Wells H-636 Installation Manual

ELECTRICAL

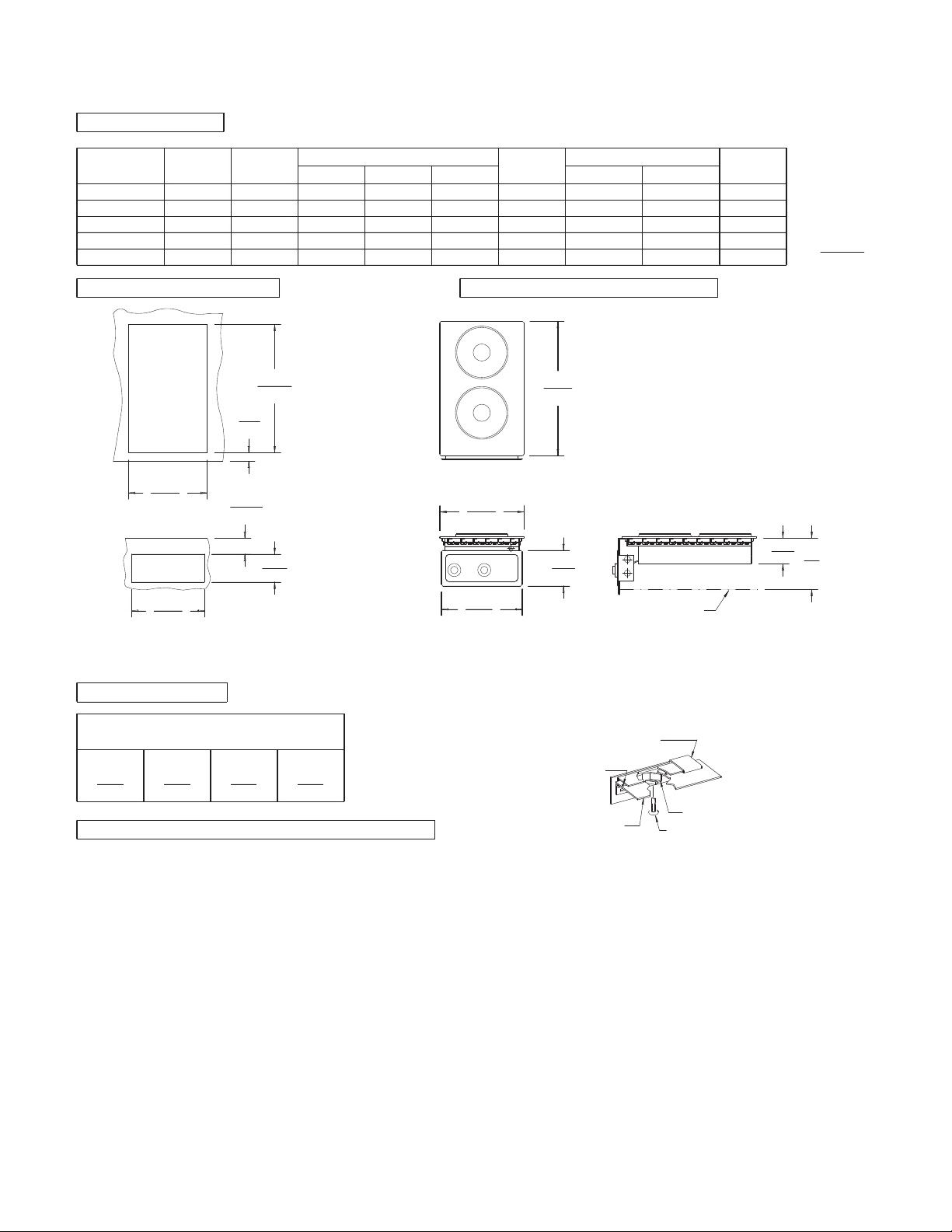

H-706

240H-706

INSTALLATION INSTRUCTIONS

BUILT-IN HOTPLATES

MODEL H-706, H-636

WATTSVOLTSMODEL

AMPS PER LINE 3 PHASE

L3L2L1

7.27.2

10.810.818.85200240H-636

AMPS

SINGLE

PHASE

16.78.38.314.44000

21.7 14 AWG Cu 10

FIELD WIRING GAUGE

3 PHASE 1 PHASE

14 AWG Cu14.412.53000208

10

10

10-16.7-H-706EU 220-240 4000 - 1014 AWG Cu18.89.49.416.33900208H-636

TEMP.

RATING

90°C

90°C14 AWG Cu

90°C

90°C

90°C

INCHES

(MM)

PRODUCT DIMENSIONSCUTOUT DETAILS

13 3/4

(349)

12 3/4

(324)

2 13/16

CLEARANCES

SUGGESTED CLEARANCE FROM

UNIT TO THE NEAREST SURFACE

21

(25)

INSTALLATION INSTRUCTIONS

1 1/2

(38)

(71)

9

(229)(51)

22 7/16

(570)

4 7/8

(124)

23 1/2

(597)

14 3/4

(375)

4 1/2

9

6 1/4

(159)

14 1/8

(359)

HOTPLATE FLANGE

FRONTBOTTOMSIDEBACK

1

(25)

GASKET

COUNTERTOP

METAL SHIELD

WELLSLOK

SCREWDRIVER

(114)

(229)

UNIT MUST BE INSTALLED IN AN ALL METAL COUNTER

THE INSTALLATION OF RECOGNIZED COMPONENT UNITS REQUIRES

ADDITIONAL EVALUATIONS TO UNDERWRITERS LABORATORIES

STANDARDS.

INSTALLER MUST MEET CONDITIONS OF ACCEPTABILITY OUTLINED

BELOW UPON INSTALLATION:

1. This appliance must be installed in an all metal counter with suitable

wiring and control enclosures conforming to national and local electrical

codes.

2. Electrical component temperatures, including wiring, within and

surrounding the appliance must be monitored in the end use installation

for suitability.

3. Electrical grounding of all dead metal parts must be reliably

connected to the grounding means of the appliance and must comply with

requirements outlined in the appropriate Underwriters Laboratories Inc.

classification, national and local electrical codes.

4. Increased clearances are required if storage of combustible materials

is in close proximity to this appliance.

5. Unit shall be accessible for servicing from bottom.

6. The name/rating plate information shall be accessible.

WELLS/BLOOMFIELD * VERDI, NV

TO FABRICATE AND INSTALL:

1. Lay out cutout dimensions on countertop and control

apron as shown in cutout details.

2. Cut and/or drill holes as required in countertop and apron.

3. Place gasket on underside of flange (see detail above).

4. Locate Hotplate over counter to cutout. Pass control panel

through countertop cutout and bring it through control cutout

on apron. Seat Hotplate on countertop.

5. From underneath, insert screwdriver into slots on patented

Wellslok frame and twist ears counterclockwise to secure

flange tightly to countertop.

6. Mount control box to apron using screws supplied. Connect

service leads to terminal block located at right of control

box. Mount front panel to control box.

NOTE: INSTALLATION MUST MEET LOCAL AND NATIONAL

ELECTRICAL CODES.

37118-1 REV (-)

Loading...

Loading...