warning is used to indicate the presence of a hazard which can cause

personal injury and possibly death, or major property damage, in the event the statement is ignored.

CAUTION - Caution is used to indicate the presence of a hazard which will or can

cause minor personal injury, or property damage in the event the statement is ignored.

CAUTION - Used to indicate the presence of an electrical hazard which will or can

cause personal injury, or property damage in the event the statement is ignored.

cause severe personal injury, death, or substantial property damage in the

event the statement is ignored.

NOTE - Note is used to notify personnel of installation, operation or maintenance information

which is important, but not hazard related.

Hazard Communication Standard (HCS) - The procedures in this manual may include the use of chemical

products. These chemical products will be highlighted with bold face letters followed, by the abbreviation

(HCS). See the Hazard Communication Standard section of this manual for the appropriate Material Safety

Data Sheet(s).

FRYER PRECAUTIONS AND GENERAL INFORMATION

1. This fryer is intended for use to deep fry food products for human consumption. No other use

is recommended or authorized.

2. This fryer is intended for use in commercial establishments, where all operators are familiar with

the appliance use, limitations and associated hazards. Operating instructions and warnings must

be read and understood by all operators and users.

3. Your WELLS fryer is equipped with an oil filtration system, which is designed to filter hot liquid

shortening ONLY. Water, cleaning agents or other liquids will damage the FILTER PUMP.

4. This piece of equipment is made in the USA and has American sizes on hardware.

5. Any trouble shooting guides, component views or parts lists included in this manual are for general

reference only, and are intended for use by qualified technical personnel.

6. This manual should be considered a permanant part of this appliance. This manual and all

supplied instructions, diagrams, schematics, parts break downs, notices and labels must remain

with the appliance if it is sold or moved to another location.

4

Page 7

INSTALLATION INSTRUCTIONS

A. UNPACKING AND INSPECTION

1. Carefully remove the FRYER from the carton. Remove all protective plastic film, packaging

materials and accessories from the FRYER and the FILTER RESERVOIR before connecting

electrical power to the FRYER or otherwise performing any installation procedures.

NOTE: DO NOT discard the CARTON and other PACKAGING MATERIAL until you have

inspected the fryer for hidden damage and tested it for PROPER OPERATION.

Refer to SHIPPING DAMAGE CLAIM PROCEDURE on the inside front cover of this manual.

2. Read all instructions in this manual carefully before starting installation of this fryer. READ

AND UNDERST AND ALL LABELS AND DIAGRAMS ATTACHED TO THE FRYER.

3. Carefully account for all components and accessories before discarding packing materials.

Store the accessories in a convenient place for later use:

COMPONENTS

1 ea. CONDENSATE DRIP TRAY

1 ea. FILTER RESERVOIR

1 ea. FILTER SCREEN

1 ea. FILTER PAPER HOLDER

4 ea. OIL FILTER SUCTION TUBE O-RING

1 ea. BASKET

1 ea. BASKET HANDLE

ACCESSORIES

1 ea. LITERATURE PACKAGE

1 pk. FILTER PAPER

1 pk. FILTER POWDER

1 ea. HIGH TEMPERATURE BRUSH

1 ea. CLEANOUT DOWEL (WOOD ROD)

B. SERVICE TECHNICIAN INSTALLATION NOTES

1. Installation and start up should be performed by an authorized installation company.

Installer must complete the WARRANTY REGISTRATION / FRYER CHECKOUT form, and

record fryer installation particulars on the CUSTOMER SERVICE DATA form on page 19 of

this manual.

2. Verify that this FRYER installation is in compliance with the specifications listed in this manual

and with local code requirements. THIS IS THE RESPONSIBILITY OF THE INST ALLER.

3. Certain codes require fryers to be restrained with a TETHER or other RESTRAINT DEVICE.

It is the RESPONSIBILITY OF THE INSTALLER to check with the AUTHORITY HA VING

JURISDICTION, in order to ascertain the applicability of this requirement to THIS SPECIFIC

FRYER INST ALLATION.

5

Page 8

90º CONDUIT

C. EQUIPMENT SET-UP

1. Setup the FRYER only on a firm, level, non-combustable surface. Verify local codes for

requirements. Concrete, tile, terrazzo or metal surfaces are recommended. Metal over

combustible material may not meet code for non-combustible surfaces.

