Wells WATER-MAX, WM-TR Owner's Manual

705

OWNERS MANUAL

WATER-MAX

WM-TR

Includes

INSTALLATION

USE & CARE

SERVICE

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

p/n 305681 Rev.(-) M705 110802 cps

IMPORTANT: DO NOT DISCARD THIS MANUAL

LIMITED WARRANTY STATEMENT

This Water-Max™ hot water dispenser manufactured by

GENERAL

WELLS MFG. CO. is warranted against defects in materials

and workmanship for a period of two years from the date of

original installation and is for the benefit of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY WARRANTY

EXPRESSED OR IMPLIED IN LAW OR IN FACT, INCLUDING

BUT NOT LIMITED TO, WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR ANY PARTICULAR PURPOSE, AND/OR FOR

DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH WELLS MFG. CO. PRODUCTS.

This warranty

an authorized service agency, the equipment has been modified

misused, misapplied, improperly installed, or damaged in

transit or by fire, flood or act of God. It also does not apply if

the serial nameplate has been removed, or if service is performed

by unauthorized personnel. The prices charged by Wells

Mfg. Co. for its products are based upon the limitations in

is void if it is determined that, upon inspection by

,

this warranty.

the repair of defects without charge by a Wells Mfg. Co. factory

authorized service agency or one of its sub-service agencies

service will be provided on customer’s premises for nonportable models. Portable models (a device with a cord and

plug) must be taken or shipped to the closest authorized

,

service agency, transportation charges prepaid, for service.

In addition to restrictions contained in this warranty, specific

limitations are shown in the Service Policy and Procedure

Guide. Wells Mfg. Co. authorized service agencies are located

principal cities. This warranty is valid in the United States

and Canada and void elsewhere. Please consult your classified

telephone directory, your foodservice equipment dealer or

write the Factory Service Department

Wells Manufacturing Company, P.O. Box 280

Verdi, Nevada, USA 89439

Phone: (775) 689-5700 or (888) 492-2782,

and other details

Seller’s obligation under this warranty is limited

concerning warranty.

to

. This

in

for information

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specified on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted for

ninety (90) days from date of purchase on nonwarranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged

by skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Manufacturing cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

xi

TABLE OF CONTENTS

GENERAL

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 4

AGENCY LISTING INFORMATION 4

INSTALLATION

SET-UP 5

PLUMBING 6

ELECTRICAL 7

INSTALLATION CHECKOUT FORM 9

USE AND CARE

USING WATER-MAX™ 11

CLEANING INSTRUCTIONS 12

DELIMING INSTRUCTIONS 14

OVERNIGHT CLEANING 17

SERVICE & REPAIR

TROUBLESHOOTING SUGGESTIONS 18

SAFETY FEATURES & ERROR CODES 19

TEMPERATURE CALIBRATION 20

WIRING DIAGRAM - DISPENSER 21

EXPLODED VIEWS & PARTS LIST - DISPENSER 22

WIRING DIAGRAM - TANK 24

EXPLODED VIEWS & PARTS LIST - DISPENSER 25

SERVICING INSTRUCTIONS 26

PARTS & SERVICE INFORMATION 41

CUSTOMER SERVICE DATA 41

Thank you for purchasing this

Wells Manufacturing Co.

Water-Max™ hot water

dispenser.

Proper installation, professional

operation and consistent

maintenance of this appliance

will ensure that it gives you the

very best performance and a

long, economical service life.

This manual contains the

information needed to properly

install the dispenser, to use

and care for the dispenser, and

to service and repair the

dispenser in a manner which

will ensure its optimum

performance.

GENERAL

SPECIFICATIONS

Electrical: 208 Volts, Single Phase 35 Amps

240 Volts, Single Phase 35 Amps

NOTE: Requires a dedicated 50 Amp circuit

Plumbing: Water Inlet: 1/4” Male Flare Fitting

Supply: 1/4” Female Flare supplied by a 1/4” O.D. or larger water supply line

NOTE: If water supply run from main supply line to Water-Max™ exceeds 12 feet,

a 3/8” O.D. or larger water supply line is required. Water supply line must be rated for

at least 180ºF.

For higher capacity, hook-up to a hot water line.

DO NOT use a saddle valve to connect to supply line.

IMPORTANT: This dispenser must be installed in compliance with all applicable

federal, state and local codes and ordinances.

Dimensions: Height: 28-11/16”

Width: 10-1/16” (without tank) 15” (with tank installed)

Depth: 22-7/16” (without tank) 25-1/4” (with tank installed)

Weight: 74 lbs. (without tank) 150 lbs. (with tank installed and filled)

APPLICABILITY

This manual covers Wells Water-Max™ hot water dispensers built after Nov. 1, 2002.

