Page 1

WELLS BLOOMFIELD, LLC

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

OPERATION MANUAL

HEAVY DUTY GAS HOTPLATE

HDHP1230G

HDSU1230G

HDHP2430G

HDSU2430G

HDHP3630G

HDSU3630G

226

MODELS

Includes

INSTALLATION

Model HDHP3630G

FOR YOUR SAFETY

Do not store gasoline or other flammable liquids

in the vicinity of this or any other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

IMPORTANT:

The purchaser of this equipment must post in a prominent location instructions to be followed in the

event the user smells gas. This information shall be obtained by consulting the local gas supplier.

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS U S ING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

USE & CARE

p/n 2M-306627 Rev. F M226 101109

Page 2

ENGLISH

Unless otherwise specified, all commercial cooking

equipment manufactured by WELLS MANUFACTURING is

warranted against defects in materials and workmanship for

a period of one year from the date of original installation or

18 months from the date of shipment from our factory,

whichever comes first, and is for the benefit of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW OR IN

FACT, INCLUDING BUT NOT LIMITED TO, WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR ANY

PARTICULAR PURPOSE, AND/OR FOR DIRECT,

INDIRECT OR CONSEQUENTIAL DAMAGES IN

CONNECTION WITH WELLS BLOOMFIELD PRODUCTS.

This warranty is void if it is determined that, upon inspection

by an authorized service agency, the equipment has been

modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God. It also

does not apply if the serial nameplate has been removed, or

if service is performed by unauthorized personnel. The prices charged by Wells Manufacturing for its products are

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

LIMITED WARRANTY STATEMENT

based upon the limitations in this warranty. Seller’s obligation under this warranty is limited to the repair of defects

without charge by a Wells Manufacturing factory authorized

service agency or one of its sub-service agencies. This

service will be provided on customer’s premises for nonportable models. Portable models (a device with a cord and

plug) must be taken or shipped to the closest authorized

service agency, transportation charges prepaid, for service.

In addition to restrictions contained in this warranty, specific

limitations are shown in the Service Policy and Procedure

Guide. Wells Manufacturing authorized service agencies

are located in principal cities. This warranty is valid in the

United States and Canada and void elsewhere. Please

consult your classified telephone directory, your foodservice

equipment dealer or contact:

Service Department, Wells Manufacturing

10 Sunnen Dr., St. Louis, MO 63143

phone (314) 678-6314 or fax (314) 781-2714

for information and other details concerning warranty.

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specified on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted for

ninety (90) days from date of purchase on nonwarranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

should be done within fifteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Manufacturing cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

226 306627 OpManual for HDHP-Series Hot Plates

xi

Page 3

TABLE OF CONTENTS

ENGLISH

WARRANTY xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY LISTING INFORMATION 3

INSTALLATION 4

OPERATION 8

CLEANING INSTRUCTIONS 10

TROUBLESHOOTING SUGGESTIONS 12

PARTS & SERVICE 13

CUSTOMER SERVICE DATA 13

EXPLODED VIEW & PARTS LIST 15

FRANÇAIS

DESCRIPTION ET AVERTISSEMENTS DE SÛRETÉ 16

SPÉCIFICATIONS 17

FONCTIONNALITÉS ET COMMANDES 18

PRÉCAUTIONS & RENSEIGNEMENTS D’ORDRE

GÉNÉRAL 19

INFORMATIONS CONCERNANT LES AGENCES 19

INSTALLATION 20

FONCTIONNEMENT 24

INSTRUCTIONS POUR LE NETTOYAGE 26

CONSEILS POUR LE DÉPANNAGE 28

ENGLISH

INTRODUCTION

Thank You for purchasing this Wells Manufacturing appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure that it

gives you the very best performance and a long, economical service life.

This manual contains the information needed to properly install this appliance, and to use and care for the

appliance in a manner which will ensure its optimum performance.

SPECIFICATIONS

226 306627 OpManual for HDHP-Series Hot Plates

MODEL STYLE FUEL

HDHP1230G

HDSU1230G

HDHP2430G

HDSU2430G

HDHP3630G

HDSU3630G

2 Burners w/

Individual Control

4 Burners w/

Individual Control

6 Burners w/

Individual Control

Natural Gas 5.0” W.C. 53,000

Propane (LP) 10” W.C.

Natural Gas 5.0” W.C. 106,000

Propane (LP) 10” W.C.

Natural Gas 5.0” W.C. 159,000

Propane (LP) 10” W.C.

MANIFOLD

PRESSURE

Total B.T.U.

per HOUR

134,000

44,670

89,330

1

Page 4

ENGLISH

Y

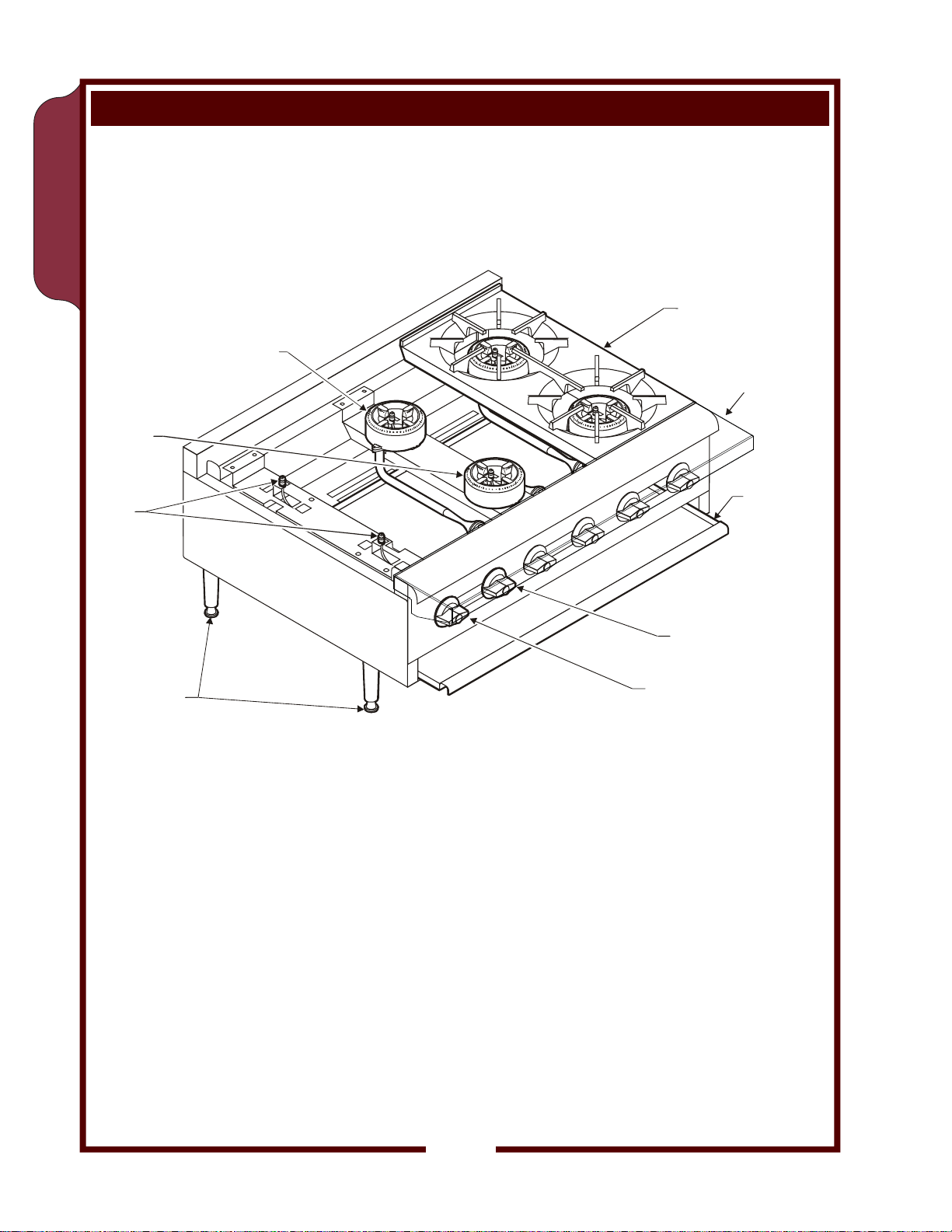

FEATURES & OPERATING CONTROLS

FRONT

BURNER

COOKING GRATE

REAR BURNER

PLATE SHELF

(ACCESSORY)

PILOT

ADJUSTABLE

LEG

DRIP TRA

FRONT BURNER

CONTROL

REAR BURNER

CONTROL

IL2995

226 306627 OpManual for HDHP-Series Hot Plates

Fig. 1 Heavy Duty Hot Plate - Features & Operating Controls

2

Page 5

PRECAUTIONS AND GENERAL INFORMATION

This appliance is intended for use in commercial establishments

only.

This appliance is intended

No other use is

agents.

This appliance must be installed by a technician qualified and certified

or licensed to install gas-fired equipment. A licensed technician must

perform the initial start-up and adjustment of the appliance.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

DO NOT submerge appliance or burners in water. This appliance is

not jet stream approved. DO NOT direct water jet or steam jet at this

appliance, or at any control. DO NOT splash or pour water on, in or

over any controls. DO NOT wash counter around this appliance with

water jet. Burners which have become wet must be thoroughly dried

before use.

Burner and grate surfaces will be very hot when in use. Contact will

cause severe injury.

This appliance must be operated with the supplied 4” legs properly

installed.

Do not operate this appliance if the smell of gas is present. Turn off

all gas supply valves and move to a remote location to call your

Authorized Wells Service Agent for service.

The technical content of this manual, including any parts breakdown

illustrations and/or adjustment procedures, is intended for use by qualified technical personnel only.

Any procedure which requires the use of tools must be performed by a

qualified technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

recommended or authorized by the manufacturer or its

to prepare food for human consumption.

WARNING:

FIRE HAZARD

All servicing of the gas

supply and combustion

components of this appliance

must be performed by a

technician trained and

certified in the maintenance

of gas appliances.

Improper servicing of gas

equipment can result in fire

and explosion.