2. LEVELING: Verify that the fryer sits firmly ON BOTH CASTERS AND ON BOTH LEGS.

With a spirit level, check that the fryer is level front-to-back and side-to-side. With the

adjustable legs, adjust as required to level the fryer.

D. ELECTRICAL INSTALLATION

DANGER

ELECTRICAL SHOCK HAZARD

ELECTRICAL CONNECTIONS MUST BE MADE BY A LICENSED

ELECTRICIAN

Electrical shock will cause death or serious injury.

1. Refer to the nameplate on the front of the fryer. Verify the ELECTRICAL SERVICE POWER.

Voltage and phase must match the nameplate specifications, and available electrical service

amperage must meet or exceed the specifications listed on page 1.

Wiring must be no less than12 ga. solid copper wire, rated for at least 75ºC.

NOTE: Wire gauge, insulation type and temperature rating , as well as type, size and

construction of conduit, must meet or exceed applicable specifications of local codes and

of the National Electrical Code.

2. Fryers are shipped from the factory wired for 3Ø electrical service. Refer to theThree-Phase

Wiring Diagram included with this fryer, and verify that field wiring conforms to this diagram .

NOTE: FRYERS are FIELD CONVERTIBLE to 1Ø. If single-phase operation is required,

refer to the 3-phase to 1-phase Instructions included with the FRYER, and verify that both

internal wiring and field wiring conform to the included single-phase wiring diagram .

IMPORTANT: Field wiring must be routed and

secured away from the FRYPOT, TUBING

and FIL TER PUMP AND MOTOR.

NOTE: Field wiring must allow access to the

rear of the FRYER for cleaning and for access

to the oil filter pump motor RESET BUTTON.

FILTER

PUMP &

MOTOR

POWER

CORD

FRYPOT

FITTING

6

Page 9

E. EQUIPMENT PREPARATION PRIOR TO OPERATION

CAUTION:BURN HAZARD / HOT WATER SPLATTER

TURN THERMOSTAT TO LOWEST TEMPERATURE SETTING

(FULLY COUNTERCLOCKWISE).

USE ONLY LOW-FOAMING COMMERCIAL FRYER CLEANER.

CAREFULLY FOLLOW CLEANSER INSTRUCTIONS AND WARNINGS.

DO NOT LEAVE FRYER UNATTENDED WHILE BOILING OUT THE KETTLE.

WHEN WATER FOAMING OCCURS, BE PREPARED TO TURN THE POWER SWITCH OFF.

Boiling water will splatter and could result in serious injury.

1. CLEANING: Prior to leaving the factory, the fryer is tested for proper operation with peanut oil.

After testing is complete, the oil is removed but oil residue remains. Therefore, it is necessary

to clean the frypot before filling it with fresh oil.

NOTE: Use a LOW-FOAMING COMMERCIAL FRYER CLEANSER ONLY.

a. Turn the TEMPERATURE CONTROL THERMOSTAT (item 10) to the lowest

temperature position (fully counter-clockwise).

b. Turn the DRAIN VALVE LEVER to the CLOSED (horizontal) position and fill the

FRYPOT with 4 gallons of cold water.

c. Press the POWER SWITCH to the FRYER position.

d. When the water to come to a full boil, press the POWER SWITCH to OFF. When the

boiling ceases, slowly add, and stir-in, the LOW FOAMING COMMERCIAL FRYER

CLEANSER. Using the HIGH TEMPERATURE BRUSH supplied with the fryer, stir

until the cleanser is completely mixed with the water.

e. Press the POWER SWITCH to FRYER. When the water begins to boil, press it to

OFF . When the boiling subsides, again press the POWER SWITCH to FRYER.

Repeat this procedure (i.e. FRYER-boil-OFF) continuously for five (5) minutes.

f. Press the POWER SWITCH OFF. Allow the solution to cool to 120ºF or less.

g. Place a suitable container under the DRAIN VALVE. Turn the DRAIN VALVE LEVER to

the OPEN (vertical) position to drain the cleaning solution. Recommend draining no

more than 4” of solution at a time into the container, to prevent splashing and spilling.

Dispose of the used solution as required by local ordinances.

h. Rinse the FRYPOT with clean water. Dry with a clean non-abrasive cloth.

2. Install the LIFT CRADLE onto

the CRADLE LIFT ROD.

Note the oil level indicator.

