Page 1

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 314-678-6314

fax: 314-781-2714

www.wells-mfg.com

025

HDW-2

OWNER

'S MANUAL

BUILT-IN

DISHER WELL

WARMER

MODELS

HDW-2

HDW-2D

Includes

INSTALLATION

USE & CARE

EXPLODED VIEW

PARTS LIST

WIRING DIAGRAM

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

2M-Z14353 Rev. E

04/2018

Page 2

LIMITED EQUIPMENT WARRANTY

Wells Manufacturing warranties new products to be free from defects

in material and/or workmanship for a period of one [1] year from the

date of original installation, except as noted below. Defects that occur

as a result of normal use, within the time period and limitations defined

in this warranty, will at Wells’ discretion have the parts replaced or

repaired by Wells or a Wells-authorized service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Wellsauthorized service agency. Wells will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Wells-authorized service agency must be used.

Wells will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specific

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation prepaid .

CO NTAC T

Should you require any assistance regarding the operation or

maintenance of any Wells equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone 314.678.6314

Fax 314.781.2714

Email customerservice@star-mfg.com

www.wells-mfg.com

WARRA

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been installed, cleaned, maintained,

or used in accordance with the directions published in the appropriate

installation sheet and/or owner’s manual as well as national and local

codes, including incorrect gas or electrical connection. Wells is not liable

for any unit which has been mishandled, abused, misapplied, subjected

to chlorides, harsh chemicals, or caustic cleaners, damaged from

exposure to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have an altered

or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls, air

and gas burner/bypass/pilot adjustments, gas or electrical system

checks, voltage and phase conversions, cleaning of equipment,

or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety controls,

or reset buttons.

• Replacement of broken or damaged glass components, quartz heating

elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and hotplates,

including but not limited to burners, grates, and radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform service.

• Parts that fail or are damaged due to normal wear or labor for

replacement of Items that can easily be replaced during a daily cleaning

routine. such as but not limited to silicone belts, PTFE non-stick sheets,

knobs, control labels, bulbs, fuses, quartz heating elements, baskets,

racks, and grease drawers.

• Components that should be replaced when damaged or worn, but have

been field-repaired instead [eg. field-welded fry pots].

• Any loss of business or profits.

ADDITIONAL WARRANTIES

Specialty/chain specific versions may also have additional and/or

extended warranties.

