Wells HRCP-7300SL Installation Manual

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

phone: 314-678-6314

fax: 314-781-2714

www.wells-mfg.com

OPERATIONS MANUAL

DROP-IN HOT AND COLD

NS, SLIM LINE

PA

HRCP-7200SL

HRCP-7300SL

HRCP-7400SL

407

MODELS

Model HRCP-7200SL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

INST

USE & CARE

WIRING DIAGRAM

IMPORTANT: DO NOT DISCARD THIS MANUAL

Includes

ALLA

TION

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS U S ING OR

2M-Z16055 Rev. C

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

04/18

LIMITED EQUIPMENT WARRANTY

Wells Manufacturing warranties new products to be free from defects

in material and/or workmanship for a period of one [1] year from the

date of original installation, except as noted below. Defects that occur

as a result of normal use, within the time period and limitations defined

in this warranty, will at Wells’ discretion have the parts replaced or

repaired by Wells or a Wells-authorized service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Wellsauthorized service agency. Wells will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Wells-authorized service agency must be used.

Wells will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specific

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation prepaid .

CO NTAC T

Should you require any assistance regarding the operation or

maintenance of any Wells equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone 314.678.6314

Fax 314.781.2714

Email customerservice@star-mfg.com

www.wells-mfg.com

WARRA

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been installed, cleaned, maintained,

or used in accordance with the directions published in the appropriate

installation sheet and/or owner’s manual as well as national and local

codes, including incorrect gas or electrical connection. Wells is not liable

for any unit which has been mishandled, abused, misapplied, subjected

to chlorides, harsh chemicals, or caustic cleaners, damaged from

exposure to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have an altered

or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls, air

and gas burner/bypass/pilot adjustments, gas or electrical system

checks, voltage and phase conversions, cleaning of equipment,

or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety controls,

or reset buttons.

• Replacement of broken or damaged glass components, quartz heating

elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and hotplates,

including but not limited to burners, grates, and radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform service.

• Parts that fail or are damaged due to normal wear or labor for

replacement of Items that can easily be replaced during a daily cleaning

routine. such as but not limited to silicone belts, PTFE non-stick sheets,

knobs, control labels, bulbs, fuses, quartz heating elements, baskets,

racks, and grease drawers.

• Components that should be replaced when damaged or worn, but have

been field-repaired instead [eg. field-welded fry pots].

• Any loss of business or profits.

ADDITIONAL WARRANTIES

Specialty/chain specific versions may also have additional and/or

extended warranties.

