Page 1

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 800-264-7827

www.wells-mfg.com

OWNERS MANUAL

WAFFLE

BAKER

MODELS

WB2WHNTB

213

Includes

INSTALLATION

USE & CARE

EXPLODED VIEW

PARTS LIST

WIRING DIAGRAM

Model WB2WHNTB

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

p/n 2M-Z19604 Rev. E 06/2019

Page 2

LIMITED WARRANTY STATEMENT

LIMITED EQUIPMENT WARRANTY

Wells Manufacturing warranties new products to be

free from defects in material and/or workmanship

for a period of one [1] year from the date of original

installation, except as noted below. Defects that occur

as a result of normal use, within the time period and

limitations defined in this warranty, will at Wells’

discretion have the parts replaced or repaired by Wells

or a Wells-authorized service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be

performed by a Wells authorized service agency. Wells

will not be responsible for charges incurred or service

performed by non-authorized repair agencies. In all

cases, the nearest Wells-authorized service agency

must be used. Wells will be responsible for normal

labor charges incurred in the repair or replacement

of a warrantied product within 50 miles (80.5 km)

of an authorized service agency. Time and expense

charges for anything beyond that distance will be

the responsibility of the owner. All labor will need

to be performed during regular service hours. Any

overtime premium will be charged to the owner. For all

shipments outside the U.S.A. and Canada, please see

the International Warranty for specific details. It is the

responsibility of the owner to inspect and report any

shipping damage claims, hidden or otherwise, promptly

following delivery. No mileage or travel charges will be

honored on any equipment that is deemed portable. In

general, equipment with a cord and plug weighing less

than 50 lb. (22.7 kg) is considered portable and should

be taken or shipped to the closest authorized service

agency, transportation prepaid.

CONTACT

Should you require any assistance regarding the

operation or maintenance of any Wells equipment;

write, phone, fax or email our service department. In all

correspondence mention the model number and serial

number of your unit, as well as the voltage or type of

gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central

Standard Time (CST)

Telephone: (800)-264-7827

Fax: (314)-781-2714

Email: Customerservice@star-mfg.com

www.wells-mfg.com

WARRANTY EXCLUSIONS

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been used, cleaned, maintained,

or installed in accordance with the directions published in the

appropriate installation sheet and/or owner’s manual as well

as national and local codes, including incorrect gas, electrical,

or water connection. Lang is not liable for any unit which has

been mishandled, abused, misapplied, subjected to chlorides,

harsh chemicals, or caustic cleaners, damaged from exposure

to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have

an altered or missing serial number.

• Installation, labor, and job checkouts, calibration of heat

controls, air and gas burner/bypass/pilot adjustments, gas

or electrical system checks, voltage and phase conversions,

cleaning of equipment, or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety

controls, or reset buttons.

• Replacement of broken or damaged glass components,

quartz heating elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers

and hotplates, including but not limited to burners, grates,

and radiants.

• Any labor charges incurred by delays, waiting time, or operating restrictions that hinder a service technician’s ability to

perform service.

• Replacement of items subject to normal wear or items that

can easily be replaced during a daily cleaning routine, such as

but not limited to knobs, bulbs, fuses, quartz heating elements, baskets, racks, and grease drawers.

• Components that should be replaced when damaged or

worn, but have been field-repaired instead [eg. field-welded

fry pots]

• Any loss of business or profits.

ADDITIONAL WARRANTIES

• Specific/chain specific versions may also have additional

and/or extended warranties.