NTY EXCLUSIONS

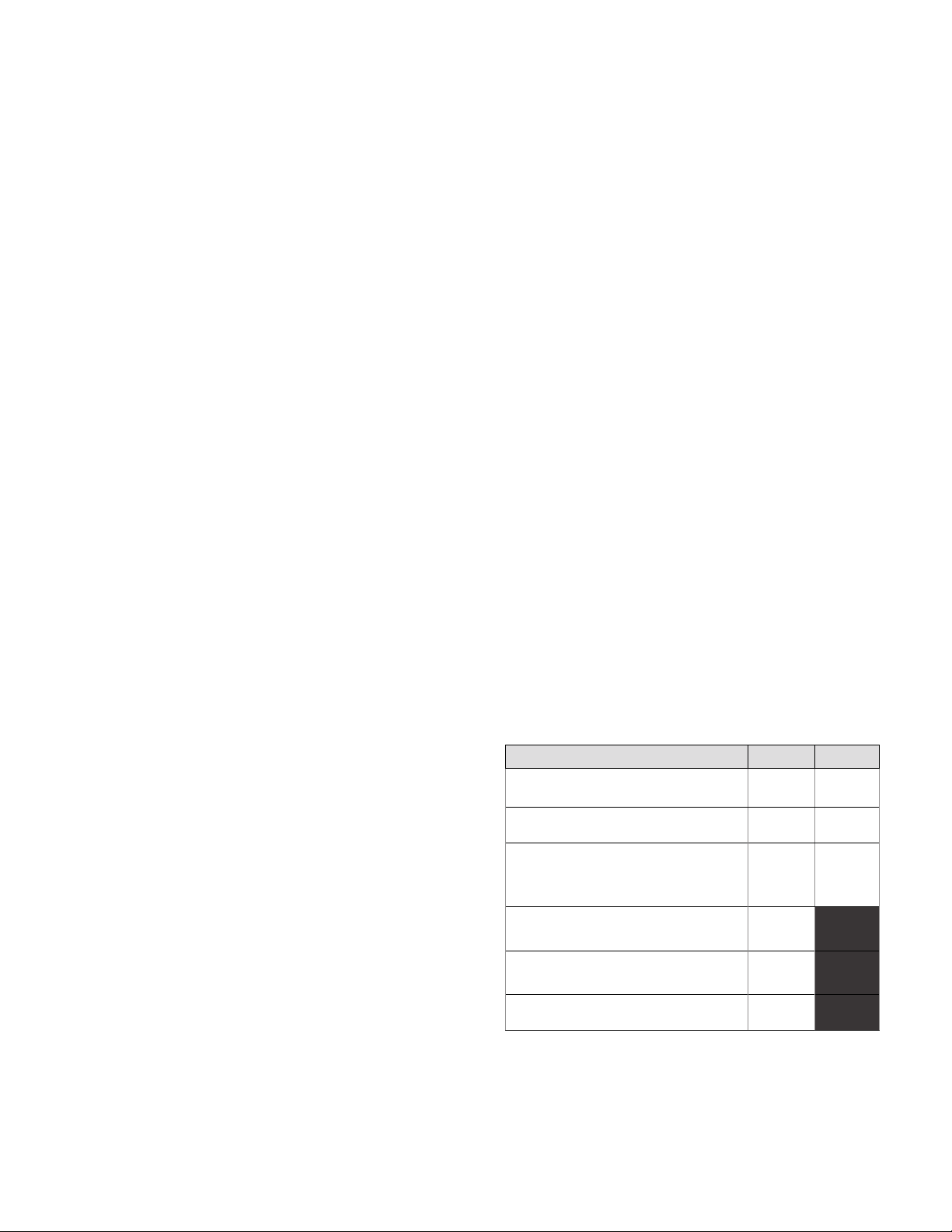

PRODUCTS PARTS LABOR

universal ventless hoods 2 years 1 year

canopy hoods 2 years 1 year

“Cook’n Hold” equipment [HW10,

HWSMP, LLSC7, LLSC7WA, LLSC11,

2 years 1 year

an d LLSC 1 1WA]

cast iron grates, burners, and burner

shields

original Wells parts sold to repair

Wells equipment

1 year

90 days

Service First 1 year

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty. 2M-Z22393 • Rev A • 02.2018

Page 3

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

TABLE OF CONTENTS

WARRANTY

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY LISTING INFORMATION 3

INSTALLATION 4

OPERATION 6

MAINTENANCE INSTRUCTIONS 7

CLEANING INSTRUCTIONS 8-9

TROUBLESHOOTING SUGGESTIONS 10

WIRING DIAGRAM 11

EXPLODED VIEW & PARTS LIST 12-13

PARTS & SERVICE 17

CUSTOMER SERVICE DATA 17

INTRODUCTION

Thank You for purchasing this Wells Manufacturing appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that it

gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for the

appliance in a manner which will ensure its optimum performance.

