Page 1

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 314-678-6314

fax: 314-781-2714

www.wells-mfg

.com

OWNERS MANUAL

for

COUNTERTOP ELECTRIC

CHAR-BROILERS

Models:

B40

B44

161

Model B40

B50

includes:

INSTALLATION

USE and CARE

PARTS LISTS

WIRING DIAGRAMS

Model B50

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

2M-303672 Rev. G

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

03/18

Page 2

161 2M-303672 OpManual for Countertop Electric Charbroilers

LIMITED EQUIPMENT WARRANTY

Wells Manufacturing warranties new products to be free from defects

in material and/or workmanship for a period of one [1] year from the

date of original installation, except as noted below. Defects that occur

as a result of normal use, within the time period and limitations defined

in this warranty, will at Wells’ discretion have the parts replaced or

repaired by Wells or a Wells-authorized service agency.

THIS WARRANTY IS SUBJECT TO ALL LISTED CONDITIONS.

Repairs performed under this warranty are to be performed by a Wellsauthorized service agency. Wells will not be responsible for charges

incurred or service performed by non-authorized repair agencies.

In all cases, the nearest Wells-authorized service agency must be used.

Wells will be responsible for normal labor charges incurred in the repair

or replacement of a warrantied product within 50 miles (80.5 km) of

an authorized service agency. Time and expense charges for anything

beyond that distance will be the responsibility of the owner. All labor

will need to be performed during regular service hours. Any overtime

premium will be charged to the owner. For all shipments outside the

U.S.A. and Canada, please see the International Warranty for specific

details.

It is the responsibility of the owner to inspect and report any shipping

damage claims, hidden or otherwise, promptly following delivery.

No mileage or travel charges will be honored on any equipment that is

deemed portable. In general, equipment with a cord and plug weighing

less than 50 lb. (22.7 kg) is considered portable and should be taken or

shipped to the closest authorized service agency, transportation prepaid .

CO NTAC T

Should you require any assistance regarding the operation or

maintenance of any Wells equipment; write, phone, fax or email

our service department. In all correspondence mention the

model number and the serial number of your unit, as well as

the voltage or type of gas you are using.

Business hours are 8:00 a.m. to 4:30 p.m. Central Standard Time

Telephone 314.678.6314

Fax 314.781.2714

Email customerservice@star-mfg.com

www.wells-mfg.com

WARRA

THE FOLLOWING WILL NOT BE COVERED UNDER WARRANTY.

• Any product which has not been installed, cleaned, maintained,

or used in accordance with the directions published in the appropriate

installation sheet and/or owner’s manual as well as national and local

codes, including incorrect gas or electrical connection. Wells is not liable

for any unit which has been mishandled, abused, misapplied, subjected

to chlorides, harsh chemicals, or caustic cleaners, damaged from

exposure to hard water, modified by unauthorized personnel, damaged

by flood, fire, or other acts of nature [or God], or which have an altered

or missing serial number.

• Installation, labor, and job checkouts, calibration of heat controls, air

and gas burner/bypass/pilot adjustments, gas or electrical system

checks, voltage and phase conversions, cleaning of equipment,

or seasoning of griddle surface.

• Replacement of fuses or resetting of circuit breakers, safety controls,

or reset buttons.

• Replacement of broken or damaged glass components, quartz heating

elements, and light bulbs.

• Labor charges for all removable parts in gas charbroilers and hotplates,

including but not limited to burners, grates, and radiants.

• Any labor charges incurred by delays, waiting time, or operating

restrictions that hinder a service technician’s ability to perform service.

• Parts that fail or are damaged due to normal wear or labor for

replacement of Items that can easily be replaced during a daily cleaning

routine. such as but not limited to silicone belts, PTFE non-stick sheets,

knobs, control labels, bulbs, fuses, quartz heating elements, baskets,

racks, and grease drawers.

• Components that should be replaced when damaged or worn, but have

been field-repaired instead [eg. field-welded fry pots].

• Any loss of business or profits.

ADDITIONAL WARRANTIES

Specialty/chain specific versions may also have additional and/or

extended warranties.