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

ENGLISH

226 306627 OpManual for HDHP-Series Hot Plates

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions and

maintained according to the instructions in this manual.

This appliance meets ANSI Z.83.11 specifications for gas-fired food

service equipment.

This appliance is Canadian Standards Association design certified for

gas operation

3

STD 4

Page 6

ENGLISH

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

This appliance must be

properly ventilated. Failure to

provide and maintain proper

ventilation of exhaust gasses

can result in severe injury or

death.

WARNING:

FIRE HAZARD

Do not store gasoline or

any other flammable or

combustible material near this

appliance. The open flame

can cause such materials to

ignite.

The area where the hotplate is

installed must be kept clear of

combustibles and flammables.

This includes mops, rags,

grease, wrapping paper and

electric cords.

NOTICE: Manufacturer’s

warranty on this hotplate is in

effect only when the hotplate

is installed in accordance with

these instructions and local

codes and ordinances or, in

the absence of local codes,

the National Fuel Gas Code,

ANSI Z223.1 (current edition).

The manufacturer of this

hotplate assumes no liability

for any damage or injury

resulting from failure to

comply with this notice.

DANGER:

HEALTH

HAZARD

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all

protective plastic film, packing materials and accessories from the

appliance before connecting performing any installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the

appliance.

Carefully account for all components and accessories before

discarding packing materials. Store all accessories in a convenient

place for later use.

COMPONENTS

Cooking Grate (-1230G, 1 ea.; -2430G, 2 ea.;-3630G, 3 ea.)

Front Burner (-1230G, 1 ea.; -2430G, 2 ea.;-3630G, 3 ea.)

Rear Burner (-1230G, 1 ea.; -2430G, 2 ea.;-3630G, 3 ea.)

Adjustable Legs (set of 4)

Drip Tray, 1 ea.

SETUP

This appliance is designed for use in non-combustible locations

only. Setup the hotplate only on a firm, level, non-combustible

surface.

Verify local codes for requirements. Concrete, tile, terrazzo or metal

surfaces are recommended. Metal or tile over combustible material

may not meet code for non-combustible surfaces.

Clearances to non-combustible surfaces must be maintained.

Maintain 0” from side and rear to non-combustible walls, and 4” from

non-combustible counter as established by provided 4” legs.

Maintain adequate clearances for cleaning and proper operation.

The hotplate must be installed in an area with sufficient make-up air

for proper combustion, and must be installed such that the flow of

combustion and ventilation air will not be obstructed.

For servicing, Wells Mfg. recommends 6” clearance from rear of the

appliance to wall.

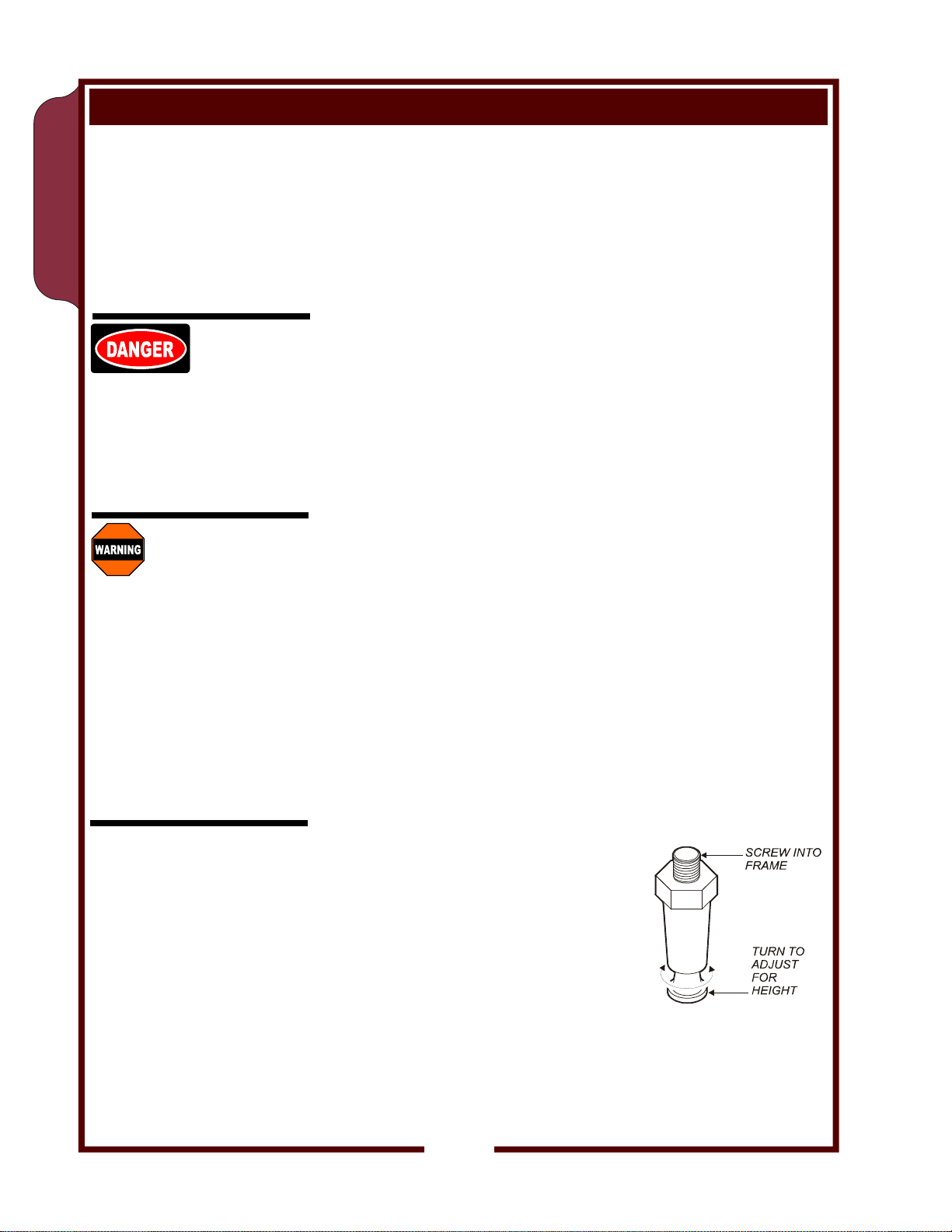

Install adjustable legs, one on each corner of

the appliance, in the holes provided. Verify

that the unit sits firmly ON ALL FOUR LEGS.

With the adjustable legs, adjust as required

to level the appliance. All four legs must be

adjusted to firmly contact the floor in order to

prevent tipping.

When used with an exhaust fan, special precautions must be

observed to avoid interference with the operation of the hotplate, such

as drafts and air starvation.

226 306627 OpManual for HDHP-Series Hot Plates

4

Page 7

INSTALLATION (continued)

GAS APPLIANCE CODE COMPLIANCE

The installation of gas piping from the outlet side of the gas meter or

service regulator to the hotplate must be performed by a technician

qualified and certified or licensed to install gas-fired equipment.

A licensed and qualified technician must perform the initial startup and

adjustment of this appliance.

The installation of this gas-fired appliance must conform to local codes,

or in the absence of such codes, with the current edition of

National Fuel Gas Code ANSI Z223.1.

For use in the State of Massachusetts, this appliance must be installed

in compliance with Massachusetts Fuel Gas and Plumbing Code

CMR 248.

The installation of this gas-fired appliance must comply with

applicable portions of NFPA 96 for ventilation. The current edition of

NFPA 96 (Standard for the Installation of Equipment for the Removal

of Smoke and Grease Laden Vapors from Commercial Cooking

Equipment) specifies ventilation requirements to ensure the removal

of exhaust gasses and products of combustion.

IT IS THE RESPONSIBILITY OF THE INSTALLER TO ENSURE

THAT THIS GAS HOTPLATE INSTALLATION CONFORMS TO ALL

APPLICABLE CODES AND ORDINANCES.

The venting of this appliance must not be obstructed, nor may such

venting interfere with the flow of combustion air required for proper

operation of the gas burners.

Additionally:

1. The gas supply line used to connect the hotplate to the gas

supply system must be black iron pipe, or other material as

approved by local ordinance for gas piping.

2. Gas supply piping must be inside 3/4” diameter or greater.

3. Use pipe sealant made specifically for gas piping on all pipe joints.

Apply sealant sparingly to the male threads only.

Sealant must be resistant to the action of LP gas.

4. Verify that all supply piping is clean and free of obstructions, dirt,

chips and pipe sealant compound prior to installation.

5. All pipe joints must be checked for leaks before lighting. Leak

checks should be performed with a soap and water solution.

NEVER CHECK FOR LEAKS WITH AN OPEN FLAME.

226 306627 OpManual for HDHP-Series Hot Plates

DANGER:

FIRE AND

EXPLOSION

HAZARD

NEVER use an open flame to

check for gas leaks. Fire and

explosion may result.

WARNING:

RISK OF INJURY

Installation procedures must

be performed by a qualified

technician with full knowledge

of all applicable gas-fired

appliance codes. Failure can

result in personal injury and

property damage.

IMPORTANT:

All pipe joints must be

checked for leaks before

lighting. Leak checks should

be performed with a soap and

water solution.

IMPORTANT:

Information on the

construction and installation

of ventilating hoods may be

obtained from the current

edition of NFPA 96

Standard for the Installation

of Equipment for the Removal

of Smoke and Grease Laden

Vapors from Commercial

Cooking Equipment.

Copies of this standard are

available from the

Nation Fire Protection Assn.:

NFPA

1 Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9101

ENGLISH

5

Page 8

ENGLISH

INSTALLATION (continued)

DANGER:

FIRE AND

EXPLOSION

HAZARD

NEVER use an open flame to

check for gas leaks. Fire and

explosion may result.

IMPORTANT:

All pipe joints must be checked

for leaks before lighting. Leak

checks should be performed

with a soap and water solution.

WARNING:

FIRE HAZARD

This hotplate is supplied with a

gas pressure regulator.

Failure to properly install the

supplied regulator will result in

an extremely hazardous

condition.

Flow arrow stamped on body

of regulator must point toward

the hotplate.

