Wells H-2412G Operators Manual

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 314-678-6314

www.wells-mfg

.com

OPERATION

MANUAL

for

COUNTER TOP

GAS HOTPLATE

Model

H-2412G

INSTANT-ON

Includes

INSTALLATION

USE & CARE

228

Model H-2412G

Instant-On

FOR YOUR SAFETY

Do not store gasoline or other ammable liquids in the vicinity of this or any

other appliance.

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

IMPORTANT:

The purchaser of this equipment must post in a prominent location instructions to be followed in the

event the user smells gas. This information shall be obtained by consulting the local gas supplier.

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

2M-306916 Rev. G

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

04/18

LIMITED EQUIPMENT WARRANTY

Wells Manufacturing warranties new products to be free from defects

in material and/or workmanship for a period of one [1] year from the

date of original installation, except as noted below. Defects that occur

as a result of normal use, within the time period and limitations defined

in this warranty, will at Wells’ discretion have the parts replaced or

repaired by Wells or a Wells-authorized service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Wellsauthorized service agency. Wells will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Wells-authorized service agency must be used.

Wells will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specific

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation prepaid .

CO NTACT

Should you require any assistance regarding the operation or

maintenance of any Wells equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone 314.678.6314

Fax 314.781.2714

Email customerservice@star-mfg.com

www.wells-mfg.com

WARRA

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been installed, cleaned, maintained,

or used in accordance with the directions published in the appropriate

installation sheet and/or owner’s manual as well as national and local

codes, including incorrect gas or electrical connection. Wells is not liable

for any unit which has been mishandled, abused, misapplied, subjected

to chlorides, harsh chemicals, or caustic cleaners, damaged from

exposure to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have an altered

or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls, air

and gas burner/bypass/pilot adjustments, gas or electrical system

checks, voltage and phase conversions, cleaning of equipment,

or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety controls,

or reset buttons.

• Replacement of broken or damaged glass components, quartz heating

elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and hotplates,

including but not limited to burners, grates, and radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform service.

• Parts that fail or are damaged due to normal wear or labor for

replacement of Items that can easily be replaced during a daily cleaning

routine. such as but not limited to silicone belts, PTFE non-stick sheets,

knobs, control labels, bulbs, fuses, quartz heating elements, baskets,

racks, and grease drawers.

• Components that should be replaced when damaged or worn, but have

been field-repaired instead [eg. field-welded fry pots].

• Any loss of business or profits.

ADDITIONAL WARRANTIES

Specialty/chain specific versions may also have additional and/or

extended warranties.

NTY EXCLUSIONS

PRODUCTS PARTS LABOR

universal ventless hoods 2 years 1 year

canopy hoods 2 years 1 year

“Cook’n Hold” equipment [HW10,

HWSMP, LLSC7, LLSC7WA, LLSC11,

2 years 1 year

an d LLSC 11WA]

cast iron grates, burners, and burner

shields

original Wells parts sold to repair

Wells equipment

1 year

90 days

Service First 1 year

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty. 2M-Z22393 • Rev A • 02.2018

TABLE OF CONTENTS

WARRANTY

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY APPROVAL INFORMATION 3

INSTALLATION 4

INITIAL ADJUSTMENT 7

OPERATION 8

TROUBLESHOOTING 10

CLEANING INSTRUCTIONS 11

ASSEMBLY DIAGRAM 12

PARTS & SERVICE 13

CUSTOMER SERVICE DATA 13

Thank You for purchasing this

Wells Bloomeld appliance.

Proper installation, professional

operation and consistent

maintenance of this equipment

will ensure that it gives you the

very best performance and a long,

economical service life.

This manual contains the

information needed to properly

install this equipment, and to use

and care for the equipment in a

manner which will ensure its

optimum performance.