NTY EXCLUSIONS

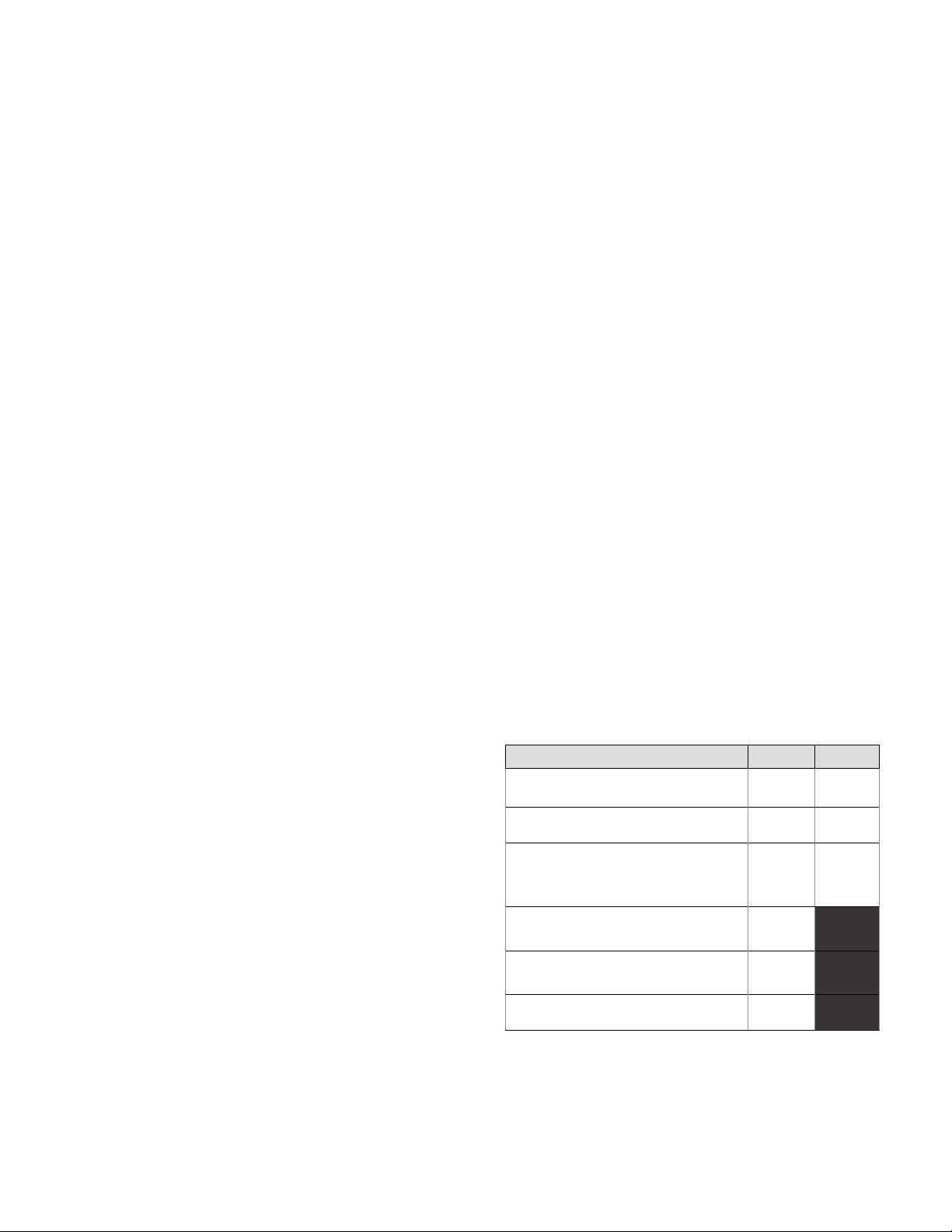

PRODUCTS PARTS LABOR

universal ventless hoods 2 years 1 year

canopy hoods 2 years 1 year

“Cook’n Hold” equipment [HW10,

HWSMP, LLSC7, LLSC7WA, LLSC11,

2 years 1 year

an d LLSC 1 1WA]

cast iron grates, burners, and burner

shields

original Wells parts sold to repair

Wells equipment

1 year

90 days

The fore going warrant y is in lieu of any and a ll other warranti es expresse d or implied and c onstitutes the e ntire warranty. 2M-Z22393 • Rev A • 02.2018

Service First 1 year

Page 3

TABLE OF CONTENTS

WARRANTY

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 4

AGENCY LISTING INFORMATION 4

INSTALLATION 5

OPERATION 7

SUGGESTED COOKING TIMES 9

CLEANING INSTRUCTIONS 10

TROUBLESHOOTING SUGGESTIONS 11

EXPLODED VIEW & PARTS LIST 12—17

WIRING DIAGRAM 18

PARTS & SERVICE 25

CUSTOMER SERVICE DATA 25

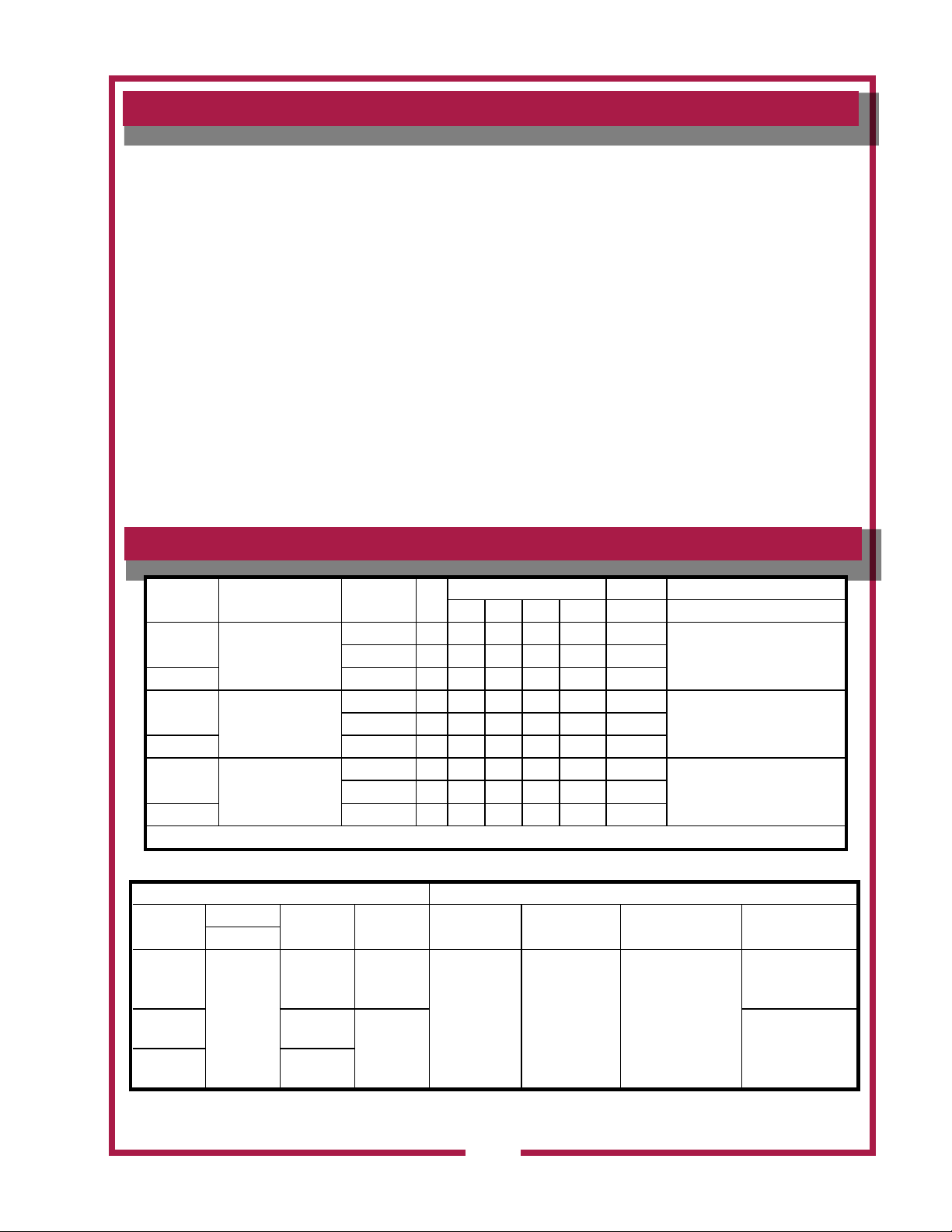

SPECIFICATIONS

MODEL ELEMENT VOLTS KW

B40

*B40EU 380-415 5.5 7.6 7.6 7.6 N/A

B44

*B44EU 380-415 5.5 7.6 7.6 7.6 N/A -

B50

*B50EU 380-415 11 15 15 15 N/A

SINGLE ASSEMBLY

SINGLE ASSEMBLY

DUAL ASSEMBLIES

208 5.5 12.9 12.9 22.4 N/A 26

208 5.5 11.5 22.4 14.4 N/A 26

208 11 30 30 30 N/A -

* for export model, also refer to European Operation Manual…, p/n 2M-301500

AMPS PER LEG 3Ø AMPS POWER

L1 L2 L3 NEUT. 1Ø CORD

Thank you for purchasing this

Wells Manufacturing appliance.