OIL LEVEL INDICATOR

MAX (COLD)

30 LB. 13KG OIL LEVEL

MIN (HOT)

7

CRADLE PIVOT

CRADLE

LIFT ROD

CRADLE

LIFT

Page 10

3. Install the SUCTION TUBE O-RING, FILTER SCREEN, FILTER PAPER and FILTER PAPER

FILTER

HOLDER

(clip inserts into

RESERVOIR

RESERVOIR

CROSS-SECTION VIEW

“O” RING

HOLDER into the FILTER RESERVOIR.

Install the assembled FILTER RESERVOIR into the fryer.

PAPER

FILTER

PAPER

ASSEMBLY

The O-RING for the filter reservoir

suction tube, and up to three spare

O-RINGS, are stored as shown:

FILTER

SCREEN

drain opening)

FILTER

STORAGE FOR 3

SPARE “O” RINGS

“O” RING IN

“O” RING GROOVE

4. Install the DRIP PAN (item 17) into the mounting bracket behind the fryer door at the lower right

front of the fryer.

Note: Failure to install the DRIP PAN will allow the grease, moisture and other liquids that

accumulate on the fryer top panel to drip onto the floor, creating a SLIPPING HAZARD.

SLIPPING AND FALLING HAZARD / SPILLED OIL

DO NOT OPERATE UNLESS THE DRIP PAN IS INSTALLED.

Oil will drip onto the floor and falls will result. Death or serious injury may

result from slipping and falling in spilled oil.

5. Close the DRAIN VALVE LEVER (item 11).

SLIPPING & FALLING HAZARD / SPILLED OIL

CLOSE THE DRAIN VALVE BEFORE FILLING WITH OIL.

IF THE DRAIN VALVE IS OPEN, OIL POURED INTO THE KETTLE WILL

DRAIN INTO THE FILTER RESERVOIR OR ONTO THE FLOOR.

Death or serious injury may result from falls caused by slipping in oil

Oil spills may occur.

8

Page 11

6. Lower the LIFT CRADLE. Fill the FRYPOT to the COLD (MAX) line on the LIFT CRADLE

RESET

FRYER MUST BE OFF

BEFORE USING FILTER

DRAIN

VALVE

FILTER

RESERVOIR

DRAIN

VALVE

LEVER

SET COOK

TEMPERATURE

LOWER CONTROL PANEL

with room temperature commercial-quality LIQUID SHORTENING. This requires 30lbs. of oil.

NOTE: This fryer is designed for LIQUID SHORTENING ONLY. DO NOT USE SOLID

SHORTENING OR LARD. Solid shortening will solidify in the filter reservoir and filter

pump. This condition will render the filter system inoperable. Repairs caused by the use

of anything other than liquid shortening are not covered under warranty.

7. Check operation of FRYER and all CONTROLS.

UPPER CONTROL PANEL

FRYER

OFF

FILTER

POWER

FILTER

ON

SET COOK

TIME

CAUTION

OFF

START

COOKHEAT

COOK CYCLE

THERMOSTAT

325

300

350

250

HI-LIMIT

275

375

ºF

RESET

HI-LIMIT

FILTER PUMP SWITCH

POWER () SWITCHFRYER - OFF - FILTER

DRIP

PAN

8. DETERMINE MAXIMUM LOAD WEIGHT: For operational safety, it is very important to

determine the maximum load weight for the specific operation. This can be accomplished by

starting out with small loads and gradually increasing to the largest load size which will allow a

cook cycle to be completed without oil foaming out of the FRYPOT.

See OPERATING INSTRUCTIONS, page 10.

POTENTIAL FOR OIL SPLATTER

The weight of product which can be safely cooked in this fryer will vary

with oil level, product moisture content, oil temperature, and other various

conditions.

FAILURE TO OBSERVE THIS WARNING WILL RESULT IN HOT OIL

RELEASE FROM THE FRYER.

HOT OIL WILL CAUSE SEVERE BURNS ON CONTACT.

9

Page 12

OPERATING INSTRUCTIONS

A. PRE-HEATING THE FRYER

1. Make sure FRYPOT is filled with cooking oil to the 30 LB. OIL level.

2. Open the door and set the THERMOSTAT (item 10) to the desired cooking temperature.

CLOSE THE DOOR.

3. Set the POWER SWITCH (item 1) to the FRYER position. The POWER LIGHT (item 2) and

HEAT LIGHT (item 3) will turn on. The HEAT LIGHT will cycle on and off with the HEATING

ELEMENTS. When the HEAT LIGHT first goes off, the fryer is ready to cook the product.