1

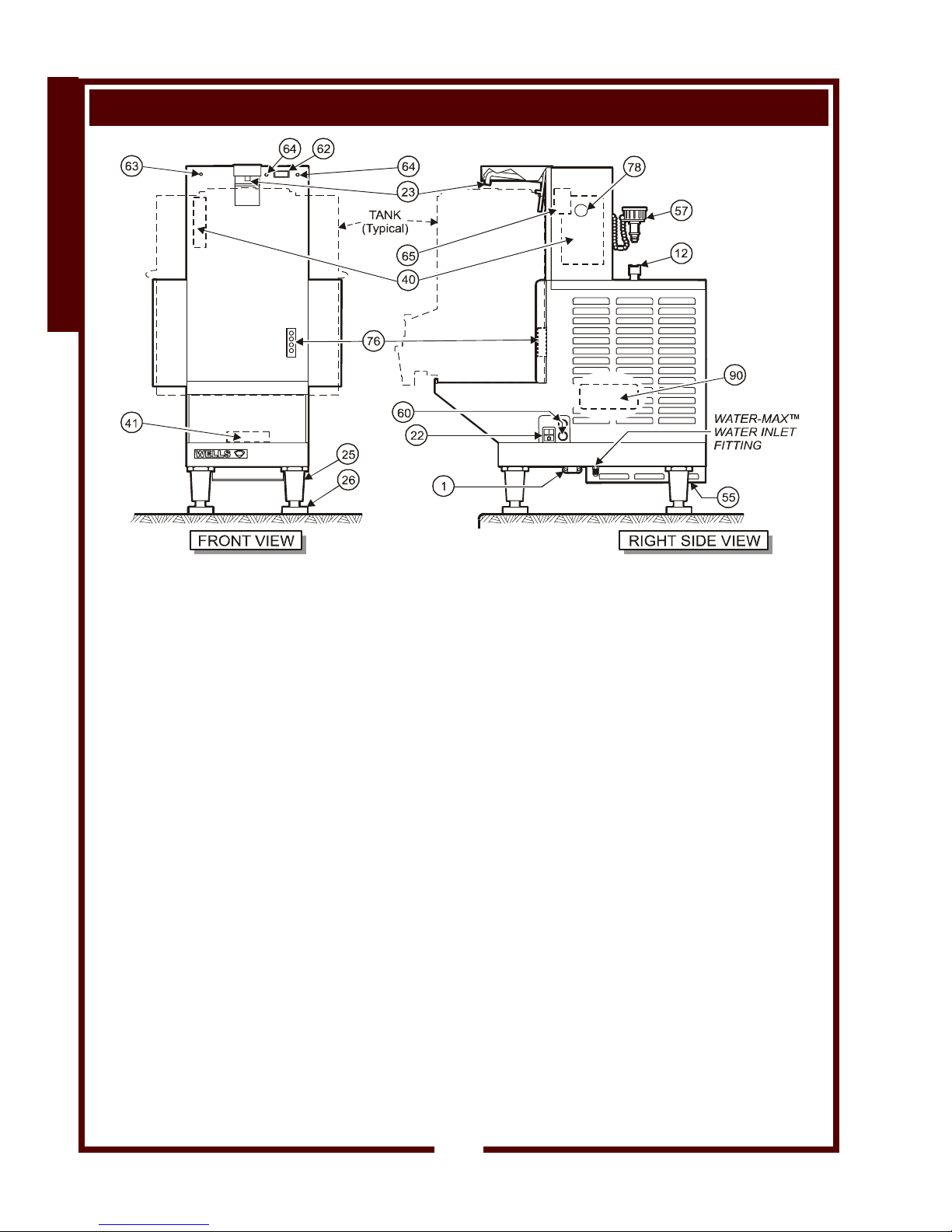

FEATURES & OPERATING CONTROLS

GENERAL

Fig. 1 Features & Operating Controls - Water Max™ Dispenser

1. STRAIN RELIEF (Left Side, Bottom) Field supply wiring enters the appliance here.

12. DELIMING FITTING Tank mounted quick disconnect fitting for deliming procedure.

22. POWER SWITCH Energizes the appliance.

17. POWER INDICATOR Glows when Water-Max™ is ON and operating normally.

23. DISPENSER NOZZLE Hot water is dispensed here. Inserting water tank lowers nozzle into “dispense” position.

25. ADJUSTABLE LEG Provides required clearance to counter, and allows unit to be leveled.

26. RUBBER FOOT Allows Water-Max™ to operate without “walking” or sliding.

40. CONTROLLER

CIRCUIT BOARD

41. TERMINAL BLOCK (Inside, under tank shelf) Field supply wiring connects here.

55. AIR FLOW CHANNEL Provides a measure of protection for transformer cooling air outlet.

57. DELIMING FITTING Quick disconnect fitting attaches to deliming solution bottle.

60. FUSES Provide protection for electrical circuits.

62. TANK INDICATORS LEFT - Tank must be delimed

63. STATUS INDICATOR Glows when filling, flashes when controller is in “error” mode.

65. TANK POSITION

SWITCH

76. CONNECTOR Allows WATER TANK to connect to Water-Max™.

78. VIEW PORT Allows digital readout of controller to be observed.

(Inside left side) Access by qualified technician only.

Access by qualified technician only.

RIGHT - Glows when tank is properly installed.

Held ON when WATER TANK depresses DISPENSER NOZZLE. Unit will not operate

unless WATER TANK is in place.

Also provides power to keep tank contents hot.

90. NAMEPLATE (Left side) Gives manufacturer information; lists model no., serial no. and electrical

specifications.

2

FEATURES & OPERATING CONTROLS (continued)