SPECIFICATIONS

MODEL

H-2412G

Instant-On

Dual Pilot

COOKING

SURFACE

11-7/32” Wide,

22-27/32” Deep

STYLE FUEL

2 BURNERS

WITH INDIVIDUAL

CONTROL

MANIFOLD

PRESSURE

Natural

Gas

Propane 10.0” W.C. 12,000 24,000

5.0” W.C. 12,000 24,000

B.T.U /HR/

BURNER

TOTAL

B.T.U./HR

M228 2M-306916 OpM H-2412 Instant-On Dual Pilot Gas Hotplate

1

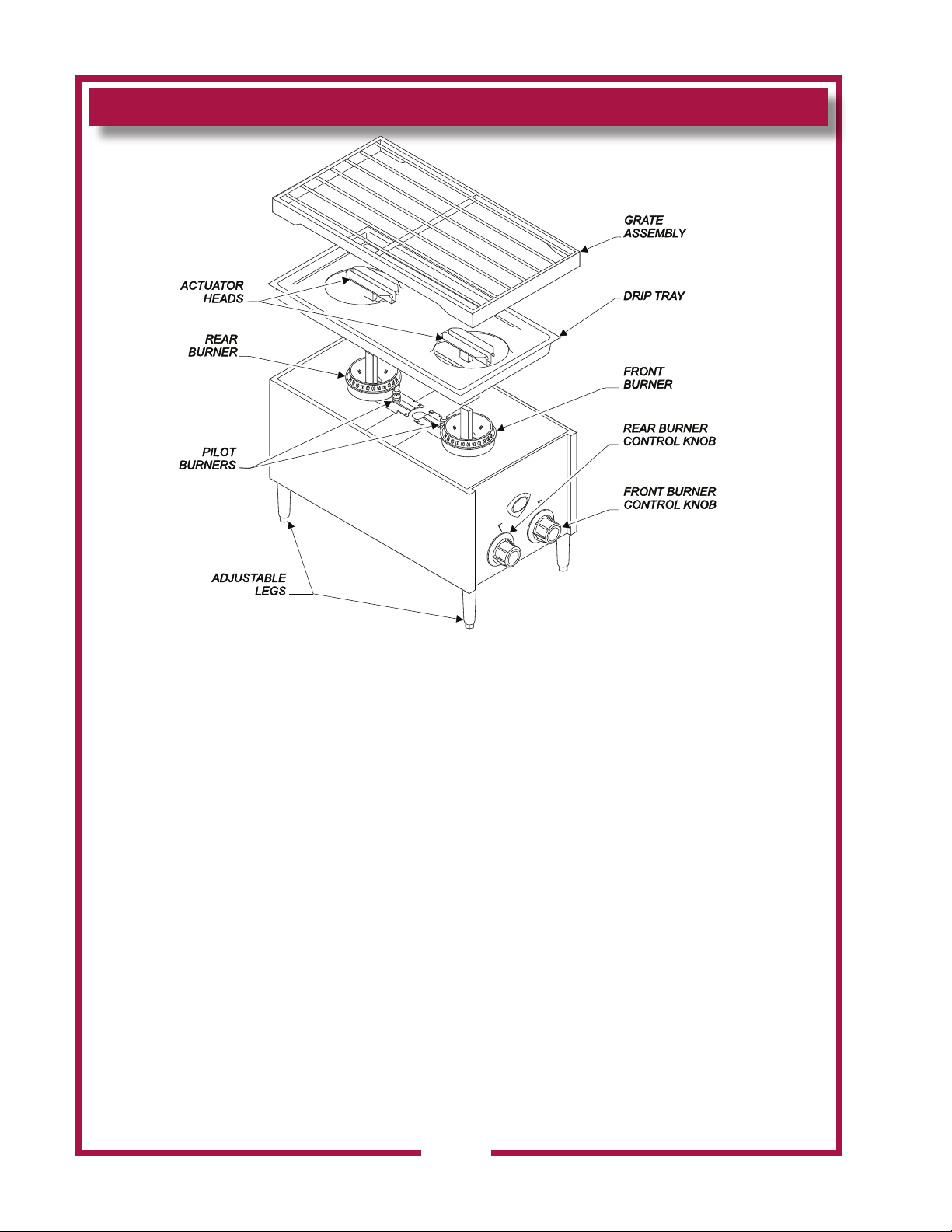

FEATURES & OPERATING CONTROLS

Fig. 1 Countertop Gas Hotplate - Features & Operating Controls

BURNERS Provide cooking heat

Front and rear burners are individually controllable

Removable for easy cleaning

BURNER CONTROL Provide individual control of front and rear burners

KNOBS

PILOT LIGHT Provides ignition source for main burners

ACTUATOR Admits gas to burner when depressed. Actuator head removable

for easy cleaning

GRATE ASSEMBLY Holds food product at proper distance from burner ame

Removable for easy cleaning

DRIP TRAY Catches drippings

Removable for easy cleaning

ADJUSTABLE LEGS Allow for ventilation under hotplate. Provide means of

leveling the appliance, and of cleaning underneath

NAMEPLATE Gives Manufacturer, Model and Serial Number

(on back—not shown) Also provides fuel specications and agency approval information

2

M228 2M-306916 OpM H-2412 Instant-On Dual Pilot Gas Hotplate

PRECAUTIONS AND GENERAL INFORMATION

This appliance is intended for use in commercial establishments

only.

This appliance is intended

No other use is recommended or authorized by the manufacturer or its

agents.

This hotplate must be installed by a technician qualied and certied or

licensed to install gas-red equipment. A licensed technician must

perform the initial startup and adjustment of this appliance.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

DO NOT submerge hotplate or burners in water. DO NOT splash

or pour water into interior of hotplate. Burners which have been

allowed to become wet must be thoroughly dried before use.

Hotplate must be operated with supplied 4” legs properly

installed.