SPECIFICATIONS

MODEL VOLTS AMPS WATTS POWER SUPPLY CORD

HDW-2, HDW-2D, HDW-2F 120 VAC 1ø 2.5A 300W NEMA 5-15 PLUG

HDW-2-240V 240 VAC 1ø 1.25A 300W NEMA 6-15 PLUG

1

Page 4

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

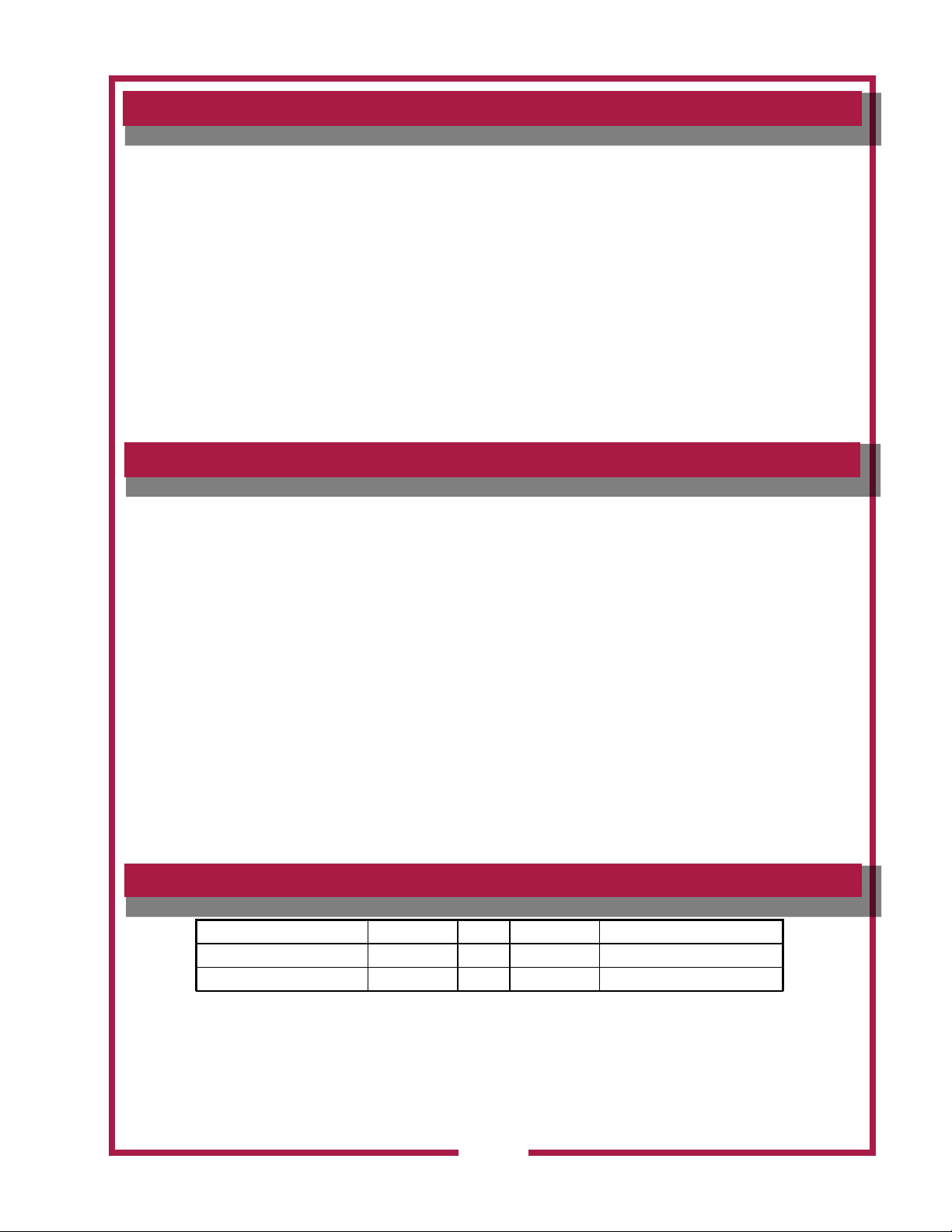

FEATURES & OPERATING CONTROLS

Faucet

(optional with some models)

Stand Pipe &

Drian Overflow

3/4” Drain

Power Cord

See Detail

A

Lighted

Power Switch

Nameplate

IL2157a

MOUNTING

BRACKET

Detail

A

A. CONTROLS

1. Units are equipped with a lighted power switch which illuminates when the

unit is turned on.

2. When the unit begins heating, ll the basin with water.

A temperature of 145°F to 160°F (62°C to 71°C) will be maintained.

B. MOUNTING

1. Units are equipped with Bowl Clamps (qty 3) which are designed to secure

the unit rmly in place on a stainless steel countertop.

NOTE:This appliance is designed to be used on stainless steel countertop only.

2. See the Installation Instructions, supplied with the this appliance, for

details.

C. DRAINS

1. These units are equipped with an overow drain and a Stand Pipe

Assembly. When the Stand Pipe is removed the entire bowl drains.

2

Page 5

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

PRECAUTIONS AND GENERAL INFORMATION

This appliance is intended for use in commercial establishments only.

This appliance is a perpetual-ow sink used to rinse utensils

being used for food preparation

authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

Disconnect this appliance from electrical power before performing any

maintenance or servicing.

This appliance is not jet stream approved. Do not direct water jet

or steam jet at this appliance, or at any control panel or wiring. Do

not splash or pour water on, in or over any controls, control panel or

wiring.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

Do not operate this appliance if the control panel is damaged.

Call your Authorized Wells Service Agent for service.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualied technical personnel.

Any procedure which requires the use of tools must be performed by a

qualied technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics,

parts breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

. No other use is recommended or

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

CAUTION:

RISK OF

DAMAGE

DO NOT connect or energize

this appliance until all

installation instructions are

read and followed. Damage

to the appliance may result

if these instructions are not

followed.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

AGENCY LISTING INFORMATION

Refer to the product nameplate for the specic appliance for agency

listings. In general:

This appliance conforms to NSF Standard 2 for sanitation only if

installed in accordance with the supplied Installation Instructions.

UL Listed warmers are U Listed under UL File E27255.