NTY EXCLUSIONS

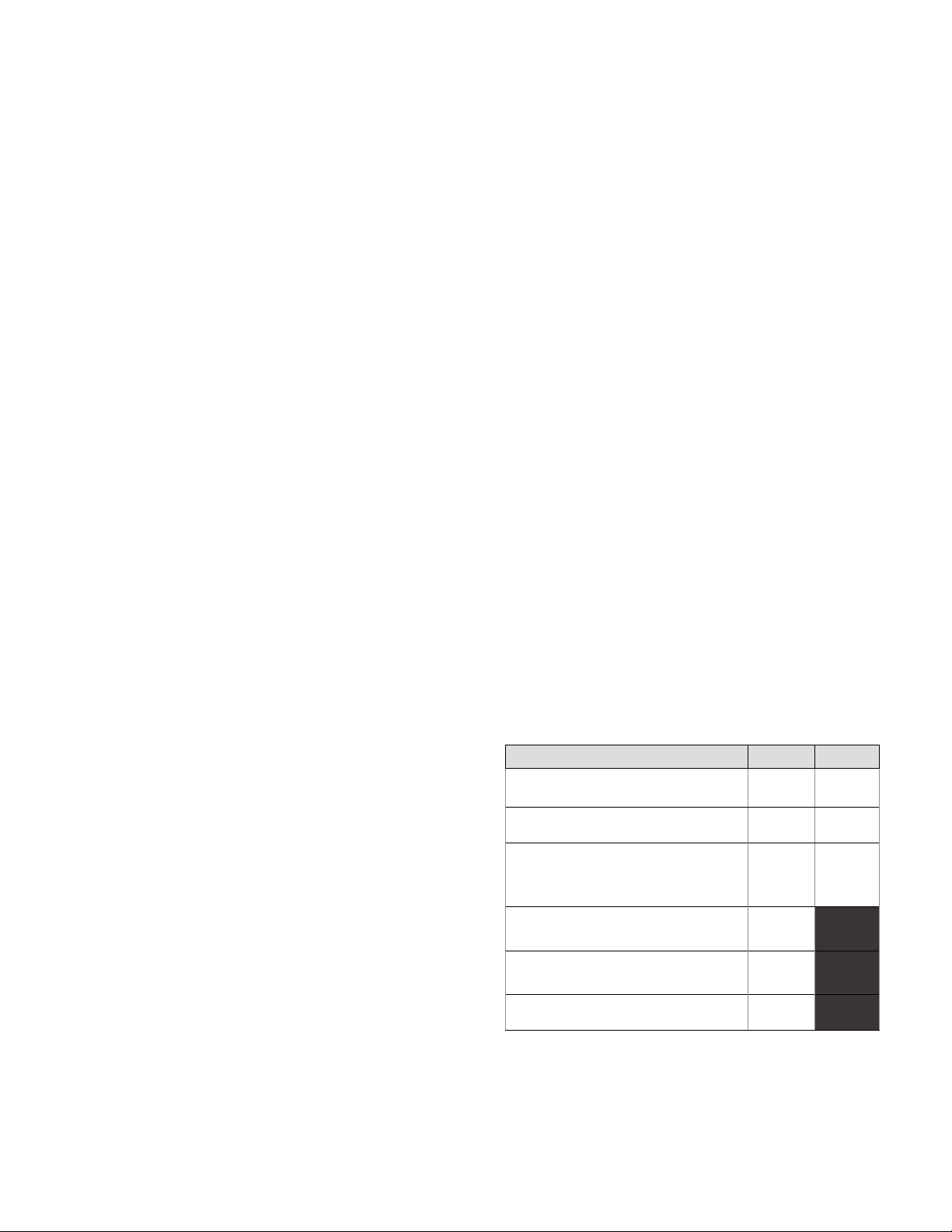

PRODUCTS PARTS LABOR

universal ventless hoods 2 years 1 year

canopy hoods 2 years 1 year

“Cook’n Hold” equipment [HW10,

HWSMP, LLSC7, LLSC7WA, LLSC11,

2 years 1 year

an d LLSC 1 1WA]

cast iron grates, burners, and burner

shields

original Wells parts sold to repair

Wells equipment

1 year

90 days

Service First 1 year

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty. 2M-Z22393 • Rev A • 02.2018

TABLE OF CONTENTS

WARRANTY , SHIPPING DAMAGE PROCEDURE

INTRODUCTION & SPECIFICATIONS ................................ 1

FEATURES & OPERATING CONTROLS ............................ 2

PRECAUTIONS & GENERAL INFORMATION .................... 3

AGENCY LISTING INFORMATION ...................................... 4

INSTALLATION ............................................................. 5, 6, 7

OPERATION ....................................................................... 8, 9

CLEANING INSTRUCTIONS ............................................... 10

TROUBLESHOOTING SUGGESTIONS .............................. 11

MAINTENANCE INSTRUCTIONS .............................12, 13, 14

WIRING & REFRIG. DIAGRAM............................................. 15

SERVICE PARTS LIST ........................................................ 16

BLANK PAGE FOR NOTES………. ...................................... 17

CUSTOMER SERVICE DATA ............................................. 17

INTRODUCTION

Thank you for purchasing this Wells Bloomfield appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that

it gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install, use and care for this appliance t in a

manner which will guarantee its optimum performance.