The technical content of this manual, including any parts breakdown

illustrations and/or adjustment procedures, is intended for use by

qualied technical personnel only.

Any procedure which requires the use of tools must be performed by a

qualied technician.

This manual is considered to be a permanent part of the appliance.

This manual and all supplied instructions, diagrams, schematics, parts

breakdown illustrations, notices and labels must remain with the

appliance if it is sold or moved to another location.

to prepare food for human consumption.

WARNING

In the event a gas odor is

detected, shut down the unit

at the main gas shutoff and

contact your local gas supplier

from a neighboring location

for service.

WARNING:

FIRE HAZARD

CAUTION:

FALL HAZARD

DO NOT stand or sit on the

hotplate.

CAUTION:

FALL HAZARD

DO NOT use the hotplate as a

stool or ladder.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

AGENCY APPROVAL INFORMATION

This unit complies with NSF standard 4 only if maintained and

operated per the instructions in this manual.

This appliance meets ANSI Z83.11 specications for gas-red food

service equipment.

This appliance is CSA listed for gas operation.

M228 2,M-306916 OpM H-2412 Instant-On Dual Pilot Gas Hotplate

3

STD 4

INSTALLATION

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

DANGER:

HEALTH

HAZARD

This appliance must be

properly ventilated.

Failure to provide proper

ventilation of exhaust

gasses can result in severe

injury and death.

WARNING

Do not store ammable or

combustible materials near this

appliance. The open ame of

this appliance can cause such

materials to ignite.

NOTICE:

Manufacturer’s warranty on

this hotplate is in effect only

when the hotplate is installed

and operated in accordance

with these instructions and

local codes and ordinances or,

in the absence of local codes,

the National Fuel Gas Code,

ANSI Z223.1 (current edition).

The manufacturer of the

hotplate assumes no liability

for any damage resulting from

failure to comply with this

notice.