B. SET THE COOK TIMER AND LOAD PRODUCT

CAUTION:

BURN HAZARD / HOT OIL SPLATTER

HOT OIL CAN CAUSE SERIOUS BURNS ON CONTACT.

WEAR PROTECTIVE CLOTHING WHEN COOKING.

1. Set the TIMER (item 5) to the desired cooking time.

2. FROZEN PRODUCT: Load frozen product into the BASKET. Using the BASKET HANDLE

(item 16) set the BASKET on the LIFT CRADLE. REMOVE THE HANDLE. Press the red

button on the TIMER to lower the BASKET into the FRYPOT.

3. FRESH PRODUCT: Using the BASKET HANDLE, Set the BASKET on the LIFT CRADLE.

REMOVE THE HANDLE. Press the red button on the TIMER to lower the BASKET into the

FRYPOT. Manually drop each piece of fresh product into the hot oil, just above the oil level to

minimize splattering. ALWAYS USE PROTECTIVE EQUIPMENT, SUCH AS INSULATED

GLOVES, TO PROTECT AGAINST HOT OIL BURNS.

C. COOK CYCLE AND BUZZER

1. When an audible alarm is desired at the end of the cook cycle, turn the BUZZER SWITCH

(item 7) ON afer the TIMER has been started. The BUZZER LIGHT (item 6) will turn ON.

Note: If the BUZZER SWITCH is turned ON before the BASKET is lowered the BUZZER will

sound until the BASKET is down.

2. At the end of the cook cycle, the BASKET will raise and the BUZZER will sound until the

BUZZER SWITCH is turned OFF, or until the next cook cycle is started.

5. Use the BASKET HANDLE (item 16) to remove the BASKET of cooked product from the

LIFT CRADLE. Serve or dispense cooked product as required.

10

Page 13

MAINTENANCE INSTRUCTIONS

A. FILTER PAPER INSTALLATION

BURN HAZARD / HOT OIL SPLATTER

DO NOT REMOVE FILTER RESERVOIR WHEN IT CONTAINS HOT OIL.

Contact with hot oil can cause death or serious injury.

PROTECTIVE CLOTHING AND GLOVES MUST BE WORN DURING

DO NOT REMOVE THE FILTER RESERVOIR IF IT IS HOT.

WEAR INSULA TED GLOVES, OR ALLOW IT TIME TO COOL.

The hot oil will quickly heat the reservoir. Serious burns could result from

touching the hot filter reservoir with bare hands

DANGER

THE FILTERING PROCESS.

BURN HAZARD

Replace FILTER P APER after each day’s filtration, or as needed to return oil promptly to the kettle.

1. Open the FRYER DOOR and slide the FILTER RESERVOIR forward to remove it.

2. Remove the FILTER PAPER HOLDER, used FILTER PAPER and FILTER SCREEN.

Discard the used filter paper and make sure the filter reservoir, filter screen and filter paper

holder are clean and dry. Crumbs and other debris left in the filter reservoir can keep the filter

paper from sealing properly to the filter reservoir bottom. This will cause incomplete filtration.

3. Install the FILTER SCREEN in the FILTER RESERVOIR with the spring clip on the filter

screen pressed firmly into the filter reservoir drain hole, and aligned parallel to the sides of the

reservoir. See diagram, page 8.

4. Place a new sheet of FILTER PAPER on the FILTER RESERVOIR with the edges of the paper

evenly overhanging the filter reservoir flanges.

5. Center the FILTER PAPER HOLDER over the FILTER PAPER and press it firmly into the

FILTER RESERVOIR. Make sure the filter paper holder rests firmly on the bottom of the filter

reservoir, with the filter paper protruding evenly up all sides.

6. Inspect the “O” RING on the FILTER SUCTION TUBE for damage. Replace the “O” ring if it

is cut, cracked or scuffed.

7. Install the filter reservoir into the fryer. Make sure the “O” ring closest to the end of the

SUCTION TUBE is firmly seated in the SUCTION LINE RECEPT ACLE.

11

Page 14

B. FILTERING OIL

IMPORTANT: Filtering the cooking oil helps to ensure the quality of the food product.

Careful observation of the finished food product will help you determine your optimal filtering

frequency. (Example: filter the oil after each six loads of fresh breaded product.)

NOTE: Your Wells fryer filtration system is designed to filter hot liquid shortening ONLY.

Water, cleaning agents or other liquids will damage the FILTER PUMP.