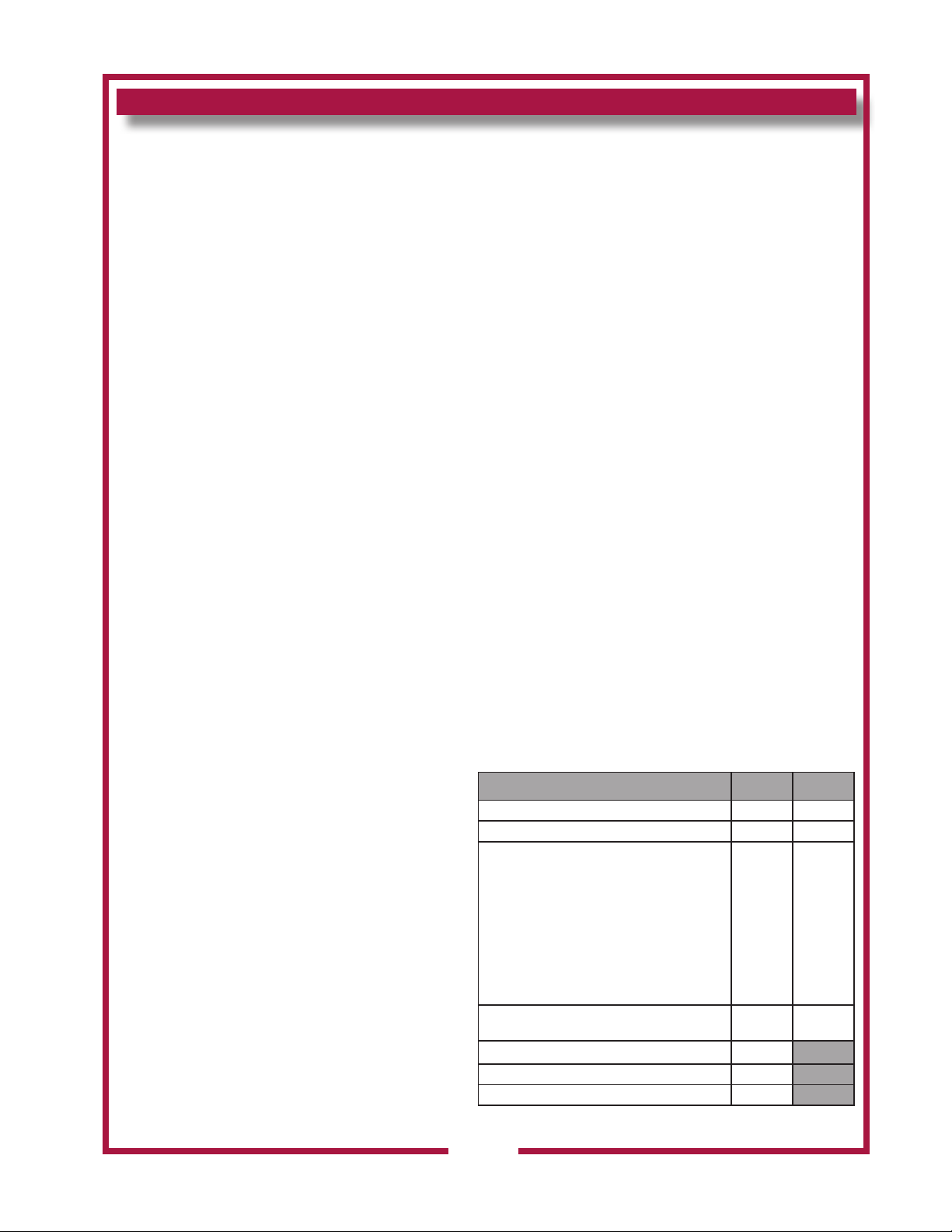

PRODUCTS PARTS LABOR

Universal ventless hoods (WVU)

Canopy ventless hoods (WVC)

*Universal ventless hoods and/or

canopy ventless hoods purchased

with approved Southbend-Star

electric equipment

*Southbend-Star approved electric

equipment purchased and installed

under ventless hood

**Universal Ventless Hood and

Southbend-Star electric equipment

must be on the same PO and listed

on the ventless start-up document

for the 2 year warranty to apply

“Cook’n Hold” equipment [HW10, HWSMP,

LLSC7, LLSC7WA, LLSC11, and LLSC11WA]