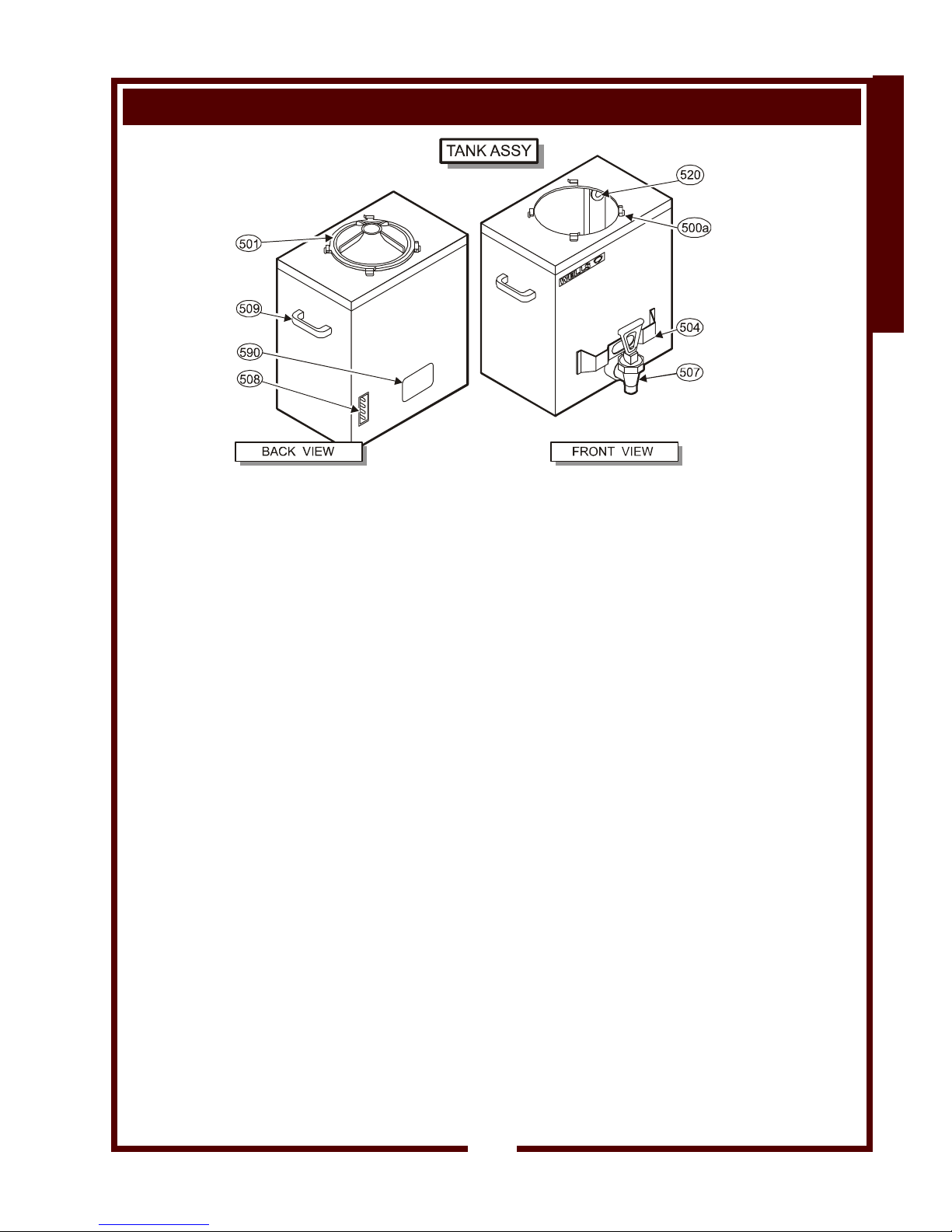

Fig. 2 Features & Operating Controls - Water Max™ 5 Gallon Tank

500A. LID HOLDING CLIPS Ears on LID seat in these clips to secure lid to tank.

GENERAL

501. TANK LID Hot water is dispensed into the tank here.

504. FAUCET PROTECTOR Provides some protection for FAUCET from damage.

507. FAUCET ASSEMBLY Controls delivery of hot water to container for food prep, etc.

508. CONTROL RECEPTACLE Allows WATER TANK to connect to Water-Max™.

509. RESERVOIR CARRYING HANDLE

520. WATER LEVEL SENSOR Inside WATER TANK. Senses water level.

590. NAMEPLATE Gives manufacturer information; lists model no., serial no. and electrical specifications.

Turns clockwise to latch into HOLDING CLIPS.

IMPORTANT: NOT A HANDLE

Also provides connection to power to keep tank contents hot.

Used to position the WATER TANK on Mater-Max™

CAUTION - DO NOT ATTEMPT TO MOVE OR CARRY THE WATER TANK

WHEN IT CONTAINS HOT WATER! SEVERE BURNS MAY RESULT.

3

PRECAUTIONS AND GENERAL INFORMATION

GENERAL

WARNING:

Electric

Shock hazard

All servicing requiring

access to non-insulated

electrical components

must be performed by a

factory authorized

technician.

DO NOT open any access

panel which requires the

use of tools. Failure to

follow this warning can

result in severe electrical

shock.

CAUTION:

Risk of

Damage

DO NOT connect or

energize this appliance

until all installation

instructions are read and

followed. Damage to the

appliance will result if

these instructions are not

followed.

Water-Max™ hot water dispenser is intended for use in

commercial establishments only.

This dispenser is

preparation of food for human consumption. No other use is

recommended or authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions.

Operating instructions,

understood by all persons using or installing this appliance.

Cleanliness of this dispenser is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT submerge the dispenser or water tank in water. Do not

splash or pour water on, in or over any controls, control panel or wiring.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualified technical personnel.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

designed to dispense hot water used in the

warnings and labels must be read and

E6070

E6070

STD 4

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions.

This appliance is

This appliance is

U Listed under File E6070.

V Listed under File E6070.

4

INSTALLATION

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all

protective plastic film, packing materials and accessories from

the appliance before connecting electrical power or otherwise

performing any installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read all instructions in this manual carefully before starting

installation of this dispenser. READ AND UNDERSTAND ALL

LABELS AND DIAGRAMS ATTACHED TO THE DISPENSER.

Carefully account for all components and accessories before

discarding packing materials.

1 ea. WATER-MAX™ DISPENSER

1 ea. AIR OUTLET GUARD

4 ea. ADJUSTABLE LEGS

1 ea. WATER TANK ASSEMBLY with LID

1 ea. DELIMING SOLUTION BOTTLE

1 ea. LITERATURE PACKAGE

Store these components in a convenient place for later use:

SETUP

Verify that this dispenser installation is in compliance with the

specifications listed in this manual and with local code requirements.

THIS IS THE RESPONSIBILITY OF THE INSTALLER.

Recommended height of the faucet is 38” to 42” above the floor.

However, the actual installed height will vary with the requirements of the

individual store.

Install temperature gauge in water tank. Install plastic holding nut hand

tight only. Refer to exploded view, page 23.

For countertop installation

The counter at the installation location must be level, provide a

clear space at least 17-1/2”” deep and must be structurally capable

of safely supporting 150 pounds.

Set Water-Max™ on its back. Install the AIR OUTLET GUARD.

Guard is positioned on the bottom of Water-Max™, fully to the rear,

with the open portion toward the front. Install the REAR LEGS to

hold the guard in place.

Install the FRONT LEGS. Make certain all four legs have the

RUBBER FEET installed. Set Water-Max™ upright on the counter.

With the dispenser in its final installed location, adjust for level with

the adjustable legs. With a spirit level, check and adjust the

dispenser for level front-to-rear and side-to-side.

For wall mount installation:

Kits are available to wall mount Water-Max™. See important note at

right. Wall mount kits are listed on page 41.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

Risk of

personal injury

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable electrical and

plumbing codes. Failure can

result in personal injury and

property damage.

IMPORTANT:

Water dispensed from faucet

or nozzle of Water-Max™ will

be VERY HOT. Also, a one

gallon pitcher full of water will

weigh about 8-1/2 pounds.

IMPORTANT:

For wall mount installations

contact your Authorized Wells

Service Agency:

Only factory- produced wall

mounting brackets are

authorized for use with WaterMax™.

Use of any mounting means or

method other than the

factory-produced bracket voids

all warranty on this appliance.