3

STD 2

E27255

UL Listed Warmers

Page 6

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

INSTALLATION

OPTIONAL FAUCET

0.875” for Wells Supplied

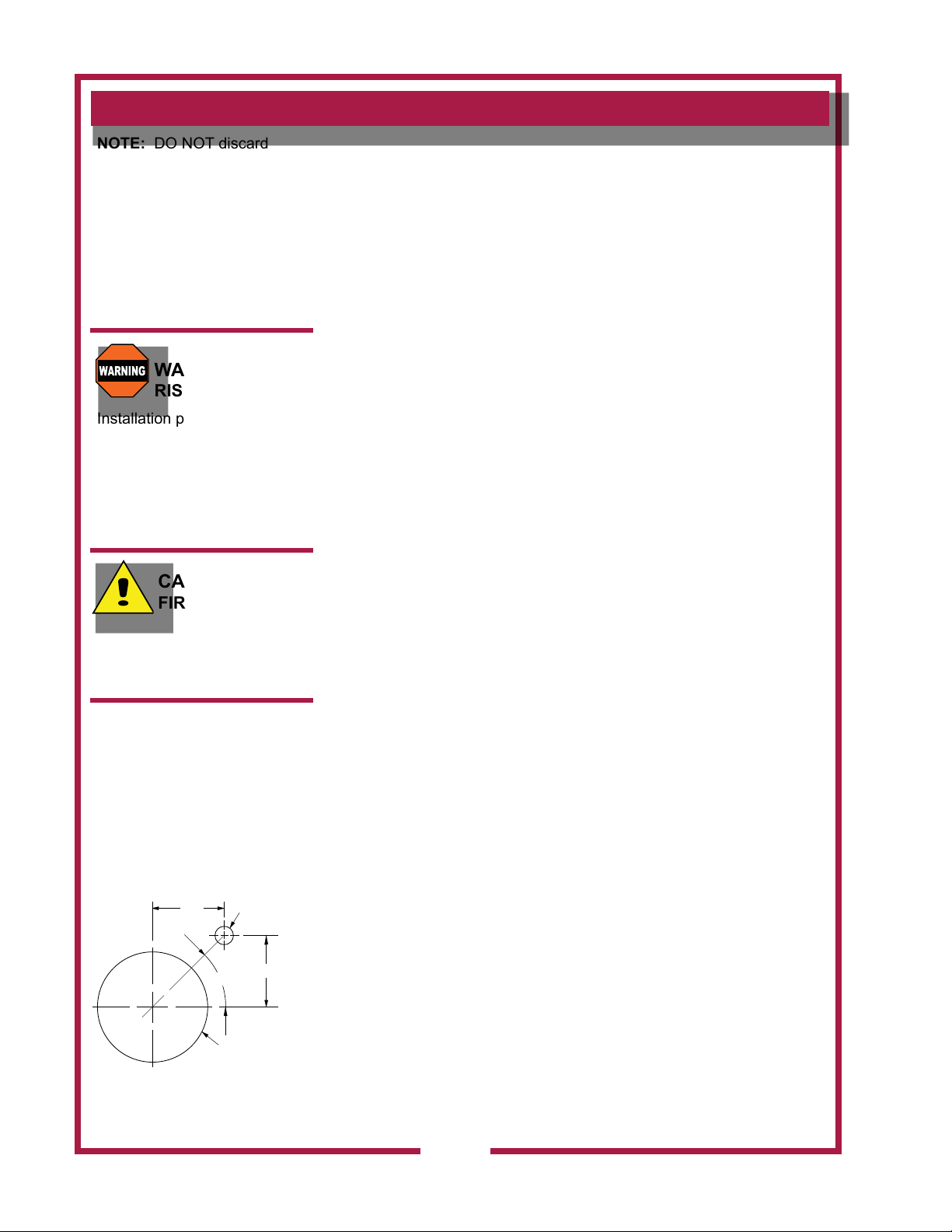

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

RISK OF INJURY

Installation procedures must

be performed by a qualied

technician with full knowledge

of all applicable electrical and

plumbing codes. Failure can

result in personal injury and

property damage.

CAUTION

FIRE HAZARD

Avoid storing ammable or

combustible materials in, on

or near the appliance.

NOTE: Damage caused

by leaks due to improper

installation is NOT covered by

warranty.

3 1/8”

IL2159a

FRONT

Faucet Other Faucets

Sizes May Vary

3 1/8”

45°

6” Dia.

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all protective

plastic lm, packing materials and accessories from the Appliance

before connecting electrical power or otherwise performing any

installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before

discarding packing materials. Store all accessories in a convenient

place for later use.