Vent hole must point UP.

IMPORTANT:

Verify fuel gas type. If the

available fuel does not match

the nameplate specification,

exchange the hotplate for the

correct type.

IMPORTANT:

The appliance and its

individual manual shutoff valve

must be disconnected from

supply system piping during

any pressure testing of that

system at pressures in excess

of 1/2 p.s.i. (3.5 kPa).

Also, the appliance must be

isolated from the gas supply

piping system by closing its

individual manual shutoff valve

during any pressure testing of

the gas supply piping at test

pressures equal to or less than

1/2 p.s.i. (3.5 kPa).

INSTALLING THE HOTPLATE

Refer to the nameplate. Verify the fuel type and pressure, which must

match the nameplate specifications. Connecting the hotplate to the

wrong fuel type and/or pressure will compromise the safety and/or

performance of the appliance.

The hotplate must be placed in its final operational position and

leveled front-to-back and side-to-side, with a spirit level, prior to

beginning the gas piping installation. Re-check the level of the unit

at the conclusion of the gas piping installation.

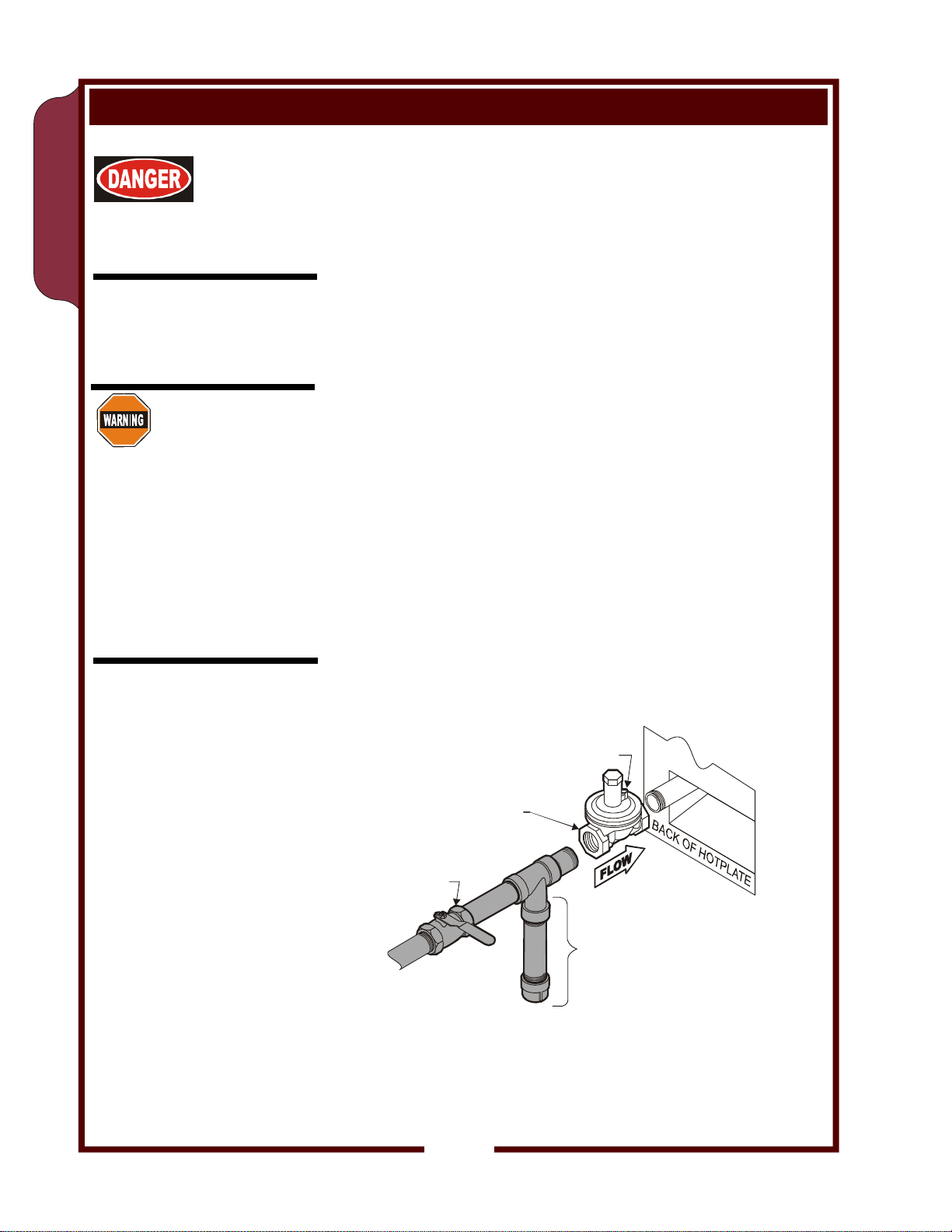

Each gas hotplate is supplied with a separate gas pressure

regulator, which must be installed on the manifold pipe protruding

from the rear of the hotplate. Ensure that the regulator is installed

such that the flow arrow stamped on the body of the regulator points

toward the hotplate. Failure to properly install the supplied regulator

will result in an extremely hazardous condition.

A moisture trap (drip leg) consisting of a tee, 4” nipple pointing down,

and cap must be installed upstream of the gas pressure regulator.

A manual gas shut-off valve may be required by local codes and is,

in any case, strongly recommended. The shut-off valve must be

installed between the gas supply piping and the gas pressure

regulator.

It is the responsibility of the gas piping installer to

identify the code requirement for a shut-off valve.

Shut-off valves, moisture trap and all associated piping must be

supplied by the gas piping installer.

SHUT-OFF

Fig. 2 Gas Supply Piping

SUPPLIED

REGULATOR

GAS

VALVE*

GAS

SUPPLY*

VENT

DRIP LEG*

* by others

226 306627 OpManual for HDHP-Series Hot Plates

6

Page 9

INSTALLATION (continued)

SET GAS PRESSURE:

Gas pressure regulator is factory set.

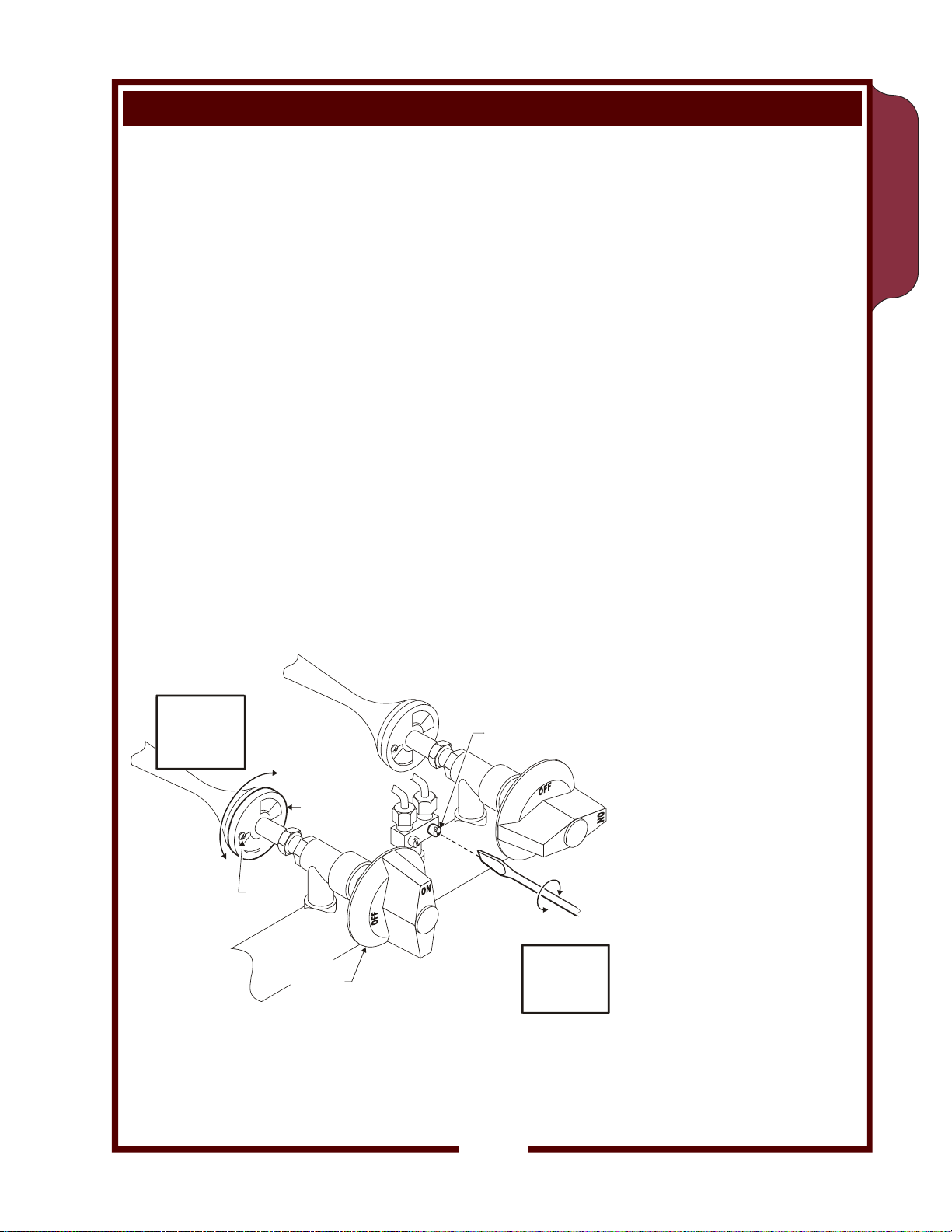

SET PILOT FLAME:

The pilot adjustments are located between the control valves for

each set of burners. The right valve controls the front pilot; the

left valve controls the rear pilot.

Using a small, flat-blade screwdriver, turn the screw clockwise to

decrease the flame size, or counter-clockwise to increase the

flame size.

Adjust the pilot flame to 1/4” high. Test for operation: inside and

outside sections of the burner must light without undue delay.

Drafty conditions may require a higher flame to allow the pilot to

remain lit.

