Page 1

WELLS MANUFACTURING COMPANY

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

Customer Service (775) 345-0444 Ext.502

fax: (775) 345-0569

www.wellsbloomfield.com

SERVICE MANUAL

SERVICE MANUAL

DROP-IN DISHWARE

DISPENSERS

AAA-AAA

MODELS

UTS & UTY

TROUBLESHOOTING

SUGGESTIONS

SERVICING

INSTRUCTIONS

EXPLODED VIEW

PARTS LIST

WIRING DIAGRAM

432

MODEL

UT, UTH

Includes:

Model UTH8

IMPORTANT:

DISSEMINATION OF THIS INFORMATION TO ANYONE OTHER THAN

WELLS AUTHORIZED SERVICE AGENTS IS STRICTLY PROHIBITED.

TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR

USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY.

p/n 503849 Rev. (-) S432 061201 cps

WELLS MANUFACTURING PROPRIETARY INFORMATION.

Page 2

PRECAUTIONS AND GENERAL INFORMATION

WARNING:

Risk of

personal injury

Electrical installation of

heated dispensers must

be performed by a

qualified technician with

full knowledge of all

applicable electrical and

plumbing codes. Failure

can result in personal

injury and property

damage.

WARNING:

Electric

Shock hazard

All servicing requiring

access to non-insulated

electrical components

must be performed by a

qualified technician.

DO NOT open any

access panel which

requires the use of tools.

Failure to follow this

warning can result in

severe electrical shock.

CAUTION:

Risk of

Damage

DO NOT connect or

energize heated

dispensers until all

installation

instructions are read and

followed. Damage to the

dispenser will result if

these instructions are not

followed.

This dispenser is intended for use in commercial establishments

only.

This dispenser is intended

size and shape. No other use is

manufacturer or its agents.

to dispense dinnerware of an appropriate

recommended or authorized by the

Operators of this dispenser must be familiar with the dispenser use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this dispenser.

Cleanliness of this dispenser is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect heated dispensers from electrical power before performing

any maintenance or servicing.

DO NOT submerge heated dispensers in water. Do not splash or pour

water on, in or over any controls, control panel or wiring.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualified technical personnel.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This dispenser is made in the USA. Unless otherwise noted, this

dispenser has American sizes on all hardware.