INSTALLATION NOTES

1. Installation and start up of built-in warmers MUST be performed

by an authorized installation company.

2. It is the RESPONSIBILITY OF THE INSTALLER to verify that

this warmer installation is in compliance with the specications listed in

this manual and on the specication sheet provided.

3. It is the RESPONSIBILITY OF THE INSTALLER to check with

the AUTHORITY HAVING JURISDICTION, in order to verify

that this warmer installation is in compliance with local code

requirements.

4. Water supply and drain installation must meet all applicable

local, state and federal plumbing codes and ordinances.

5. Refer to Installation Instructions included with the warmer for

Underwriters Laboratories conditions of acceptability, electrical

requirements and other installation concerns.

BUILT-IN WARMERS

1. This is a GENERAL GUIDE. For specic cutout dimensions

and other installation details, refer to the Installation Instructions

supplied with the warmer.

2. Cutout dimensions for disher well and optional faucet are listed on the

Installation Instructions provided with the warmer.

NOTE: Verify the dimensions are correct for the installation before

making the cutout.

3. Securing the disher well to a stainless steel countertop:

a. Verify that provided sealants are applied to the underside

of the warmer top ange prior to setting the unit into the cutout.

b.

Units are equipped with Bowl Clamps (qty 3) which are designed

to secure the unit rmly in place on a stainless steel countertop.

c. Apply a thin bead of food-grade silicone sealant around the

ange to seal it to the counter.

NOTE: IF THE WARMER IS INSTALLED ABOVE A FOOD STORAGE

CABINET. A SEALED BARRIER MUST BE PROVIDED BELOW THE

WARMER

4

Page 7

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

INSTALLATION

ELECTRICAL INSTALLATION

1. Refer to the product nameplate. Verify the electrical service power.

Voltage and phase must match the nameplate specications.

Wiring the warmer to the wrong voltage can severely damage the

unit or cause noticeably decreased performance.

2. Available electrical service amperage must meet or exceed the

specications listed on the specication sheet provided with the

warmer.

3. Warmer and control unit must be connected to an appropriate

building ground. Ground connection will be marked “GND” or

” “ .

NOTE: Wire gauge, insulation type and temperature rating , as

well as type, size and construction of conduit, must meet or exceed

applicable specications of local codes and of the National

Electrical Code.

E. PLUMBING INSTALLATION

For use in the State of Massachusetts, this appliance must be

installed in compliance with Massachusetts Fuel Gas and

Plumbing Code CMR 248.

1. IMPORTANT: All plumbing installations must be performed by

a qualied plumber.

2. These units are equipped with a 3/4” drain and will require a

DRAIN LINE: Some jurisdictions may require an approved air

gap or other back-ow prevention device in the drain. It is the

responsibility of the plumber to determine such requirement, to

provide and properly install the required device.

3. For HDW-2 units, the 3/4” drain must be attached with a union

at the drain line tting. This is necessary to provide for future

maintenance to the unit.

CAUTION:

SHOCK HAZARD

The ground lug of this

appliance must be connected

to a suitable building ground.

IMPORTANT:

Contact a licensed electrician

to install and connect electrical

power to the appliance.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

IMPORTANT: Electrical

installation other than as

specied on the specication

sheet will void the UL listing,

and may void the warranty.

NOTE: Plumb connections

must be made in compliance

with all Federal, State and

Local Plumbing Codes and

Ordinances.

NOTE: Damage caused

by leaks due to improper

installation is NOT covered by

warranty.

5

Page 8

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

OPERATION

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

CAUTION:

SHOCK HAZARD

DO NOT splash or pour water

onto control panel or wiring.

DO NOT place food directly

into the warmer.

DO NOT put ice into a

warmer pan. This will cause

condensation on the inside of

the warmer. Damage caused

by condensation is NOT

covered by warranty.

WET OPERATION for DISHER WELL

1. This unit is designed to be used for WET operation, add tap water

before turning the warmer on.

approximately 30 minutes prior to using.

a. Check the water level frequently and add water as necessary

to refresh the water in the basin, or to prevent the warmer from

running dry.

b. If your wet-operation warmer is allowed to run dry, turn it OFF and

allow to cool to room temperature before adding water.

4. Damage caused by allowing a wet-operation warmer to run dry,

is NOT covered by warranty. Damage caused by adding water

to a dry warmer when hot is NOT covered by warranty.

OPERATION

1. Use this appliance as a safe location to store and rinse your

utensils, DO NOT place food directly into the warmer.

2. Check water level in the warmer frequently during use.

3.