Cast iron grates, burners; and burner shields

Wells parts sold to repair equipment 90 days

Service First 1 year

1 year 1 year

1 year 1 year

2 years 2 years

2 years 1 year

1 year

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

xi

2M-Z22393 ∙ Rev. B ∙ 01.2019

Page 3

TABLE OF CONTENTS

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY LISTING INFORMATION 3

INSTALLATION 4

OPERATION 5

CLEANING INSTRUCTIONS 6, 7

MAINTENANCE - SET BAKING TEMPERATURE 8

TROUBLESHOOTING SUGGESTIONS 8

WIRING DIAGRAM 9

EXPLODED VIEW & PARTS LIST 10,11

CUSTOMER SERVICE DATA Back Cover

INTRODUCTION

Thank You for purchasing this Wells Manufacturing appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that

it gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for

the appliance in a manner which will ensure its optimum performance.

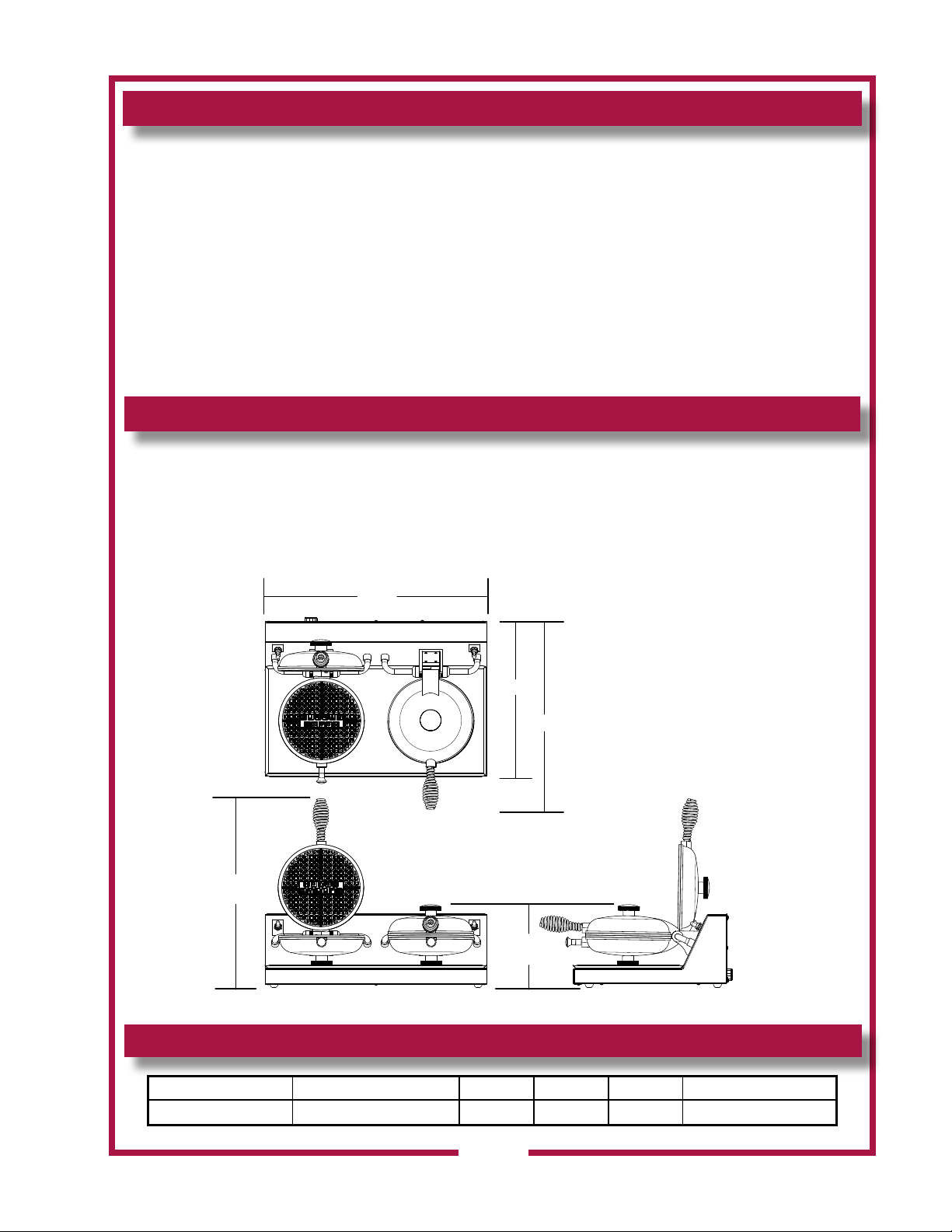

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

16 11/16”

Open

19 3/4”

13 3/4”

16 1/2”

TOP

7 1/8”