ADJUST BURNER FLAME:

Remove all burner control knobs, then remove the front panel.

Turn an individual burner on. The right knob controls the front

burner; the left knob controls the rear burner.

Loosen the locking screw on the shutter.

Turn the shutter to admit more or less air as required. Adjust the

air shutter until the flame is mostly blue in color.

Tighten the locking screw when finished. Replace the front panel

and all knobs before returning the unit to service.

IMPORTANT:

Adjustments must be performed

by a qualified technician only.

IMPORTANT:

This hotplate is shipped from

the factory equipped for either:

natural gas and adjusted for

sea level to 2000 feet elevation;

or, propane (LP) gas and

adjusted for sea level to 5000

feet elevation.

For operation other than listed

above, contact your Authorized

Wells Service Agency.

ENGLISH

BURNER

FLAME

ADJUST

MORE AIR

226 306627 OpManual for HDHP-Series Hot Plates

Fig. 3 Adjustments

LESS

AIR

LOCKING

SCREW

SHUTTER

BURNER

CONTROL

KNOB

PILOT

FLAME

ADJUST

MORE

FLAME

7

LESS

FLAME

PILOT

FLAME

ADJUST

IL2996

Page 10

ENGLISH

OPERATION

WARNING:

FIRE HAZARD

IF YOU SMELL GAS:

¤ DO NOT try to light

any appliance.

¤ DO NOT touch any

electrical switch

¤ DO NOT use any

telephone in your

building.

In the event a gas odor is

detected, shut down the

unit at the main gas

shutoff valve and contact

your local gas supplier

from a neighboring location.

Follow the instructions

received from the gas

supplier immediately

and exactly.

GENERAL OPERATIONAL NOTES

Carefully read the description of the hotplate operation on the

specification sheet.

Do NOT use this appliance if it has been submerged in water.

Call a qualified technician to examine the appliance and to service

or replace any component which has been submerged. Burners

which have been allowed to become wet must be thoroughly dried

before use.

For initial startup, and any time the gas supply has been shut-off, it

may take several minutes to light the pilot while air in the piping and

manifolds is purged.

The burner control knobs must be turned by hand only. Never use

tools to turn the control knob. If the knob will not turn by hand, do

NOT attempt to force or repair it. Contact your Authorized Wells

Service Agency for repairs. Forced or improperly repaired valves

pose the risk of fire and/or explosion.

Make sure burners, pilot burner and grate assembly are properly

installed before attempting to operate.

LIGHTING THE PILOT LIGHT

Before lighting the pilot light, smell all around the appliance area for

gas. Be sure to smell near floor level because some gas is heavier

than air and will settle to the floor.

For initial startup, and any time the gas supply has been shut-off, it

may take several minutes to light the pilot while air in the piping and

manifolds is purged.

The pilot light must be lighted by hand:

Turn both control knobs to the full OFF position.

Be sure the gas shut-off valve is ON and the appliance has had

time for the air to be purged from the lines.

Light the pilot with a long match or fireplace lighter. Use of a

cigarette lighter is NOT recommended.

SHUT DOWN INSTRUCTIONS

Turn all burner knobs to OFF.

Turn all pilots OFF.

Turn the main gas supply OFF.

226 306627 OpManual for HDHP-Series Hot Plates

8

Page 11

OPERATION (continued)

OPERATION

Inspect the unit for cleanliness before use. Clean as necessary: See

Cleaning Instructions, page 11.

Be sure the pilot light is lit before operation. See Lighting the Pilot

Light, page 8.

The burner control knobs must be turned by hand only. Never use

tools to turn the control knob.

The control used in this gas hotplate provides a continuous range of

settings from OFF to ON.

The right knob controls the front burner

The left knob controls the rear burner

Light the burner by turning the control knob to the ON position until fire

forms completely around the inner and outer sections of the burner.

Set the control knob to the desired position. The setting can be

readjusted at any time.

Fig. 4 Burner Control

Cooking Recommendations:

Save energy by turning the temperature control knob OFF any time the

hotplate is not in use. Gas burners provide full heat instantly, making it

unnecessary to leave the unit on during intermittent use.

WARNING:

FIRE HAZARD

NEVER attempt to force

or repair a stuck control

valve.

Contact your Authorized

Wells Service Agency for

repairs.

Forced or improperly

repaired valves pose the

risk of fire and/or

explosion.

WARNING:

FIRE AND

EXPLOSION

HAZARD

If the pilot light should be

extinguished, turn off the

gas shut-off valve and

remove the grate and drip

pan. Allow the appliance

to vent for five minutes

before attempting to

re-light.

CAUTION:

HOT SURFACE

Exposed surfaces can be

hot to the touch and may

cause burns.

ENGLISH

226 306627 OpManual for HDHP-Series Hot Plates

9

Page 12

ENGLISH

CLEANING INSTRUCTIONS

WARNING:

FIRE HAZARD

Shut off the gas

supply valve before

cleaning.

CAUTION:

BURN HAZARD

Allow hotplate to

cool completely before

cleaning.

IMPORTANT: DO NOT spill

or pour water into controls,

DO NOT submerge hotplate

cabinet in water. Damage to

internal components will

occur.

Damage to internal

components from water

damage is NOT covered by

warranty.

DO NOT steel wool or

metal scouring pads to clean

cabinet, drip tray or crumb

tray.

Good sanitation is vital to the

quality of the final food

product. Be sure to clean in

all corners and crevices

where grease and other

cooking debris can

accumulate.

PREPARATION

Turn gas shut-off valve OFF before cleaning.

Allow hotplate to cool completely before cleaning.

FREQUENCY

Daily

TOOLS

Bristle Brush

Clean Cloth or Sponge

Mild Detergent

Cleaner Formulated for Stainless Steel

Warm Water

CLEANING

Turn gas shut-off valve OFF before cleaning.

Allow hotplate to cool completely before cleaning.

Remove grate(s) and drip tray by lifting from cabinet.

Note position of front and rear burner assemblies in cabinet. Remove

burner assemblies.

Clean food particles from grate drip tray with warm water, mild

detergent and a bristle brush. Rinse with clean water. Wipe dry

with a soft clean cloth.

Examine burner assemblies. Note position of air shutters before

cleaning. Clean food particles from burners with warm water, mild

detergent and a bristle brush. Rinse by wiping with a soft cloth

dampened with clean water. Wipe exterior surfaces dry with a soft

clean cloth. Allow burners to air dry so that interior passages are

completely free of water.

Wipe the outer portions of the hotplate cabinet with a clean soft cloth or

sponge dampened with warm water and a mild detergent or cleaner

formulated for cleaning stainless steel. DO NOT use steel wool to

clean hotplate cabinet. Rinse by wiping hotplate cabinet with a clean

soft cloth or sponge moistened with clean warm water. Dry cabinet by

wiping with a clean soft dry cloth.

Examine burners to be sure the air shutters are in their proper position.

Reinstall burner assemblies in cabinet (see fig. 5, page 11):

Burner with short venturi tube is the front burner. The venturi / air

shutter slides over the nozzle of the right control valve. The pegs

on the bottom of the burner set in corresponding notches at the

front of the burner support bracket.

Burner with long venturi tube is the rear burner. The venturi / air

shutter slides over the nozzle of the left control valve. The pegs

on the bottom of the burner set in corresponding notches at the

rear of the burner support bracket.

Turn shut-off valve ON and light pilot light.

Reinstall drip tray and grate.

Procedure is complete.

226 306627 OpManual for HDHP-Series Hot Plates

10

Page 13

CLEANING INSTRUCTIONS (continued)

COOKING GRATE

FRONT

BURNER

ENGLISH

REAR

BURNER

HDHP-SERIES

BURNER

REAR

BURNER

SUPPORT

BRACKET

REAR BURNER

CONTROL VALVE

FRONT BURNER

CONTROL VALVE

DRIP TRAY

COOKING GRATES

FRONT

BURNER

226 306627 OpManual for HDHP-Series Hot Plates

HDSU-SERIES

Fig. 5 Hotplate Assembly

FRONT BURNER

CONTROL VALVE

BURNER

SUPPORT

BRACKETS

DRIP TRAY

REAR BURNER

CONTROL VALVE

11

Page 14

ENGLISH

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE SUGGESTED REMEDY

Pilot will not light Gas supply off Check main / unit gas valves

Burners won’t light Gas supply off Check main / unit gas valves

Air in lines Turn pilot valve on. Attempt to

light pilot every 15 sec.

Pilot valve not on Turn pilot valve on / adjust

Air in lines Turn gas valve on. Attempt to

light pilot every 15 sec.

Pilot valve not lit Turn off gas - allow unit to

vent for 5 minutes. Turn gas

back on and light pilot

Front or rear burner

won’t light

Burner not hot enough

NOTE: There are no user

Control not on Turn temperature control to ON

Set to desired setting when lit

Water in burner Remove burner and dry

thoroughly

Damaged temperature control,

Burner or other internal

component

Temperature control not set Adjust for desired temperature

Shutter or nozzle out of

adjustment

Damaged temperature control,

burner or other internal

component

Contact Authorized Wells

Service Agency for repairs

Contact qualified technician for

adjustment

Contact Authorized Wells

Service Agency for repairs

serviceable components in the

burner assemblies or in the control valves. In all cases of damage or malfunction,

contact your Authorized Wells

Service Agency for repairs.

226 306627 OpManual for HDHP-Series Hot Plates

12

Page 15

PARTS & SERVICE

DESCRIPTION PART NO.

LEGS, ADJUSTABLE 4” METAL (SET of 4) 5D-20563

36” PLATE SHELF I7-WL0768

IMPORTANT: Use only

factory authorized service

parts and replacement

filters.