Proper installation, professional operation and consistent

maintenance of this appliance

will ensure that it gives you the

very best performance and a

long, economical service life.

This manual contains the information needed to properly install this appliance in a manner

which will ensure its optimum

performance.

OPTIONAL NEMA 6-30P 240 5.5 11.2 11.2 19.4 N/A 22.5

NOT SUPPLIED 240 5.5 10 19.5 12.5 N/A 22.5

NOT SUPPLIED 240 11 26 26 26 N/A 45

DIMENSIONS MINIMUM CLEARANCES

MODEL

B40

161 2M-303672 OpManual for Countertop Electric Charbroilers

B44

B50

HIGH

w/4” LEGS

15-3/8”

(39 CM)

WIDE DEEP BACK SIDE BOTTOM TOP

24-3/4”

(62.7 CM)

19-7/16”

(49.4 CM)

36-1/2”

(92.7 CM)

23-1/2”

(59.7 CM)

29-9/16”

(75.1 CM)

6”

(15.2 CM)

1

7”

(17.8 CM)

21”

(53.3 CM)

4”

(10.2 CM)

30”

(76.2 CM)

Page 4

161 2M-303672 OpManual for Countertop Electric Charbroilers

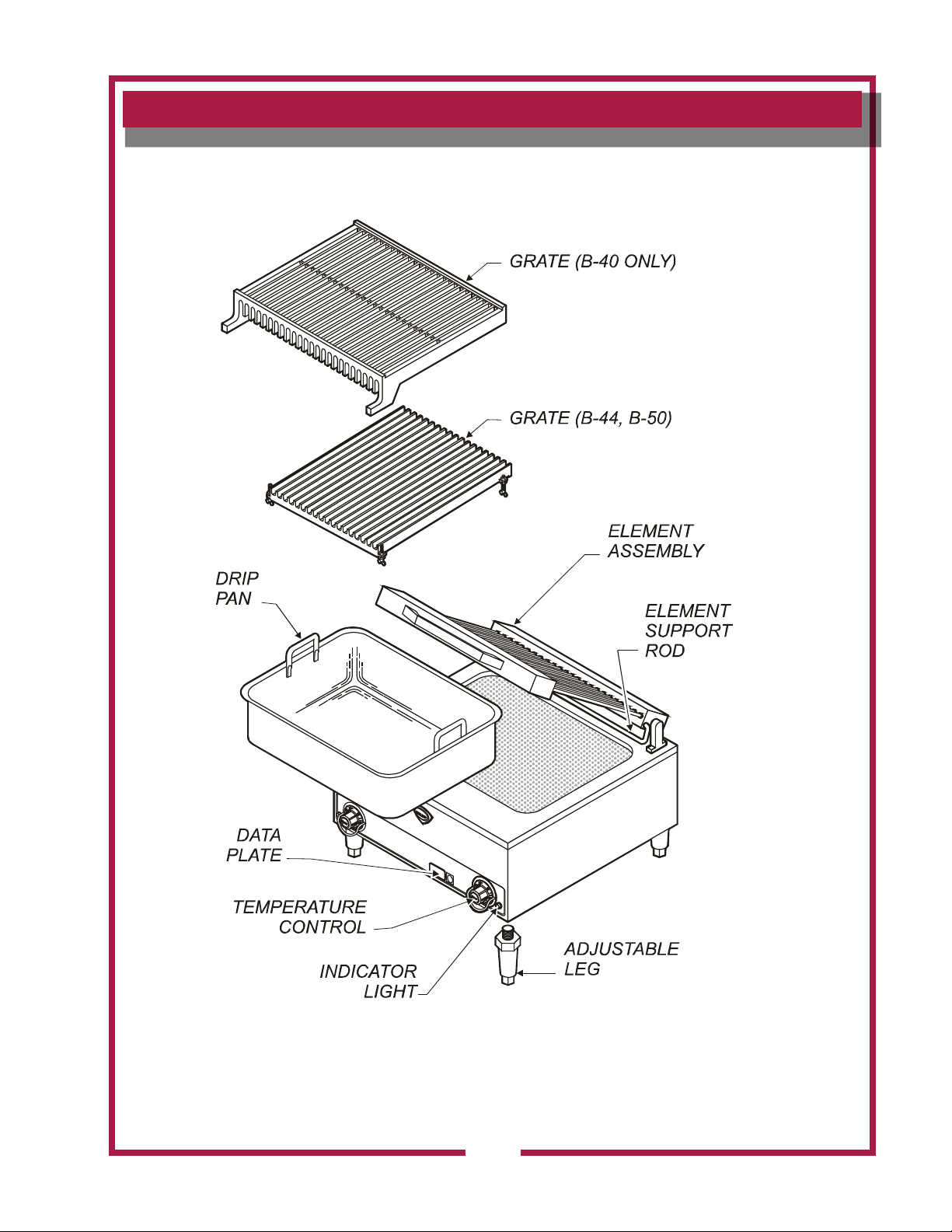

FEATURES & OPERATING CONTROLS

FEATURES & OPERATING DEFINITIONS

ITEM COMMENT

TEMPERATURE

CONTROL

INDICATOR LIGHT Light will glow when the innite switch is in any position other that OFF.

HEATING ELEMENT

GRATE

ELEMENT SUPPORT

ROD

DRIP PAN

DATA PLATE

ADJUSTABLE LEGS

The char-broiler is INFINITE SWITCH CONTROLLED. Power is applied to the heating elements based on

the control knob position and the amount of energy used.

The char-broiler element assembly may be raised for cleaning, or to add water to the drip pan. It is held

the “up” position by a support rod which automatically engages as the element is raised.

The grate is designed to protect the individual elements from food contact and spatula abrasion, resulting

in prolonged element life and reduced carbonization. The grate is easily removed for cleaning.