Closed

FRONT SIDE

SPECIFICATIONS

IL2944a

Model Style Voltage Watts Amps Power Suppy Cord

WB2WHNTB Double Wafe Baker 120V 1800 15A NEMA 5-20P

1

Page 4

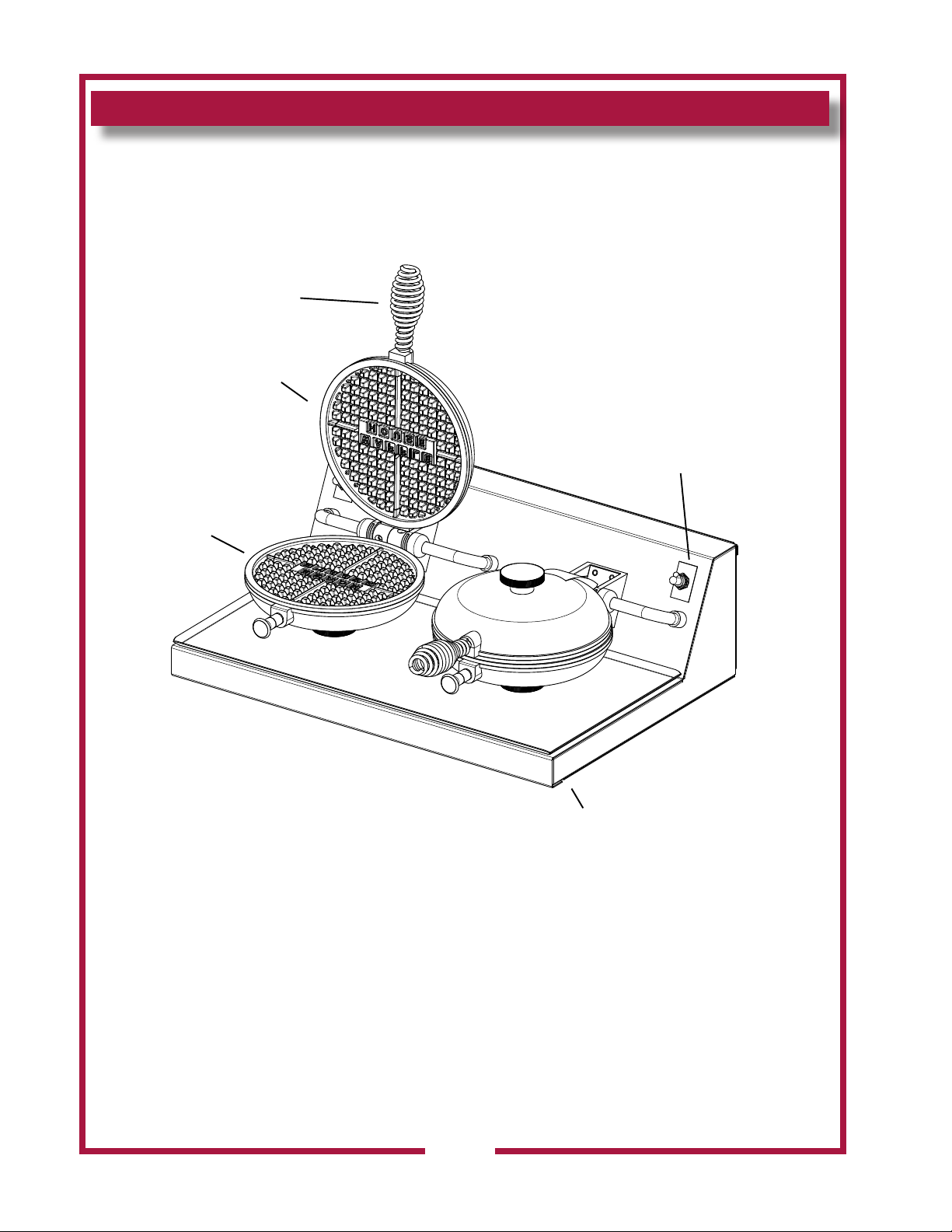

FEATURES & OPERATING CONTROLS

Handle

Upper Grid

(Raised Position)

Lower Grid

Power Switch

(separate switches each side)

Non-Slip Feet

Fig. 1 Wafe Baker - Features & Operating Controls (WB2WHNTB shown,)

2

IL2945a

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

Page 5

PRECAUTIONS AND GENERAL INFORMATION

DANGER: BURN HAZARD

Contact with cooking grid surface will cause severe burns. Use the handle to lift the

grid. Avoid contact with grid surfaces.

WARNING: ELECTRIC SHOCK HAZARD

All servicing requiring access to non-insulated components must be performed by

qualied service personnel. DO NOT open any access panel that requires the use

of tools. Failure to heed this warning may result in severe electric shock.

This appliance is intended for use in commercial establishments only.

This appliance is intended to prepare food for human consumption.

No other use is recommended or authorized by the manufacturer or its

agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT submerge this appliance in water. This appliance is not jet

stream approved. Do not direct water jet or steam jet at this appliance,

or at any control panel or wiring. Do not splash or pour water on, in or

over any controls, control panel or wiring.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

The technical content of this manual, including any wiring

diagrams,schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualied technical personnel. Any

procedure which requires the use of tools must be performed by a

qualied technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics,

parts breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result if

these instructions are not