WARNING:

FIRE HAZARD

UNPACKING & INSPECTION

Carefully remove the hotplate from the carton. Remove all

protective plastic lm, packing materials and accessories from the

hotplate before connecting the hotplate to fuel gas or otherwise

performing any installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the hotplate before starting any

installation.

Read and understand all labels and diagrams attached to the

hotplate.

Carefully account for all components and accessories before

discarding packing materials. Store all accessories in a convenient place

for later use.

Thoroughly clean the appliance before use. See Cleaning

Instructions, page 11.

SETUP

Setup the hotplate only on a rm, level, non-combustible surface.

The hotplate must be leveled with a spirit level in its nal operational

position, prior to beginning the gas piping installation.

Clearances to adjacent surfaces must be maintained.

Maintain a minimum of 3” from hotplate sides and 3” from rear of the

hotplate to combustible walls; 0” from sides and rear of the hotplate

to non-combustible walls; and; 4” from non-combustible counter as

established by provided 4” legs. Supplied legs must be properly

installed. Once installed, the legs should NOT be removed.

Maintain adequate clearances for cleaning and proper operation.

The hotplate must be installed in an area with sufcient make-up air for

proper combustion, and must be installed such that the ow of combustion

and ventilation air will not be obstructed.

For servicing, Wells Mfg. recommends 6” clearance from rear of the

hotplate to wall.

When used with an exhaust fan, special precautions must be observed to

avoid interference with the operation of the hotplate, such as drafts and air

starvation.

The current edition of NFPA 96 (Standard for the Installation of

Equipment for the Removal of Smoke and Grease Laden Vapors from

Commercial Cooking Equipment) species ventilation requirements to

ensure the removal of exhaust gasses and products of combustion.

IT IS THE RESPONSIBILITY OF THE INSTALLER TO ENSURE THAT

THIS GAS HOTPLATE INSTALLATION CONFORMS TO ALL

APPLICABLE CODES AND ORDINANCES.

The area where the hotplate is installed must be kept clear of combustibles

and ammables. This includes mops, rags, grease, wrapping paper and

electric cords.

4

M228 2M-306916 OpM H-2412 Instant-On Dual Pilot Gas Hotplate

INSTALLATION (continued)

GAS APPLIANCE CODE COMPLIANCE

The installation of gas piping from the outlet side of the gas meter or

service regulator to the hotplate must be performed by a technician

qualied and certied or licensed to install gas-red equipment.

A licensed and qualied technician must perform the initial startup and

adjustment of this appliance.

The installation of this gas-red appliance must conform to local

codes, or in the absence of such codes, with the current edition of

National Fuel Gas Code ANSI Z223.1.

For use in the State of Massachusetts, this appliance must be

installed in compliance with Massachusetts Fuel Gas and Plumbing

Code CMR 248.

The installation of this gas-red appliance must comply with

applicable portions of NFPA 96 for ventilation.

The venting of this appliance must not be obstructed, nor may such

venting interfere with the ow of combustion air required for proper

operation of the gas burners.

Additionally:

1. The gas supply line used to connect the hotplate to the gas

supply system must be black iron pipe, or other material as

approved by local ordinance for gas piping.

2. Gas supply piping must be inside 3/8” diameter or greater.

3. Use pipe sealant made specically for gas piping on all pipe

joints. Apply sealant sparingly to the male threads only.

Sealant must be resistant to the action of LP gas.

DANGER:

FIRE AND

EXPLOSION HAZARD

NEVER use an open ame to

check for gas leaks. Fire and

explosion may result.

IMPORTANT:

All pipe joints must be checked

for leaks before lighting. Leak

checks should be performed

with a soap and water solution.

IMPORTANT:

Information on the

construction and installation of

ventilating hoods may be

obtained from the current

edition of NFPA 96

Standard for the Installation of

Equipment for the Removal of

Smoke and Grease Laden

Vapors from Commercial

Cooking Equipment.