Additionally, owner and/or

installer assume all liability in

connection with injury or

damage resulting from use of

any mounting means or

method other than the

appropriate factory-produced

bracket.

INSTALLATION

5

INSTALLATION (continued)

CAUTION:

Risk of Damage

DO NOT connect or energize

this appliance until all Installation

Instructions are read and followed.

Damage to the dispenser will

occur if these instructions are

not followed.

IMPORTANT: Water supply

MUST be a minimum of 1/4”

line, and MUST be capable of

supplying 25 p.s.i. AT ALL

INSTALLATION

TIMES during the operation of

the dispenser.

IMPORTANT: Water line

material must be rated for at

least 180ºF.

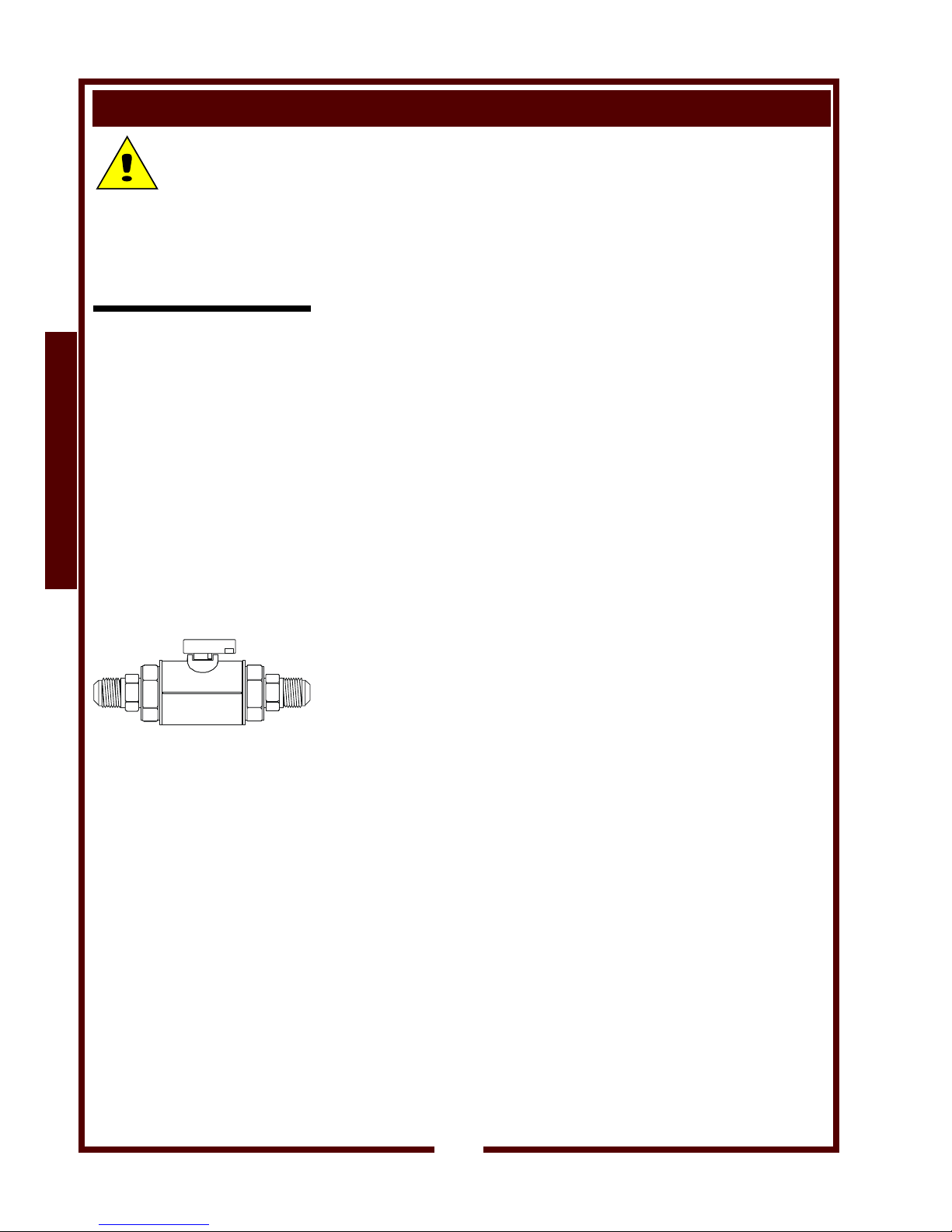

Fig. 3 1/4 Turn Ball Valve

IMPORTANT INSTALLATION NOTICE

Installer will be required to test water pressure, water flow, water total

hardness, electrical voltage and amperage; and to record dispenser

installation particulars on the INSTALLATION CHECK OUT form (see

page 9).

PLUMBING LINE CONNECTION

If power has been run to the dispenser, verify that the circuit breaker is

turned

Water-Max™ has an internal sensor to verify that there is sufficient

water pressure to operate. Water-Max™ will not operate until a water

supply is connected to the unit or if water pressure is less than 25 p.s.i.

Water-Max™ must be connected to a potable water supply.

INSTALLED AND MAINTAINED ACCORDING TO FEDERAL, STATE,

May be connected to either hot or cold water line. Temperature of a

hot water line must not exceed 140ºF.

DO NOT use a saddle valve to connect Water-Max™ to main supply

line. Connecting to a hot water line will increase the volume flow of the

dispenser.

Minimum 1/4” copper or flex tubing supply line (3/8” minimum if run

from main supply exceeds 12 feet) with 1/4” female flare fitting. Water

line material must be rated for at least 180ºF.

Minimum 25 psi / maximum 75 psi water pressure at full flow.

The installation of a SHUTOFF VALVE (must be provided by plumbing

installer) on the incoming water line is required. A 1/4 turn ball valve is

recommended to minimize restricting the water flow during operation.

DO NOT use a saddle valve to connect Water-Max™ to main supply

line.

Clean the incoming waterline: Run water through the line into a sink or

bucket to flush any foreign particles or debris from the waterline.

Assemble incoming water line to the inlet fitting. Turn on water supply

valve and check for leaks.

Test water for pressure at full flow. If a pressure regulator is installed,

adjust pressure to 40 p.s.i. Record this reading on the INSTALLATION

CHECK OUT form.