For factory authorized

service, or to order factory

authorized replacement parts,

contact your Wells authorized

service agency, or call:

Wells Manufacturing

10 Sunnen Dr.

St. Louis, MO 63143

Service Parts Dept.

phone: (888) 356-5362

fax: (314) 781-2714

Service Parts Department can

supply you with the name and

telephone number of the

WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

ENGLISH

CUSTOMER SERVICE DATA

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. _______________

226 306627 OpManual for HDHP-Series Hot Plates

EQUIPMENT SERIAL NO. _______________

FUEL (check one) NATURAL GAS PROPANE / LP

please have this information available if calling for service

13

Page 16

ENGLISH

NOTES

14

226 306627 OpManual for HDHP-Series Hot Plates

Page 17

EXPLODED VIEW & PARTS LIST

PLATE SHELF

HDHP2430GPS; I7-WL0595

36” ; I7-WL0768

ENGLISH

COOKING GRATE

DD-23221

AIR SHUTTER, VENTURI

2F-506637

LOCKING SCREW, SHUTTER

2C-70813

REGULATOR

CONVERTIBLE

FOR LP OR NAT

2J-306629

BURNER ASSY, REAR

WS-507165

BURNER ASSY, FRONT

WS-507164

PILOT BURNER ASSY

(CUT TO LENGTH)

WS-507188

ORIFICE HOOD (ONLY)

SEE CONVERSION CHART

FOR LP / PROPANE and/or

OPERATION ABOVE 3000’

ELEVATION

PILOT ADJUST, DUAL

WS-506632

PILOT ADJUST, SINGLE

2K-39315

GAS CONTROL VALVE ASSY

(NAT ORIFICE - SEA LEVEL

TO 5000’) WS-506631

226 306627 OpManual for HDHP-Series Hot Plates

LEG, 4” METAL

WS-507177

CONTROL KNOB

WS-507160

DRIP TRAY

WS-507170 (HDHP1230)

WS-507171 (HDHP2430)

WS-507172 (HDHP3630)

IL2074c

HDHP-SERIES HEAVY DUTY HOTPLATE

15

Page 18

DE LA PLAQUE CHAUFFANTE PROFESSIONNELLE AU GAZ WELLS

HDHP1230G, HDSU1230G

HDHP2430G, HDSU2430G

HDHP3630G, HDSU3630G

FRANÇAIS

Modéle

HDHP3630G

Ne pas stocker d’essence ou d'autres liquides inflammables au voisinage de cet

L’installation, le réglage, les modifications, l’entretien ou la maintenance effectués

de manière incorrecte peuvent entraîner des dommages matériels, corporels ou même

la mort. Lire attentivement les instructions relatives à l’installation, au fonctionnement,

à l’entretien et à la maintenance avant d’installer ou de réparer l’équipement.

L’acquéreur de ce matériel doit afficher, en pleine vue du public, les instructions à

suivre en cas de détection d’une odeur de gaz par l’utilisateur. Cette information

doit être obtenue après consultation de la société locale distributrice du gaz.

Ce guide fait partie de l’appareil et doit être remis au propriétaire, au directeur du

restaurant ou à la personne responsable de la formation des utilisateurs de l’appareil.

Des guides supplémentaires sont disponibles chez votre distributeur Wells.

Ce guide doit être lu et compris par toutes personnes installant ou utilisant cet appareil.

Contacter votre distributeur Wells pour toutes questions au sujet de l’installation, du

MANUEL DE L’UTILISATEUR

MODÈLES

Comprend :

INSTALLATION,

MODE D’EMPLOI & ENTRETIEN

POUR VOTRE SÉCURITÉ

appareil ou autres appareils ménagers.

AVERTISSEMENT !

226 306627 OpManual for HDHP-Series Hot Plates

IMPORTANT :

IMPORTANT : NE PAS JETER CE GUIDE

fonctionnement ou de l’entretien de cet appareil.

16

Page 19

TABLE DES MATIÈRES

FRANÇAIS

DESCRIPTION ET AVERTISSEMENTS DE SÛRETÉ 14

SPÉCIFICATIONS 15

FONCTIONNALITÉS ET COMMANDES 16

PRÉCAUTIONS & RENSEIGNEMENTS D’ORDRE

GÉNÉRAL 17

INFORMATIONS CONCERNANT LES AGENCES 17

INSTALLATION 18

FONCTIONNEMENT 22

INSTRUCTIONS POUR LE NETTOYAGE 24

CONSEILS POUR LE DÉPANNAGE 26

INTRODUCTION

Merci d’avoir acquis cet appareil Wells Manufacturing. L’installation correcte, le fonctionnement professionnel et l’entretien régulier de cet appareil assureront ses meilleures performances et sa longue durée

de service aux meilleurs coûts. Le présent manuel contient l’information nécessaire pour installer

correctement l’appareil et pour l’utiliser et l’entretenir de manière à ce qu’il fonctionne avec des

performances optimales.

MODÈLE STYLE COMBUSTIBLE

HDHP1230G

HDSU1230G

HDHP2430G

HDSU2430G

HDHP3630G

HDSU3630G

*Propane (gaz de pétrole liquide--GPL)

226 306627 OpManual for HDHP-Series Hot Plates

2 brûleurs avec

commandes

individuelles

4 brûleurs avec

commandes

individuelles

6 brûleurs avec

commandes

individuelles

SPÉCIFICATIONS

Gaz naturel 5.0” W.C. 53,000

Propane* 10” W.C.

Gaz naturel 5.0” W.C. 106,000

Propane* 10” W.C.

Gaz naturel 5.0” W.C. 159,000

Propane* 10” W.C.

PRESSION DU

COLLECTEUR

FRANÇAIS

CONSOMMATION

D’ÉNERGIE

TOTALE (BTU) par

heure

43,000

86,000

129,000

17

Page 20

FONCTIONNALITÉS ET COMMANDES

GRILLE DE CUISSON

FRANÇAIS

BRÛLEUR

BRÛLEURS

VEILLEUSES

D'ALLUMAGE

RÉGLABLES

BRÛLEUR ARRIÈRE

AVANT

DE

PIEDS

Fig. 6 Foncionnalites et Commandes se la Plaque Chauffante Professionelle á Gaz

COMMANDE

DU BRÛLEUR

AVANT

COMMANDE

DU BRÛLEUR

ARRIÈREL

PLATEAU

POUR LA

GRAISSE

226 306627 OpManual for HDHP-Series Hot Plates

18

Page 21

PRÉCAUTIONS & RENSEIGNEMENTS D’ORDRE GÉNÉRAL

Cet appareil est prévu exclusivement à l’usage des

établissements commerciaux.

Cet appareil est destiné à la cuisson d’aliments pour la consommation

humaine. Aucun autre usage n’est recommandé ni autorisé par le

fabricant ou ses agents.

Cet appareil doit être installé par un technicien qualifié ou et certifié

ou agréé pour l’installation des équipements fonctionnant au gaz. Un

technicien qualifié et agréé doit assurer la mise en service et le réglage

initiaux de l'appareil.

Les utilisateurs de l’appareil doivent être familiarisés avec l’utilisation

de l’appareil, ses limites et ses restrictions associées. Le mode

d’emploi doit être lu et compris par toutes les personnes installant ou

utilisant cet appareil.

La propreté de cet appareil est essentielle à de bonnes conditions sanitaires. Lire et suivre toutes les instructions relatives au nettoyage et

aux programmes visant à assurer l’innocuité des produits alimentaires.

NE PAS submerger l’appareil ou les brûleurs dans l’eau. Cet appareil

n’est pas approuvé pour supporter les jets d’eau. NE PAS orienter

de jet d’eau ou de vapeur directement sur cet appareil ou de ses

commandes. NE PAS éclabousser ni verser d’eau sur, dans ou par

dessus les commandes. NE PAS laver le comptoir entourant l’appareil

avec un jet d’eau. Les brûleurs mouillés doivent être complètement

séchés avant usage.

Les surfaces de cuisson deviennent très chaudes pendant l’usage.

Leur contact provoquera des brûlures graves.

Cet appareil doit être utilisé avec ses pieds de 10 cm (4 po.) de haut

correctement installés.

Ne pas utiliser cet appareil en présence d’une odeur de gaz. Fermer

tous les robinets à gaz et se rendre dans un lieu éloigné pour appeler

un technicien d’entretien agréé par Wells.

La partie technique du présent manuel, y compris tous les schémas

éclatés illustrant les pièces et/ou les procédures de réglage, est

destinée exclusivement à l’usage de techniciens qualifiés.

Toute procédure exigeant l’emploi d’outils doit être accomplie par un

technicien qualifié.

Le présent manuel est considéré être une pièce permanente de

l’appareil. Ce manuel et toutes les instructions, schémas, illustrations

de pièces éclatées, notices et étiquettes fournis doivent demeurer avec

l’appareil si ce dernier est revendu ou déménagé dans un autre local.

AVERTISSEMENT!

DANGER D’INCENDIE

Toutes les opérations

d’entretien et de réparation

des composants servant à

l’alimentation et à la

combustion du gaz dans cet

appareil doivent être

effectuées par un technicien

qualifié et agréé pour la

maintenance des appareils

à gaz. L’entretien incorrect

des appareils à gaz peut

entraîner des incendies et

des explosions.

ATTENTION:

SURFACE CHAUDE

Les surfaces exposées

peuvent être chaudes au

toucher et peuvent

occasionner des brûlures.

FRANÇAIS

INFORMATIONS CONCERNANT LES AGENCES

Cet appareil n’est conforme à la Norme 4 de la fondation nationale de

normalisation sanitaire des États-Unis (National Sanitation Foundation-

-NSF) que s’il est installé conformément aux Instructions relatives à

226 306627 OpManual for HDHP-Series Hot Plates

l’installation fournies avec l’appareil et si ce dernier est entretenu selon

les instructions du présent manuel.

Cet appareil est conforme aux spécifications ANSI Z.83.11 pour les

appareils à gaz utilisés dans les établissements préparant des

aliments.

Cet appareil est d’une conception certifiée pour le fonctionnement au

gaz par l’Association canadienne de normalisation (ACN/CSA).

19

Norme 4

Page 22

L'INSTALLATION

FIXATION PAR

VIS DANS LE

CADRE

TOURNER

POUR

RÉGLER

LA HAUTEUR

REMARQUE : NE PAS jeter le

carton ni les autres matériaux

d’emballage jusqu’à ce que

l’appareil ait été inspecté pour la

détection de vices cachés et ait

subi des tests de fonctionnement

satisfaisants. Consulter la

PROCÉDURE DE RÉCLAMATION EN CAS DE DOMMAGES

DUS AU TRANSPORT imprimée

sur la face interne de la première

page de couverture du présent

manuel.