DO NOT use metal tools, steel wool, or caustic or abrasive cleanser to

clean warmer pan.

Allow the disher well to preheat for

6

Page 9

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

MAINTENANCE INSTRUCTIONS

CARE OF STAINLESS STEEL

Stainless steel is a marvelous material: strong, lustrous and low maintenance. With

a minimum of care, it will normally retain its beauty and durability for the life of the

equipment. In some applications, however, special care is required in order to maintain

stainless steel’s special properties.

External components, such as cabinets and control panels, are nished with a grain

pattern. This pleasing nish is best maintained by cleaning with a non-abrasive

cleanser applied with a soft cloth. Rub only in the direction of the grain. In the absence

of visible grain, rub only along the longest axis of the appliance.

Restore stainless steel’s luster by applying a polish specically made for stainless steel.

Spray on, wipe off with a soft cloth, rubbing in the direction of the grain.

Never use metal implements, wire brushes, abrasive scratch pads or steel

wool to clean stainless steel.

Warmer pans, insets and other vessels are subject to a harsher environment. Wells

Manufacturing uses an very high quality stainless steel (#304DDQ) for our food warmer

pans. Even the highest quality stainless steel, however, is mostly iron, and will rust, pit

and corrode under the following conditions:

• Poor Water Quality: Hard water (water with a high content of dissolved miner-

als) will leave mineral deposits when allowed to dry. Calcium (lime) can buildup on

heated surfaces, even under water. If left unattended, hard water spots and lime

buildup can lead to rusting, corrosion and pitting.

• Contact with Chlorides: Chlorides (specic compounds of chlorine) are found in

food, table salt and many cleansers. Chlorides can attack the surface of stainless

steel, resulting in corrosion and pitting.

Keep your stainless steel warmers clean and free from calcium buildup.

Use alkaline, alkaline chlorinated or non-chloride cleanser.

Use citric acid-based cleaners to remove calcium deposits.

For additional information, please read the NAFEM Stainless Steel Equipment and

Cleaning Guide. Contact NAFEM at :

North American Association of Food Equipment Manufacturers

401 N. Michigan Avenue

Chicago, Illinois 60611-4267

(312) 644-6610

7

Page 10

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

CLEANING INSTRUCTIONS

CAUTION

:

SHOCK HAZARD

Do NOT splash or pour water

into or over any control panel

or wiring.

CAUTION:

SHOCK HAZARD

Disconnect warmer from

electric power before cleaning

CAUTION:

BURN HAZARD

Allow warmer to cool

completely before cleaning.

DAILY CLEANING INSTRUCTIONS

PREPARATIONS: Turn main power switch to OFF. Allow warmer to

cool before proceeding.

Remove any insets, utinsils and/or inserts.

Drain or remove water from well..

FREQUENCY: Minimum - daily.

TOOLS: Mild Detergent

Solution: 10 Parts Warm Water to 4 Parts Vinegar

Plastic Scouring Pad

Clean Cloth or Sponge

Food-Grade Silicone Sealant

1. Wipe entire unit down using a clean cloth or sponge and mild

detergent.

2. Use a plastic scouring pad to remove any hardened food particles

or mineral deposits.

IMPORTANT: DO NOT use steel wool for cleaning.

3. Rinse warmer thoroughly with a vinegar and water solution to

neutralize all detergent cleanser residue.

4. Inspect warmer ange-to-counter seal. Reseal with food-grade

silicone sealant if necessary. Failure to do so may allow grease and

water to leak into insulation and heating element, causing a potential

re and/or electric shock hazard.

5. Clean the Stand-Pipe (drain/overow assy) and insert using mild

detergnet and warm water.

6. Install the Stand-Pipe & insert, add proper amount of water and

rinse the basin. Turn the main power switch ON and check for proper

operation.

Procedure Complete.

8

Page 11

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

CLEANING INSTRUCTIONS

MONTHLY CLEANING INSTRUCTIONS

PREPARATIONS: Remove any insets, utinsils.

Drain or remove water from well.

FREQUENCY: Weekly, or whenever lime or scale is seen

accumulating on the sides of the warmer pans.

TOOLS: Commercial Delime Cleaner

Plastic Scouring Pad

Clean Cloth or Sponge

1. Add water to pans until water is at normal operating level

or covers accumulated scale.

2. Heat water to maximum temperature (145ºF).

3. Pour contents of one package of commercial delime cleaner

into each basin. Stir to dissolve cleaner. Turn heat control OFF.

4. Allow solution to soak at least one hour, or overnight for heavy

scale buildup.

