Wells BMW-206RTD Installation Manual

ELECTRICAL

MODEL VOLTS WATTS AMPS PHASE WIRING

BMW-206RT

BMW-206RT

BMW-206RT

BMW-206RTD

BMW-206RTD

BMW-206RTD 240

120 1200

208

240

120

208

1240

1650

1200

1240

1650

10.0

6.0

6.9

10.0

6.0

6.9 SINGLE

SINGLE

SINGLE

SINGLE

SINGLE

SINGLE

#14 AWG Cu

#14 AWG Cu

#14 AWG Cu

#14 AWG Cu

#14 AWG Cu

#14 AWG Cu

FIELD

GAUGE

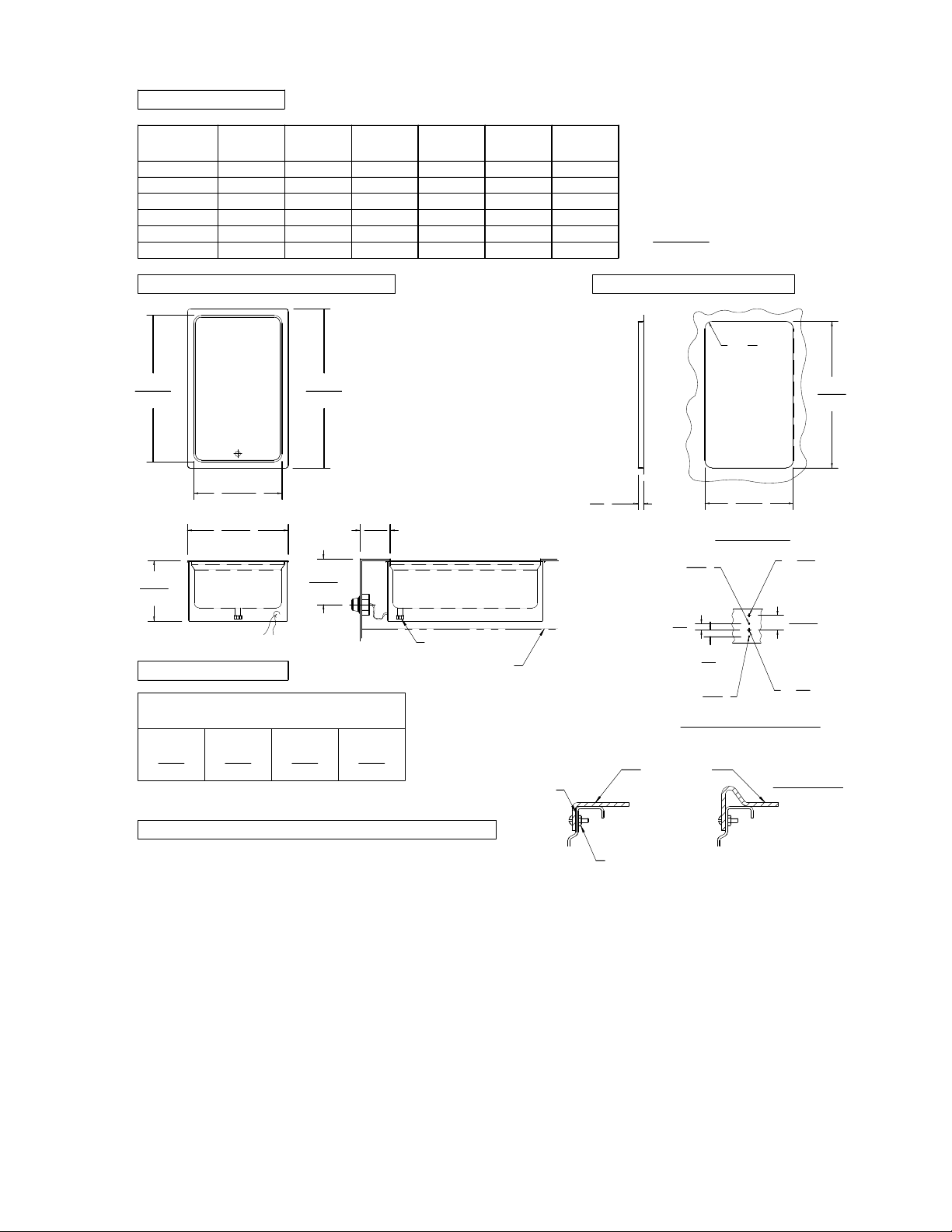

INSTALLATION INSTRUCTIONS

BUILT-IN (BOTTOM MOUNT) INSULATED

TEMP.