Oil should be at 300ºF (149ºC). DO NOT attempt to filter cold oil.

DO NOT store oil in the FILTER RESERVOIR overnight, or other extended period.

DO NOT attempt to pump oil less than 300ºF. The filter pump will not pump cold oil through

the filter paper. Pumping cold oil will result in premature failure of the FIL TER PUMP.

CAUTION:

BURN HAZARD / HOT OIL SPLATTER

PROTECTIVE CLOTHING AND GLOVES MUST BE WORN DURING

THE FILTERING PROCESS.

Hot oil may splatter, which could result in serious injury.

1. Press the POWER SWITCH (item 1) to the FILTER position. The heating elements will

de-energize.

CAUTION: BURN HAZARD

THE FIL TER RESER VOIR MAY BE HOT.

WEAR INSULA TED GLOVES OR ALLOW THE FILTER

RESERVOIR TO COOL BEFORE TOUCHING IT.

2. Remove and examine the FILTER RESERVOIR. Verify that a serviceable sheet of FILTER

PAPER is properly installed, and that the SUCTION TUBE O-RING is in place and in good

condition. Install the FILTER RESERVOIR ASSEMBLY into the FRYER, making sure the

SUCTION TUBE is properly seated in the SUCTION RECEPTACLE.

3. Press the FILTER PUMP SWITCH (item 6) to the ON position to start the FILTER PUMP.

4. Slowly rotate the DRAIN VALVE LEVER (item 11) to the OPEN( vertical) position.

The oil will drain from the kettle, and the filter pump will circulate the oil through the filter paper,

returning it to the kettle.

IMPORTANT: Do not leave the FRYER unattended during the filtering process.

Continuously monitor the oil level in the reservoir to avoid overflowing the reservoir

and spilling oil on the floor.

12

Page 15

5. FILTER POWDER absorbs acids and other contaminants in the cooking oil, allowing the

cooking oil to be used for a longer period of time before it must be replaced. Carefully and

slowly add the contents of one package of FILTER POWDER to the oil in the FRYPOT.

Sprinkle the FILTER POWDER onto the surface of the cooking oil at the point where it is being

drawn down the drain and into the FILTER RESERVOIR.

BURN HAZARD

PROTECTIVE CLOTHING AND INSULATED GLOVES MUST BE WORN

WHEN CLEANING THE KETTLE WITH THE HI-TEMP BRUSH AND

WHEN UNCLOGGING THE DRAIN WITH THE WOOD CLEANOUT DOWEL.

The kettle will be hot and hot oil may splatter. Serious injury may result.

6. Using the high temperature brush that was supplied with the fryer, brush down the kettle sides

and bottom to loosen crumbs and flush them from the fryer.

If the crumb build-up in the kettle clogs the kettle drain, unplug the drain by using the WOOD

CLEANOUT DOWEL that was supplied with the fryer. Unplug the drain by pushing the dowel

down throughthe drain hole in the front center of the kettle.

7. When filtering is complete, rotate the DRAIN VALVE LEVER to the SHUT (horizontal) position.

8. When bubbles begin to appear in the oil being pumped into the frypot, wait approximately

fifteen (15) seconds. Then, press the FILTER PUMP SWITCH to the OFF position.

IMPORTANT: VERIFY THAT ALL OIL HAS BEEN RETURNED TO THE KETTLE AT

THE END OF THE FILTERING CYCLE.

9. Press the POWER SWITCH to either:

a. the FRYER position (to resume cooking); or,

b. the OFF position (to service the filter or shut down the fryer)

Service the FILTER and Replace FILTER P APER after each day’s filtration, or as needed to return

oil promptly to the kettle:

1. Allow the FILTER RESERVOIR to cool. Remove the FILTER RESERVOIR and disassemble.

2. Dispose of used FILTER PAPER as required by local ordinances.

3. Clean the FILTER RESERVOIR, FILTER SCREEN and FILTER PAPER HOLDER using

warm water and mild soap or detergent, or clean in a dishwasher. Reassemble FILTER

RESERVOIR using a clean sheet of FILTER PAPER.

NOTE: Crumbs and other debris in the bottom of the FILTER RESERVOIR will prevent

the FILTER PAPER from sealing properly, resulting in incomplete filtration.

13

Page 16

D. DISCARDING USED OIL

IMPORTANT NOTE: The following instructions for discarding used oil from the fryer

may be disregarded if you use a WELLS MOBILE CADDY WAOC-1 (part no. 22470).