Test water for total hardness. Record readings on the INSTALLATION

CHECK OUT form.

OFF, and that the power switch is in the OFF [O] position.

NOTICE:

WATER PIPE CONNECTIONS AND FIXTURES DIRECTLY

CONNECTED TO A POTABLE WATER SUPPLY SHALL BE SIZED,

AND LOCAL ORDINANCES.

6

INSTALLATION (continued)

ELECTRICAL INSTALLATION

NOTICE:

A DEDICATED CIRCUIT OF AT LEAST 50 AMPS IS REQUIRED.

WIRING MUST BE AT LEAST 6 ga., SUITABLE FOR 75º C.

CONDUIT, WIRING AND CONNECTIONS MUST BE INSTALLED

AND MAINTAINED IN COMPLIANCE WITH

FEDERAL, STATE, AND LOCAL ORDINANCES.

Conduit, wiring and connections must comply with the specifications in

this manual, and with local ordinances. A 208V or 240V single phase,

50 amp circuit required.

Field supply wiring must pass thru, and be secured by, the strain relief

on the bottom left side of the dispenser.

Field wiring supply power must connect to the rear-most side of the

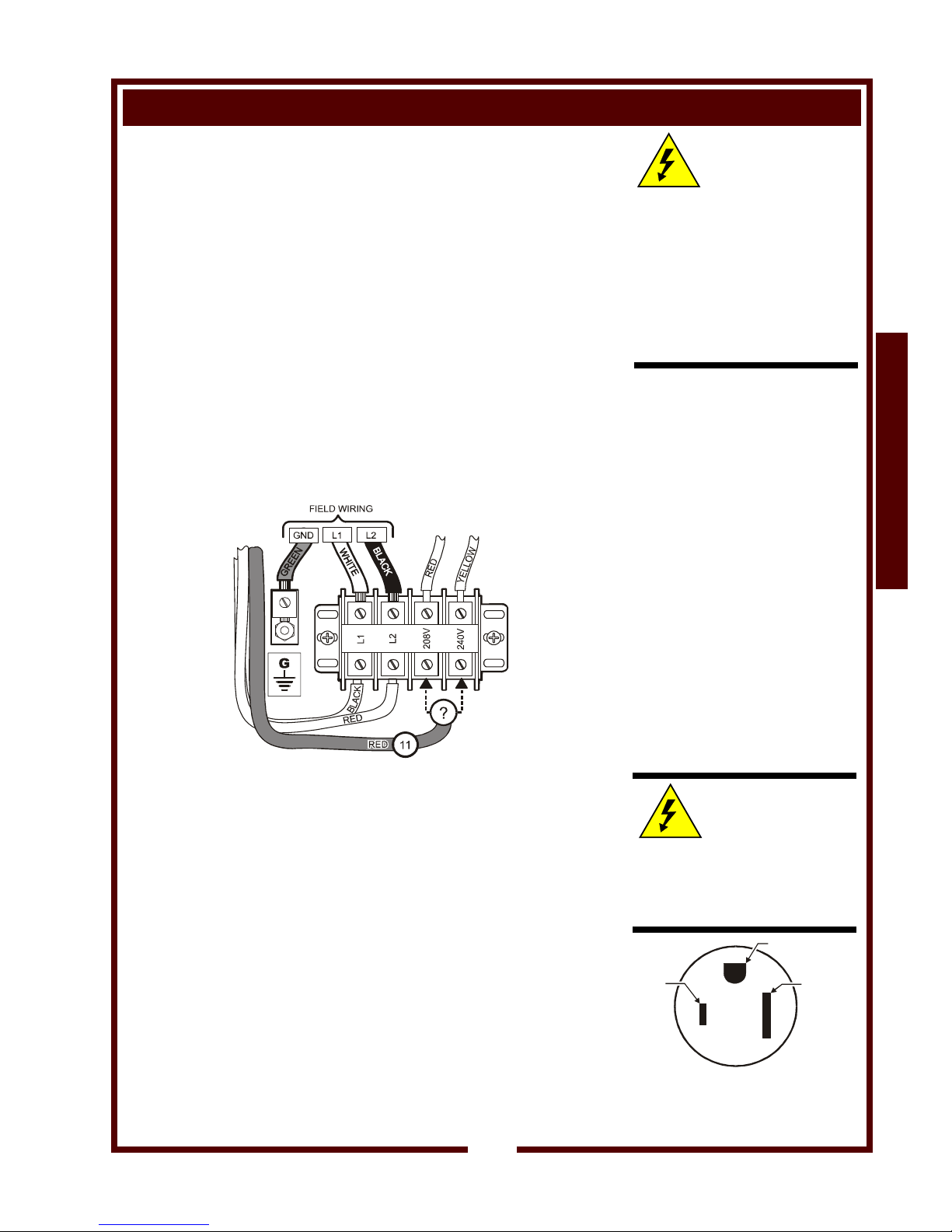

terminal block, terminals L1 and L2 as shown in Fig. 4.

NOTE: Terminal block is accessible by removing the tank shelf.

Remove the two screws under the shelf and lift the shelf off of the unit.

See wiring tag.

Fig. 4 Terminal Block Wiring

The dispenser is shipped with red wire #11 unattached. Configure the

dispenser for either 208 volt or 240 volt use:

Determine input voltage.

READ CAUTION TAG. Remove tag and wire nut from wire #11.

Attach wire #11 to either the terminal labeled “208V”, or to the

terminal labeled “240V”, as appropriate for the input voltage.

Optional cord set uses a 4’ cord and NEMA 6-50P plug (see Fig. 5).

A suitable earth ground must be connected to the ground lug located to

the left of the terminal block (see Fig. 4. above).

Check all connections to terminal block for tightness.

Test electrical supply for voltage and amp draw while unit is filling water

tank. Record readings on the INSTALLATION CHECKOUT form.

Upon completion of the electrical hook-up and testing, properly reinstall

all panels.

CAUTION:

SHOCK HAZARD

Removal of any exterior panel

will result in exposed electrical

circuits. Electrical connection

must be performed by a

qualified technician only.

Use care whenever working

around exposed electrical

circuits.