followed.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions and

maintained according to the instructions in this manual.

This appliance is U Listed under UL File E6070 for 120V.

3

®

C US

STD 4

E6070

Page 6

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance will result

if these instructions are not

followed.

CAUTION:

ELECTRICAL

SHOCK

HAZARD

The ground prong of the power

cord is part of a system

designed to protect you from

electric shock in the event of

internal damage to the

appliance.

NEVER CUT OFF THE

GROUND PRONG

(large round prong).

NEVER TWIST A PRONG TO

FIT AN EXISTING

RECEPTACLE.

Contact a licensed electrician

to install an electrical

receptacle appropriate to

the voltage and amperage

requirements of the

wafe baker.

IMPORTANT:

Damage due to being

connected to the wrong voltage

or phase is NOT covered by

warranty.

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all protective

plastic lm, packing materials and accessories from the appliance

before connecting performing any installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before discarding

packing materials. Store all accessories in a convenient place for later

use.

COMPONENTS

1 ea. DRIP TRAY

2 ea. HANDLE(S)

4 ea. NON-SLIP FEET

SETUP

Lightly lubricate threaded boss of upper grid using vegetable oil.

Thread handle onto boss, making sure that they are fully seated.

Handles are not removable once installed.

Setup the appliance only on a rm, level, non-combustible surface.

Verify local codes for requirements. Concrete, tile, terrazzo or metal

surfaces are recommended.

Install the provided non-slip feet, one on each corner of the appliance,

in the holes provided. Verify that the unit sits rmly on ALL FOUR FEET.

Adjust as required to level the appliance. All four feet must be adjusted

to rmly contact the countertop in order to prevent tipping.