FRANÇAIS

Cet appareil doit être situé dans

un local correctement aéré. Le

défaut d’assurance et de maintien

d’une aération convenable avec

mise à l’évent des gaz de

combustion peut entraîner des

dommages corporels graves ou

même la mort.

d’essence ou d'autres matériaux

combustibles ou

inflammables à proximité de cet

appareil. Toute flamme nue peut

provoquer l’inflammation de ces

matériaux. La zone où le grill est

installé doit être dépourvue de

tout matériau combustible ou

inflammable. Ceux-ci

comprennent, notamment, les

serpillères, les lavettes ou les

chiffons, la graisse, le papier

d’emballage et les cordons

d’alimentation électriques

NOTICE : La garantie du

fabricant concernant cet appareil

entre en vigueur exclusivement si

l’appareil est installé

conformément aux présentes

instructions, aux dispositions de

la réglementation et des codes

locaux, ou en l’absence de codes,

de la norme ANSI Z223.1 (édition

en vigueur) du code national

relatif au gaz combustible

(National Fuel Gas Code). Le

fabricant de ce grill décline toute

responsabilité en cas de

dommages corporels ou matériels

résultant du défaut d'application

des dispositions de la présente

notice.

AVERTISSEMENT :

Danger d’incendie

Ne pas stocker

DANGER:

Danger pour la

santé

.

DÉBALLAGE & INSPECTION

Sortir l’appareil du carton avec précaution. Enlever tous les films de

protection en plastique, les matériaux d’emballage et les accessoires

de l’appareil avant d'entamer toute procédure d'installation et de connexion.

Lire attentivement toutes les instructions du présent manuel et de la

Notice-–Instructions relatives à l’installation, incluse avec l’appareil,

avant de commencer l’installation.

Lire et assimiler la signification de toutes les étiquettes et schémas

fixés sur l’appareil.

Vérifier que tous les composants et accessoires sont présents avant de

jeter les matériaux d'emballage. Ranger tous les accessoires dans un

lieu convenable pour les utiliser plus tard.

COMPOSANTS

Grille de cuisson

Brûleur avant

Brûleur arrière

(-1230G, 1 pièce; -2430G, 2 pièce; -3630G, 3 pièce)

(-1230G, 1 pièce; -2430G, 2 pièce; -3630G, 3 pièce)

(-1230G, 1 pièce; -2430G, 2 pièce; -3630G, 3 pièce)

Pieds réglables, (jeu de 4)

Plateau pour la graisse, 1 pour chaque

INSTALLATION

Installer l’appareil uniquement sur une surface solide, horizontale et

non combustible. Vérifier les conditions imposées par les codes locaux.

Les surfaces en ciment, en carreaux de céramique ou de marbre, ou

en métal sont recommandées. Le métal ou les carreaux de céramique

posés sur des matériaux combustibles peuvent

être incompatibles avec les dispositions du

code imposant des surfaces non combustibles.

Installer les pieds fournis avec l’appareil,

un pied à chaque coin de l’appareil, dans

les trous préparés. Vérifier que l’unité est

stable et repose bien SUR LES QUATRE

PIEDS. Les pieds étant réglables, les ajuster

selon les besoins pour que l’appareil soit

horizontal. Les quatre pieds doivent être

ajustés pour faire solidement contact avec

le comptoir afin d’éviter tout basculement.

Ménager des dégagements adéquats dans l’armoire pour les orifices

d’aération. Consulter la Notice—Intructions relatives à l’installation,

pour obtenir les dimensions de dégagement obligatoires. Conserver

les distances de dégagement nécessaires entre l’appareil et les

surfaces combustibles adjacentes.

L’appareil doit être installé dans un lieu où l’air est suffisamment

renouvelé pour assurer une combustion correcte et de telle manière

que le courant de l’air de combustion et d’aération ne soit pas obstrué .

Lorsqu’on utilise l’appareil avec un ventilateur d’extraction, il faut

prendre des précautions spéciales pour éviter toute interférence avec

le fonctionnement de l’appareil, tels que courants d’air et privation

d’air .

226 306627 OpManual for HDHP-Series Hot Plates

20

Page 23

L'INSTALLATION (a continué)

CONFORMITÉ AU CODE RELATIF AUX APPAREILS À GAZ

L’installation des tuyauteries du gaz entre le côté sortie du compteur à

gaz ou du régulateur de l’alimentation publique et l’appareil doit être

effectuée par un technicien qualifié et certifié ou agréé pour l’installation

des appareils à gaz.

Un technicien qualifié et agréé doit assurer la mise en service et le

réglage initiaux de l'appareil.

L’installation de cet appareil à gaz doit être conforme aux codes locaux,

ou en l’absence de codes, à l’édition en vigueur de la norme ANSI

Z223.1 du Code national applicable au gaz combustible (National Fuel

Gas Code—NFGC).

Pour l'usage dans l'Etat de Massachusetts, cet appareil doit être installé

en conformité avec le Massachusetts Fuel Gas and Plumbing Code

CMR 248.

L’installation de cet appareil à gaz doit être conforme aux parties

applicables de la norme NFPA 96 relatives à l’aération. L’édition

courante de la norme NFPA 96 précise les conditions obligatoires à

remplir pour l'extraction des gaz et des produits de combustion.

L’INSTALLATEUR EST RESPONSABLE D’ASSURER QUE

L’INSTALLATION DE CE GRILL À GAZ SOIT CONFORME À TOUS

LES CODES ET À TOUTE RÉGLEMENTATION APPLICABLES.

La mise à l’évent de cet appareil ne doit pas être obstruée, et cette

mise à l’évent ne doit en aucun cas interférer avec le courant de l’air

de combustion exigé pour le fonctionnement correct des brûleurs à gaz.

En outre :

1. La ligne d’alimentation de gaz utilisée pour raccorder le grill au

système d’alimentation de gaz doit être un tuyau en acier non

revêtu (fer noir) ou autre matériau approuvé par la réglementation

locale applicable aux tuyauteries de gaz.

2. La tuyauterie du gaz doit avoir un diamètre intérieur égal ou

supérieur à ¾ po. (1,9 cm).

3. Utiliser un mastic pour l’étanchéité des raccords de tuyauterie,

spécial pour les tuyauteries à gaz, sur tous les raccords de

tuyauterie. Appliquer le mastic en petite quantité uniquement sur

les filetages mâles.

Le mastic doit être résistant à l'action du gaz GPL.

4. Vérifier que toute la tuyauterie d’alimentation de gaz est propre et

épourvue de toute obstruction, saleté, débris et particules de mastic

d'étanchéité avant l’installation .

5. Tous les raccords de tuyauterie doivent être inspectés pour la

226 306627 OpManual for HDHP-Series Hot Plates

détection de fuites éventuelles avant l’allumage. Détecter les fuites

avec une solution d’eau savonneuse. NE JAMAIS DÉTECTER DE

FUITES AVEC UNE FLAMME NUE .

DANGER :

DANGER

D’INCENDIE ET

D’EXPLOSION

NE JAMAIS utiliser de

flamme nue pour détecter des

fuites de gaz. Un incendie et

une explosion pourrait se

produire.

AVERTISSEMENT :

DANGER DE DOM-

MAGE CORPOREL

Les procédures d’installation

doivent être accomplies par

un technicien qualifié ayant

pleine connaissance des

dispositions des codes en

vigueur relatives aux

appareils à gaz. À défaut, des

dommages corporels et

matériels peuvent survenir.

IMPORTANT : Tous les raccords

de tuyauterie doivent être

inspectés pour la détection de

fuites éventuelles avant

l’allumage. Détecter les fuites

avec une solution d’eau

savonneuse.

IMPORTANT : L’information

relative à la construction et

l’installation des hottes d’aération

doit être obtenue dans l’édition

en vigueur de la norme NFPA 96

Standard for the Installation of

Equipment for the Removal of

Smoke and Grease Laden apors

from Commercial Cooking Equipment. (Norme relative à l’installation d’équipements destinés à

l’extraction des fumées et des

vapeurs chargées de graisse

générées par les appareils de

cuisson commerciaux.)

Des exemplaires de cette norme

sont disponibles auprès de

l’Association nationale pour la

protection contre les incendies

(National Fire Protection

Association—NFPA)

NFPA

1 Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9101

FRANÇAIS

21

Page 24

L'INSTALLATION (a continué)

DANGER :

DANGER

D’INCENDIE ET

D’EXPLOSION

NE JAMAIS utiliser de flamme

nue pour détecter des fuites de

gaz. Un incendie et une

explosion pourrait se produire.

IMPORTANT :

Tous les raccords de

tuyauterie doivent être

inspectés pour la détection de

FRANÇAIS

fuites éventuelles avant

l’allumage. Détecter les fuites

avec une solution d’eau

savonneuse .

AVERTISSEMENT :

DANGER

D’INCENDIE

Cet appareil à gaz est vendu

avec un régulateur de

pression. Le défaut

d’installation correcte du

régulateur de pression crée

une situation extrêmement

dangereuse. La flèche gravée

sur le corps du régulateur doit

pointer vers le grill. Le trou

d’aération doit pointer vers le

HAUT.

IMPORTANT :

Vérifier la nature du gaz

combustible. Si le combustible

disponible ne correspond pas

aux spécifications de la plaque

signalétique, échanger

l’appareil contre un autre, de

type correct.

INSTALLATION DU GRILL À GAZ

Consulter la plaque signalétique. Vérifier la nature et la pression du combustible, qui doivent correspondre aux spécifications indiquées sur la plaque signalétique. Le raccordement de l’appareil à une

alimentation en combustible incorrecte ou sous pression incorrecte compromettrait la sécurité et/ou les performances de l’appareil.

VÉRIFIER QUE LES DISTANCES DE DÉGAGEMENT OBLIGATOIRES PAR

RAPPORT AUX SURFACES COMBUSTIBLES SONT

RESPECTÉES.