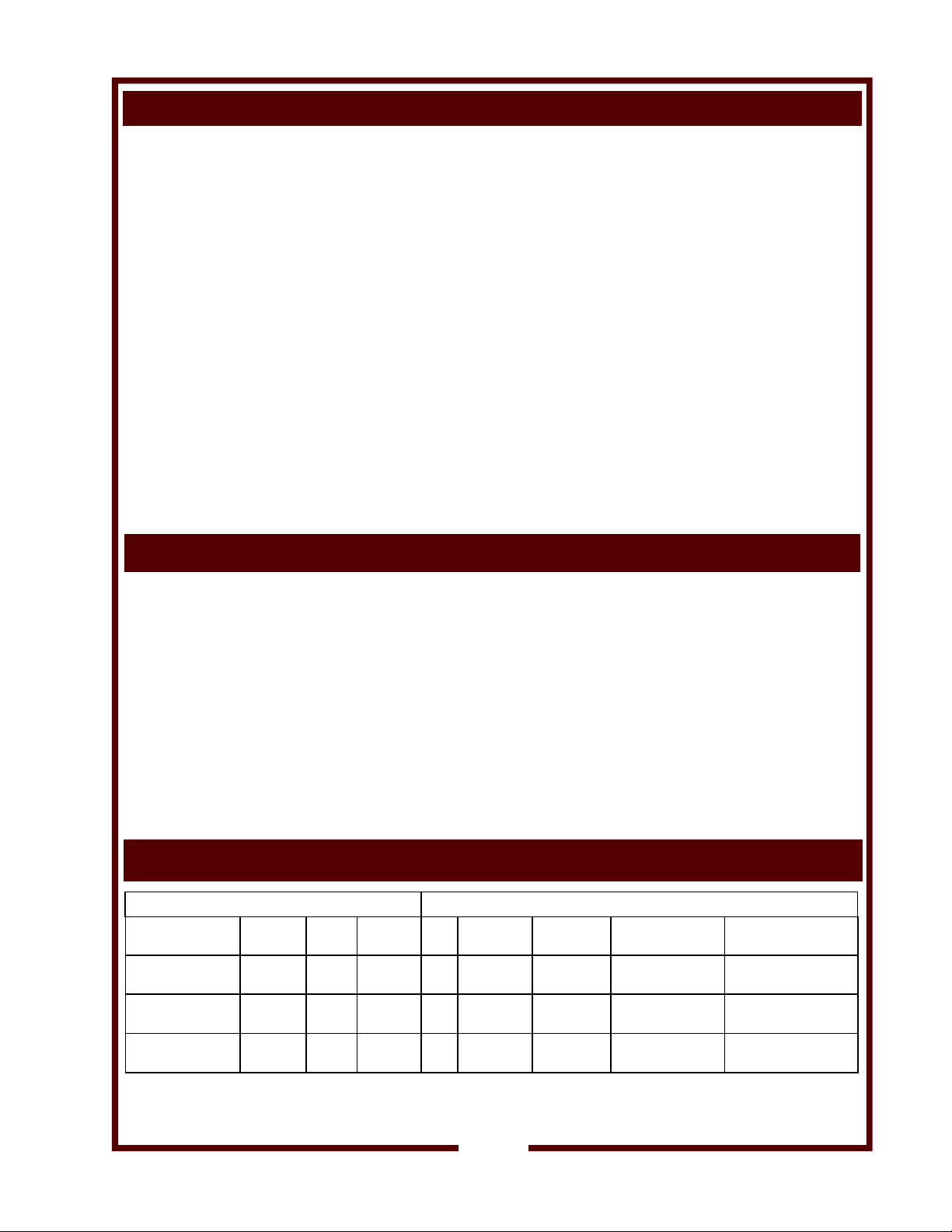

ELECTRICAL & REFRIGERATION SPECIFICATIONS

WARMER REFRIGERATION

MODEL VOLTS KW 1ø AMPS HP VOLTS 1ø AMPS REFRIGERANT

HRCP-7200SL

HRCP-7300SL

HRCP-7400SL

M407 p/n 2M-Z16055 Owners Manual HRCP-SL Series Heated Cld Pans

208/240

60Hz

208/240

60Hz

208/240

60Hz

1.9/2.5 9/10.4 1/4

3.0/4.0 14.4/16.7 1/3

3.8/5.0 18.1/20.8 1/2 120 60Hz 8.9 R-404a

120 60Hz

120 60Hz

4.9 R-134a

5.5 R-134a

POWER SUPPLY

REQUIREMENT

3-wire: L1, L2, N

#10 AWG min. 60ºC

3-wire: L1, L2, N

#10 AWG min. 60ºC

3-wire: L1, L2, N

#10 AWG min. 60ºC

NOTE: For equipment and cut-out dimensions, refer to the Installation Instructions provided with each unit.