IMPORTANT:

Contact a licensed electrician

to install and connect

electrical power to the

dispenser.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

IMPORTANT:

Field wiring supply voltage

must correspond to the

position of red wire #11

(i.e. 208V or 240V). Failure to

match wire #11 position to

input voltage can result in

equipment damage or reduced

performance.

Such damage is not covered

by warranty.

CAUTION:

SHOCK HAZARD

Failure to connect the chassis

ground to a suitable earth

ground will result in a potential

shock hazard.

L1

Fig. 5 NEMA 6-50P Plug

GROUND

L2

NEMA 6-50P

INSTALLATION

7

INSTALLATION (continued)

CAUTION:

Hot Surface

Exposed surfaces can be hot

to the touch and may cause

burns.

CAUTION:

Burn Hazard

WEAR PROTECTIVE

INSTALLATION

GLOVES AND GOGGLES

This procedure requires

operating Water-Max™

without the tank lid. Some

splashing may occur.

Splashed water will be very

hot.

INSTALLATION START-UP AND CHECKOUT

Countertop must be at least 17-1/2” deep to safely support the

dispenser.

Before turning on power or water to Water-Max™, visually verify:

a. Unit is level, air outlet guard in place, with all legs touching the

counter (countertop installation); or,

Wall brackets securely mounted to wall and unit properly and

securely mounted to brackets (all screws tight) with outlet guard

installed (wall mount installation).

b. All electrical connections properly made and tightened.

Water connections properly made.

c. Verify faucet is properly installed in tank.

Turn on water to Water-Max™. Visually inspect unit for leaks.

Apply power to Water-Max™. Install tank on Water-Max™ shelf (leave

tank lid off at this time). Press power switch to ON and observe

operation:

a. POWER INDICATOR will glow when POWER SWITCH is ON.

TANK INDICATOR will glow when tank is properly installed.

b. After a five second delay, Water-Max™ tank should begin filling.

STATUS INDICATOR will glow steadily while tank is filling,

indicating normal operation.

c. Within the first minute of operation, and while tank is filling,

CAREFULLY remove the tank from the shelf. Verify that water flow

stops when the tank is removed.

d. Reinstall the water tank. Verify that water flow stops when water

reaches the water level probe.

Press power switch to OFF. Discard all water generated thus far by

dispensing containers of water from the faucet until the tank is empty.

Remove the tank from the shelf. Install tank lid on tank.

Reinstall tank on Water-Max™. Press power switch to ON and allow

tank to fill. Monitor time to fill and record on the INSTALLATION

CHECKOUT form.

Test water temperature at faucet. Water should be at 202ºF minimum.

8

INSTALLATION (continued)

TYPE OR PRINT CLEARLY

Please use a ballpoint pen

and press hard.

Check boxes and fill in

spaces where applicable.

Authorized Service Co

To be completed by an

Authorized WELLS MFG.

Service representative

. ____________________________________Agency Invoice # ________________ Date ________

Address_____________________________________________ ____Contact Name _______________ ________________

City ____________________________________ State ____ ZIP _____________ Phone (___) ______________Ext. _____

Business Name

___________________________________________Installation Requested By ______________________

Address__________________________________________________Accepted By ___________________Store# _______

City ____________________________________State ____ ZIP _____________ Phone (_____) ________________

MODEL NO. SERIAL NO. VOLTAGE Ø __

( Check box after item is completed. Note any discrepancies.)

INSTALLATION INSPECTION

A Accessories and components identified

and accounted for

B Compliance with Electrical Codes verified

C Compliance with Building Codes verified

E Verify that all protective film and packing

materials have been removed

_________________ _______________ _______ ___

;

E All fasteners checked for tightness

F Unit installed on hard surface and leveled,

Counter at least 17-1/2” deep, or

Wall mount unit securely installed and leveled

and

Unit securely attached to wall mount

D Water tank assembled and installed

( Check box after item is completed. Note any discrepancies.)

STARTUP INSPECTION

WATER SUPPLY

A Verify min. 1/4“ supply line

B Verify min. 25 psi

C Optional Equipment (Strainer, Regulator, Water

Hammer Arrestor) properly installed in supply line

D Shut off valve installed in supply line

E Test and record total hardness of water supply:

;

INSTALLATION

A Verify all switches / electronic controls work

B Verify power and status indicator light operation

C Check for leaks

D Check tank position safety switch for operation

E Check / adjust dispensed water temperature

F Check time to fill tank

INSTALLATION

ELECTRICAL SUPPLY

A Verify input voltage matches nameplate voltage

B Verify dedicated 50A circuit

C Field wiring completed

D Unit ground stud connected to a suitable ground

E Verify Wire #11 position matches input voltage

F All connections at terminal block tight

G All connections at control circuit board tight

( Check box after item is completed. Note discrepancies.)

OPERATOR TRAINING AND OPERATIONAL INSPECTION

A Safety features and controls identification and operation

B Component and accessory identification

C Discuss safety procedures

D Demonstrate operation

DATA

A

Record all pertinent data on

form in the

Record voltages and amperages at circuit breaker:

B

Operation Manual

CUSTOMER SERVICE DATA

Power switch off _____V _____A

Water tank filling _____V _____A (min 35A/max. 39A)

C Record water data: _______ psi

Total hardness _______ grain tH

Temperature _______ºF

Time to fill tank _______ min.

;

G Discuss / demonstrate food preparation

H Explain warranty. Return copies to office and factory

I Discuss use and availability of supplies available from

the distributor

E Demonstrate cleaning the dispenser and tanks

F Discuss preventative maintenance procedures

:

WATER-MAX™ INSTALLATION PERFORMED BY

Name ____________________________________________________________________ Date__________________

Time In ___________ Time Out ____________

Thank you for your help. This information is used to

evaluate our continuing efforts in maintaining the highest

quality product for you, our valued customer.

RESTAURANT OWNER, MANAGER or SUPERVISOR

Print Name

Signature

9

INSTALLATION (continued)

CAUTION:

Hot Surface

Exposed surfaces can be hot

to the touch and may cause

burns.

INSTALLATION

START-UP TROUBLESHOOTING

Power indicator not lit.

a. Verify electrical power is properly hooked-up to Water-Max™ and

circuit breaker is turned ON.

b. Verify power switch is turned ON.

c. Verify that water tank is properly in place and mated with the

receptacle.

d. Verify water supply is properly installed, is turned on, and is

providing at least 25 p.s.i.