Copies of this standard are

available from the

Nation Fire Protection Assn.:

NFPA

1 Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9101

4. Verify that all supply piping is clean and free of obstructions, dirt,

chips and pipe sealant compound prior to installation.

5. All pipe joints must be checked for leaks before lighting. Leak

checks should be performed with a soap and water solution.

NEVER CHECK FOR LEAKS WITH AN OPEN FLAME.

M228 2M-306916 OpM H-2412 Instant-On Dual Pilot Gas Hotplate

5

INSTALLATION (continued)

DANGER:

FIRE AND

EXPLOSION HAZARD

NEVER use an open ame to

check for gas leaks. Fire and

explosion may result.

IMPORTANT:

All pipe joints must be checked

for leaks before lighting. Leak

checks should be performed

with a soap and water

WARNING

solution.

WARNING:

FIRE HAZARD

This hotplate is supplied with a

gas pressure regulator.

Failure to properly install the

supplied regulator will result in

an extremely hazardous

condition.

Flow arrow stamped on body

of regulator must point toward

the hotplate.

Regulator adjusting screw and

vent hole must point UP.

INSTALLING THE HOTPLATE

Refer to the nameplate. Verify the fuel type and pressure, which must

match the nameplate specications. Connecting the hotplate to the

wrong fuel type and/or pressure will compromise the safety and/or

performance of the appliance.

The hotplate must be placed in its nal operational position and

leveled front-to-back and side-to-side, with a spirit level, prior to

beginning the gas piping installation. Re-check the level of the unit at

the conclusion of the gas piping installation.