1

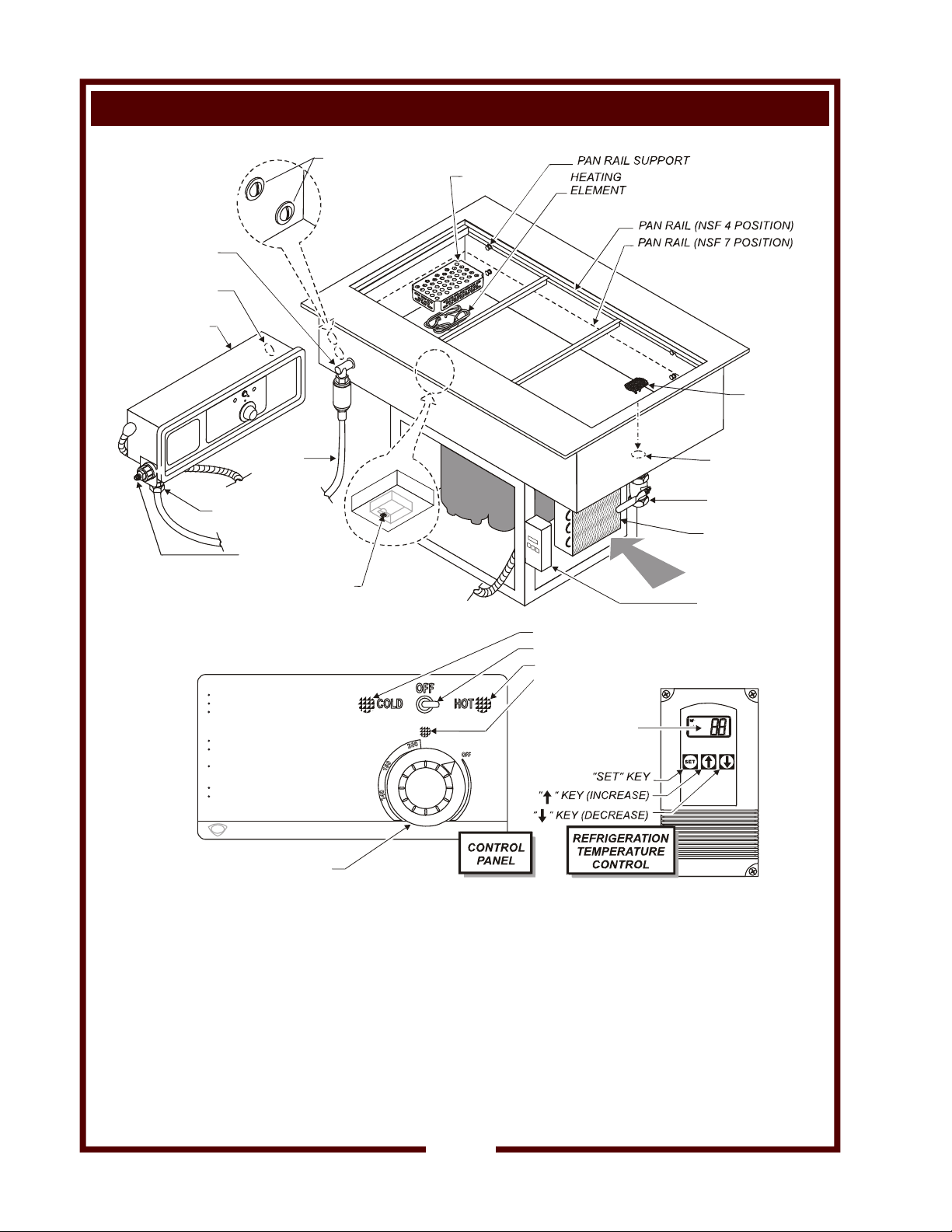

FEATURES & OPERATING CONTROLS

N

AIRFLOW

WATER LEVEL

PROBES

(inside pan)

PS-304943

AUTOFILL

BACKFLOW

PREVENTER

2V-47650

ELECTRICAL

SUPPLY INLET

CONTROL

ASSEMBLY

(rotated 90° to

show detail)

AUTOFILL

TUBE

P2-46587

AUTOFILL TUBE

CONNECTION

WATER SUPPLY

CONNECTION

MANUAL RESET

OVER-TEMP SAFETY

NOTE: Reset is on bottom

of element and is accessible

from outside bottom of tank.