ELECTRICAL INSTALLATION

Refer to the nameplate. Verify the electrical service power. Voltage

and phase must match the nameplate specications. Connecting the

wafe baker to the wrong voltage can severely damage the unit or

cause noticeably decreased performance.

IMPORTANT: Damage due to being connected to the wrong voltage is

NOT covered by warranty.

REALESE AGENT CAUTION

If you nd it necessary to use a release agent to keep wafes from

sticking, you should brush it on. Spraying may oversaturate the grids

and the excess has the possibility of building up inside the baker and

causing damage. If you only have a spray type commercial wafe

baker release agent, try spraying it into a container and applying the

contents with a pastry brush.

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

4

Page 7

OPERATION

SEASONING THE GRIDS

Lightly spray commercial wafe baker spray on both upper and lower

grid.

Carefully close the upper grid. Turn the power switch on, then allow the

wafe baker to pre-heat for at least 20 minutes.

Using the handle, lift the upper grid and lightly re-coat both upper and

lower grid. Lower the upper grid.

The appliance is now ready for use.

GENERAL OPERATIONAL NOTES

Carefully read the description of the wafe baker operation on the

specication sheet.

DO NOT attempt to perform any maintenance or service unless the

wafe baker is disconnected from electrical power.

DO unplug the wafe baker before cleaning, servicing or performing

any maintenance.

DO NOT use sharp objects or metal implements to clean the grids.

DO use a plastic spatula or plastic scouring pad to remove burned-on

food product.

OPERATION

Turn power switch to the on position.

With the upper grid closed, allow to preheat for at least 20 minutes.

Using the handle, lift the upper grid. Pour desired amount of wafe

batter onto the lower grid.

Using the handle, carefully close the upper grid.

When nished raise the upper grid and remove the wafe.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

Cooking Recommendations:

Keep the grids closed when not in use to maintain temperature.

Use a soft bristle brush to lightly brush and clean cooking debris from

the grids between wafes.

Reseason grids every 3 - 4 wafes to guard against wafes sticking.

This interval may be extended by adding oil or butter to the wafe

batter.

Always use fresh batter that contains sufcient shortening. Add

shortening as necessary, and do not store batter for extended periods.

Ensure a perfect, great-tasting wafe by cleaning and re-seasoning

frequently. After every third wafe, and anytime the wafe baker has

been left idle for over one-half hour, lightly brush grids with commercial

wafe baker release agent.

Never apply beeswax, parafn or other such materials to the grids.

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

Use only a quality commercial wafe baker release agent.

Never use sharp implements (i.e. knives, forks, metal tongs) to remove

wafes from the grid. Use a plastic spatula or plastic tongs.

5

Page 8

CLEANING INSTRUCTIONS

PREPARATION

Unplug appliance from electric power

Allow appliance to cool completely.

FREQUENCY

Daily

TOOLS

Plastic Scouring Pad, Soft-Bristled Fiber Brush

Mild Detergent, Non-Abrasive Cleanser

Clean Soft Cloth / Sponge

CLEANING

1. Allow the wafe baker to cool to room temperature.

2. Clean grids by using a soft-bristle brush to remove any

remaining cooking residue.

3. Clean the outside of the Wafe Baker by wiping it with a soft,

clean cloth dampened with warm water and a mild detergent.

NEVER USE AN ABRASIVE CLEANSER.

4. Rinse by wiping with a soft, clean cloth dampened with clean

water. Allow to air dry.

5. Re-season the grids after cleaning by spraying with a

commercial wafe baker spray.

Procedure complete

CAUTION:

BURN HAZARD

Allow wafe baker to cool

completely before cleaning.

IMPORTANT:

DO NOT spill or pour water

into controls.

DO NOT submerge appliance

in water. This will damage

internal components. Damage

to internal components from

water is NOT covered by

warranty.

DO NOT use steel wool or

metal scouring pads to clean

appliance or drip tray.

Good sanitation is vital to

the quality of the nal food

product. Be sure to clean in

all corners and crevices where

grease and other cooking

debris can accumulate.