RATING

90°C MIN.

90°C MIN.

90°C MIN.

90°C MIN.

90°C MIN.

90°C MIN.

"ROUND CORNER" FOOD WARMERS

MODELS BMW-206RT (D)

INCH

(MM)

CUTOUT DETAILSPRODUCT DIMENSIONS

1

R

(25)

20 5/32

(512)

12 5/32

(309)

13 7/8

(352)

8 5/16

(211)

CLEARANCES

SUGGESTED CLEARANCE

FROM UNIT TO THE NEAREST SURFACE

BACK SIDE BOTTOM FRONT

1 1

(25)

SEE CONDITIONS OF ACCEPTABILITY BELOW

(25) (171)

21 15/16

6 3/4

(557)

6 5/16

(160)

4 1/8

(105)

4 1/8

(105)

1/2 IN DRAIN NPT

BMW-206RTD

METAL SHIELD

3/4

(19)

(MAX TURN DOWN)

SEALANT

INSTALLATION INSTRUCTIONS

UNIT MUST BE INSTALLED IN AN ALL METAL COUNTER

THE INSTALLATION OF RECOGNIZED COMPONENT UNITS REQUIRES

ADDITIONAL EVALUATIONS TO UNDERWRITERS LABORATORIES

STANDARDS.

INSTALLER MUST MEET CONDITIONS OF ACCEPTABILITY

OUTLINED BELOW UPON INSTALLATION:

1. This appliance must be installed in an all metal counter with

suitable wiring and control enclosures conforming to national and

local electrical codes.

2. Electrical component temperatures, including wiring, within and

surrounding the appliance must be monitored in the end use

installation for suitability.

3. Electrical grounding of all dead metal parts must be reliably

connected to the grounding means of the appliance and must

comply with requirements outlined in the appropriate Underwriters

Laboratories Inc. classification, national and local electrical codes.

4. Increased clearances are required if storage of combustible

materials is in close proximity to this appliance.

5. Unit shall be accessible for servicing from bottom.

6. The name/rating plate information shall be accessible.

7. For water and waste connections: This appliance is to be

installed to comply with applicable federal, state and local

plumbing codes.

WELLS/BLOOMFIELD * VERDI, NV

TO FABRICATE AND INSTALL:

1. Lay out cutout dimensions on countertop and control

panel as shown in cutout details.

2. Cut and/or drill holes as required in countertop and apron.

3. Turn down flange with round corners (maximum 3/4 inch).

4. To install, position warmer underneath so that turn down is

positioned onto embossed shoulders of warmer. Drill as required.

5. Remove warmer and apply a bead of silicone sealant to

shoulder area. Remount and secure warmer to fixture with

stainless steel screws (see Detail "A" above).

6. Mount control to apron.

7. Connect supply connection wiring to thermostat. Check

nameplate for correct voltage.

NOTE: The BMW-206RTD warmer is supplied with a drain hole at

one end and a 1/2 inch female N.P.T. drain nipple.

NOTE: INSTALLATION MUST MEET LOCAL AND NATIONAL PLUMBING

ELECTRICAL CODES.

5/32

Ø

7/8

(22)

COUNTERTOP

NO.8X5/8 LONG

STAINLESS STEEL PAN

HEAD SCREW. LOCK

WASHER & NUT

12 1/8

(308)

TOP CUTOUT

(4)

7/8

(22)

5/32

Ø

(4)

FRONT PANEL CUTOUT

Ø

Ø

DETAIL 'A'

NOTE: DRILL SCREW

CLEARANCE HOLES

IN ASSEMBLY

SEAL HOLES AND

FASTENERS WITH

SILICONE SEALANT

46034-1 REV (-)

5/16

(8)

PILOT

LIGHT

2 1/32

(52)

3/8

(10)

20 1/8

(511)

Loading...

Loading...