Error indicator flashing. Tank is not filling.

(Check Error Code in View Port)

a. Possible cause; sufficient inlet water pressure is not sensed during

tank filling:

Be sure water supply is adequate during all phases of operation.

Other equipment on the water line may be robbing water volume

and/or pressure from Water-Max™. Also, be sure any supply line

filters are clean.

b. Possible cause; sufficient temperature rise is not sensed between

inlet and output water while tank is filling:

Be sure electrical supply voltage remains at rated value during all

phases of operation. Otherwise, refer to Service Instructions, page

16.

Water-Max™ will not flow water from the dispense nozzle.

a. Verify that power indicator is lit, and status indicator is not flashing.

Check that tank is properly positioned and that the tank indicator is

lit.

b. Verify that the water tank is in place holding the tank position

momentary switch ON;.

c. Verify that the water level is below the water level sensor. If water

level is low, verify that the water level sensor and surrounding area

are clean and free from lime and scale. To clean, drain and remove

tank. Remove lid. Clean around probe then reinstall lid on tank

and tank on Water-Max™. See Cleaning Instructions, page 15.

The water tank heater will not heat:

a. Verify the water tank connector is fully mated with the receptacle.

The tank indicator will glow when the tank is properly installed.

b. Verify power switch is ON.

c. Check ohms at connector on tank: L1 to L2 = 144Ω

Status Indicator Flashing:

Water-Max™ control board has encountered an error condition.

Read error code through view port. Refer to page 19 for error code

meanings and suggested remedial action.

10

OPERATION

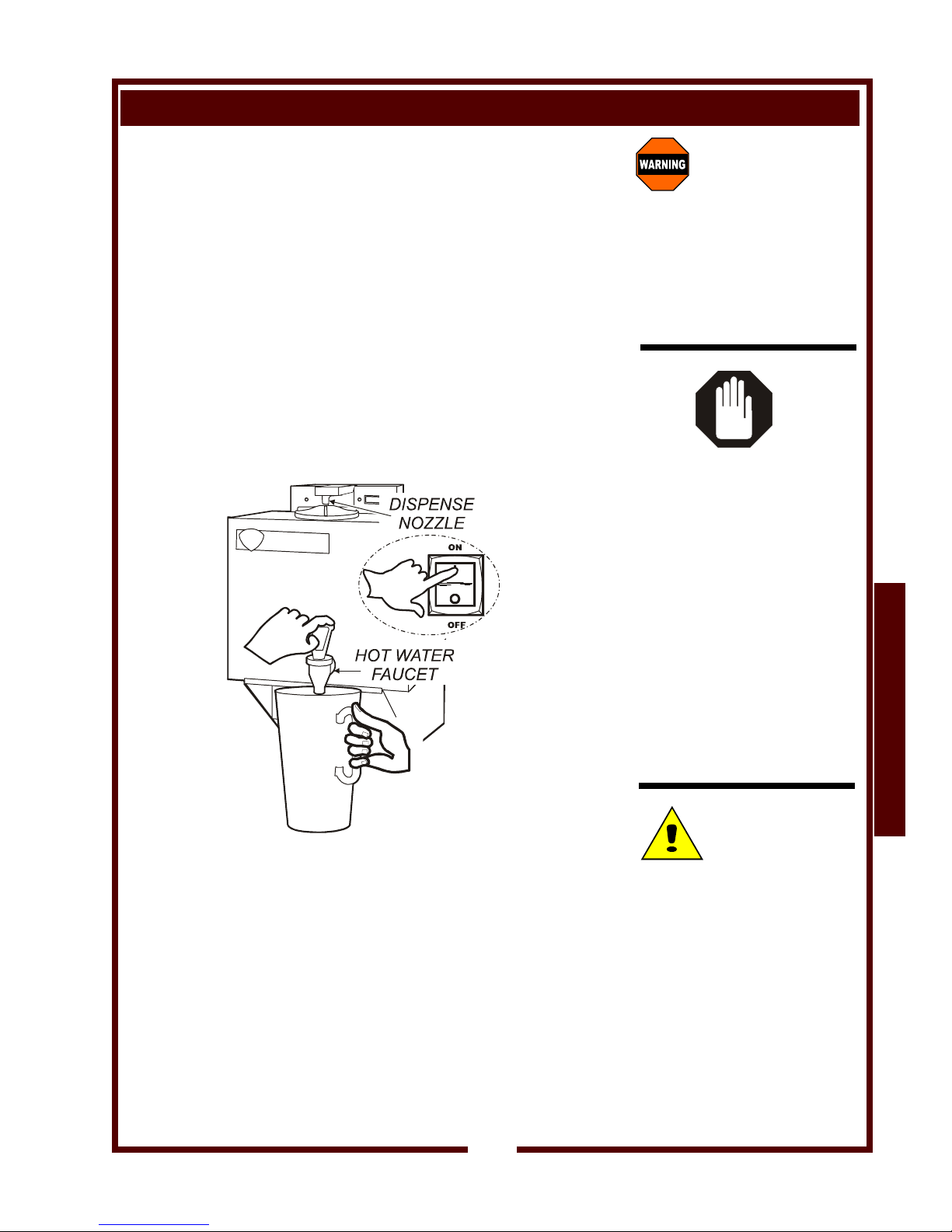

USING WATER-MAX™

Water-Max™ is used to dispense hot water for food preparation.

Set-Up and Usage

Install the water tank on the Water-Max™ shelf.

Make sure that the tank is properly positioned, that the connector is

seated and that the dispensing nozzle lowered into position in the water

tank lid.

Press the power switch to

water.

Status indicator will glow when the tank is filling.

Status indicator will go out when the tank is full.

Place an appropriate container under the faucet. Being careful to not

overflow the container, pull the faucet handle to dispense hot water.

Fig. 6 Water-Max™ Operation

To Keep Water in Tank Hot

Leave the power switch ON. Water-Max™ will maintain tank water

temperature at 202ºF minimum, and will be ready to dispense hot

water.

ON and allow the water tank to fill with hot

WARNING:

BURN HAZARD

Water-Max™ is designed to

operate with a matching 5 gal.

water tank only.

Do not hold anything other

than the matching water tank

under the dispensing nozzle.