IMPORTANT: B-40 grate mounts above the element. B-44 and B-50 grates can mount above or below

the elements. Always remove a top-mounted grate before lifting the element assembly.

Hold element assembly in up position. Engages automatically when the element assembly is raised.

The heavy-duty removable drip pan is located under the element assembly. The drip pan catches food

particles and grease drippings

IMPORTANT: Remember to dis-engage the support rod before lowering element assembly.

IMPORTANT: DO NOT pour water over elements to rell drip pan.

During broiler operation. Maintain 2 inches of water in the drip pan at all times during operation of the

broiler. The drip pan is easily removed for cleaning.

Gives manufacturer, make, model and serial number. Also voltage and phase information, and agency

approvals.

The char-broiler is equipment with adjustable 4” legs.

Legs allow for:

a. leveling the broiler

b. ventilation around the broiler, and

c. cleaning the broiler

The supplied legs MUST be properly installed before the broiler is place into operation.

2

Page 5

FEATURES & OPERATING CONTROLS (continued)

161 2M-303672 OpManual for Countertop Electric Charbroilers

Fig. 1 Countertop Electric Charbroiler

IL2757

3

Page 6

161 2M-303672 OpManual for Countertop Electric Charbroilers

PRECAUTIONS AND GENERAL INFORMATION

WARNING:

Electric Shock

Hazard

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which require the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

CAUTION:

Risk of Damage

DO NOT connect or energize

this appliance until all installation instructions are read

and followed. Damage to the

appliance will result if these

instructions are not followed.

Broilers are intended for use to cook food products for human

consumption. No other use is recommended or authorized by the

manufacturer or its agents.

Broilers are intended for use in commercial establishments, where all

users are familiar with the appliance limitations, use and associated

hazards. Operating instruction and warnings must be read and

understood by all operators and users.

Do not submerge broilers in water. Do not splash, or pour water onto

controls, control panels or wiring.

Disconnect the broiler from electrical power before performing any

service or maintenance.

Allow drip pan to cool before removing from broiler. Do not operate

broiler without the drip pan installed. Do not operate the broiler without

2 inches of water in the drip pan.

Any parts replacement, maintenance procedure or servicing procedure

requiring the use of tools must be performed by an Authorized Service

Agency.

Any troubleshooting guides, component view, parts lists or installation

guides provided with this equipment are intended for the use of the

qualied technical personnel only.

Except where otherwise noted, this piece of equipment is made in the

USA and has American sizes on hardware.

This manual should be considered a permanent part of this appliance.

This manual and all supplied instructions, diagrams, schematics, parts

break downs, notices and labels must remain with the appliance if it

sold or moved to another location.

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions.

STD 4

E6070 E6070

EXPORT

MODELS

ONLY

This appliance is and Listed under E6070.

Refer to installation instructions included with the broiler for

Underwriters Laboratories conditions of acceptability, electrical

requirements and other installation concerns.

Export versions only of this appliance meet standards.

4

Page 7

INSTALLATION

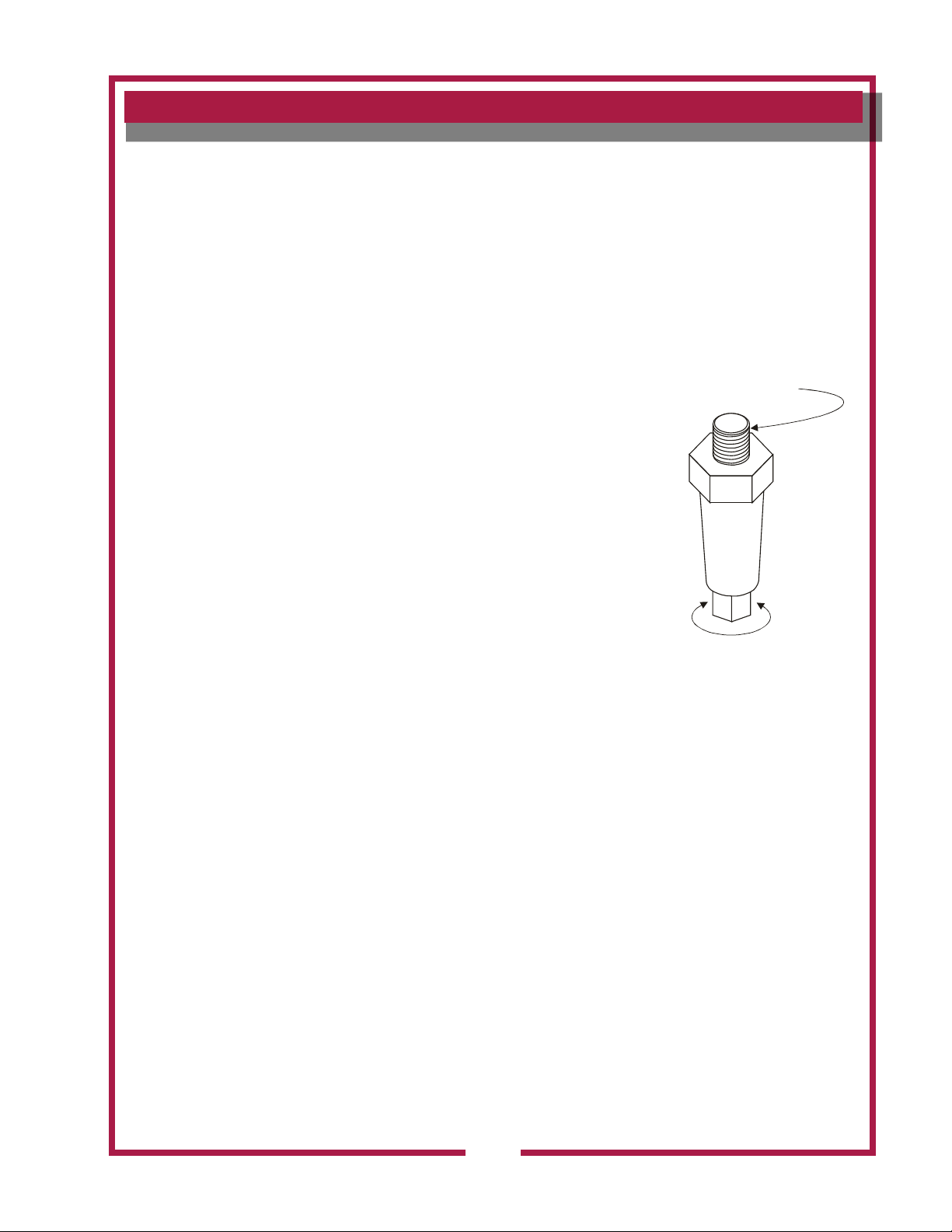

IL2758

SCREW INTO CABINET

MOUNTING HOLES

TURN TO

ADJUST HEIGHT

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all protective

plastic lm, packing materials and accessories from the appliance

before connecting electrical power or otherwise performing any

installation procedure.