xi

Page 3

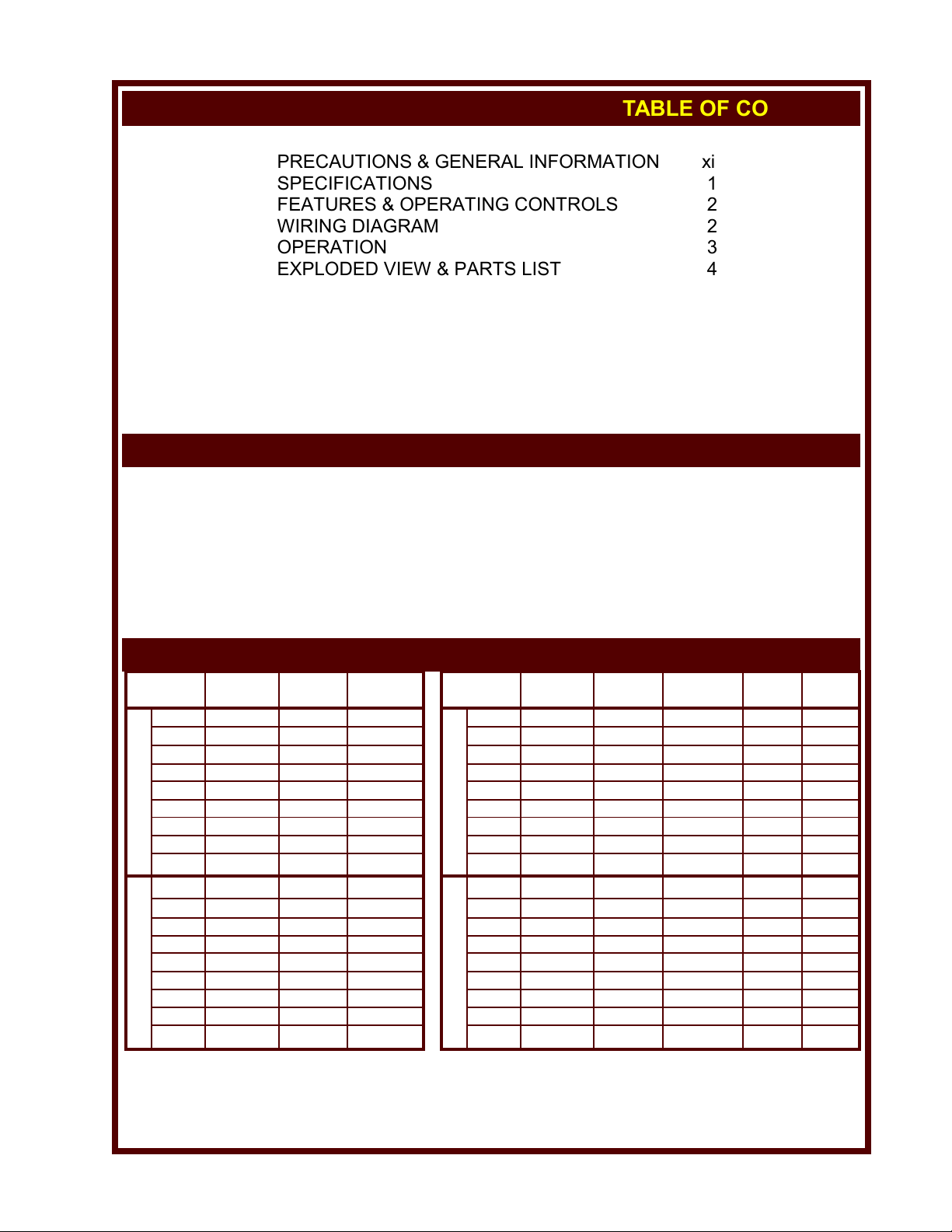

TABLE OF CONTENTS

PRECAUTIONS & GENERAL INFORMATION xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

WIRING DIAGRAM 2

OPERATION 3

EXPLODED VIEW & PARTS LIST 4

INTRODUCTION

This manual contains the information needed to properly service and repair this equipment.

MODEL DISH FLANGE REQ’D.

NO. DIA. DIA. CUTOUT*

UT4 UP TO 4” 7h ” 6d ” dia.

UT5 4d ”-5” 8h ” 7d ” dia.

UT57 5d ”-5H ” 9 ” 7d ” dia.

UT65 5L ”-6p ” 9H ” 8D ” dia.

UT7 6D ”-7h ” 10p ” 9l ” dia.

UT8 7L ”-8d ” 11L ” 10h ” dia.

UT9 8h ”-9d ” 12l ” 11h ” dia.

OPEN DROP-IN TUBES SHIELDED DROP-IN TUBES

UT10 9h ”-10h ” 13l ” 12l ” dia.

UT12 10l ”-12” 15d ” 14d ” dia.

UTS4 UP TO 4” 7h ” 6j ” dia.

UTS5 4d ”-5” 8h ” 7n ” dia.

UTS57 5d ”-5H ” 9 ” 8f ” dia.

UTS65 5L ”-6p ” 9H ” 8D ” dia.

UTS7 6D ”-7h ” 10p ” 9F ” dia.

UTS8 7L ”-8d ” 11L ” 10B ” dia.

UTS9 8h ”-9d ” 12l ” 11B ” dia.

UTS10 9h ”-10h ” 13l ” 12B ” dia.

UTS12 10l ”-12” 15d ” 14j ” dia.

* NOTE: Verify dimensions by referring to the Installation Instructions included with the dispenser.

For metric sizes refer to the Specification Sheet included with the dispenser.

UTH and UTY heated dispensers are shielded. UTS shielded dispensers are not heated.

