Wells UT Installation Manual

Chromalox

®

DIVISION 4 SECTION

GR/U

SALES

REFERENCE

DATE

SERVICE REFERENCE

Installation

and

MAINTENANCE INSTRUCTIONS

PD445

NOVEMBER, 1996

161-562653-001

© 2010 Chromalox, Inc.

GENERAL

CAUTION: Handle GRTF Teflon®coils with extreme

care. Contact with sharp or blunt objects may

cause tubes to rupture.

1. Inspect the product for any damage during shipment. Consult

factory if any damage is evident.

2. Insure the equipment is correct dimensionally as ordered. Be

certain the unit is set up for the proper heat transfer mode

(steam or fluid).

3. It is ultimately up to the customer to choose the proper materi-

al of construction based upon their knowledge of the chemical

composition of the solution being heated/cooled. Chromalox

will aid in the selection process, but cannot warrant any product due to failure by corrosion that is the result of operating

conditions beyond our control.

Type GR & U Heating/Cooling Coils

INSTALLATION

1. Care should be used when handling Teflon®products.

2. When installing coils, insure all threaded fittings are held

securely in place by a wrench.

3. Use approved sealant material when installing piping.

4. For Teflon

®

products, make certain line pressure does not

exceed 25 PSI or 450˚F. Metal products should not exceed

100 psi.

5. If counter-weights are being used, make certain they are ade-

quate to keep coils submerged. Consult factory if coils begin

to float.

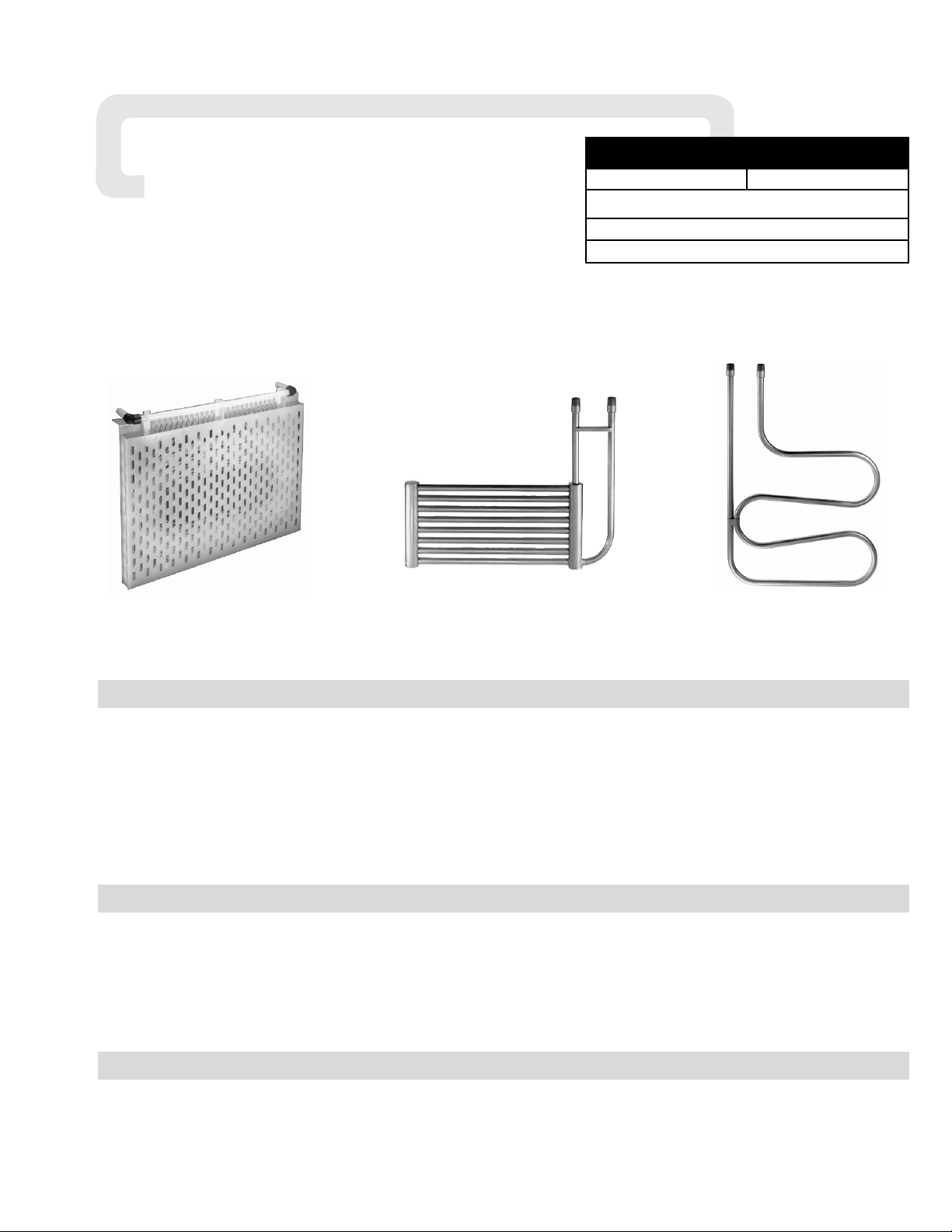

GRTF

(Teflon)

GRT

(316 Stainless or Titanium)

UT, US

(316 Stainless or Titanium)

MAINTENANCE

1. Check coils periodically for coatings and corrosion buildup.

Cleaning of coils is most effectively done chemically. Insure that

the chemical agent is compatible with the coil material. A wire

brush can be used on metal heat exchangers. Never use wire

brush on Teflon

®

coils. Follow all safety precautions as recom-

mended by the cleaning agent manufacturer, including goggles,

gloves, aprons, etc.

* Teflon

®

is a registered trademark of DuPont

TA - Q0 - EF

Litho in U.S.A.

103 GAMMA DRIVE, PITTSBURGH, PA 15238

Phone: 800-443-2640 www.chromalox.com

Limited Warranty:

Please refer to the Chromalox limited warranty applicable to this product at

http://www.chromalox.com/customer-service/policies/termsofsale.aspx.

Loading...

Loading...