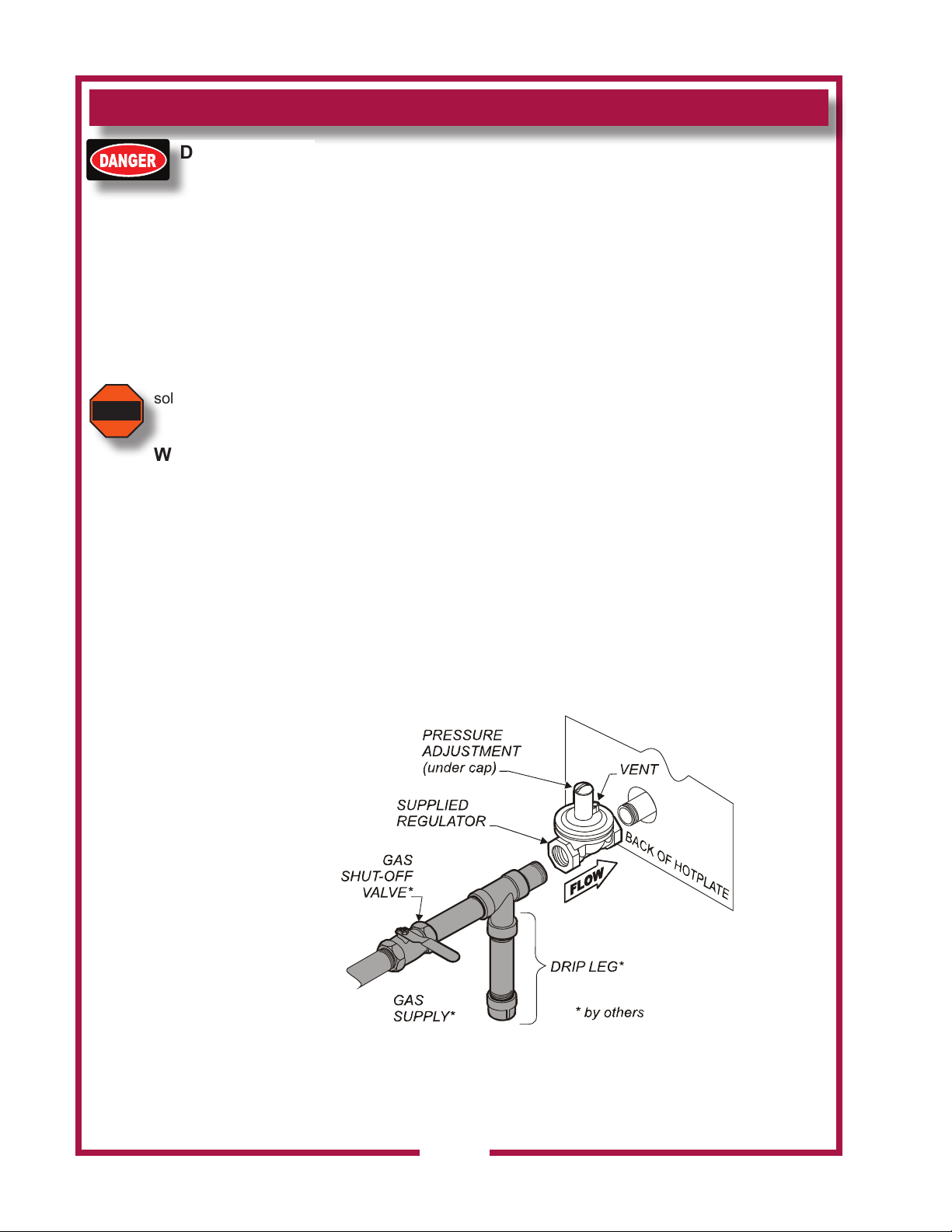

Each gas hotplate is supplied with a separate gas pressure regulator,

which must be installed on the manifold pipe protruding from the rear

of the hotplate. Ensure that the regulator is installed such that the

ow arrow stamped on the body of the regulator points toward the

hotplate. Failure to properly install the supplied regulator will result in

an extremely hazardous condition.

A moisture trap (drip leg) consisting of a tee, 4” nipple pointing down,

and cap must be installed upstream of the gas pressure regulator.

A manual gas shut-off valve may be required by local codes and

is, in any case, strongly recommended. The shut-off valve must

be installed between the gas supply piping and the gas pressure

regulator.

It is the responsibility of the gas piping installer toidentify the code

requirement for a shut-off valve.

Shut-off valves, moisture trap and all associated piping must

besupplied by the gas piping installer.

IMPORTANT:

Verify fuel gas type. If the

available fuel does not match

the nameplate specication,

exchange the hotplate for the

correct type. DO NOT attempt

to modify a unit in the eld to

accept a different fuel.

IMPORTANT:

Avoid damage to the regulator:

if the gas supply piping system

is pressure tested at pressures

exceeding 1/2 psig (3.45kPa),

the hotplate must be isolated

or disconnected from the gas

piping system for the duration

of the test.