MODEL DISH FLANGE REQ’D. WATTS AMPS

NO. DIA. DIA. CUTOUT*

UTH4 UP TO 4” 7h ” 6j ” dia. 240 2.0

UTH5 4d ”-5” 8h ” 7n ” dia. 240 2.0

UTH57 5d ”-5H ” 9 ” 8f ” dia. 240 2.0

UTH65 5L ”-6p ” 9H ” 8D ” dia. 300 2.5

UTH7 6D ”-7h ” 10p ” 9F ” dia. 300 2.5

UTH8 7L ”-8d ” 11L ” 10B ” dia. 300 2.5

UTH9 8h ”-9d ” 12l ” 11B ” dia. 300 2.5

UTH10 9h ”-10h ” 13l ” 12B ” dia. 500 4.2

UTH12 10l ”-12” 15d ” 14j ” dia. 500 4.2

120V 1ø HEATED DROP-IN TUBES

UTY4 UP TO 4” 7h ” 6j ” dia. 240 1.0

UTY5 4d ”-5” 8h ” 7n ” dia. 240 1.0

UTY57 5d ”-5H ” 9 ” 8f ” dia. 240 1.0

UTY65 5L ”-6p ” 9H ” 8D ” dia. 300 1.3

UTY7 6D ”-7h ” 10p ” 9F ” dia. 300 1.3

UTY8 7L ”-8d ” 11L ” 10B ” dia. 300 1.3

UTY9 8h ”-9d ” 12l ” 11B ” dia. 300 1.3

UTY10 9h ”-10h ” 13l ” 12B ” dia. 500 2.1

UTY12 10l ”-12” 15d ” 14j ” dia. 500 2.1

240V 1ø HEATED DROP-IN TUBES

SPECIFICATIONS

1

Page 4

FEATURES & OPERATING CONTROLS

CARRIAGE

1

2

3

CARRIAGE

SPRINGS

1

2

3

KEY

1

UT Series

2

UTS Series

3

UTH Series

4

UTY Series

PLATE GUIDES

1

2

3

4

4

FLANGE

1

2

3

4

POWER

SWITCH

3

4

POWER

INDICATOR

3

4

TEMPERATURE

ADJUSTMENT

4

OPEN

3

4

TUBE

1

2

3

4

SHIELD

2

3

4

POWER

CORD

3

4

HEATING

ELEMENT

3

4

Fig. 1 Features & Operating Controls - Drop-In Round Dinnerware Dispensers

WIRING DIAGRAM

SILICONE

SLEEVE

POWER

SWITCH

INDICATOR

LIGHT

2

THERMOSTAT

HEATING

ELEMENT

Page 5

OPERATION

OPERATING SUGGESTIONS

Load the dispenser with the appropriate size dinnerware.

Dinnerware which is too large may be broken or may jam the

carriage.

Dinnerware which is too small cannot be safely dispensed, and

may be broken or may jam the carriage.

Load no more than a 6” stack of dinnerware at a time.

Dispensers are designed for EMPTY dinnerware only.

For heated dispensers, turn the power switch to ON. When the switch

is ON the indicator light will glow.

Unused dispensers should be covered with the optional tube cover

(p/n 503985 or 503986).

TROUBLESHOOTING SUGGESTIONS

SYMPTOM

Carriage movement

erratic

Heated dispenser will not

heat (indicator light not on)

Heated dispenser will not

heat (indicator light on)

Heated dispenser indicator

light not lit (unit operating

normally)

Heated dispenser

temperature incorrect

POSSIBLE CAUSE

Debris between carriage and tube

Broken, disconnected or mis-matched

springs

Unit unplugged or circuit breaker

tripped or power switch OFF

Power plug or cord damaged

Power switch damaged or

disconnected

Thermostat set too low

Thermostat or wiring damaged

Heating element damaged or

disconnected

Indicator light damaged or

disconnected

Thermostat damaged

Thermostat not properly set

CAUTION:

Hot Surface

Exposed surfaces of heated

dispensers can be hot to the

touch and may cause burns.

CAUTION:

Pinch Hazard

Hold dinnerware by the sides

when loading the dispenser.

Holding dinnerware by the

bottom can allow fingers to

become trapped between the

plates and the dispenser

walls.