L’appareil doit être mis en place dans sa position de fonctionnement

définitive et mis à niveau horizontalement (l’arrière par rapport au devant, un

côté par rapport à l’autre) à l’aide d’un niveau à bulle, avant de

commencer l’installation de la tuyauterie du gaz.

Vérifier de nouveau le niveau horizontal de l’unité après l’installation de la

tuyauterie du gaz.

Chaque appareil à gaz est vendu avec un régulateur de pression séparé, qui

doit être installé sur le tuyau du collecteur dépassant à l’arrière de l’appareil.

Vérifier que le régulateur est installé de manière à ce que la flèche indiquant le

débit, gravée sur le corps du régulateur, pointe vers le grill. Le défaut

d’installation correcte du régulateur de pression crée une situation

extrêmement dangereuse.

Un purgeur de condensat (collecteur de condensat) comportant un Té, un

mamelon de 4 po. (10 cm) pointant vers le bas et un capuchon doit être

installé en amont du régulateur de pression de gaz .

Un robinet d’arrêt de gaz manuel peut être exigé par les codes locaux et son

installation est fortement recommandée dans tous les cas. Le robinet d’arrêt

doit être installé entre la tuyauterie d’alimentation de gaz et le régulateur de

pression .

RÉGULATEUR

FOURNI AVEC

L'APPAREIL

ROBINET

D'ARRÊT

DU GAZ *

ALIMENTATION

DE GAZ *

Fig. 7 Tuyauterie d’alimentation du gaz

L’installateur de la tuyauterie du gaz est responsable d’identifier les dispositions

obligatoires du code relatives aux robinets d'arrêt de gaz .

Les robinets d’arrêt, le purgeur de condensat et toute la tuyauterie associée

doivent être fournis par l’installateur de la tuyauterie du gaz.

ÉVENT

SENS DU

COURANT

PURGEUR DE

CONDENSAT *

* par des tiers

ARRIÈRE DU GRILL

226 306627 OpManual for HDHP-Series Hot Plates

22

Page 25

L'INSTALLATION (a continué)

RÉGLAGE DE PRESSION DU GAZ :

Le régulateur de pression du gaz est réglé en usine .

RÉGLAGE DE LA VEILLEUSE D’ALLUMAGE :

Les réglages de veilleuse sont situés entre les robinets de

commande de chacun des jeux de brûleurs.

Le robinet de droite commande la veilleuse avant et le robinet de

gauche la veilleuse arrière.

À l’aide d’un petit tournevis plat, tourner la vis dans le sens

horaire pour diminuer la hauteur de la flamme ou dans le sens

inverse au sens horaire pour augmenter la hauteur de la flamme.

Régler la flamme de la veilleuse à 0,64 cm (1/4 po.) de hauteur.

Essai de fonctionnement : toutes les sections de brûleur doivent

s’allumer sans délai. Dans les lieux à courants d’air, une flamme

plus haute peut être nécessaire pour que la veilleuse reste

allumée.

RÉGLAGE DE LA FLAMME DE BRÛLEUR :

Enlever tous les boutons de commande des brûleurs puis enlever

le panneau avant.

Allumer l’un des brûleurs.

Desserrer la vis de blocage sur le volet.

Tourner le volet pour admettre plus ou moins d’air, le cas

échéant. Régler le volet d’aération jusqu’à ce que la flamme soit

principalement bleue.

Serrer la vis de blocage quand l’opération est terminée. Remettre

le panneau avant et tous les boutons en place avant de remettre

l’unité en service .

L'AJUSTEMENT DE

DE BRULEUR

226 306627 OpManual for HDHP-Series Hot Plates

FLAMME

PLUS D'AIR

VIS DE

BLOCAGE

MOINS

D'AIR

VOLET

BOUTON DE

COMMANDE

DU BRÛLEUR

ON

OFF

OUVERTURE

FERMETURE

RÉGLAGE DE

LA VEILLEUSE

D'ALLUMAGE

OFF

FLAMME

PLUS

FLAMME

PLUS

GRANDE

L'AJUSTEMENT DE

D'ALLUMAGE

PETITE

FLAMME

ON

IMPORTANT :

L’appareil et son robinet d’arrêt

manuel individuel doivent être

déconnectés de la tuyauterie

du système d’alimentation

pendant les essais de pression

de ce système dépassant 1/2

p.s.i. (3,5 kPa).

Il faut également isoler

l’appareil du système

d’alimentation de gaz en

fermant son robinet d’arrêt

manuel individuel pendant tous

les essais de tuyauterie

d’alimentation lorsque les

pressions d’essai de la

tuyauterie sont égales ou

inférieures à 1/2 p.s.i. (3,5 kPa).

IMPORTANT:

Les réglages doivent être

exécutés exclusivement par un

technicien qualifié.

IMPORTANT:

L’appareil à gaz est expédié de

l’usine tout équipé pour le gaz

naturel et réglé pour fonctionner

à une altitude comprise entre le

niveau de la mer et 660 mètres

(2 000 pieds). Pour convertir

l’appareil au gaz de pétrole

liquide (LP) ou au propane,

ou pour fonctionner à une

altitude de plus de 660 mètres

(2 000 pieds), veuillez contacter

votre distributeur agréé Wells.

FRANÇAIS

Fig. 8 Réglages

23

Page 26

FONCTIONNEMENT

AVERTISSEMENT:

DANGER

D’INCENDIE

SI VOUS SENTEZ LE GAZ:

¤

NE PAS tenter d’allumer

l’appareil

¤ NE toucher à AUCUN

bouton électrique.

¤ NE PAS utiliser le

téléphone situé dans le

FRANÇAIS

bâtiment

.

Si l’on détecte une odeur de

gaz, mettre l’unité à l’arrêt en

fermant le robinet d’arrêt

principal du gaz et contacter la

société responsable de

l’alimentation en gaz à partir

d’un poste téléphonique du

voisinage

.

Suivre immédiatement et

exactement les instructions

fournies par la société

distributrice du gaz

COMMENTAIRES D’ORDRE GÉNÉRAL SUR

LE FONCTIONNEMENT

Lire attentivement la description du fonctionnement du grill sur

la notice de spécifications.

NE PAS utiliser l’appareil s’il a été immergé dans l'eau. Appeler un

technicien qualifié pour examiner l’appareil et le réparer ou remplacer

.

tout composant ayant été submergé. Les brûleurs qui ont pu être

mouillés doivent être complètement séchés avant usage.

Pour la mise en route initiale, et chaque fois que l’alimentation de

gaz a été coupée, il pourra falloir plusieurs minutes pour allumer

la veilleuse pendant que l’air est purgé de la tuyauterie et des

collecteurs.

Les boutons de commande des brûleurs ne doivent être tournés

qu’à la main. Ne jamais utiliser d’outil pour tourner les boutons.

Si un bouton ne tourne pas à la main, NE PAS essayer de le forcer

ni de le réparer. Pour toute réparation, contacter le distributeur agréé

Wells. Les boutons ou robinets forcés ou mal réparés posent un

risque d’incendie et/ou d’explosion.

S’assurer que les brûleurs, le brûleur de la veilleuse et le plateau

à graisse sont correctement installés avant d’essayer la mise en

marche.

ALLUMAGE DE LA VEILLEUSE

Avant d’allumer la veilleuse, sentir l’atmosphère autour de l’appareil

pour détecter toute trace de gaz. Ne pas oublier de sentir près du sol

.

parce que le gaz est plus lourd que l’air et s’accumulerait au niveau

du sol.

Pour la mise en route initiale, et chaque fois que l’alimentation de gaz

a été coupée, il pourra falloir plusieurs minutes pour allumer la

flamme de la veilleuse pendant que l’air est purgé de la tuyauterie et

des collecteurs.

La flamme de la veilleuse doit être allumée à la main :

226 306627 OpManual for HDHP-Series Hot Plates

Tourner tous les boutons de commande jusqu’à la positions OFF

(FERMETURE).

La veilleuse est adjacente à l’un des pieds de brûleur et est

accessible à travers l’ouverture du panneau avant .

S’assurer que le robinet d’arrêt du gaz est sur ON (OUVERTURE)

et que l’air a eu le temps d’être purgé des lignes de gaz. Essayer

d’allumer la flamme de la veilleuse toutes les 15 secondes après

avoir ouvert le robinet d’arrêt du gaz .

Allumer la veilleuse avec une longue allumette ou un briquet pour

feu de cheminée. NE PAS utiliser de briquet pour cigarette.

INSTRUCTIONS POUR LA MISE À L’ARRÊT

Tourner tous les boutons de brûleur jusqu’à la position OFF

(FERMETURE).

Éteindre toutes les veilleuses d’allumage .

Mettre le robinet d’arrêt général sur la position OFF (FERMETURE).

24

Page 27

FONCTIONNEMENT (a continué)

OFF

ON

OFF

ON

FONCTIONNEMENT DE LA PLAQUE CHAUFFANTE

Inspecter l’unité pour vérifier sa propreté avant usage. Nettoyer le cas

échéant : voir page 24 .

S’assurer que la veilleuse est allumée avant de faire fonctionner le

grill. Voir la section Allumage de la flamme de la veilleuse, page 22 .

Les boutons de commande des brûleurs ne doivent être tournés qu’à

la main. Ne jamais utiliser d’outil pour tourner les boutons.

Le bouton de commande de cette plaque chauffante à gaz offre une

plage continue de réglages entre la position OFF (FERMETURE) à

ON (OUVERTURE).

Allumer la veilleuse en tournant le bouton de commande jusqu’à la

position ON (OUVERTURE), et ce, jusqu’à ce que l’allumage soit

complet dans toutes les sections de brûleur. Régler le bouton de

commande sur la position souhaitée. On peut ajuster le réglage à tout

moment .

POSITION OFF (FERMETURE) POSITION ON (OUVERTURE)

Fig. 9 Commande de brûleur

RECOMMANDATIONS POUR LA CUISSON :

Économiser l’énergie en tournant le bouton de commande de

température jusqu’à la position OFF (FERMENTURE) chaque fois que

le grill reste inutilisé. Les brûleurs à gaz fournissent instantanément

une pleine chaleur, ce qui rend inutile de laisser l’unité allumée

lorsqu’on n’a pas besoin de l’utiliser.