Carefully read all instructions in this manual and the Installation

Instruction Sheet packed with the appliance before starting any

installation.

Read and understand all labels and diagrams attached to the appliance.

Carefully account for all components and accessories before discarding

packing materials. Store all accessories in a convenient place for later

use.

SETUP

Setup the appliance only on a rm level surface. Non-combustible

material (e.g. metal, terrazzo) is recommended.

Supplied 4” legs must be properly installed and the broiler leveled.

(See Fig. 2) Move the broiler carefully to avoid damage to the legs.

Refer to the Installation Instruction Sheet for required clearances.

Maintain required clearances between the appliance and adjacent

combustible and non-combustible surfaces.

Sufcient overhead clearance must be provided to allow the element

assembly to be raised. Refer to the Installation Instruction Sheet for

required clearances.

Install drip pan and grate prior to heating and using broiler.

Avoid storing ammable or combustible materials near the appliance.

This includes gasoline and other fuels, mops, rags and wrapping paper.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation. Refer to

SHIPPING DAMAGE CLAIM

PROCEDURE on the inside

front cover of this manual.

Fig. 2 Adjustable Leg

161 2M-303672 OpManual for Countertop Electric Charbroilers

5

Page 8

161 2M-303672 OpManual for Countertop Electric Charbroilers

INSTALLATION (continued)

WARNING:

Risk of personal

injury

Installation procedures must

be performed by a qualied

technician with full knowledge

of all applicable electrical

codes. Failure can result in

personal injury and property

damage.

CAUTION:

Electrical Shock

Hazard

The broiler must be

electrically grounded.

Connect the terminal marked

“GND” or “ ” to a suitable

building ground.

IMPORTANT:

Contact a licensed electrician

to install and connect

electrical power the broiler.

Electrical installation must

be performed by a licensed

electrician in compliance with

all local ordinances and code

requirements.

ELECTRCAL HOOK-UP

Refer to the nameplate. Verify the electrical service power. Voltage

and phase must match the nameplate specications. Connecting the

griddle to the wrong voltage can severely damage the unit or cause

noticeable decreased performance.

Use copper wire suitable for a minimum of 90°C for electrical supply

connections.

Broilers are factory wired three-phase (3Ø). For single-phase (1Ø)

wiring, refer to the wiring diagram attached to the broiler. Conversion to

1Ø must be performed by a licensed electrician.

This broiler is not fused. Protect the circuit with properly sized fuses or

circuit breaker.

An electrical disconnect must be installed readily accessible to the

operator of the broiler.

IMPORTANT:

Damage due to being

connected to the wrong

voltage or phase is NOT

covered by warranty.

6

Page 9

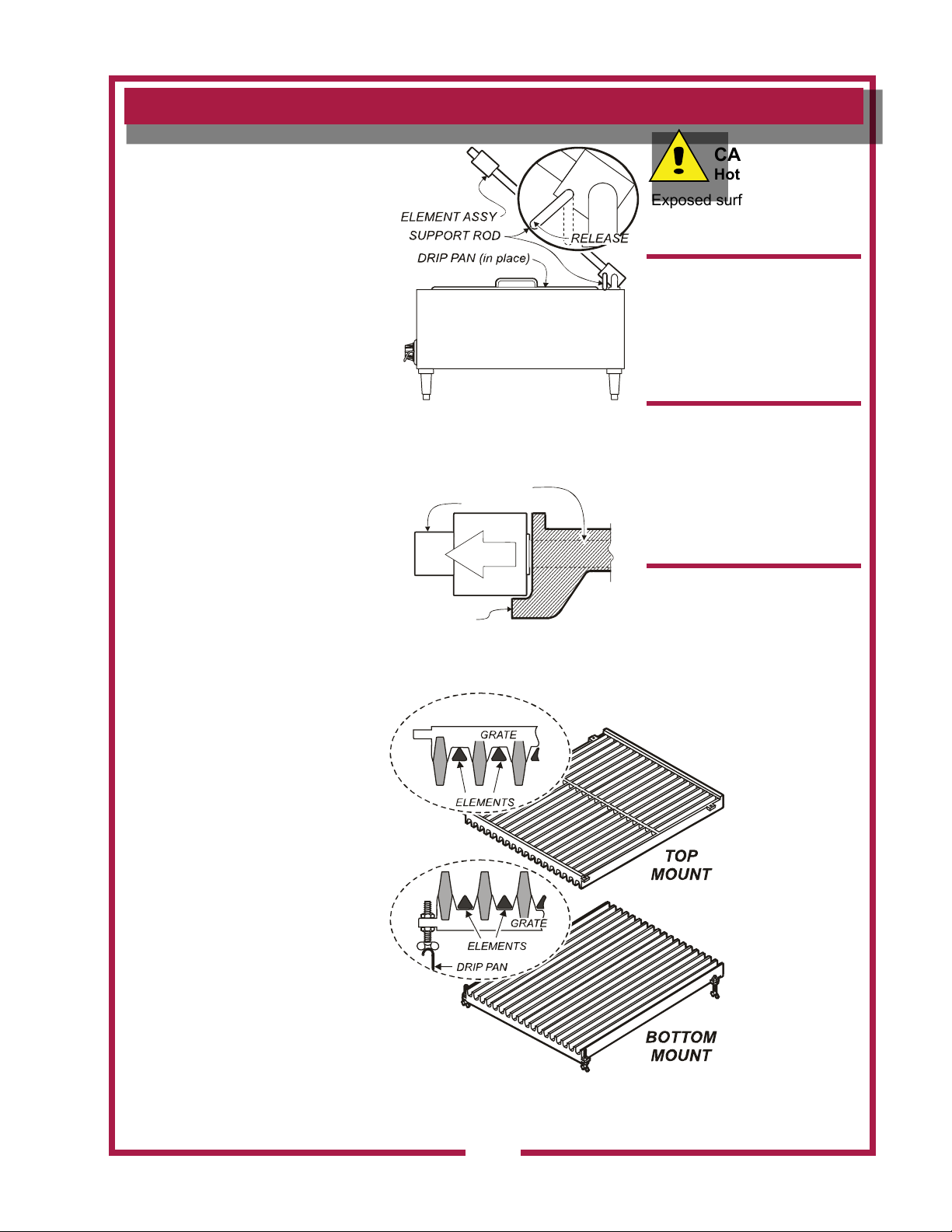

OPERATION

HANDLE

ELEMENT

GRATE TANG

FRONT

IL2760

PREPARE THE CHAR-BROILER

FOR USE

When using the broiler for the rst

time, wipe the entire unit with a

clean damp cloth or sponge and mild

detergent. Rinse thoroughly clean

water. Dry with a soft clean cloth.