5. Drain water from well. Scrub with a plastic scouring pad.

Rinse thoroughly with hot water, then dry.

6. Rell pans with tap water and resume operation.

7. Heavy scale buildup may require additional treatments.

CAUTION:

CHEMICAL BURN

HAZARD

Deilimng chemicals may be

caustic. Wear appropriate

personal protective equipment.

Follow cleaner manufacturer’s

instructions for safest use.

9

Page 12

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

TROUBLESHOOTING SUGGESTIONS

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

No power to warmer Circuit breaker off or tripped Reset circuit breaker

Warmer will not heat Temperature control not set Set control to desired temperature

Wet insulation

Warmer trips circuit breaker

Warmer slow to heat

Drain-equipped unit will not hold

water

There are no user-serviceable components in this appliance.

In all instances of damage or malfunction, contact your Authorized Wells Service Agency for repairs.

Pan leaking or other internal damage

Internal damage

Mineral deposits on pan acting as a

insulator

Wired to wrong voltage

Drain valve not fully closed

Drain valve damaged or pan(s) leaking

Verify ange-to counter seal is sound, or

reseal with food-grade silicone sealant

Contact your Authorized Wells Service

Agency for repairs

Contact your Authorized Wells Service

Agency for repairs

Clean pan(s) with delime cleaner

Verify supply voltage - must match

voltage on warmer nameplate

Check drain valve for debris and close

fully

Contact your Authorized Wells Service

Agency for repairs

10

Page 13

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

WIRING DIAGRAM

POWER

SWITCH

BLACK

7

3

THERMOSTAT

HIGH LIMIT

THERMOSTAT

8

5

1

2

6

HEATING

ELEMENT

4

WHITE

HDW-2 Wiring Diagram

GROUND

SK2488

11

Page 14

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

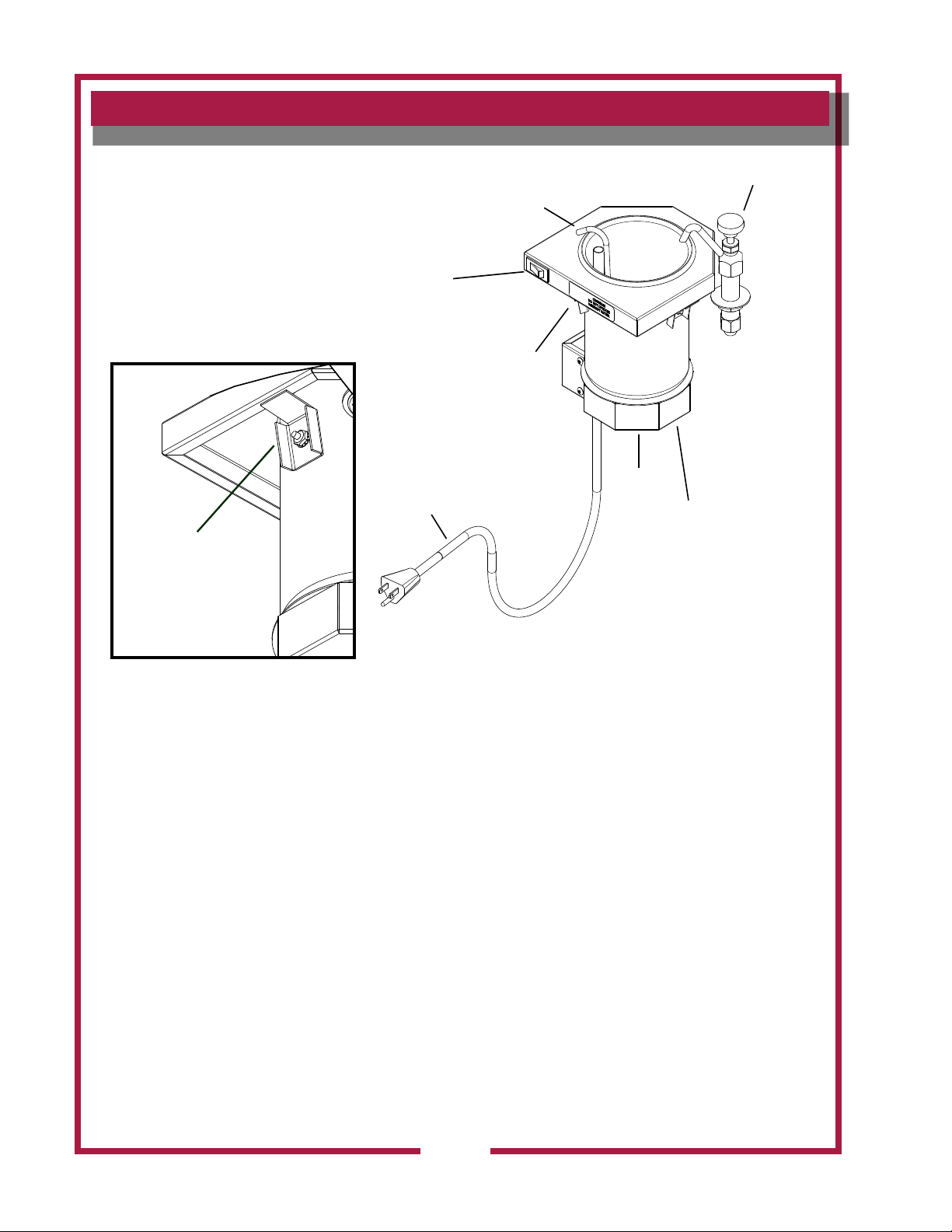

EXPLODED VIEW: HDW-2 DISHER WELL

Model: HDW-2 DISHER WELL

22

23

24

1

2

3

4 5

16

25

26

20

20

20

19

11

18

21

17

6

7

8

9

10

11

12

11

131415

SK2489, Rev. B, 2/24/2014

12

Page 15

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

PARTS LIST: HDW-2 DISHER WELL

Model: HDW-2 Dipper Well

Fig No Part No Qty Description Applications

1 P2-Z14195

2 2V-Z15955