Knob

Grid’s can be removed and placed

in the dishwasher for easy cleaning.

IL2946a

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

6

Page 9

CLEANING INSTRUCTIONS (continued)

IMPORTANT:

Carbon Cleaner or Wafe

baker cleaner can damage

the protective coating on

the grids. DO NOT use any

cleaner other than mild soap.

CAUTION:

ELECTRIC

SHOCK

HAZARD

DO NOT submerge the wafe

baker in water. If internal

components become wet, the

operator may suffer electrical

shock, and the wafe baker

will be damaged.

PREPARATION

Unplug appliance from electric power

FREQUENCY

As needed

TOOLS

1” Bristle Brush, Stiff Fiber Brush

Clean Soft Cloth / Sponge

REMOVE CARBONIZATION FROM GRIDS

1. Turn power off the unit.

2. While unit is still warm, take a clean cloth, get it wet and

wring the water out.

3. Place on the lower grid

4. Close the upper grid and allow the appliance to stand for

several hours, or overnight, depending upon the extent of the

carbonization.

5. Remove cloth, using a non-metalic bristle brush (rated for

high temp) loosen any carbon material from the grids.

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

DO NOT USE ANY METAL BRUSHES ON COATED GRIDS, IT

WILL DAMAGE THE COATING.

5. Clean the outside of the Wafe Baker by wiping it with a soft,

clean cloth dampened with warm water and a mild detergent.

NEVER USE AN ABRASIVE CLEANSER.

6. Rinse by wiping with a soft, clean cloth dampened with clean

water. Allow to air dry.

7. Re-seasoning is not necessary with coated grids.

Procedure complete

7

Page 10

MAINTENANCE

CAUTION:

BURN HAZARD

Exposed surfaces of the

wafe baker may be hot to the

touch and can cause burns.

Wafe baker grids are very

hot and will cause serious

burns on contact.

Proper temperature for baking

wafes is 390ºF (200ºC).

Variations in altitude and/

or batter mix may require a

slightly different temperature

for best results.

SET BAKING TEMPERATURE

Wells wafe bakers are factory set for 390ºF ±5ºF (200ºC ± 3ºC).

CHECK TEMPERATURE

1. Use a digital thermometer with an oven probe.

2. Place the probe on the lower grid, then gently close the upper

grid.

3. Press the power switch “ON”. Wait 15 minutes for the wafe

baker to come up to heat, and for the temperature to stabilize.

4. Read the temperature on the digital thermometer.

ADJUST TEMPERATURE

1. Unplug the unit from the electrical source

2. Each wafe baker section has an individual temperature

control. Remove the rear panel.

2. Use a thin at-blade screwdriver to turn the temperature

adjustment dial. Rotate clockwise to increase temperature;

counter-clockwise to decrease temperature.

NOTE: Make small incremental changes only.

4. Plug unit back in, turn on and allow ample time for

temperature to stabilize before making another adjustment.

5. When desired temperature is reached reinstall the rear panel.

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

Power cord not plugged in, or circuit breaker

tripped

Will not heat

Does not maintain

temperature

NOTE: There are no user serviceable components in the cabinet or cooking grids. In all cases of damage or malfunction,

contact your Authorized Wells Service Agency for repairs.

Power switch off Turn power switch on

Internal component damage

Excessive carbonization of grids Decarbonize grids

Internal component damage

8

Establish main power. Be sure appliance is

plugged in

Contact an authorized Wells Service Agency for

repairs.

Contact an authorized Wells Service Agency for

repairs.

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

Page 11

TOP ELEMENT

(2)

WiIRING DIAGRAM

120V MODEL WB-2

SINGLE PHASE

LIGHTED

POWER SW.

(2)

2

BOTTOM

ELEMENT

10

1

(2)

THERMISTOR

PROBE (2)

7

5

6

COM

230

115

VAC

9

N.O.