Remove the GRATE and raise the

ELEMENT ASSEMBLY.

Install the DRIP PAN and add 2

2 inches (5cm) of tap water.

Release the ELEMENT SUPPORT

ROD by lifting the element assembly

slightly, then pulling the lower portion

of the support rod forward. Lower

the ELEMENT ASSEMBLY gently.

MODEL B-40: Grate must be

installed ABOVE elements.

Install the GRATE, front edge rst.

The TANGS of the grate go DOWN

and point toward the FRONT. The

grooves on the underside of the

grate align with the elements. The

rear edge of the grate can be

lowered until it rests rmly on the

elements.

IL2759

Fig. 3 ELEMENT SUPPORT ROD

Fig. 4 B-40 GRATE INSTALLATION

CAUTION:

Hot Surface

Exposed surfaces can be hot

to the touch and may cause

burns.

IMPORTANT:

DO NOT attempt to raise the

element assembly without

rst removing the grate.

Damage to the hinges will

result. Such damage is NOT

covered by warranty.

IMPORTANT:

Allow drip pan to cool before

removing from the broiler.

DO NOT operate the broiler

without the drip pan installed.

DO NOT operate the broiler

without 2” (5cm) of water in

the drip pan.

IMPORTANT:

DO NOT attempt to lower the

element assembly without

rst releasing the support rod.

Damage to the hinges will

result. Such damage is NOT

covered by warranty.

MODELS B-44 and B-50: Grate(s)

can be installed above or below the

elements.

ABOVE: Gently lower grate over

elements. The end with ush tabs

goes toward the front.

BELOW: Install one wing bolt in

each tab. The notch in the wing

rests on the lip of the drip pan. The

end with ush tabs must go toward

the front Adjust the wing bolts so

161 2M-303672 OpManual for Countertop Electric Charbroilers

that , when the element assembly

is lowered, the top of the element

is 1/4” (6mm) below the top of the

grate ns.

IL2761

Fig. 5 B-44 and B-50 GRATE INSTALLATION

7

Page 10

161 2M-303672 OpManual for Countertop Electric Charbroilers

OPERATION (continued)

CAUTION:

Hot Surface

IL2762

Fig. 6 TEMPERATURE CONTROL

Exposed surfaces can be hot

to the touch and may cause

burns.

IMPORTANT: DO NOT

POUR WATER OVER

ELEMENTS TO REFILL PAN.

DO NOT splash or pour water

onto controls, control panels

or wiring.

TEMPERATURE CONTROLS

Each section of the broiler is equipped with an individual temperature

control. The desired temperature is controlled by rotating the

TEMPERATURE CONTROL KNOB. Any time the control is turned

“ON”, the adjacent indicator light will glow. Each section of the broiler

may be set to a different temperature setting.

“OFF” removes power from the element., allowing the element to cool.

Use OFF to turn the broiler off at the end of the cooking day.

“LO” is the lowest temperature settings. Use LO for stand-by operation.

“2” thru “8” are temperature settings. Higher number indicate higher

temperature.

“HI” is a continuous ON setting. Use HI for pre-heating the broiler.

USING THE CHAR-BROILER

Pre-Heat the broiler ten (10) minutes by turning the TEMPERATURE

CONTROL to “HI”.

After the pre-heat period, turn the TEMPERATURE CONTROL to the

desired setting (refer to the Broiler Chart at right for recommended

settings).

After every order, use the brush provided to brush any remaining food

particles from grate and elements. Keeping the cooking surfaces clean

will help in maintaining food taste.

Visually check the water level in the drip pan during operation. Add

water as required to maintain 2” (5cm) water depth in the drip pan.

8

Page 11

OPERATION (continued)

BROILER CHART

RECOMMENDED COOKING TIMES AND DIAL SETTINGS

NOTE: The times and dial settings in this chart are suggestions only. Your own experience with your

own menu items will be your best guide to achieving the best food product.

PRODUCT

Condition SETTING Minutes Total

THICKNESS

COOKING

DIAL

TIME

BEEF Frozen 1/2” Rare 8 4 -6

“ 1/2” Medium 8 7 - 9

“ 3/4” Rare 7 7 - 9

“ 3/4” Medium 7 8 - 10

“ 1” Rare 7 12 - 14

“ 1” Medium 7 14 - 16

“ 1-1/4” Rare 6 23 - 25

“ 1-1/4” Medium 6 25 - 27

BEEF Non-Frozen 3/4” Rare HI 4 - 6

3/4” Medium HI 5 - 7

1” Rare HI 7 - 9

1 Medium HI 8 - 10

1-1/4” Rare HI 12 - 14

1-1/4” Medium HI 13 - 15

1-1/2” Rare HI 14 - 16

1-1/2” Medium HI 18 - 20

161 2M-303672 OpManual for Countertop Electric Charbroilers

9

Page 12

161 2M-303672 OpManual for Countertop Electric Charbroilers

CLEANING INSTRUCTIONS

CAUTION:

Electric Shock

Hazard

Disconnect appliance

from electric power before

cleaning.

CAUTION:

Burn Hazard

Allow appliance to cool

completely before cleaning.

CAUTION:

Electric Shock

Hazard

Do not submerge appliance

in water.

IMPORTANT: DO NOT spill

or pour water into controls,

control panel or wiring.

PREPARATION

Turn both temperature control knobs OFF.

Allow broiler to cool completely.

Disconnect broiler from electric power.

FREQUENCY

Daily.