3 2I-Z14209

1

WELL INSERT

2 HDW-2D

1

STAND-PIPE ASSEMBLY

2 HDW-2D

1

O-RING

4 HDW-2D

4 P2-WL0183 1 WELL ASSEMBLY

5 2K-Z14206 1 FAUCET, DIPPER HDW-2D, HDW-2F

6 P2-Z15039 1 ELEMENT, PLATE

2N-Z14199 1 ELEMENT 300W 120V

7

2N-Z20969 1 ELEMENT 300W 240V

8 2C-Z14325 1 WASHER FLAT .75OD X .344ID COPPER

2T-Z14200 1 THERMOSTAT 120V

9

2T-Z21176 1 THERMOSTAT 240V

10 P2-Z14190 1 CLAMP, THERMOSTAT

11

2C-Z6929

7

10-24 KEPS NUT S.S.

9 HDW-2D

12 P2-Z14196 1 HOUSING, ELEMENT

13 2K-H5417 1 BUSHING, HEYCO #SR-6P-3-4

14 P2-Z14191 1 COVER, CONTROL

15 2C-6349 2 SCREW #8 x 3/8 B THP STL NP

P2-WL0198 1 CORDSET HDW-2 120V MODELS

16

P2-WL0790 1 CORDSET HDW-2 240V MODELS

17 2C-1494 1 SCREW #8 -32 X .5 RH NP

18 P2-Z14506 1 BRACKET - HIGH LIMIT

19 2T-Z14503 1 THERMOSTAT 325°F

20 2C-73457 7 8-32 KEPS NUT SS

21 P2-Z14189 3 CLAMP BOWL

22 2M-Z14204 1 LABEL - WELLS LOGO AND CAUTION

23 2E-Z14201 1 SWITCH, STST-LIGHTED

24 P2-Z14193 1 WIRE CHANNEL

25 P2-Z18249 1 WIRE COVER

26 2C-1810 3 WASHER 3/16” STL

HDW-2, HDW-2F

HDW-2, HDW-2F

HDW-2, HDW-2F

HDW-2

February 24, 2014

13

Page 16

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

NOTES

14

Page 17

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

NOTES

15

Page 18

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

NOTES

16

Page 19

M025 2M-Z14353 Owners Manual for Built-In Disher Well Warmer

PARTS & SERVICE

DESCRIPTION PART NO.

IMPORTANT: Use only factory

authorized service parts and

replacement lters.

For factory authorized service,

or to order factory authorized

replacement parts, contact

your Wells authorized service

agency, or call:

Wells Manufacturing

265 Hobson Street

Smithville, Tennessee 37166 U

Service Dept.

phone: (314) 678-6314

fax: (314) 781-2714

Service Parts Department

can supply you with the name

and telephone number of

the WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

.S.A.

CUSTOMER SERVICE DATA

please have this information available if calling for service

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. _______________

EQUIPMENT SERIAL NO. _______________

VOLTAGE:(checkone) 120 208 240

17

Page 20

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 314-678-6314

fax: 314-781-2714

www.wells-mfg.com

Loading...

Loading...