The WAOC-1 is a manual oil pump/removal system which allows you to pump the used

oil directly into the caddy, and to then pump the used oil into your oil disposal container

by simply reversing the pump rotation.

REMEMBER: The Mobile Oil Caddy is designed to handle COLD oil. Always, and without

fail, allow the oil to cool to 120ºF or less prior to pumping the oil into the OIL CADDY.

HOT OIL WILL BURN YOU!

DANGER

OIL MUST COOL TO 120°F (49°C) OR COOLER

BEFORE DRAINING OIL FROM THE FRYER FOR REMOVAL.

Normal operating temperature of the fryer is 375°F (191°C).

Death or serious injury will result from contact with hot oil.

1. Press the POWER SWITCH to the OFF position and allow the oil to cool to 120ºF (49ºC), or

less, before attempting to drain the oil from the fryer.

2. With a suitable METAL container under the drain valve, slowly rotate the DRAIN VALVE

LEVER to theOPEN( vertical) position. Fill the container until it has no more than 4” of oil in it.

BURN HAZARD / HOT OIL

SLIPPING & FALLING HAZARD / SPILLED OIL

DO NOT USE THE FILTER RESERVOIR TO DISCARD OIL.

DO NOT FILL DISPOSAL CONTAINER MORE THAN 1/2 FULL.

DO NOT LEAVE FRYER UNATTENDED WHEN DRAINING OIL.

Oil spills may occur.

Death or serious injury may result from falls caused by slipping in oil

3. Close the drain valve by rotating the DRAIN VALVE LEVER to the horizontal position.

4. Carefully remove the container from under the fryer. Dump the used oil into your WASTE OIL

CONTAINER. Repeat the process until the kettle is empty.

BURN HAZARD - FILTER RESERVOIR

WHEN REMOVING THE FILTER RESERVOIR AFTER FIL TERING OIL,

WEAR INSULA TED GLOVES, OR ALLOW IT TIME TO COOL.

The hot oil will quickly heat the reservoir. Serious burns could result from

touching the hot filter reservoir with bare hands

5. Be sure the DRAIN VALVE LEVER is returned to the CLOSED position when finished.

14

Page 17

E. CLEANING THE FRYER

CLEANING THE KETTLE: HOT BOIL-OUT METHOD

SLIPPING & FALLING HAZARD / SPILLED OIL

DO NOT STORE OIL IN THE FILTER RESERVOIR WHILE

CLEANING THE KETTLE. IF CLEANING FLUID IS ACCIDENTALLY

DRAINED INTO THE FILTER RESERVOIR, OIL WILL SPILL ON THE

Death or serious injury may result from falls caused by slipping in oil

NOTE: Use a LOW-FOAMING COMMERCIAL FRYER CLEANSER ONLY.

1. Press the POWER SWITCH to the OFF position.

2. Discard old oil as detailed in section D, page 14.

3. Fill the with 4 gallons of cold water.

FLOOR.

4. With the FRYPOT COVER open, press the POWER SWITCH to the FRYER position.

5. Allow the water to come to a full boil, then press the POWER SWITCH to OFF. When the

boiling ceases, slowly add, and stir-in, the LOW FOAMING COMMERCIAL FRYER

CLEANSER. Stir until the cleanser is completely mixed with the water using the HIGH

TEMPERATURE BRUSH supplied with the fryer.

CAUTION:

BURN HAZARD / HOT WATER SPLATTER

TURN THERMOSTAT TO LOWEST TEMPERATURE SETTING

(FULLY COUNTERCLOCKWISE).

USE ONLY LOW-FOAMING COMMERCIAL FRYER CLEANER.

CAREFULLY FOLLOW CLEANSER INSTRUCTIONS AND WARNINGS.

DO NOT LEAVE FRYER UNATTENDED WHILE BOILING OUT THE KETTLE.

WHEN WATER FOAMING OCCURS, BE PREPARED TO TURN THE POWER SWITCH “OFF”.

Boiling water will splatter and could result in serious injury.

5. Press the POWER SWITCH to FRYER. When the water begins to boil, press it to OFF .

When the boiling subsides, again press the POWER SWITCH to FRYER. Repeat this

procedure (i.e. FRYER-boil-OFF) continuously for five (5) minutes.