SUGGESTED ACTION

Remove from counter and

clean

Inspect springs— replace or

re-connect springs so that all

four sections are configured

the same

Check / reset circuit breaker

Make sure unit is plugged in

and power switch is ON

Check— replace or repair

Check— replace or repair

Set thermostat

Check— replace or repair

Check— replace or repair

Check— replace or repair

Check— replace or repair

Set thermostat

3

Page 6

EXPLODED VIEW & PARTS LIST

ITEM DESCRIPTION PART NO. USED ON SERIES QTY

1 RING, SPRING RETAINING UT, UTS, UTH, UTY 2

2 STAGE, PLATE CARRIAGE 4” 503987 UT, UTS, UTH, UTY 1

STAGE, PLATE CARRIAGE 5” 503988

STAGE, PLATE CARRIAGE 5-3/4” 503989

STAGE, PLATE CARRIAGE 6-1/2” 503990

STAGE, PLATE CARRIAGE 7” 503991

STAGE, PLATE CARRIAGE 8” 503992

STAGE, PLATE CARRIAGE 9” 503993

STAGE, PLATE CARRIAGE 10” 503994

STAGE, PLATE CARRIAGE 12” 503995

3 COLLAR, PLATE CARRIAGE UT, UTS, UTH, UTY 1

4 RING, INNER SUPPORT UT, UTS, UTH, UTY 1

5 SPACER, INNER SUPPORT UT, UTS, UTH, UTY 5

6 SPRING, COARSE NON-HEATED 503966 UT, UTS 20

SPRING, FINE NON-HEATED 503960 UT, UTS

SPRING, COARSE HEATED 503961 UTH, UTY

SPRING, FINE HEATED 503950 UTH, UTY

4

Page 7

ITEM DESCRIPTION PART NO. USED ON SERIES QTY

7 GLIDE, PLATE CARRIAGE, TEFLON 503952 UT, UTS, UTH, UTY 8

8 GUIDE, PLATE PLASTIC 503951 UT, UTS, UTH, UTY 3

9 ASSY, FRAME NON-HEATED UT, UTS 1

ASSY, FRAME HEATED UTH, UTY

10 SHIELD, NON-HEATED UT, UTS 1

SHIELD, HEATED UTH, UTY

11 BOTTOM, SHIELD NON-HEATED UT, UTS 1

BOTTOM, SHIELD HEATED UTH, UTY

20 ASSEMBLY, CONTROL

21 SWITCH, POWER 503959 UTH, UTY 1

22 INDICATOR, POWER RED 120 VOLT 503957 UTH 1

INDICATOR, POWER RED 240 VOLT 503964 UTY

23 TROUGH, WIRING UTH, UTY 1

24 BRACKET, TEMP CONTROL UTH, UTY 1

25 CONTROL, TEMP BI-METAL 503956 UTH, UTY 1

31 ELEMENT, 120 VOLT, 4”, 5”, 5-3/4” 503953 UTH 1

ELEMENT, 120 VOLT, 6-1/2”, 7”, 8”, 9” 503967

ELEMENT, 120 VOLT, 10”, 12” 503969

ELEMENT, 240 VOLT, 4”, 5”, 5-3/4” 503962 UTY

ELEMENT, 240 VOLT, 6-1/2”, 7”, 8”, 9” 503968

ELEMENT, 240 VOLT, 10”, 12” 503970

32 ASSY, POWER CORD 120 VOLT 503983 UTH 1

ASSY, POWER CORD 240 VOLT 503984 UTY

33 STRAIN RELIEF UTH, UTY 1

50 PLATE COVER, 7” - 8” TUBE 503985 OPTIONAL

PLATE COVER, 9” - 10” TUBE 503986 OPTIONAL

a SCREW, PH 10-24 x 1-1/2” SS UT, UTS, UTH, UTY 5

b SCREW, PH #8 x 1/4” SMS SS UT, UTS, UTH, UTY 8

c SCREW, #12 x 3” RHWS Zi UT, UTS, UTH, UTY 3

d NUT, 10-32 SS UTH, UTY 2

e NUT, 10-32 x 7/8” Alum UTH, UTY 2

f NUT, KEP 10-24 SS UT, 5

UTS, UTH, UTY 8

g RIVET, BLIND 3/32 x 1/4 Alum UTS 4

UTH, UTY 6

h RETAINER, WIRING UTH, UTY 3

5

Page 8

IMPORTANT:

WELLS MANUFACTURING PROPRIETARY INFORMATION.

DISSEMINATION OF THIS INFORMATION TO ANYONE OTHER THAN

WELLS AUTHORIZED SERVICE AGENTS IS STRICTLY PROHIBITED.

TECHNICAL CONTENT OF THIS MANUAL IS DESIGNED FOR

USE BY QUALIFIED PROFESSIONAL TECHNICIANS ONLY.

WELLS MANUFACTURING COMPANY

DIVISION OF CARRIER REFRIGERATION

2 ERIK CIRCLE, P. O. Box 280

Verdi, NV 89439

Customer Service (775) 345-0444 Ext.502

fax: (775) 345-0569

www.wellsbloomfield.com

Loading...

Loading...