Fig. 2 Gas Supply Piping

6

IL1638

M228 2M-306916 OpM H-2412 Instant-On Dual Pilot Gas Hotplate

INITIAL ADJUSTMENT

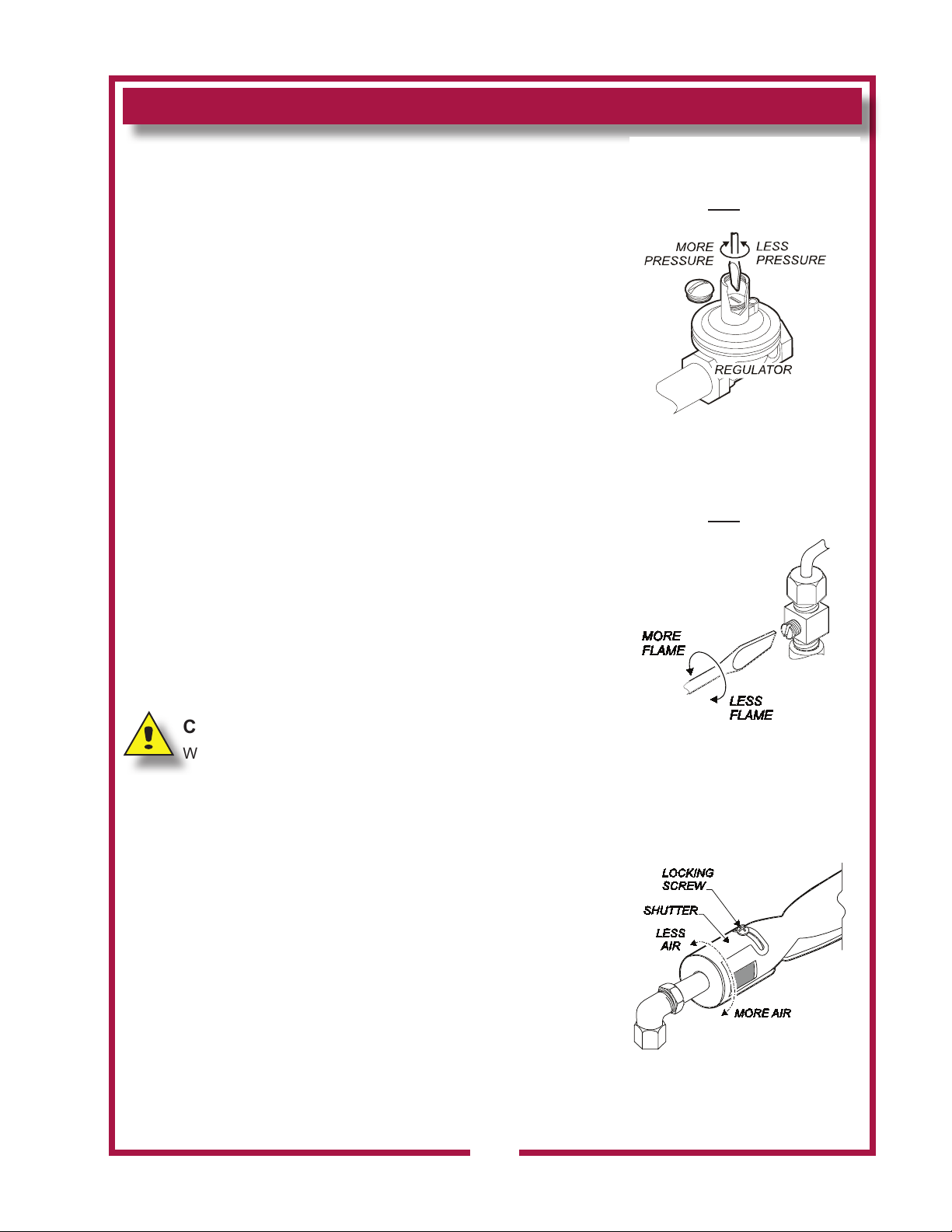

SET GAS PRESSURE:

Turn the gas shut-off valve OFF.

A gas pressure test tap is provided on the gas supply manifold.

Remove both burner control knobs and the front panel. Remove

plug in gas pressure test tap and attach a manometer.

Turn the shut-off valve ON. Light the pilot light and turn both gas

control valves to HI. Depress both actuator heads.

Remove the cap from the pressure regulator. Turn the adjusting

screw clockwise to increase pressure; counter-clockwise to

decrease pressure. Adjust the gas pressure regulator for:

5” water column (natural gas); or, 10” water column (propane).

When nished, replace cap on regulator, turn shut-off valve OFF,

remove manometer and reinstall plug in tap. Reassemble

hotplate, turn shut-off valve back ON and relight pilot light.

SET PILOT FLAMES:

Remove left side (rear burner) control knob by pulling straight off.

Pilot ame adjustment screw is located to the right side of the

burner control valve.

Using a small, at-blade screwdriver, turn the screw clockwise to

decrease the ame size, or counter-clockwise to increase the

ame size.