TOOLS

Steel Brush with scraper

Plastic Scouring pad, Soft-Bristled Fiber Brush

Mild Detergent, Non-Abrasive Cleanser

Clean Soft Cloth / Sponge

CLEANING

1. Remove the grate from the broiler. Clean grate

a. Use the supplied steel brush with scraper to remove

food particles and residue from grate surfaces.

b. Grate may be washed in sink or dishwasher.

c. Dry the grate and apply a light coating of cooking oil.

DO NOT submerge broiler

in water. Damage to

internal components will

occur. Damage to internal

components from water

damage is not covered by

warranty.

2. Raise the element assembly until it latches. Remove and

clean the drip pan:

a. Stubborn food particles maybe removed with a

plastic scouring pad.

b. Drip pan may be washed in a sink or dishwasher.

3. Clean the element assembly:

a. Use a soft-bristled ber brush to remove any remaining food

particles from the elements.

b. Clean the element rods with a soft damp cloth or sponge and

mild detergent. Rinse by wiping with a soft cloth moistened

with clean water. Dry with a soft cloth.

4. Clean broiler cabinet:

a. Use a plastic scouring pad to remove any remaining food

particles from the cabinet.

b. Clean the cabinet with a soft damp cloth or sponge and mild

detergent. Rinse by wiping with a soft cloth moistened with

clean water. Dry with a soft cloth.

5. Reassemble broiler:

a. Reinstall drip pan.

b. Unlatch element support rod and carefully lower the element

assembly.

c. Reinstall the grate.

Procedure complete

10

Page 13

SYMPTON POSSIBLE CAUSE SUGGESTED REMEDY

Won’t heat - - no indicator lights

One or more section won’t

heat—or not hot enough

One or more section too hot

Element assy loose, or difcult to

raise or lower

Element assy does not latch in up

position

TROUBLESHOOTING SUGGESTIONS

Not plugged in, or Check plug

Circuit breaker tripped. Check / reset circuit breaker

Temperature control not set Set temperature control knob to desired temperature

240V unit run on 208V Verify proper voltage

Damaged component or wiring

Temperature control not set Set temperature control knob to desired temperature

208V unit run on 240V Verify proper voltage

Damaged component or wiring

Damaged hinge

(see page 7 for precautions)

Damaged support rod assembly

Contact an Authorize Wells Service Agency for

repairs

Contact an Authorized Wells Service Agency for

repairs

Contact an Authorized Wells Service Agency for

repairs

Contact an Authorized Wells Service Agency for

repairs

There are no user-serviceable

components in this unit.

In all instances of damage or

malfunction, contact your

Authorized Wells Service

Agency for repairs.

161 2M-303672 OpManual for Countertop Electric Charbroilers

11

Page 14

161 2M-303672 OpManual for Countertop Electric Charbroilers

EXPLODED VIEW & PARTS LIST

Model: B40 Electric Charbroiler

WELLS

1

2

3

6

7

8

9

10

11

IL1728 Rev. B 4/20/12

14

20

21

19

18

15

16

17

12

13

4

5

PL161

COUNTERTOP ELECTRIC

CHAR BROILER

MODEL B-40

12

Page 15

EXPLODED VIEW & PARTS LIST

B40 Electric Charbroiler

Fig No Part No Qty Description Application

1 WS-21707 1 BROILER GRATE B40/B406

2 H6-32728 1 COVER RR ELEM ASS

3 WS-57509 1 CASTING ASSY ELEM REAR

4 WS-52729 1 ROD SUPPORT B40 406

5 2P-32428 1 SPRING SUPPORT ROD

6 H6-35594 1 PAN GREASE B40

7 2A-32840 1

2E-37465

8

2E-40310 TERM BLOCK 4POLE 75AMP B40-400V

9 2A-32841 1

10 2A-32806 2 COVER PIVOT BRKT

2A-Z0314

11

2A-30586 FEET ADJ 4” GRAY PLASTIC

12 H6-Z12082 2 BASE, SHELL

13 2M-300534 1 TRADEMARK DOMED LABEL

14 2R-30371 2 KNOB ASSY WARMERS

15 D8-30256 2 TRIM RING ASSY

16 2E-34593 2 SW INF 240V B CAM 13/16S

17 2J-30516 2 LIGHT SIGNAL AMBER M3938P

WS-500686

18

2R-300666 HANDLE BROILERS DIE CASET

19 WS-57508 1 CASTING ASSY ELEM FRONT

WS-52722

20

WS-52723 ELEM ASSY 240V B40 / B406

DD-503811 ELEM ASSY B40EU 220/380V B40-400V

WS-50007

21

WS-50005 ELEM 120V 225W BROILER B40-240V

2N-303805 ELEM 110V 225W BROILER B40-400V

L PIVOT BRKT (use mount screw 2C-33890)

TERM BLOCK 3 POLE 85AMP 208/240V

1

R PIVOT BRKT (use mount screw 2C-33890)

FEET 4” DIE CAST.

4

KIT HANDLE B40/B406

1

ELEM ASSY 208V B40 / B406

1

ELEM 104V 225W BROILER B40-208V

24

161 2M-303672 OpManual for Countertop Electric Charbroilers

13

Page 16

161 2M-303672 OpManual for Countertop Electric Charbroilers

EXPLODED VIEW & PARTS LIST

Model: B44 Electric Charbroiler

IL1729 Rev. A 4/14/09

PL161

WELLS

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

2223

14

COUNTERTOP ELECTRIC

CHAR BROILER

MODEL B-44

14

Page 17

EXPLODED VIEW & PARTS LIST

B44 Electric Charbroiler

Fig No Part No Qty Description Application

1 H6-38623 1 GRATE AS RECD BROILER

2 H6-32740 1 COVER RR ELEM ASSY B44

3 WS-57507 1 CASTING ASSY ELEM REAR

4 2P-32428 1 SPRING SUPPORT ROD

5 2A-34061 1 ROD HEAD SUUORT B44/B446

6 H6-35593 1 PAN GREASE B44-50

7 2A-32840 1

8 2A-32841 1

9 2A-32806 2 COVER PIVOT BRKT

10 E7-37893 1 COVER ACCESS F101 ROHS

11 2E-Z14960 1 CONTACTOR 40A 208/240COIL

12

13 DD-52128 1 TUBING TIMER WIRES F3672

14

15 2J-30516 2 LIGHT SIGNAL AMBER M3938P

16 2R-30371 2 KNOB ASSY WARMERS

17 D8-30256 2 TRIM RING ASSY

18 2E-34593 2 SW INF 240V B CAM 13/16S

19 2M-300534 1 TRADEMARK DOMED LABEL

20

21 WS-57506 1 CASTING ASSY ELEM FRNT

22

23

NI 2E-35635 2 CAPCTR, .015

WS-50131

2E-4310 TERM BLOCK 4POLE 75AMP B44-400

2A-Z0314 4 FEET 4” DIE CAST.