6. With the POWER SWITCH OFF, allow the hot solution to set for thirty (30) minutes.

15

Page 18

7. With the POWER SWITCH in the OFF position, drain the cleaning solution.

NOTE: Allow the solution to cool to 120ºF (49ºC) or less for safe handling. Using a suitable

METAL container, drain the cleaning solution until the container is no more than one-half full.

Always safely dispose of used cleaning solution as required by local ordinances.

8. Rinse the kettle thoroughly with warm, clean water. Drain into the same container as used to

dispose of the cleaning solution.

IMPORTANT: NEVER turn the FILTER PUMP ON with anything other than shortening in the

filter reservoir. Water can cause severe oil splatter, as well as damage to the pump and

contamination of the cooking oil.

CLEANING THE RESERVOIR

CLEAN THE RESERVOIR ONL Y WHEN EMPTY. The reservoir should be cleaned, and the FILTER

PAPER replaced, after each day’s filtration, or as needed to return oil promptly to the kettle.

1. Remove the empty FILTER RESERVOIR from the fryer. Discard the used FILTER P APER.

BURN HAZARD - FILTER RESERVOIR

WHEN REMOVING THE FILTER RESERVOIR AFTER FIL TERING OIL,

WEAR INSULA TED GLOVES, OR ALLOW IT TIME TO COOL.

The hot oil will quickly heat the reservoir. Serious burns could result from

touching the hot filter reservoir with bare hands

2. Wash the FILTER PAPER HOLDER, FILTER SCREEN, and FILTER RESERVOIR in the

dishwasher, or in the sink, using mild soap or detergent.

3. Rinse thoroughly with clean warm water to remove all residue. Be sure to flush out the FILTER

RESERVOIR SUCTION TUBE.

4. Dry all parts thoroughly with a non-abrasive cloth.

5. Assemble the RESERVOIR. Use a fresh sheet of filter paper. Refer to section B, page 10.

DAILY CLEANING OF FRYER

1. FRYER EXTERIOR: As required, wash the exterior of the fryer with warm water, mild soap or

detergent, and a clean, non-abrasive cloth. Dry with a clean, non-abrasive cloth.

16

Page 19

TROUBLESHOOTING

NOTE: Any servicing or adjustment which requires the removal of any cover or other

protective panel must be performed by a Wells Mfg. Authorized Service Agency.

A. PROBLEM: FRYER WILL NOT HEAT

1. If: POWER LIGHT (item 2 ) NOT ON. Check the SERVICE POWER BREAKER. Reset if

TRIPPED. If breaker continues to trip, contact a licensed electrician to repair field wiring (if

that is the cause), or contact a Wells Mfg. Authorized Service Agency for repairs.

2. If: POWER LIGHT (item 2 ) NOT ON. Check the HI-LIMIT THERMOSTAT (item 7). Reset

by pressing the HI LIMIT RESET button on the LOWER CONTROL PANEL until it “clicks” .

CAUTION: FIRE HAZARD / HOT OIL

THE HI-LIMIT THERMOSTAT IS A FIRE PROTECTION DEVICE.

If tripping persists, contact your authorized Wells service agency for repairs.

DO NOT ATTEMPT TO BYPASS OR HOLD IN THE BUTTON OF THE

HI-LIMIT THERMOSTA T. A FIRE MAY RESULT.

3. If: POWER LIGHT (item 2 ) ON / HEAT LIGHT (item 3) NOTON. Check setting of

TEMPERATURE CONTROL THERMOSTAT (item 8). If turning the thermostat fully clockwise

(i.e. to a higher temperature )does not turn the HEAT LIGHT ON, and also cause the oil to

heat, or if the CONTROL THERMOSTAT calibration is significantly incorrect, contact a Wells

Mfg. Authorized Service Agency for repairs.

4. If: POWER LIGHT (item 2 )ON / HEAT LIGHT (item 3) ON. Probable cause is a damaged

internal component. Contact a Wells Mfg. Authorized Service Agency for repairs.

B. PROBLEM: CRADLE LIFT WILL NOT LOWER or

CRADLE LIFT WILL NOT RAISE

1. Verify that the TIMER is set time other than 0. When the red button in the center of the

timer is pressed, the cradle lift should lower.

2. When the TIMER reaches 0, the CRADLE LIFT should raise.

3. If the CRADLE LIFT does not behave as described above, probable cause is an

internal adjustment, or one or moredamaged internal components.

Contact a Wells Mfg. Authorized Service Agency for repairs.