VAC COM

321

8 8

6 7

3

4

4

7

5

6

10

230

VAC

115

VAC COM

3

COM

N.O.

321

2

6 7

1

9

WHITE

BLACK

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

VOLTS NOMINAL AMPS

WB-2

120 15.0

9

POWER

SUPPLY

CORD

2M-Z16088 REV(A)

Page 12

EXPLODED VIEW: WB2WHNTB WAFFLE BAKERS

2

7

6

5

28

12

3

4

5

6

7

27

13

14

15

16

8

18

17

20

19

21

1

9

10

11

29

30

31

26

25

24

MODEL: WB2WHNTB

Waffle Baker

2

18

SK2838 Rev. A 12/17/15

22

23

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

10

Page 13

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

PARTS LIST: WB2WHNTB WAFFLE BAKERS

Model: WB2WHNTB Wafe Baker

Fig No Part Number Quantity Description

1 2R-30335 2 HANDLE SPRING PLATED

2 2R-Z18589 4 KNOB,KNURL,1/4-20X1.3STUD

3 2F-Z17128 2 TOP CASTING MACH’D WH

4 B8-WL0609 4 ASM-RING ELEM MTG PLATE

5 2A-Z19506 4 FITTING-ELEM.BRACKET-WH

6 2N-Z18456 4 ELEMENT,RING 448W-120V

7 2F-Z19383 4 GRID CASTING W/ WH LOGO

8 B8-Z15901 1 TRAY, DRIP

9 2K-Z15801 4 CONDUIT-90 DEG-1/2”TUBE

10 2A-Z17001 4 BUSHING-CONDUIT/HINGE SS

11 B8-WL0303 2 ASY-HINGE MOUNTING PLATE

12 2F-Z15902 2 HINGE, WB1&2, W/4HOLES

13 2C-Z2893 8 NUT 10-24 HEX STL ZP

14 2I-05-07-0013 2 BOOT SWITCH

15 2M-12-07-0038 2 LABEL ON & OFF

16 2E-30330 2 SWITCH ON OFF TOGGLE 20A

17 B8-Z15898 1 PANEL, REAR

18 2C-33935 16 SCREW 6ABX5/16 PH PAN SMS

19 2C-2553 4 NUT 6-32 HEX STL NP

20 2T-Z20480-380 2 CONTROL TEMP W/ RTV

21 2K-Z15511 1 STRAIN REL-LIQ TIGHT.875

22 B8-Z15899 1 PANEL, BOTTOM

23 2A-45728 4 FOOT RUBBER LLW LLF

24 2R-Z17057 2 KNOB, BLK, DAVIES 3003SM

NI 2C-Z16665 2 STUD-ALL THD-1/4-20X1.25

25 2V-Z17056 2 SPACER-1/2 TUBE X 1/2 SS

26 2F-Z15888 2 BOTTOM CASTING-MACH’D

27 2J-Z16944 2 PROBE TEMP-RTD-20” LEADS

28 B8-WL0609 1 ASM-RING ELEM MTG PLATE

29 thru 31 IS PART OF B8-WL0609

29 2C-Z20958 2 NUT 10-32 HEX MS ALUM

30 2P-Z20959 1 SPRING COMP .36POD, .5

31 2C-1508 1 SCREW 10-32X3/4 STL

NI 2E-Z15407 1 CORD SET ASM L5-20P 12 GA

NI 2M-Z16088 1 LABEL,DIA WIR WB1,2 120V

NI 2P-Z20436 1 LADLE-PLASTIC-4OZ-13IN

NI 2P-Z20437 1 FORK-SERV-PLASTIC-HITEMP

NI 2P-Z20438 1 BRUSH-CLEANING-WB

11

December 17, 2015, Rev C

Page 14

NOTES

12

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

Page 15

NOTES

M213 2M-Z19604 Owners Manual for WB2WHNTB Wafe Bakers

13

Page 16

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 800-264-7827

fax: 314-781-2714

www.wells-mfg.com

Loading...

Loading...