2A-30586 4 FEET ADJ 4” GRAY PLASTIC

WS-500687 1 KIT HANDLE B44/446 B50/506

2R-300666 1 HANDLE BROILERS DIE CASTE

WS-52737

WS-52738 ELEM ASSY 240V B44,50 BASE

H6-303816 ELEMENT ASSY B44 EU B44-400

WS-50020

WS-50019 ELEM 115V 300W BROILER

2N-303802UL ELEM 110W 300W BROILER B44-400

1

1

18

L PIVOT BRKT (use mount screw 2C-33890)

R PIVOT BRKT (use mount screw 2C-33890)

TERM BLK KIT 3-POLE 85AMP 208/240

ELEM ASSY 208V BASE B44, B50

ELEM 104V 300W BROILER

161 2M-303672 OpManual for Countertop Electric Charbroilers

15

Page 18

161 2M-303672 OpManual for Countertop Electric Charbroilers

EXPLODED VIEW & PARTS LIST

WELLS

Model: B50 Electric Charbroiler

IL1730 Rev. C 7/27/11

PL161

1

2

3

4

5

6

7

8

9

11

12

13

14

14

15

17

18

19

20

21

22

2324

16

10

COUNTERTOP ELECTRIC

CHAR BROILER

MODEL B-50

16

Page 19

EXPLODED VIEW & PARTS LIST

B50 Electric Charbroiler

Fig No Part No Qty Description

1 H6-38623 2 GRATE MACH BROILER ASSY

2 H6-32740 2 COVER RR ELEM ASSY B44, B50

3 2E-30001 30 JUMPER, ELEMENT LONG

4 2E-30002 18 JMPR-ELEMENT,1-1/4” BRLR

5 WS-57507 2 CASTING ASSY ELEM REAR

6 2P-32428 2 SPRING SUPPORT ROD

7 2A-32741 2 ROD HEAD SUPPORT ASSY

8 H6-35593 2 PAN GREASE B44-50

9 2A-32840 2

10 H6-33245 1 COVER DOUBLE PIVOT BRKT

11 2E-Z14960 1 CONTACTOR 40A 208/240COIL

12 WS-50131 2 TERM BLK KIT 3-POLE 85AMP

13 2A-32841 1

14 2A-32806 2 COVER PIVOT BRKT TUMBLED

15

16 2M-300534 1 TRADEMARK DOMED LABEL

17 2R-30371 2 KNOB ASSY WARMERS

18 D8-30256 2 TRIM RING ASSY

19 2E-34593 2 SW INF 240V B CAM 13/16S

20 2J-30516 2 LIGHT SIGNAL AMBER

21

22 WS-57506 1 CASTING ASSY ELEM FRNT

23

24

NI 2E-35635 2 CAPCTR, .015

NI 2A-33038 4 FEET ADJ BROILER GRATES

2A-Z0314 4 FEET 4” DIE CAST.

2A-30586 4 FEET ADJ 4” GRAY PLASTIC

WS-500687

2R-300666 HANDLE BROILERS DIE CASTE

WS-52737

WS-52738 ELEM ASSY 240V B44, B50

WS-50020

WS-50019 ELEM 115V 300V BROILER

2

2

36

L PIVOT BRKT (use mount screw 2C-33890)

R PIVOT BRKT (use mount screw 2C-33890)

KIT HANDLE B44/446 B50/506

ELEM ASSY 208V B44, B50

ELEM 104V 300W BROILER

161 2M-303672 OpManual for Countertop Electric Charbroilers

17

Page 20

161 2M-303672 OpManual for Countertop Electric Charbroilers

EXPLODED VIEW & PARTS LIST

CONTROL KNOB IDENTIFICATION

All versions of the Wells Electric Char-Broiler use control knob p/n 2R-30371.

IL2763

18

Page 21

WIRING DIAGRAM

161 2M-303672 OpManual for Countertop Electric Charbroilers

19

Page 22

161 2M-303672 OpManual for Countertop Electric Charbroilers

WIRING DIAGRAM

20

Page 23

WIRING DIAGRAM

161 2M-303672 OpManual for Countertop Electric Charbroilers

21

Page 24

161 2M-303672 OpManual for Countertop Electric Charbroilers

WIRING DIAGRAM

22

Page 25

NOTES

161 2M-303672 OpManual for Countertop Electric Charbroilers

23

Page 26

161 2M-303672 OpManual for Countertop Electric Charbroilers

NOTES

24

Page 27

PARTS & SERVICE

DESCRIPTION SERVICE

PART NO.

CORDSET 240V 30A NEMA 6-30P,

B-40, B-44 2E-35259

GREASE PAN, B-44 (1 PER UNIT)

B-50 (2 PER UNIT) H6-35593

GREASE PAN, B-40 H6-35594

LEGS, 4”, METAL SET OF 4 2A-Z0314

GRATE, B-44 (1 PER UNIT)

B-50 (2 PER UNIT) H6-38623

GRATE, B-40 WS-21707

BRUSH, BROILER 2P-30013

IMPOR TANT: Use only factory

authorized service parts and

replacement

For factory authorized service,

or to order factory authorized

replacement parts, contact your

Wells authorized service agency,

or call:

Wells Manufacturing

10 Sunnen Dr.

Smithville, Tennessee 37166 U.S.A.

Service Dept.

phone: (314) 678-6314

fax: (314) 781-2714

Service Parts Department

can supply you with the name

and telephone number of

the WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

lters.

CUSTOMER SERVICE DATA

please have this information available if calling for service

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. ______________ EQUIPMENT SERIAL NO. _______________

VOLTAGE: (check one) 208 240 480

161 2M-303672 OpManual for Countertop Electric Charbroilers

25

Page 28

WELLS MANUFACTURING

265 Hobson Street, Smithville, Tennessee 37166

telephone: 314-678-6314

fax: 314-781-2714

www.wells-mfg

.com

Loading...

Loading...