17

Page 20

C. PROBLEM: FILTER PUMP WILL NOT RUN

1. Verify that the POWER SWITCH (item 1, upper control panel) is in the FILTER position, and

that the FILTER PUMP SWITCH (item 6, lower control panel) is in the ON position.

2. Press the red RESET button (item 9) on the FILTER PUMP MOTOR, accessible on the back

of the fryer. If the pump motor continues to trip out, or if no other cause is apparent for the

pump’s failure to run, contact a Wells Mfg. Authorized Service Agency for repairs.

D. PROBLEM: FILTER RESERVOIR OVERFLOWS DURING FILTER CYCLE

CAUTION:

BURN HAZARD / HOT OIL SPLASH / SPLATTER

PROTECTIVE CLOTHING AND GLOVES MUST BE WORN

WHENEVER SERVICING THE FILTER DURING THE FILTERING

CYCLE

Hot oil may splatter, which could result in serious injury.

1. The oil level in the reservoir must be constantly monitored during the filter cycle, and the flow

controlled by means of the DRAIN VALVE LEVER (item 11).

2. The surface of the FILTER PAPER may become clogged with crumbs or other debris. If this

happens, turn OFF the DRAIN VALVE LEVER (item 11); when bubbles begin appearing in the

oil returned to the FRYPOT, turn OFF the FILTER PUMP SWITCH (item 6).

Carefully slide the FILTER RESERVOIR out approximately 6”. Gently run the end of the

WOOD CLEANOUT DOWEL across the surface of the FILTER PAPER and scrape the

crumbs toward the edges. Carefully slide the FILTER RESERVOIR back into place, making

sure the SUCTION TUBE is properly seated in the RECEPTACLE.

Resume filtering, but remember to replace the FILTER PAPER before the next filtering cycle.

E. PROBLEM: FILTER PUMP WON’T PUMP, or PUMPS AIR DURING FILTERING

BUBBLES in the oil while filtering, and/or a failure of the pump to achieve or maintain prime

indicate that air is entering the suction side of the pump.

1. Examine the SUCTION TUBE O-RING. A damaged or improperly seated O-RING can cause

the FILTER PUMP to lose suction. This will result in a failure to filter the oil, and in a failure of

the oil to be returned to the FRYPOT.

Replace SUCTION TUBE O-RING if it is missing, cracked, distorted or scuffed with one of the

spare O-rings.

2. Verify that he SUCTION TUBE is fully seated in the SUCTION LINE RECEPTACLE.

3. Internal component damage. Contact a Wells Mfg. Authorized Service Agency.

18

Page 21

SERVICE PARTS LIST

IMPORTANT: Use only factory authorized service parts and replacement filters.

For factory authorized service, or to order factory authorized replacement parts, contact your

WELLS AUTHORIZED SERVICE AGENCY, or call:

Wells Manufacturing Company

2 Erik Circle, P. O. Box 280

Verdi, NV 89439

phone: (775) 345-0444 ask for Service Department fax: (888) 492-2783

Service Parts Department can supply you with the name / telephone number of the WELLS

AUTHORIZED SERVICE AGENCY nearest you.

FRYER ACCESSORIES PART#

BRUSH, HEA TING ELEMENT CLEANING 21647

FLAVOR SA VER OIL FIL TER POWDER (45 pk) 22410

WAOC-1 MOBILE OIL DISPOSAL CADDY 22470

PADDLE, STIRRING CHICKEN 22515

BRUSH, FRYPOT CLEANING 22516

HANDLE, BASKET ASSY 500249

BASKET ASSEMBLY W/HANDLE 500254

NORMAL MAINTENANCE ITEMS PART #

FILTER P APER, 30-SERIES FRYER (100 pk) 21711

“O” RING, SUCTION TUBE 66474

DOWEL, CLEANING 69752

CUSTOMER SERVICE DATA

please have this information available if calling for service

RESTAURANT _____________________________ LOCA TION _______________

INSTALLATION DA TE ________________________ TECHNICIAN _____________

SERVICE COMP ANY __________________________________________________

ADDRESS ___________________________ ST ATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. ______________________________________________

EQUIPMENT SERIAL NO. ______________________________________________

VOLTAGE: (check one) 120V 208V 240V

19

Page 22

WELLS MANUFACTURING COMPANY

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

Customer Service (775) 345-0444 Ext. 502

fax: (775) 345-0569

www.wellsbloomfield.com

Loading...

Loading...