2T-Z22604

COLD OPERATION

set selector to COLD position

cold pan temperature factory set

run until 30 minutes before adding

pre-chilled product

HOT OPERATION

set selector to HOT position

turn thermostat dial to desired

water bath position

pan fills with water automatically

SWITCHING FROM HOT TO COLD OPERATION

set selector to OFF position

drain hot water and allow to cool

NEVER SELECT COLD OPERATION

WHEN WATER REMAINS IN PAN

WELLS MANUFACTURING COMPANY . ST. LOUIS, MO USA

TEMPERATURE CONTROL

HOT OPERATION

Thermal Control, 36” Capillary: 2T-304937

Thermal Control, 48” Capillary: 2T-304937A

Knob: 2R-Y7690

ELEMENT

COVER

2N-304144; 2.5KW

2N-304145; 4.0KW

AIRFLOW

INDICATOR - COLD OPERATION

SELECTOR - COLD - OFF - HOT

INDICATOR - HOT OPERATION

INDICATOR - HEATING

LCD READOUT

2E-Z17505

DRAIN

SCREEN

P2-31869

DRAIN

DRAIN

VALVE

REFRIGERATIO

CONDENSER

REFRIGERATION

TEMPERATURE

CONTROL

2E-Z17505

2J-40563

2E-304936

2J-31157

2J-30385

IL2693

M407 p/n 2M-Z16055 Owners Manual HRCP-SL Series Heated Cld Pans

NOTE: This drawing represents an HRCP-7300SL not to scale. Other models in the series are similar.

Parts Not Shown:

2E-302789 CONTACTOR 50A 3 PHASE 208

2E-304270 SOLENOID VALVE 1/4NPT 240

2E-304938 CONTROL WATER LEVEL HRCP

2E-305479 FUSE CLASS T TYPE JJS 15A

2E-37465 TERM BLOCK 3POLE 85AMP

2E-70889 RELAY 30AMP 120V

2

PRECAUTIONS AND GENERAL INFORMATION

This appliance is intended for use in commercial establishments

only, and is intended

consumption. Food may be held either hot or cold. No other use is

recommended or authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

For hot operation, the appropriate water level must be maintained at

all times. Food must be kept in appropriate inserts. Never place food

directly into the tank.

Cleanliness of this appliance is essential to good sanitation. Read

and follow all included cleaning instructions and schedules to ensure

the safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

DO NOT submerge this appliance in water. This appliance is not jet

stream approved. Do not direct water jet or steam jet at this appliance,

or at any control panel or wiring. Do not splash or pour water on, in

or over any controls, control panel or wiring. Do not wash floor

around this appliance with water or steam jet.

Do not operate this appliance if the control panel is damaged.

Call your Authorized Wells Service Agent for service.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualified technical personnel.

Any procedure which requires the use of tools must be performed by

a qualified technician.

to hold previously prepared food for human

WARNING:

ELECTRIC

SHOCK HAZARD

All servicing requiring access

to non-insulated electrical

components must be

performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to

follow this warning can

result in severe electrical

shock.

CAUTION:

RISK OF

DAMAGE

DO NOT con

energize this appliance

until all installation

instructions are read and

followed. Damage to the

appliance will result if these

instructions are not

followed.

nect or

CAUTION:

HOT SURFACE

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics,

parts breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance uses all American-sized hardware.

M407 p/n 2M-Z16055 Owners Manual HRCP-SL Series Heated Cld Pans

3

Exposed

to the touch and may cause

burns.

surfaces can be hot

AGENCY LISTING INFORMATION

This appliance is performance tested to NSF Standard 4 for holding hot

STD 4

STD 7

UL197

UL471

foods. This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions and

maintained according to the instructions in this manual.

This appliance is performance tested to NSF Standard 7 for storage of

potentially hazardous foods. This appliance meets NSF Standard 7

only when the pan rails are installed in the lowest position.

HRCP units are ETL listed for US and Canada

HRCP units are evaluated to UL standards 197 and 471.

Components used in the manufacture of this unit are Underwriters

Laboratory recognized.

4

M407 p/n 2M-Z16055 Owners Manual HRCP-SL Series Heated Cld Pans

Loading...

Loading...