OFF

ON

ON

OFF

AVERTISSEMENT:

DANGER

D’INCENDIE

NE JAMAIS tenter de forcer

ou de réparer un bouton ou

robinet de commande bloqué.

Pour toute réparation,

contacter le distributeur agréé

Wells. Les boutons ou robinets

forcés ou mal réparés posent

un risque d’incendie et/ou

d’explosion

.

AVERTISSEMENT:

DANGER

D’INCENDIE ET

D’EXPLOSION

Si la veilleuse d’allumage

venait à s’éteindre, arrêter le

gaz au robinet d’arrêt général.

Laisser l’appareil se purger

pendant cinq minutes avant

d’essayer de rallumer la

veilleuse.

ATTENTION :

SURFACE CHAUDE

Les surfaces exposées peuvent

être chaudes au toucher et

peuvent occasionner des

brûlures .

FRANÇAIS

226 306627 OpManual for HDHP-Series Hot Plates

25

Page 28

INSTRUCTIONS POUR LE NETTOYAGE

AVERTISSEMENT:

DANGER

D’INCENDIE

Fermer le robinet d’arrêt du

gaz avant le nettoyage

ATTENTION :

DANGER DE

BRÛLURES

Laisser complètement refroidir

l’appareil avant de le nettoyer.

FRANÇAIS

IMPORTANT :

NE PAS renverser ni verser

d’eau sur les boutons de

commande.

NE PAS submerger l’armoire

du grill dans l'eau. Ceci

endommagerait les

composants internes. Les

dommages occasionnés par

l’eau aux composants

internes ne sont PAS couverts

par la garantie.

NE PAS utiliser de tampons

métalliques à récurer pour

nettoyer l’armoire ou le

plateau à graisse.

Un bonne hygiène est vitale

pour la qualité des produits

alimentaires finis. Il faut

s'assurer de bien nettoyer

dans tous les coins et toutes

les fissures où la graisse ou

autres débris alimentaires

ont pu s'accumuler .

PRÉPARATION

Tourner le robinet de commande jusqu’à un réglage bas avant le

nettoyage. Laisser refroidir le grill jusqu’à son réglage le plus bas avant de

nettoyer.

.

FRÉQUENCE

Tous les jours

USTENSILES

Brosse à soies Chiffon ou éponge propre

Détergent doux Eau chaude

Produit nettoyant compatible avec l’acier inoxydable

NETTOYAGE QUOTIDIEN

1. Fermer le robinet d’arrêt (sur la position OFF/FERMETURE) avant le

nettoyage. Laisser complètement refroidir la plaque chauffante avant de

la nettoyer.

2. Enlever la ou les grilles et le plateau pour la graisse en les soulevant de

l’armoire.

3. Repérer la position des ensembles de brûleur avant et arrière dans

l’armoire. Examiner les ensembles de brûleur.

4. Nettoyer les débris alimentaires de la grille du plateau pour la graisse à

l’eau chaude, avec du détergent doux et une brosse à soies. Rincer à l’eau

propre. Sécher en essuyant avec un chiffon propre et doux.

5. Examiner les ensembles de brûleur. Repérer la position des volets

d’aération avant le nettoyage. Nettoyer les débris alimentaires des

brûleurs à l’eau chaude, avec du détergent doux et une brosse à soies.

Rincer et essuyer avec un chiffon doux et humecté d'eau propre. Essuyer

les surfaces extérieures avec un chiffon propre, sec et doux. Laisser

sécher les brûleurs à l’air pour que les passages intérieurs soient

totalement dépourvus d’eau. (voir fig. 10, page 25) :

6. Essuyer les parties externes de l’armoire de plaque chauffante à l’aide

d’un chiffon propre et doux ou d’une éponge humectée d’eau chaude et

de détergent doux ou d’un produit de nettoyage compatible avec l’acier

inoxydable. NE PAS utiliser de tampon métallique à récurer pour nettoyer

l’armoire de la plaque chauffante. Rincer en essuyant l’armoire de la

plaque chauffante avec une chiffon propre et doux ou une éponge

humectée d’eau propre et chaude. Sécher l’armoire en l’essuyant avec un

chiffon sec propre et doux.

7. Examiner les brûleurs pour vérifier la bonne position des volets d’aération.

Réinstaller les ensembles de brûleur dans l’armoire.

8. Le brûleur avec tube venturi court est le brûleur avant. Le venturi/volet

d’aération glisse sur la buse du robinet de commande. Les ergots situés

sur le fond du brûleurs’enclenchent dans des cavités correspondantes sur

le support du brûleur avant.

9. Le brûleur avec tube venturi long est le brûleur arrière. Le venturi/volet

d’aération glisse sur la buse du robinet de commande de gauche. Les

ergots situés sur le fond du brûleur s’enclenchent dans des cavités

correspondantes sur le support du brûleur arrière.

10. Ouvrir le robinet d’arrêt (sur la position ON/OUVERTURE) et allumer la

veilleuse.

11. Réinstaller le plateau pour la graisse et la grille.

La procédure de nettoyage est terminée.

226 306627 OpManual for HDHP-Series Hot Plates

26

Page 29

INSTRUCTIONS POUR LE NETTOYAGE (a continué)

GRILLE DE CUISSON

BRÛLEUR

AVANT

BRÛLEUR

ARRIÈRE

HDHP-SERIES

BRÛLEUR

ARRIÈRE

SOUTIEN

DE BRÛLEUR

ROBINET DE

COMMANDE DU

BRÛLEUR ARRIÈRE

ROBINET DE

COMMANDE DU

BRÛLEUR AVANT

PLATEAU

POUR LA

GRAISSE

FRANÇAIS

GRILLES DE CUISSON

BRÛLEUR

AVANT

SOUTIENES

DES BRÛLEURES

226 306627 OpManual for HDHP-Series Hot Plates

HDSU-SERIES

Fig. 10 Ensemble de plaque chauffante

ROBINET DE

COMMANDE DU

BRÛLEUR AVANT

PLATEAU

POUR LA

GRAISSE

ROBINET DE

COMMANDE DU

BRÛLEUR ARRIÈRE

27

Page 30

CONSEILS POUR LE DÉPANNAGE

SYMPTÔMES CAUSE POSSIBLE SOLUTION CONSEILLÉE

Alimentation de gaz fermée

Vérifier les robinets d’arrêt principal/de

chaque unité.

La veilleuse ne s’allume pas

FRANÇAIS

Les brûleurs ne s'allument

pas

Un ensemble de brûleur

ne s’allume pas

Air dans les lignes

Le bouton d’allumage de la

veilleuse n’est pas ouvert

Alimentation de gaz fermée

Air dans les lignes

La veilleuse n’est pas allumée

Le bouton de commande est

fermé

De l’eau dans le brûleur

Bouton de commande de

température, brûleur ou

autre composant interne endommagé

Allumer la veilleuse. Essayer d’allumer

la veilleuse toutes les 15 secondes.

Ouvrir/régler le bouton d’allumage de

la veilleuse

Vérifier les robinets d’arrêt principal/de

chaque unité.

Allumer la veilleuse. Essayer d’allumer

la veilleuse toutes les 15 secondes.

Fermer le robinet d’arrêt du gaz – laisser l’unité se purger à l'évent pendant

5 minutes. Ouvrir le robinet d’arrêt du

gaz et allumer la veilleuse.

Ouvrir le bouton de commande (ON/

OUVERTURE).

Régler les flammes de brûleurs.

Enlever le brûleur et le laisser sécher

complètement

Contacter le distributeur agréé Wells

pour effectuer les réparations.

Des parties de brûleur ne s’allument pas ou leur flamme est

irrégulière

La flamme du brûleur n’est

pas assez chaude

Volet ou buse déréglée

REMARQUE : Les ensembles de brûleur ou les robinets de commande ne comportent aucune pièce

que l’utilisateur puisse réparer. Dans tous les cas de dommage ou de fonctionnement défectueux, contacter le distributeur agréé Wells pour procéder aux réparations.

Brûleur mouillé ou trous d’allumage bouchés

Le bouton de commande de

température n’est pas réglé

28

Nettoyer et laisser sécher le brûleur.

Régler à la température souhaitée.

Contacter un technicien qualifié pour

procéder au réglage.

226 306627 OpManual for HDHP-Series Hot Plates

Page 31

PIÈCES DE RECHANGE ET SERVICE DE RÉPARATIONS

DESCRIPTION PART NO.

Pieds, réglables en métal (jeu de 4) 20563

IMPORTANT :

Utiliser exclusivement des

pièces de rechange et des

filtres de remplacement agréés

par l’usine.

Wells Manufacturing

10 Sunnen Drive

St. Louis, MO 63143

phone: (314) 678-6314

fax: (314) 781-2714

(Service des pièces détachées)

Le Service des pièces

détachées peut fournir le nom

et le numéro de téléphone du

distributeur agréé WELLS le

plus proche de chez vous.

FRANÇAIS

RENSEIGNEMENTS À FOURNIR AU SERVICE APRÈS-VENTE

Il est recommandé d’avoir les renseignements suivants sous la main lors d’un appel pour service après-vente

RESTAURANT ________________________________ ADRESSE __________________________

DATE D’INSTALLATION ________________NOM DU TECHNICIEN __________________________

SOCIÉTÉ PRESTATAIRE DE SERVICES________________________________________________

ADRESSE ___________________________ PROVINCE/ÉTAT ______ CODE POSTAL __________

NUMÉRO DE TÉLÉPHONE (_____)_____-_________

NUMÉRO DE MODÈLE DE L’ÉQUIPEMENT ____________________________

NUMÉRO DE SÉRIE DE L’ÉQUIPEMENT ______________________________

COMBUSTIBLE (L'UN MARQUER)

226 306627 OpManual for HDHP-Series Hot Plates

Gaz naturel Gas de pétrole liquide

29

Page 32

WELLS BLOOMFIELD, LLC

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

Loading...

Loading...