Splashing hot water will cause

serious burns.

GENERAL GUIDELINES

NEVER hold or place

anything, other than the proper

tank, under the dispense

nozzle. Draw water only from

the hot water faucet of the

water tank.

NEVER attempt to remove or

carry a water tank while full of

water.

NEVER attempt to operate

Water-Max™ without the lid

properly installed on the water

tank.

CAUTION:

Hot Surface

Exposed surfaces can be hot

to the touch and may cause

burns.

IMPORTANT:

If water temperature will not

rise out of the RED zone,

Water-Max™ must be delimed.

See page 14.

USE AND CARE

11

CLEANING INSTRUCTIONS

CAUTION:

BURN HAZARD

Water in tank is extremely

hot. Use care when draining

tank.

CAUTION:

HOT SURFACES

Exposed surfaces can be hot

to the touch and may cause

burns.

CAUTION:

SHOCK HAZARD

DO NOT submerge

tank in water

IMPORTANT:

DO NOT use bleach,

abrasive cleansers or

cleansers containing

chlorides.

USE AND CARE

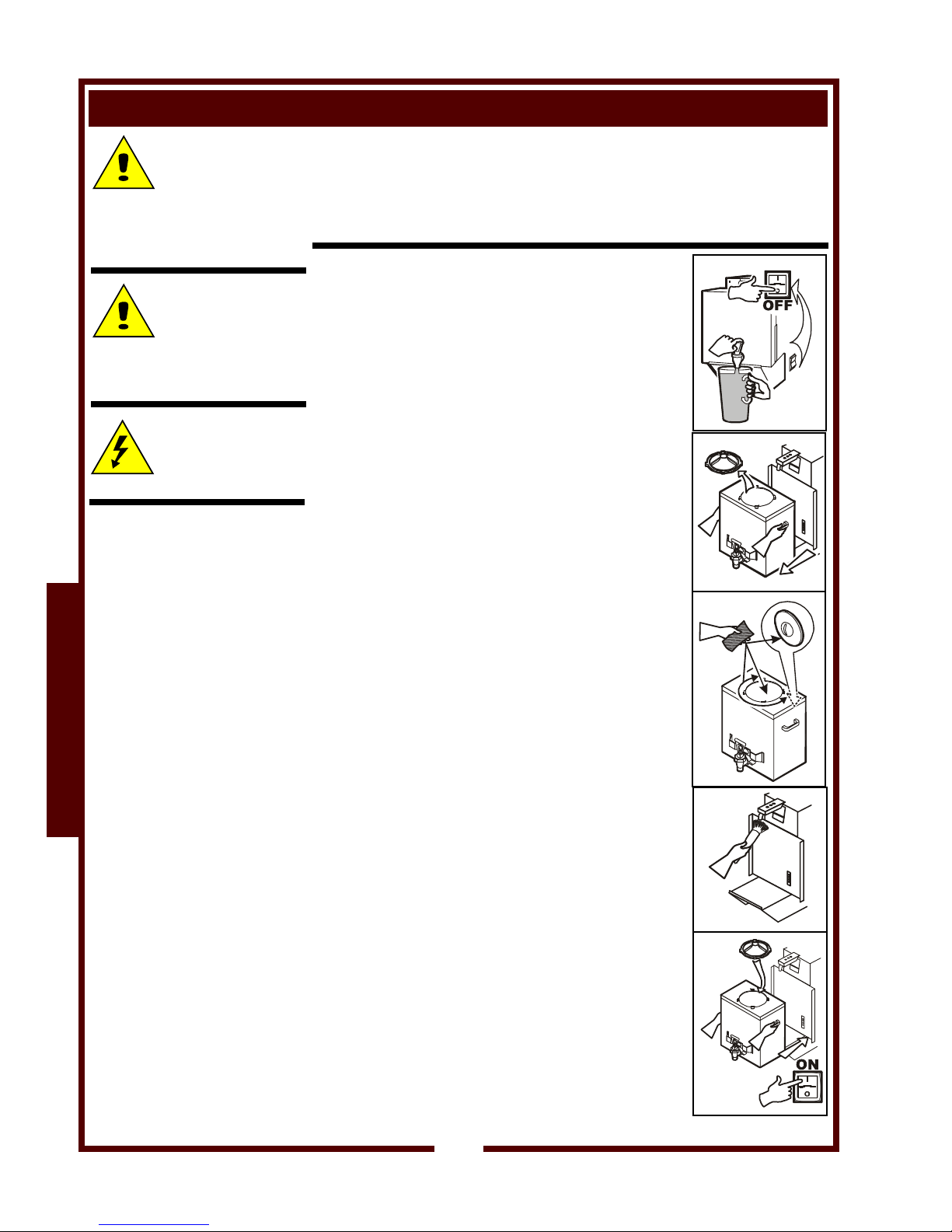

CLEANING - DAILY

1. Wipe down unit

• Spray a clean, sanitizer-soaked towel with TITAN Solution.

• Wipe exterior surfaces.

CLEANING - MONTHLY

Clean Tank

1. Drain Tank

• Press power switch to the OFF position.

• Drain all water from tank into pitcher. As

each pitcher is full, turn faucet off and dump

pitcher of water into sink. It will take about

6 pitcher to completely empty tank.

2. Remove and clean tank.

• Remove tank from hot water dispenser.

Take tank to sink to clean.

3. Clean probe, lid, nozzle, and faucet.

• Wipe water level probe and top opening of

tank with a clean, damp, sanitizer-soaked

towel.

• Wash, rinse, and sanitize tank lid in the 3compartment sink. Allow to air dry.

Check operation of faucet.

• Fill the tank with cool tap water. Check the

operation of the dispensing faucet.

• If the faucet leaks, see Problem Solving.

• Drain Tank. Wipe down exterior of the tank

with a clean, damp, sanitized towel.

Clean Water-Max

TM

.

• Use a soft bristle brush to remove any

calcium or lime build-up on the end of the

water input nozzle. Wipe water input nozzle

with a clean, damp, sanitized-soaked towel.

• Wipe down entire unit with a clean,

damp, sanitizer-soaked towel.

Reinstall tank.

• Reinstall tank on Water-Max

TM

shelf.

Press power switch to the ON position.

12

Loading...

Loading...