Burner should light quickly and completely when burner actuator

is depressed. Adjust pilot ame to 1/4” high. Drafty conditions

may require a higher ame to allow pilot ame to remain lit.

Reinstall the control knob.

IMPORTANT:

Pressure adjustment must

be performed by a qualied

technician only.

IL1639

Fig. 3 Gas Pressure Adjustment

IMPORTANT:

Flame adjustment must be

performed by a qualied

technician only.

IL1640

ADJUST BURNER FLAME:

CAUTION: BURN HAZARD

Wear heat protective gloves. Avoid contact with ame.

Remove grate, drip tray and actuator heads. Turn both burner

control knobs full on. Adjust one burner at a time.

Loosen locking screw on a burner assembly shutter. Using a

metal implement such as a long-handle ladle, press the actuator

to light burner.

Turn shutter to admit more or less air as required. Adjust air

shutter until ame is mostly blue in color.

Tighten locking screw. Reassemble hotplate when nished.

M228 2M-306916 OpM H-2412 Instant-On Dual Pilot Gas Hotplate

Fig. 4 Pilot Flame Adjustment

NOTE:

The right knob controls the front

burner; the left knob controls

the rear burner.

IL1641

Fig. 5 Burner Flame Adjustment

7

OPERATION

WARNING

WARNING:

FIRE HAZARD

IF YOU SMELL GAS:

¤ DO NOT

try to light

any appliance.

¤ DO NOT touch any

electrical switch

¤ DO NOT use any

telephone in your

building.

IF YOU SMELL GAS:

Shut down the unit at the main

gas shutoff valve and contact

your local gas supplier from a

neighboring location.

Follow the instructions

received from the gas

supplier immediately

and exactly.

CAUTION:

BURN HAZARD

DO NOT press either actuator

by hand. The burner will

light anytime the plunger is

pressed.

GENERAL OPERATIONAL NOTES

Carefully read the description of the hotplate operation on the

specication sheet.

Do NOT use this appliance if it has been submerged in water.

Call a qualied technician to examine the appliance and to service or

replace any component which has been submerged. Burners which

have been allowed to become wet must be thoroughly dried

before use.

For initial startup, and any time the gas supply has been shut-off, it

may take several minutes to light the pilot as air in the piping and

manifolds is purged.

The burner control knobs must be turned by hand only. Never use

tools to turn the control knob. If the knob will not turn by hand, do

NOT attempt to force or repair it. Contact your Authorized Wells

Service Agency for repairs. Forced or improperly repaired valves

pose the risk of re and/or explosion.

Make sure burners, pilot burner, drip tray, actuators and grate

assembly are properly installed before attempting to operate.

LIGHTING THE PILOT FLAMES

Before lighting the pilot light, smell all around the appliance area for

gas. Be sure to smell near oor level because some gas is heavier

than air and will settle to the oor.

For initial startup, and any time the gas supply has been shut-off, it

may take several minutes to light the pilot as air in the piping and

manifolds is purged.

The pilot ame must be lighted by hand:

Turn both control knobs to the full OFF position.

Be sure the gas shut-off valve is ON and the appliance has had

time for the air to be purged from the lines.

Remove the grate and drip pan. The pilots are located adjacent

to their respective burner.

Light the pilot with a long match or replace lighter.

Use of a cigarette lighter is NOT recommended.

IF THE UNIT DOES NOT LIGHT or IN THE EVENT OF A GAS

INTERRUPTION:

Turn main valve to unit. Wait 5 minutes for gas to clear.

Turn off all knobs and pilot valves.

Turn on main valve and light pilots.

Turn burner knobs to desired setting. Depress actuator to light

burner.

SHUT DOWN INSTRUCTIONS

Turn all burner knobs to OFF.

Turn all pilots OFF.

Turn the main gas supply OFF.

8

M228 2M-306916 OpM H-2412 Instant-On Dual Pilot Gas Hotplate

Loading...

Loading...